Magnetic ZnO composite piezoresistive material and method of manufacturing the same

A varistor and magnetic technology, applied in the field of ZnO composite varistor materials and their preparation, can solve problems such as inability to adjust, cannot be used, application limitations, etc., to achieve increased service life, accurate circuit protection, and enhanced reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

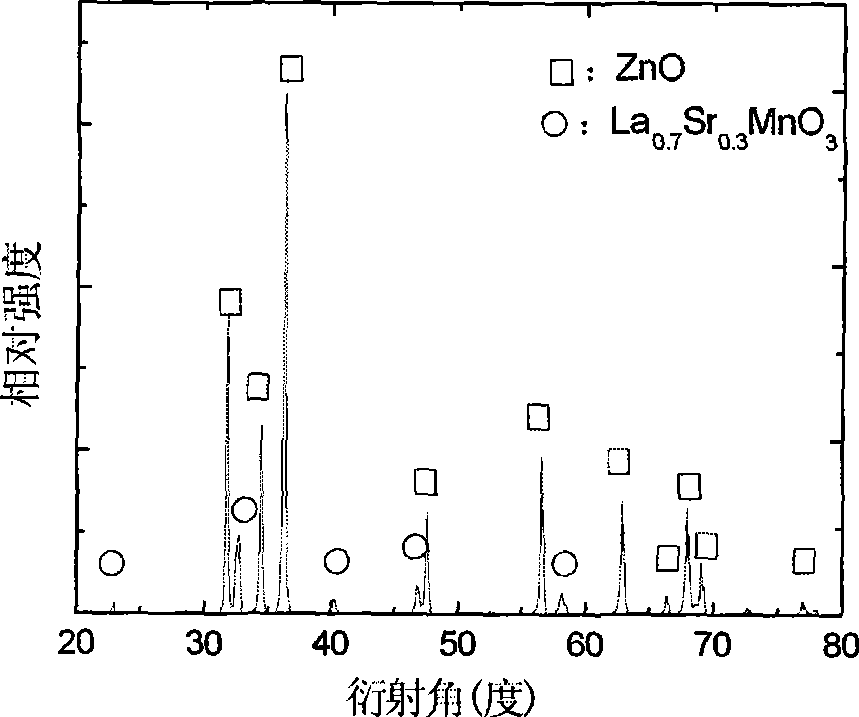

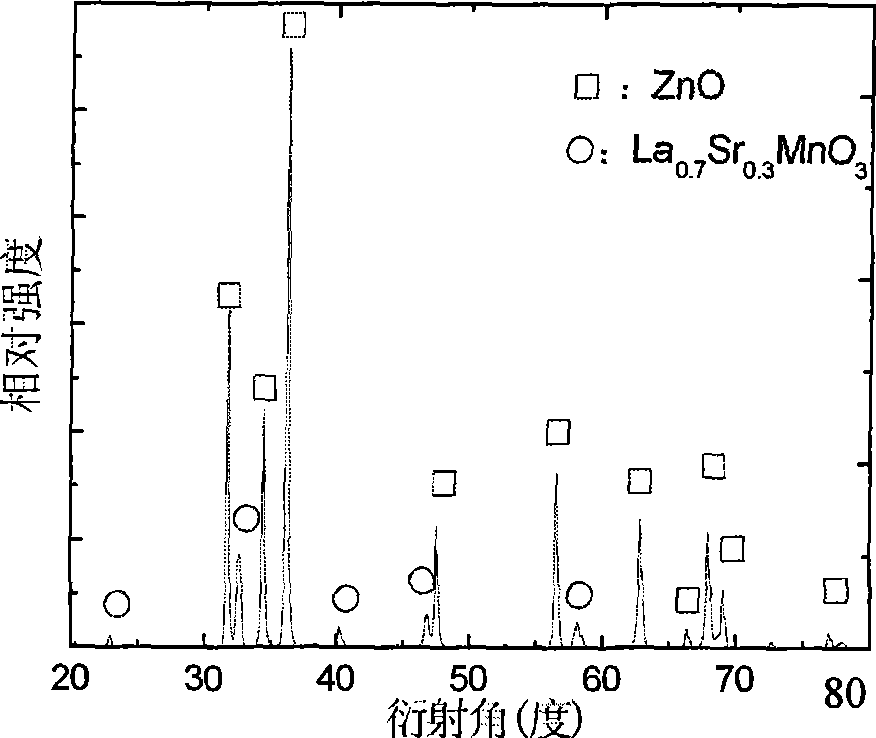

Image

Examples

Embodiment 1

[0018] A kind of concrete implementation method of the present invention is:

[0019] A method for preparing a magnetic ZnO composite varistor material, the method is:

[0020] (1)La 0.7 Sr 0.3 MnO 3 Precursor powder preparation La 2 o 3 , SrCO 3 , MnO 2 According to the molecular formula La 0.7 Sr 0.3 MnO 3 After preparing the raw materials, grinding, calcination and grinding after calcination, each time the calcination temperature is 1100 ° C, and the time is 5 hours, to obtain La 0.7 Sr 0.3 MnO 3 precursor powder;

[0021] (2) Mixing and molding The prepared precursor powder and ZnO powder are mixed at a weight ratio of 100:1, then ground, granulated, pressed into tablets under a pressure of 10Mpa, and then sintered at 1000°C for 2 hours to form the ZnO powder containing 100 parts heavy zinc oxide, 1 part heavy perovskite manganese oxide La 0.7 Sr 0.3 MnO 3 Magnetic ZnO composite varistor material.

Embodiment 2

[0023] A method for preparing a magnetic ZnO composite varistor material, the method is:

[0024] (1)La 0.7 Sr 0.3 MnO 3 Precursor powder preparation La 2 o 3 , SrCO 3 , MnO 2 According to the molecular formula La 0.7 Sr 0.3 MnO 3 After preparing the raw materials, grinding, calcination and grinding after calcination for 3 times, each time the calcination temperature is 1300 ℃, the time is 20 hours, and La 0.7 Sr 0.3 MnO 3 precursor powder;

[0025] (2) Mixing and molding The prepared precursor powder and ZnO powder are mixed at a weight ratio of 100:10, then ground and granulated, pressed into tablets under a pressure of 800Mpa, and then sintered at 1300°C for 20 hours to form the ZnO powder containing 100 parts heavy zinc oxide, 10 parts heavy perovskite manganese oxide La 0.7 Sr 0.3 MnO 3 Magnetic ZnO composite varistor material.

Embodiment 3

[0027] A method for preparing a magnetic ZnO composite varistor material, the method is:

[0028] (1)La 0.7 Sr 0.3 MnO 3 Precursor powder preparation La 2 o 3 , SrCO 3 , MnO 2 According to the molecular formula La 0.7 Sr 0.3 MnO 3 After preparing the raw materials, grinding, calcination and grinding after calcination, each time the calcination temperature is 1200 ℃, the time is 10 hours, and La 0.7 Sr 0.3 MnO 3 precursor powder;

[0029] (2) Mixing and molding The prepared precursor powder and ZnO powder are mixed at a weight ratio of 100:7.5, then ground and granulated, pressed into tablets under a pressure of 100Mpa, and then sintered at 1100°C for 2 hours to form the ZnO powder containing 100 parts heavy zinc oxide, 7.5 parts heavy perovskite manganese oxide La 0.7 Sr 0.3 MnO 3 Magnetic ZnO composite varistor material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com