Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

170results about How to "Fire retardant" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Seashell-diatom ooze wall surface decoration wall material and production and construction method thereof

The invention discloses a seashell-diatom ooze wall surface decoration wall material and a production and construction method thereof. The decoration wall material comprises: 20 to 98 parts of shell powder, 8 to 30 parts of silica, 4 to 100 parts of kieselguhr, 2 to 20 parts of medical stone, 3.8 to 48 parts of mica powder, 2 to 10 parts of magnesium-rich silicate, 6 to 26 parts of scolecite, 1.5to 36 parts of hydrosilicate, 0 to 50 parts of titanium dioxide powder, 2 to 50 parts of calcium carbonate, 0.1 to 0.3 part of vegetable fiber, 1 to 30 parts of pigment, 4.8 to 40 parts of kelp powder, 1 to 30 parts of cold soluble polyvinyl alcohol powder and 1 to 20 parts of hydroxypropyl methyl cellulose. The production and construction method comprises: placing the raw material components into a stirrer for uniform stirring; filling the mixture in bags, packing the bags in boxes, sealing the boxes and storing the boxes in a storehouse; adding water into the mixture and stirring the mixture uniformly; and pasting the mixture on a wall surface to be decorated to make various texture patterns. The seashell-diatom ooze wall surface decoration wall material has the advantages of: (1) soft texture and no toxicity, fading nor stripping; (2), characteristics of eliminating indoor pollution, regulating indoor humidity, eliminating odor, isolating noises and offering high skin texture feel; (3) fire proofing and flame retarding; and (4) rich color.

Owner:青岛泉佳美硅藻泥科技有限公司

Fly ash/bentonite ceramsite concrete hollow insulation block and preparation method thereof

ActiveCN103253906ALightweight and low densityCorrosion resistantSolid waste managementCeramicwareSoluble glassNano al2o3

The invention discloses a fly ash / bentonite ceramsite concrete hollow insulation block and a preparation method thereof. The block is prepared from the following raw materials by weight: 100 to 150 parts of ordinary Portland cement grade 42.5, 500 to 600 parts of stone chippings, 30 to 40 parts of fly ash, 10 to 15 parts of bentonite, 5 to 10 parts of paper pulp waste liquid, 2 to 4 parts of nanometer alumina, 3 to 6 parts of light calcium carbonate, 20 to 30 parts of soluble glass, 10 to 15 parts of straw powder, 4 to 6 parts of a foaming agent, 1 to 2 parts of foots, 2 to 3 parts of a glass fiber, 0.5 to 1.5 parts of a redispersible latex powder and 150 to 210 parts of water. The boron fly ash / bentonite ceramsite concrete hollow insulation block produced in the invention has the advantages of high strength, low density, good heat insulation performance, good impact resistance, small possibility of water absorption, fire resistance, flame retardation, good weatherability, environment-friendliness, energy conservation and the like and has great market space and development prospects in the application field of building energy conservation in China.

Owner:池州市新蕾绿色建材有限公司

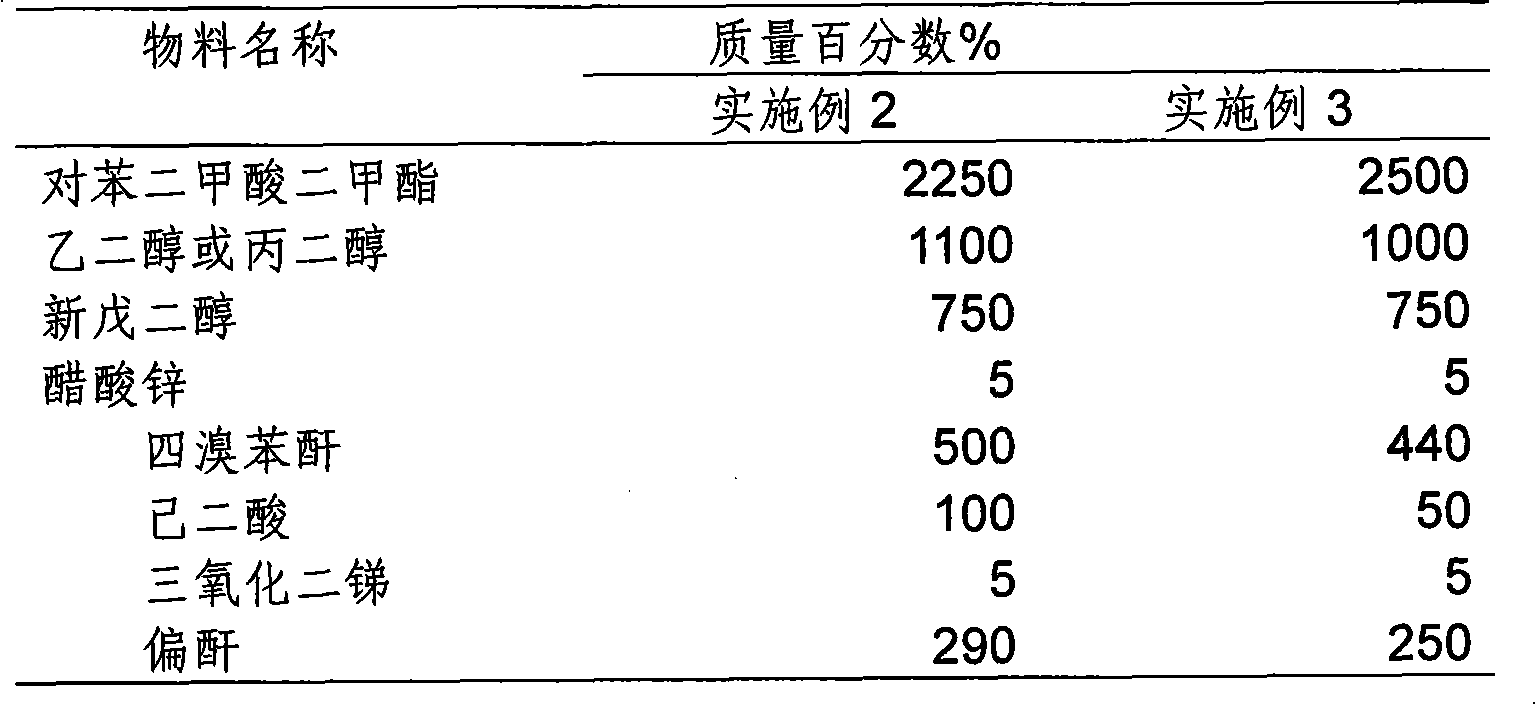

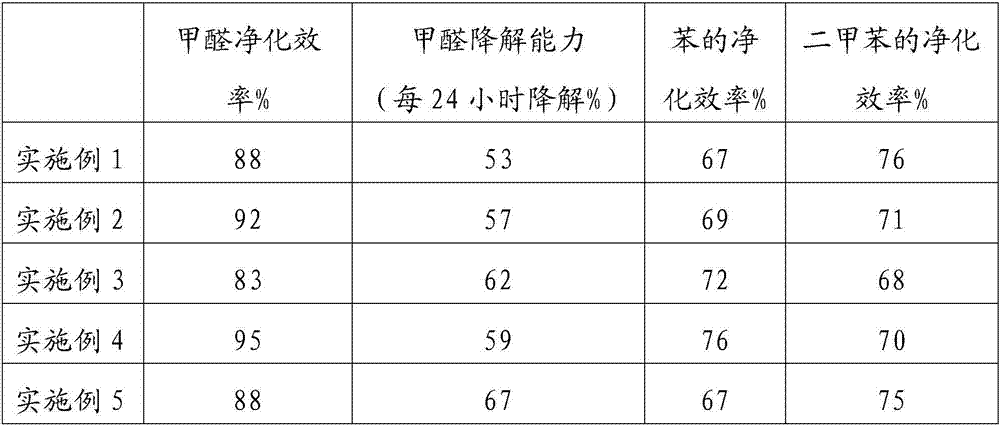

Powder fire-proof paint containing bromine-carbon polyester and preparation method thereof

InactiveCN101255310AImprove decorationGood weather resistanceFireproof paintsPowdery paintsBromineZinc Acetate Dihydrate

The invention provides a powder fire-retardant coating containing bromine carbon polyester and preparation method thereof, comprising( by weight percentage): end-carboxyl bromine carbon polyester resin 55.0-70.0%, curing agent 5.5-7.0%, dicyandiamide 0.3-0.5%, solid flow agent 1.5-2.0%, liquid flow agent 0.5-1.0%, epoxy resin 4.5-9%, white titanium pigment 5.0-20.0%, precipitated barium sulfate 2.0-15.0%, zinc oxide 2.0-15.0%, light calcium carbonate 0-5.0%, zinc acetate 0.3-0.5%, antimony oxide 0.2-0.5%, molybdenum hemitrioxide 0.2-1.0% and zinc borate. The preparation method thereof comprises: mixing the liquid flow agent and epoxy resin; mixing the end-carboxyl bromine carbon polyester resin, solid flow agent and liquid flow agent; adding curing agent, dicyandiamide, white titanium pigment, precipitated barium sulfate, zinc oxide, light calcium carbonate, zinc acetate, antimony oxide, molybdenum hemitrioxide and zinc borate; fusing and extruding the mixture using an extruder; tabletting, crushing, whirlwind separating and screening to obtain the coating.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

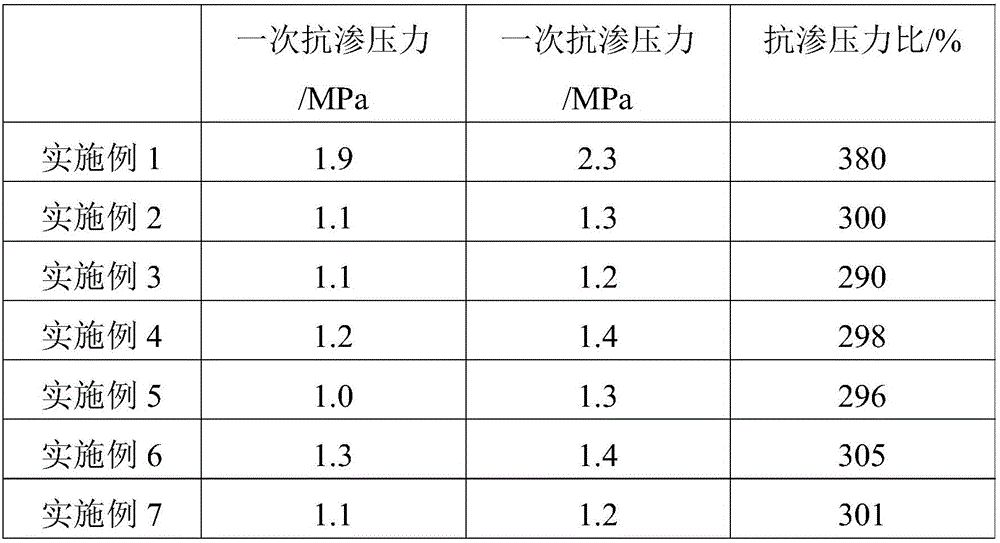

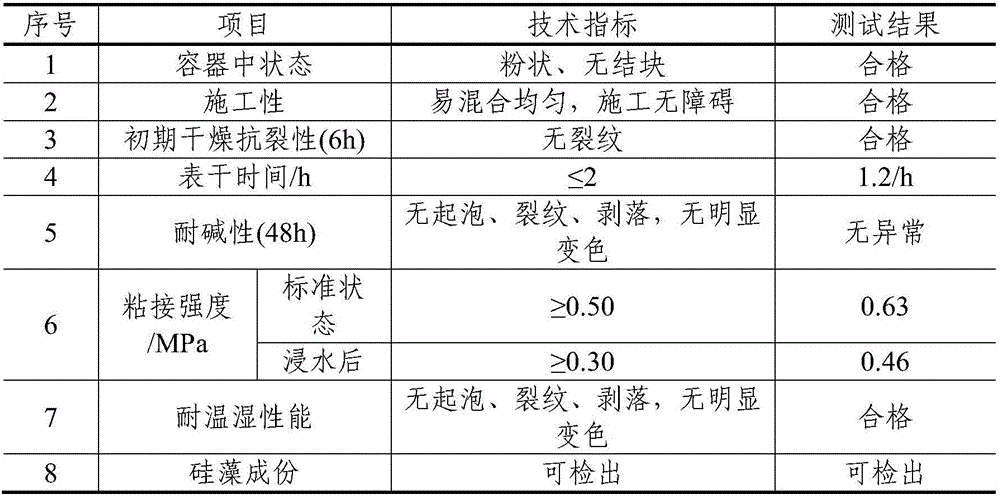

Novel environment-friendly waterborne inorganic paint and preparation method thereof

InactiveCN107266944AFire retardantAntibacterial and antifungalFireproof paintsAntifouling/underwater paintsPolyvinyl alcoholFire resistance

The invention discloses novel environment-friendly waterborne inorganic paint and a preparation method thereof. The novel environment-friendly waterborne inorganic paint is prepared from, by weight, 55-65 parts of kaolin, 12-20 parts of sodium silicate, 20-30 parts of titanium dioxide, 1-5 parts of nano zinc oxide, 5-10 parts of ultrafine wollastonite powder, 1-10 parts of nano calcium carbonate, 1-5 parts of ultrafine white mica powder, 7-15 parts of polyvinyl alcohol, 1-4 parts of ultrafine molybdenum disulfide powder, 2-10 parts of nano silicon dioxide, 2-12 parts of nano magnesium oxide, 2-12 parts of nano aluminum oxide, 1-3 parts of magnesium chloride, 1-3 parts of a sodium silicate hardening accelerator, 2-5 parts of a pH value regulating agent, 1-8 parts of a waterproof agent, 6-10 parts of an antifoaming leveling agent, 1-3 parts of a thickening anti-settling agent and 280-310 parts of water. The novel environment-friendly waterborne inorganic paint which is environment-friendly waterborne inorganic paint for buildings is high in storage stability, excellent in water resistance and alkali resistance, strong in adhesion, high in fire resistance, high in strength and hardness, resistant to scratching and contamination, excellent in corrosion resistance and antibacterial property, free of formaldehyde, benzene compounds, VOC (volatile organic compounds) and heavy metal elements, completely environmental friendly and nontoxic, suitable for industrial production, easy for painting and convenient and quick in construction.

Owner:CHENGDU POLYTECHNIC

Method for Functional Coating of Basalt Fiber and of Basalt Fiber Core Twisted Yarn, Basalt Fiber and Basalt Fiber Core Twisted Yarn by Using the Method and Fabric Woven Therefrom

InactiveUS20080261013A1Improved perforation resistance propertyEase of colorabilityFibre treatmentPretreated surfacesYarnSolvent

Disclosed herein is a method of functionally coating a basalt fiber, including: coating a basalt fiber by passing the basalt fiber through an aqueous fluorine-based solution including 50˜60 wt % of polytetrafluoroethylene (PTFE), 2˜5 wt % of a nonionic surfactant and water at a passing speed of 1˜2 m / minute, the solution being maintained at a temperature of 20˜25° C.; drying the coated basalt fiber at a temperature of 80˜110° C.; heating the dried basalt fiber to a temperature of 180˜270° C.; and sintering the heated basalt fiber at a temperature of 360˜420° C. Further, disclosed herein is a method of functionally coating a basalt core yarn, including: preparing a basalt core yarn by winding a sub fiber around a basalt fiber, which is a main fiber, and then twisting the sub fiber and basalt fiber; coating the basalt core yarn by passing the prepared basalt core yarn through a coating solution including 35˜45 wt % of a phosphorus-based fire retardant, 50˜59.9 wt % of toluene, which is a solvent, and 0.1˜10 wt % of a thermostabilizer at a passing speed of 280˜320 m / hour, the coating solution being maintained at a temperature of 95 1050C; and drying the coated basalt core yarn.

Owner:SECOTECH

Simulated marble slab and production method thereof

InactiveCN102700205AHard textureImprove wear resistanceNatural patternsSynthetic resin layered productsBuilding materialSubstrate surface

The invention relates to a marble slab, in particular to an artificial simulated marble slab and a production method of the artificial simulated marble slab. The invention aims to overcome defects of natural marble and provide the simulated marble slab which has low price, is light, is easy to pave, has no harm and pollution and can replace the natural marble. The simulated marble slab comprises a substrate layer. A priming paint layer, a marble pattern layer and a finish layer are sequentially arranged on the positive face of the substrate layer from bottom to top. The invention also aims to provide a production method of the simulated marble slab, which comprises the following steps of: selecting a substrate; tailoring the selected substrate to a required size; tenoning on tailored substrate; coating priming paint on the positive surface of the substrate; spraying natural marble patterns on the surface coated with the priming paint of the substrate; and coating finish on the surface sprayed with the natural marble patterns of the substrate. The simulated marble slab provided by the invention can be widely applied in multiple industries such as building material, advertisement, furniture, decoration and the like.

Owner:GUANGZHOU GUANGYANG FU BULGARI HOME MATERIAL

Non-combustible compact plate and preparation method thereof

ActiveCN102423940AHigh strengthImprove adhesionSynthetic resin layered productsLaminationFiberVolumetric Mass Density

The invention relates to a non-combustible high-density compact plate and a preparation method thereof. The non-combustible compact plate comprises a core plate and decoration paper on two sides of the core plate, and is characterized in that: the core plate comprises the following components in percentage by weight: 30 to 45 percent of fiber, 30 to 40 percent of phenolic resin, 10 to 20 percent of inert filler, 10 to 20 percent of flame retardant, 0.3 to 1 percent of dye and 0.15 to 0.7 percent of coupling agent, wherein the diameter of inert filler solid particles is 0.01 to 0.5mm, and the inert filler is one or a combination of more of calcium carbonate, kaolin and talcpowder. The compact plate has the characteristics of high strength, high adhesion, fire resistance and flame retardance, and has the density of about 1.4g / cm<2>, combustion performance reaches a non-combustible level A1 in the national standard on the premise that the high performance such as high density and the like of the compact plate are not changed, and the requirement of special industry on high fire resistance of building decoration materials is met.

Owner:深圳市特艺达装饰设计工程有限公司

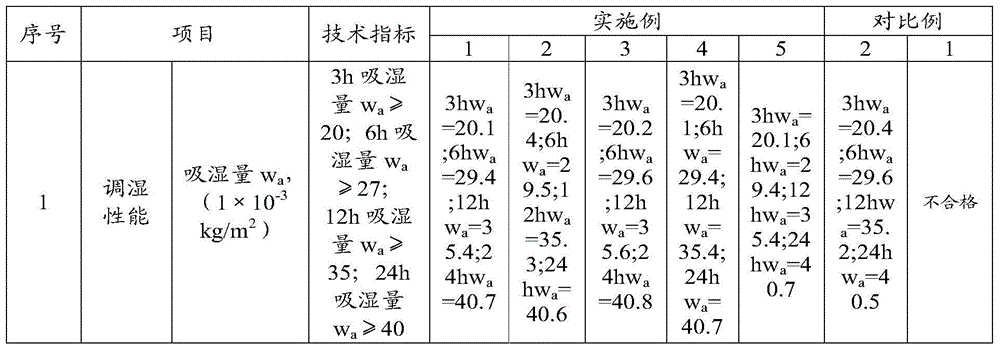

Decoration board containing diatomite and production method of decoration board

The invention discloses a decoration board containing diatomite and a production method of the decoration board. The decoration board containing the diatomite comprises, by weight, 100-150 parts of diatomite, 50-70 parts of kaolin, 30-50 parts of titanium dioxide, 50-90 parts of shell powder, 80-120 parts of corn straw powder, 40-80 parts of polyvinyl chloride, 15-30 parts of glass fibers, 5-20 parts of foaming regulator, 5-15 parts of stearic acid and 50-80 parts of water. The produced decoration board can effectively purify indoor air, remove harmful substances such as formaldehyde, benzene and xylene, and effectively degrade the formaldehyde.

Owner:白山和一硅藻科技股份有限公司

Nanometer silver carbon based inner wall coating

The invention provides a nano-silver carbon silicon interior wall paint. Calcium powder and diatomite powder crushed into 300 meshes to 400 meshes of fine powder, perlite powder and active carbon powder crushed into 50 meshes to 70 meshes of fine powder are mixed and added with nano-silver and water to be blended into slurry state to form the paint. The paint of the invention utilizes the nano-silver broad-spectrum high-efficiency sterilization (virus killing) mechanism, and the coconut shell carbon and diatomite adsorption filtration energy-conservation principle to accct on the surface of the wall, and is characterized by sterilization, mold resistance, adsorption, air purification, negative ion releasing, fireproofness, fire retardation, heat preservation, energy conservation, etc., and remedies and solves all the disadvantages of traditional wall materials. The paint of the invention is applicable to the decoration and fitment of all interior walls as the wall materials.

Owner:吉林省嘉鹏硅藻土研发有限责任公司

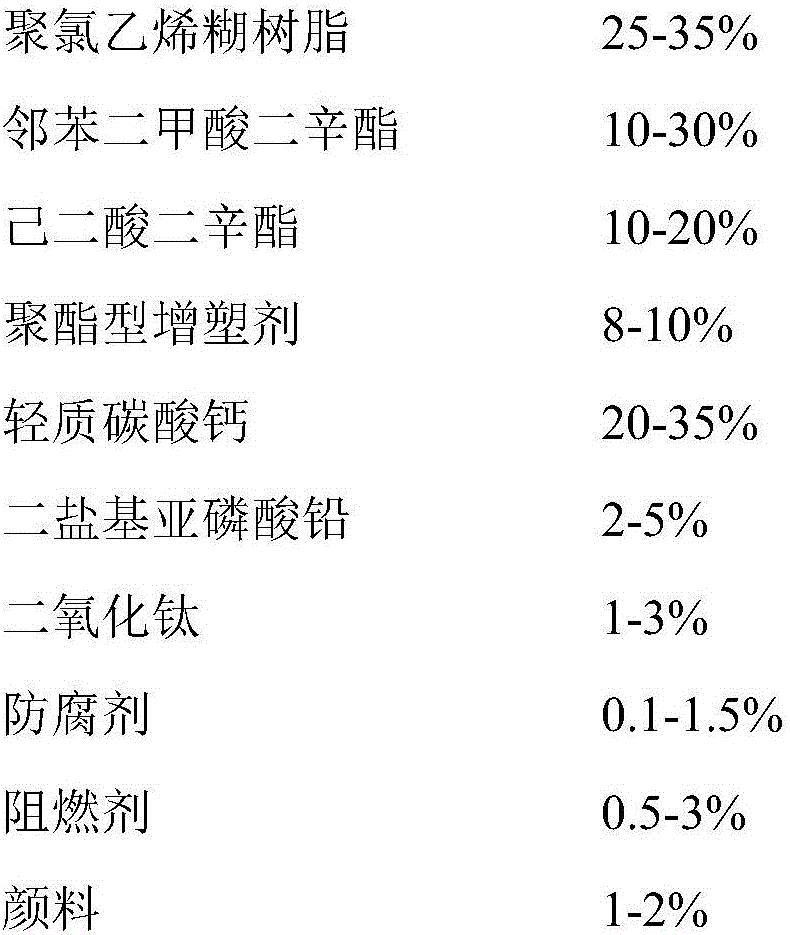

Canvas for canoe and preparing method thereof

ActiveCN106087441AGuaranteed StrengthStrength hasFireproof paintsAntifouling/underwater paintsPolyesterPolyvinyl chloride

Canvas for a canoe comprises gray fabric, an inner coating and an outer coating, wherein the gray fabric is filament woven plain cloth, the inner coating is prepared from, by weight, 25-35% of polyvinyl chloride paste resin, 10-30% of dioctyl phthalate, 10-20% of dioctyl adipate, 8-10% of polyester type plasticizer, 20-35% of light calcium carbonate, 2-5% of lead oxide phosphite hydrate, 1-3% of titanium dioxide, 0.1-1.5% of preservative, 0.5-3% of flame retardant and 1-2% of pigment, and the inner coating is 0.5-1 mm thick; the outer coating is a polypropylene calendering film and is prepared from, by weight, 60-70% of polypropylene resin, 0.3-0.8% of ultraviolet light absorber, 15-30% of flame retardant, 10-15% of glass fiber and 0.6-1% of pigment, and a polyamide film which is purchased from market and 0.2-0.4 mm thick can also be adopted. A method for preparing the canvas mainly comprises the steps of padding and sizing, plasticizing in an oven, surface flattening and cooling into coils.

Owner:NINGBO TIANDUN WATERPROOF MATERIAL CO LTD

High-temperature-resisting, insulating and inflaming-retarding power cable material and preparing method thereof

InactiveCN105924715AImprove bending strengthHigh strengthPlastic/resin/waxes insulatorsElastomerFiber

The invention discloses a high-temperature-resisting, insulating and inflaming-retarding power cable material and a preparing method thereof. The material is prepared from, by mass, polyolefin elastomer, nano-zirconia, glass fiber, PBO fiber, polyimide fiber, polypropylene, pentaerythritol tetrakis(2-mercaptoacetate), trioctylphosphine orthophthalic triformate, polybutylene terephthalate, cyclohexanedicarboxylic acid diglycidyl ester and toluene diisocyanate. The power cable material is high in bending strength, bending modulus, tensile strength, weather resistance and high temperature resistance, the influence of the environment on a cable sheath is reduced, strength is high, hardness is high, impact resistance is high, stability is excellent, service life is long, corrosion resistance, fire retardancy and insulating property are realized, and the material is worth application and popularization in multiple fields.

Owner:WUHU CHENGTONG AUTOMATION EQUIP

Nanometer silver carbon based inner wall prime

The invention provides a nano-silver carbon-based interior wall basic paint. Active carbon powder crushed into 800 meshes to 1200 meshes of fine powder, calcium powder crushed into 300 meshes to 400 meshes of fine powder and pearlite powder crushed into 50 meshes to 70 meshes of fine powder are mixed and added with nano-silver, an organic adhesive and water to form the paint of the invention. The paint of the invention utilizes the nano-silver broad-spectrum high-efficiency sterilization (virus killing) mechanism, and the coconut shell carbon and diatomite adsorption filtration energy-conservation principle to act on the surface of the wall, and is characterized by sterilization, mold resistance, adsorption, air purification, negative ion releasing, fireproofness, fire retardation, heat preservation and energy conservation, etc., and remedies and solves all the disadvantages of traditional wall materials. The paint of the invention is applicable to the decoration and fitment of all interior walls as the wall materials.

Owner:NORTHEAST NORMAL UNIVERSITY

Environment-friendly floor tile and preparation method thereof

The invention discloses an environment-friendly floor tile. The environment-friendly floor tile is prepared from the following components in parts by weight: 15 to 30 parts of cement, 10 to 20 parts of diatom ooze, 30 to 40 parts of quartz sand, 6 to 8 parts of bamboo fiber, 8 to 17 parts of silica gel, 5 to 9 parts of aluminum hydroxide, 1 to 3 parts of talcum powder, 2 to 4 parts of graphite, 3 to 6 parts of carbon black, 4 to 8 parts of straw powder, 5 to 10 parts of toughening agent, 8 to 15 parts of fire retardant, 0.8 to 1.5 parts of antioxidant and 3 to 10 parts of plant extracting solution. The environment-friendly floor tile is prepared from the natural and environment-friendly materials, and has the function of adsorbing harmful gases such as formaldehyde.

Owner:合肥慧林建材有限公司

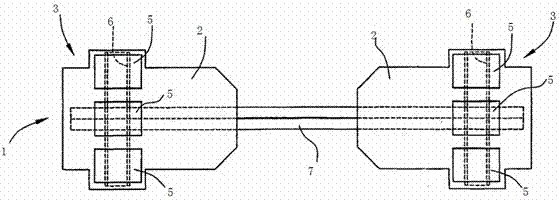

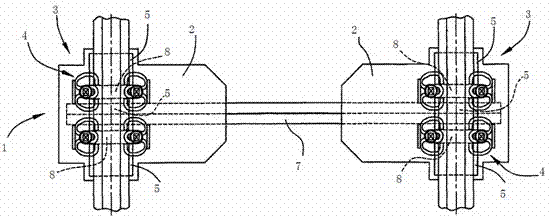

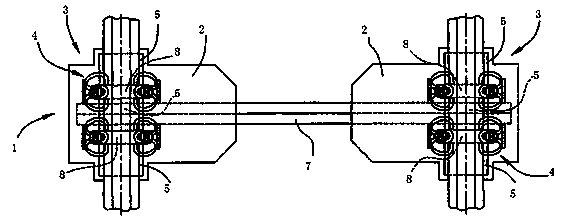

Railroad sleeper

A railroad sleeper comprises a sleeper body (1) and railway bearing areas (3). Each railway bearing area (3) is provided with a railway bearing face (5), first reinforcing components (6) and second reinforcing components (7). The sleeper body (1), the first reinforcing components (6) and the second reinforcing components (7) are all made of composite materials, and the surface of the sleeper body (1) is sequentially provided with a flame retardant layer, a wear-resisting layer and a flame retardant layer. The composite materials comprise polyurethane resin formed in a foaming mode and a plurality of glass fibers arranged in the polyurethane resin. The flame retardant layers are formed by polyurethane resin coatings added with inorganic filler materials, and the polyurethane resin coatings are the same as the polyurethane resin of the sleeper body (1) in texture. The railroad sleeper is low in density, long in service life, good in damping effect, capable of bearing high load, stable in performance, high in weather fastness, easy to machine and install.

Owner:HAIMEN THE YELLOW SEA ENTREPRENEURSHIP PARK SERVICE CO LTD

Coating with air purifying function

The invention belongs to the field of environmental protection, and discloses a coating with the air purifying function. The coating is prepared from 30%-50% of a modified bentonite formaldehyde adsorbing agent, 5%-10% of modified bentonite, 10%-20% of modified sepiolite, 10%-20% of kaolin, 0.2%-1% of a nanometer silver-carrying antibacterial agent, 4%-8% of titanium dioxide, 5%-15% of calcium carbonate, 2%-6% of kieselguhr tailings, 1%-5% of methylcellulose and 0.3%-1% of wood fiber. A preparing method includes the steps that the raw materials are put into a stirring machine and jointly mixed and stirred to be even, and the powdery coating with the air purifying function is obtained. According to the coating with the air purifying function, an existing air purifying material is low in purifying efficiency, and has the harmful defects, and the coating with the air purifying function is free of rubber powder and cement, high in purifying efficiency, nontoxic and free of pollution.

Owner:三台县祺又环保科技有限公司

Inorganic mineral environment-friendly fire-retardant coating and preparation method thereof

InactiveCN105925024AImprove waterproof performanceImprove scratch resistanceAlkali metal silicate coatingsFire retardantStain

The invention discloses an inorganic mineral environment-friendly fire-retardant coating and a preparation method thereof. The inorganic mineral environment-friendly fire-retardant coating is prepared from, by weight, 15-35 parts of a potassium silicate solution, 1-1.5 parts of a dispersing agent, 1-2.5 parts of a thickening agent, 1-3 parts of dimethyl silicone, 3-9 parts of emulsion, 1-10 parts of titanium dioxide, 1-9 parts of ferric oxide, 1-9 parts of sepiolite, 1-6 parts of zinc oxide, 1-8 parts of tourmaline, 1-4 parts of kaolin, 0.5-2.5 parts of silica sol and 10-50 parts of water. According to the inorganic mineral environment-friendly fire-retardant coating and the preparation method thereof, the variety and using amount of the thickening agent and the dispersing agent which are suitable for an exterior wall coating are preferably selected through the reasonable proportion, the water resistance, the scratch resistance, the stain resistance, the breathability and the weather resistance of a coating film are improved, peeling and color fading are avoided, and meanwhile the advantages of being resistant to fire and flame, capable of achieving sterilization without generating mildew stain and environmentally friendly are achieved; in addition, construction is easy and convenient, and the environmental adaptability is better.

Owner:上海嘉柏丽实业有限公司

Fly-ash fiber heat-insulation acoustic board and preparation method thereof

The invention provides a fly-ash fiber heat-insulation acoustic board and a preparation method thereof. Raw materials and weight percentages are as follows: 80.0-94.8 wt% of a fly-ash fiber, 3.1-10.0 wt% of an adhesive and 2.1-10.0 wt% of an additive. The fly-ash fiber heat-insulation acoustic board employs the fly-ash fiber as a matrix, wherein the raw material of the fly-ash fiber is fly ashes of industrial solid waste of power plants. The obtained product has volume density of 350-450 kg / m<3>, noise reduction coefficient of 0.45-0.65 and thermal resistance of 0.40-0.60 (m<2>.K) / W. The combustion performance of the fly-ash fiber heat-insulation acoustic board reaches to the requirements of A-grade non-combustible standard. The fly-ash fiber heat-insulation acoustic board has no materials poisonous and harmful to human and environment, such as formaldehyde, benzenes and the like, and can be widely applied in furred ceilings of indoor top surfaces and decoration and heat-insulation of walls for restaurants, hotels, commercial buildings, dwelling houses, office buildings, auditoriums, markets, movie theaters, subways, stations, factories, hospitals, airports, tunnels, etc.

Owner:SHANGHAI HUAMING HI TECH GRP

Micro-interpenetrating network cross-linked low-smoke halogen-free flame-retardant cable material and preparation method thereof

InactiveCN109651693AGood performanceGood service lifePlastic/resin/waxes insulatorsLow-density polyethyleneCross-link

The invention discloses a micro-interpenetrating network cross-linked low-smoke halogen-free flame-retardant cable material and a preparation method thereof. The cable material includes, by weight, 10-25 parts of ethylene-vinyl acetate copolymer, 20-40 parts of silane-grafted linear low-density polyethylene, 15-25 parts of a polyolefin thermoplastic elastomer, 10-25 parts of ultra-low-density polyethylene, 10-15 parts of functionalized polyolefin resin, 0.5-2.5 parts of high molecular weight polysiloxane, 0.5-1.5 parts of a crosslinking sensitizer, 0.5-2 parts of an auxiliary crosslinking agent, 0.1-0.5 part of a chain extender, 120-180 parts of a high efficiency composite flame retardant, 0.5-2.5 parts of a tubular microcrystalline nano-carbon forming agent, 1-2 parts of organosilane, 0.5-2 parts of an anti-oxidant, and 0.5-1.5 parts of a processing auxiliary agent. The cable material has excellent comprehensive performance and service life, good mechanical property, good dielectric and insulating properties and small creep poles, and is high and low temperature resistant, water resistant, acid and alkali resistant, solvent resistant, wear resistant, creep resistant, ozone resistant and bending resistant; and the cable material can meet different application scene demands of cables, and has the comprehensive performance of dealing with complex and changeable environments.

Owner:WUXI JAKE PLASTIC

Producing and processing method for flue sheet material prepared by mixing straws

InactiveCN102674790AWith thermal insulationLubriciousSolid waste managementEcological environmentAdditional values

The invention provides a producing and processing method for flue sheet material prepared by mixing straws, and relates to flue sheet material for floor. The flue sheet material has the advantages of resisting fire and flaming, resisting moisture and mildew, and resisting insects and moth, and is good in waterproof property and high-temperature-resistant, is capable of being sawed and planed, is endurable, simple in production process, safe and convenient to operate, and high in production efficiency, thus being novel flue sheet material. Straws of rice and wheat are utilized as main raw material of the flue sheet, thus reducing pollution of burning the straws of rice and wheat to the environment, being low in cost, changing wastes into valuables, being high in additional value, lowering the manufacturing cost of the flue sheet, protecting the ecological environment, benefiting the country and people, and making contributions for creating economic and low-carbon society for China.

Owner:YANCHENG JINMA NEW ENVIRONMENT FRIENDLY BUILDING MATERIALS MFG

Polyester fiber reinforced anti-cracking diatom ooze material, and preparation method thereof

The invention discloses a polyester fiber reinforced anti-cracking diatom ooze material, and a preparation method thereof. The polyester fiber reinforced anti-cracking diatom ooze material comprises, by mass, 15 to 35 parts of diatomite, 20 to 40 parts of heavy calcium carbonate, 8 to 20 parts of ash calcium powder, 8 to 20 parts of quartz sand, 2 to 5 parts of nanometer titanium dioxide, 1 to 4 parts of tourmaline, 0.5 to 2.5 parts of cellulose ether, 0.1 to 0.5 part of pregelatinized starch, and 0.1 to 2 parts of polyester fiber. According to the preparation method, diatomite, heavy calcium carbonate, ash calcium powder, quartz sand, nanometer titanium dioxide, tourmaline, and polyester fiber are taken as the raw materials, nontoxic and renewable adhesives cellulose ether and pregelatinized starch are also added, so that the obtained polyester fiber reinforced anti-cracking diatom ooze material possesses excellent cracking resistance and anti-pulverization ability; the preparation method is safe, and is friendly to the environment; production cost is low; and large-scale production can be realized easily.

Owner:东莞市爱乐居环保科技有限公司

Low-alkalinity sulphoaluminate cement gel material for house 3D printing

The invention discloses a low-alkalinity sulphoaluminate cement gel material for house 3D printing. The low-alkalinity sulphoaluminate cement gel material is prepared from low-alkalinity sulphoaluminate cement, inorganic powder, alkali resistant glass fibers, calcium carbonate, a water reducer, a coagulation accelerator, a delayed coagulant, metakaolin, saltcake and a modifier. The low-alkalinity sulphoaluminate cement gel material has a reasonable formula, is prepared from easily available materials, has good material caking properties and good stability and has a good pump-out form keeping capability and bonding properties. A build prepared from the low-alkalinity sulphoaluminate cement gel material has low alkalinity, high early strength, fire prevention, flame retardation, water prevention, immersion resistance, sound absorption, sound insulation, thermal insulation, thermal insulation, good volume stability and super strong weatherability, and satisfies building 3D printing construction continuity and building strength requirements so that the building has good integral stability and use safety.

Owner:ZHUODA NEW MATERIALS TECH GRP WEIHAI CO LTD

PVC wood-plastic foaming floor

The invention relates to a decorative material and provides a PVC wood-plastic foaming floor. The PVC wood-plastic foaming floor is provided with a PVC wood-plastic foaming base material layer and is characterized in that a PVC base plate balancing layer is bonded on the bottom face of the PVC wood-plastic foaming base material layer, a PVC wood-grain decorative plate layer is bonded on the upper surface of the PVC wood-plastic foaming base material layer, and an aluminum oxide abrasion-resisting layer is coated on the outer surface of the PVC wood-grain decorative plate layer. The base material layer of the PVC wood-plastic foaming floor is waterproof and fireproof and does not deform and crack. The abrasion-resisting layer is green and environment-friendly, can be recycled and is very good in abrasion-resisting performance, high in elasticity, very good in impact resistance, fireproof, flame-retardant, waterproof, damp-proof and is lifelike in grains, absorbs sound and prevents noise. The balancing layer is anti-slipping, anti-static and stable in balance, and the PVC wood-plastic foaming floor is widely used for indoor decoration of various house buildings.

Owner:湖北舒嘉科技有限公司

Water-permeable floor tiles

InactiveCN104909712AGood water permeabilityImprove hydrophilic abilityCeramic materials productionClaywaresMontmorilloniteMetal fibers

The invention discloses water-permeable floor tiles and relates to the technical field of building materials. The water-permeable floor tiles are prepared from the following raw materials in parts by weight: 25-35 parts of coal cinder, 25-35 parts of calcium carbonate, 5-10 parts of montmorillonite clay, 5-10 parts of diatomite and 1-2 parts of metal fiber. The length of the metal fiber is 0.8-1mm, the fineness of the coal cinder is 7-20 meshes, the fineness of the diatomite is 36-40 meshes, and the fineness of the montmorillonite clay and calcium carbonate is 120-220 meshes respectively. The water-permeable floor tiles can be used for solving the problem of the existing floor tiles that the water permeability is poor.

Owner:LIUZHOU PUYA TRADE

Multifunctional heat-storage diatom ooze and preparation method thereof

The invention provides a multifunctional heat-storage diatom ooze and a preparation method thereof. The multifunctional heat-storage diatom ooze is prepared from, by weight, 10-30 parts of diatomite, 5-20 parts of phase-change heat-storage capsules, 10-25 parts of calcium carbonate, 10-25 parts of talcum powder, 0.1-0.4 part of anti-crack fibers, 0.1-2 parts of powdered mildew preventive, 0.1-0.7 part of cellulose ether and 3-7 parts of rubber powder. The multifunctional heat-storage diatom ooze has the effects of preventing fire, resisting abrasion, purifying air, eliminating odors and retarding a flame. The multifunctional heat-storage diatom ooze is a phase-change stripe decoration diatom ooze material used indoors, the bi-directional reversible room-temperature adjusting function is achieved, and the effects of reducing indoor energy consumption and improving the indoor environment are achieved. According to the preparation method of the multifunctional heat-storage diatom ooze, the materials are sequentially put according to weights of the materials, and the method has the advantages of being convenient, simple, easy to operate and the like.

Owner:BEIJING DAIJIN DIATOMITE NEWLY BUILDING MATERIAL

Making method of diatom ooze bricks

InactiveCN106830880AFire retardantSterilization, deodorization, moisture absorption and deodorizationClaywaresBrickOxygen ions

A method for making diatomite bricks belongs to the technical field of inorganic non-metallic materials. The invention consists of materials: natural diatomite, kaolin, attapulgite, sepiolite powder, vermiculite powder, bentonite, water, bamboo powder, alginate, silicon carbide, and carboxymethyl cellulose. Diatomite bricks are prepared through the production process of configuring materials, pouring molds into billets, and microwave drying and sintering. The microwave drying and sintering method adopted in the present invention has fast heating speed, improved production efficiency, uniform heating, shortened production cycle, high efficiency, energy saving and no pollution. The diatomite brick produced by the invention is environmentally friendly and non-toxic, and has the functions of eliminating formaldehyde, purifying air, adjusting humidity, releasing negative oxygen ions, preventing fire and flame, sterilizing, deodorizing, absorbing moisture and deodorizing, absorbing sound and reducing noise.

Owner:青岛宏致复合织造有限公司

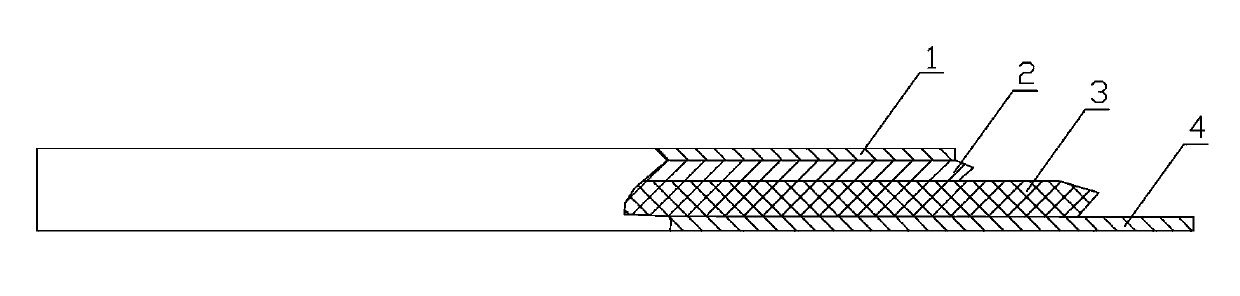

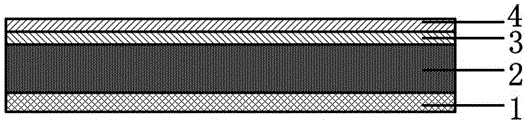

Antibacterial, soundproof and environment-friendly diatomite wallpaper

InactiveCN106499135AWith humidity controlWith deodorizing functionCovering/liningsSynthetic resin layered productsGlass fiberWear resistant

The invention discloses antibacterial, soundproof and environment-friendly diatomite wallpaper which comprises a bottom layer (1), a diatomite layer (2), a pattern color layer (3) and a wear-resistant layer (4) sequentially arranged from top to bottom, wherein the wear-resistant layer (4) is made of a polytetrafluoroethylene material. The thickness of the diatomite layer (2) is 0.1-0.3 mm. The bottom layer (1) is a glass fiber fabric, a nonwoven fabric or chemical fiber cloth. Bamboo carbon black is arranged on the wear-resistant layer (4). Diatomite in the diatomite layer (2) is obtained by adding raw diatomaceous earth with a grain size of 800-3000 meshes and a surface treating agent occupying 0.5-1 percent of the weight of the raw diatomaceous earth into a high-speed stirring machine capable of temperature rise, stirring at a high speed under the condition of 80-120 DEG C and treating for 90 minutes. The diatomite wallpaper disclosed by the invention is good in antibacterial, sound insulation, humidity control and absorption capacities and has good environment-friendly performance compared with a similar product.

Owner:营口渤海科技有限公司

Polyimide knitted fabric and preparation method thereof

InactiveCN105951286AHigh temperature resistantStrong burst resistanceWeft knittingYarnPolyesterBursting strength

The invention discloses a polyimide knitted fabric and a preparation method thereof. The preparation method comprises the steps of loose wool dyeing, wool mixing, wool carding, doubling and twisting, panel knitting, after finishing and the like; a gray fabric is prepared by weaving blended yarn of polyimide, wool, cashmere, spandex, nylon, acrylic fibers and polyester (or modified polyester) fibers. The knitted fabric prepared by blending the raw materials of different proportions has the advantages of being capable of resisting high temperature, high in bursting strength resistance, capable of resisting fire, retarding inflaming and resisting ultraviolet, soft, not prone to pill and the like, and compared with a conventional multifunctional finished fabric, the production and aftertreatment processes are greatly simplified, and the production efficiency is improved.

Owner:王剑

High-temperature resistant comfortable fabric

InactiveCN103738013AFire retardantProtect against infringementSynthetic resin layered productsPoly(benzimidazole)Polypropylene fiber

The invention discloses a high-temperature resistant comfortable fabric. The high-temperature resistant comfortable fabric comprises a surface high-temperature resistant fabric layer, and an inner hygroscopic breathable fabric layer; the surface high-temperature resistant fabric layer is prepared via blended weaving of 65 to 72wt% of polythiadiazole fiber and 28 to 35wt% of polybenzimidazole fiber; the inner hygroscopic breathable fabric layer is prepared via blended weaving of 53 to 59wt% of polypropylene fiber and 41 to 47wt% of plumetis fiber. A double layer structure design is adopted; the surface high-temperature resistant fabric layer possesses fire resistance and high-temperature resistance, and is capable of protecting human bodies from hurt; and the inner hygroscopic breathable fabric layer is hygroscopic and breathable, is soft and comfortable, possesses elasticity, and is comfortable for wearing.

Owner:SUZHOU TANXI TEXTILE TECH CO LTD

Railroad sleeper with multiplayer structure

A railroad sleeper comprises a sleeper body (1) and track bearing areas (3). Every track bearing area (3) is provided with a track bearing surface (5), a first reinforcing element (6) and a second reinforcing element (7). The sleeper body (1), the first reinforcing elements (6) and the second reinforcing elements (7) are made of composite materials, the surface of the sleeper body (1) is provided with a multiplayer structure, and the thermal expansion coefficient of the multiplayer structure is sequentially reduced outwards from the surface of the sleeper body (1). The railroad sleeper is low in density and long in service life, not only has good damping effect and is high in load carrying capacity, but also is stable in performance and high in weather resistance and guarantees tightness of connection of every layer.

Owner:HAIMEN THE YELLOW SEA ENTREPRENEURSHIP PARK SERVICE CO LTD

Multi-functional composite plate with functions of fire prevention, sound insulation and corrosion prevention, and preparation method

PendingCN111844273AImprove fire performanceImprove flammabilityOther plywood/veneer working apparatusWood treatment detailsEngineeringComposite plate

The invention discloses a multi-functional composite plate with functions of fire prevention, sound insulation and corrosion prevention, and a preparation method. The multi-functional composite platecomprises an anti-flaming veneer of a layered structure, a high-strength glass fiber net, a damp rubber plate, a sound insulation pad, an anti-flaming solid wood core plate, an anti-flaming baseplateand an anti-damp baseplate balance layer which are disposed successively from top to bottom, wherein each plate layer is adhered together by improved macromolecule WBP anti-flaming waterproof glue. The composite plate disclosed by the invention is characterized by being fireproof and anti-flaming, waterproof and anti-damp, resistant to damping, capable of sound insulation, environment-friendly orthe like and can be well applied to the manufacturing industry and high-grade decorated floor structures. The composite plate disclosed by the invention adopts the WBP environment-friendly glue, has good weather resistance and waterproof performance, has good environment-friendly performance, can be applied to all the damp and water-existing environments with fire-proof requirements, such as a coastal hotel holiday village, construction of a wood structure house, a garden architecture, a cruise ship, internal decoration of a yacht and a ship, ship industrial manufacture, further manufacture and other decoration projects, and has a wide scope of application.

Owner:河北传媒学院

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com