High-gloss high-weather-resistant acrylic acid paint

A high-weather-resistant, acrylic technology, used in wax coatings, coatings, etc., can solve problems affecting production efficiency and surface effects, achieve high fullness, high weather resistance, and reduce painting costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Thermoplastic liquid acrylic resin (170 liquid resin Suzhou Jiadian Chemical)

[0017] Aldehyde and Ketone Resin (A-81 Yueyang Coriver)

[0018] Chlorinated paraffin (52# Yancheng Shuanghong Chemical)

[0019] Pigment (carbon black powder (6# Degussa, rutile titanium dioxide 940+ town titanium titanium dioxide)

[0020] Extender pigment (precipitated barium sulfate)

[0021] Glass Phosphorus Flake Powder (Glass Phosphorus Flake Powder Yixing Chentangqiao Chemical Industry)

[0022] Dispersant (BYK161 BYK)

[0023] Leveling agent (3777 Efka)

[0024] Anti-settling agent (201P Deqian Chemical)

[0025] Mixed solvent: Toluene, xylene, butyl ester, ethyl ester, butanone, MIBK, CAC, anti-white water, DBE, butanol, isopropanol, and ethanol are mixed in equal proportions.

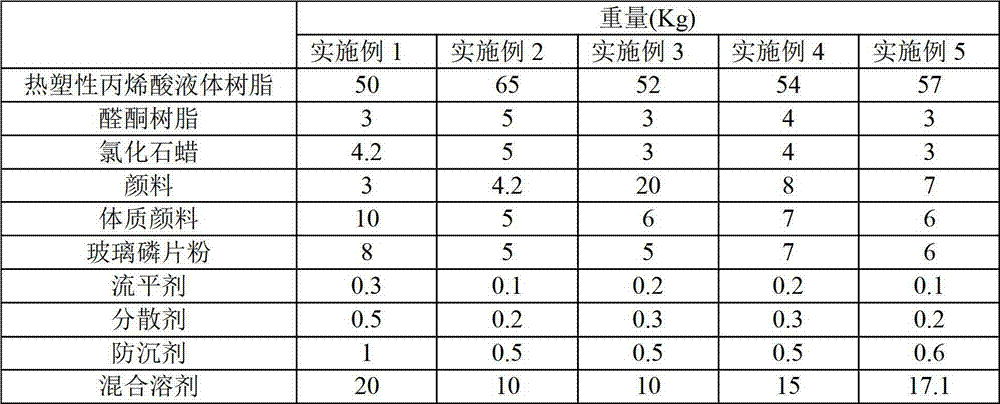

[0026] The pure black acrylic enamel formula proportioning of table 1 embodiment 1~embodiment 5

[0027]

[0028] Preparation:

[0029] (1) Use a part of the mixed solvent to dissolve the aldehyd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com