Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32 results about "Ethoxyethyl acetate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

2-Ethoxyethyl acetate is an organic compound with the formula CH 3 CH 2 OCH 2 CH 2 O 2 CCH 3. It is the ester of ethoxyethanol and acetic acid . A colorless liquid, it is partially soluble in water.

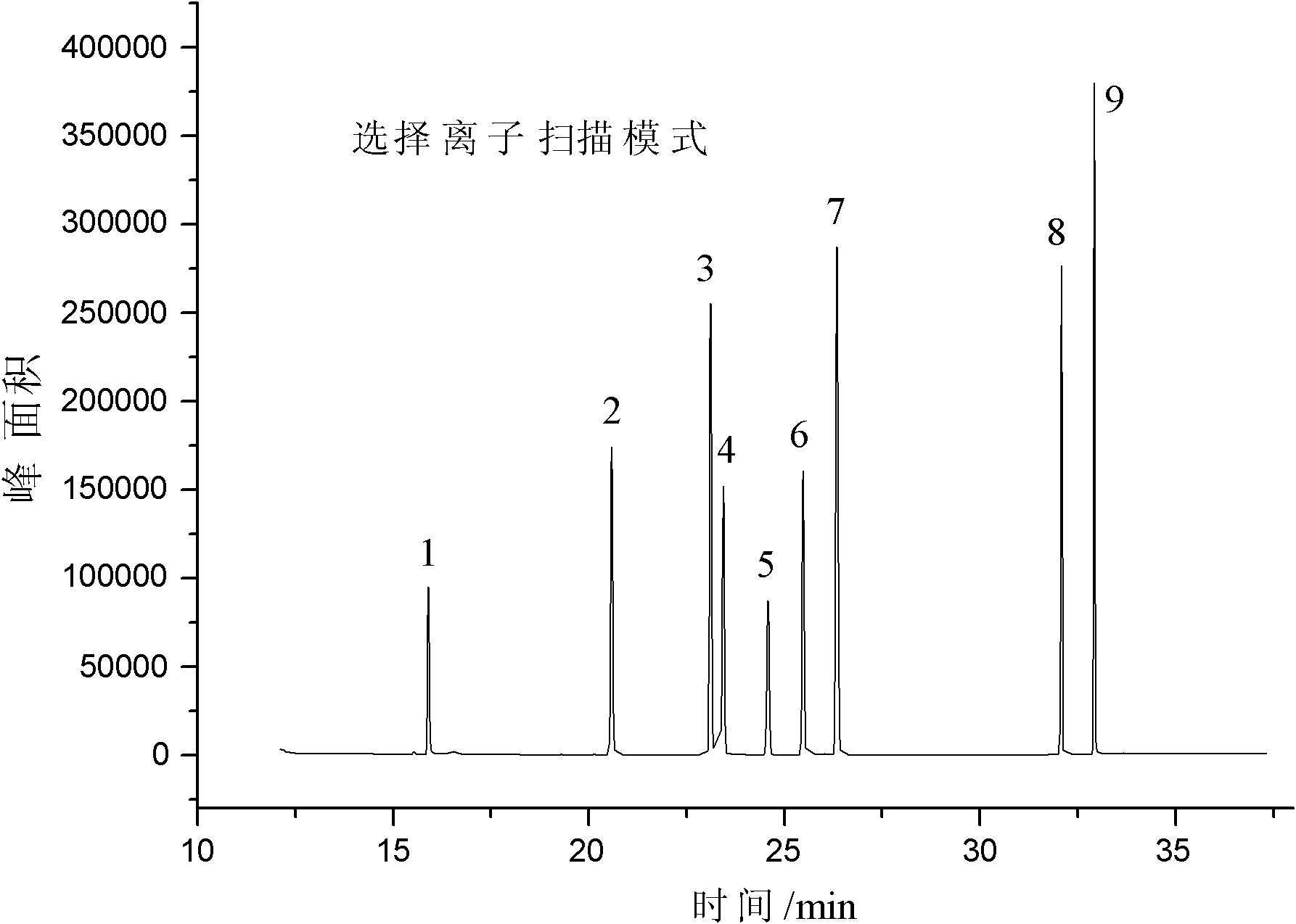

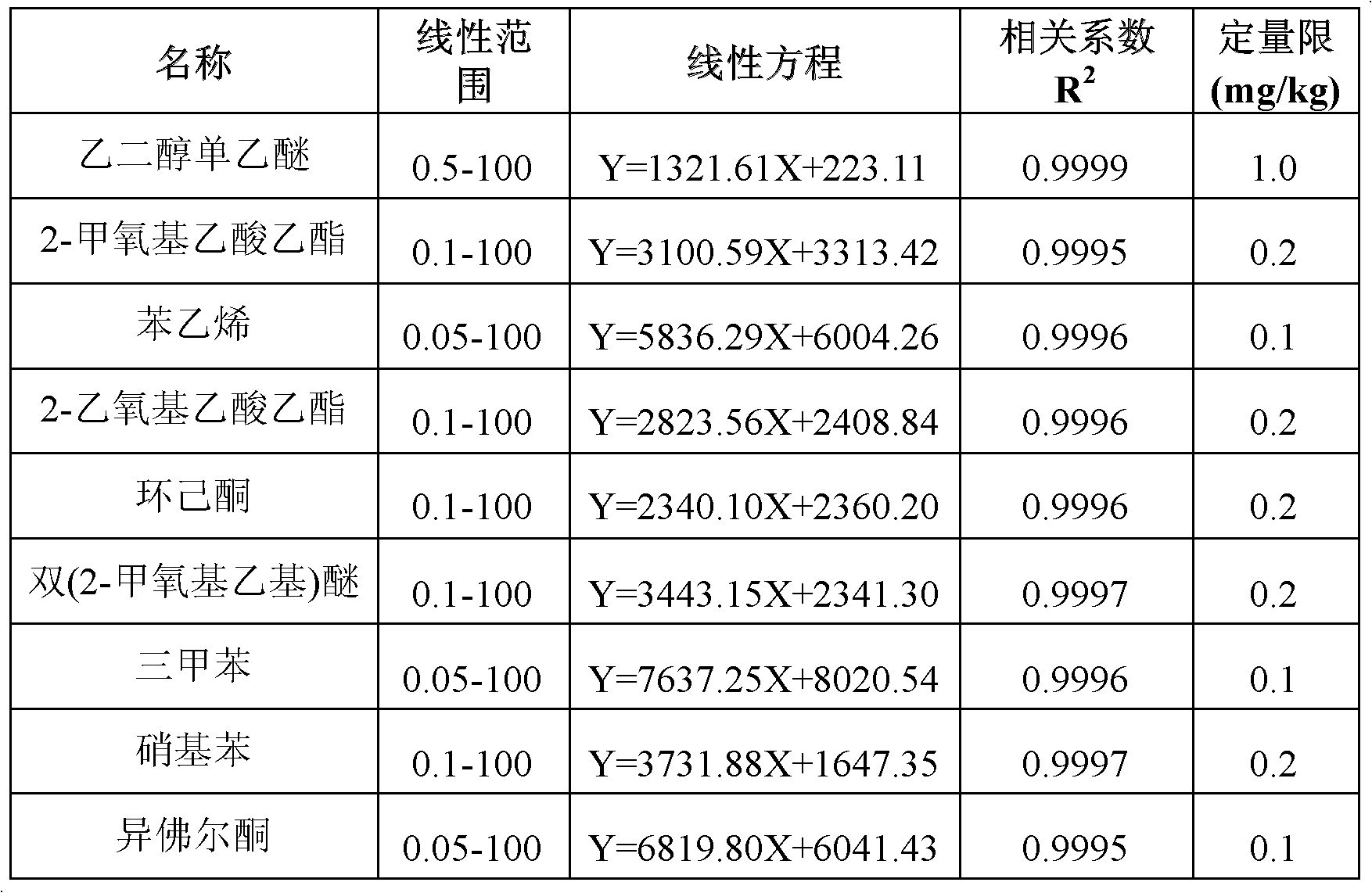

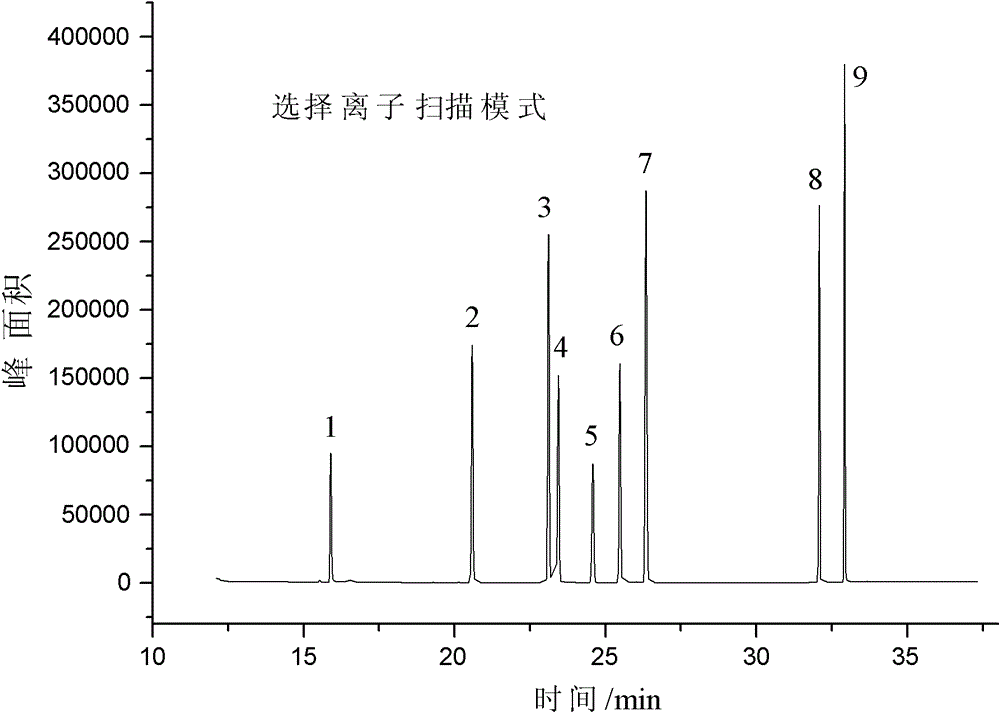

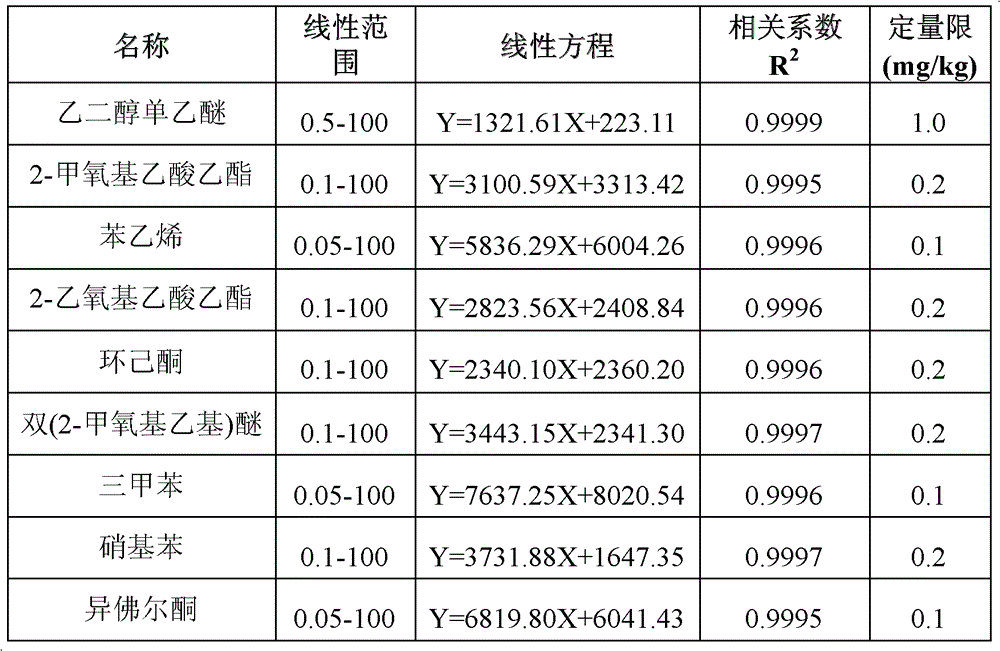

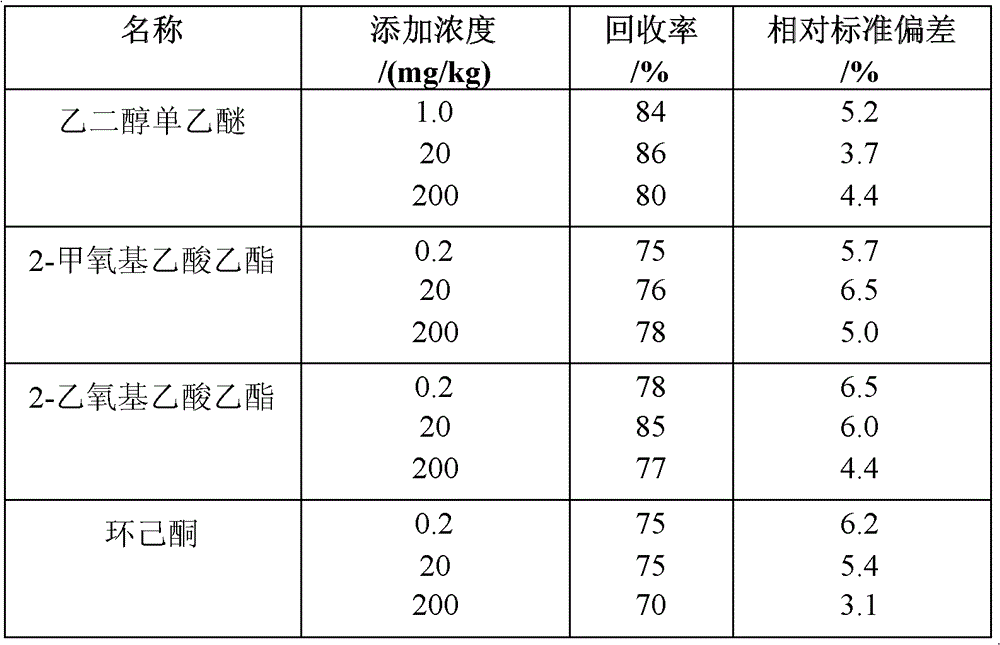

Determination method of harmful organic substance residue in toy sample

InactiveCN102608225AShorten the timeImprove efficiencyComponent separationCyclohexanoneMethoxyacetic acid

The invention adopts gas chromatography-mass spectrometry (GC-MS) to originally simultaneously determine residual contents of 9 kinds of organic substances in toy, including ethylene glycol monoethyl ether (EGEE), styrene, trimethylbenzene, isophorone, 2-methoxyethyl acetate, 2-ethoxyethyl acetate, cyclohexanone, bis(2-methoxyethyl) ether, and nitrobenzene. Common detection device is adopted in the method. The method provided by the invention has the advantages of easy popularization, simultaneous detection to save time, improved efficiency, low cost, high detection rate and sensitivity, and high application value in toy production and quality detection.

Owner:CHINESE ACAD OF INSPECTION & QUARANTINE

Waterproof and moisture permeable type thermoplastic polyurethane film and preparation method thereof

InactiveCN104448788AGood waterproof and moisture permeabilityPrevent penetrationToluene diisocyanateWater vapor

The invention discloses a waterproof and moisture permeable type thermoplastic polyurethane film and a preparation method thereof. The waterproof and moisture permeable type thermoplastic polyurethane film is prepared from the following components in percentage by weight: 80-85 percent of thermoplastic polyurethane, 8-10 percent of a slipping agent and 7-10 percent of a Matt agent, wherein the thermoplastic polyurethane is prepared from the following raw materials in parts by weight: 58-63 parts of poly(tetramethylene ether glycol), 30-35 parts of toluene diisocyanate, 5-8 parts of 2-ethoxyethyl acetate and 1-3 parts of dibutyl tin diacetate. By virtue of the mode, the waterproof and moisture permeable type thermoplastic polyurethane film is excellent in waterproof and moisture permeable performance, is capable of preventing permeation of water drops and ensuring free penetration of water vapor and can be used in a bad environment.

Owner:JIANGSU HONGYUAN NEW MATERIAL TECH

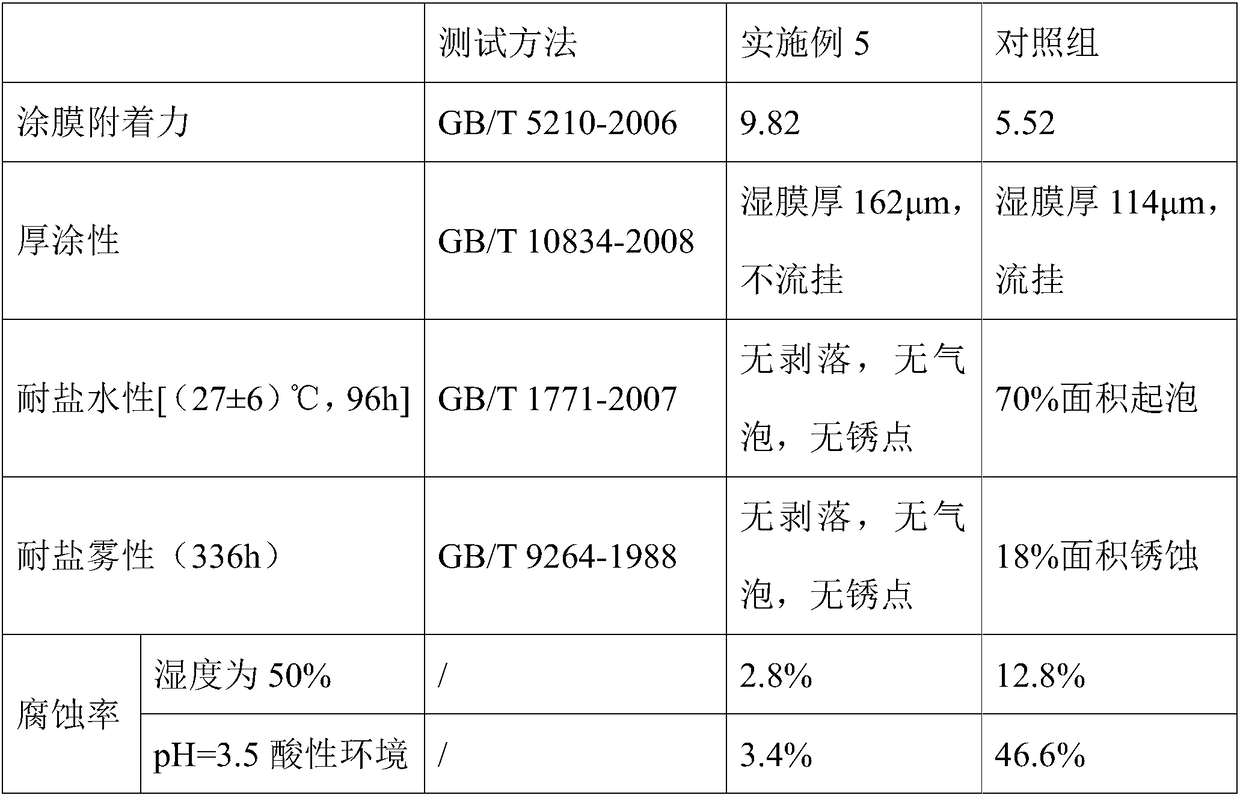

Chromium-free zinc-aluminum anticorrosive paint with phosphomolybdic acid hydrate as passivating agent

PendingCN109778159AMeet anti-corrosion requirementsImprove anti-corrosion performanceAnti-corrosive paintsMetallic material coating processesPhosphomolybdic acidChromium free

The invention discloses a water-borne chromium-free zinc-aluminum anticorrosive paint with phosphomolybdic acid hydrate as a passivating agent. The water-borne chromium-free zinc-aluminum anticorrosive paint with the phosphomolybdic acid hydrate as the passivating agent includes the following components, by mass, 250-310 parts of zinc powder, 10-30 parts of aluminum powder, 3-10 parts of the phosphomolybdic acid hydrate, 110-150 parts of polyethylene glycol, 70-140 parts of a silane coupling agent, 3-8 parts of 2-ethoxyethyl acetate, 1-18 parts of a surfactant, 1-6 parts of a defoaming agent,10-60 parts of tetraisopropyl titanate, 10-18 parts of boric acid and 380-480 parts of deionized water. The polyethylene glycol and the silane coupling agent being 35-50% of the total amount of formula, the 2-ethoxyethyl acetate, the surfactant and the defoaming agent are stirred to be made into an A component; the deionized water, the phosphomolybdic acid hydrate and the silane coupling agent inthe weight ratio and being 50-65% of the total amount of the formula, the tetraisopropyl titanate and the boric acid are stirred to be made into a B component; before use, the A component and the B component are mixed and stirred uniformly according to the weight ratio of 1:1-1.4, and the finished paint is prepared. The thermal stability of the prepared product of the water-borne chromium-free zinc-aluminum anticorrosive paint with the phosphomolybdic acid hydrate as the passivating agent is improved, and a coating after coating conforms to the comprehensive performance requirements of a thincoating, high adhesive strength, good anticorrosive performance and the like required by an automobile fastener.

Owner:沈阳市航达科技有限责任公司

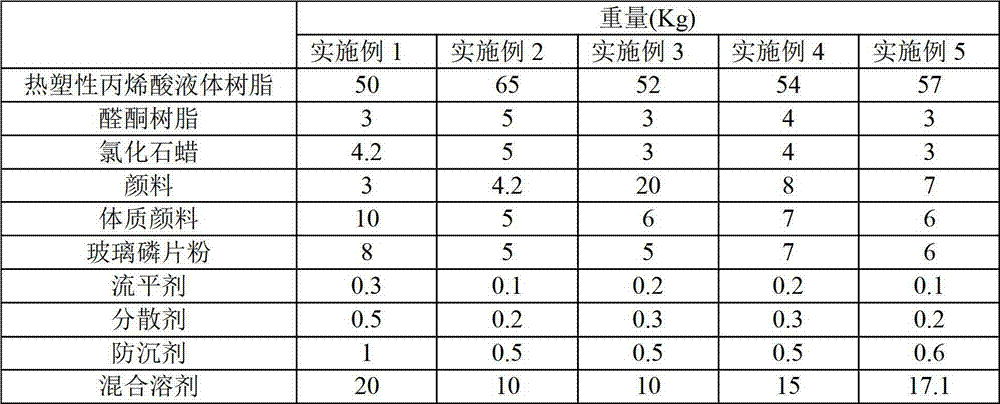

High-gloss high-weather-resistant acrylic acid paint

The invention provides high-gloss high-weather-resistant acrylic acid paint and belongs to the technical field of paint. The paint comprises, by weight, 50-65% of acrylic resin, 3-5% of aldehyde ketone resin, 3-5% of chlorcosane, 3-20% of pigment, 5-10% of extender pigment, 5-8% of glass flake powder, 0.1-0.3% of flatting agents, 0.2-0.5% of dispersants, 0.5-1% of anti-settling agents and 10-20% mixed solvent. Toluol, xylene, butyl ester, ethyl ester, butanone, methyl isobutyl ketone (MIBK), 2-ethoxyethyl acetate (CAC), ethylene glycol monobutyl, dibasic ester (DBE), butanol, isopropanol and ethanol are mixed in any proportion to form the mixed solvent. The paint has quick drying, high gloss, leveling property, fullness, weather resistance, vividness and anti-corrosive resistance. The paint has good adhesive force for all types of metal elements and all types of primer.

Owner:JIANGSU HUAXIA PAINT MAKING

Anti-corrosion and fireproof antibacterial epoxy paint

InactiveCN106752724AFire retardantWear-resistantFireproof paintsAntifouling/underwater paintsAntibacterial propertyEthoxyethyl acetate

The invention relates to an anti-corrosion and fireproof antibacterial epoxy paint. The anti-corrosion and fireproof antibacterial epoxy paint contains the following raw materials in percentage by weight: 20-30% of epoxy resin, 3-8% of phenolic aldehyde amine, 3-8% of nanometer titania, 3-8% of nanosilicon dioxide, 3-8% of nano-zinc oxide, 5-10% of deionized water, 3-8% of methylisothiazolinone, 2-5% of polyhedral oligomeric silsesquioxane, 4-8% of butylated amino resin, 3-6% of flaky graphite, 2-4% of glass flake, 1-3% of sericite powder, 1-3% of aluminium triphosphate, 1-3% of zinc phosphate, 1-4% of aluminium oxide, 1-2% of a tertiary amine curing accelerator, 1-3% of a silane coupling agent, 5-10% of ethoxyethyl acetate, 1-2% of a diluent, 2-4% of cellulose acetate, 2-5% of melamine fiber and 2-6% of waterborne magnesium hydroxide. The anti-corrosion and fireproof antibacterial epoxy paint obtained according to the formula has the advantages of fireproof and flame-retardant property, antibacterial property, tough paint film, wear resistance, good adhesion force, chemical corrosion resistance, water resistance and so on.

Owner:合肥英索莱特新材料科技有限公司

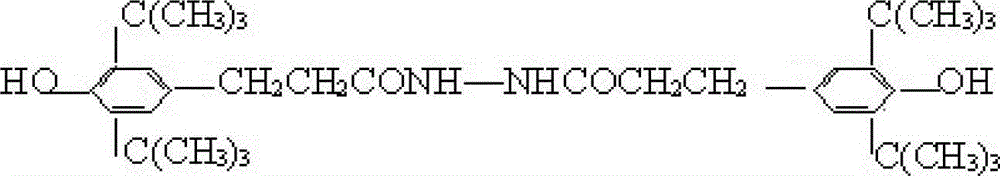

Environment-friendly neoprene sealant and preparation method thereof

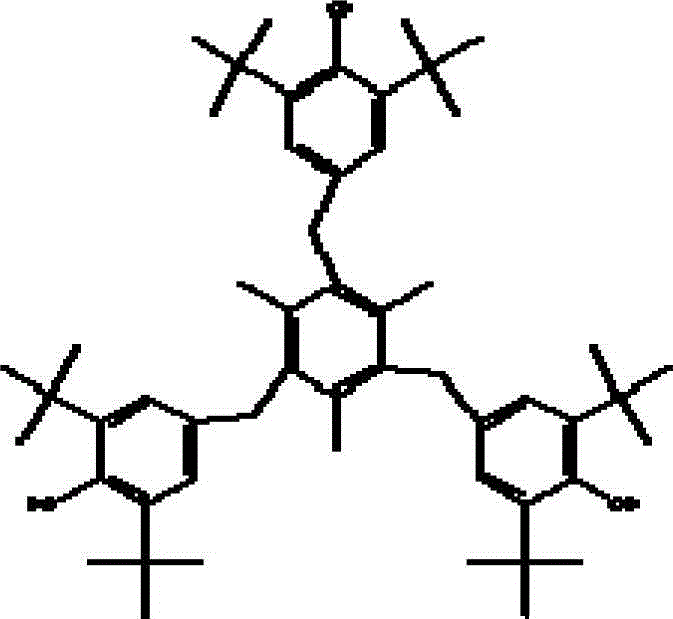

ActiveCN102911623AMeet physical and mental health requirementsProtect the environmentNon-macromolecular adhesive additivesChloroprene adhesivesAdhesiveMethyl carbonate

The invention belongs to the field of adhesives, and particularly relates to an environment-friendly neoprene sealant and a preparation method thereof. The environment-friendly neoprene sealant comprises the following components: neoprene, filler, esters solvent, solvent oil, phytoextraction essential oil, softener and antioxygen, wherein the filler is a mixture made of one or more than two of talcum powder, light calcium carbonate, titanium dioxide, magnesium oxide, kaolin and blanc fixe; the esters solvent is the mixture made of one type or a mixture of more than two types of methyl acetate, acetic ether, n-butyl acetate, amyl acetate, isoamyl acetate, dimethyl carbonate, ethoxyethyl acetate and propylene glycol monomethyl ether acetate; and the solvent oil is one type or a mixture of more than two types of 6 # solvent oil, 90 # solvent oil, 120 # solvent oil and 200 # solvent oil. The environment-friendly neoprene sealant has the advantages of environmental protection, innocuity, pressure resistance, good sealing performance and high strippable property.

Owner:GLEIHOW NEW MATERIALS CO LTD

Antibacterial plate and preparation method thereof

InactiveCN105602326AEasy to prepareEase of mass productionAntifouling/underwater paintsPaints with biocidesDiethylene glycol monobutyl etherSodium lactate

The invention discloses an antibacterial plate, comprising a base material and antibacterial coating applied to the surface of the base material; the antibacterial coating comprises a nano-sliver antibacterial agent, nano zinc oxide, ethoxyethyl acetate resin dispersant, titanium dioxide, acrylic copolymer emulsion, polyethylene wax emulsion, diethylene glycol monobutyl ether, cetylpyridinium bromide, tributyl phosphate, sodium lactate, isopropyl myristate, deionized water, a plasticizer, a thickener, a dispersing agent, a defoaming agent and a solidifying agent. The invention has the advantages that the antibacterial plate of the invention has a bactericidal efficiency of higher than 99% for Escherichia coli, Staphylococcus aureus, Bacillus subtilis var. Niger and the like; the antibacterial plate can release anions constantly under 600-1000 / s.cm<3>, decreasing the concentration of indoor high-concentration formaldehyde organic matters within specified index concentration (80 ppm); the preparation method is simple and convenient for batch production.

Owner:ZHUO DA NEW MATERIAL TECH GRP

Acrylic resin waterproof paint

The invention discloses an acrylic resin waterproof paint which is mainly prepared by mixing the following raw materials in parts by weight: 72 parts of acrylic resin, 16 parts of bamboo short fiber, 15 parts of organic amine, 30 parts of ethyl dimethylbenzoate, 5 parts of acetone, 10 parts of heavy calcium carbonate, 15 parts of 2-ethoxyethyl acetate, 10 parts of polypropylene fiber, 10 parts of kieselguhr, 60 parts of water, 8 parts of adhesive, 6 parts of film forming assistant, 6 parts of dispersant and 5 parts of defoaming agent. The product can be used outdoors, has strong elasticity, and can prevent cracking caused by different water contents of coating.

Owner:SUZHOU MEIYAMEI CONSTR COATINGS

Waterborne polyurethane waterproofing paint

ActiveCN103540251AGood weather resistanceImprove aging resistancePolyurea/polyurethane coatingsSodium metasilicateWeather resistance

The invention discloses a waterborne polyurethane waterproofing paint, which is composed of the following raw materials in parts by weight: 40-50 parts of waterborne polyurethane resin, 5-8 parts of 2-ethoxyethyl acetate, 20-30 parts of teflon, 10-15 parts of actinolite powder, 2-3 parts of sodium metasilicate, 1-2 parts of sodium dodecyl sulfate, 2-3 parts of poly-(tetramethylene ether) glycol, 1-2 parts of dodecyl trimethyl ammonium chloride, 5-10 parts of deionized water, and 7-10 parts of a bonding aid. The waterproofing paint disclosed by the invention is non-toxic and tasteless, and does not pollute the environment, therefore, the waterproofing paint is green and environmental-friendly; the waterproofing paint is good in weathering resistance, does not flow at high temperature and does not crack at low temperature; and the waterproofing paint is good in aging resistance, high in elongation at break, and good in waterproofing effect.

Owner:上海鸿鹄化工科技有限公司

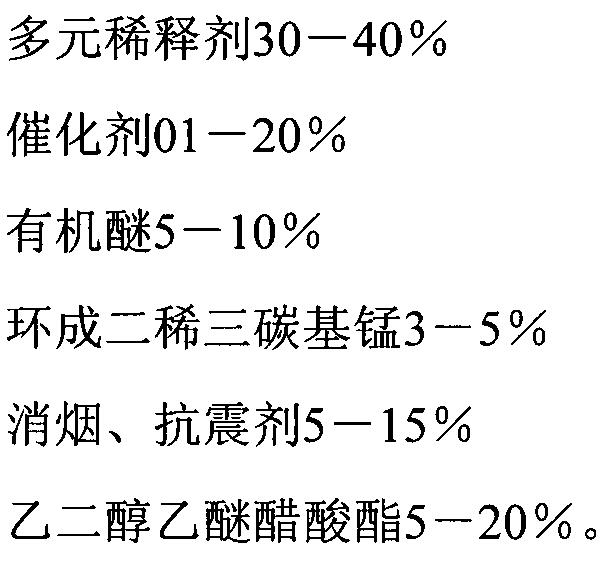

Multifunctional quick-acting fuel oil additive

InactiveCN102703142ABoost octaneImprove combustion effectLiquid carbonaceous fuelsFuel additivesOil additiveManganese

The invention provides a multifunctional quick-acting fuel oil additive which comprises the following components (by weight): 30-40% of multicomponent diluents, 10-20% of catalysts, 5-10% of organic ether, 3-5% of cyclopentadienyl tricarbonyl manganese, 5-15% of smoke-removing anti-knock agents, and 5-20% of ethoxyethyl acetate. The above components are added into an enclosed stirrer in order, stirred for 10-15 min, and sieved by a metal mesh to obtain the finished product. The beneficial effects of the invention are that the fuel oil additive can not only increase the fuel oil octane number and combustion performance, but also improve fuel oil storage and usage stability, prevent fuel oil from oxidation and gum formation, comprehensively remove fuel oil soluble gum, insoluble precipitated gum, adhesive gum and carburettor coked charcoal, reduce tail gas discharge harmful indexes, and form unique synergistic effect. The fuel oil additive has extensive applications, has flexibility, is suitable for gasoline and diesel oil with different models, and can be randomly blended into commercial unleaded gasoline such as 90#, 93#, 95# and the like, and -10# diesel oil according to its properties.

Owner:JIANGSU TAIYANGDAO ENERGY TECH

High-performance self-crosslinking acrylic resin environmental-friendly cathode electrophoretic paint and preparation method

The invention discloses a formula of high-performance self-crosslinking acrylic resin environmental-friendly cathode electrophoretic paint. The formula of the cathode electrophoretic paint comprises the following raw materials in parts by weight: 15-25 parts of acrylic resin, 0.3-1 part of a neutralizer, 0.1-0.2 part of an environmental-friendly catalyst, 0.1-0.5 part of a film-forming agent, 1-2parts of color paste and 60-70 parts of deionized water. Synthetic raw materials of the acrylic resin comprise monomers, an initiator and a solvent; the initiator comprises 1-3 parts of azodiisobutyronitrile; the solvent comprises one or more of isopropanol, glycol ethylene ether, butyl cellosolve, ethyl acetate, n-butyl acetate and ethoxyethyl acetate; the environmental-friendly catalyst comprises one or a complex of two of bismuth isooctoate and yttrium naphthenate. The invention further provides a preparation method. The cathode electrophoretic paint which has high gloss and of which the hardness and film thickness can meet user requirements can be prepared, VOC in the paint can be effectively reduced, and the load of the paint on the environment is alleviated.

Owner:东莞市同丰高分子材料有限公司

Electroplating finish and preparation method thereof

InactiveCN102311684AHigh convenienceDoes not affect inherent glossPaints for electrolytic applicationsWaxDiluent

The invention discloses an electroplating finish mainly comprising the following components by weight: 16.2% of nitrocotton, 15% of bismaleimide resin, 6.8% of ethyl ester, 30% of isobutyl ester, 14.5% of keto-aldehyde resin, 8.5% of 2-ethoxyethyl acetate, 3.5% of matt powder, 1.8% of sodium silicate, 3.2% of wax powder, and 0.5% of a polyether modified dimethyl siloxane solution. The preparation method of the electroplating finish includes the steps of: first mixing bismaleimide resin, ethyl ester, isobutyl ester and keto-aldehyde resin in proportion and stirring them uniformly so as to obtain a diluent; then adding the nitrocotton, 2-ethoxyethyl acetate, matt powder, sodium silicate, wax powder, polyether modified dimethyl siloxane solution and diluent in proportion into a dispenser for stirring well. The finish product of the invention has the advantages of good handle feel and adhesion, good surface gloss and rapid drying speed, as well as no influence on the inherent gloss of an electroplating piece, etc. Also the method for producing the electroplating finish has simple technology and low cost.

Owner:JIANGSU ANYANG CULTURE CREATIVE IND PARK

Abrasion-resistant rubber anti-slip material

The invention discloses an abrasion-resistant rubber anti-slip material, which consists of sulphur powder, zinc oxide, accelerant, thickener, anti-slip particles, white carbon black, carbon fibers, tricresyl phosphate, 2-ethoxyethyl acetate, dispersing additive and ethyl acetate. According to percentage by weight, the abrasion-resistant rubber anti-slip material consists of 1 to 3 parts of sulphur powder, 0.1 to 3 parts of zinc oxide, 1 to 5 parts of accelerant, 3 to 7 parts of thickener, 5 to 10 parts of anti-slip particles, 1 to 5 parts of white carbon black, 10 to 15 parts of carbon fibers, 5 to 10 parts of tricresyl phosphate, 5 to 10 parts of 2-ethoxyethyl acetate, 2 to 5 parts of dispersing additive and 10 to 15 parts of ethyl acetate. Thus the abrasion-resistant rubber anti-slip material provided by the invention has high abrasion resistance and anti-slip property, moreover, the materials in the formula are easy to purchase, and in the process of production, because the formula is simple and easy to operate, great convenience is brought to manufacturers.

Owner:SUZHOU QUNLI NON SLIP MATERIAL

Anti-corrosive epoxy paint

InactiveCN106752725AImprove adhesionStrong adhesionAnti-corrosive paintsEpoxy resin coatingsEpoxyCellulose acetate

The invention relates to an anti-corrosive epoxy paint. The anti-corrosive epoxy paint contains the following raw materials in percentage by weight: 20-30% of epoxy resin, 4-10% of nanometer titania, 7-10% of deionized water, 5-8% of coal tar pitch, 6-10% of butylated amino resin, 2-6% of flaky graphite, 1-3% of aluminium triphosphate, 1-3% of zinc phosphate, 2-5% of aluminium oxide, 3-5% of a tertiary amine curing accelerator, 3-5% of a silane coupling agent, 8-12% of ethoxyethyl acetate, 1-4% of a diluent, 4-8% of cellulose acetate and 4-8% of waterborne magnesium hydroxide. The anti-corrosive epoxy paint obtained according to the formula has the advantages of tough paint film, durability, good adhesion force, chemical corrosion resistance, strong alkali resistance, water resistance, solvent resistance, oil resistance, good insulation and so on.

Owner:合肥英索莱特新材料科技有限公司

Synthesis method of 2, 2-ethoxyethanol

InactiveCN102115431BEasy to operateSimple processOrganic chemistryOrganic compound preparationChemical industrySynthesis methods

The invention relates to a synthesis method of 2, 2-ethoxyethanol, belonging to the technical field of medicine and chemical industry. The method comprises the steps of: taking compound of a formula (I) as a raw material, and hydrolytically reacting the raw material with inorganic acid to obtain dichloroacetic acid; reacting the obtained dichloroacetic acid with caustic alcohol in absolute ethyl alcohol in a backflow way, adding hydrochloric acid ethanol solution in a cooling way after the reaction, adjusting PH value, filtering and distilling to obtain 2, 2-ethyl diethoxyacetate; and reacting the 2, 2-ethyl diethoxyacetate obtained in step b with KBH4 and inorganic catalyst in inorganic catalyst in a backflow way to obtain the 2, 2-ethoxyethanol. The synthesis method has the advantages that the raw material is easily obtained, the technical process is simple, the reaction condition is stable, the reaction can be performed without high pressure, and the synthesis method is suitable for the industrial production on a large scale. The solvent ethanol can be recovered and used mechanically, the atom economy is good, the cost is low, the product yield is high, and the product quality is more than 98%.

Owner:TAIZHOU UNIV

Additive for adhesive and adhesive composition

The adhesive composition comprises an additive for adhesive composed of (a) >=10 mass% and <=30 mass% water-soluble ketone, (b) >=10 mass% and <=30 mass% high boiling point alcohol, (c) >=20 mass% and <=40 mass% high boiling point ester and (d) >=10 mass% and <=10 mass% low boiling point alcohol and (e) >=3 mass% and <=10 mass% water, and a solvent type adhesive. The water-soluble ketone (a) is preferably diacetone alcohol and the high boiling point alcohol (b) is preferably cyclohexanol and the high boiling point ester (c) is preferably 2-ethoxyethyl acetate and the low boiling point alcohol (d) is preferably methanol.

Owner:MITSUBISHI RAYON CO LTD

Nanometer composite film material and preparation method thereof

InactiveCN109111625AExcellent gas barrier propertiesMeet industry requirementsLow-density polyethyleneComposite film

The invention discloses a nanometer composite film material and a preparation method thereof. The nanometer composite film material is prepared from the following raw materials by weight: 90-100 partsof low-density polyethylene, 75-85 parts of polyvinylidene fluoride, 25-35 parts of epoxy acrylate, 18-22 parts of ethoxyethyl acetate, 15-25 parts of polyurethane resin, 6-10 parts of N-cyclohexyl p-methoxyaniline, 5-7 parts of nanometer magnesium borate, 3-5 parts of poly-3-hydroxybutyrate, 1-3 parts of a nucleating agent, 1-3 parts of a plasticizer and 1 to 3 parts of an antistatic agent. Theprepared nanometer composite film material has excellent gas barrier properties and is resistant to aging. At the same time, the invention also discloses the corresponding preparation method.

Owner:苏州清之绿新材料有限公司

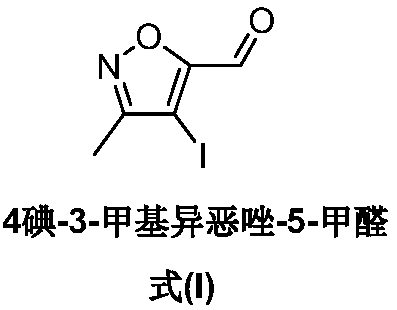

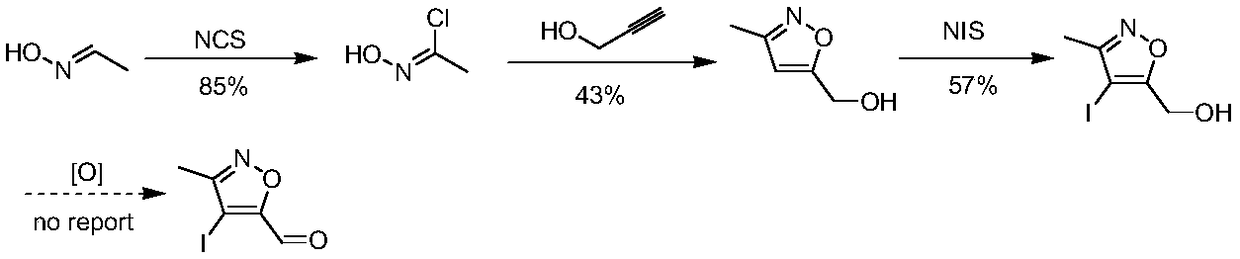

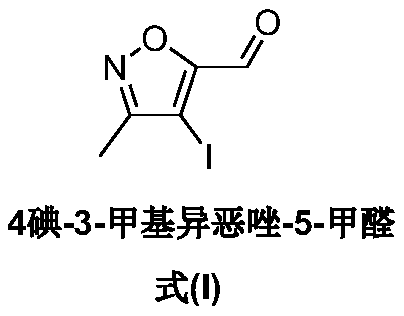

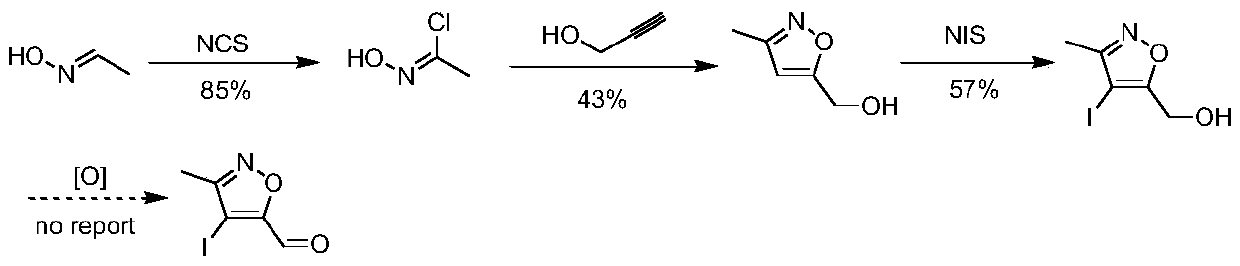

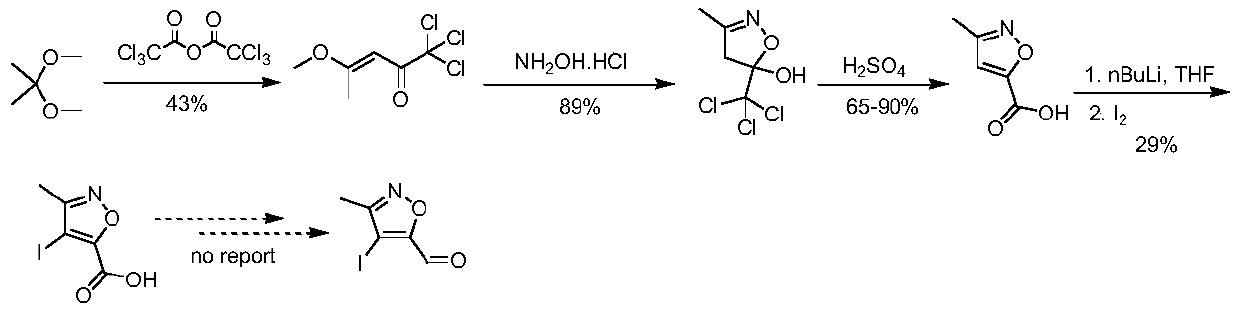

Synthesizing method of 4-iodo-methylisoxazole-5-formaldehyde

The invention belongs to the technical field of organic synthesis and provides a synthesizing method of 4-iodo-methylisoxazole-5-formaldehyde. The synthesizing method of the 4-iodo-methylisoxazole-5-formaldehyde comprises (1) condensation reaction including condensing the raw material of acetone oxime with 2, 2-ethyl diethoxyacetate to obtain 5-(diethoxymethyl)-3-methyl-4, 5-dihydroisoxazole-5-alcohol, (2) acylation reaction including aromatizing the 5-(diethoxymethyl)-3-methyl-4, 5-dihydroisoxazole-5-alcohol through methylsulfonyl chloride to obtain 5-(diethoxymethyl)-3-methylisoxazole, (3) iodination reaction including iodinating the 5-(diethoxymethyl)-3-methylisoxazole in acetonitrile through iodosuccinimide to obtain the 4-iodo-methylisoxazole-5-formaldehyde. The preparation method ofthe 4-iodo-methylisoxazole-5-formaldehyde is short in reaction path, low in costs of raw materials, simple in operation and applicable large-scale industrial production.

Owner:成都道合尔医药技术有限公司

Synthesis method of 2, 2-ethoxyethanol

InactiveCN102115431AEase of industrial productionSimple processOrganic chemistryOrganic compound preparationChemical industrySynthesis methods

The invention relates to a synthesis method of 2, 2-ethoxyethanol, belonging to the technical field of medicine and chemical industry. The method comprises the steps of: taking compound of a formula (I) as a raw material, and hydrolytically reacting the raw material with inorganic acid to obtain dichloroacetic acid; reacting the obtained dichloroacetic acid with caustic alcohol in absolute ethyl alcohol in a backflow way, adding hydrochloric acid ethanol solution in a cooling way after the reaction, adjusting PH value, filtering and distilling to obtain 2, 2-ethyl diethoxyacetate; and reacting the 2, 2-ethyl diethoxyacetate obtained in step b with KBH4 and inorganic catalyst in inorganic catalyst in a backflow way to obtain the 2, 2-ethoxyethanol. The synthesis method has the advantages that the raw material is easily obtained, the technical process is simple, the reaction condition is stable, the reaction can be performed without high pressure, and the synthesis method is suitable for the industrial production on a large scale. The solvent ethanol can be recovered and used mechanically, the atom economy is good, the cost is low, the product yield is high, and the product quality is more than 98%.

Owner:TAIZHOU UNIV

Preparation method of polyurethane waterproofing paint comprising polytetrahydrofuran and copolyether thereof

InactiveCN104479535AImprove wear resistanceImprove water resistancePolyurea/polyurethane coatingsLow speedChloride

The invention relates to a preparation method of a polyurethane waterproofing paint comprising polytetrahydrofuran and copolyether thereof. The polyurethane waterproofing paint comprises the following components in parts by mass: 100 parts of polytetrahydrofuran and copolyether polyalcohol thereof, 15-25 parts of ethoxyethyl acetate, 7-10 parts of carbamide, 4-6 parts of potassium tripolyphosphate, 3-5 parts of light calcium carbonate, 3-5 parts of zinc acetate, 1-2 parts of calcium chloride, 150-200 parts of deionized water, 6-8 parts of defoamer and 1-10 parts of silane coupling agent. The method comprises the following steps: stirring polytetrahydrofuran and copolyether polyalcohol thereof and ethoxyethyl acetate at a low speed to react for 0.5-1h; sequentially adding carbamide, potassium tripolyphosphate, light calcium carbonate, zinc acetate and calcium chloride, stirring for 20min and then adding deionized water; and adding the defoamer and the silane coupling agent under a stirring state, and uniformly stirring.

Owner:TAIXING HEQING MACHINERY FITTINGS FACTORY

A kind of synthetic method of 4-iodo-3-methylisoxazole-5-carbaldehyde

The invention belongs to the technical field of organic synthesis and provides a synthesizing method of 4-iodo-methylisoxazole-5-formaldehyde. The synthesizing method of the 4-iodo-methylisoxazole-5-formaldehyde comprises (1) condensation reaction including condensing the raw material of acetone oxime with 2, 2-ethyl diethoxyacetate to obtain 5-(diethoxymethyl)-3-methyl-4, 5-dihydroisoxazole-5-alcohol, (2) acylation reaction including aromatizing the 5-(diethoxymethyl)-3-methyl-4, 5-dihydroisoxazole-5-alcohol through methylsulfonyl chloride to obtain 5-(diethoxymethyl)-3-methylisoxazole, (3) iodination reaction including iodinating the 5-(diethoxymethyl)-3-methylisoxazole in acetonitrile through iodosuccinimide to obtain the 4-iodo-methylisoxazole-5-formaldehyde. The preparation method ofthe 4-iodo-methylisoxazole-5-formaldehyde is short in reaction path, low in costs of raw materials, simple in operation and applicable large-scale industrial production.

Owner:成都道合尔医药技术有限公司

Pencil handwriting eliminating liquid

InactiveCN103525156ANo smellGood effect in erasing handwritingChemical paints/ink removersHandwritingEther

The invention provides a pencil handwriting eliminating liquid which is characterized in that the formula comprises materials in parts by weight as follows: 10-30 parts of ethoxy ethyl acetate, 5-10 parts of dihydroxyethyl amine ether acetic ester and 40-50 parts of triethylene glycol methyl ether acetic ester. The preparation process comprises the steps as follows: the ethoxy ethyl acetate, the dihydroxyethyl amine ether acetic ester and the triethylene glycol methyl ether acetic ester are mixed uniformly, so that the product is obtained. The pencil handwriting eliminating liquid has the advantages that the raw materials are easy to obtain, the cost is low, the liquid is environment-friendly and free from peculiar odor, and the paper surface is not damaged when the handwriting is eliminated.

Owner:韦谷林

Preparation method of LED lamp with high heat dissipation and used in humid and decomposition environment

InactiveCN109488906AHigh acid and alkali resistanceExtended service lifeAnti-corrosive paintsPolyurea/polyurethane coatingsFiberCarbon fibers

The invention discloses a preparation method of an LED lamp with high heat dissipation and used in the humid and decomposition environment. The preparation method comprises the following steps that waterborne hydroxyl fluorinated polyurethane resin, bamboo carbon fibers, and 2-butoxyethyl acetate are stirred; methyl methacrylate-butadiene-styrene terpolymer is added and continuously stirred to obtain a prefabricated material a; the prefabricated material, waterborne acrylic resin, 2-acetoxy-1-methoxypropane and 2-ethoxyethyl acetate are stirred; talcum powder, montmorillonite, light calcium carbonate, vermiculite powder, and porous powdered quartz are stirred, end vinyl silicone oil, pine tar, a compatilizer, an anti-foaming agent, and a thickening agent are added and uniformly mixed to obtain a pre-processing coating; and the pre-processing coating is applied to the clean surface of an aluminum alloy section bar, an LED rear panel is obtained after solidification, and an LED chip is sealed and packed onto the LED rear panel to obtain the LED lamp with high heat dissipation and used in the humid and decomposition environment.

Owner:ANHUI LANRUI ELECTRONICS TECH

External wall paint

InactiveCN105315807AGood low temperature stabilityImprove water resistanceCoatingsPolymer scienceMeth-

The invention discloses an external wall paint. The external wall paint is prepared from the following raw materials in parts by weight: 10-15 parts of super absorbent resin, 10-15 parts of dimethyl ethenyl carbinol, 5-18 parts of titanium dioxide, 20-30 parts of white latex, 5-10 parts of lignin, 3.8-7.2 parts of methyl nonyl acetaldehyde, 4.8-6.5 parts of ethyl ethoxyacetate, 1.2-3.5 parts of an acrylic resin modified casein film forming agent and 3.3-6.5 parts of vinyl acetate and higher fatty acid vinyl ester copolymer powder. Compared with a conventional product, the external wall paint is good in low-temperature stability and high in water and alkali resistance, allows 2,000-2,500 times of scrubbing, has a long service life, is still normal after three or more times of coating temperature alternating resistance tests, and is short in drying time and even, beautiful and elegant in coating appearance.

Owner:QINGDAO XIANGJIA INTPROP SERVICE CO LTD

Outer wall paint

InactiveCN105778593AGood low temperature stabilityImprove water resistanceAnti-corrosive paintsPolymer scienceMeth-

The invention discloses outer wall paint. The outer wall paint is prepared from, by weight, 10-15 parts of super absorbent resin, 10-15 parts of dimethyl ethenyl carbinol, 5-18 parts of titanium dioxide, 20-30 parts of white latex, 5-10 parts of lignin, 3.8-7.2 parts of methyl nonyl acetaldehyde, 4.8-6.5 parts of ethyl ethoxyacetate, 1.2-3.5 parts of an acrylic acid resin-modified casein film-forming agent and 3.3-6.5 parts of vinyl acetate and higher fatty acid vinyl ester copolymerized gelatin powder. Compared with an existing product, the outer wall paint has the advantages of being good in low-temperature stability, high in water resistance and alkali resistance, capable of resisting scrubbing for 2000-2500 times, long in service life, free of abnormities after being subjected to a coating temperature alternating resistance test for 5 times or above, short in drying time, and smooth, attractive and elegant in coating appearance.

Owner:QINGDAO JINLIANXIN BUSINESS & TRADE

Butyl acetate resin fireproof coating

InactiveCN103265876AHigh bonding strengthImprove flame retardant performanceFireproof paintsPolyether coatingsPotassium persulfatePlastic materials

The invention discloses a butyl acetate resin fireproof coating which is prepared through stirring the following main raw materials in parts by weight: 150-160 parts of butyl acetate resin, 15-25 parts of ethoxyethyl acetate, 15 parts of potassium persulfate, 13-15 parts of titanium dioxide, 17-20 parts of urea, 20-22 parts of potassium tripolyphosphate, 10-13 parts of diethanol amine, 11-13 parts of hendecyl zinc, 10-13 parts of polyethylene glycol and 12-14 parts of borax. Industrial tests prove that the butyl acetate resin fireproof coating coated on the surface of a wooden material or plastic material has the characteristics of strong bonding strength and good fire resistance performance, and also has good application property, and the raw materials are cheap.

Owner:SUZHOU FUTONG NEW MATERIALS & HIGH TECH

Non-formaldehyde adhesive used for automobile trim

InactiveCN109628013ANo pollution in the processReduce odorNon-macromolecular adhesive additivesStarch adhesivesHazardous substanceAdhesive

The invention discloses a non-formaldehyde adhesive used for an automobile trim. The non-formaldehyde adhesive is prepared from, by weight, 15-25 parts of starch, 1-1.78 parts of resin, 1-2.5 parts ofborax, 18-23 parts of a dispersing agent, 20-30 parts of polyvinyl acetate, 10-15 parts of 2-ethoxyethyl acetate, 0.1-0.2 part of a defoaming agent, 50-60 parts of liquid water, 1.6-3.2 parts of sodium hydroxide and 0.3-0.5 part of oxidation water. The oxidation time length of the oxidation water in summer is 1.5-3 hours and is 4-6 hours in winter, and the PH value of the adhesive is 7.1-7.9. Theprepared non-formaldehyde adhesive used for the automobile trim is healthy, environmentally friendly and free of pollution, peculiar smells in an automobile are reduced, potential hazards of health of a human body are prevented, meanwhile, the content of harmful substances is small, quality is stable, and application prospects are better.

Owner:LIUZHOU YAXIANG TECH CO LTD

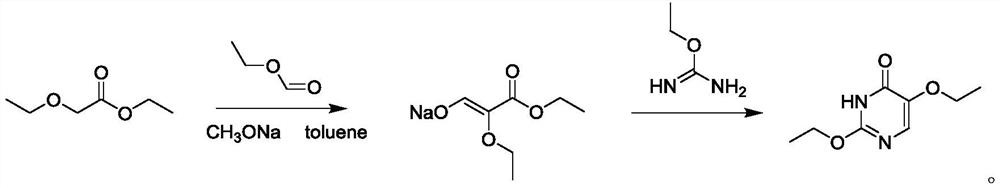

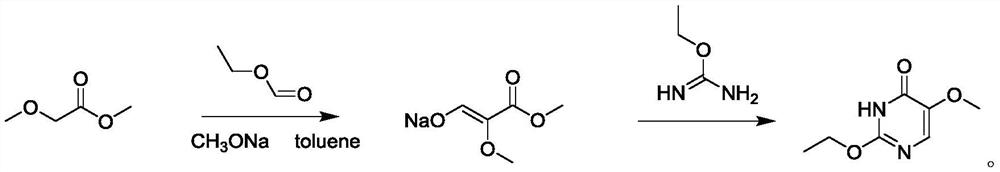

Preparation method of 2-ethoxy-5-fluorouracil impurity

The invention discloses a preparation method of a 2-ethoxy-5fluorouracil impurity. The preparation method of the 2-ethoxy-5-fluorouracil impurity comprises the following steps: (1) respectively dropwise adding a raw material and ethyl formate into a uniform mixing system which takes methyl methoxyacetate or ethyl ethoxyacetate as a raw material, sodium methoxide as alkali for hydrogen removal andtoluene as a solvent, and reacting to form a 2-ethoxy-5-fluorouracil impurity intermediate; (2) dropwise adding ethoxy isourea into the 2-ethoxy-5-fluorouracil impurity intermediate, adjusting the pHvalue to be 9-10, and then sequentially carrying out heating, reduced pressure distillation, water addition dissolution and purification treatment so as to obtain a 2-ethoxy-5-fluorouracil impurity crude product; and (3) adding water into the 2-ethoxy-5-fluorouracil impurity crude product for dissolving, and then sequentially carrying out ice water cooling crystallization, suction filtration, water washing and drying to obtain the 2-ethoxy-5-fluorouracil impurity. The preparation method disclosed by the invention is short in route and simple in post-treatment, and the prepared 2-ethoxy-5-fluorouracil impurity is relatively high in purity and can be applied to reference substance research.

Owner:JINGHUA PHARMA GRP NANTONG

Determination method of harmful organic substance residue in toy sample

InactiveCN102608225BShorten the timeImprove efficiencyComponent separationCyclohexanoneMethoxyacetic acid

The invention adopts gas chromatography-mass spectrometry (GC-MS) to originally simultaneously determine residual contents of 9 kinds of organic substances in toy, including ethylene glycol monoethyl ether (EGEE), styrene, trimethylbenzene, isophorone, 2-methoxyethyl acetate, 2-ethoxyethyl acetate, cyclohexanone, bis(2-methoxyethyl) ether, and nitrobenzene. Common detection device is adopted in the method. The method provided by the invention has the advantages of easy popularization, simultaneous detection to save time, improved efficiency, low cost, high detection rate and sensitivity, and high application value in toy production and quality detection.

Owner:CHINESE ACAD OF INSPECTION & QUARANTINE

A kind of preparation method of 2-ethoxy-5-fluorouracil impurity

The invention discloses a preparation method of 2-ethoxy-5-fluorouracil impurity. The preparation method of the 2-ethoxy-5-fluorouracil impurity comprises: (1) uniform mixing using methyl methoxyacetate or ethyl ethoxyacetate as raw material, sodium methoxide as alkali extraction hydrogen, and toluene as solvent The raw material and ethyl formate are respectively added dropwise in the system and reacted to form a 2-ethoxy-5-fluorouracil impurity intermediate; (2) ethoxylate is added dropwise to the 2-ethoxy-5-fluorouracil impurity intermediate base isourea, adjust pH=9-10, then carry out heating, underpressure distillation, water-dissolving, purification treatment successively to obtain 2-ethoxy-5-fluorouracil impurity crude product; (3) to 2-ethoxy- The 5-fluorouracil impurity crude product is dissolved in water, and then ice-water cooling and crystallization, suction filtration, washing and drying are performed successively to obtain the 2-ethoxy-5-fluorouracil impurity. The preparation method of the invention has short route, simple post-treatment, and the prepared 2-ethoxy-5-fluorouracil has high impurity purity, which can be applied to the research of reference substances.

Owner:JINGHUA PHARMA GRP NANTONG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com