Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "To achieve the purpose of circular economy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

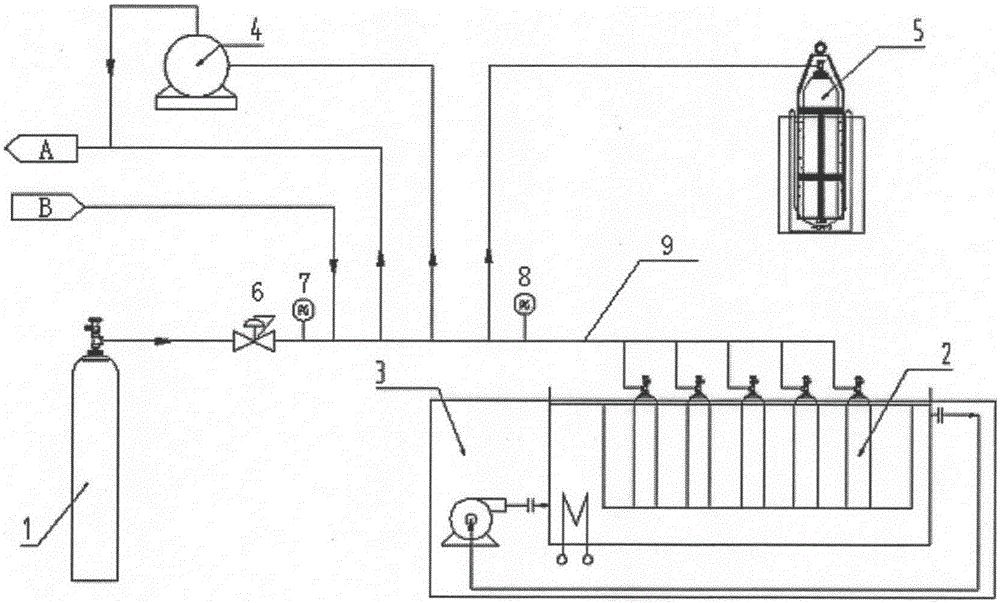

Steel cylinder filling device and method for high-purity arsine

InactiveCN104930342AImprove cleanlinessQuality is not affectedContainer discharging methodsContainer filling under pressureArsineLiquid state

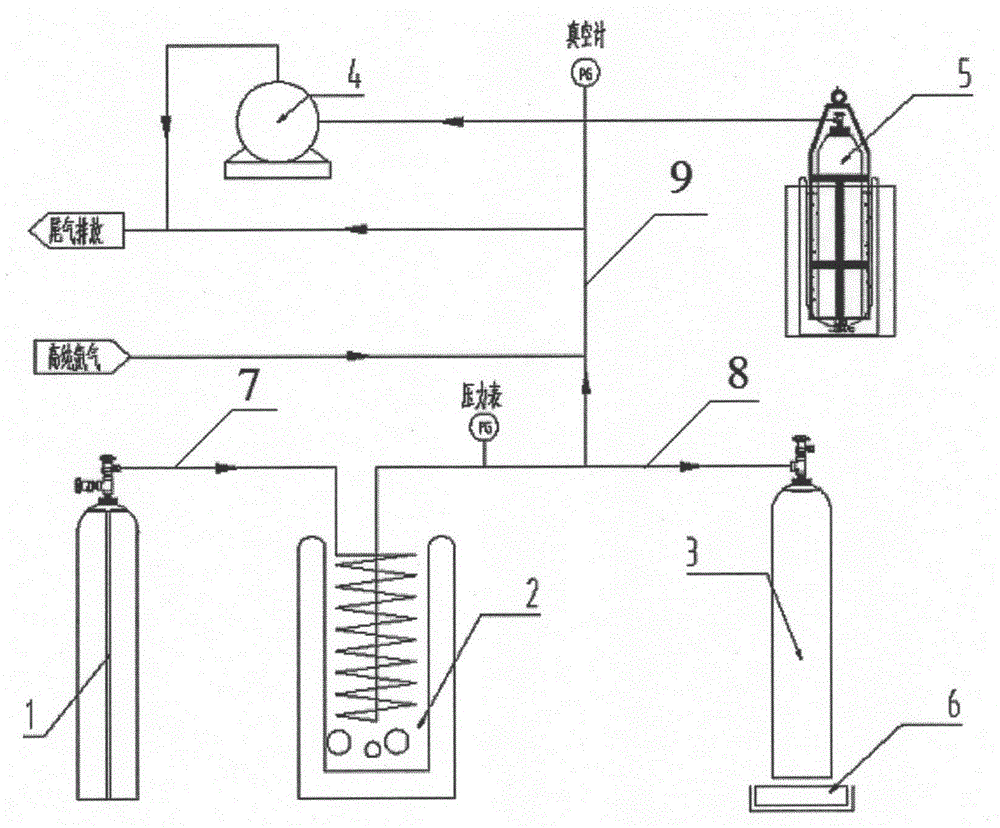

The invention provides a steel cylinder filling device and method for high-purity arsine. The steel cylinder filling device for the high-purity arsine is characterized by comprising a first pipeline, one end of the first pipeline is used for being connected with a source gas steel cylinder, the other end of the first pipeline is connected with the upper end of a cooling coil, the cooling coil is placed in a cooling tank, the lower end of the cooling coil is connected with one end of a second pipeline, the other end of the second pipeline is used for being connected with a to-be-filled steel cylinder, a main pipeline is formed by the first pipeline, the cooling coil and the second pipeline, the second pipeline is connected with a branch pipeline, the branch pipeline is connected with a cold trap collecting steel cylinder and a vacuum pump, and the branch pipeline is further connected with a high-purity helium source and an exhaust gas discharging outlet. The arsine is filled in a liquid state, a filling system is needed to be maintained cleaning in the filling process, and the quality of the arsine cannot be influenced by the pipelines and the steel cylinders.

Owner:SHANGHAI ZHENGFAN TECH +1

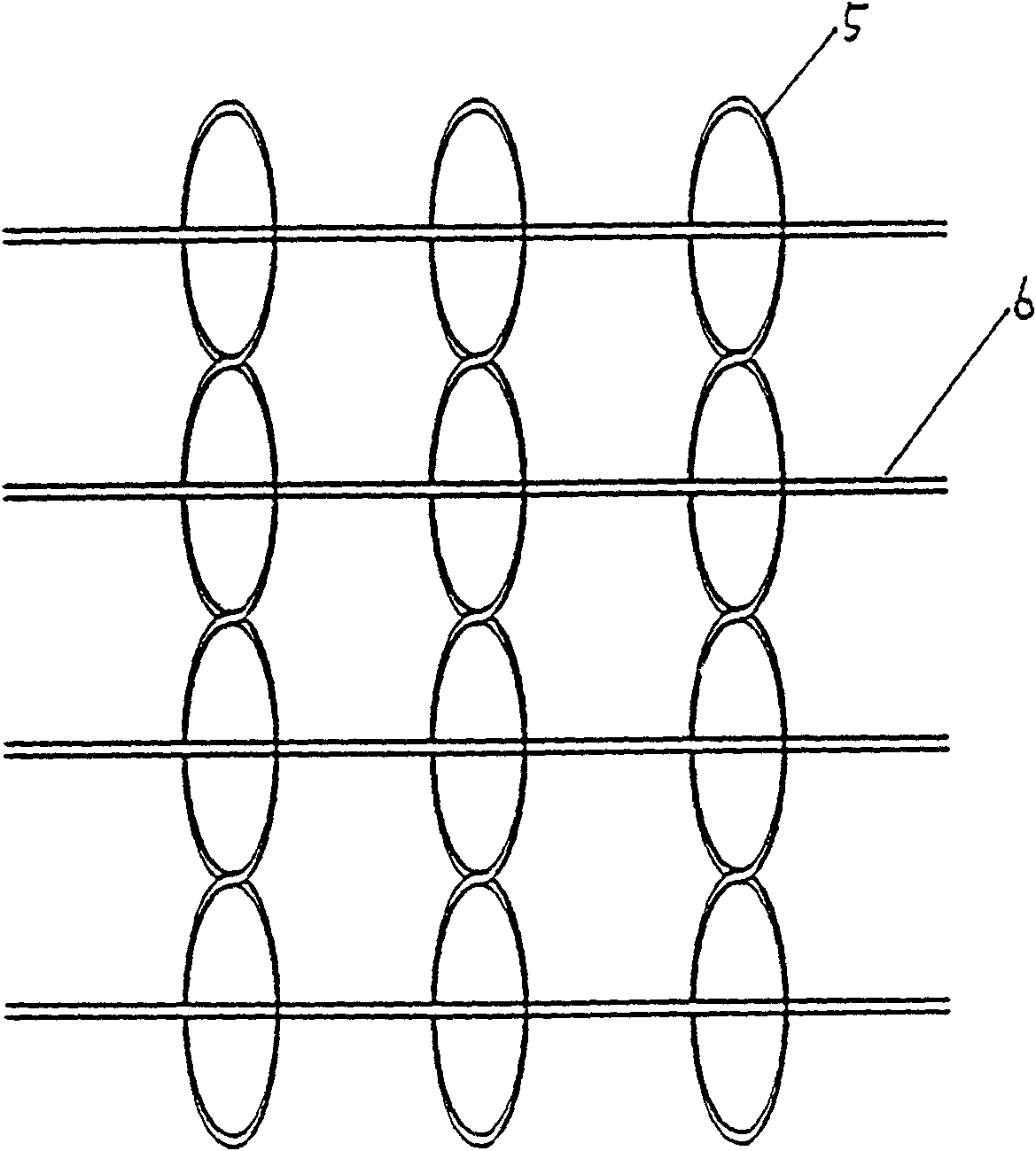

Preparing method of non-twist textiles or hollow textiles or highly-branched textiles and methods for recycling solute of alkali solutions

ActiveCN105369421AEfficient manufacturingTo achieve the purpose of circular economyArtificial filament recoveryFilament/thread formingYarnFiber

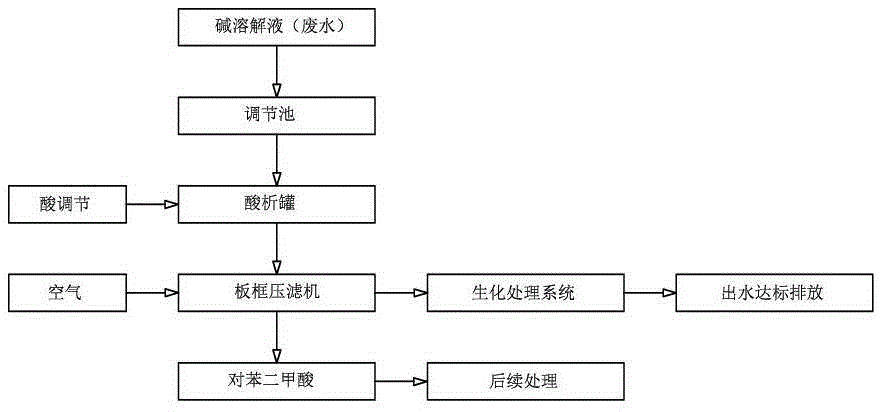

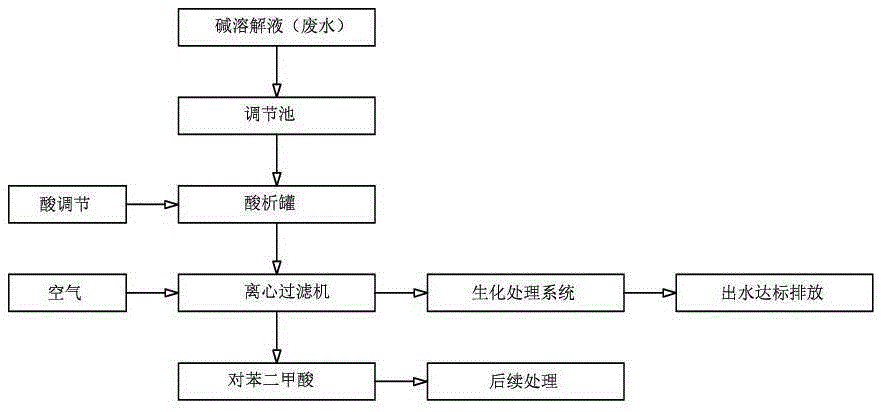

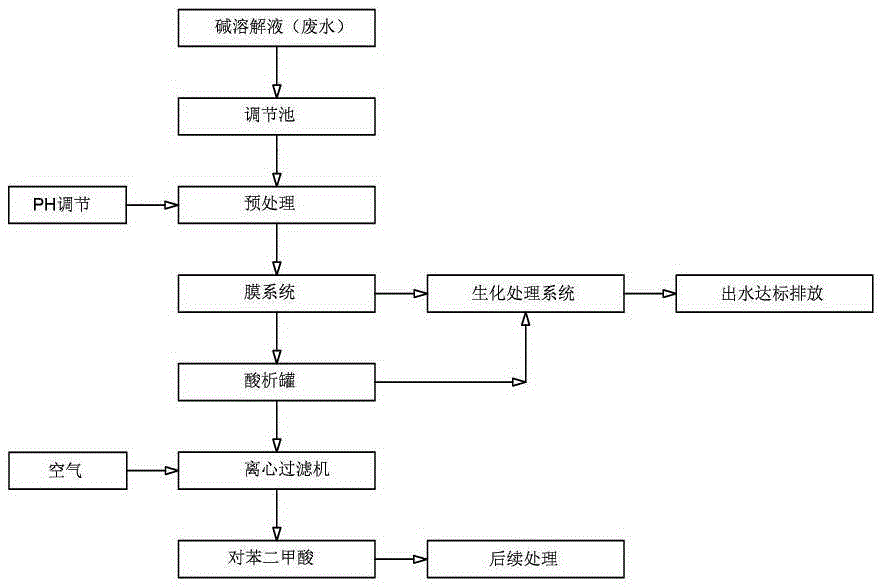

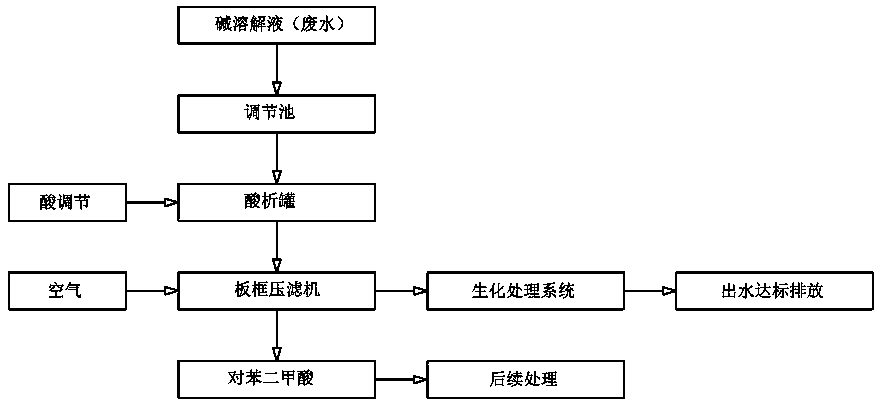

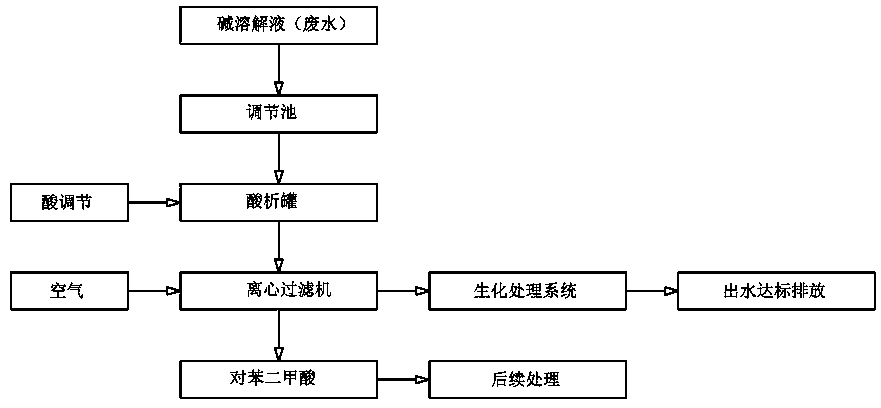

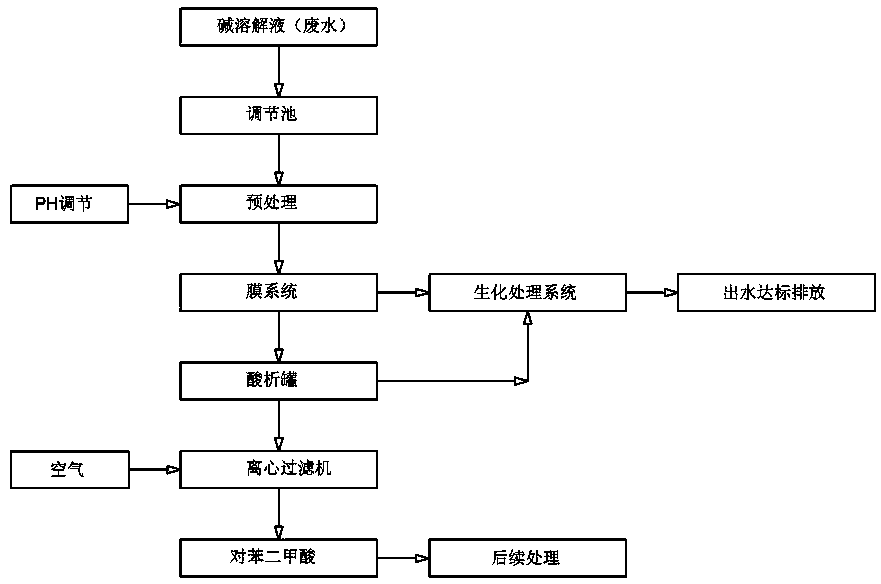

The invention discloses a preparing method of non-twist textiles or hollow textiles or highly-branched textiles and methods for recycling solute of alkali solutions. The preparing method of the non-twist textiles or the hollow textiles or the highly-branched textiles includes the following steps of a, preparing alkaline degradation sections; b, preparing blended spinning melt; c, carrying out spinning to prepare alkali-easily-dissolved degradation fibers, wherein the alkali-easily-dissolved degradation fibers include filaments, short fibers and fiber strips; d, preparing the non-twist textiles or the hollow textiles or the yarn-highly-branched textiles or embroider products. The soft and light textiles can be effectively prepared with the preparing method of the non-twist textiles or the hollow textiles or the highly-branched textiles. The methods for recycling the solute of the alkali solutions include the steps that the alkali solutions are obtained after the alkali-easily-dissolved degradation fibers are degraded, terephthalic acid is obtained after acid separation, and filtered wastewater meets a draining standard and is led into a factory biochemical treatment system. By means of the methods for recycling the solute of the alkali solutions, the alkali solutions obtained after the alkali-easily-dissolved degradation fibers are dissolved can be recycled, the environment-friendly effect is good, and the aim of circular economy can be achieved.

Owner:余燕平 +3

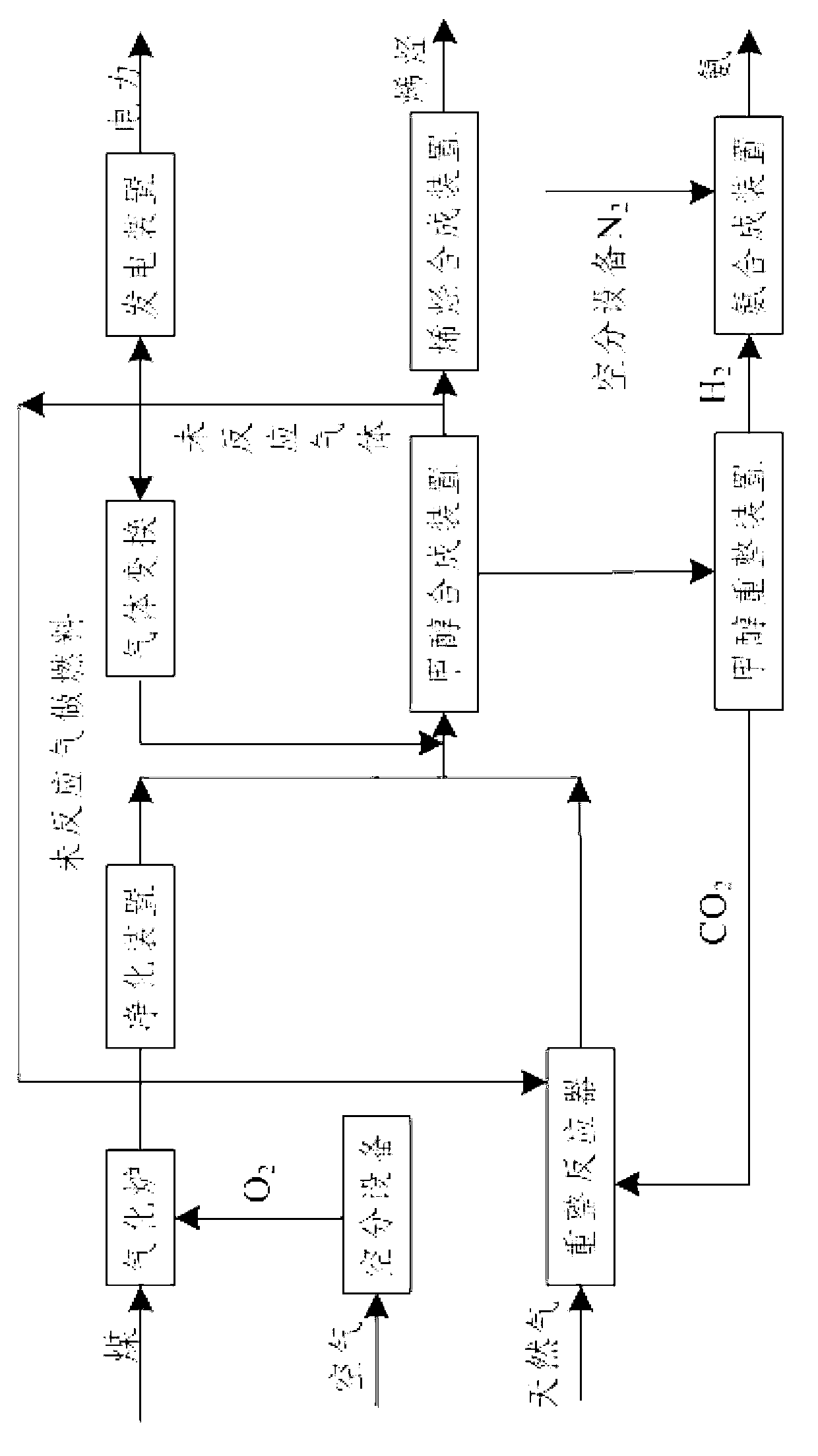

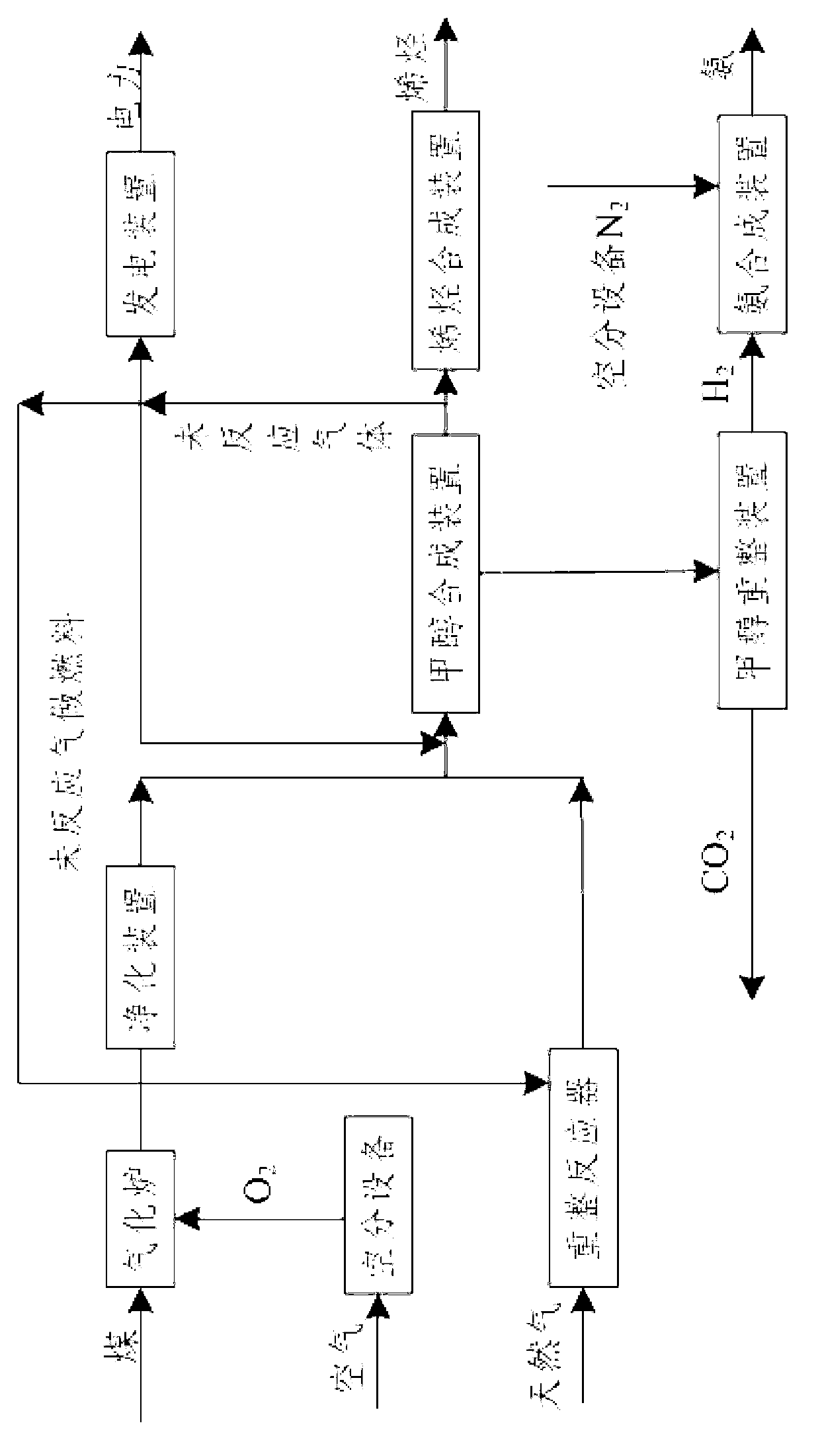

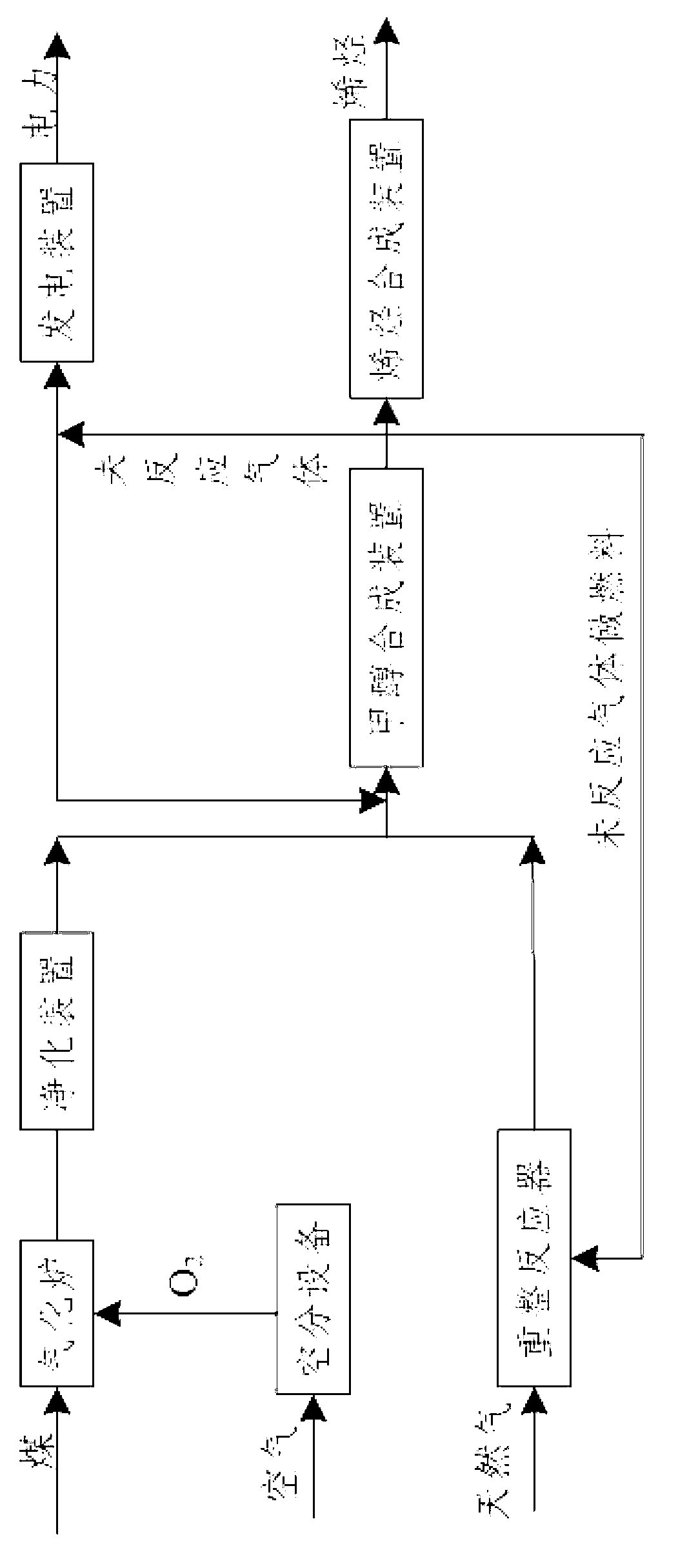

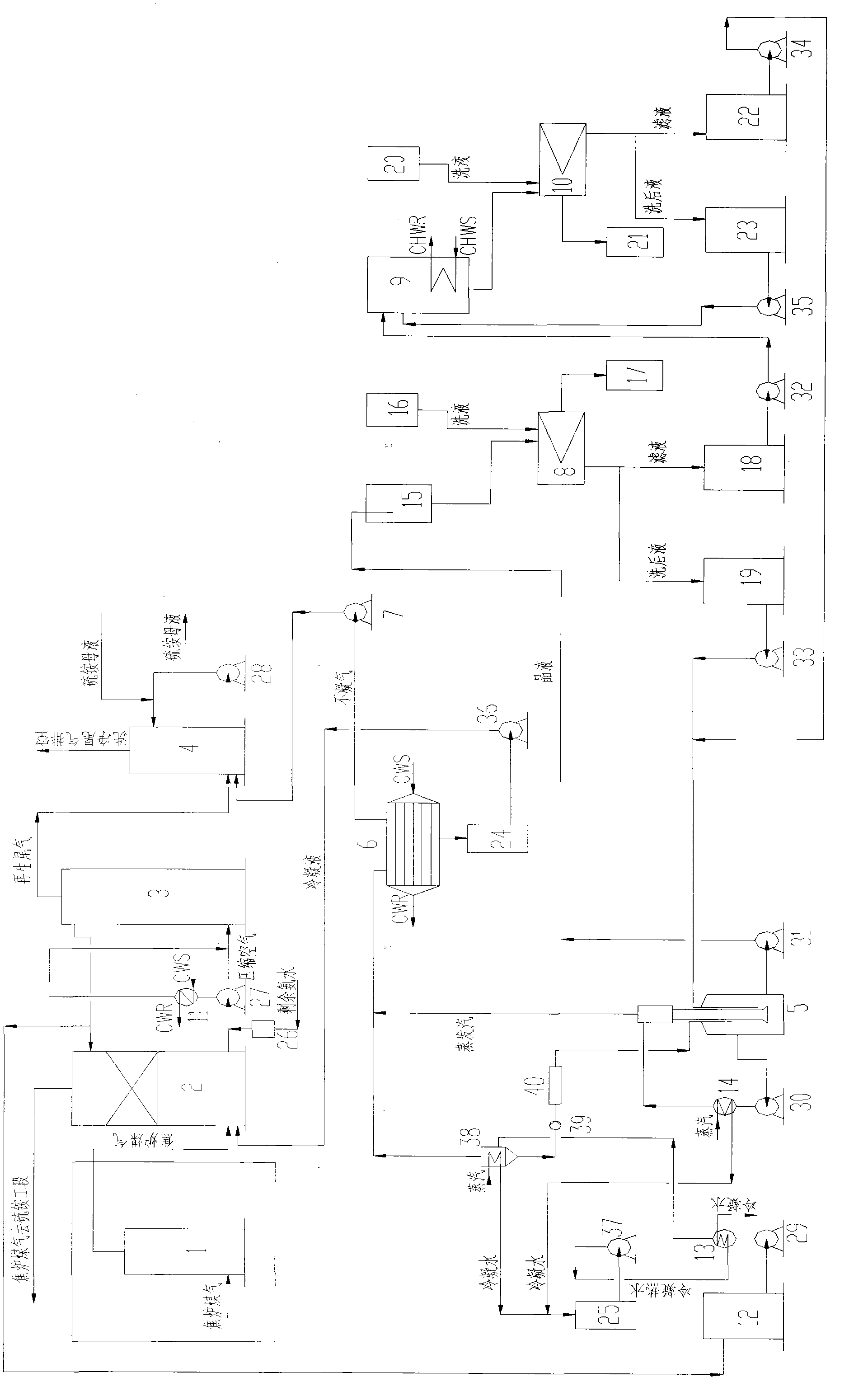

Thermoelectricity combined production method and apparatus for preparing alkene and by coal and natural gas

InactiveCN103214334AReduce consumptionReduce manufacturing costHydrogenHydrocarbon from oxygen organic compoundsWater vaporCogeneration

The invention relates to a thermoelectricity combined production method and apparatus for preparing alkene and by coal and natural gas, and the method comprises the following steps: (1) separating coal, steam and air for obtaining oxygen, gasifying oxygen for obtaining water gas by reaction, and purifying for obtaining coal-based synthetic gas; carrying out a reforming reaction from natural gas and carbon dioxide and obtaining a natural gas-based synthetic gas; (2) synthesizing methanol using the coal-based synthetic gas in the step (1) or using the coal-based synthetic gas and the natural gas-based synthetic gas; (3) separating the unreacted gas in the step (2) into three parts, and the first part is used for synthesizing methanol in the step (2), and the second part is used as fuel for providing heat for the natural gas reforming reaction, and the third part is used for power generation and heat supply for the gas turbine; (4) separating the methanol in the step (2) into two parts, and one part is used for preparing alkene and generating water; and the other part is used for the reforming reaction with the generated water for preparing hydrogen and carbon dioxide, and separating hydrogen and carbon dioxide, and synthesizing ammonia from the obtained hydrogen and nitrogen separated from air, wherein, the obtained carbon dioxide by separation is used for the natural gas reforming reaction.

Owner:PETROCHINA CO LTD +1

Preparation method for sesame-flavor white spirit

InactiveCN101824372AIncrease added valueTo achieve the purpose of circular economyAlcoholic beverage preparationMicroorganism based processesYeastAlcohol content

The invention relates to a preparation method for sesame-flavor white spirit, which comprises the following steps: (1) taking 15-60 parts of distilled yellow wine lees, adding 5-15 parts of rice and 20-50 parts of white spirit lees, after evenly mixing the raw materials, putting obtained mixture in a retort and steaming and stewing for 30-50 minutes under 0.05-0.2MPa, cooling the steamed mixture to room temperature, 2-5 parts of malt, adding 2-10 parts of yeast for making hard liquor and 0.1-0.5 part of solid yeast, evenly agitating, fermenting the obtained mixture for 24-72h at 28 DEG C-32 DEG C in a stacking way, putting the fermented mixture in a cellar and fermenting for 28-32 days, opening the cellar and adding 3-7 parts of rice chaff, putting the obtained mixture is in the retort and distilling, adding 2-5 parts of arrack spirit in spent wash, and turning on steam and slowly distilling to 60%v / v to obtain semi-finished product; and (2) putting the semi-finished product into a warehouse and storing in an earthen jar for more than two years, and adding softened water to blend into spirit with preset alcohol content to obtain the sesame-flavor white spirit. The invention has the advantages that the high-quality sesame-flavor white spirit with both flavor and taste can be obtained, the product added value is greatly improved and the economic benefit can be doubled.

Owner:SUZHOU SANJIEYANG WINE

Method for manufacturing alkaline magnesium-rich pellet ore

ActiveCN105039681AImprove performanceImprove high temperature performanceProcess efficiency improvementBrickMixed materials

The invention relates to a method for manufacturing alkaline magnesium-rich pellet ore. The method comprises the steps of I pretreatment of recycled waste magnesia-calcium bricks, wherein a, primary breaking is carried out, and the waste magnesia-calcium bricks are broken into magnesia-calcium brick blocks; b, fine grinding is carried out, and the magnesia-calcium brick blocks are ground into magnesia-calcium brick powder; II batching, wherein iron concentrate powder and the magnesia-calcium brick powder are batched into batch mixtures, and 5.5-6.6 parts of the magnesia-calcium brick powder, 100 parts of the iron concentrate powder, 0.5-1 part of pulverized coal and 1.7 parts of bentonite are adopted according to the ratio; III pretreatment of the batch mixtures, wherein roll grinding is carried out on the batch mixtures; IV mixing, wherein the batch mixtures obtained through roll grinding are mixed; V pelletizing and screening, wherein mixed materials are pelletized and screened into qualified green pellets; VI drying, preheating and calcination, wherein the qualified green pellets are calcinated into pellet ore; VIII cooling, wherein the pellet ore is cooled to obtain the alkaline magnesium-rich pellet ore. The alkaline magnesium-rich pellet ore is produced through the waste magnesia-calcium bricks, the quaternary alkalinity of the pellet ore can be above 1.15%, and MgO is larger than or equal to 3.8%.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

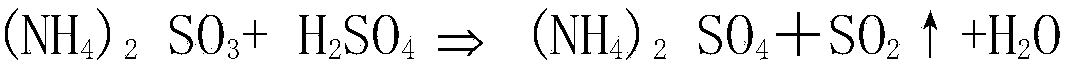

Method for processing steel bottles of high-purity arsine

ActiveCN105927851AEmission reductionTo achieve the purpose of circular economyVessel geometry/arrangement/sizeContainer filling methodsCooking & bakingArsine

The invention discloses a method for processing steel bottles of high-purity arsine. The method includes the steps that valve outlets in the tops of the multiple to-be-processed steel bottles are connected to a main pipeline through steel bottle connectors; a valve outlet of a source gas steel bottle containing arsine and a valve outlet of a cold trap collection steel bottle are connected to the main pipeline through steel bottle connectors; replacement is conducted on the main pipeline through high-purity helium, it is ensured that the pipeline is not contaminated, and then the main pipeline is vacuumized through a vacuum pump; under the condition that the vacuum pump keeps running, vacuum baking is conducted on the to-be-processed steel bottles, helium is then injected into the to-be-processed steel bottles, and then the helium is pumped out through the vacuum pump; a steel bottle valve of the source gas steel bottle is opened, and arsine gas is injected into the to-be-processed steel bottles; helium is injected into the to-be-processed steel bottles, and then the helium is pumped out through the vacuum pump; and steel bottle valves of the to-be-processed steel bottles are closed, and the to-be-processed steel bottles are completely processed at the moment. According to the method, the arsine gas used for passivation is recycled, emission of the arsine-containing gas is well reduced, and the aim of cyclic economy is achieved.

Owner:SHANGHAI ZHENGFAN TECH +1

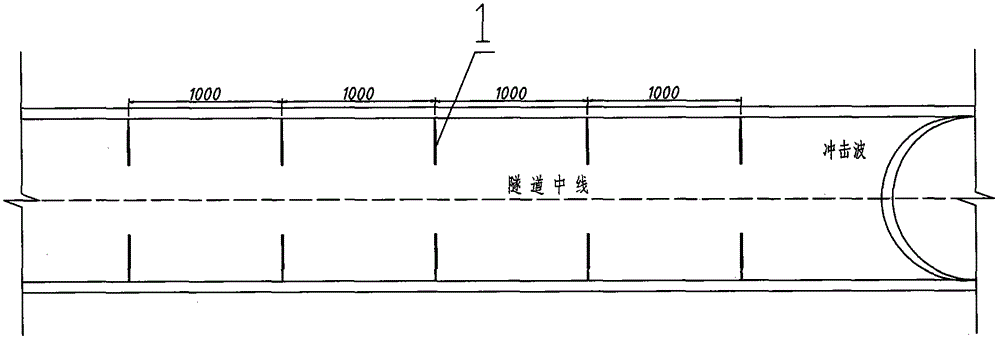

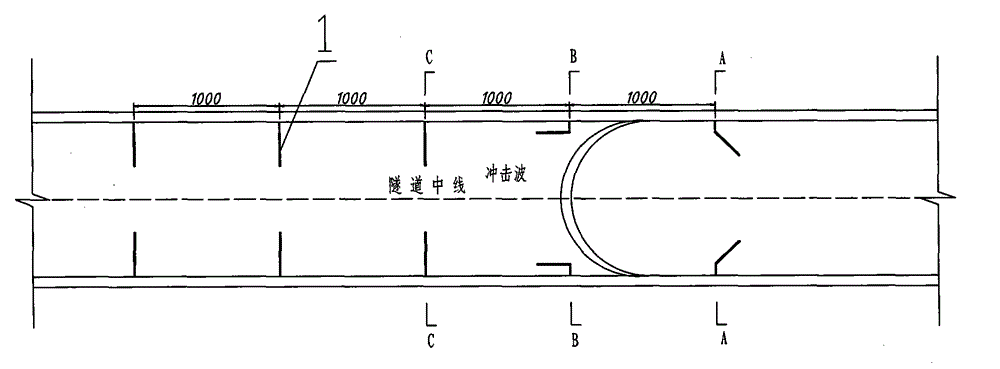

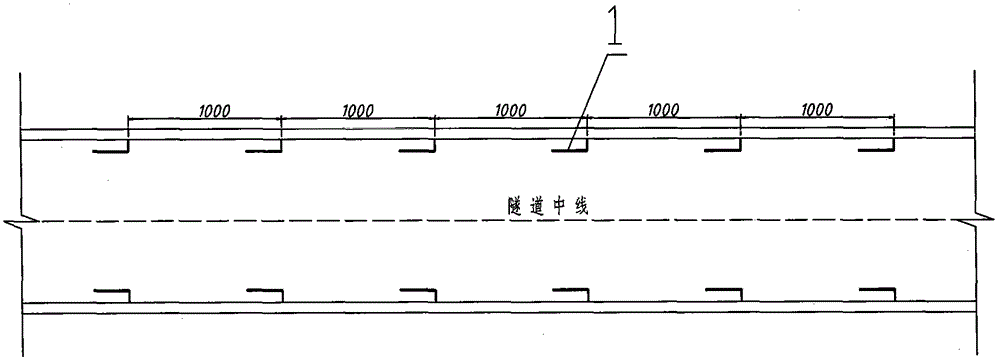

Prevention device and prevention method used for blasting air shock waves in drilling and blasting tunnel

InactiveCN104315934ASave spaceTo achieve the purpose of circular economyBlastingShock waveEngineering

The invention discloses a prevention device and a prevention method used for blasting air shock waves in a drilling and blasting tunnel. The device comprises a plurality of baffle units arranged on the side wall of the tunnel; the baffle units are arranged on the side wall of the tunnel in a bilateral symmetry manner; each baffle unit comprises a shock-resistant and high temperature-resistant baffle; each baffle is fixedly arranged on the side wall of the tunnel through a switch hinge; each baffle can rotate around the revolution axis of the corresponding switch hinge; each revolution axis is provided with a damper for providing damping for the rotation of the corresponding baffle; each baffle unit can be opened or closed under the action of the corresponding switch hinge, i.e. when blasting is performed on a tunnel face, each baffle unit is in a closed state so as to stop the shock waves; after blasting on the tunnel face is ended, each baffle unit is in an opened state, traffic in the tunnel and other construction cannot be influenced.

Owner:SOUTHWEST JIAOTONG UNIV

Process for producing building cement by domestic refuse incinerated slag

Owner:SOUTH CHINA UNIV OF TECH

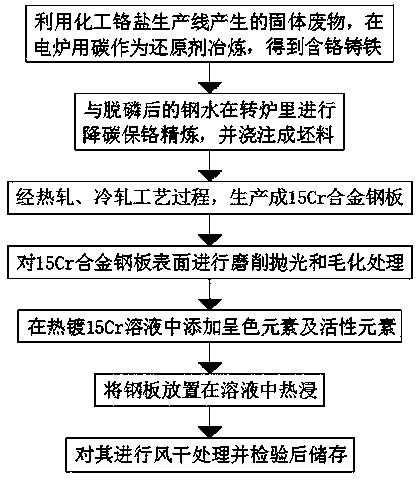

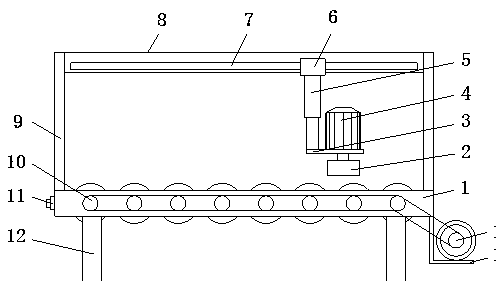

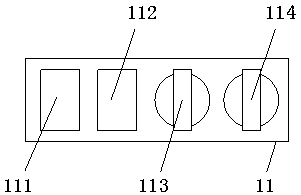

Production method for producing 15 Cr colorful alloy steel plate through calcium-free chromium slag

InactiveCN107557648ARealize secondary useAchieving zero emissionsHot-dipping/immersion processesGrinding carriagesChromium freeSlag

The invention discloses a production method for producing a 15 Cr colorful alloy steel plate through calcium-free chromium slag. The production method for the 15 Cr colorful alloy steel plate comprises the following steps that A, solid waste produced through a chemical engineering chromium salt production line is utilized, carbon serves as a reducing agent for smelting in an electric furnace, andchromium containing cast iron is obtained; B, the chromium containing cast iron and dephosphorized molten steel are subjected to carbon reducing and chromium conservation refining in a converter, anda blank is formed through pouring; C, a 15 Cr alloy steel plate is produced through the hot rolling and cold rolling technology process; D, grinding polishing and roughening treatment is conducted onthe surface of the 15 Cr alloy steel plate; E, color generation elements and active elements are added in a hot-dip 15 Cr solution; and F, the steel plate is placed in the solution to be subjected tohot dipping. According to the production method, the calcium-free chromium slag produced on a calcium-free roasting production line serves as a main raw material for producing the 15 Cr colorful alloysteel plate, on one hand, secondary utilization of scarce resources is achieved, on the other hand, zero emission of solid waste produced in chemical engineering is achieved, and the purpose of circular economy is achieved.

Owner:民乐县锦世建材新材料有限责任公司

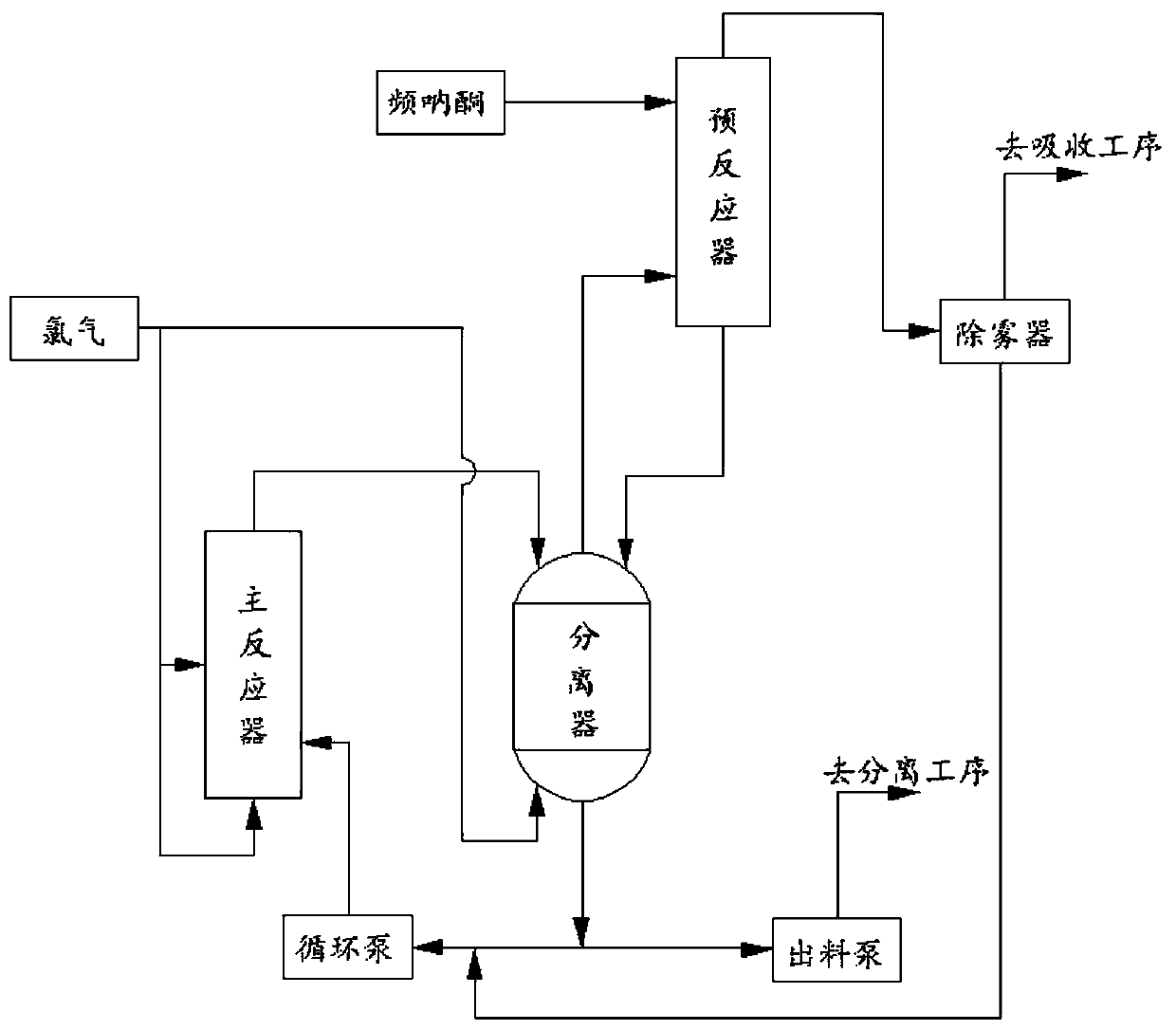

Device and process for continuously producing dichloropinacolin through differential circulation

PendingCN109912395AExtended stayHigh selectivityOrganic compound preparationCarbonyl compound preparationAcid productionHydrogen chloride

The invention provides a device and a process for continuously producing dichloropinacolin through differential circulation. The device comprises a main reactor, a pre-reactor, a separator, a circulating pump, a discharging pump, a pipeline and an auto-control instrument; each of the main reactor and the pre-reactor is a pipeline type micro-channel reaction heat exchanger, and is provided with multiple longitudinal tube passes and multiple transverse shell passes; the shell passes are used for cooling, and the tube passes are used for conveying a material; the production of the trichloropinacolin is reduced through the differential circulation technology, the product yield is improved, free chlorine in hydrogen chloride of the tail gas reacts with newly added pinacolin by utilizing the pre-reactor so as to remove the free chlorine, the side effect problem of sodium hypochlorite caused by using an alkali wash method is avoided, the reacted chlorination liquid realizes the efficient separation of the dichloropinacolin and the hydrogen chloride dissolved in the chlorination liquid by adopting a vacuum dehydrochlorination technology, and an environmental protection problem of the wastehydrochloric acid production caused by adding water to remove hydrogen chloride in the traditional intermittent method is substituted.

Owner:杭州众立化工科技有限公司

A kind of manufacturing method of alkaline high-magnesium pellets

ActiveCN105039681BImprove high temperature performanceExcellent performanceProcess efficiency improvementPelletizingPre treatment

The invention relates to a method for manufacturing alkaline magnesium-rich pellet ore. The method comprises the steps of I pretreatment of recycled waste magnesia-calcium bricks, wherein a, primary breaking is carried out, and the waste magnesia-calcium bricks are broken into magnesia-calcium brick blocks; b, fine grinding is carried out, and the magnesia-calcium brick blocks are ground into magnesia-calcium brick powder; II batching, wherein iron concentrate powder and the magnesia-calcium brick powder are batched into batch mixtures, and 5.5-6.6 parts of the magnesia-calcium brick powder, 100 parts of the iron concentrate powder, 0.5-1 part of pulverized coal and 1.7 parts of bentonite are adopted according to the ratio; III pretreatment of the batch mixtures, wherein roll grinding is carried out on the batch mixtures; IV mixing, wherein the batch mixtures obtained through roll grinding are mixed; V pelletizing and screening, wherein mixed materials are pelletized and screened into qualified green pellets; VI drying, preheating and calcination, wherein the qualified green pellets are calcinated into pellet ore; VIII cooling, wherein the pellet ore is cooled to obtain the alkaline magnesium-rich pellet ore. The alkaline magnesium-rich pellet ore is produced through the waste magnesia-calcium bricks, the quaternary alkalinity of the pellet ore can be above 1.15%, and MgO is larger than or equal to 3.8%.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

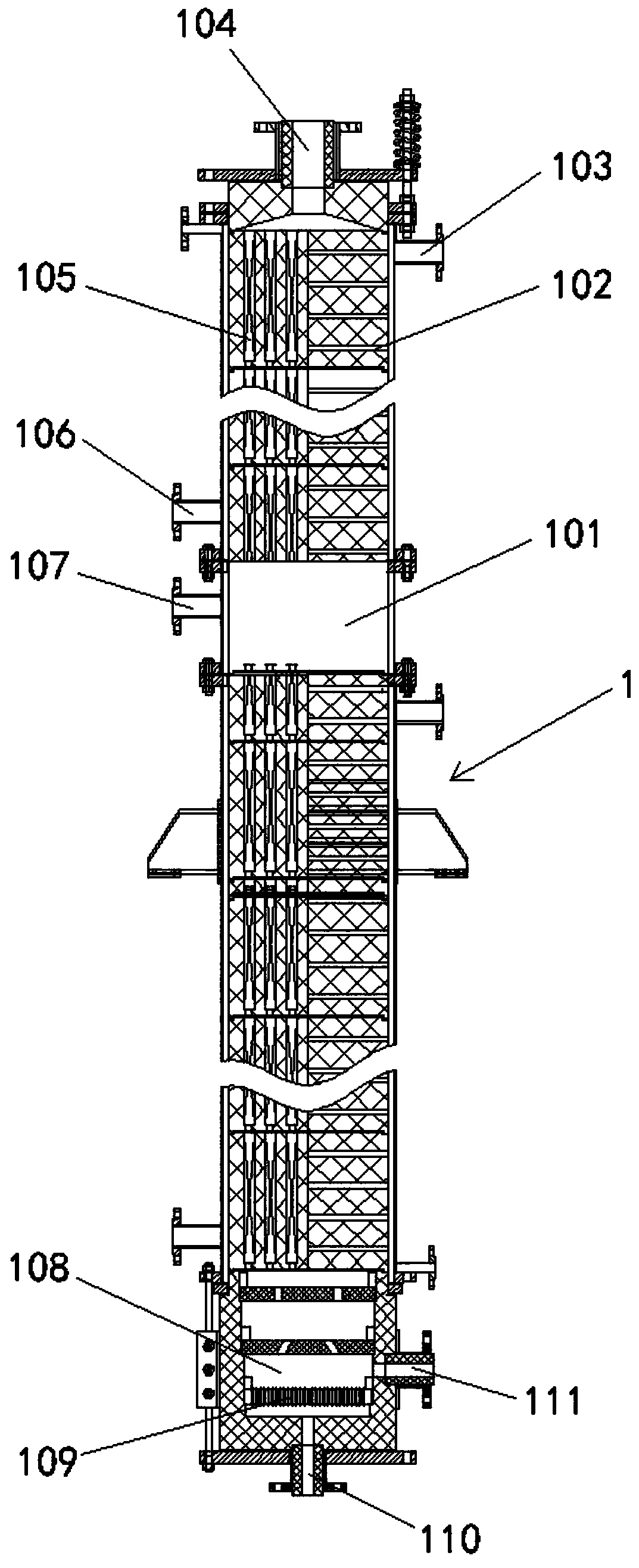

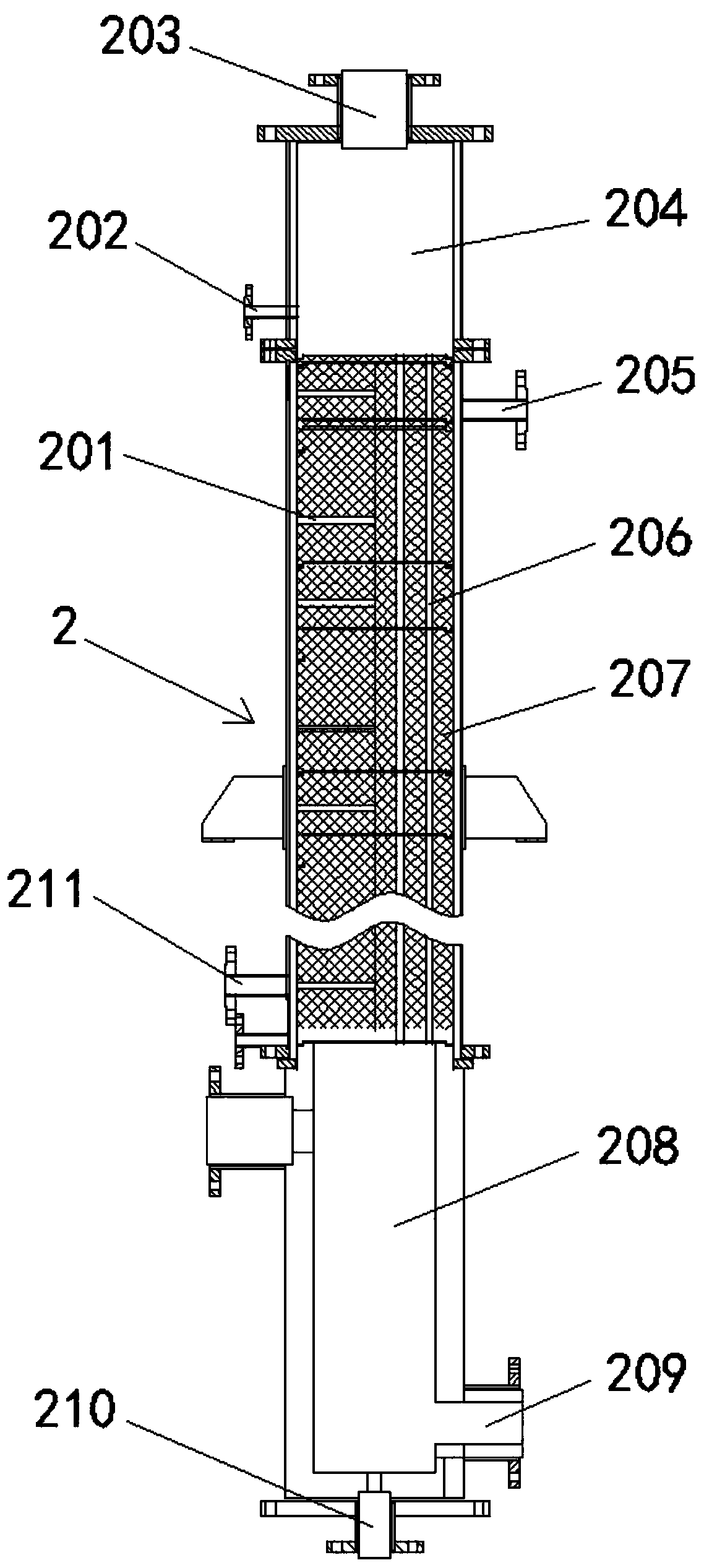

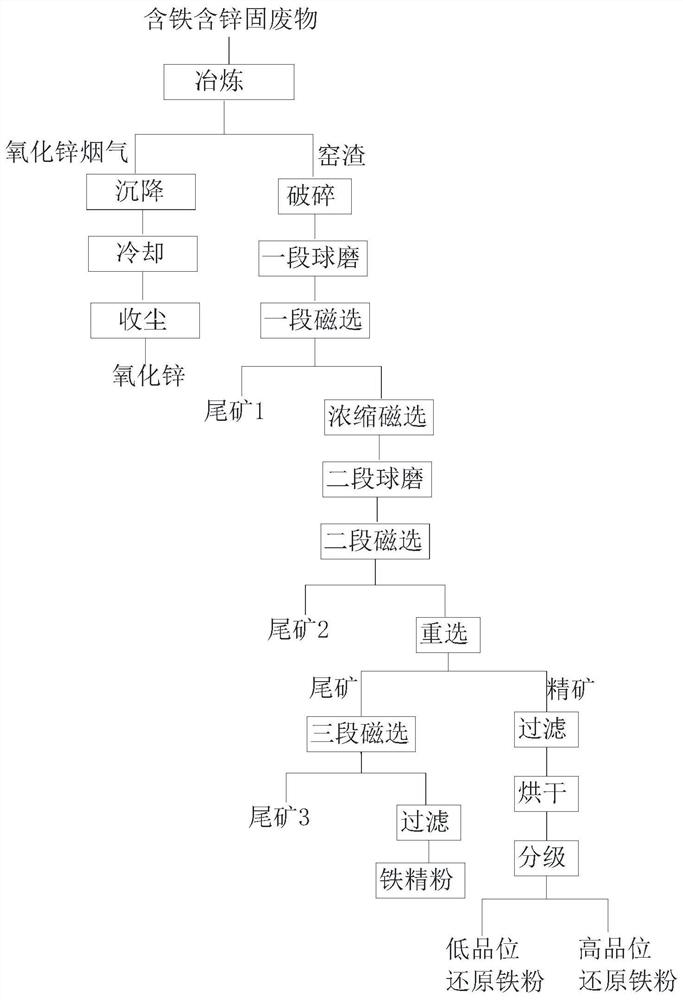

Method for recycling iron-containing and zinc-containing solid waste

InactiveCN113399110AHigh extraction rateReduce developmentRotary drum furnacesSolid separationSlagWaste treatment

The invention provides a method for recycling iron-containing and zinc-containing solid waste, and relates to the field of metal solid waste treatment and resource utilization. The method for recycling the iron-containing and zinc-containing solid waste comprises the following steps that the iron-containing and zinc-containing solid waste is firstly smelted, and zinc oxide flue gas and kiln slag are obtained; the kiln slag is crushed, then first-stage ball milling and first-stage magnetic separation are carried out, and tailings 1 and first-stage concentrate are obtained; the first-stage concentrate is subjected to concentration magnetic separation, second-stage ball milling and second-stage magnetic separation, and tailings 2 and second-stage concentrate are obtained; the second-stage concentrate is subjected to gravity separation, and gravity separation tailings and gravity separation concentrate are separated out; the gravity separation tailings are subjected to third-stage magnetic separation, tailings 3 and third-stage concentrate are obtained, and the third-stage concentrate is filtered to obtain iron fine powder; and the gravity concentrate is filtered, dried and graded, and low-grade reduced iron powder and high-grade reduced iron powder are obtained. According to the method, the extraction rate of a zinc element and an iron element is increased, and maximization of economic benefits is achieved.

Owner:苏州威固环境技术有限公司

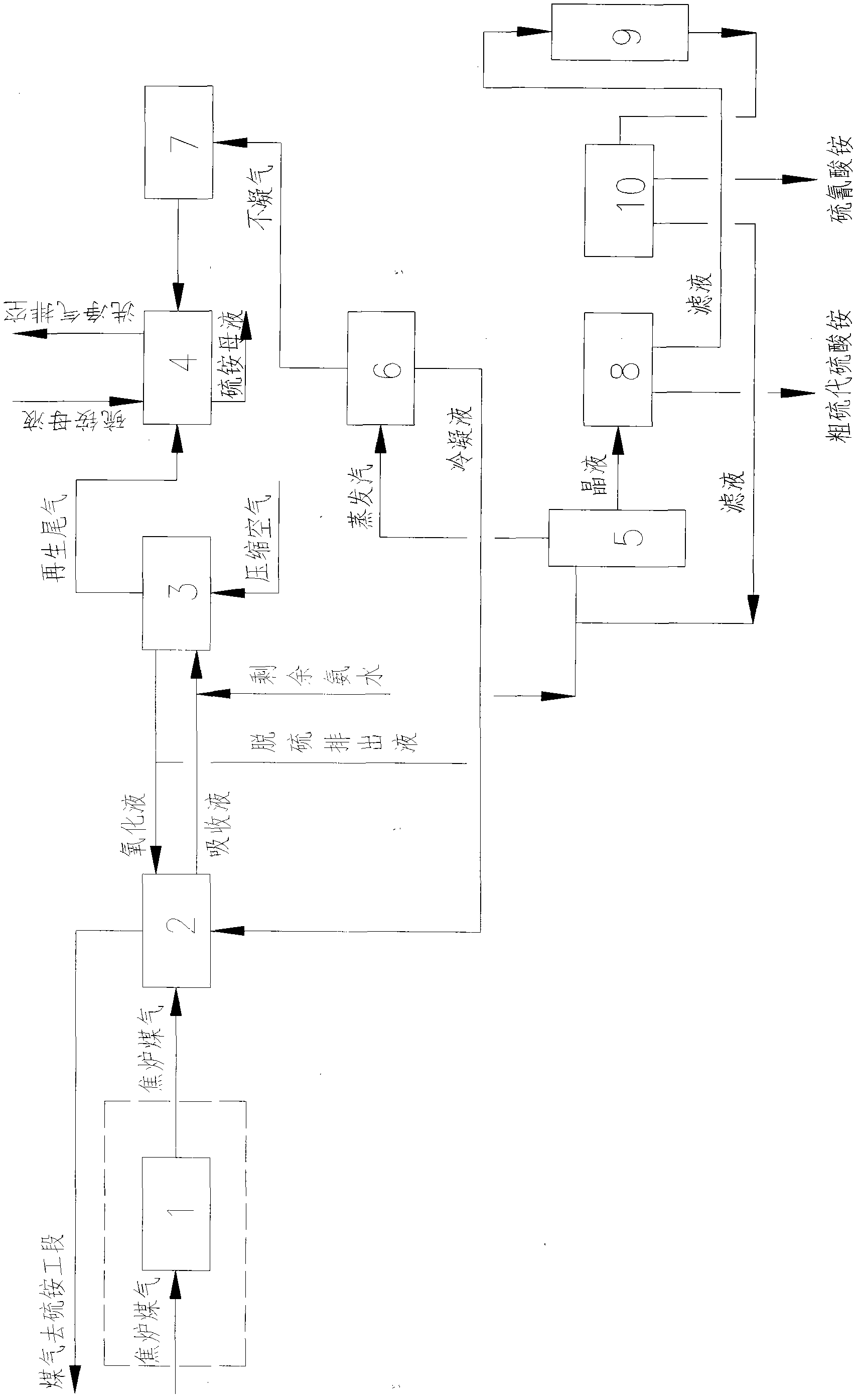

YST desulphurization and decyanation, and salt extraction method of coke-oven gas

InactiveCN102517096ATake advantage ofTo achieve the purpose of circular economyThiosulfates/dithionites/polythionitesThiocyanic acidSal ammoniacUniform system

According to the invention, various desulphurization technology experiences are integrated; residual ammonia water is used as a main catalyst; hydrogen sulfide and hydrogen cyanide in coal gas are completely converted into sulfur salt, and sulfur salt is extracted by using a physical method. With the method, sulfur is not produced, such that resources are fully utilized, and cyclic economy is realized. A production technology provided by the invention can be divided into two parts, one is an ammonia water desulphurization and decyanation technology, referred to as YS; and the other one is a chemical product sulfur salt extraction technology, referred to as T, wherein chemical products such as ammonium thiocyanate and crude ammonium thiosulfate are extracted from desulphurization drainage. The two technologies are combined into an YST technology. The two forms an inseparable uniform system.

Owner:DALIAN RES & DESIGN INST OF CHEM IND

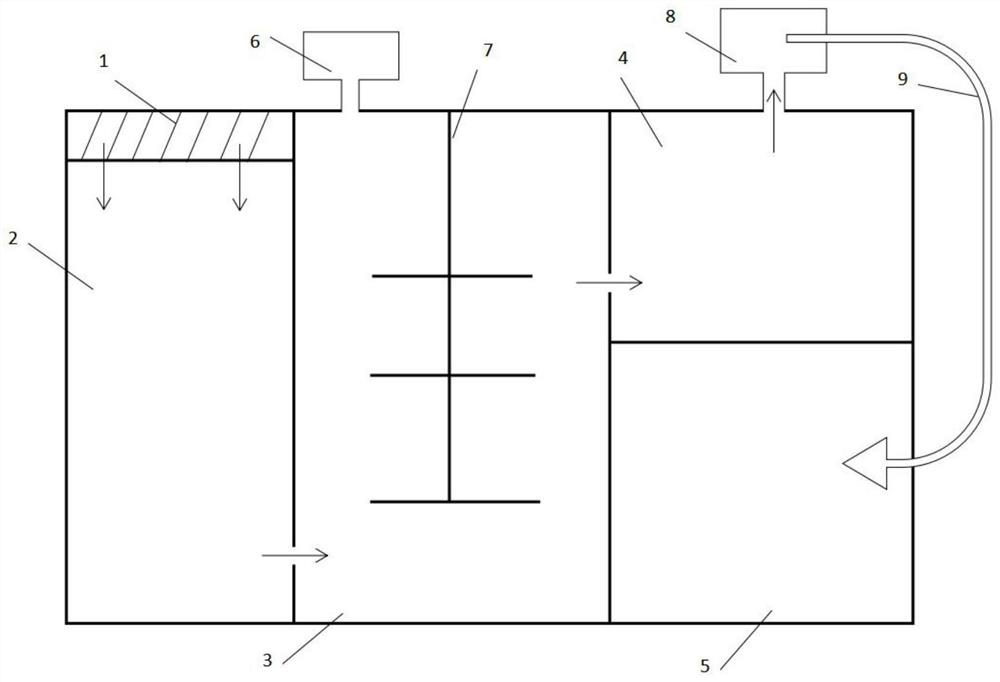

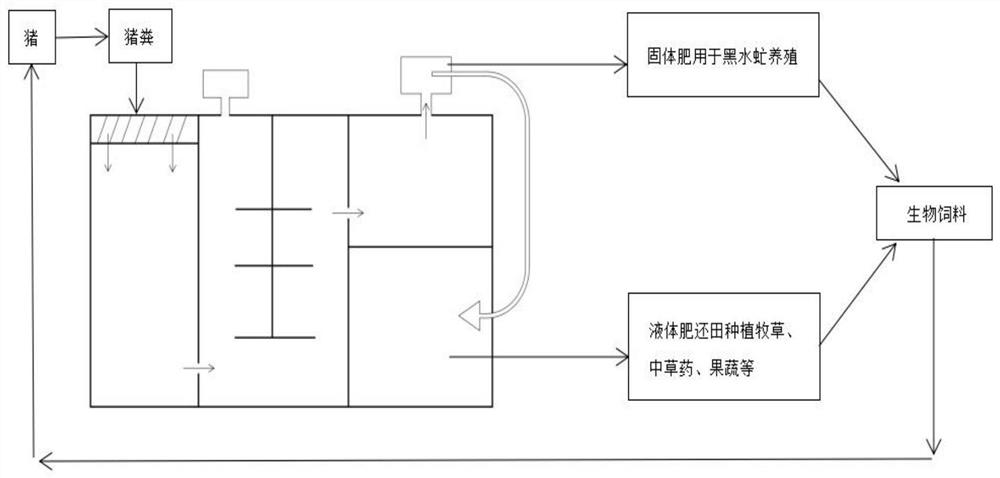

Pig manure biological treatment process and utilization method

PendingCN111875195AReduce pollutionReasonable structural designAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersFertilizerAgricultural science

The invention discloses a pig manure biological treatment process and a utilization method, and belongs to the field of manure treatment. The treatment method disclosed by the invention comprises thefollowing steps: putting pig manure into a manure treatment tank, filtering out large impurities by virtue of an impurity grid, feeding the pig manure into a manure concentration tank to precipitate impurities, and adding a complex microbial inoculant which accounts for 0.1-0.4% of the weight of the pig manure, a modifier which accounts for 2-4% of the weight of the pig manure and an additive which accounts for 6-11% of the weight of the pig manure from a storage tank; starting a stirrer, stirring and uniformly mixing the mixture for 25 hours, fermenting the mixture at 25-29 DEG C for 48-72 hours, keeping the water content of the fermented product at 50-70%, and stirring the fermented product for 30-60 minutes every 12 hours; fermenting for 60-96 hours at the temperature of 28-35 DEG C, enabling the fermented pig manure to enter a purification tank, removing harmful substances, enabling the pig manure to enter a solid-liquid separator, and enabling liquid fertilizer to enter a liquid fertilizer collection tank through a liquid fertilizer conveying pipe, so as to obtain liquid and solid fermented pig manure fertilizer. According to the pig manure treatment process, pollution generated by a farm can be greatly reduced, the pig manure can be recycled by combining application of the solid fertilizer and the liquid fertilizer, and the pig manure treatment process conforms to the concept of environment-friendly development.

Owner:GUANGXI UNIV

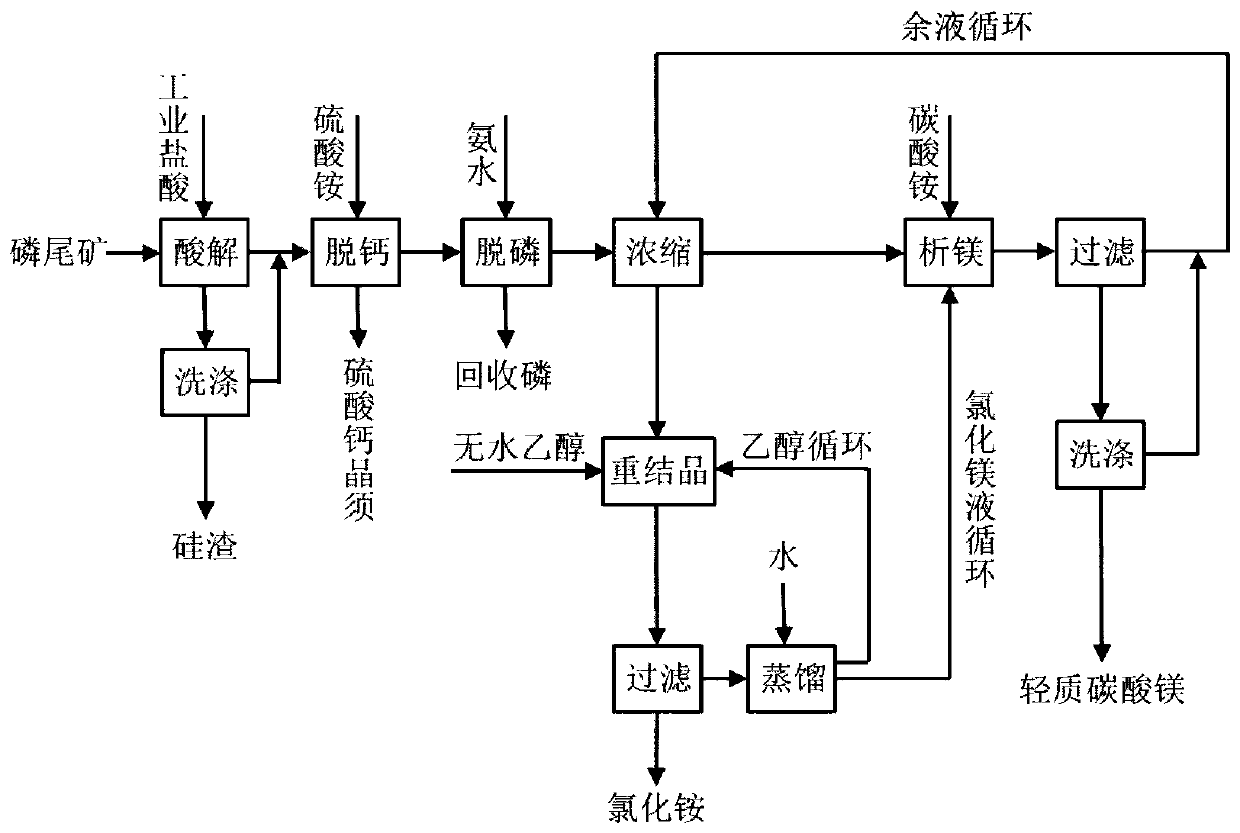

Method for preparing ammonium chloride and light magnesium carbonate from phosphate tailings and recycling ammonium chloride and light magnesium carbonate

PendingCN111484063AImprove comprehensive utilization efficiencyLower operating costsMagnesium carbonatesCalcium/strontium/barium sulfatesChemistryProcess engineering

The invention provides a method for preparing ammonium chloride and light magnesium carbonate from phosphate tailings and recycling the ammonium chloride and the light magnesium carbonate. The methodcomprises the following steps: carrying out acidolysis on the phosphate tailings, adding a decalcifying agent into the acidolysis solution, carrying out a decalcifying reaction to obtain calcium sulfate whiskers and a decalcifying mother solution, adding a dephosphorizing agent into the decalcifying mother solution, carrying out a dephosphorizing reaction, and carrying out vacuum concentration ona mixed solution obtained by the dephosphorizing reaction to obtain an ammonium chloride crude product and a magnesium chloride solution, recrystallizing the ammonium chloride crude product to obtaina fine ammonium chloride product, mixing the residual liquid obtained by carrying out reduced pressure distillation on the filtrate obtained in the recrystallization process with the magnesium chloride solution, adding a magnesium precipitation agent, carrying out a magnesium precipitation reaction to obtain magnesium carbonate, and mixing the filtrate generated by the magnesium precipitation reaction with the mixed solution obtained by the dephosphorizing reaction for recycling. The phosphorus tailings are used as a raw material to produce the ammonium chloride and the magnesium carbonate andthe byproduct calcium sulfate whiskers, the residual liquid is recycled, and the goals of changing the waste phosphorus chemical solid waste into valuable substances and clean production are implemented.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Margarya farming method

InactiveCN105191838AReduce the cost of farmingIncrease productionClimate change adaptationPisciculture and aquariaAgricultural scienceSludge

The invention discloses a margarya farming method. The margarya farming method comprises the following steps: (1) a pond is established, wherein a water inlet and a water outlet which are respectively provided with a fence are arranged in the culturing pond, the depth of the pond does not exceed 100cm, and a sunken part sunken from the periphery to the center is arranged in the culturing pond; (2) a culture medium is prepared, i.e., a loose material and a first sludge layer are sequentially paved at the bottom of the pond, the total thickness of the first sludge layer and the loose material is controlled to be 10-20cm, water is added for submerging the upper surface of the first sludge layer, and after the upper surface of the first sludge layer are soaked for 2-3 days, a rotten organic material is paved, so that the preparation of the culture medium can be completed; and (3) inoculating is carried out, before inoculating, the upper surface of the culture medium is covered by a second sludge layer with the thickness being 3-10cm, water is added until the thickness of the water layer is 10-20cm, margarya seeds are uniformly spread on the upper surface of the second sludge layer, and the culturing pond is kept in a mini flow state. According to the method, substrate materials of the culture medium are waste materials derived from agricultural production, so that the source of the substrate materials is rich and wide, and waste materials are consumed, thereby achieving the purpose of circular economy.

Owner:ZHANGJIAGANG HONGYIN BIOTECH CO LTD

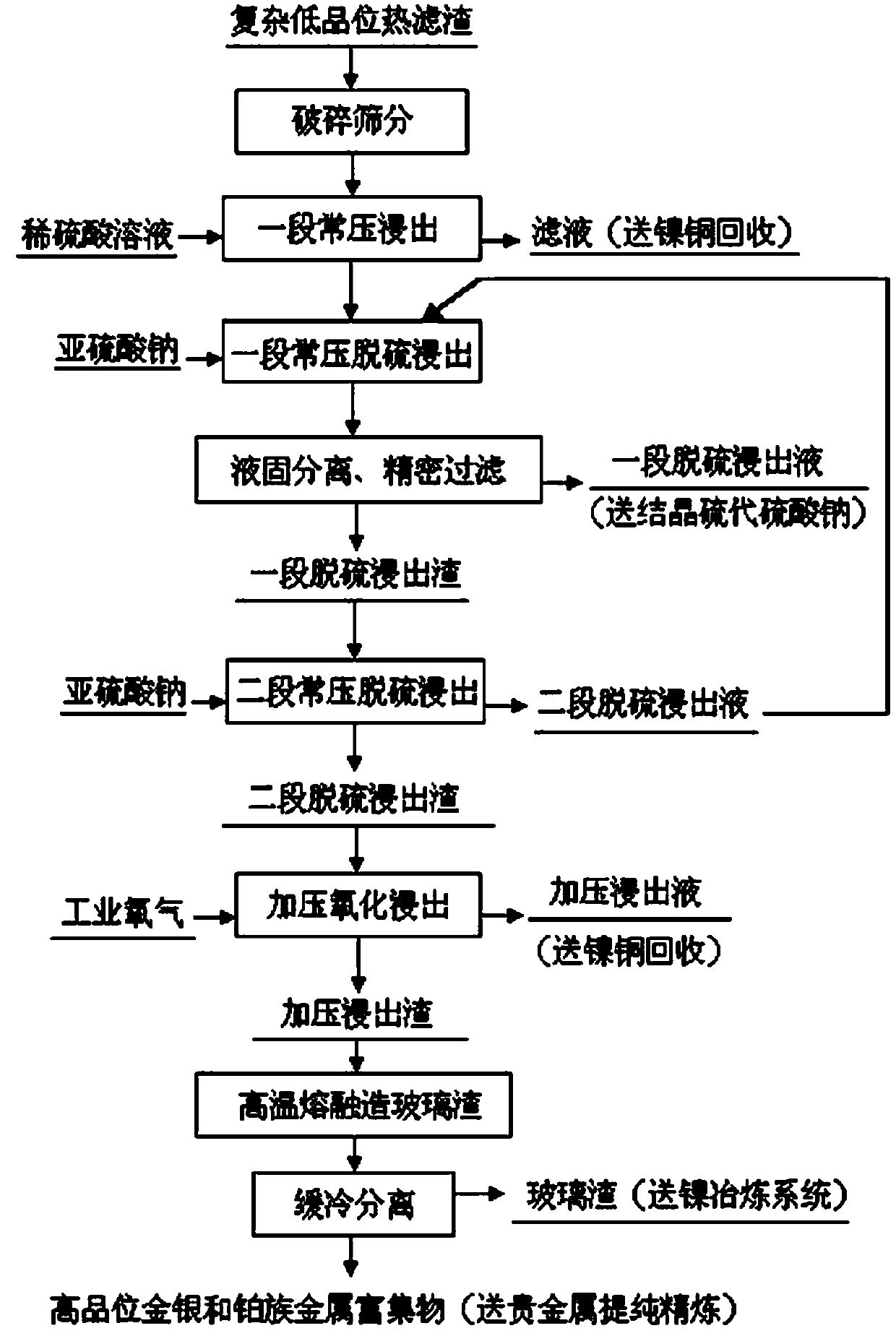

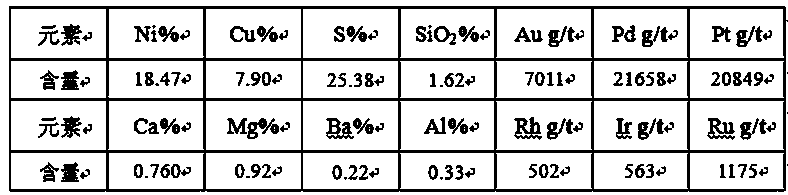

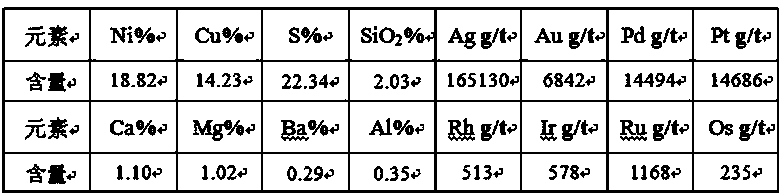

Method for efficiently enriching rare precious metals from complex low-grade heat filter residues

ActiveCN103498052BHigh removal rateEfficient separationThiosulfates/dithionites/polythionitesProcess efficiency improvementExhaust fumesSodium thiosulfate

The invention provides a method for efficiently enriching rare precious metals from complex low-grade heat filter residues. The method comprises the following steps: performing first-stage normal-pressure preliminary leaching and second-stage normal-pressure desulfurization leaching on the heat filter residues; performing evaporation, concentration and crystallization on a first-stage desulfurization liquid to obtain a sodium thiosulfate product; performing pressurization oxidation leaching on second-stage desulfurization residues; and removing silicon, iron, barium, calcium magnesium, aluminum, complex silicates and the like from glass residues prepared from pressurized residues, thereby obtaining a high-grade product rich in precious metals. The method is simple in process, environmentally-friendly, free of generation of toxic waste gases, gas residues and like as well as free of usage of toxic reagents, thereby being favorable for environmental protection. The method is easy to operate, low in working intensity, high in efficiency and easy in production process control and capable of easily realizing the process automation. According to the method, a high-grade and good-quality precious metal concentrate in which the content of gold, silver and platinum group metals can be 9% to 15% is obtained; and the recovery rate of the precious metals can be more than 99%. Thus, the method provided by the invention can be easily matched with an extraction separation refining process of the gold and platinum group metals.

Owner:JINCHUAN GROUP LIMITED

Method for preparing p-aminophenylacetonitrile by reducing p-nitrobenzeneacetonitrile by utilizing ammonium thiosulfate

InactiveCN103980157AReduce manufacturing costTo achieve the purpose of circular economyCarboxylic acid nitrile preparationOrganic compound preparationThio-Nitrobenzene

The invention discloses a method for preparing p-aminophenylacetonitrile by reducing p-nitrobenzeneacetonitrile by utilizing ammonium thiosulfate. The method comprises the following steps: putting p-nitrobenzeneacetonitrile into a mixed solution of an organic solvent and water and stirring p-nitrobenzeneacetonitrile until p-nitrobenzeneacetonitrile is totally dissolved; adding ammonium thiosulfate and carrying out reflux reaction after heating and stirring; naturally cooling the reactant to the room temperature after reaction is stopped, precipitating a solid and leaching and drying the precipitated solid, thus obtaining the final product, namely p-aminophenylacetonitrile. The method is lower in production cost, is convenient and safe to operate, is environment-friendly, is simple in equipment and is suitable for continuous production.

Owner:苏州久王环保科技股份有限公司 +1

Preparation method for sesame-flavor white spirit

InactiveCN101824372BIncrease added valueTo achieve the purpose of circular economyMicroorganism based processesAlcoholic beverage preparationYeastAlcohol content

The invention relates to a preparation method for sesame-flavor white spirit, which comprises the following steps: (1) taking 15-60 parts of distilled yellow wine lees, adding 5-15 parts of rice and 20-50 parts of white spirit lees, after evenly mixing the raw materials, putting obtained mixture in a retort and steaming and stewing for 30-50 minutes under 0.05-0.2MPa, cooling the steamed mixture to room temperature, 2-5 parts of malt, adding 2-10 parts of yeast for making hard liquor and 0.1-0.5 part of solid yeast, evenly agitating, fermenting the obtained mixture for 24-72h at 28 DEG C-32 DEG C in a stacking way, putting the fermented mixture in a cellar and fermenting for 28-32 days, opening the cellar and adding 3-7 parts of rice chaff, putting the obtained mixture is in the retort and distilling, adding 2-5 parts of arrack spirit in spent wash, and turning on steam and slowly distilling to 60%v / v to obtain semi-finished product; and (2) putting the semi-finished product into a warehouse and storing in an earthen jar for more than two years, and adding softened water to blend into spirit with preset alcohol content to obtain the sesame-flavor white spirit. The invention has the advantages that the high-quality sesame-flavor white spirit with both flavor and taste can be obtained, the product added value is greatly improved and the economic benefit can be doubled.

Owner:SUZHOU SANJIEYANG WINE

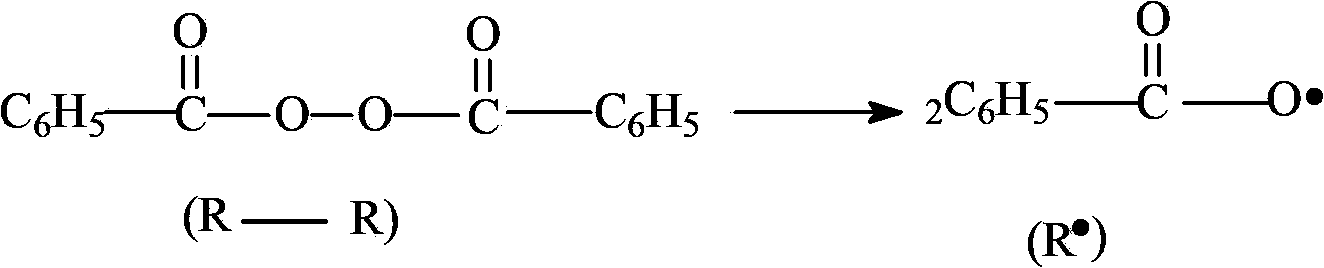

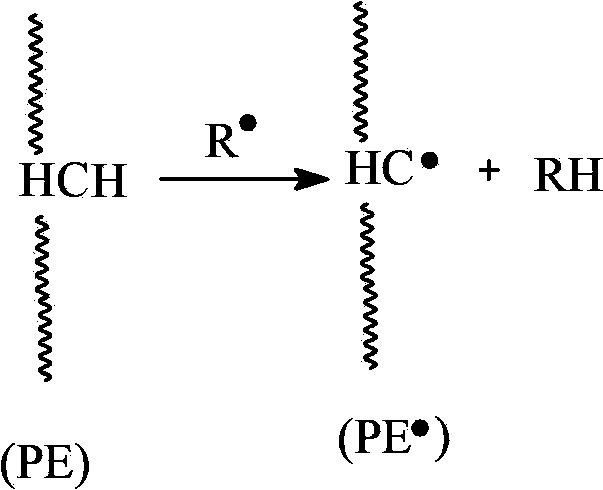

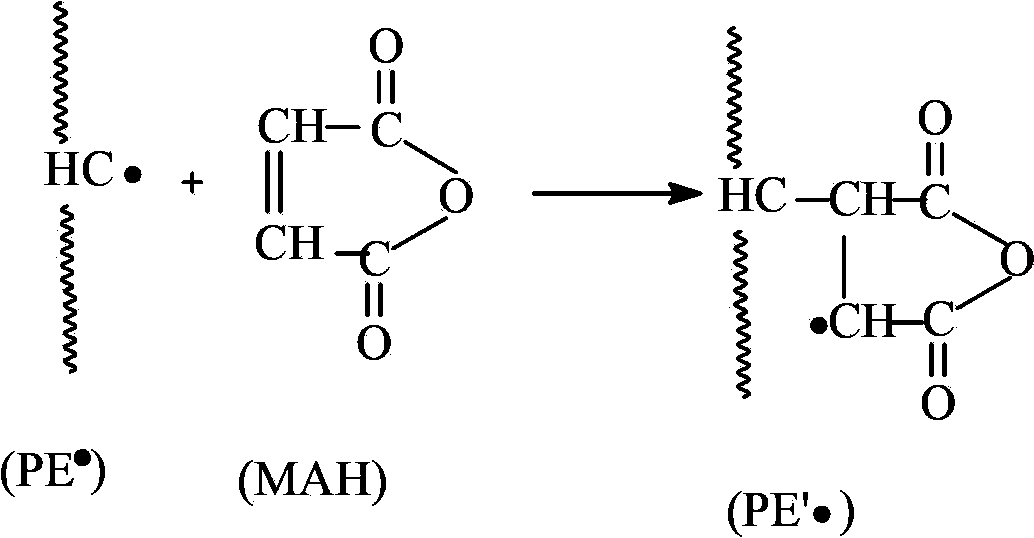

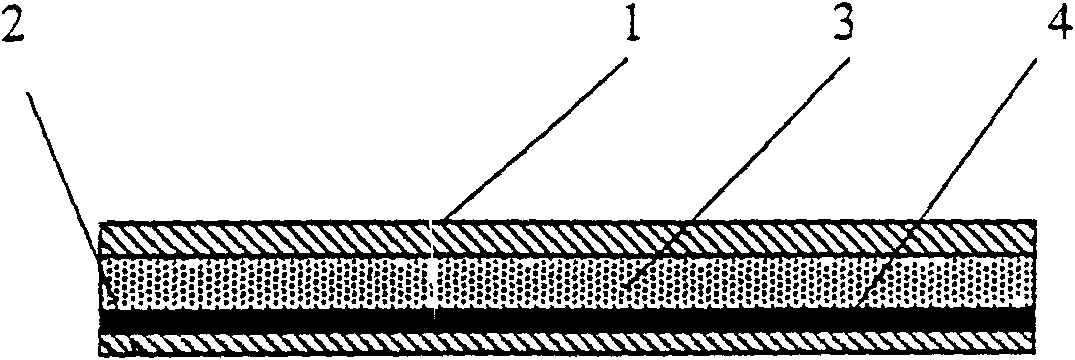

LDPE (low density polyethylene) grafting maleic anhydride waste water resourcelization recycling method

InactiveCN103012685BCompliant with reuse requirementsAchieve reuseLow-density polyethyleneLinear low-density polyethylene

The invention relates to an LDPE (low density polyethylene) grafting maleic anhydride waste water resourcelization recycling method which comprises the following steps: step 1, adopting LDPE grafting maleic anhydride waste water, adding solvent dimethyl benzene and LDPE powder in the waste water, and under the condition of backflow condensation, heating and stirring uniformly to obtain premixed liquid; step 2, adding MAH, surface-active agent and dispersing agent in the premixed liquid, heating and stirring uniformly to obtain reaction liquid; transfering the reaction liquid to a reaction vessel; step 3, heating and stirring the reaction liquid, then adding dimethyl benzene solution containing BPO in the reaction liquid, and heating continuously and stirring for reaction; step 4, stopping heating, stirring the reaction liquid, cooling and performing suction filtration to the reaction liquid to obtain solid, and washing and drying the solid to obtain powder; and step 5, adding acetone extractant into the powder, performing extraction in a soxhlet extractor, drying to constant weight, and then obtaining recycling reaction products. The method has the advantage that unreacted effective components in waste water can be fully utilized, so that the utilization ratio of raw materials and water resource can be improved.

Owner:NANJING TECH UNIV

Biological activity soiless vegetation blanket and its production process

InactiveCN100563426CProtect land resourcesLow costCultivating equipmentsSoilless cultivationLand resourcesPlant stalk

The invention relates to a biologically active vegetative blanket without soil, comprising a feed-providing layer, upper layer rotundifolia net connected with the upper side of feed-providing layer, and lower layer rotundifolia net connected with the lower side, the three of which are fixed through sewing. The lower layer rotundifolia net is adhered with lining paper, feed-providing layer is filled with grass seed, and it is comprised with disintegrated straw, corn shell, coir silk and flax silk. The straw is rich in organic matter, nitrogen, phosphorus and potassium which provide nutrient for grass seed. The said blanket can be transported to construction site by way of winding drum. The invention overcomes problem existed in traditional replanting with soil and can protect the limited land resource in China.

Owner:LUOJISHAN ENVIRONMENT PROTECTION TECHSHANGHAICO

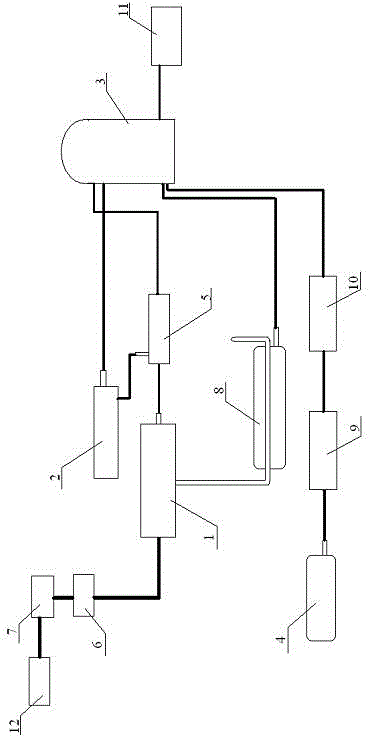

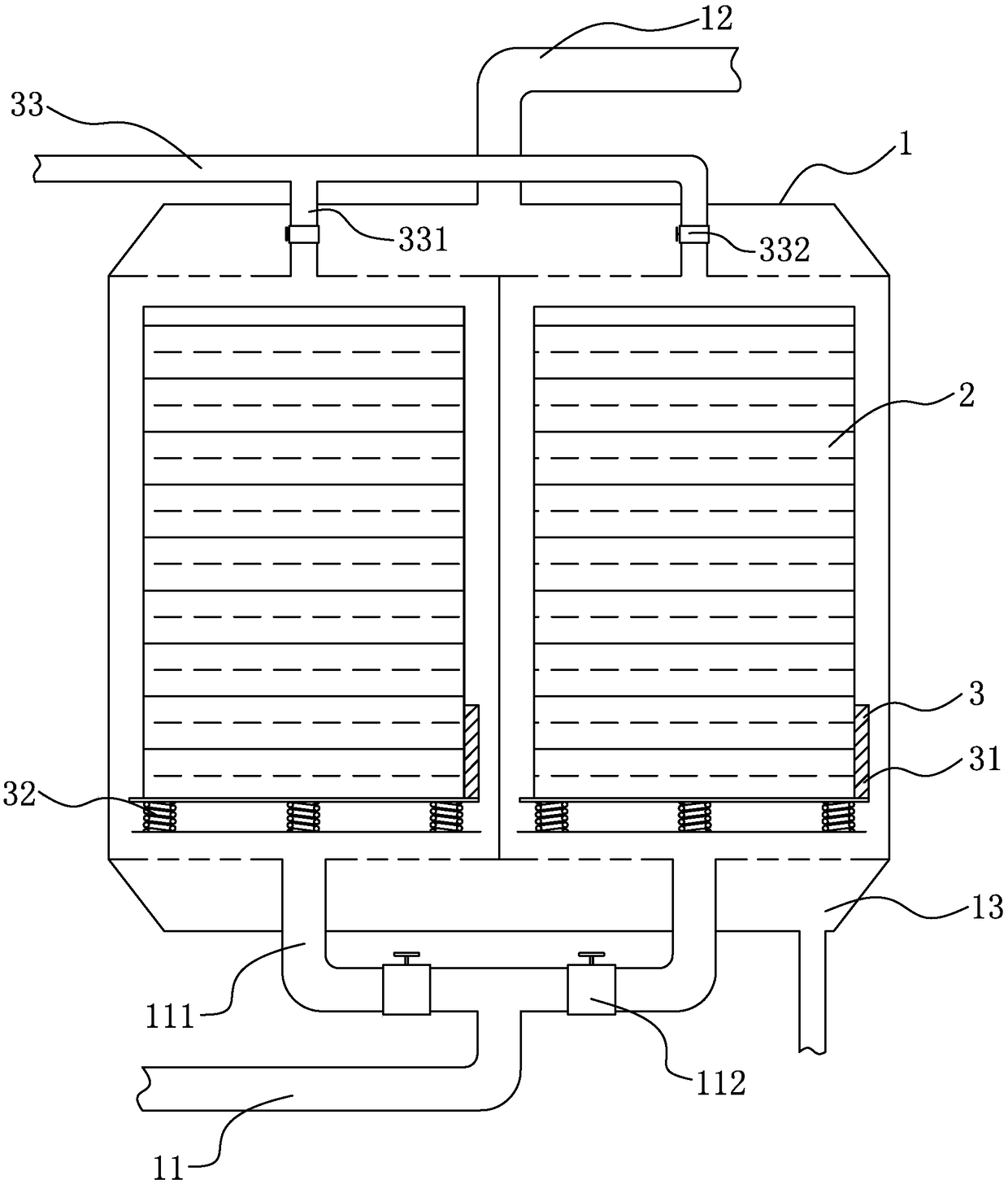

Biogas Comprehensive Utilization System

ActiveCN104030538BFully fermentedIncrease gas productionBio-organic fraction processingInternal combustion piston enginesSolar waterSlurry

The invention relates to a comprehensive biogas utilization system. The system includes a combustion gas generator set, a coal burning boiler, a biogas fermentation tank, a solar water heater, a water tank and a mixing pool. A gas inlet in the combustion gas generator set is connected with a water-gas separating tank, and the water-gas separating tank is connected with the gas outlet tube of the biogas fermentation tank; the water-gas separating tank is provided with a water conveying pipe, and the water conveying pipe is connected with the coal burning boiler; the combustion gas generator set is connected with national electrical network sequentially through a grid cabinet and a booster station; the gas discharge pipe in the combustion gas generator set traverses through the water tank and is connected with atmosphere; the water outlet pipe of the water tank is connected with the biogas fermentation tank; the coal burning boiler is provided with a hot water outlet pipe, and the hot water outlet pipe is connected with the biogas fermentation tank; the water outlet pipe II of the solar water heater is connected with the mixing pool, and the mixing pool is connected with a filter pool; the filter pool is connected with the biogas fermentation tank; and the biogas fermentation tank is connected with a biogas slurry pool. The system can realize the integration of culturing, biogas, biogas fertilizer and power generation in order to achieve the purpose of circular economy.

Owner:周海云

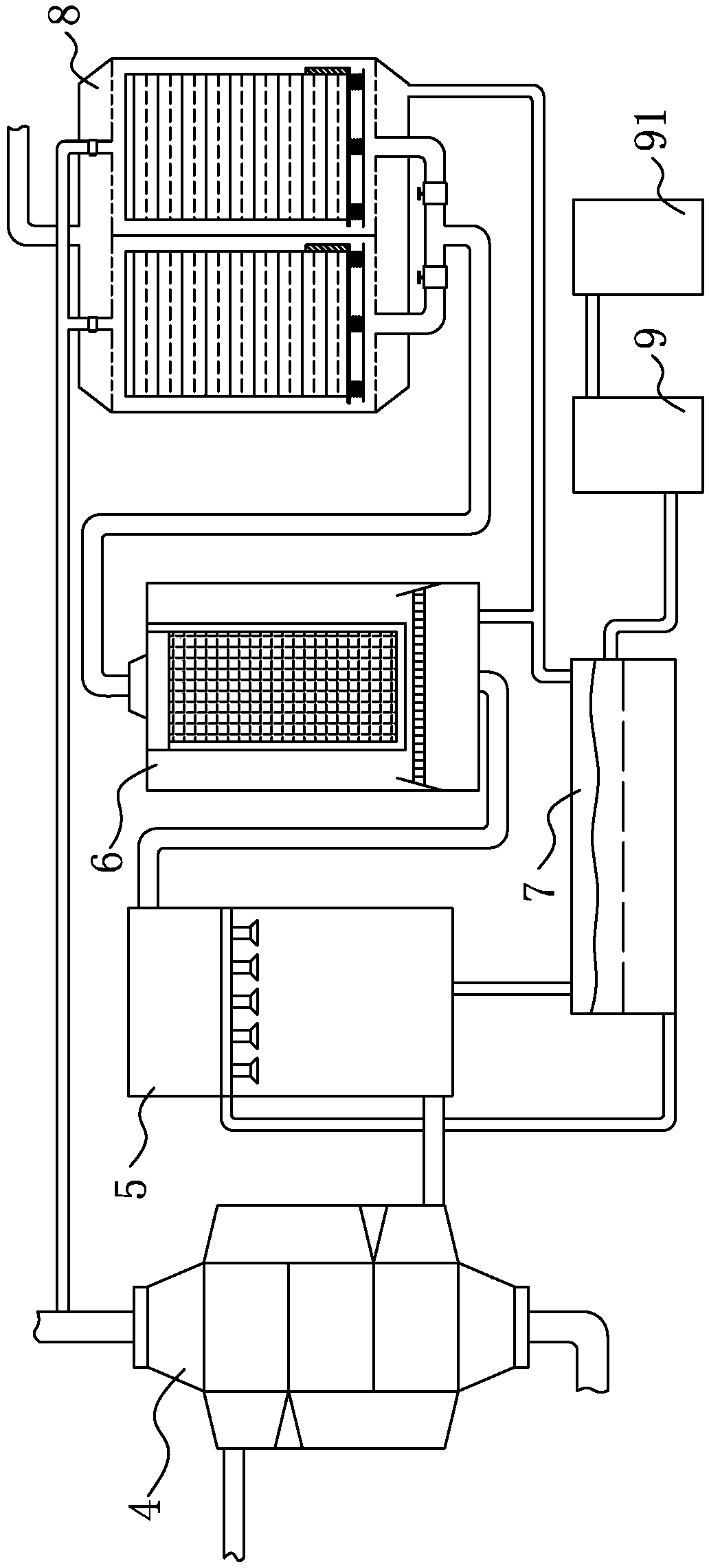

Self-cleaning electrostatic degreasing device and high temperature oily waste gas treatment system and method

ActiveCN106994390BReduce workloadIncrease profitCombination devicesExternal electric electrostatic seperatorHigh energyEngineering

Owner:威洁(石狮)中水回用技术有限公司

Method for preparing untwisted, highly branched textiles

ActiveCN105369421BEfficient manufacturingTo achieve the purpose of circular economyArtificial filament recoveryFilament/thread formingSolubilityEnvironmental effect

The invention discloses a method for preparing untwisted, hollow, highly branched textiles and a method for recovering dissolved matter in an alkali solution. The method for preparing untwisted, hollow, highly branched textiles comprises the following steps: a. preparing alkali-degradable slices; b. Preparation of blended spinning melt; c. Spinning to prepare easily alkali-soluble degradable fibers, which include filaments, staple fibers, and fiber strips; d. Untwisted textiles, hollow textiles, and highly branched yarns Textiles or embroidery products; the preparation method of the untwisted, hollow and highly branched textiles can effectively prepare soft and light textiles. The method of recovering the solute in the alkali solution is as follows: the alkali solution is obtained after the degradation of the easily alkali-soluble degraded fiber, and after acid analysis, terephthalic acid is obtained, and the filtered waste water meets the discharge standard, and is introduced into the biochemical treatment system of the factory; The method for recovering dissolved matter in the alkali solution can recover the alkali solution after the easily alkali-soluble degradable fiber is dissolved, has good environmental protection effect and can achieve the purpose of circular economy.

Owner:余燕平 +3

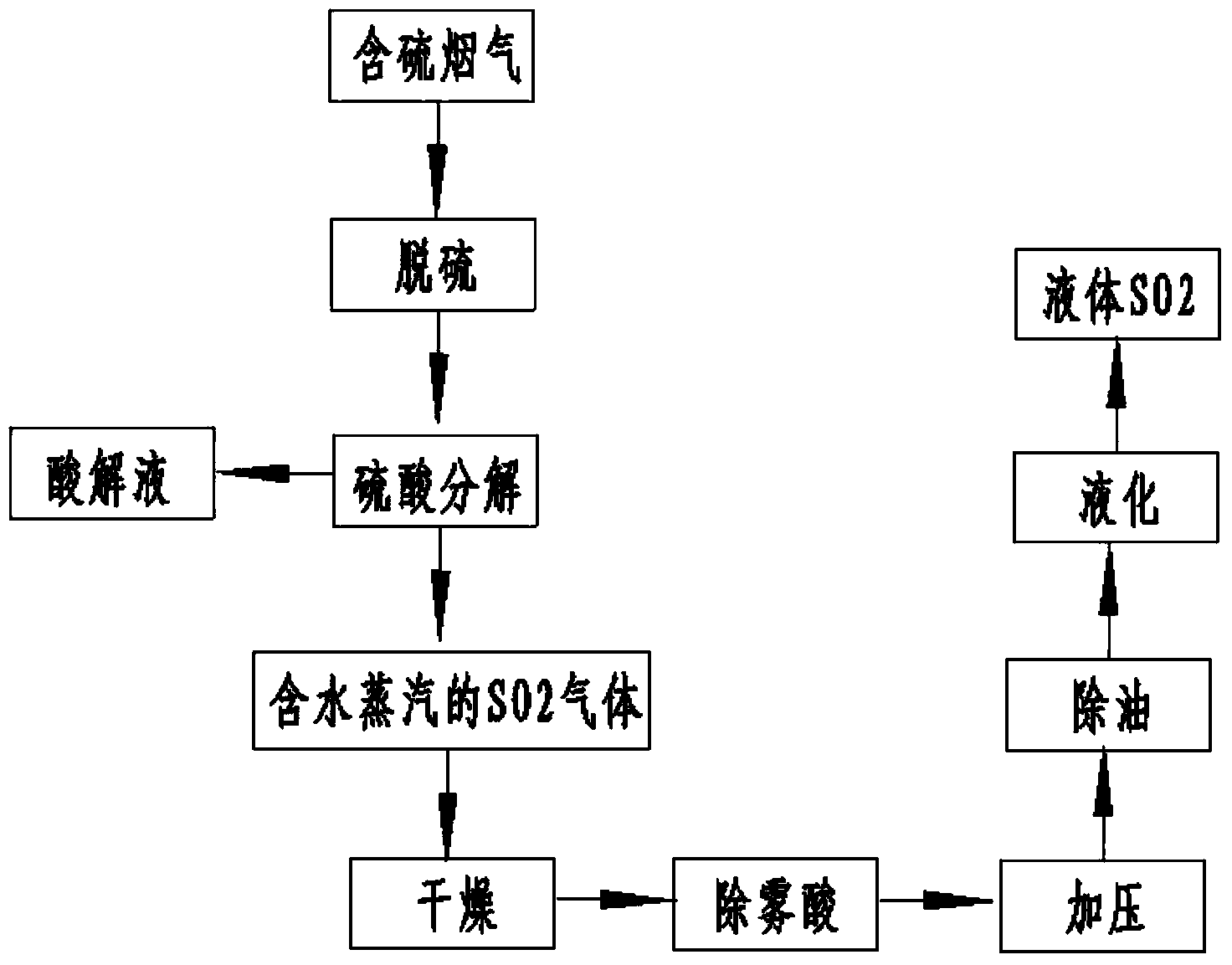

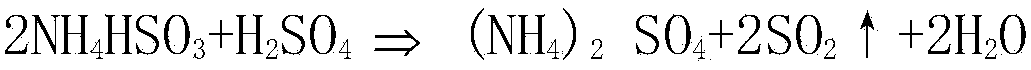

Method for producing liquid sulfur dioxide by using sulfur-containing flue gas

InactiveCN104386653AImprove economic efficiencyNo secondary pollutionSulfur-dioxide/sulfurous-acidSpecific gas purification/separationWater contentDecomposition

The invention relates to a method for producing liquid sulfur dioxide by using sulfur-containing flue gas and belongs to the technical field of chemical engineering and environment protection. The method comprises the following steps: a, absorbing the sulfur-containing flue gas by desulfurization absorption liquid to obtain a sulfur-containing absorption liquid; b, adding sulfuric acid into the sulfur-containing absorption liquid, and performing decomposition to obtain acidolysis liquid and SO2 gas containing steam; c, spraying and drying the SO2 gas containing the steam by using the sulfuric acid till the water content of the SO2 gas is smaller than or equal to 0.2 g / Nm<3>; d, pressurizing, de-oiling and liquefying the dried SO2 gas under the pressure condition of 0.25-0.7 MPa to obtain the liquid sulfur dioxide. The method has the benefits that a flue gas desulfurization byproduct is the liquid sulfur dioxide, so that the economic benefits of the flue gas are remarkably improved, and secondary pollution is avoided.

Owner:ASIA PACIFIC ENVIRONMENTAL CORP

Processing method for aquatic byproducts

InactiveCN102450388BImprove absorption and utilizationProtect environmentAnimal feeding stuffEcological environmentTrace element

The invention discloses a processing method for aquatic byproducts, comprising the following steps: (1), taking byproducts, such as snails, mussels and clams; directly crushing the snails, mussels and clams to 20-1000 meshes so as to being prepared to raw materials; (2), adding 3-10 parts by weight of bran and 2-10 parts by weight of bean pulp in 80-95 parts by weight of the raw materials or onlyadding 5-20 parts of by weight of sugar in 80-95 parts by weight of the raw materials; uniformly mixing for standby; (3), adding bacillus liquid according to 5-20% of the materials; fermenting for 24-96 hours at 20 degrees centigrade; warming to 65-85 degrees centigrade for 2 hours; standby; (4), adding lactobacillus liquid according to 5-15% of the materials; fermenting for 24-108 hours at 50 degrees centigrade in a sealing manner; standby; and (5), drying the mixture at 60 degrees centigrade; and smashing the mixture. The products prepared in the invention contain major elements, trace elements and nutrient elements, so that the rate of absorption and utilization is effectively improved; the around ecological environment is protected; and the purpose of recycling economy is achieved.

Owner:HUNAN UNIV OF ARTS & SCI

A kind of cultivation method of benthos

ActiveCN105075948BReduce the cost of farmingIncrease productionClimate change adaptationPisciculture and aquariaAgricultural scienceCircular economy

The invention discloses a breeding method of benthic animals, which comprises the following steps: 1) building a pond; 2) making a culture medium; 3) inoculating; 4) managing the pond and water body. The culture base material used in the cultivation method of the present invention is derived from waste materials in agricultural production, has a wide range of sources, low breeding cost, and is environmentally friendly, and provides a new solution for waste materials in agricultural production. For the purpose of circular economy, the yield and quality of benthic animals cultured by this method are high.

Owner:ZHANGJIAGANG HONGYIN BIOTECH CO LTD

Processing method for aquatic byproducts

InactiveCN102450388AImprove absorption and utilizationProtect environmentAnimal feeding stuffEcological environmentTrace element

The invention discloses a processing method for aquatic byproducts, comprising the following steps: (1), taking byproducts, such as snails, mussels and clams; directly crushing the snails, mussels and clams to 20-1000 meshes so as to being prepared to raw materials; (2), adding 3-10 parts by weight of bran and 2-10 parts by weight of bean pulp in 80-95 parts by weight of the raw materials or onlyadding 5-20 parts of by weight of sugar in 80-95 parts by weight of the raw materials; uniformly mixing for standby; (3), adding bacillus liquid according to 5-20% of the materials; fermenting for 24-96 hours at 20 degrees centigrade; warming to 65-85 degrees centigrade for 2 hours; standby; (4), adding lactobacillus liquid according to 5-15% of the materials; fermenting for 24-108 hours at 50 degrees centigrade in a sealing manner; standby; and (5), drying the mixture at 60 degrees centigrade; and smashing the mixture. The products prepared in the invention contain major elements, trace elements and nutrient elements, so that the rate of absorption and utilization is effectively improved; the around ecological environment is protected; and the purpose of recycling economy is achieved.

Owner:HUNAN UNIV OF ARTS & SCI

A steel cylinder method for processing high-purity arsine

ActiveCN105927851BEmission reductionTo achieve the purpose of circular economyVessel geometry/arrangement/sizeContainer filling methodsArsineProduct gas

The invention discloses a method for processing steel bottles of high-purity arsine. The method includes the steps that valve outlets in the tops of the multiple to-be-processed steel bottles are connected to a main pipeline through steel bottle connectors; a valve outlet of a source gas steel bottle containing arsine and a valve outlet of a cold trap collection steel bottle are connected to the main pipeline through steel bottle connectors; replacement is conducted on the main pipeline through high-purity helium, it is ensured that the pipeline is not contaminated, and then the main pipeline is vacuumized through a vacuum pump; under the condition that the vacuum pump keeps running, vacuum baking is conducted on the to-be-processed steel bottles, helium is then injected into the to-be-processed steel bottles, and then the helium is pumped out through the vacuum pump; a steel bottle valve of the source gas steel bottle is opened, and arsine gas is injected into the to-be-processed steel bottles; helium is injected into the to-be-processed steel bottles, and then the helium is pumped out through the vacuum pump; and steel bottle valves of the to-be-processed steel bottles are closed, and the to-be-processed steel bottles are completely processed at the moment. According to the method, the arsine gas used for passivation is recycled, emission of the arsine-containing gas is well reduced, and the aim of cyclic economy is achieved.

Owner:SHANGHAI ZHENGFAN TECH +1

Preparation method of activated carbon or activated carbon fiber and preparation method of purification medium

ActiveCN103736459BReduce consumptionReduce pollutionOther chemical processesDispersed particle separationFiberActivated carbon

The invention relates to a preparation method of active carbon or an active carbon fiber and a preparation method of a purification medium. A nano zinc dioxide photocatalyst grows on the active carbon or the active carbon fiber, then the active carbon or the active carbon fiber is processed into an active carbon air purification filter screen or an active carbon fiber air purification filter screen, and the recycling of the active carbon or the active carbon fiber is realized by the catalytic action of an ultraviolet light source. The photocatalytic regeneration of the active carbon or the active carbon fiber can greatly reduce energy consumption of the traditional heat regeneration technology, reduces air pollution and energy waste, and facilitates energy conservation and emission reduction. Further, a photocatalytic technology is combined with an active carbon or an active carbon fiber absorption technology, a high-concentration reaction location is provided for photocatalysis in the air purification by using an absorption action of the active carbon or the active carbon fiber, and the photocatalytic efficiency is improved.

Owner:天津微能新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com