Canvas for canoe and preparing method thereof

A kayak and canvas technology, applied in the field of canvas, can solve problems such as low output, poor wear resistance, poor scratch resistance, and unsightly appearance, and achieve the effects of strengthening tension, increasing strength, and improving air tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

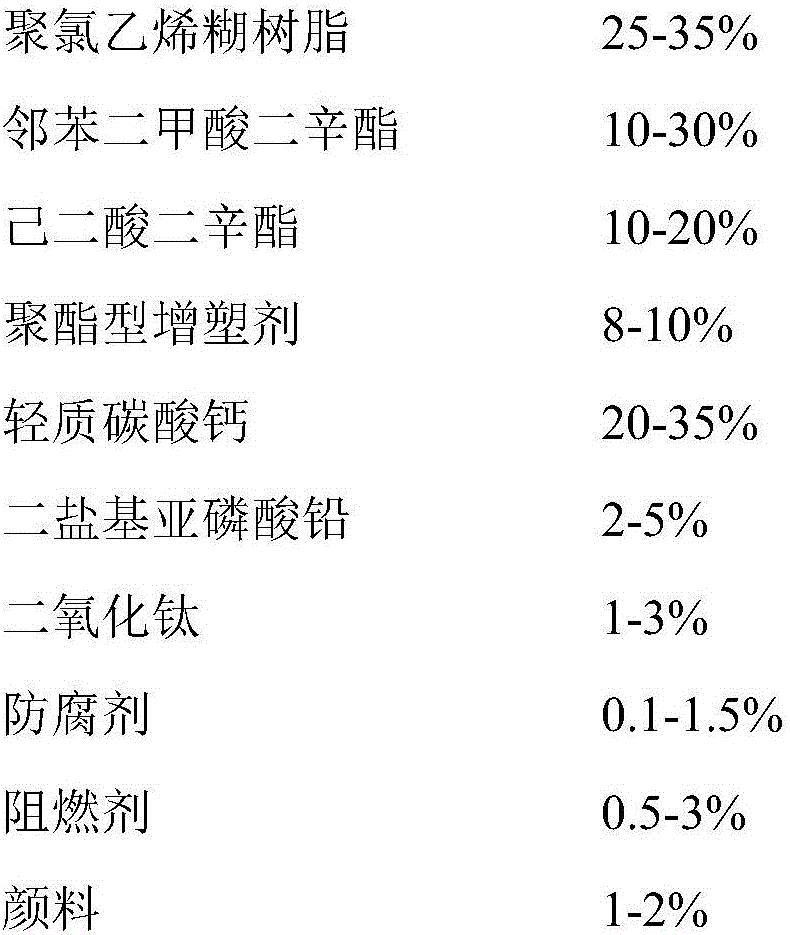

[0051] 1) Take the following raw materials by weight percentage to prepare the inner coating:

[0052]

[0053]

[0054] 2) Get the following weight percent raw materials to make a calendered film as the outer coating:

[0055]

[0056] The thickness of the calendered film was 0.2 mm.

[0057] 3) After the above raw materials are blended, put them into the mixing tank and stir them evenly with a mixer at room temperature. Since there will still be a small amount of particles in it, use a three-roller grinder to grind the mixture. It can be used after grinding for 8-10 minutes. .

[0058] 4) After the gray cloth is cleaned, it is flattened and dried by an ironing tractor at a drying temperature of 130°C.

[0059] 5) Apply the inner coating prepared in step 1) evenly on both sides of the gray cloth treated in step 4) by padding and sizing, and then plasticize in an oven.

[0060] When coating, the viscosity of the paint is 150Pa·s, the plasticizing and drying temperatu...

Embodiment 2

[0072] 1) Take the following raw materials by weight percentage to prepare the inner coating:

[0073]

[0074] 2) After the above raw materials are blended, put them into the mixing tank and stir them evenly with a mixer at room temperature. Since there will still be a small amount of particles in it, use a three-roller grinder to grind the mixture. It can be used after grinding for 8-10 minutes. .

[0075] 3) After the gray cloth is cleaned, it is flattened and dried by an ironing tractor at a drying temperature of 110°C.

[0076] 4) Apply the inner coating prepared in step 1) evenly on both sides of the gray cloth treated in step 4) by padding and sizing, and then plasticize in an oven.

[0077] When coating, the viscosity of the paint is 160Pa·s, the plasticizing and drying temperature is 200°C, and the length of the drying tunnel is 6m.

[0078] 5) On the inner coating layer 2-1 of the cloth prepared in step 5), the inner coating paint prepared in step 1) is coated a...

Embodiment 3

[0089] 1) Take the following raw materials by weight percentage to prepare the inner coating:

[0090]

[0091] 2) Get the following weight percent raw materials to make a calendered film as the outer coating:

[0092]

[0093] The thickness of the calendered film was 0.2 mm.

[0094] 3) After the above raw materials are blended, put them into the mixing tank and stir them evenly with a mixer at room temperature. Since there will still be a small amount of particles in it, use a three-roller grinder to grind the mixture. It can be used after grinding for 8-10 minutes. .

[0095] 4) After the gray cloth is cleaned, it is flattened and dried by an ironing tractor at a drying temperature of 120°C.

[0096] 5) Apply the inner coating prepared in step 1) evenly on both sides of the gray cloth treated in step 4) by padding and sizing, and then plasticize in an oven.

[0097] When coating, the viscosity of the paint is 155Pa·s, the plasticizing and drying temperature is 190°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com