Self-cleaning electrostatic degreasing device and high temperature oily waste gas treatment system and method

A waste gas treatment and self-cleaning technology, applied in separation methods, electrostatic separation, combined devices, etc., can solve the problems of decreased equipment work efficiency, clean oil fume removal, and high energy consumption, so as to improve the waste gas treatment rate, save production costs, The effect of high energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below through specific embodiments.

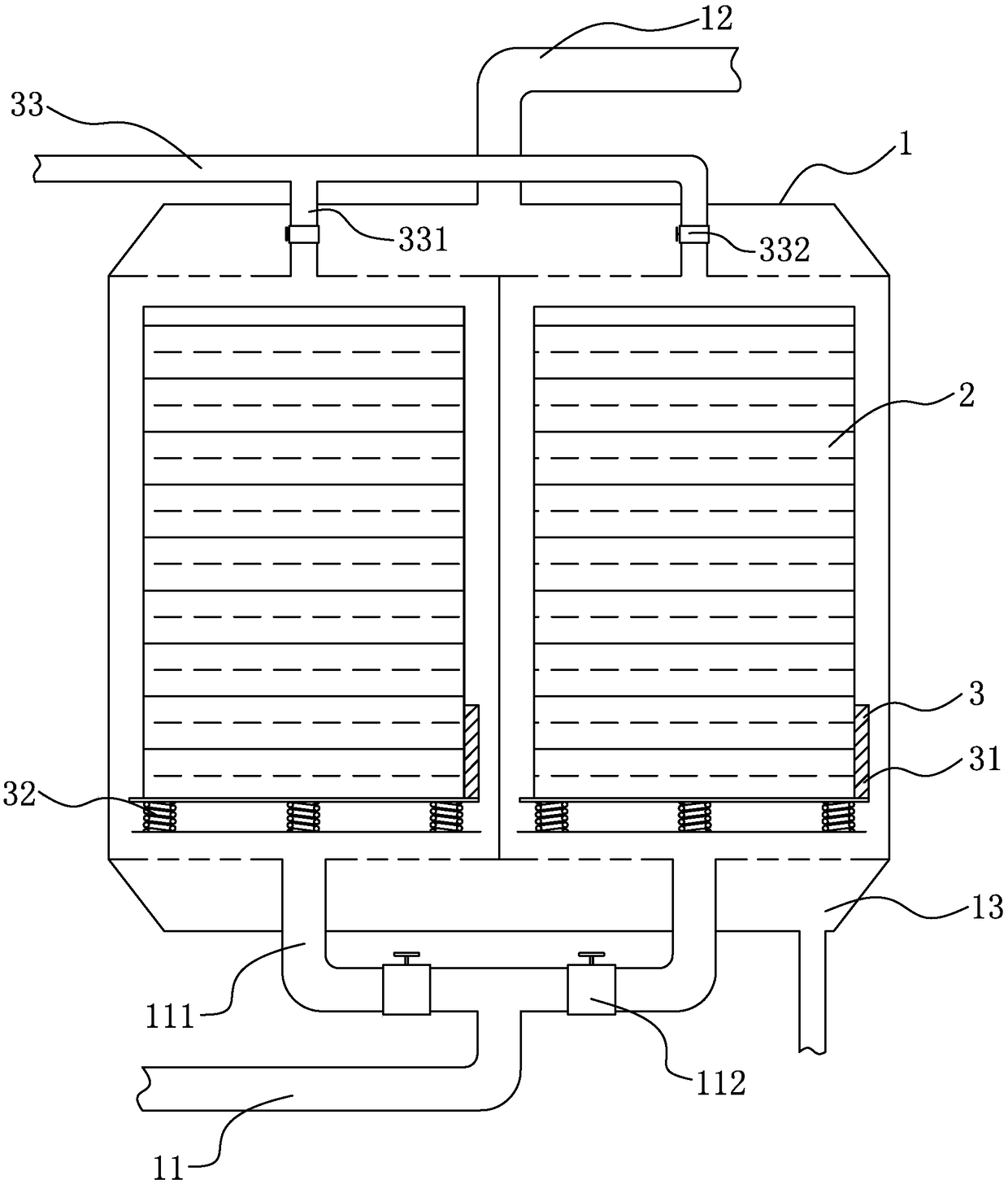

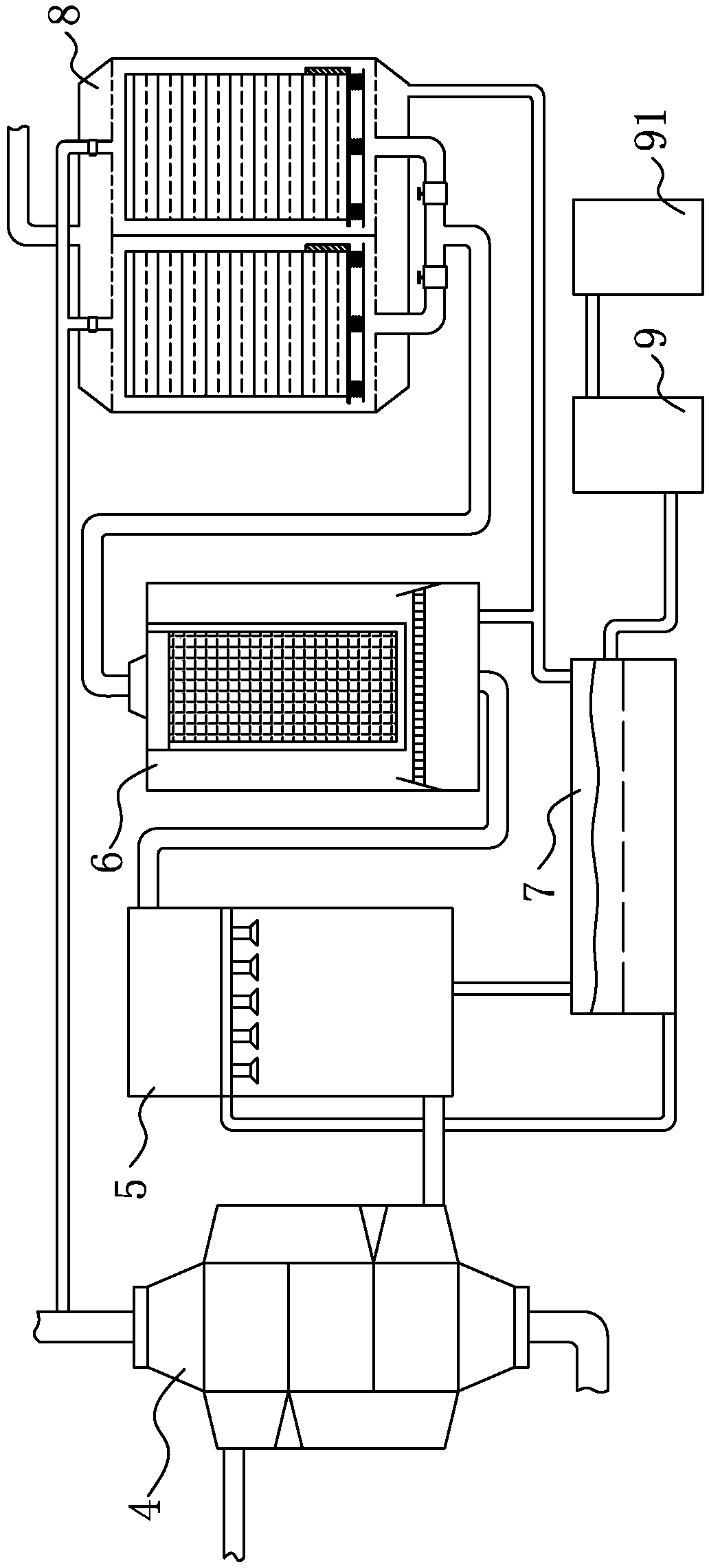

[0025] refer to figure 1 As shown, a self-cleaning electrostatic degreasing device includes a housing 1, at least two sets of electrostatic degreasing modules 2, and a cleaning device 3. The housing 1 is provided with an air inlet 11, an air outlet 12, and an oil collection tank 13. The oil collecting tank 13 is arranged at the bottom of the housing 1, the air inlet 11 of the housing 1 is provided with an intake manifold 111, and each outlet of the intake manifold 111 is provided with an intake valve 112, and each outlet corresponds to a A group of electrostatic oil fume removal modules 2, the electrostatic oil fume removal modules 2 are arranged separately in the housing 1, each group of electrostatic oil fume removal modules 2 is provided with a set of cleaning devices 3, the cleaning device 3 includes an ultrasonic vibrator 31, a spring seat 32, The hot air pipe 33 and the ultrason...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com