Thermoelectricity combined production method and apparatus for preparing alkene and by coal and natural gas

A technology of natural gas and olefins, which is applied in the field of combined heat and power generation and devices for producing olefins and ammonia from coal and natural gas, which can solve the problems of low energy utilization efficiency of the system, achieve comprehensive utilization, reduce energy waste, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

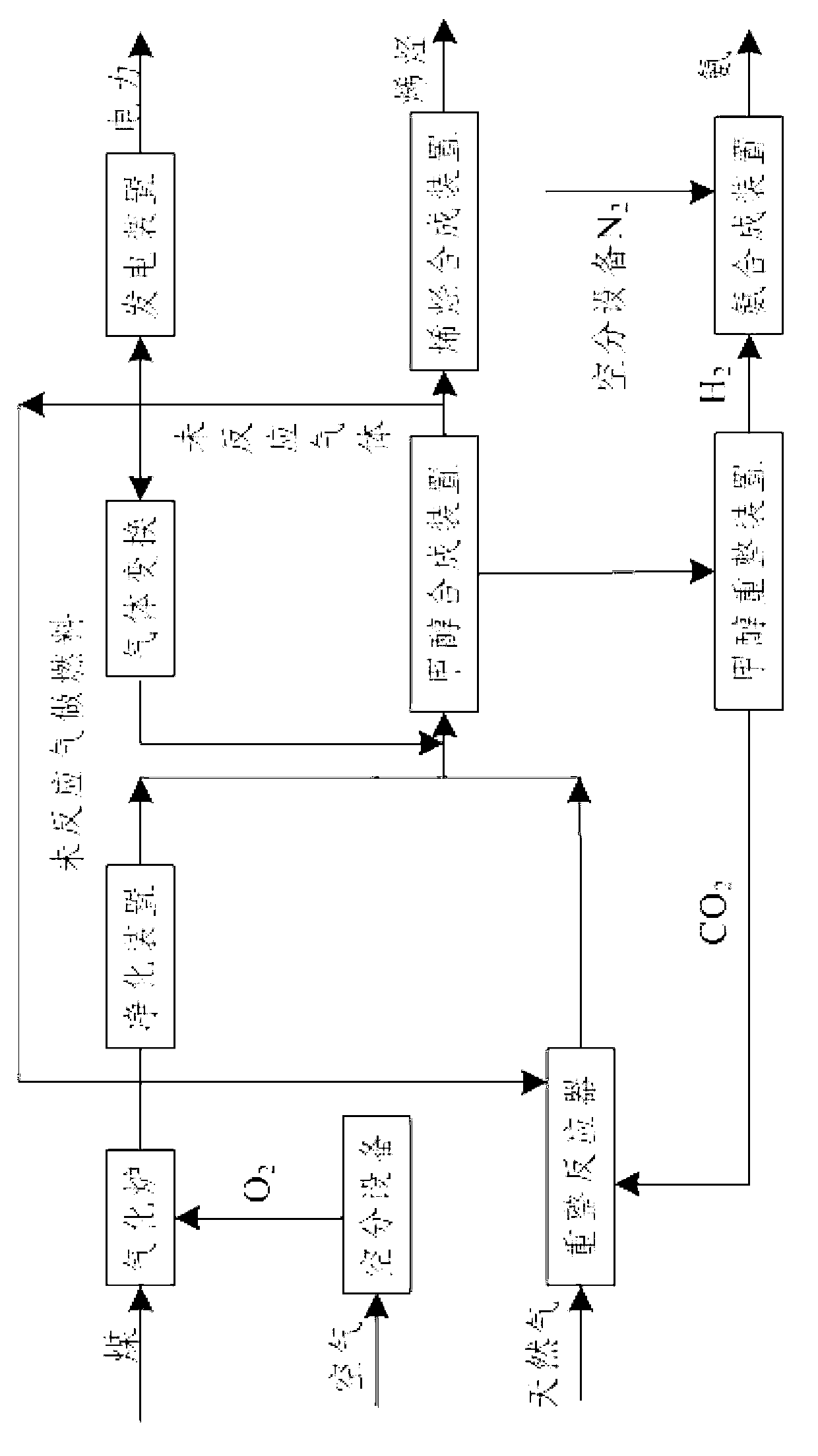

[0059] figure 1 It is a process flow chart of Embodiment 1 of the cogeneration process for producing olefins and ammonia from coal and natural gas in the present invention. In this embodiment, coal and natural gas are used as raw materials, and the existing mature technology is used to prepare synthesis gas. Among them, when coal is used as raw material to produce syngas, American Texaco entrained flow bed coal-water slurry gasification technology and Holland Shell pulverized coal gas pressurized gasification technology can be used. The hydrogen-to-carbon ratio in coal-to-synthesis gas is 0.4-0.7; Methane carbon dioxide reforming technology is used when natural gas is used as raw material to produce synthesis gas. The hydrogen-to-carbon ratio of the synthesis gas produced by methane carbon dioxide reforming technology is 1. Usually, the synthesis gas needs to undergo gas shift to adjust the hydrogen-to-carbon ratio to achieve the optimal hydrogen-to-carbon ratio of 2:1 for me...

Embodiment 2

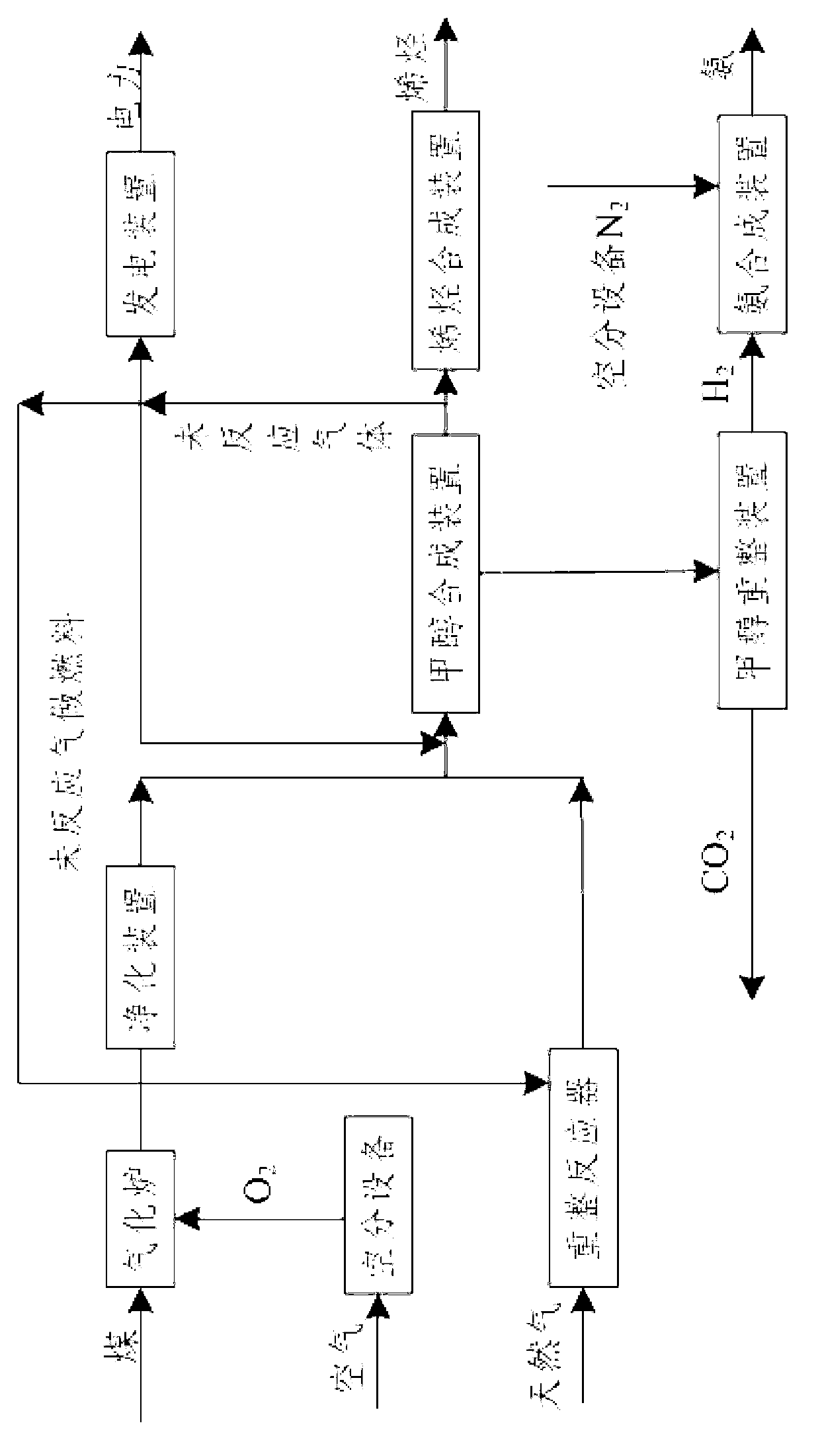

[0070] figure 2 It is the process flow chart of the second embodiment of the cogeneration process for producing olefins and ammonia from coal and natural gas of the present invention. In this embodiment, coal is used as raw material to produce synthesis gas, which can be gasified by American Texaco entrained flow bed coal water slurry Technology, Holland Shell pulverized coal gas pressurized gasification technology; natural gas steam reforming process is used when natural gas is used as raw material to produce synthesis gas. The hydrogen-carbon ratio in the synthesis gas produced by the steam reforming process of natural gas is high, generally 2.5 to 3.0. By adjusting the mass ratio of raw coal and natural gas, the coal-to-synthesis gas and natural gas-to-synthesis gas can be combined according to the preset ratio To make it meet the optimal hydrogen-carbon ratio of methanol synthesis, the mixed synthesis gas is directly sent to the synthesis of methanol, and the unreacted ga...

Embodiment 3

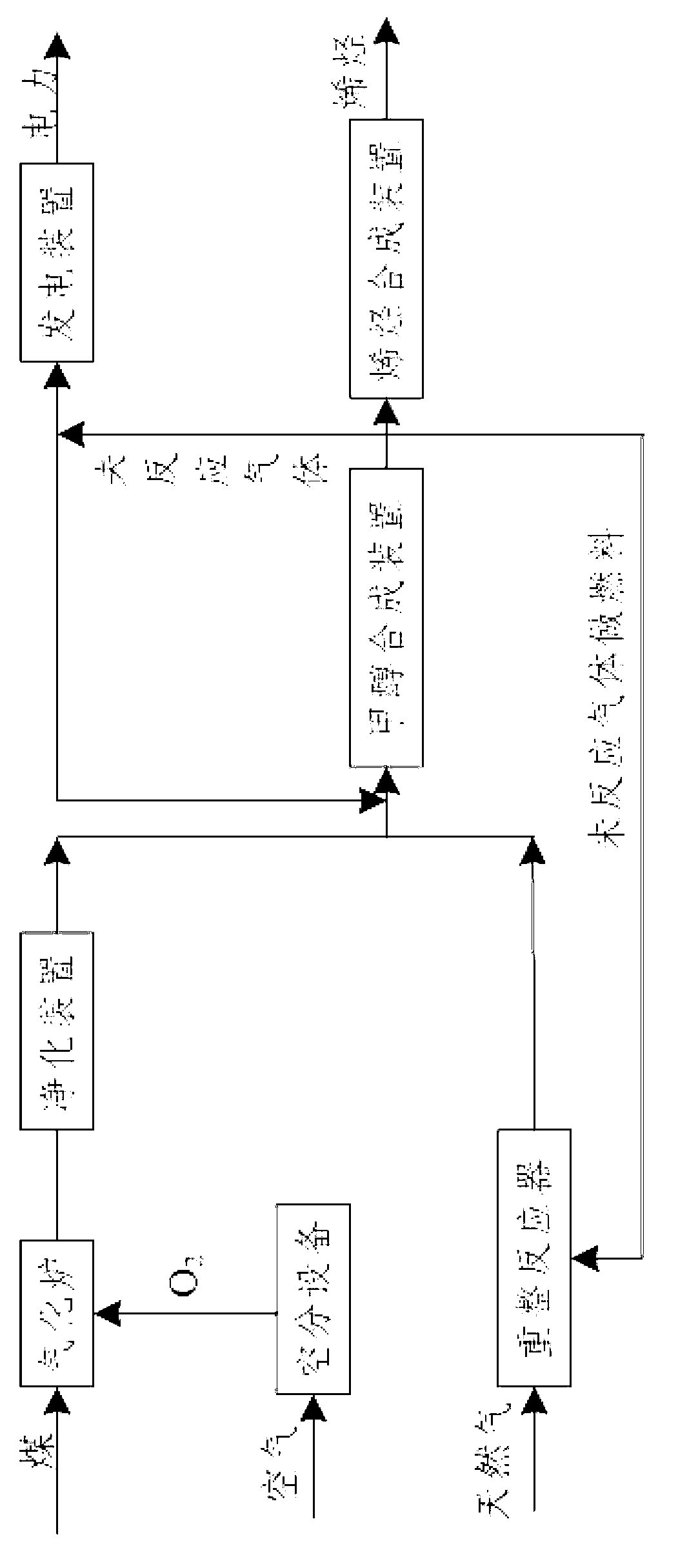

[0079] In order to make the technical scheme and advantages of the present invention clearer, the process of the present invention is analyzed below in conjunction with specific example 3, and the described process adopts the above-mentioned method of the present invention. figure 2 Part of the process, this embodiment is only a part of the present invention. This embodiment uses coal and natural gas as raw materials to produce olefins cogeneration process, and does not include ammonia synthesis process. The main steps are: primary purification and desulfurization treatment after coal gasification, natural gas is reformed and mixed with coal-based synthesis gas in a certain proportion, and then methanol synthesis and olefin synthesis are carried out. The unreacted gas from methanol synthesis is divided into three parts, one part Carry out circular synthesis of methanol, one part is used as fuel for the natural gas reforming unit, and the other part is sent to the gas turbine ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com