Multiple anti-counterfeit watermark paper and manufacturing method thereof

A production method and watermarking technology, applied in papermaking, textile and papermaking, fiber raw material processing, etc., can solve the problems of reducing the anti-counterfeiting effect, lack of identification ability, etc., and achieve the effect of strengthening the concave and convex feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

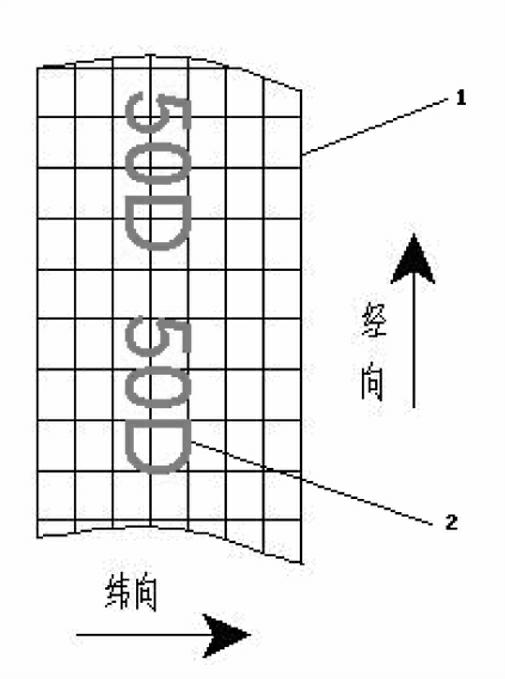

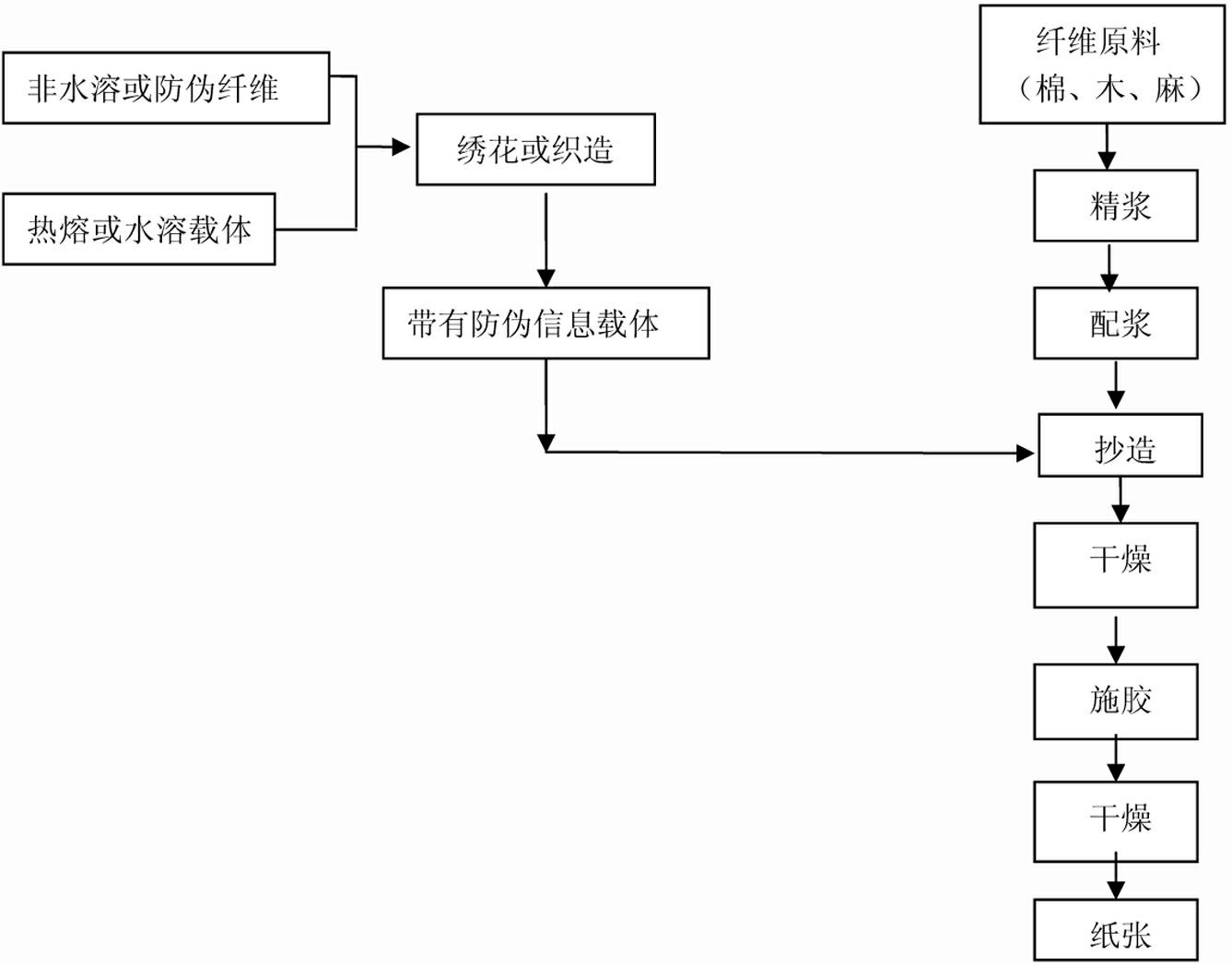

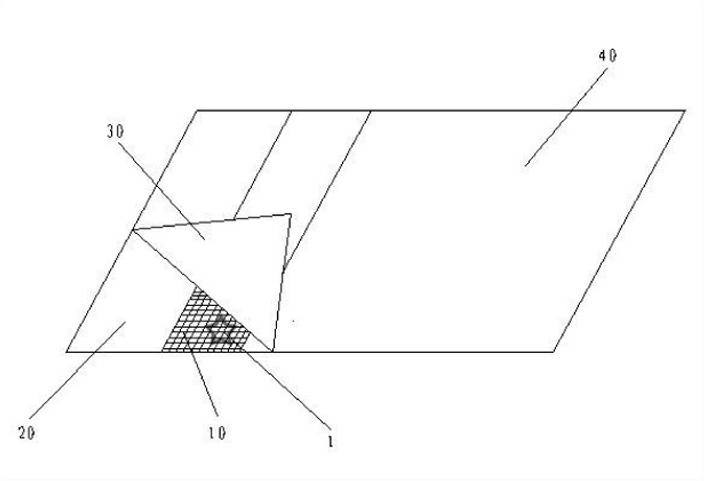

[0044] The preparation process of multiple anti-counterfeiting watermark paper of the present invention is as follows figure 2 As shown, it includes fiber raw materials (cotton, wood, hemp) through the steps of fine pulping, pulping, papermaking, drying, sizing, and drying, and finally paper is obtained. In the papermaking department, the paper with anti-counterfeiting information is placed The carrier is released in front of the paper machine wire and combined with the paper sheet; through the joint action of the water or temperature of the paper machine, the carrier dissolves or melts away, leaving only the pattern, pattern or embroidery formed by the non-water-soluble fiber or anti-counterfeiting fiber in the paper sheet. The lines give the paper a layered and concave-convex touch under transmitted light.

[0045] The carrier with anti-counterfeiting information is a film made of water-soluble material or hot-melt material, non-woven fabric or woven cloth as a carrier, and...

Embodiment 1

[0049] Water-soluble PVA fiber non-woven fabric is used as the carrier, the water-soluble temperature range is 25~90°C, the thickness is 25μm, and the width is 10mm. It has machine-embroidered patterns, patterns or lines on it. The pattern thickness is 25~75μm. The embroidery threads used are non-water-soluble fibers such as polyester. Embroidery thread can also adopt other natural plant fiber such as cotton thread, woolen thread, blended thread or its woven thread, animal fiber or its woven thread, synthetic fiber or its woven thread, or the mixed woven thread of above-mentioned fiber.

[0050] Spread the above-mentioned PVA fiber non-woven fabric embroidered with patterns in front of the paper machine net, position and spread, and the spraying amount is 5-100g / m 2 , such as 5g / m 2 , 20g / m 2 、40g / m 2 、60g / m 2 , 80g / m 2 or 100g / m 2 , and combined with wet paper on the rotary screen.

[0051] Realize the positioning and release of embroidery patterns or textile pattern...

Embodiment 2

[0053] With water-soluble PVA fiber non-woven fabric as the carrier, the water-soluble temperature range is 25~90℃, the thickness is 25μm, and the width is 2-25mm. The carrier is strip-shaped, and the width of the strip-shaped material is 2-20mm. It has machine-embroidered patterns, patterns or lines on it. The pattern thickness is 25~75μm. The embroidery thread used is PVA hot-melt fluorescent fiber, the melting temperature is 30~180°C, the concentration of phosphor powder in spinning stock solution or surface coating solution is 0.1%~80%, and it is made by blending or surface coating. The excitation wavelength is 400-800 nm.

[0054] The above-mentioned PVA fiber non-woven fabric embroidered with patterns is applied before the paper machine net, positioned and applied, and the applied amount is 10g / m 2 , and compounded with paper sheets in the twin cylinder forming section. Through the combined effect of water and temperature in the headbox of the paper machine, the carr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting temperature | aaaaa | aaaaa |

| Excitation wavelength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com