Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

65results about How to "Low proportion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thermally stable blends of highly paraffinic distillate fuel component with conventional distillate fuel component

InactiveUS20060049080A1Minimize deposit formationHigh aromatic contentLiquid organic insulatorsHydrocarbon purification/separationProcess engineeringInternal combustion engine

A stable distillate fuel blend useful as a fuel or as a blending component of a fuel that is suitable for use in an internal combustion engine, said fuel blend prepared from at least one highly paraffinic distillate fuel component and at least one highly aromatic petroleum-derived distillate fuel component and a process for preparing same involving the blending of at least two components having antagonistic properties with respect to one another.

Owner:CHEVROU USA INC

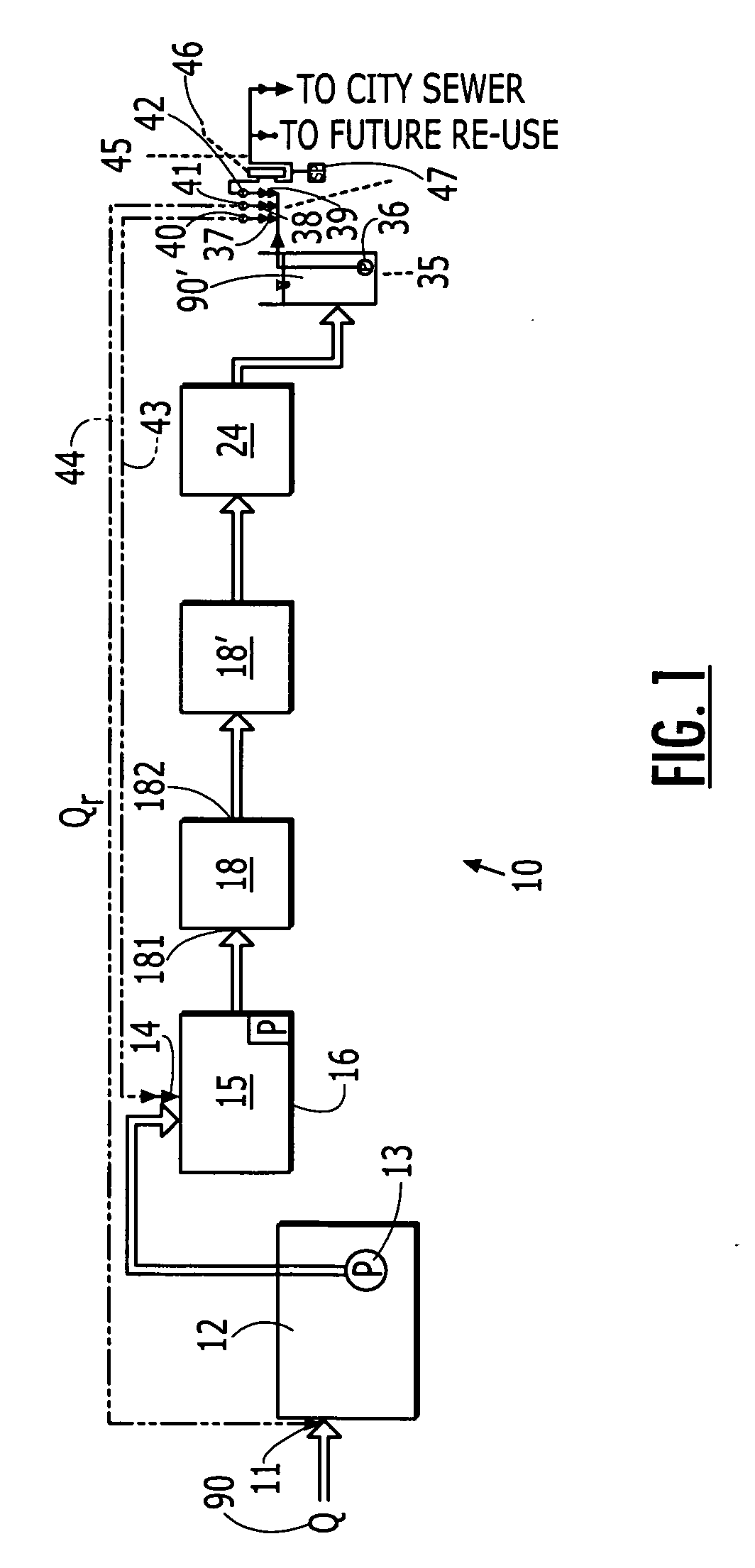

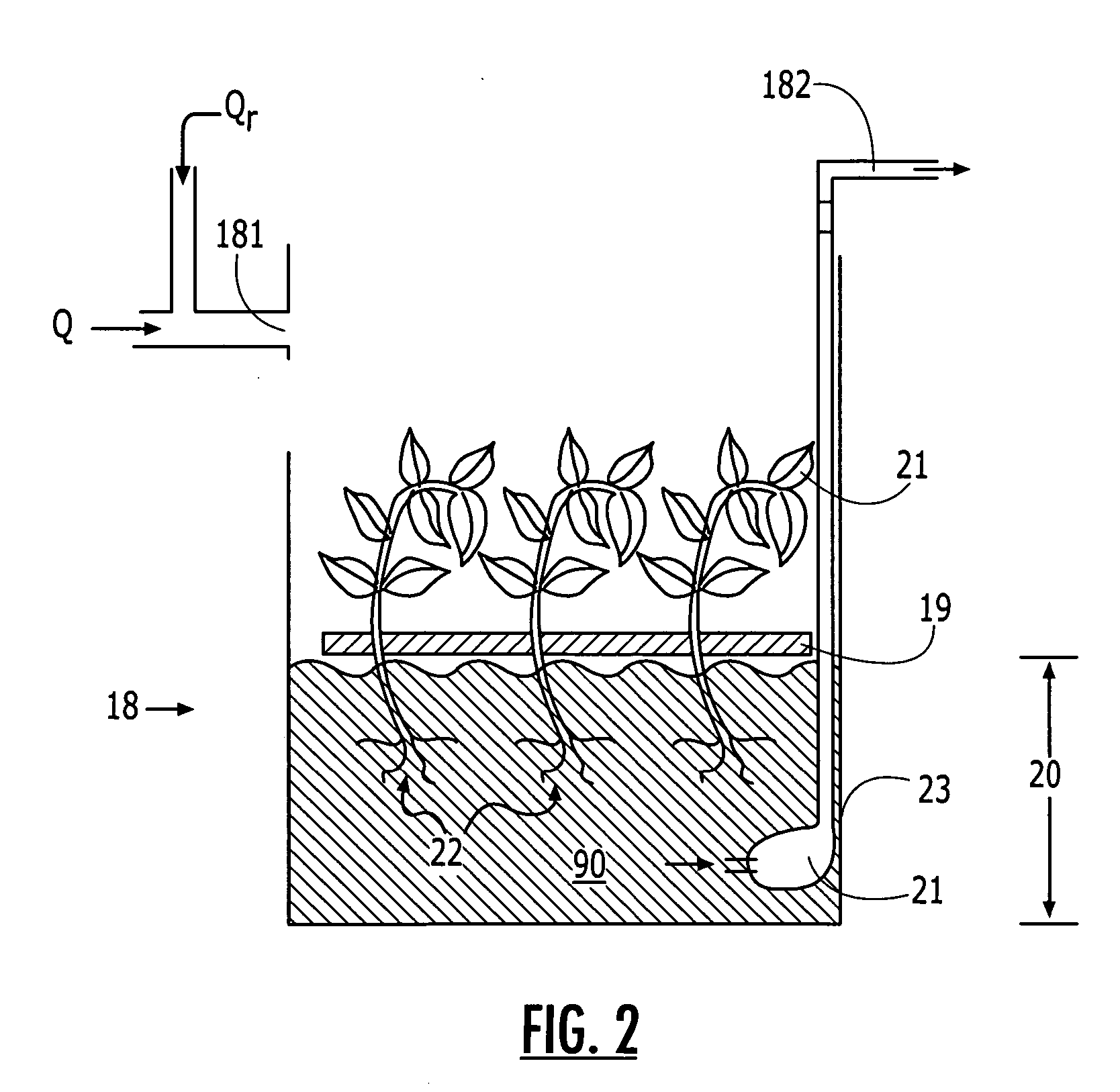

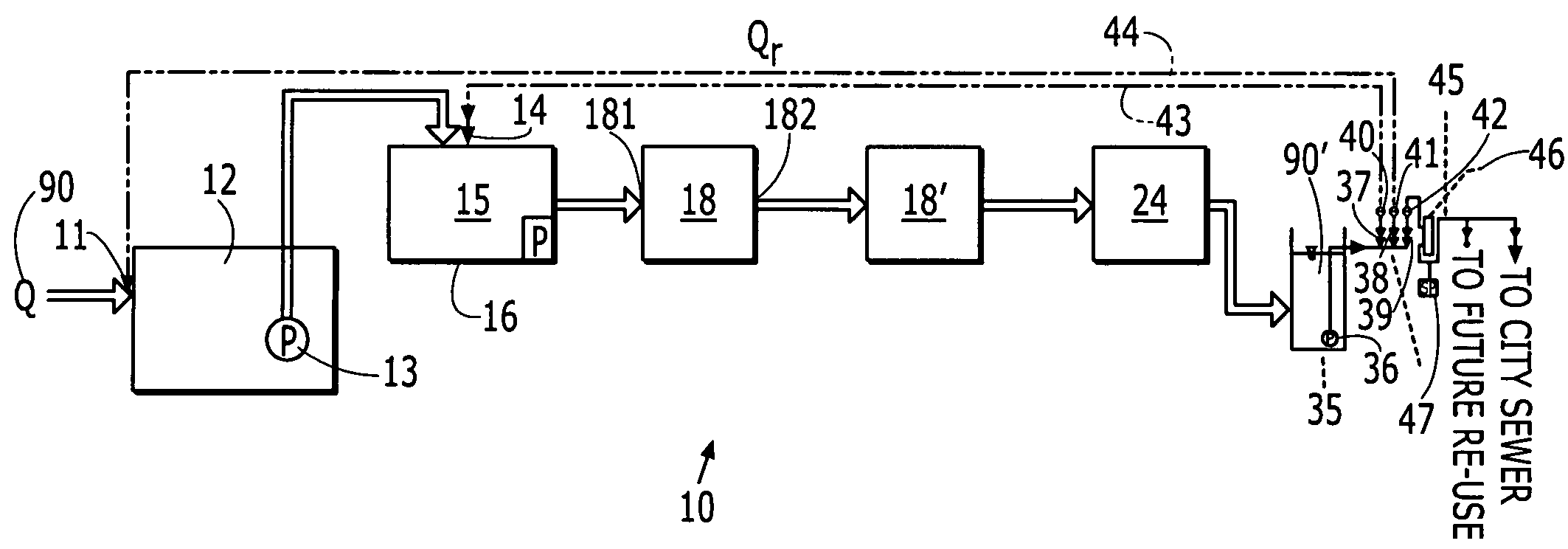

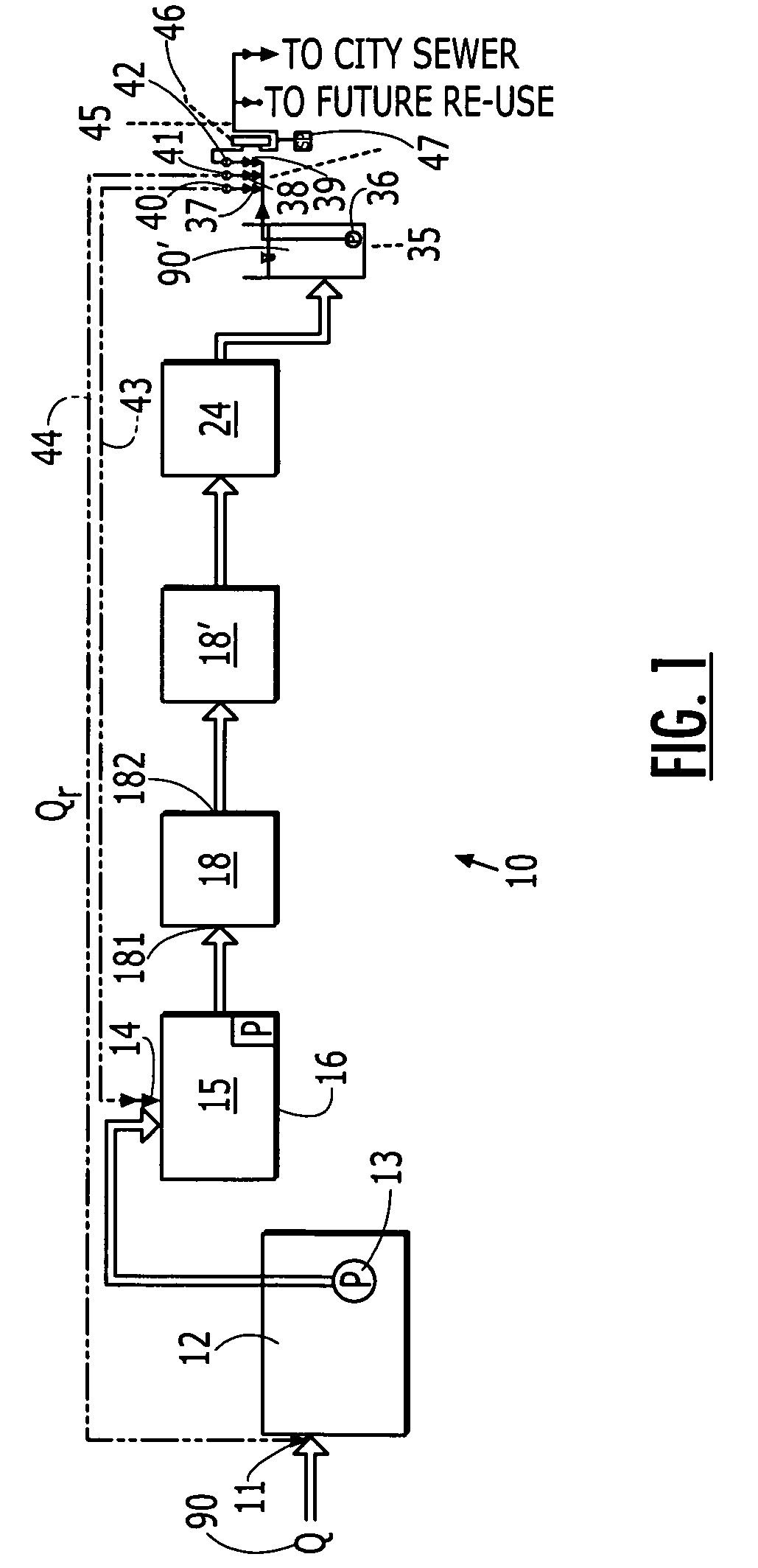

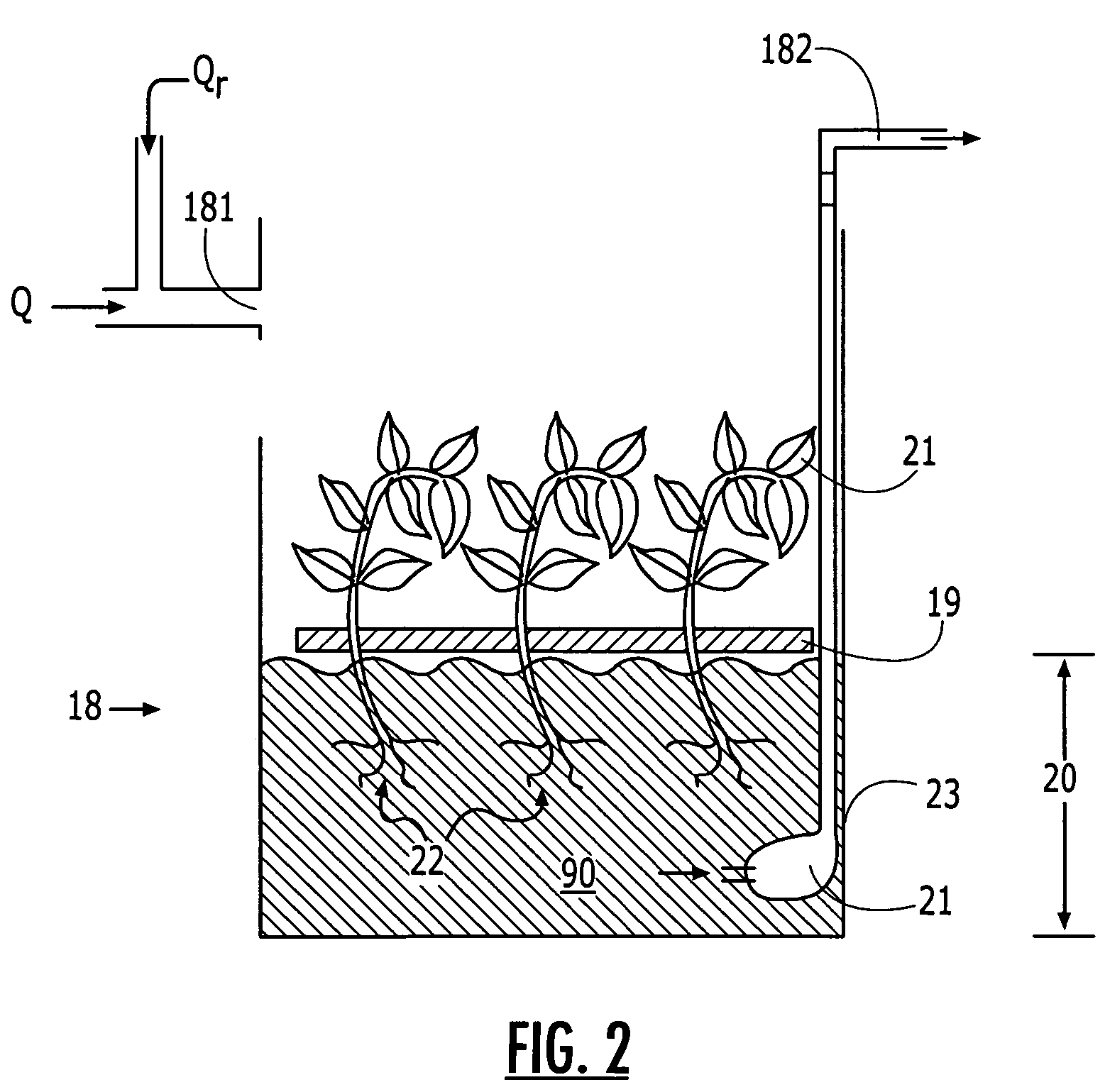

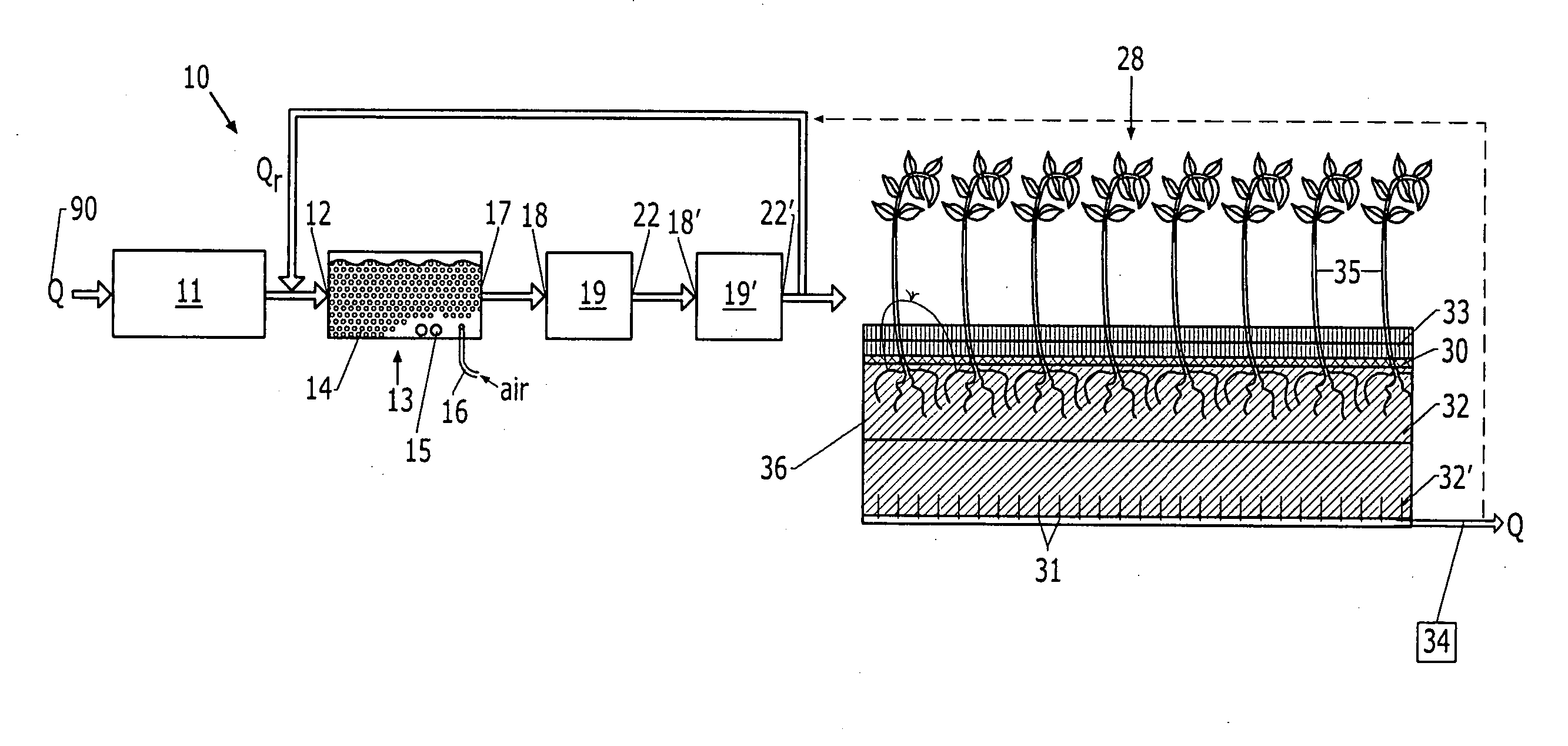

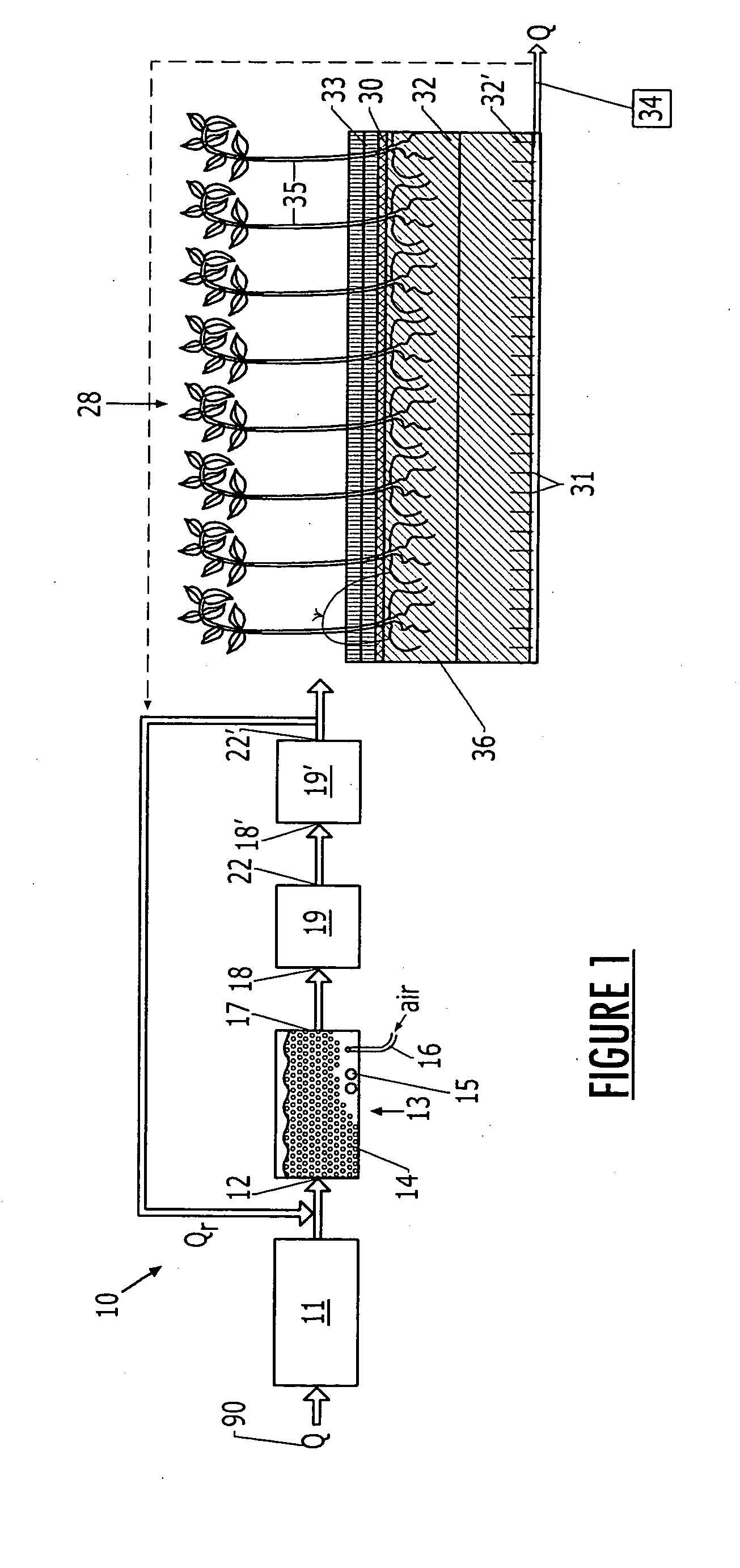

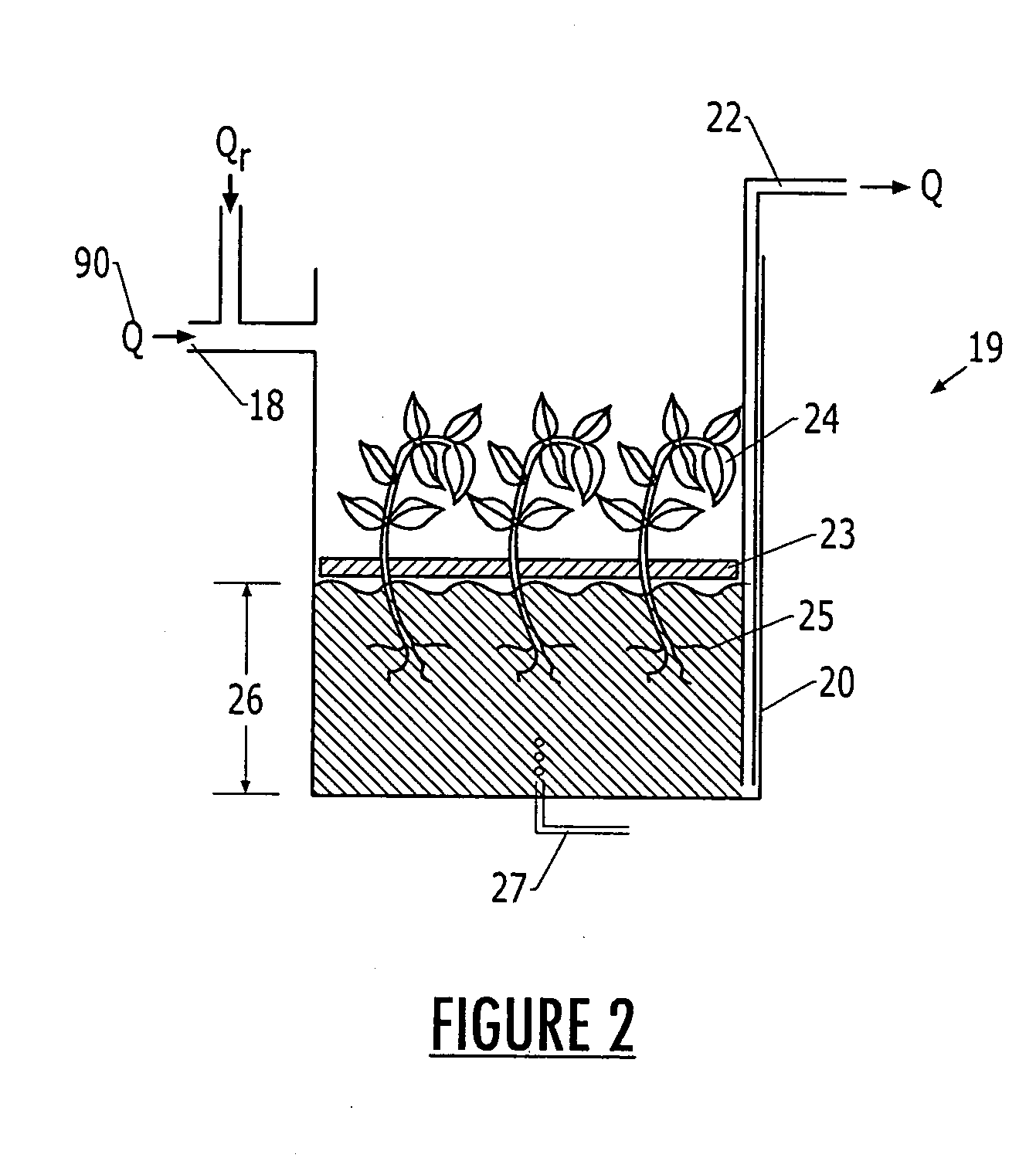

Integrated hydroponic and wetland wastewater treatment systems and associated methods

ActiveUS20060124540A1Undesirable characteristicLess land intensiveWater cleaningTreatment using aerobic processesWater treatment systemAnaerobic reactor

The wastewater treatment systems have a plurality of treatment modules between the inlet and the outlet, each for treating water with a selected process. Influent is directed to a covered anaerobic reactor, and then to an attached growth pretreatment filter that is at least intermittently exposed to atmospheric oxygen. Following the filter is a hydroponic reactor followed by a vertical-flow wetland. A second embodiment includes, following the filter, a tidal vertical-flow wetland and a pump for recycling water exiting the wetland upstream of the filter.

Owner:DHARMA IP

Process for producing middle distillates by hydrocracking of feedstocks obtained by the fischer-tropsch process in the presence of a catalyst comprising an IZM-2 solid

ActiveUS20110180455A1Shorten the timePromote formationTreatment with plural serial cracking stages onlyMolecular sieve catalystsAlkaneChemical composition

The invention relates to a process for producing middle distillates from a paraffinic feedstock produced by Fischer-Tropsch synthesis, implementing a hydrocracking / hydroisomerisation catalyst comprising at least one hydro-dehydrogenating metal selected from the group formed by the metals from group VIB and from group VIII of the periodic table and a substrate comprising at least one crystallised IZM-2 solid having a chemical composition, expressed on an anhydrous base, in terms of oxide moles, by the following general formula: XO2:aY2O3:bM2 / nO, wherein X represents at least one tetravalent element, Y represents at least one trivalent element and M is at least one alkali metal and / or an alkaline earth metal of valency n, a and b representing respectively the number of moles of Y2O3 and M2 / nO and a is between 0 and 0.5 and b is between 0 and 1.

Owner:ENI SPA +1

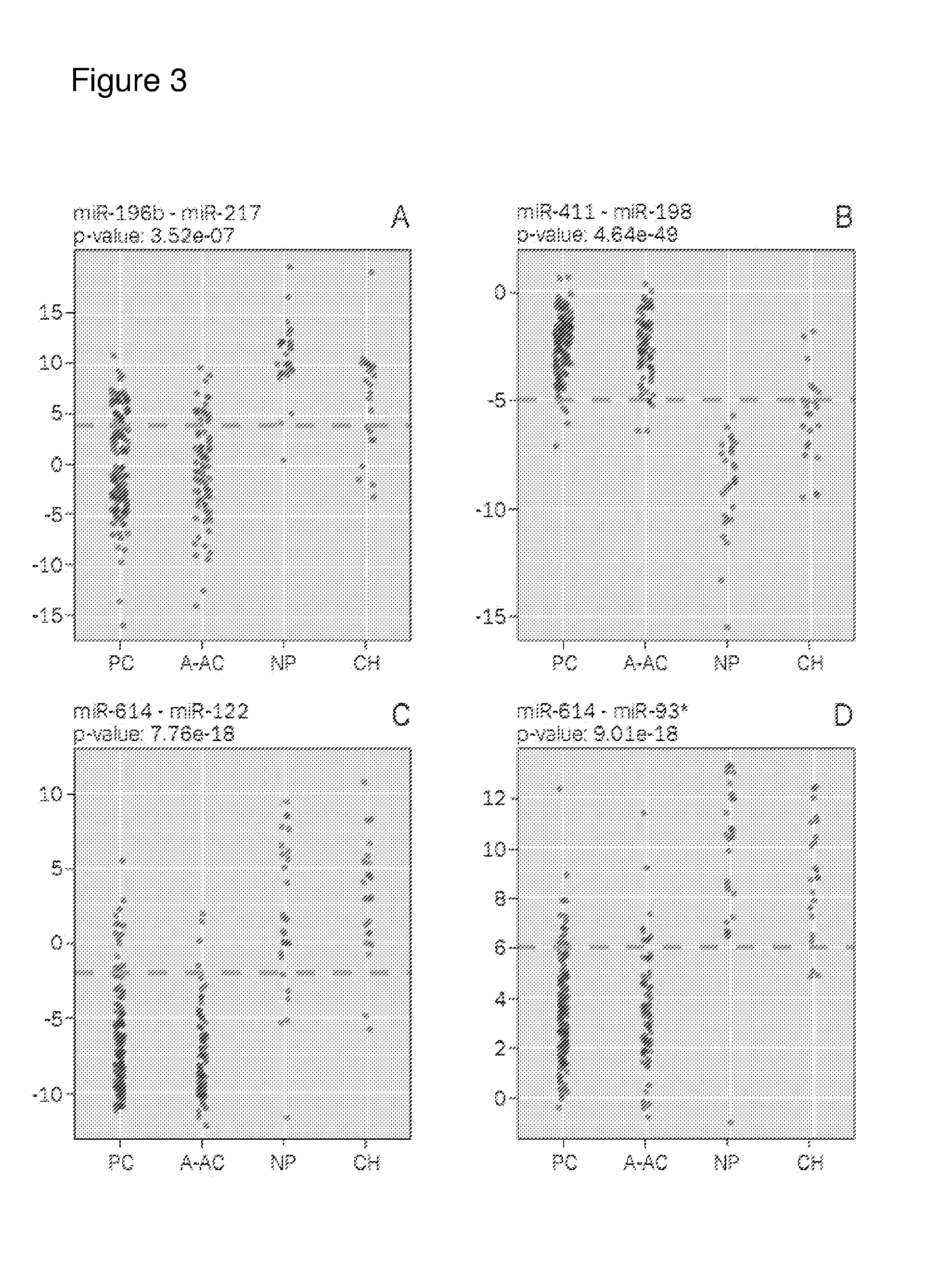

Microrna for diagnosis of pancreatic cancer

InactiveUS20130310276A1Promote resultsEarly diagnosisSugar derivativesNucleotide librariesGeneticsMicroRNA

Owner:RUPRECHT KARLS UNIV OF HEIDELBERG +1

Method for the preparation of a multilayer coating and aqueous coating material suitable for this

InactiveUS6329020B1Improve waterproof performanceImprove the immunityPretreated surfacesPolyurea/polyurethane coatingsPolyesterPolymer science

Described are a method for the preparation of a multilayer coating and a coating material from an aqueous dispersion of a polymer with a particle diameter of the polymeric phase of 10 nm to 500 nm. The polymer has a number average molecular weight of 10,000 to 500,000 and an acid number of 12 to 40. The dispersion was obtained by polymerization without addition of emulsifier and in the presence of water insoluble initiators of a) 0.65 to 9 parts by weight of carboxyl group-free unsaturated monomers which, aside from the unsaturated bond, do not contain any other groups, which are reactive under the polymerization and curing conditions, together with 0 to 65% by weight, based on the total monomers of copolymerizable, hydroxyl group-containing monomers and / or 0 to 7% by weight, based on the total monomers, of ethylenically unsaturated monomers, in b) 1 part by weight, based on the resin portion, of an aqueous dispersion of a urea group-containing polyurethane, which was produced by chain extension of an NCO group-containing prepolymer based on polyester with an NCO group content of 1.0 to 10% with at least two urethane groups per molecule, with carboxyl groups corresponding to an acid number of 20 to 50 and a number average molecular weight of 600 to 6,000, with a polyamine with primary and / or secondary amino groups and / or with hydrazine in an aqueous medium without addition of emulsifier.

Owner:HERBERTS GMBH

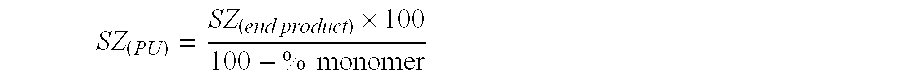

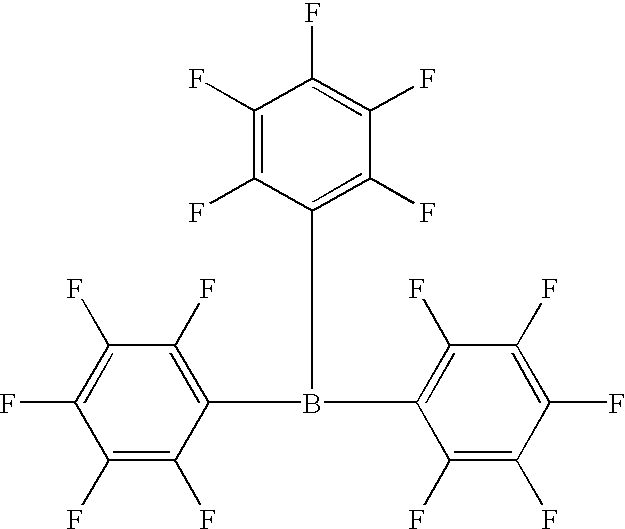

Process for alkoxylation with a boron-containing catalyst

Disclosed is a process for making alkoxylates of organic compounds. The process requires a) providing an active hydrogen organic compound having 1 to 22 carbon atoms, and b) alkoxylating the organic compound with an alkylene oxide in the presence of a catalytically effective amount of a catalyst compound corresponding to either formula (I) or formula (II): B(.phi.).sub.3 (I) H.sup.+B(.phi.).sub.4.sup.- (II) wherein B is a boron atom and H is a hydrogen atom; .phi. is a phenyl moiety having substituents selected from the group consisting of 1 to 5 fluorine atoms, 1 to 5 CF.sub.3 moieties, 1 to 5 OCF.sub.3 or SCF.sub.3 moieties or OR; wherein C is a carbon atom, O is an oxygen atom, S is a sulfur atom and F is a fluorine atom; wherein R is a hydrogen atom or an alkyl or aryl group having from 1 to 22 carbon atoms. The process affords a product of very narrow molecular weight distribution with a low degree of both residual active hydrogen organic starting material and undesirable by-products.

Owner:RHODIA OPERATIONS SAS

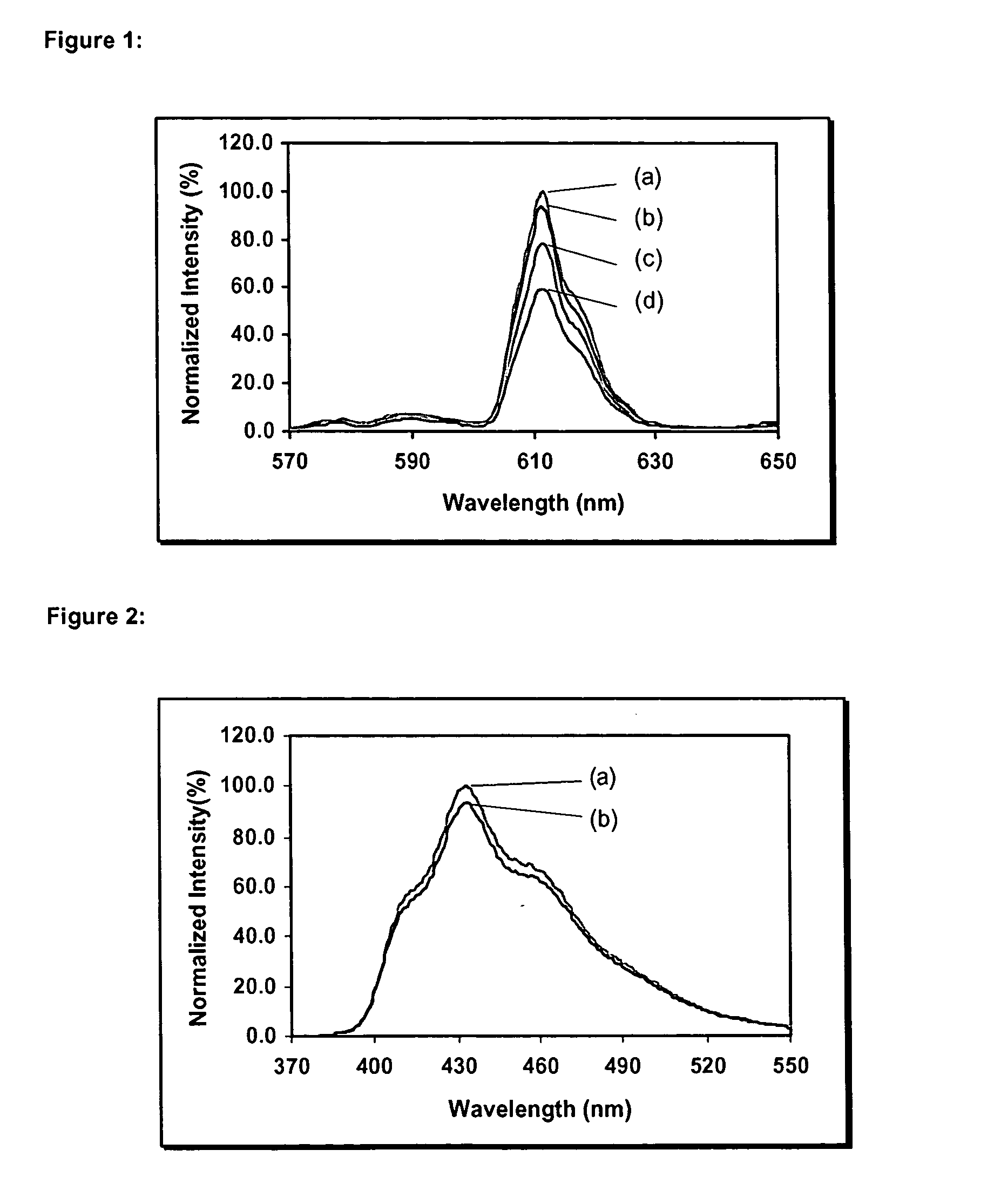

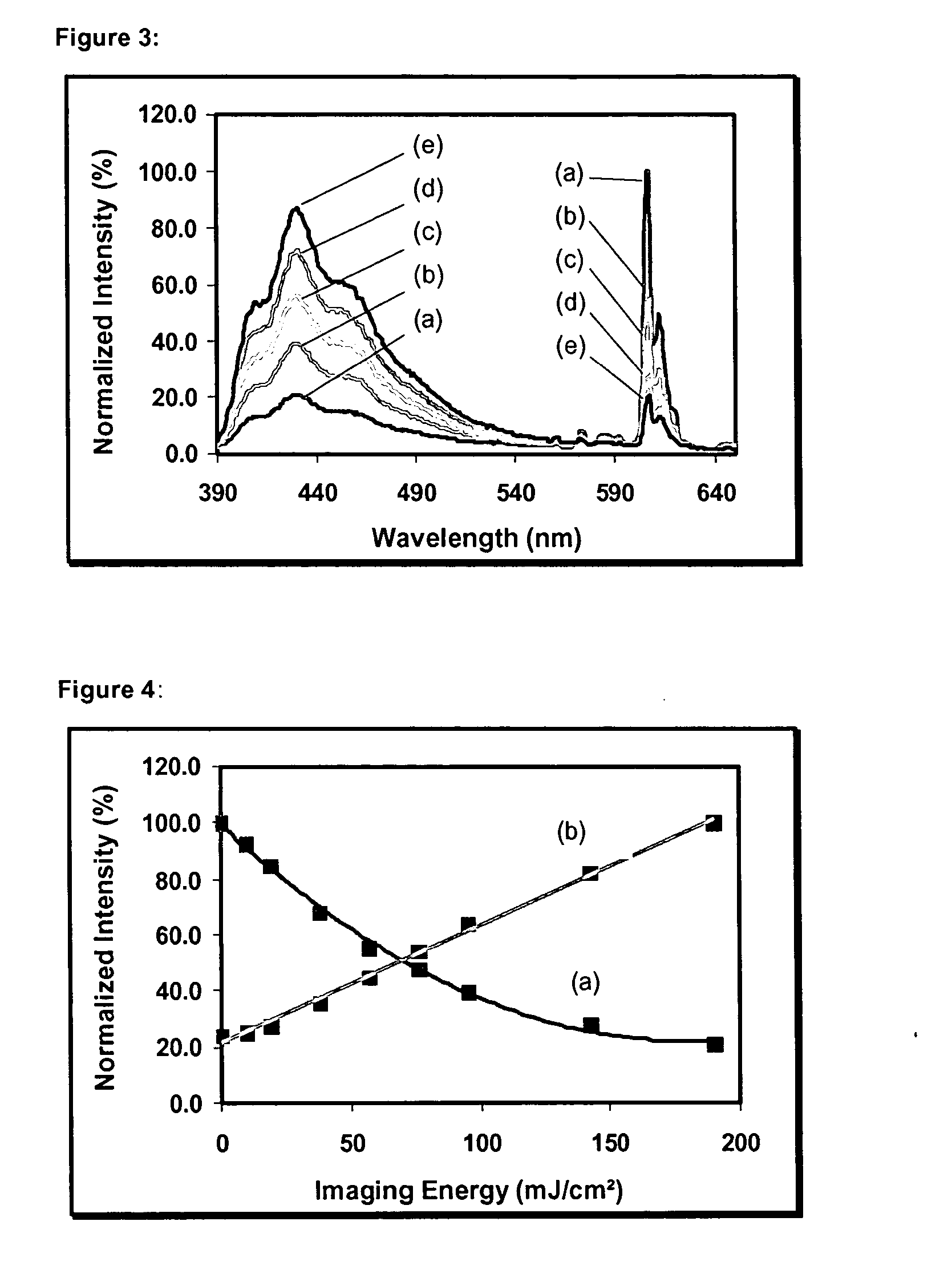

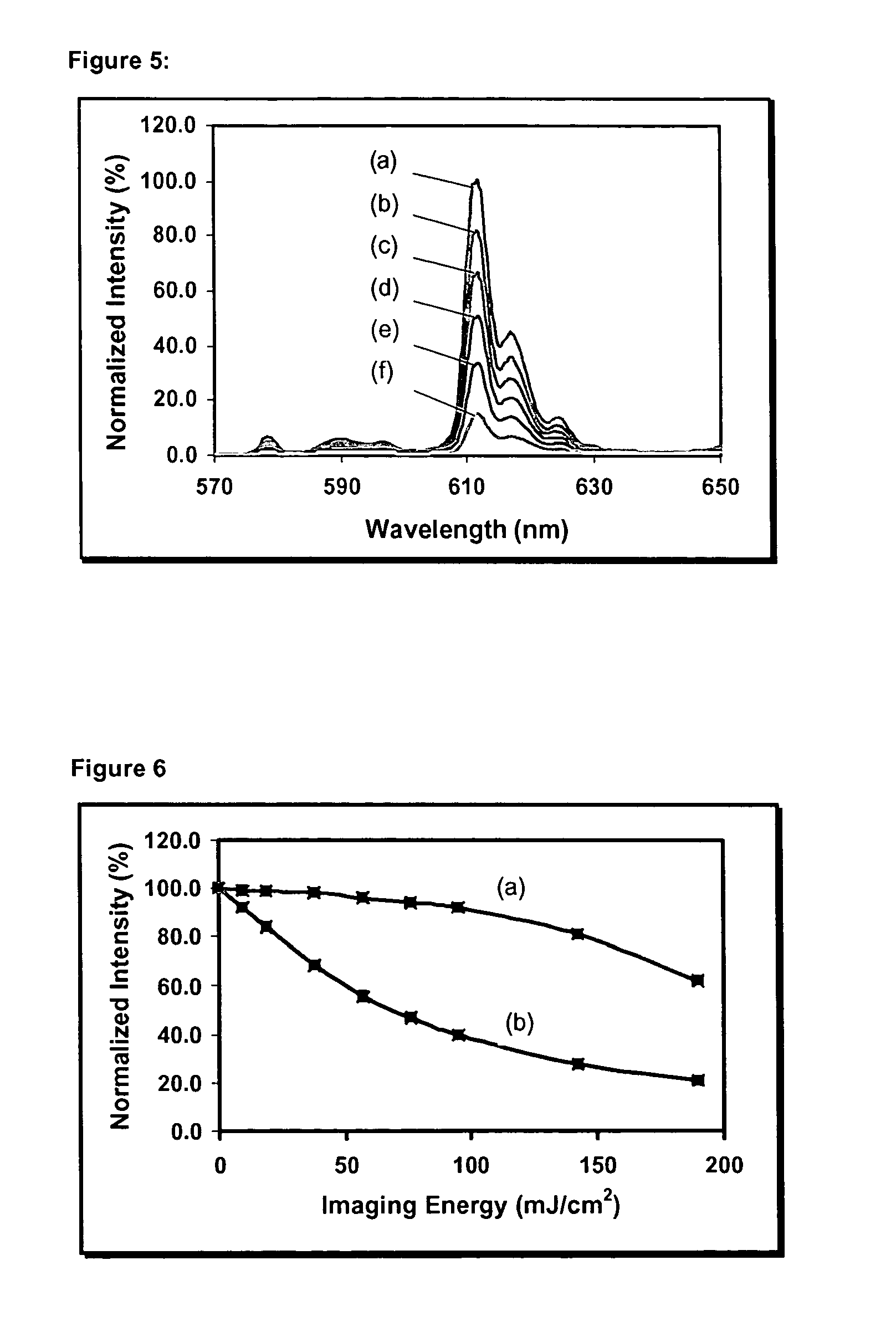

Method for recording information in luminescent compositions and uses thereof in articles of manufacture

InactiveUS20050103424A1Effective imagingLow proportionLamination ancillary operationsElectroluminescent light sourcesLength wavePhoton source

Described herein are a method for recording luminescent compositions, comprising a) providing a luminescent composition which comprises at least a first and second luminescent compound, wherein the first luminescent compound is a donor compound having a peak luminescent emission spectrum at a given wavelength, wherein the second luminescent compound is an acceptor compound having a peak absorption spectrum at a longer wavelength than the given wavelength, and wherein the emission spectrum of the donor compound at least partially overlaps the absorption spectrum of the acceptor compound; b) combining the composition with a substrate, so that at least a portion of the composition is available for exposure to a photon source; and c) embedding information at predetermined sites in the combined composition by localized exposure to a photon source, the embedding resulting in an information pattern when exposed to a luminescence deciphering device, and uses of said information pattern.

Owner:AMERICAN DYE SOURCE

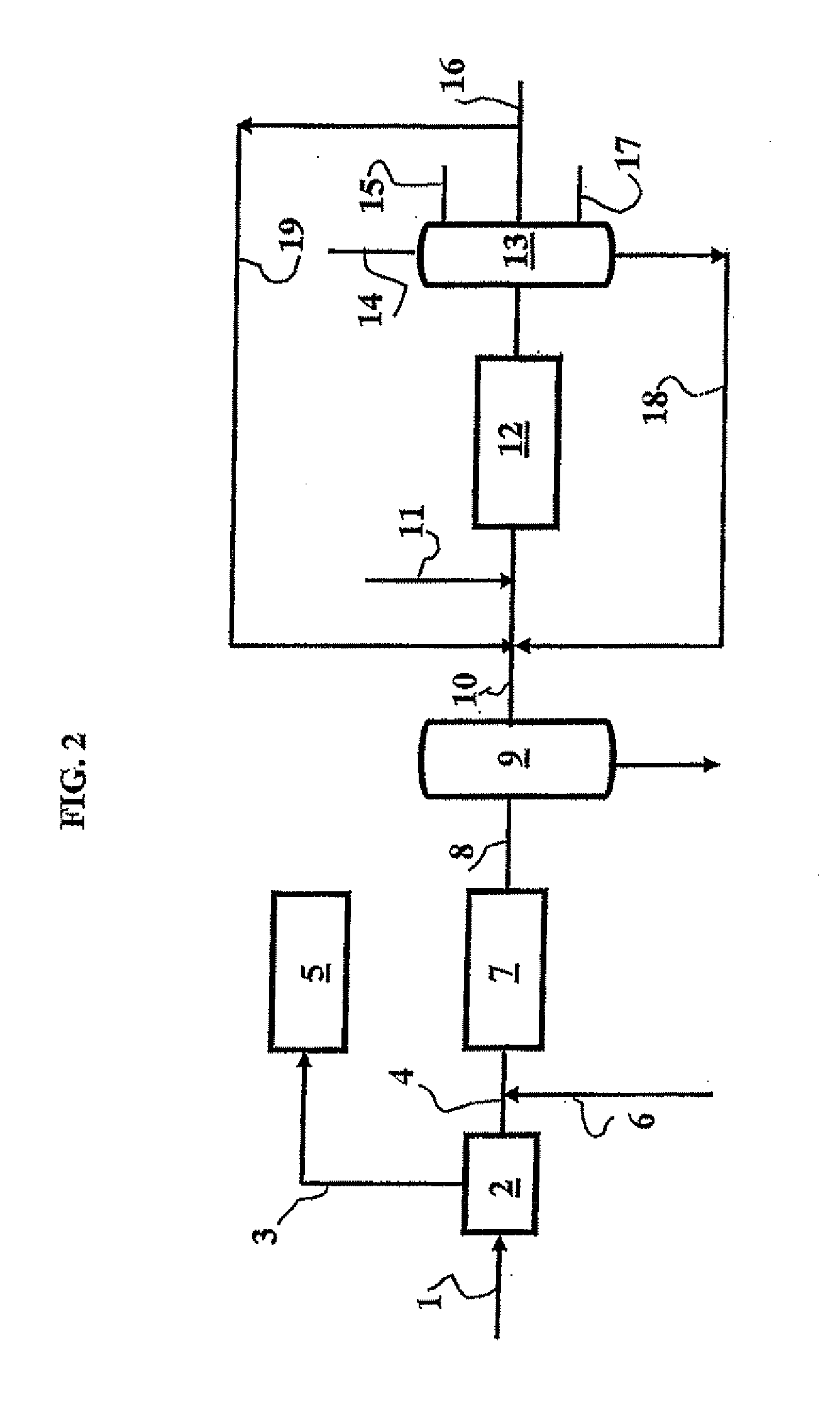

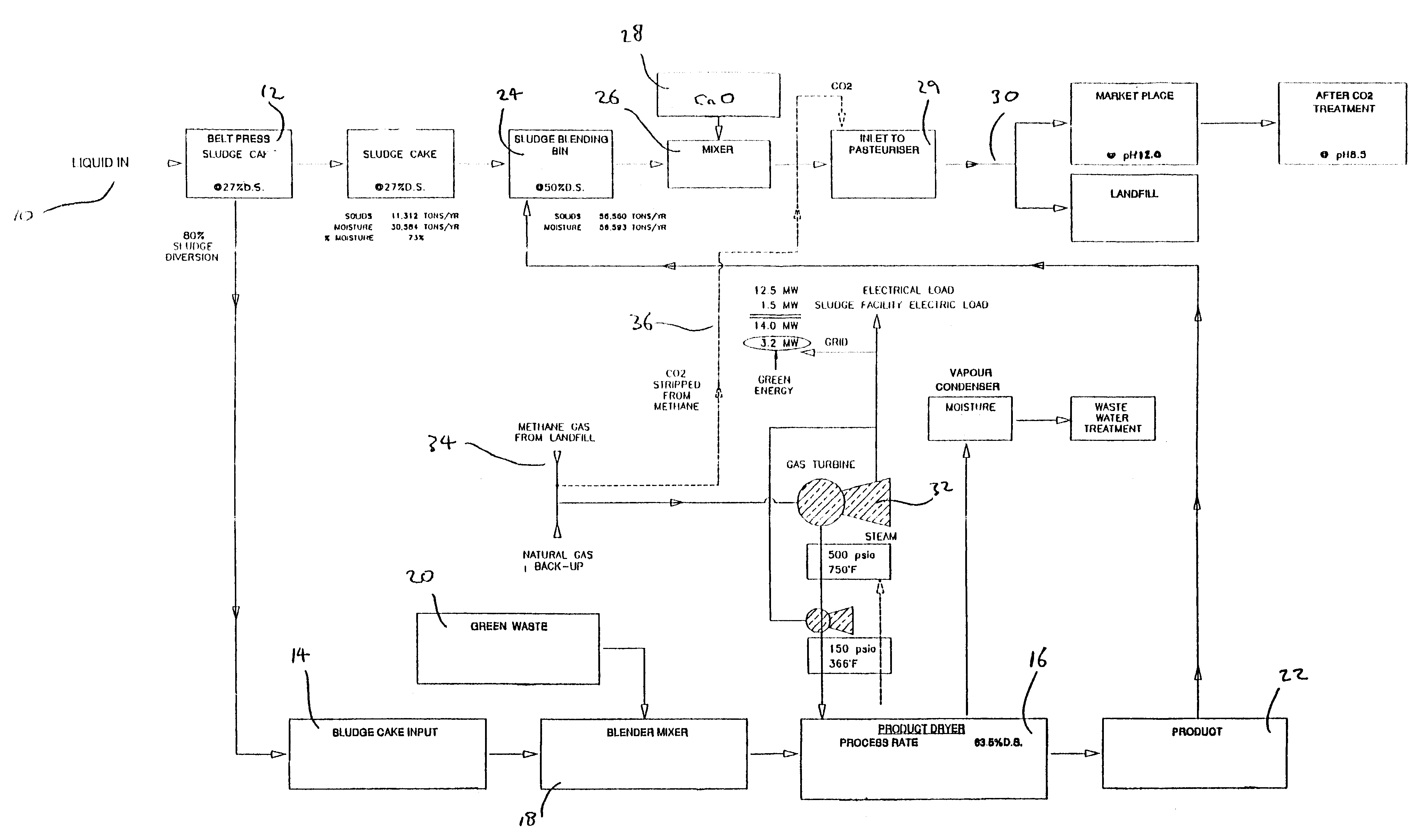

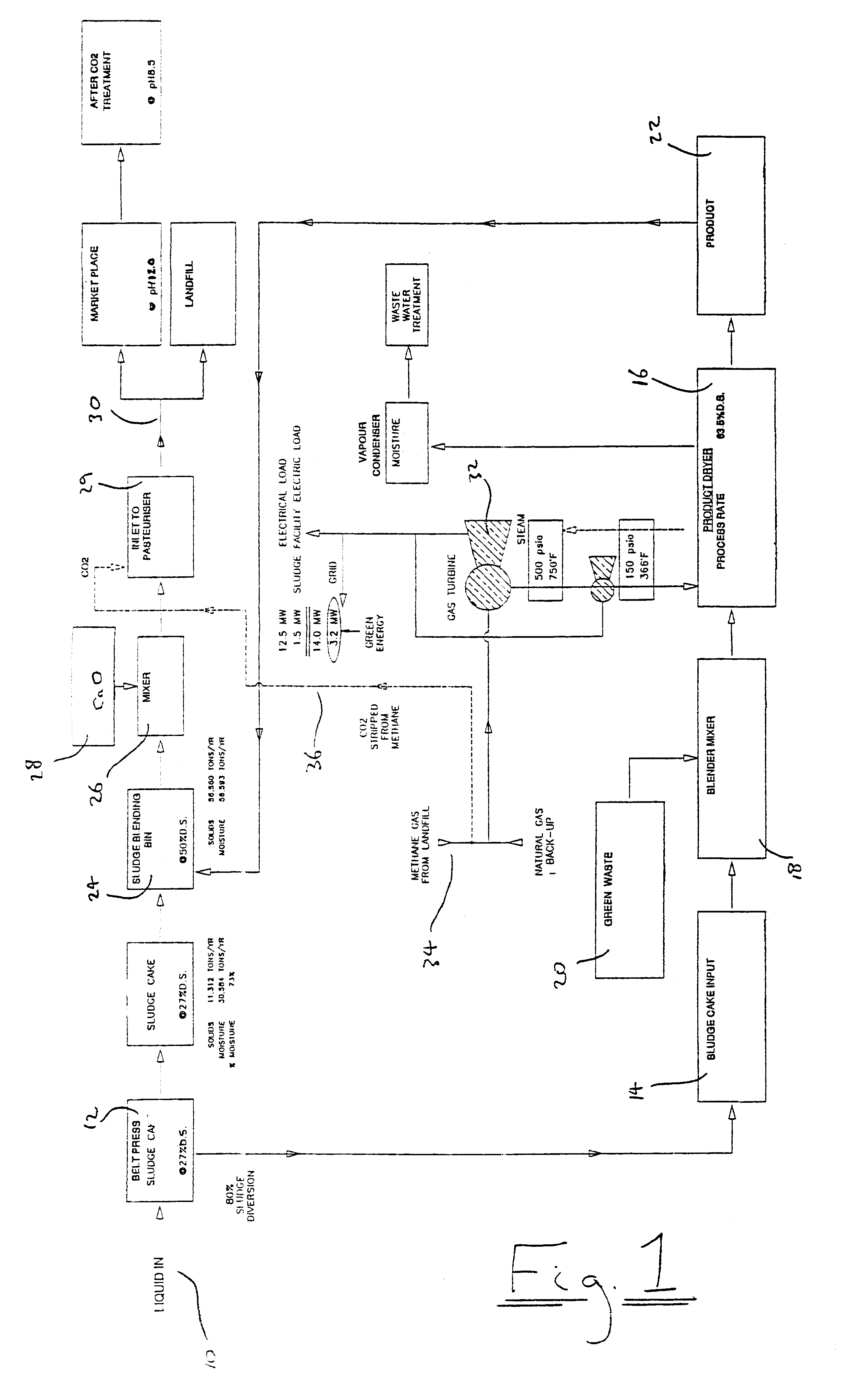

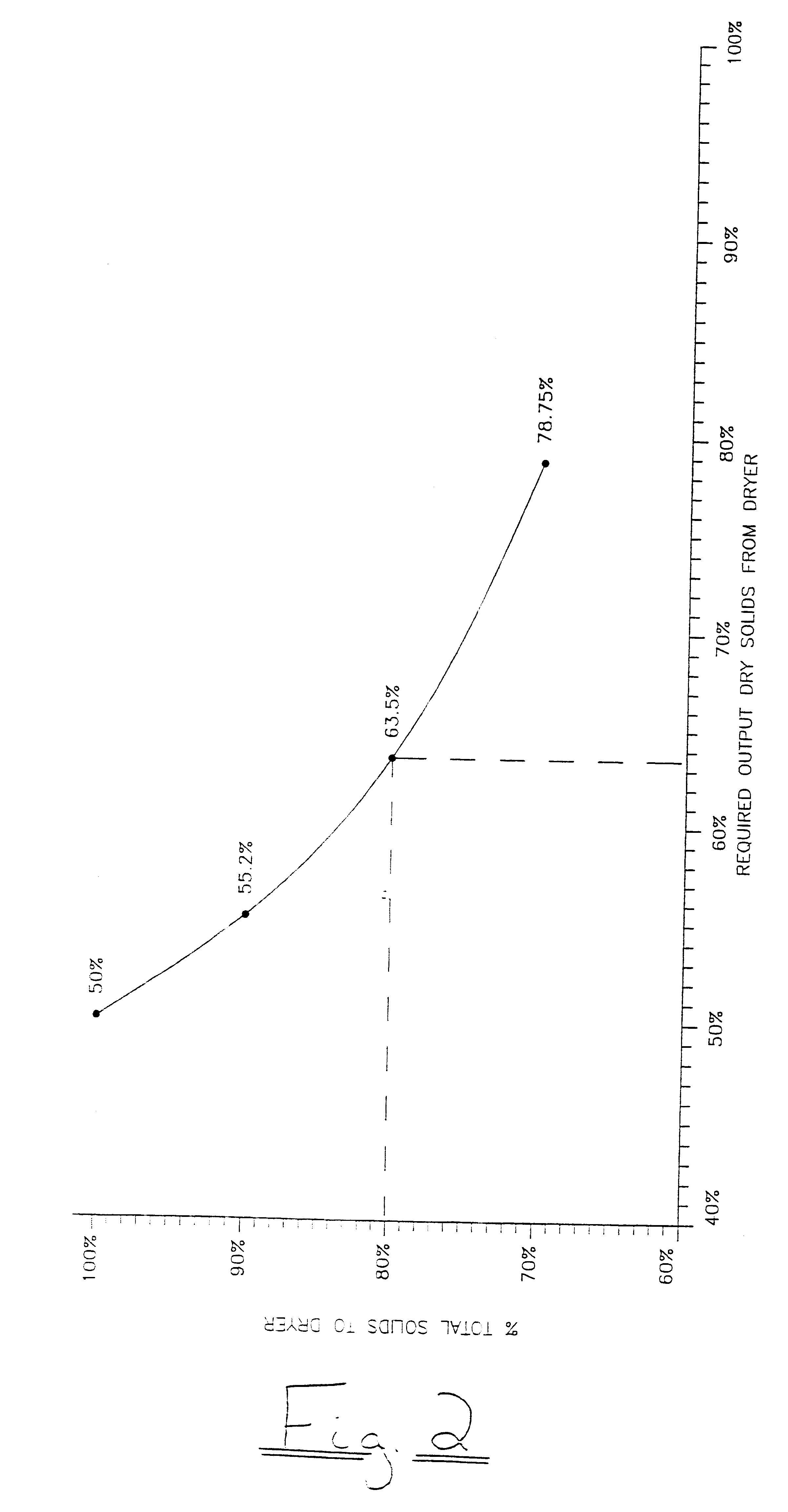

Processes and apparatus for treating sewage or like sludge

InactiveUS6387281B2Readily produced economicallyImprove long-term stabilitySludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningFistSludge

There is disclosed a process for treating sewage or similar organic sludge to produce a pasteurized and dried product comprising the steps of:dividing the sludge into at least one first portion and at least one second portion;drying the first portion so that the first portion has a higher dry solids content than that of the second portion;mixing the fist portion and the second portion to produce a mixture having a dry solids content which is intermediate between that of the first and second portions;adding an alkaline admixture to the mixture in order to pasteurize the mixture and thereby produce the product without employing subsequent drying by aeration.

Owner:BIOPHAST TECH

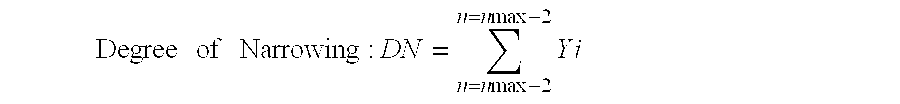

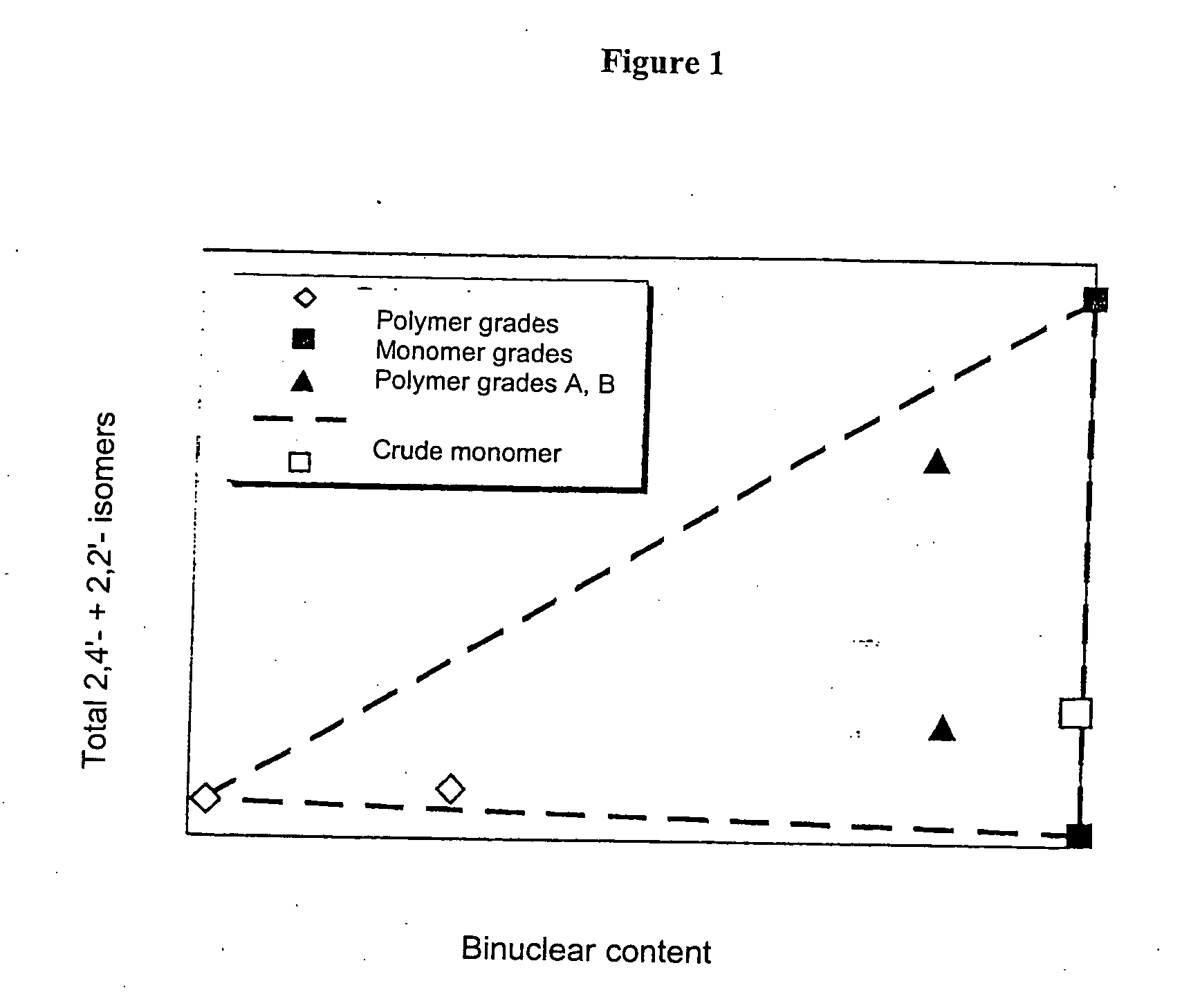

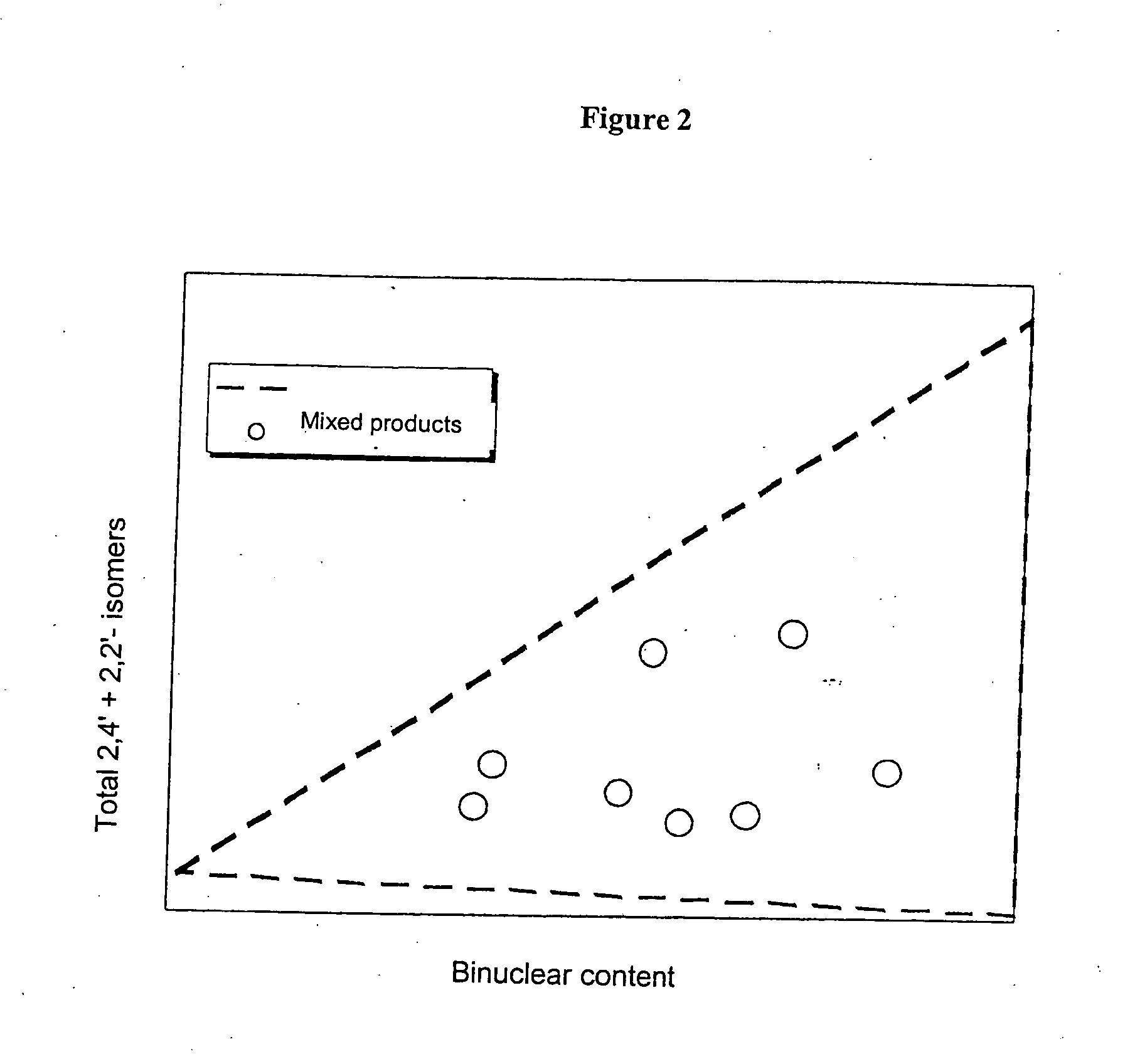

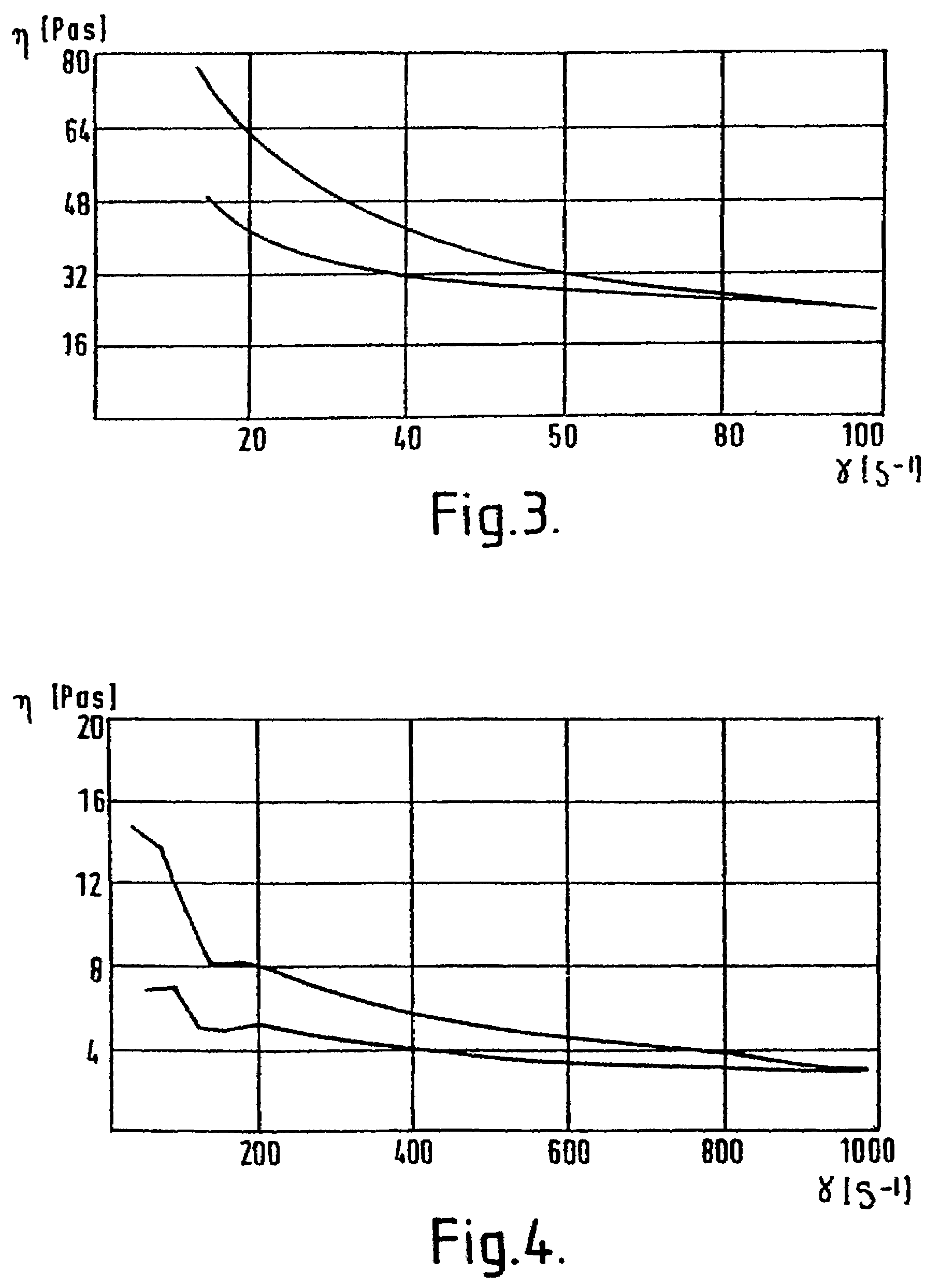

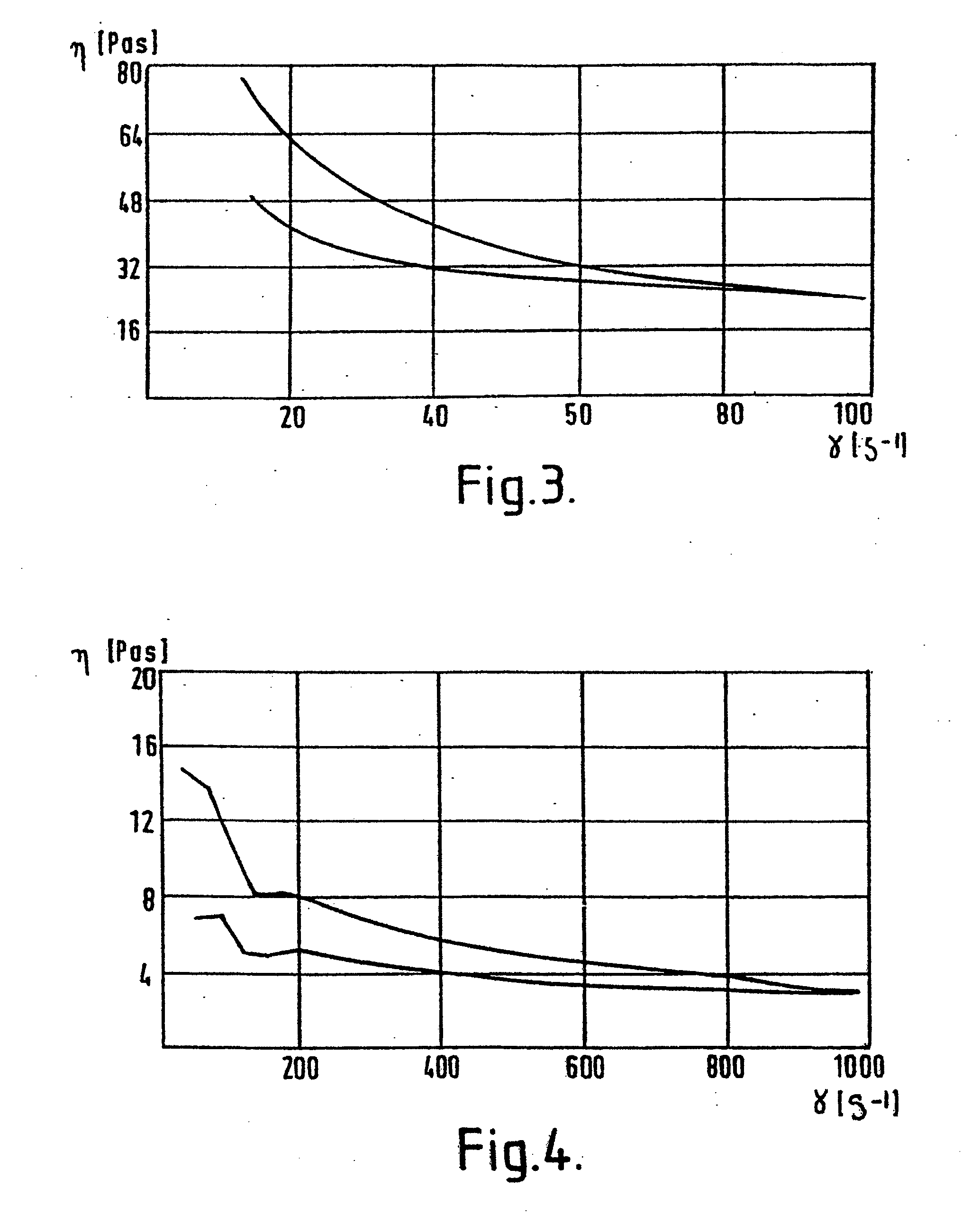

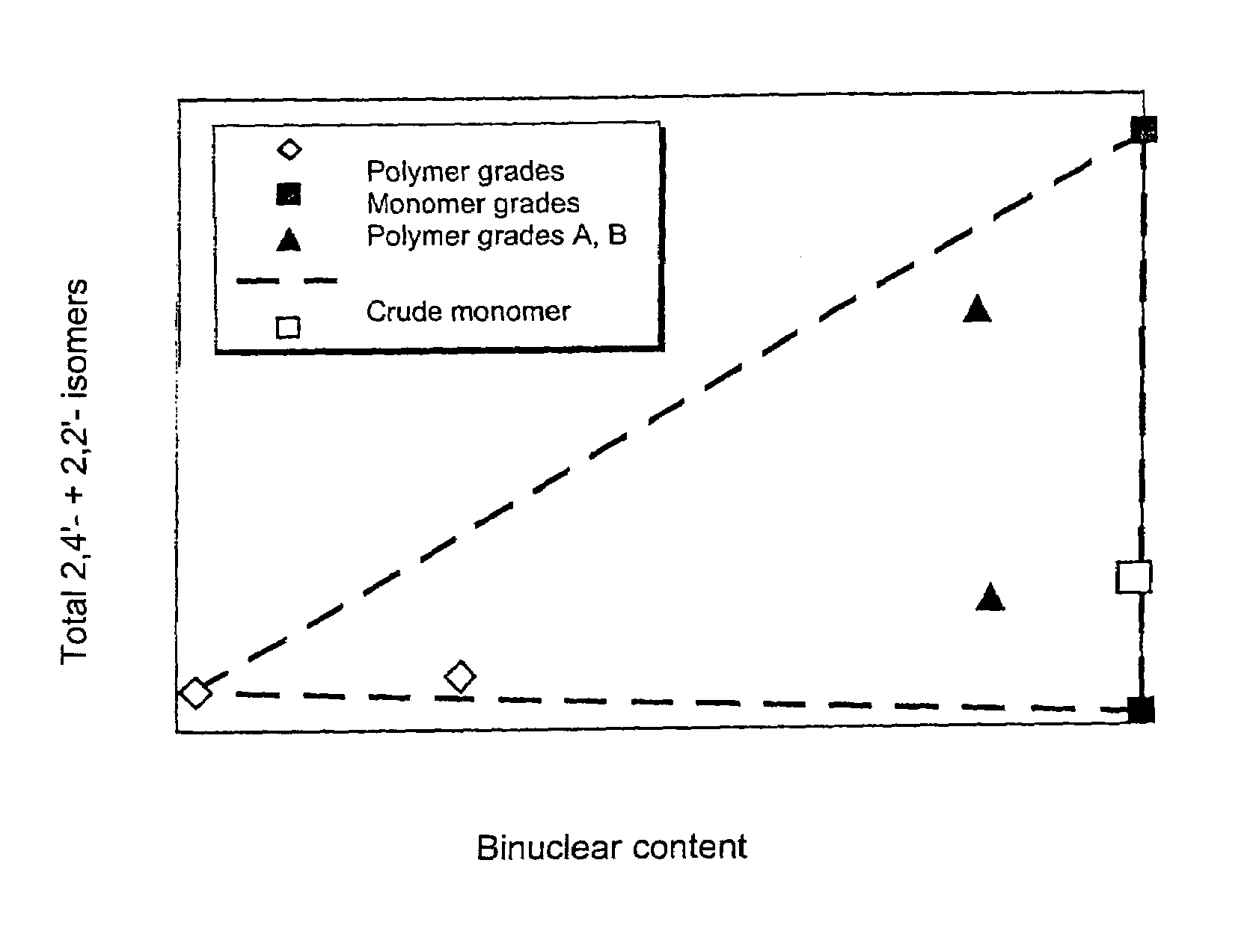

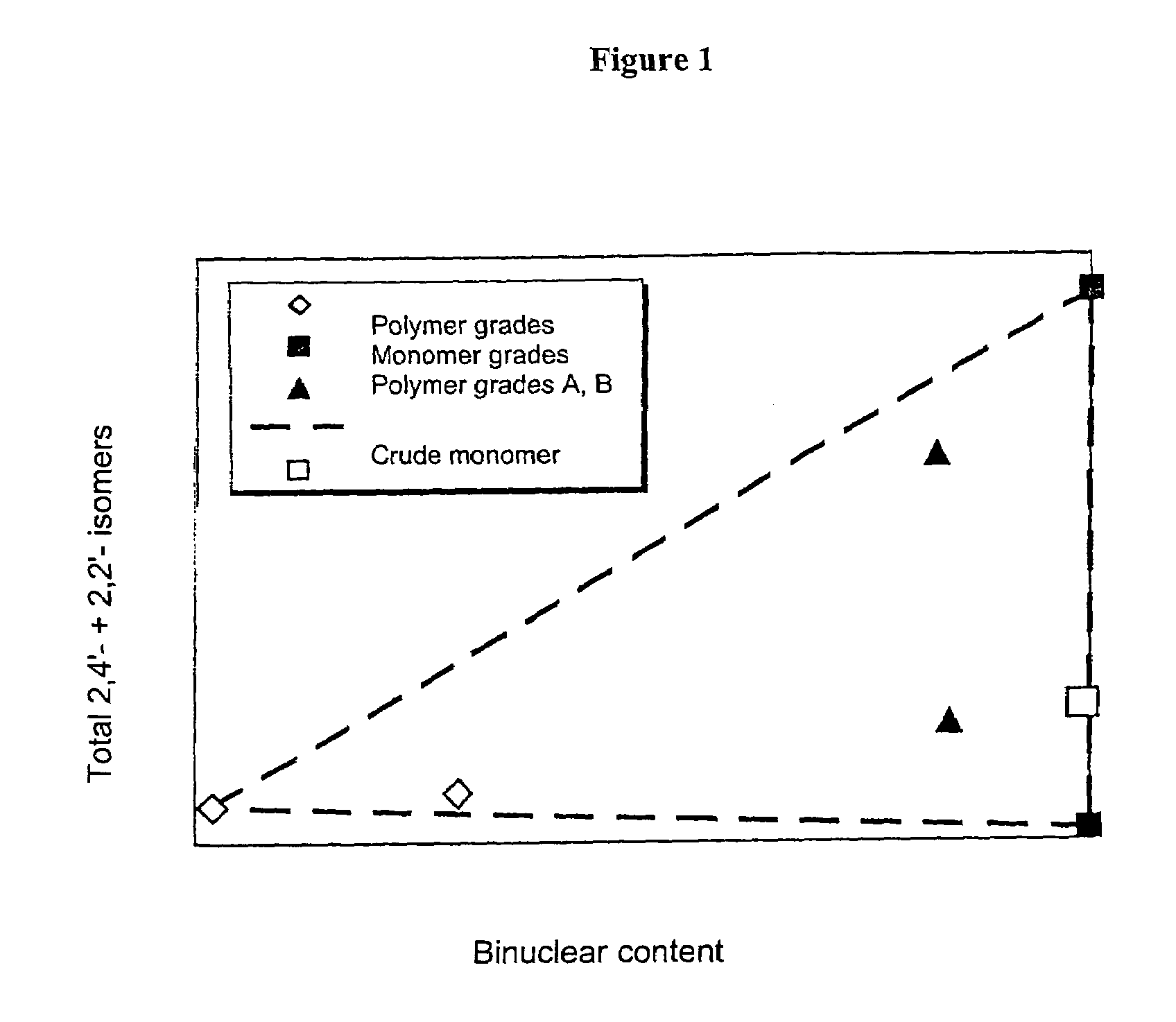

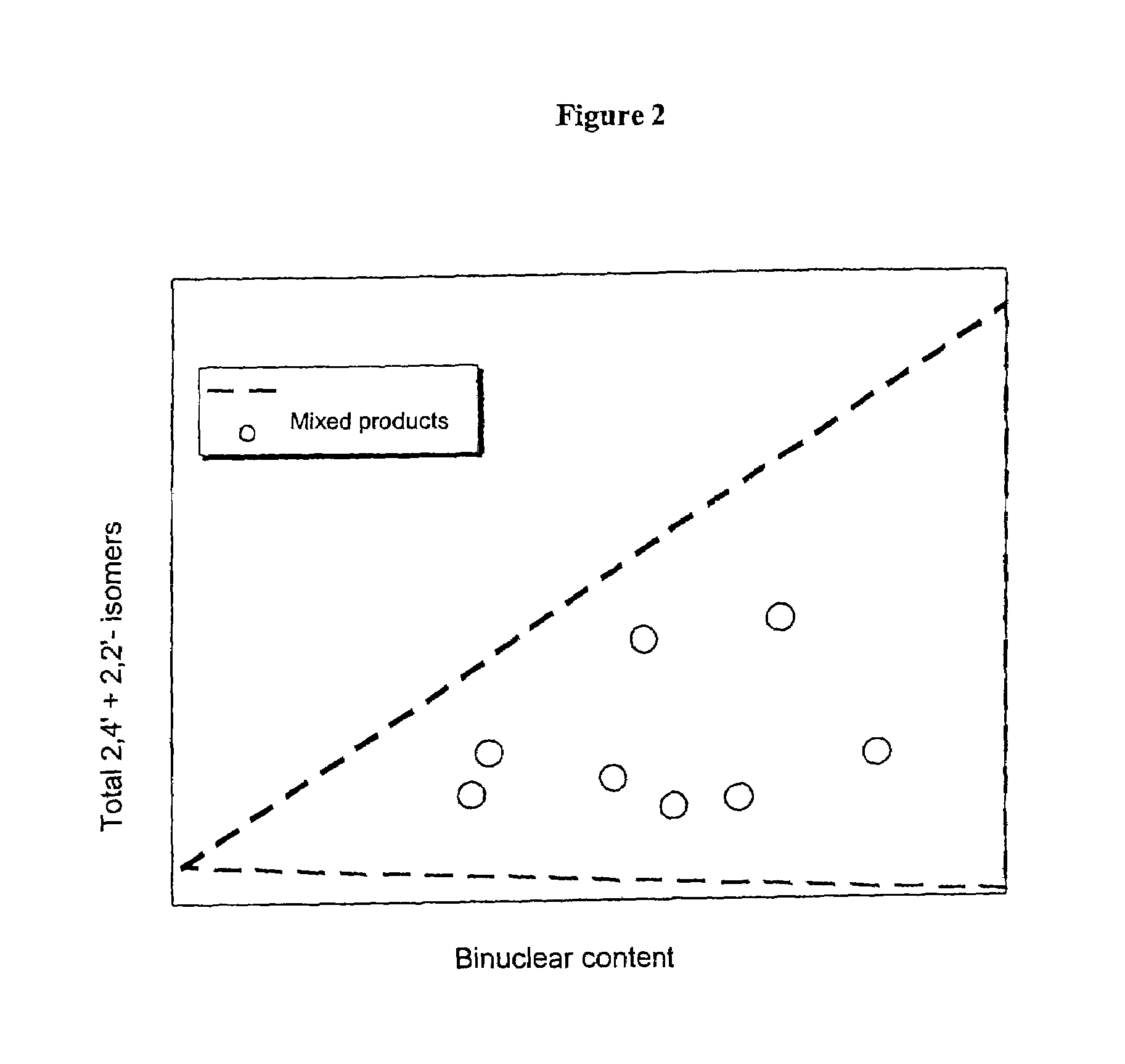

Production of mixtures of diisocyanates and polyisocyanates from the diphenylmethane series with high contents of 4,4'-methylenediphenyl diisocyanate and 2,4'-methylenediphenyl diisocyanate

ActiveUS20050020797A1Simple processLow component requirementsOrganic compound preparationIsocyanic acid derivatives purification/separationDiphenylmethaneDistillation

A fraction of diisocyanates of the diphenylmethane series containing at least 95 wt. % binuclear methylenediphenyl diisocyanate is obtained by a) reacting aniline and formaldehyde in the presence of an acid catalyst to produce diamines and polyamines of the diphenylmethane series containing binuclear methylenediphenyl diamine, b) phosgenating the diamines and polyamines produced in a), optionally in the presence of a solvent, to produce a crude diisocyanate and polyisocyanate, and c) separating a fraction containing at least 95 wt. % binuclear methylenediphenyl diisocyanate with a 4,4′-MDI content of over 60 wt. %, a 2,4′-MDI content of 4 to 35 wt. % and a 2,2′-MDI content of 0.01 to 10 wt. %, relative to the mass of the fraction, and a maximum of 20 ppm phenyl isocyanate and optionally a maximum of 50 ppm solvent from the crude diisocyanate and polyisocyanate produced in b) in a single distillation step with optional upstream and / or downstream separation of low-boiling components.

Owner:COVESTRO DEUTSCHLAND AG

Process for manufacturing tea products

InactiveUS20100086642A1Low levelIncrease heightPre-extraction tea treatmentAnimal feeding stuffChemistryFermented tea

Disclosed is a process comprising the steps of: expressing juice from a first supply of fresh tea leaves thereby to produce leaf residue and tea juice; subjecting the first supply of fresh tea leaves and / or the tea juice to a fermentation step thereby to at least partially ferment the tea juice; and combining the at least partially fermented tea juice with substantially unfermented tea material.

Owner:CONOPCO INC D B A UNILEVER

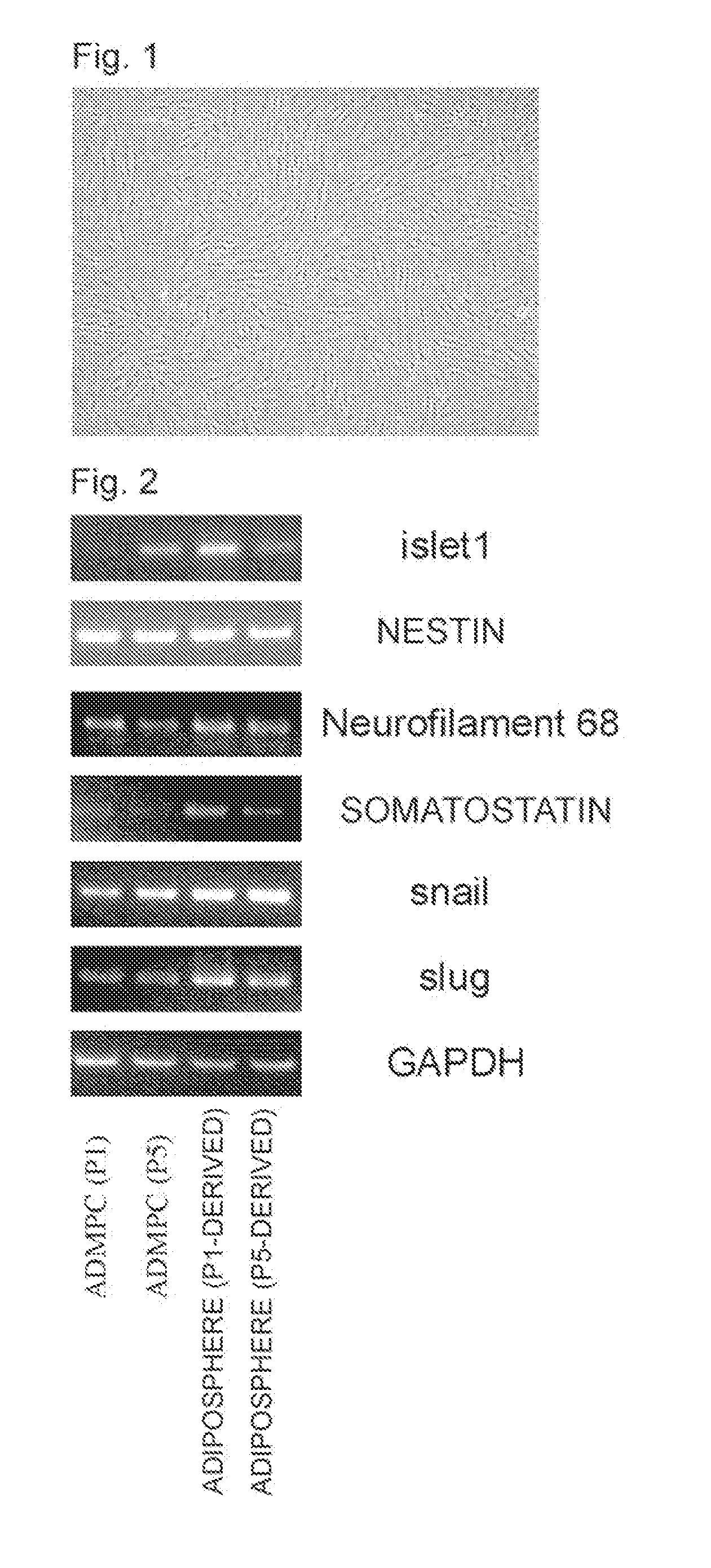

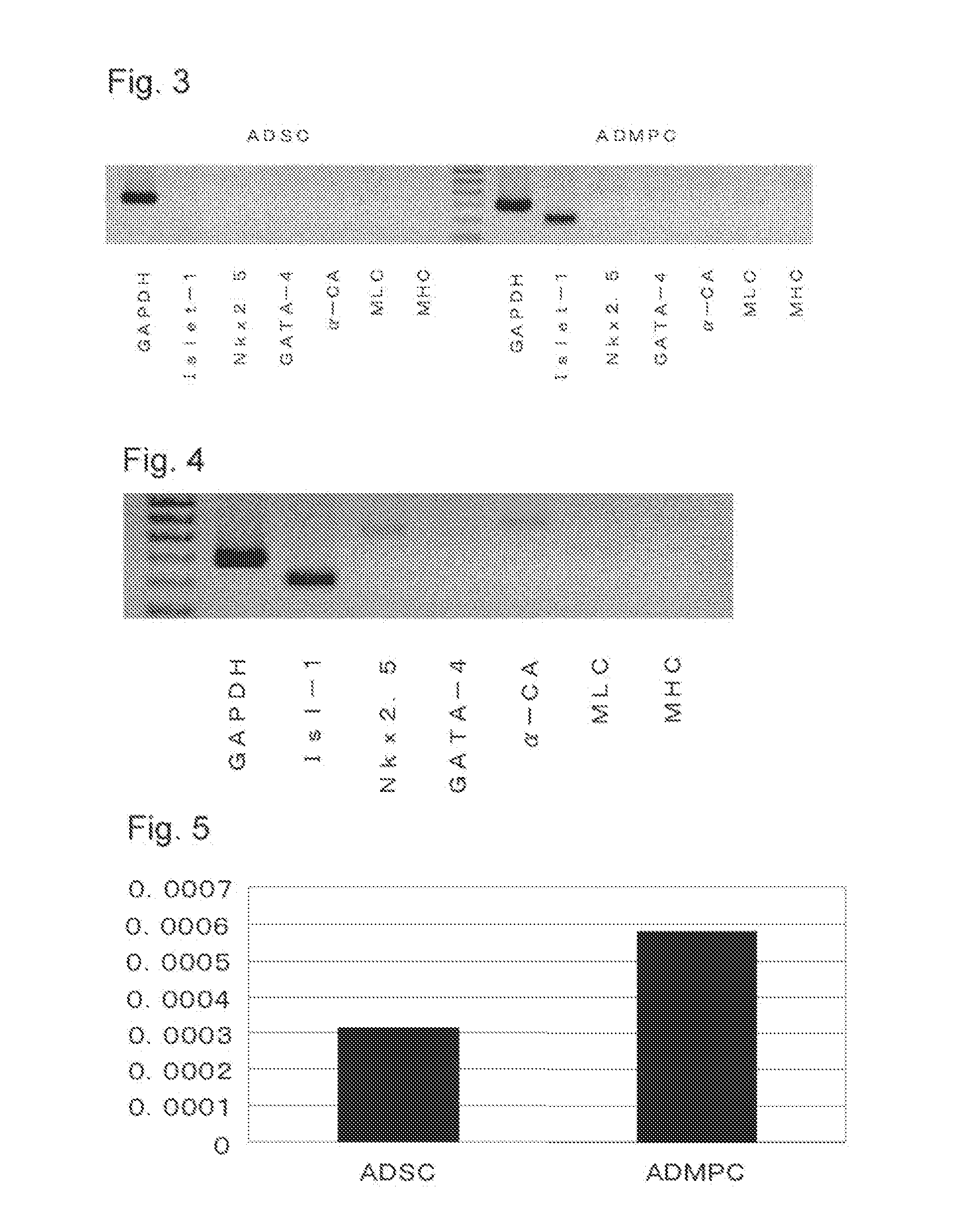

Multipotent progenitor cell derived from adipose tissue

ActiveUS20100151574A1Low proportionPurity of obtainedDigestive systemSkeletal/connective tissue cellsWhite adipose tissueCell mass

Disclosed is a cell mass containing an adipose-tissue-derived multipotent progenitor cell. Also disclosed is a method for producing an adipose-tissue-derived multipotent progenitor cell from an adipose tissue, which comprises the steps of: (a) removing erythrocytes from an adipose-tissue-derived cell mass to produce a preadipose-tissue-derived multipotent progenitor cell mass; and (b) removing cells other than the adipose-tissue-derived multipotent progenitor cell from the preadipose-tissue-derived multipotent progenitor cell mass to produce the desired adipose-tissue-derived multipotent progenitor cell. Further disclosed is an adipose-tissue-derived multipotent progenitor cell produced by the method.

Owner:MATSUYAMA PLOW MFG CO LTD

Gel compositions

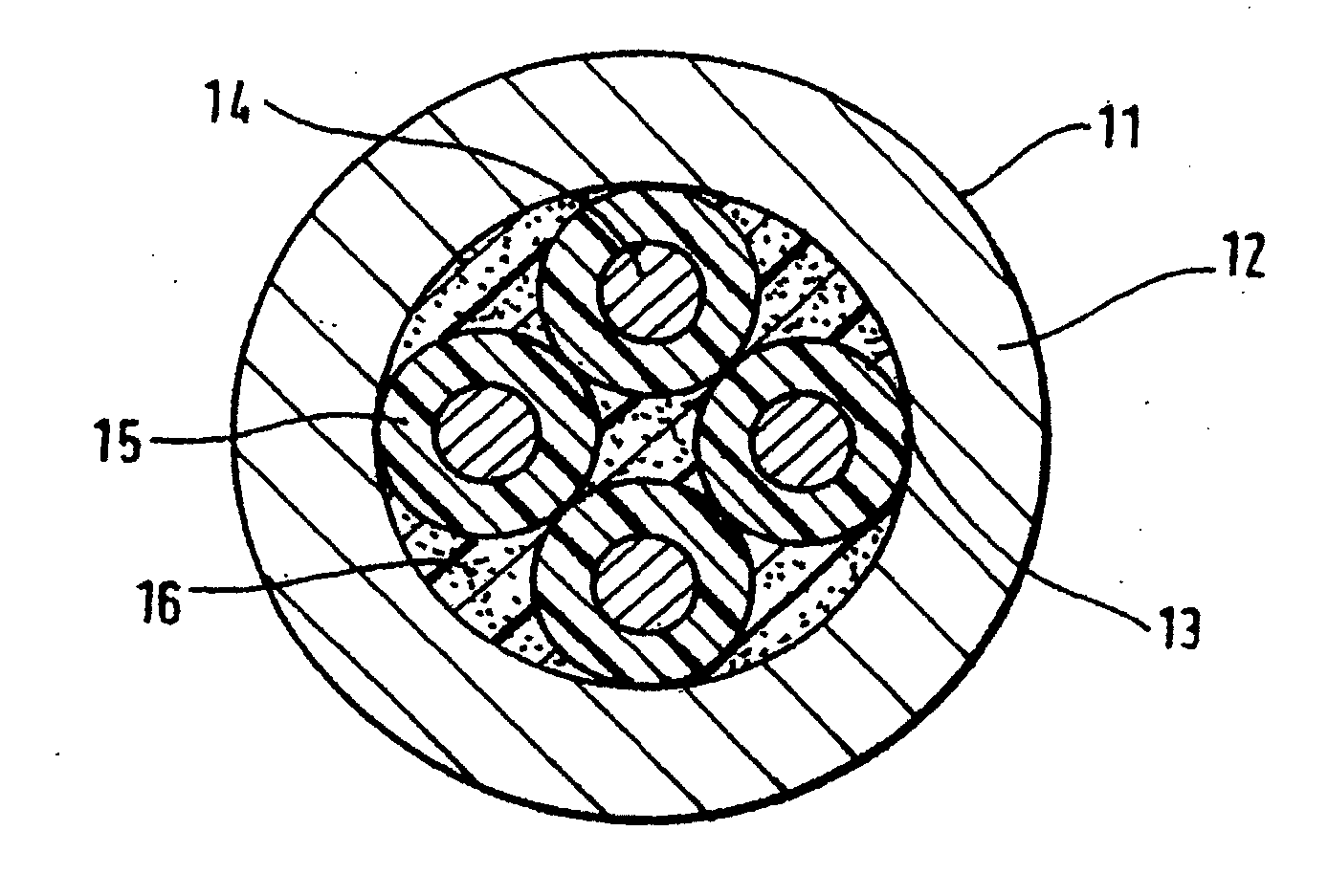

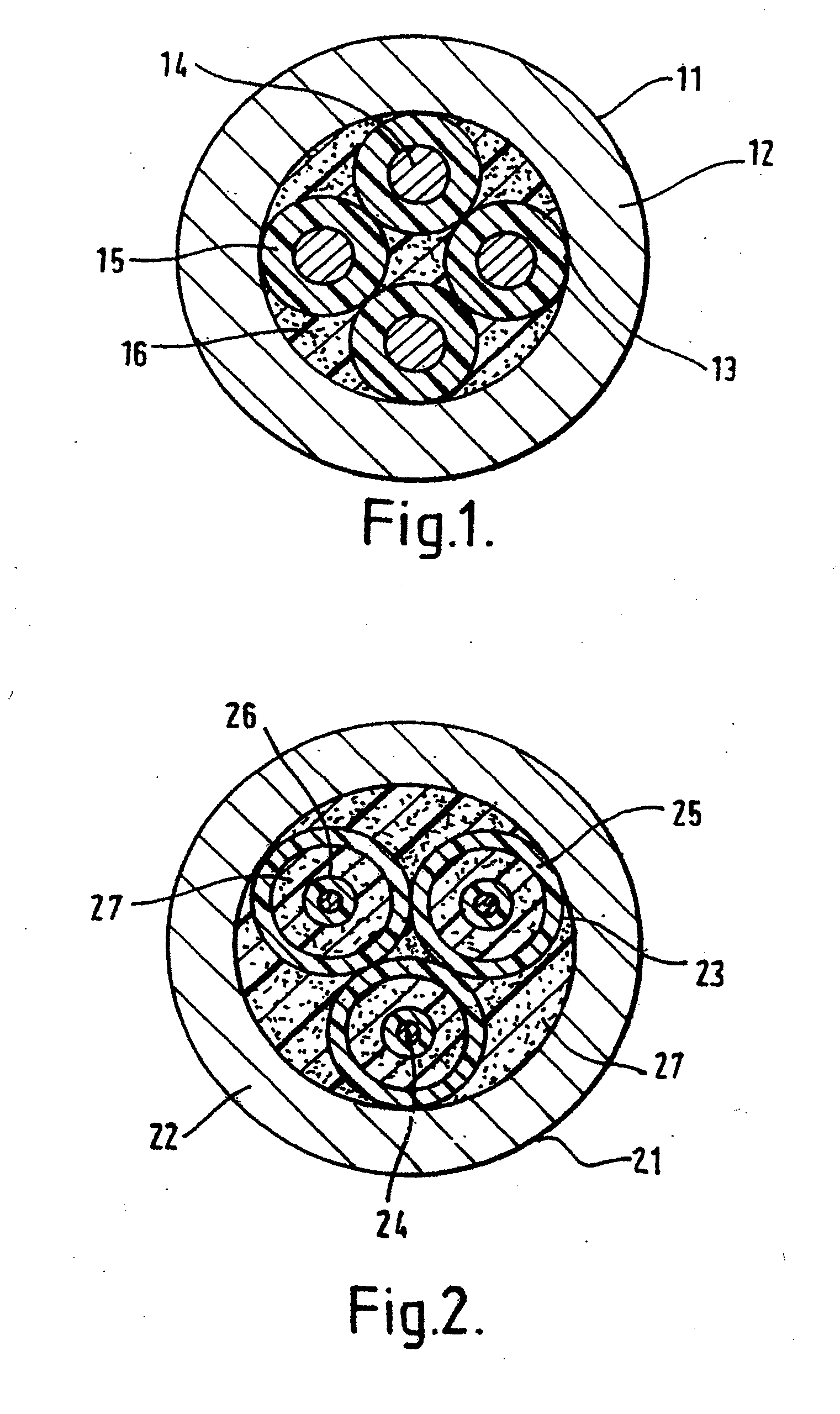

InactiveUS7253217B2Increase elasticitySpecific weightClimate change adaptationInsulated cablesChemical compositionMicrosphere

The invention relates to a composition which comprises a dispersion of micro spheres in a gel comprising an oily base and an organic polymeric gelling agent.

Owner:UNIGEL IP

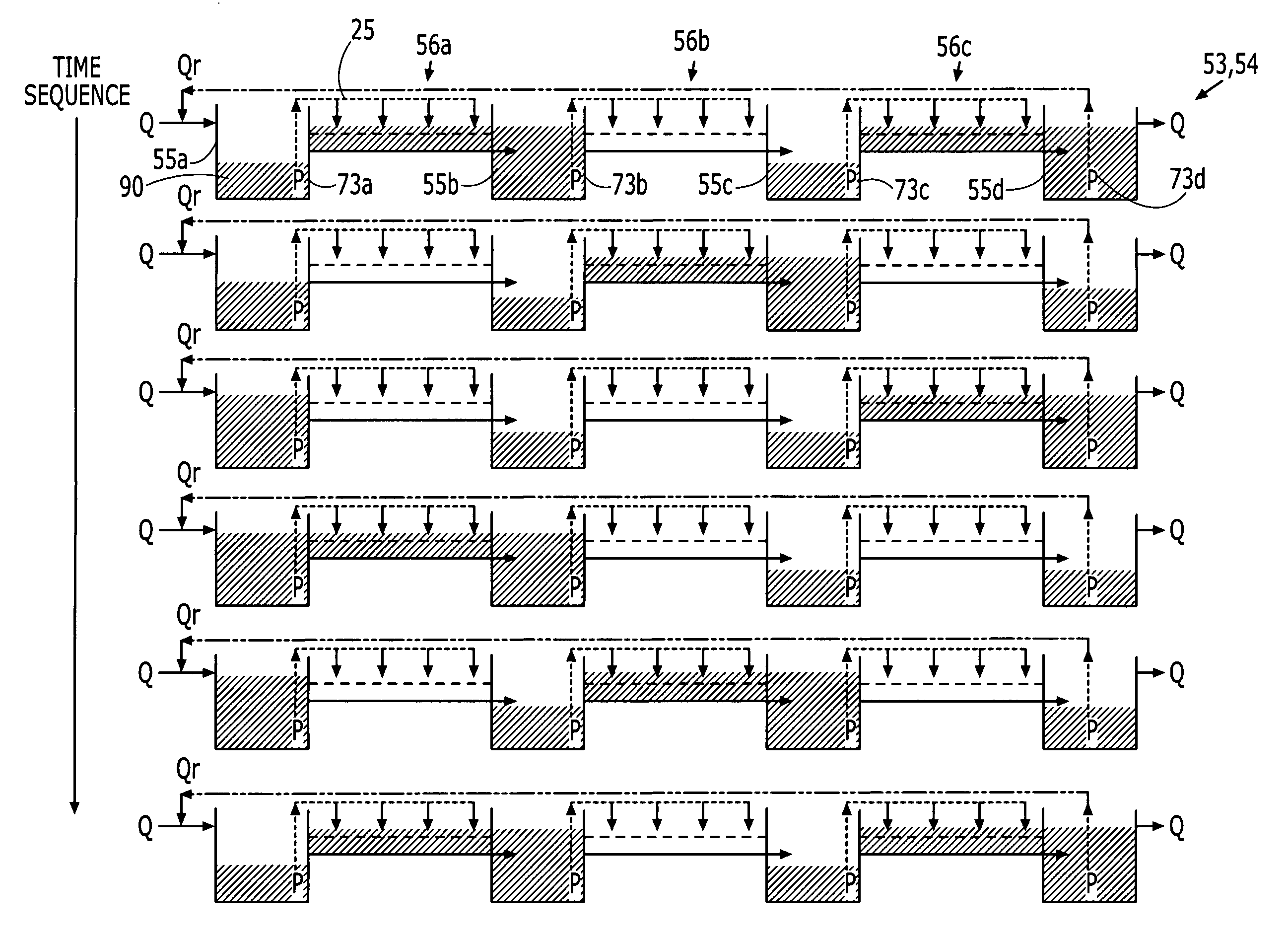

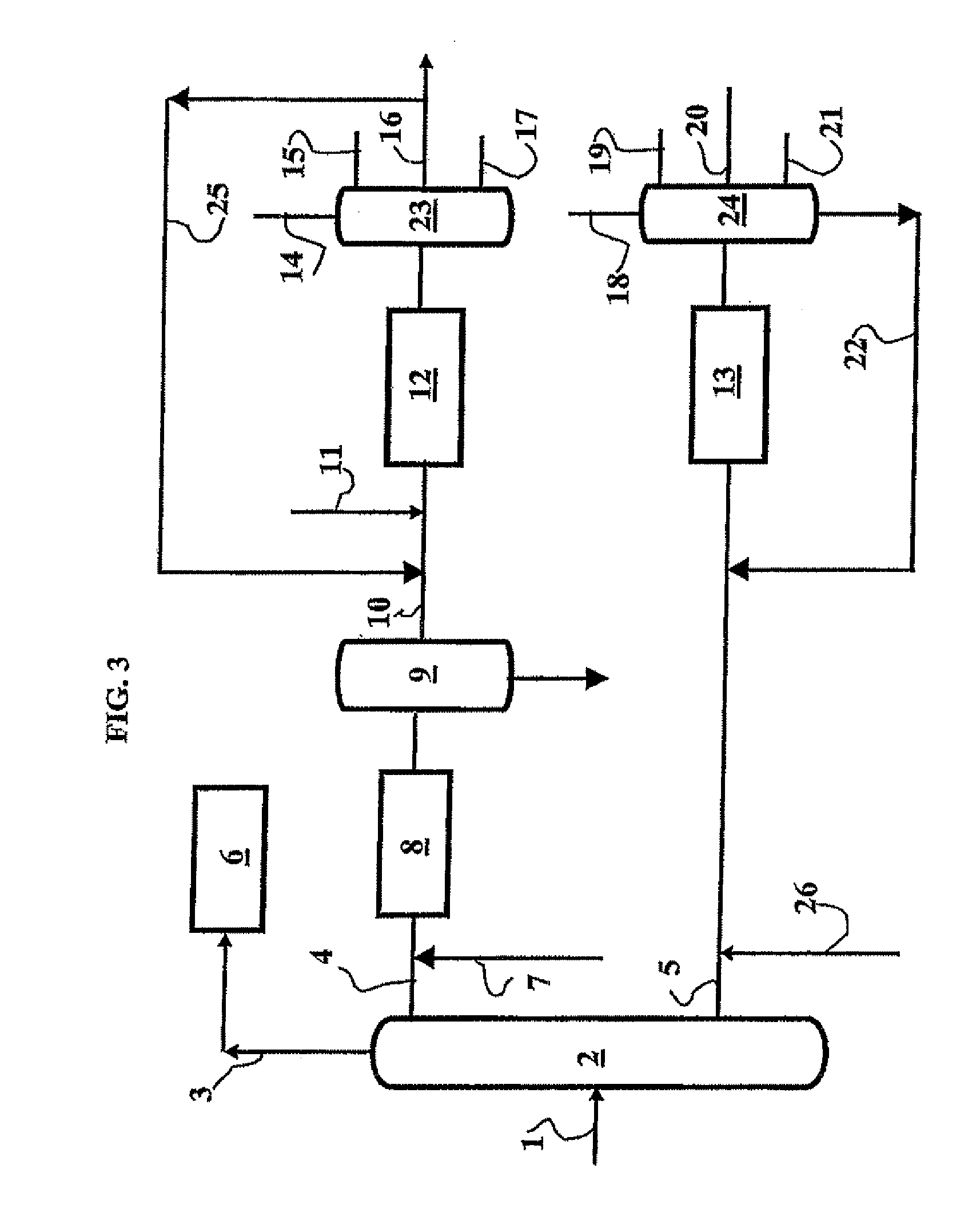

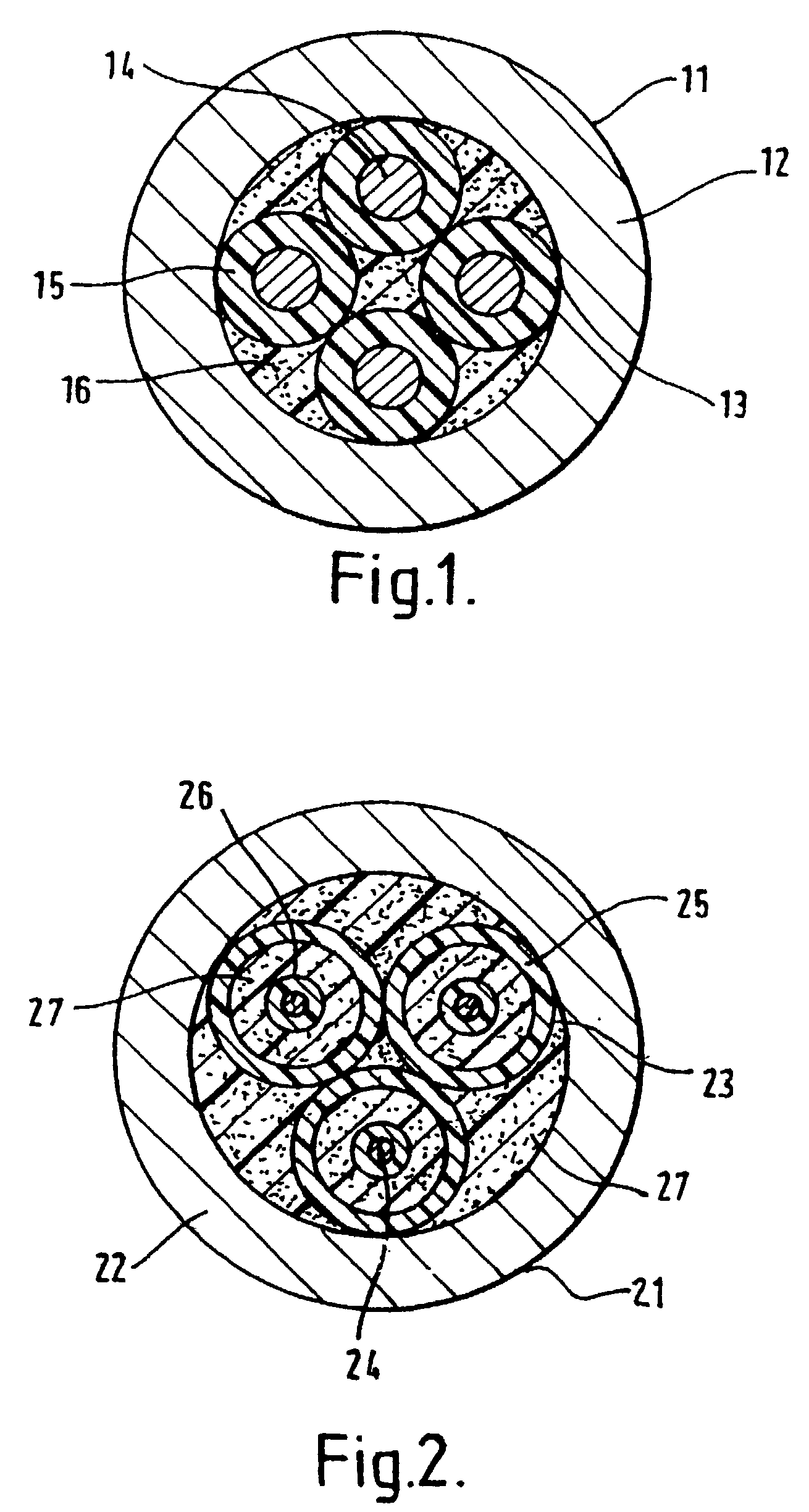

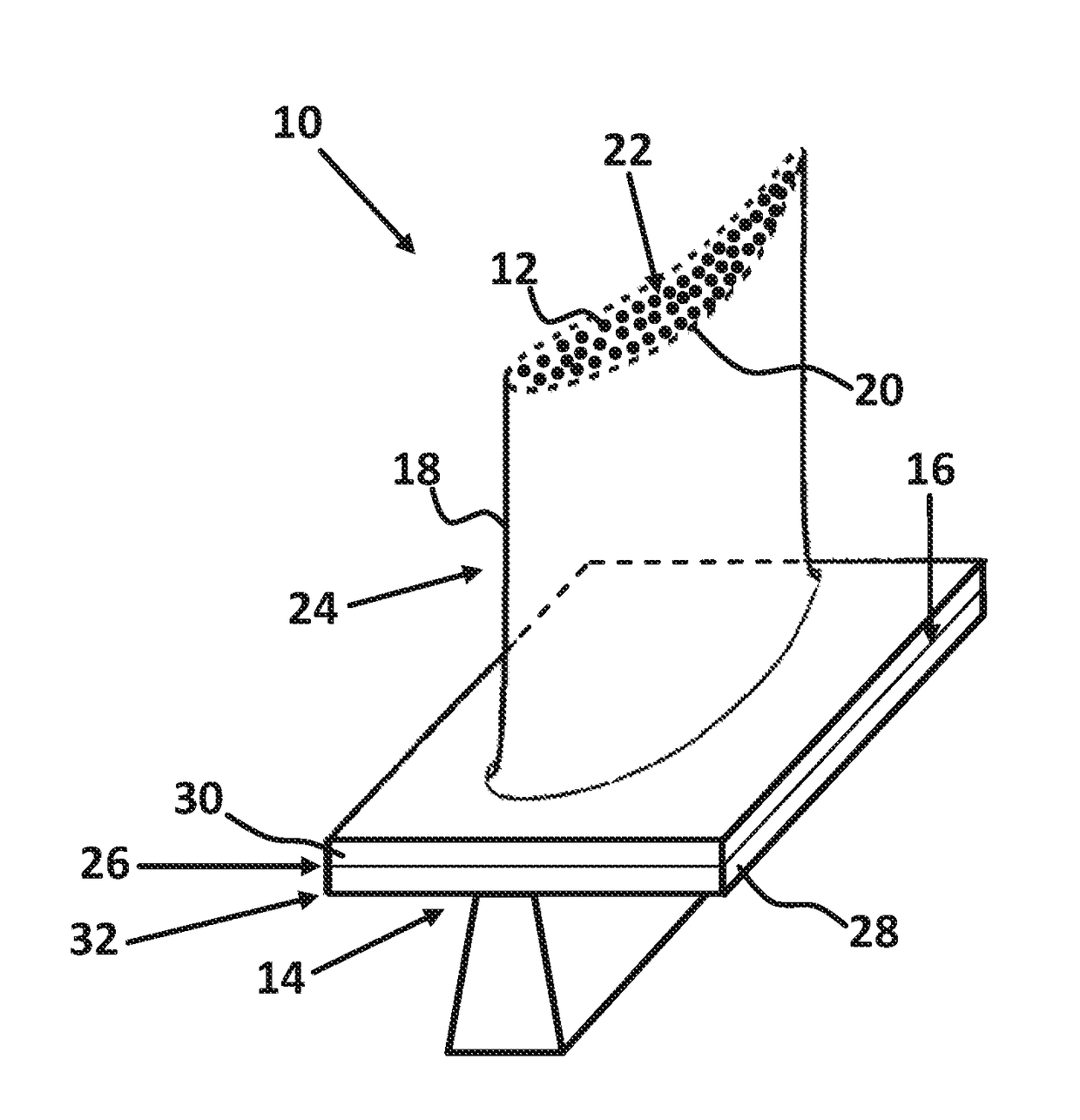

Integrated hydroponic and wetland wastewater treatment systems and associated methods

ActiveUS7320752B2Undesirable characteristicLess land intensiveWater cleaningTreatment using aerobic processesWater treatment systemAnaerobic reactor

The wastewater treatment systems have a plurality of treatment modules between the inlet and the outlet, each for treating water with a selected process. Influent is directed to a covered anaerobic reactor, and then to an attached growth pretreatment filter that is at least intermittently exposed to atmospheric oxygen. Following the filter is a hydroponic reactor followed by a vertical-flow wetland. A second embodiment includes, following the filter, a tidal vertical-flow wetland and a pump for recycling water exiting the wetland upstream of the filter.

Owner:DHARMA IP

Process for the production of ceramic green films with acetalized polyvinyl alcohols

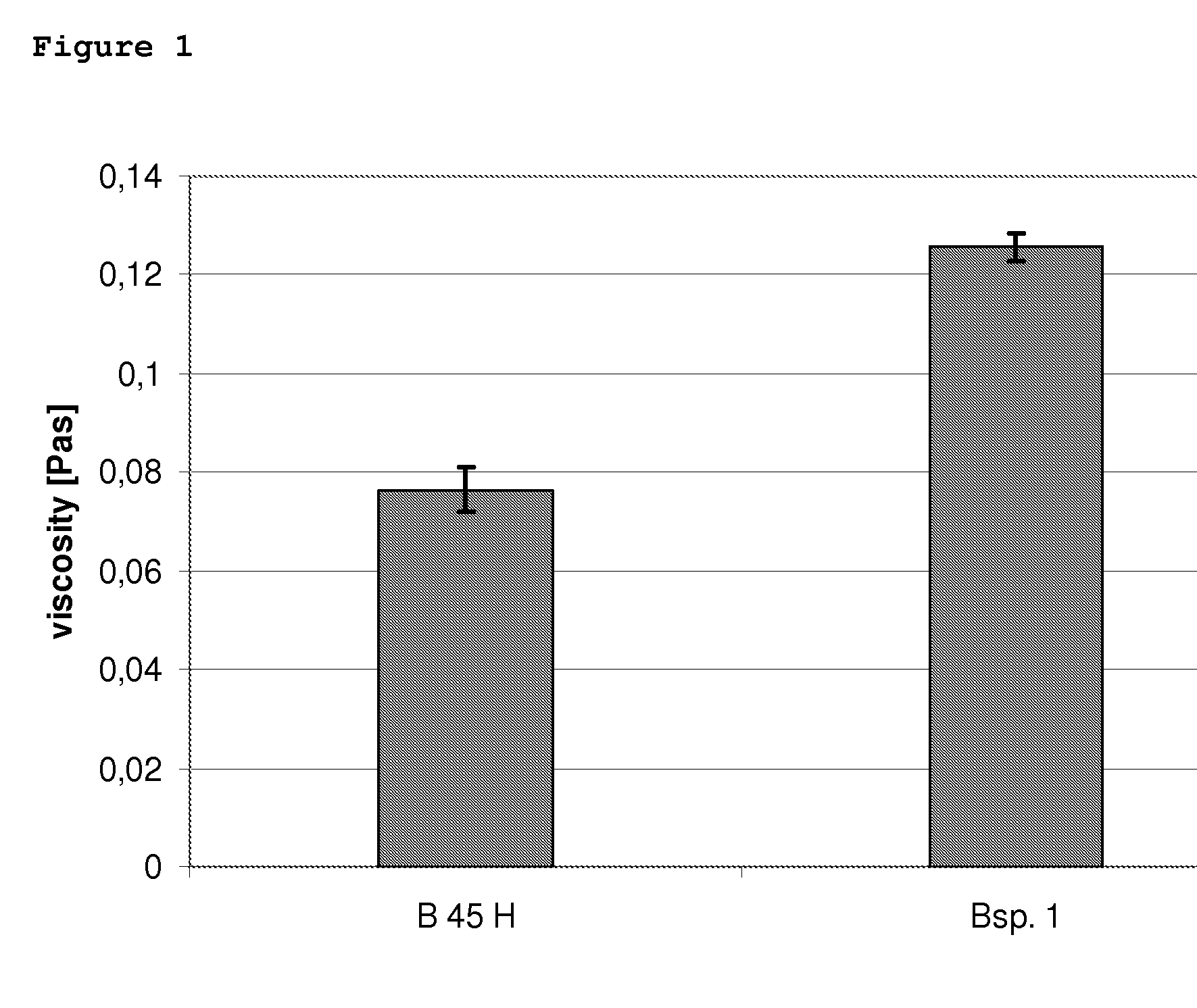

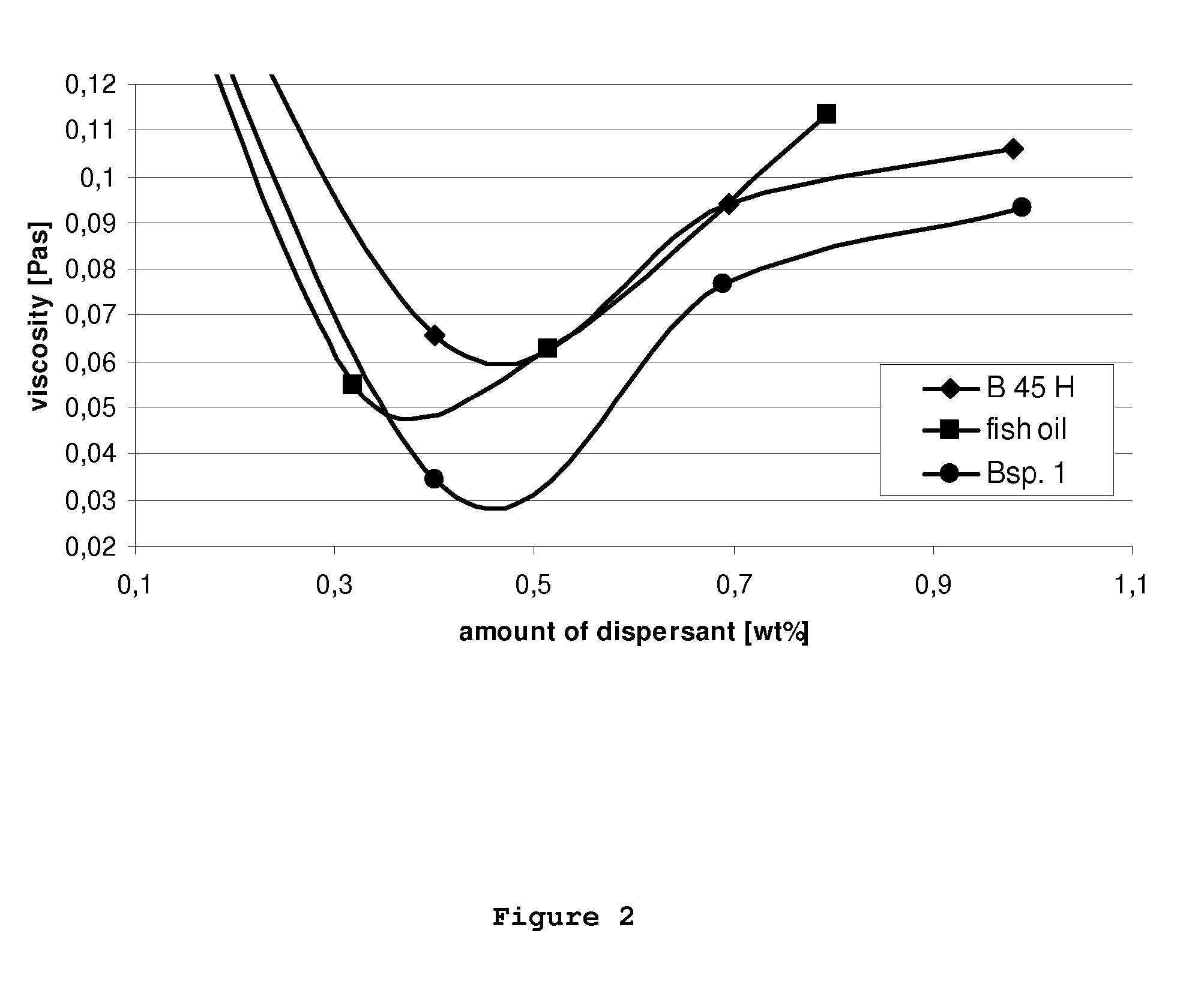

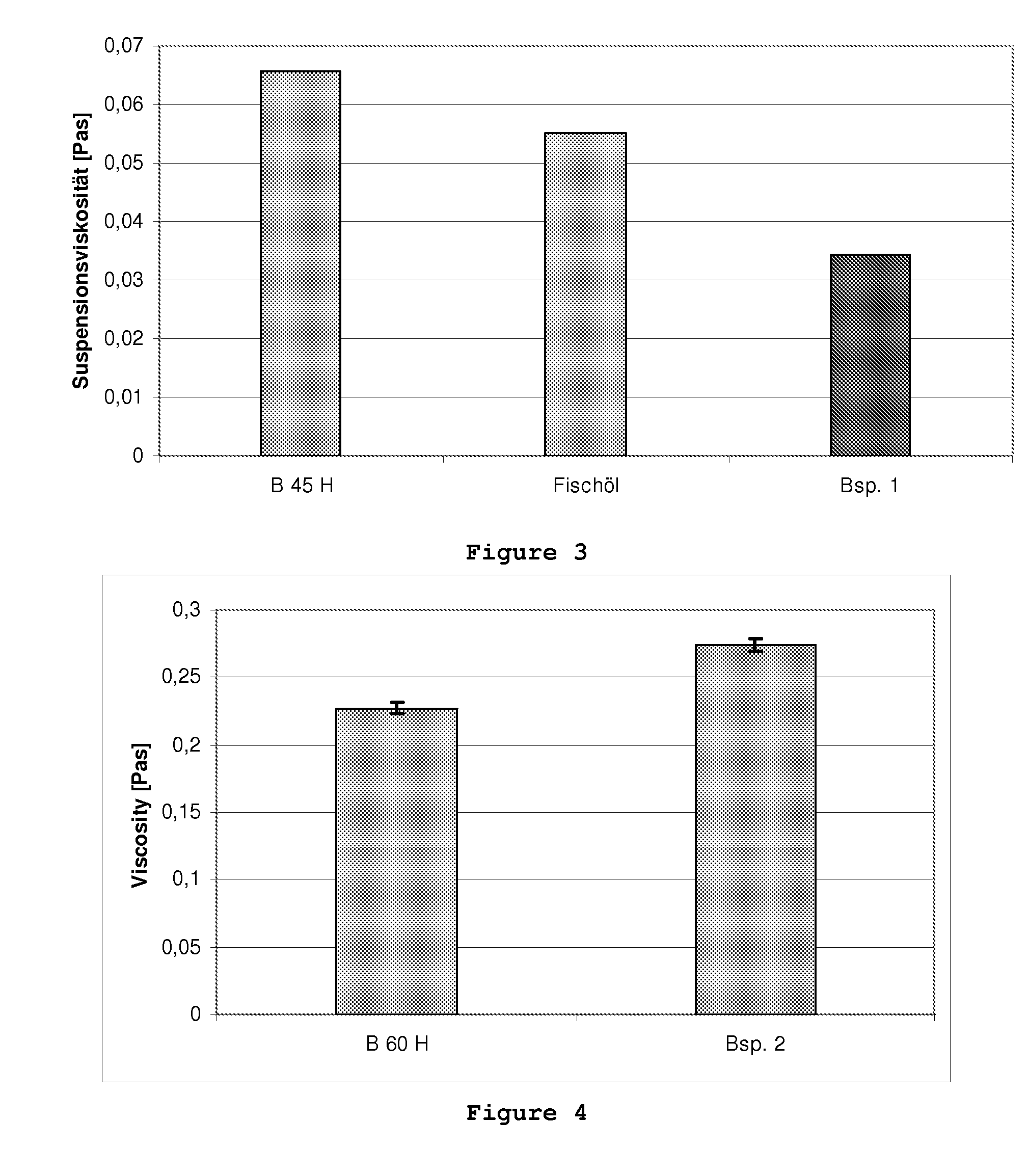

ActiveUS20070262496A1High dispersion effectLow viscosityBiocideNon-fibrous pulp additionPolyvinyl acetatePolymer science

Acetalized polyvinyl alcohols having a high residual polyvinyl acetate content are suitable as use as dispersing agents in the production of ceramic green films.

Owner:KURARAY EURO GMBH

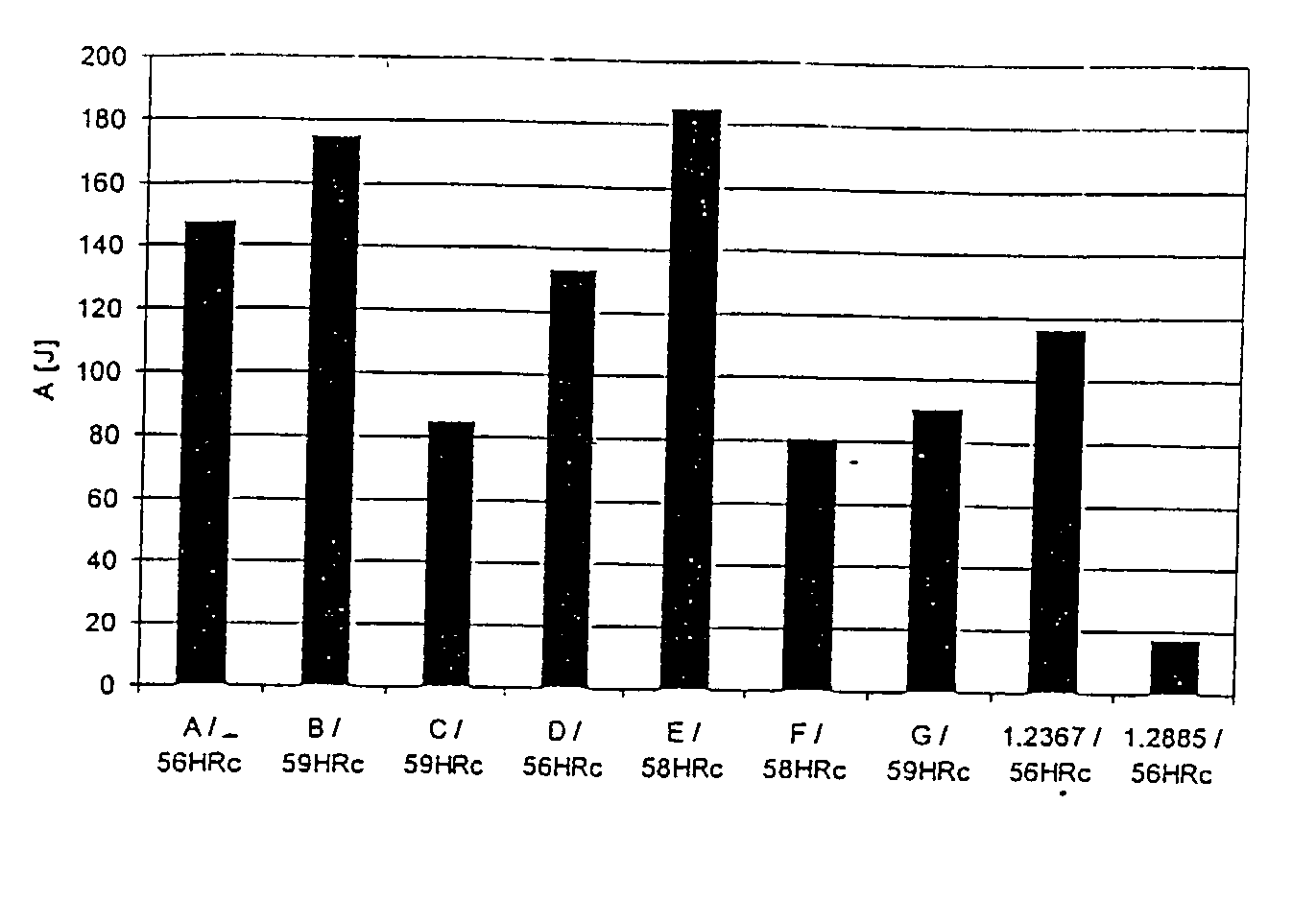

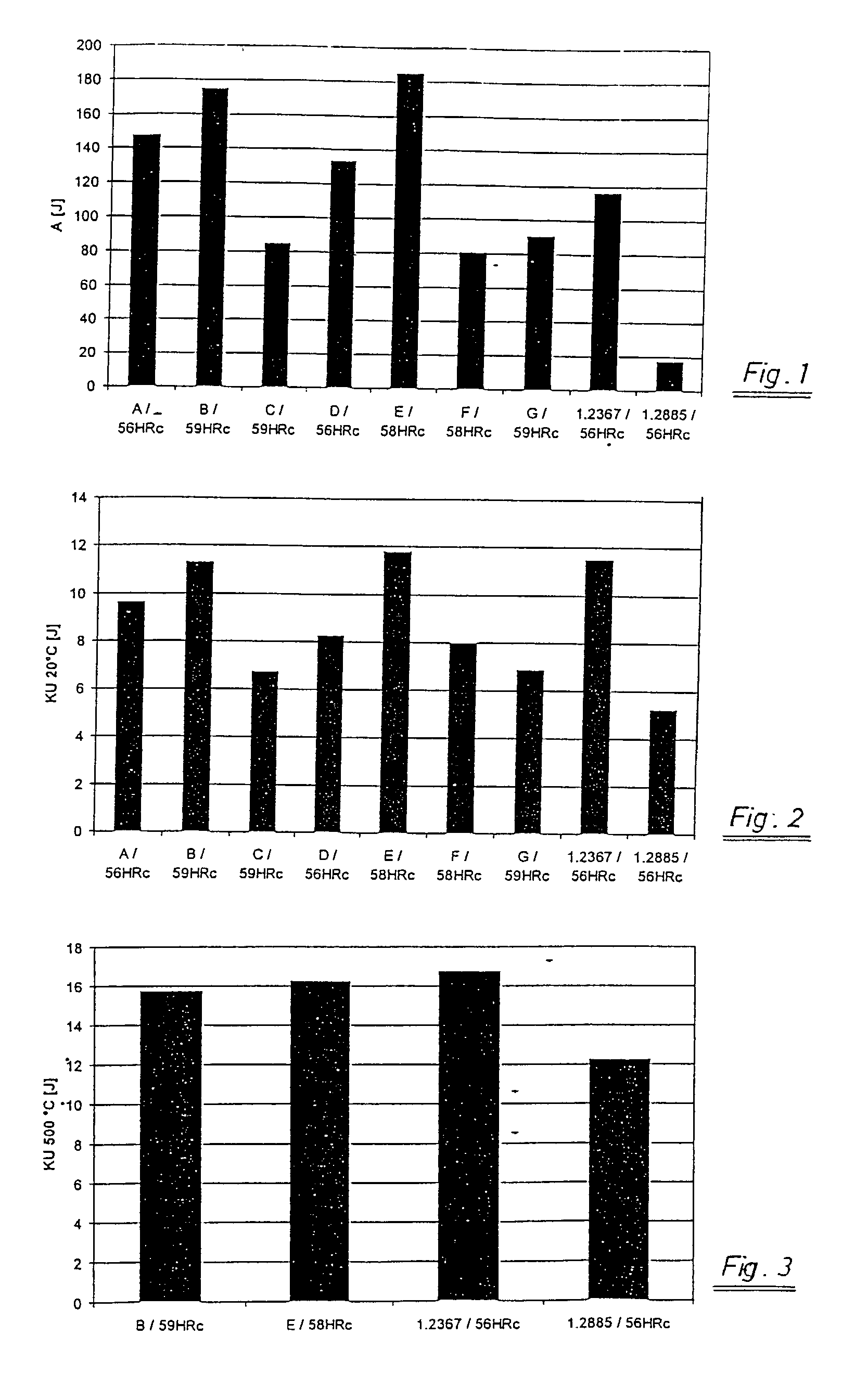

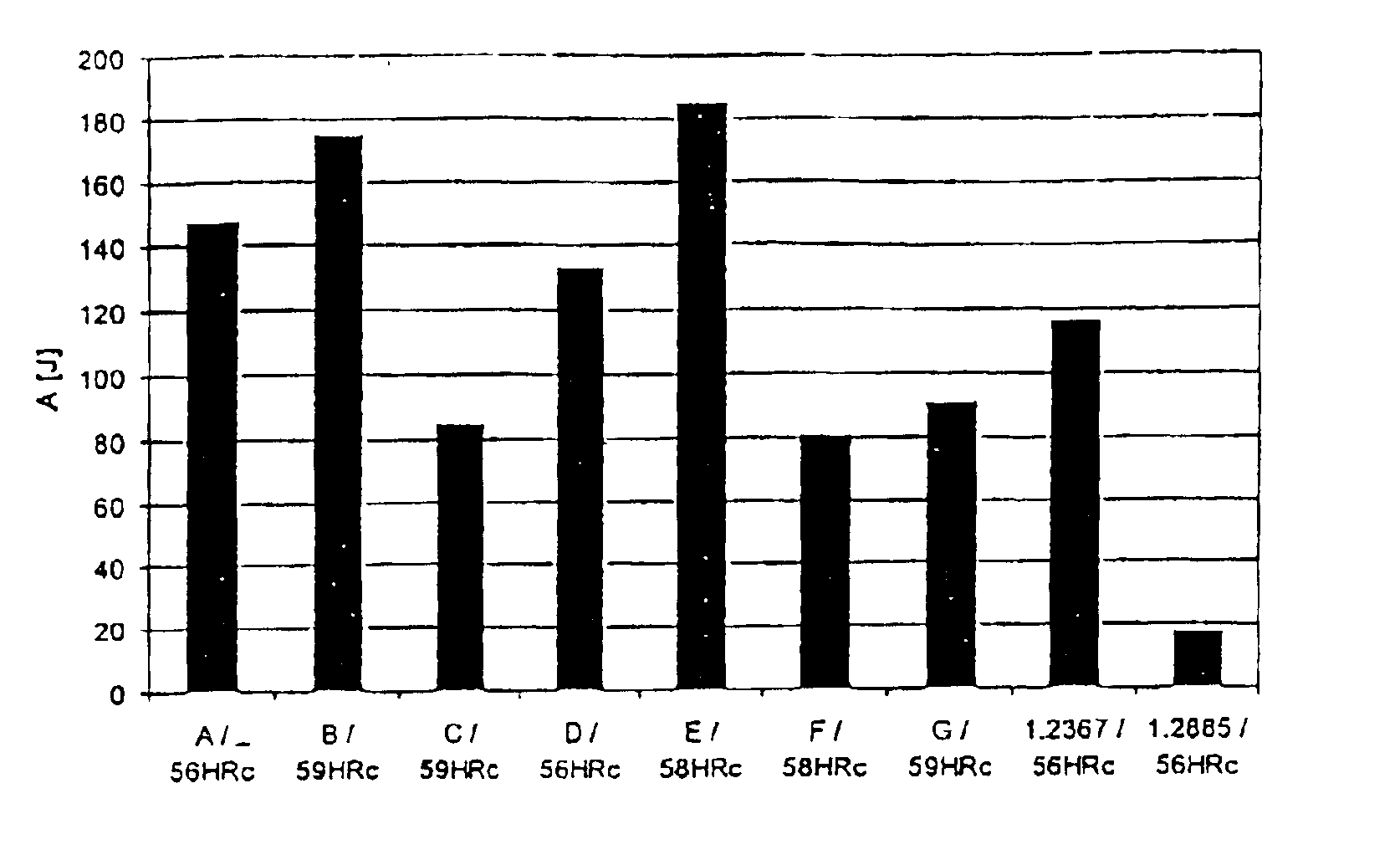

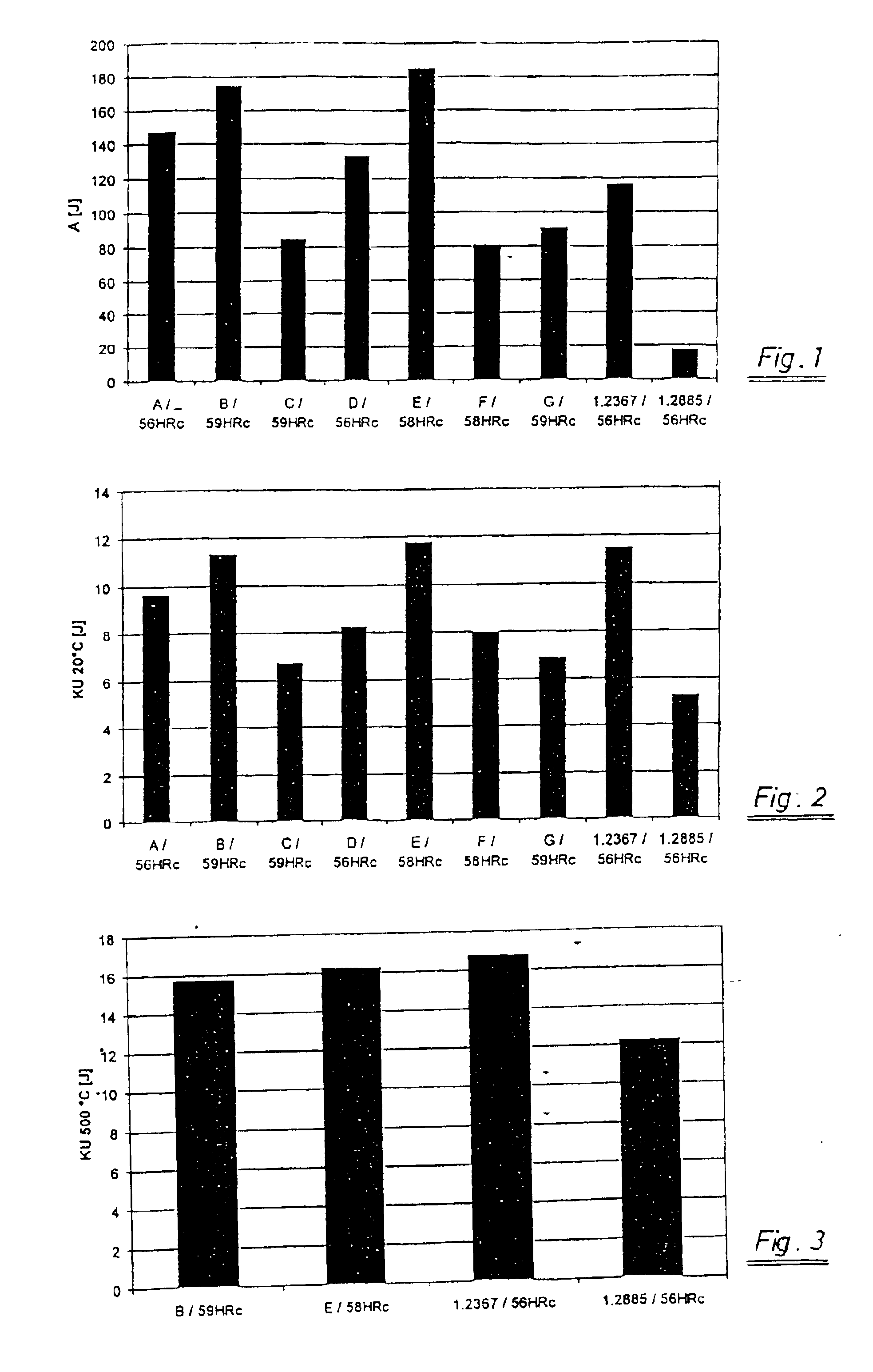

Hot-working steel article

InactiveUS20030098097A1Promotes fine-grain quality of materialSuppress a carbide hardening or a hardness-increasing separationHot working

A hot-working steel article, e.g., tool, comprising a material which comprises, in % by weight, 0.451 to 0.598 C, 0.11 to 0.29 Si, 0.11 to 0.39 Mn, 4.2 to 4.98 Cr, 2.81 to 3.29 Mo, 0.41 to 0.69 V, with the balance iron, contaminants and accompanying elements, as well as an alloy and a process for making said article.

Owner:BOHLER EDELSTAHL GMBH & CO KG

Hot-working steel article

InactiveUS6773662B2Promotes fine-grain quality of materialSuppress a carbide hardening or a hardness-increasing separationFurnace typesHeat treatment furnacesHot working

A hot-working steel article, e.g., tool, comprising a material which comprises, in % by weight, 0.451 to 0.598 C, 0.11 to 0.29 Si, 0.11 to 0.39 Mn, 4.2 to 4.98 Cr, 2.81 to 3.29 Mo, 0.41 to 0.69 V, with the balance iron, contaminants and accompanying elements, as well as an alloy and a process for making said article.

Owner:BOHLER EDELSTAHL GMBH & CO KG

Thermally stable blends of highly paraffinic distillate fuel component with conventional distillate fuel component

InactiveUS7033484B2Minimize deposit formationHigh aromatic contentLiquid organic insulatorsHydrocarbon purification/separationEngineeringInternal combustion engine

A stable distillate fuel blend useful as a fuel or as a blending component of a fuel that is suitable for use in an internal combustion engine, said fuel blend prepared from at least one highly paraffinic distillate fuel component and at least one highly aromatic petroleum-derived distillate fuel component and a process for preparing same involving the blending of at least two components having antagonistic properties with respect to one another.

Owner:CHEVROU USA INC

Gel Compositions

InactiveUS20080076854A1Specific weightIncrease elasticityClimate change adaptationInsulated cablesOrageneOrganic chemistry

The invention relates to a composition which comprises a dispersion of micro spheres in a gel comprising an oily base and an organic polymeric gelling agent.

Owner:UNIGEL IP

Production of mixtures of diisocyanates and polyisocyanates from the diphenylmethane series with high contents of 4,4'-methylenediphenyl diisocyanate and 2,4'-methylenediphenyl diisocyanate

ActiveUS7038002B2Simple processLow proportionOrganic compound preparationIsocyanic acid derivatives purification/separationDiphenylmethaneDistillation

A fraction of diisocyanates of the diphenylmethane series containing at least 95 wt. % binuclear methylenediphenyl diisocyanate is obtained bya) reacting aniline and formaldehyde in the presence of an acid catalyst to produce diamines and polyamines of the diphenylmethane series containing binuclear methylenediphenyl diamine,b) phosgenating the diamines and polyamines produced in a), optionally in the presence of a solvent, to produce a crude diisocyanate and polyisocyanate, andc) separating a fraction containing at least 95 wt. % binuclear methylenediphenyl diisocyanate with a 4,4′-MDI content of over 60 wt. %, a 2,4′-MDI content of 4 to 35 wt. % and a 2,2′-MDI content of 0.01 to 10 wt. %, relative to the mass of the fraction, and a maximum of 20 ppm phenyl isocyanate and optionally a maximum of 50 ppm solvent from the crude diisocyanate and polyisocyanate produced in b) in a single distillation step with optional upstream and / or downstream separation of low-boiling components.

Owner:COVESTRO DEUTSCHLAND AG

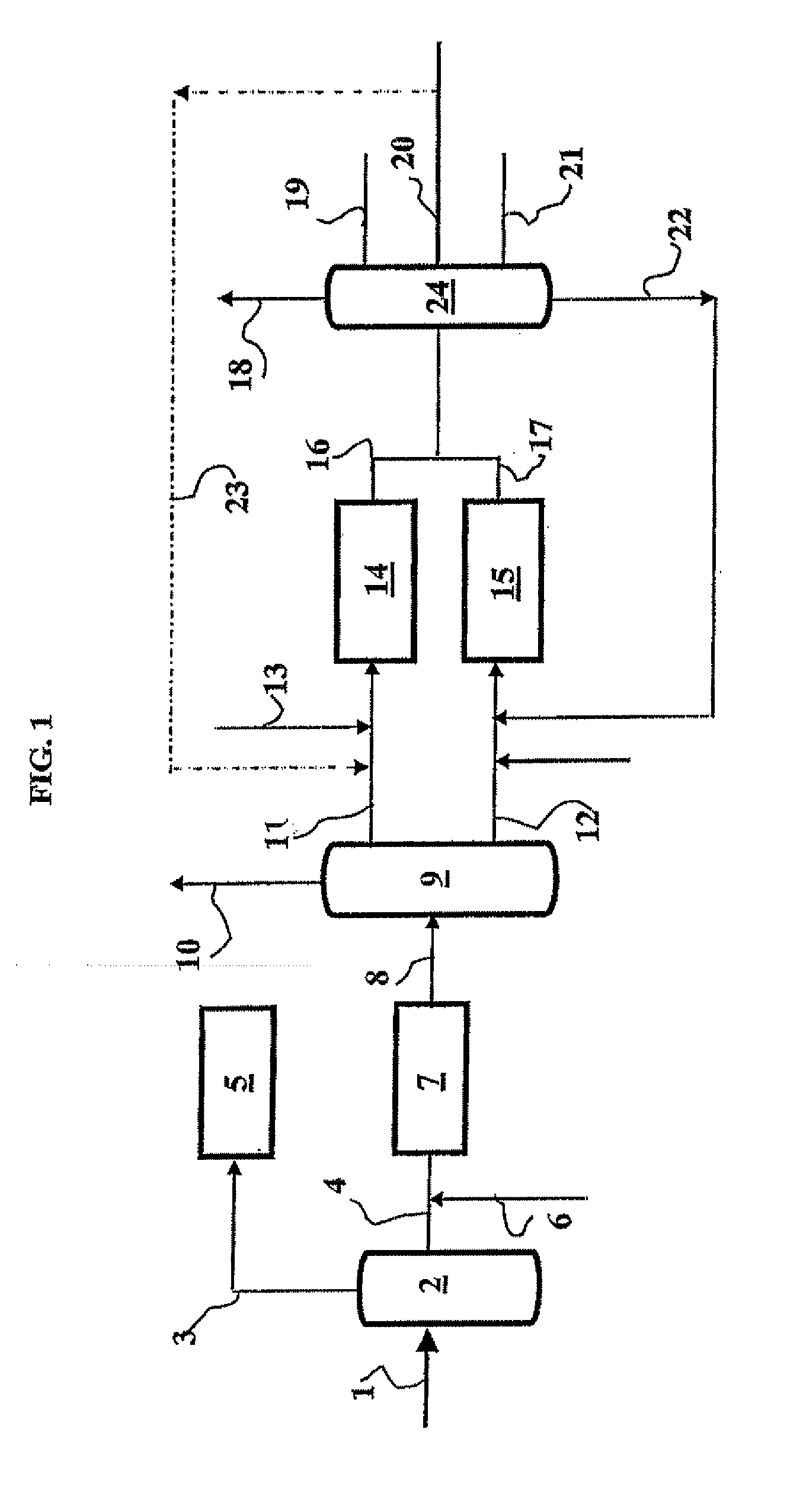

Integrated hydroponic and fixed-film wastewater treatment systems and associated methods

InactiveUS20050126991A1Small footprintUndesirable characteristicTreatment using aerobic processesWater/sewage treatment by irradiationBiosolidsTreatment system

The wastewater treatment systems have a plurality of treatment zones including a first reactor for supporting biofilms for reducing a concentration of organics and solids from wastewater to be treated and for cyclically nitrifying and denitrifying the wastewater therein. A second reactor is for supporting biosolids, the supporting means including elements for digesting suspended solids in water exiting the first reactor. A portion of the water exiting the second reactor is recycled to the first reactor.

Owner:DHARMA IP

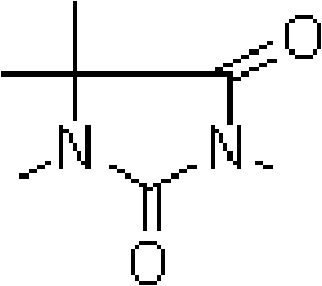

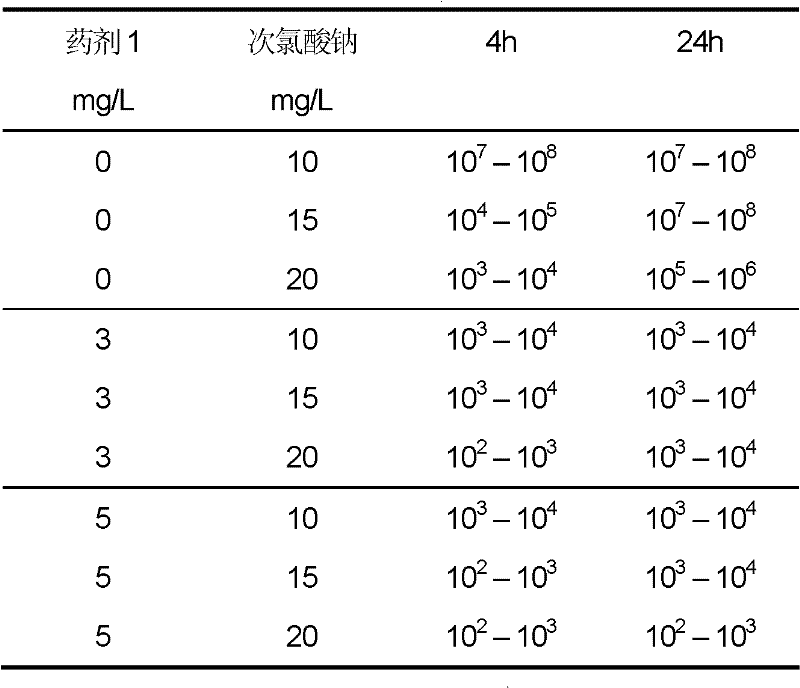

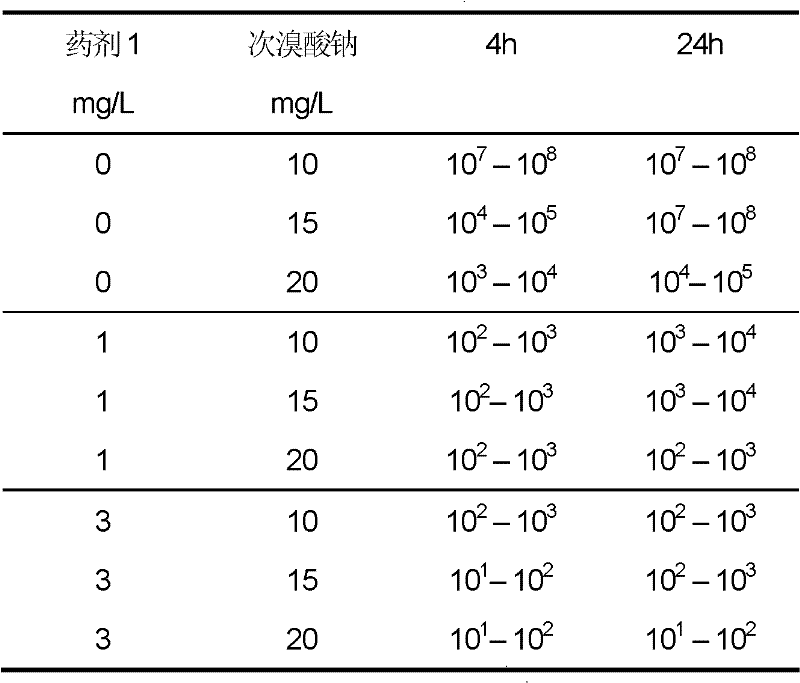

Sterilizing synergistic agent for oxidizing biocide

InactiveCN102246751AEffective penetrationEfficient removalBiocideFungicidesAmmonium compoundsHalogen

The invention provides a sterilizing synergistic agent for an oxidizing biocide. The sterilizing synergistic agent comprises 10-30 parts by weight of long-carbon-chain nitrogen-group quaternary ammonium compound with 10-60 carbon atoms, 1-10 parts by weight of hydantoin heterocyclic compound and 50-100 parts by weight of water. The sterilizing synergistic agent can be used for synergizing chlorine and bromine oxidizing biocides, can achieve a favorable sterilizing effect at an extremely-low consumption level, has a greatly increased stripping function on clay, and can be used for effectively reducing the corrosion action of halogen sterilizing agents on a metal pipeline.

Owner:SHANGHAI WEILAI ENTERPRISE

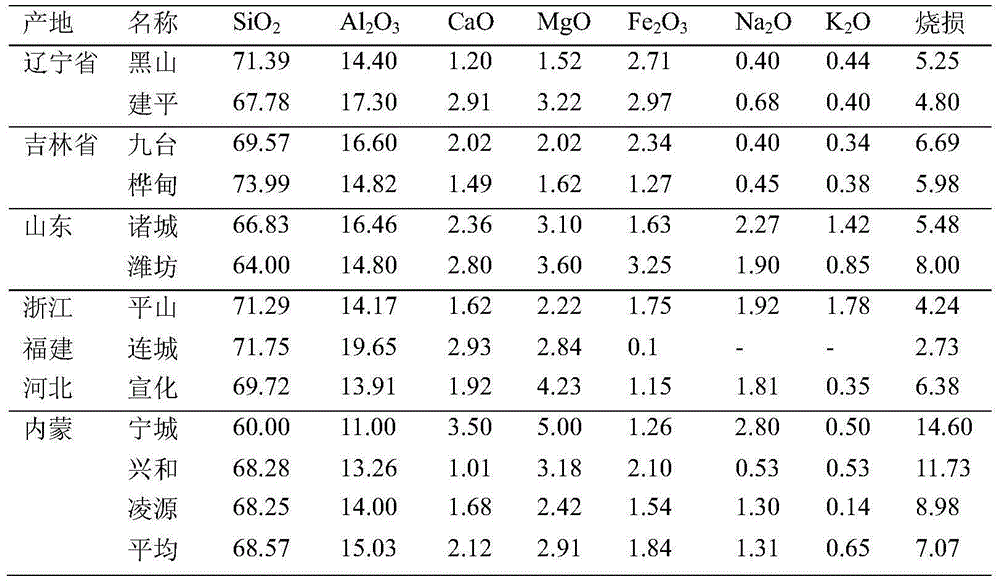

Method for manufacturing alkaline magnesium-rich pellet ore

ActiveCN105039681AImprove performanceImprove high temperature performanceProcess efficiency improvementBrickMixed materials

The invention relates to a method for manufacturing alkaline magnesium-rich pellet ore. The method comprises the steps of I pretreatment of recycled waste magnesia-calcium bricks, wherein a, primary breaking is carried out, and the waste magnesia-calcium bricks are broken into magnesia-calcium brick blocks; b, fine grinding is carried out, and the magnesia-calcium brick blocks are ground into magnesia-calcium brick powder; II batching, wherein iron concentrate powder and the magnesia-calcium brick powder are batched into batch mixtures, and 5.5-6.6 parts of the magnesia-calcium brick powder, 100 parts of the iron concentrate powder, 0.5-1 part of pulverized coal and 1.7 parts of bentonite are adopted according to the ratio; III pretreatment of the batch mixtures, wherein roll grinding is carried out on the batch mixtures; IV mixing, wherein the batch mixtures obtained through roll grinding are mixed; V pelletizing and screening, wherein mixed materials are pelletized and screened into qualified green pellets; VI drying, preheating and calcination, wherein the qualified green pellets are calcinated into pellet ore; VIII cooling, wherein the pellet ore is cooled to obtain the alkaline magnesium-rich pellet ore. The alkaline magnesium-rich pellet ore is produced through the waste magnesia-calcium bricks, the quaternary alkalinity of the pellet ore can be above 1.15%, and MgO is larger than or equal to 3.8%.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Method for producing a blade for a turbomachine

InactiveUS20170314402A1Good subtractive machining capabilityLow stressTurbinesAdditive manufacturing apparatusMaterials scienceInput method

Disclosed is a method for producing a blade for a turbomachine, which method comprises:providing a blade root, having a first platform region, from a first material;providing on the first platform region at least one capsule that is filled with a metallic and / or ceramic powder that comprises at least one second material which is different from the first material, for producing a blade airfoil having a second platform region;producing and shaping a blade airfoil from the capsule that is filled with the powder by at least one thermal input method, thereby connecting the blade root to the blade airfoil in respective platform regions.Also disclosed is a blade which is obtainable and / or obtained by this method.

Owner:MTU AERO ENGINES GMBH

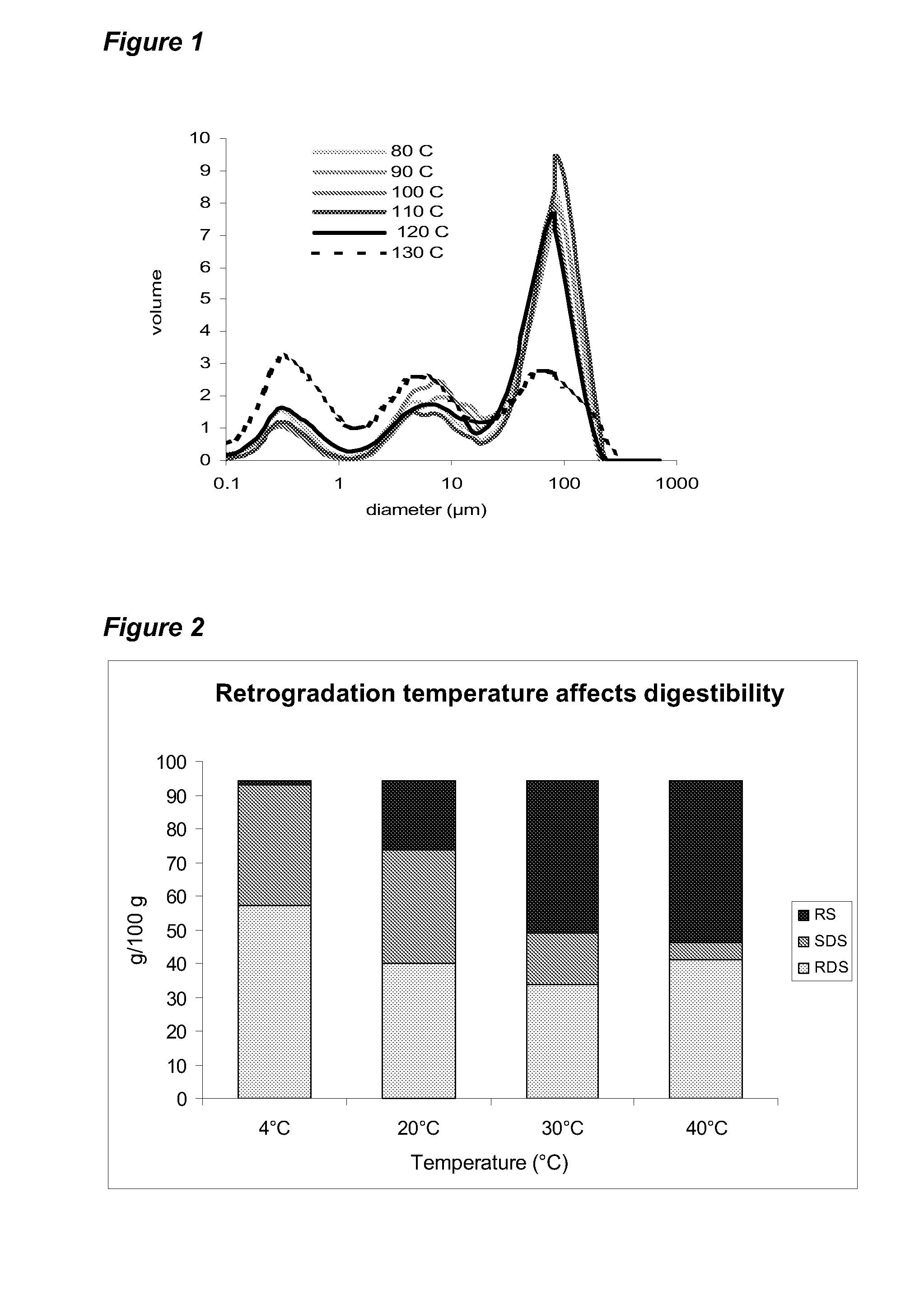

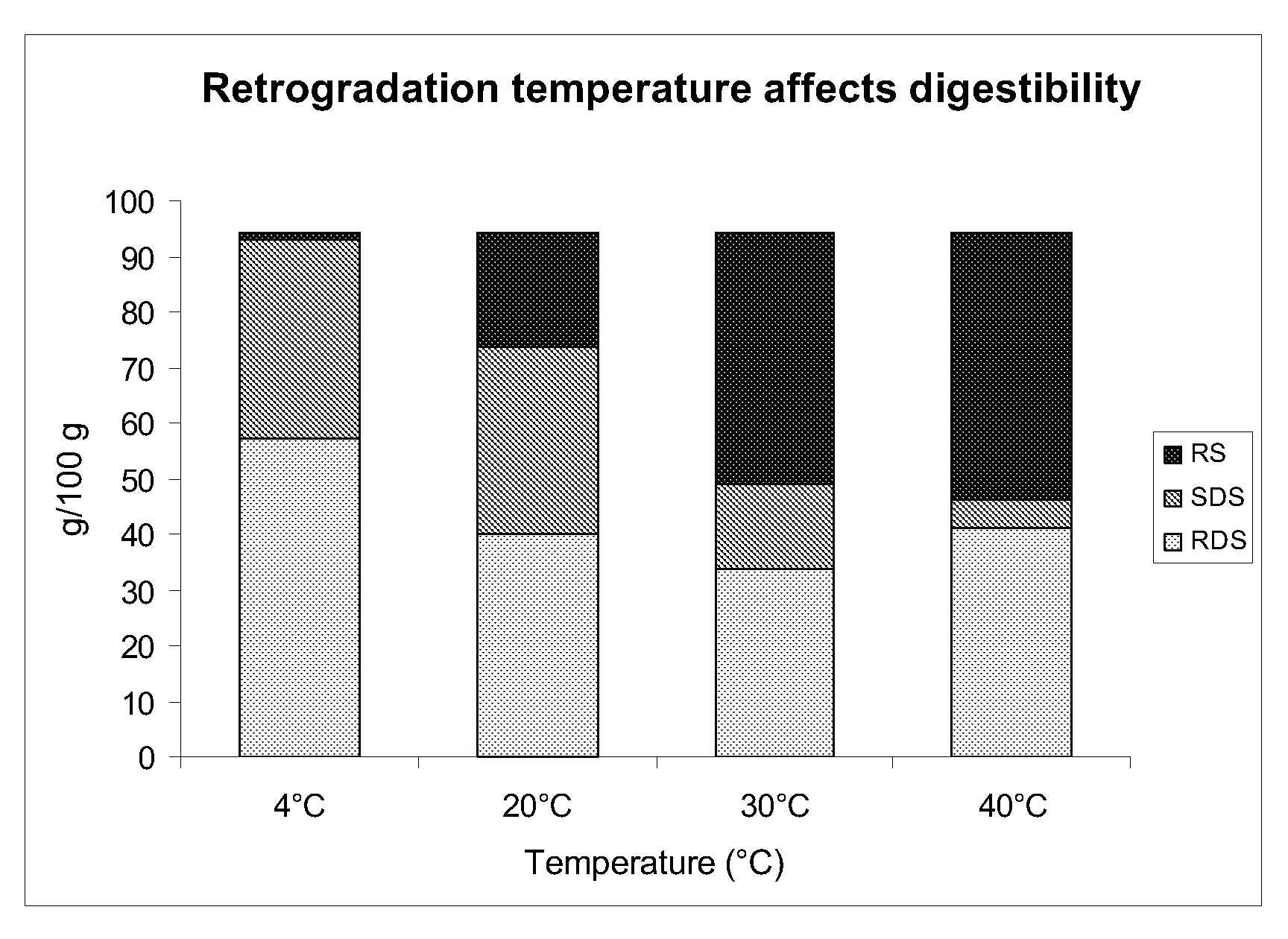

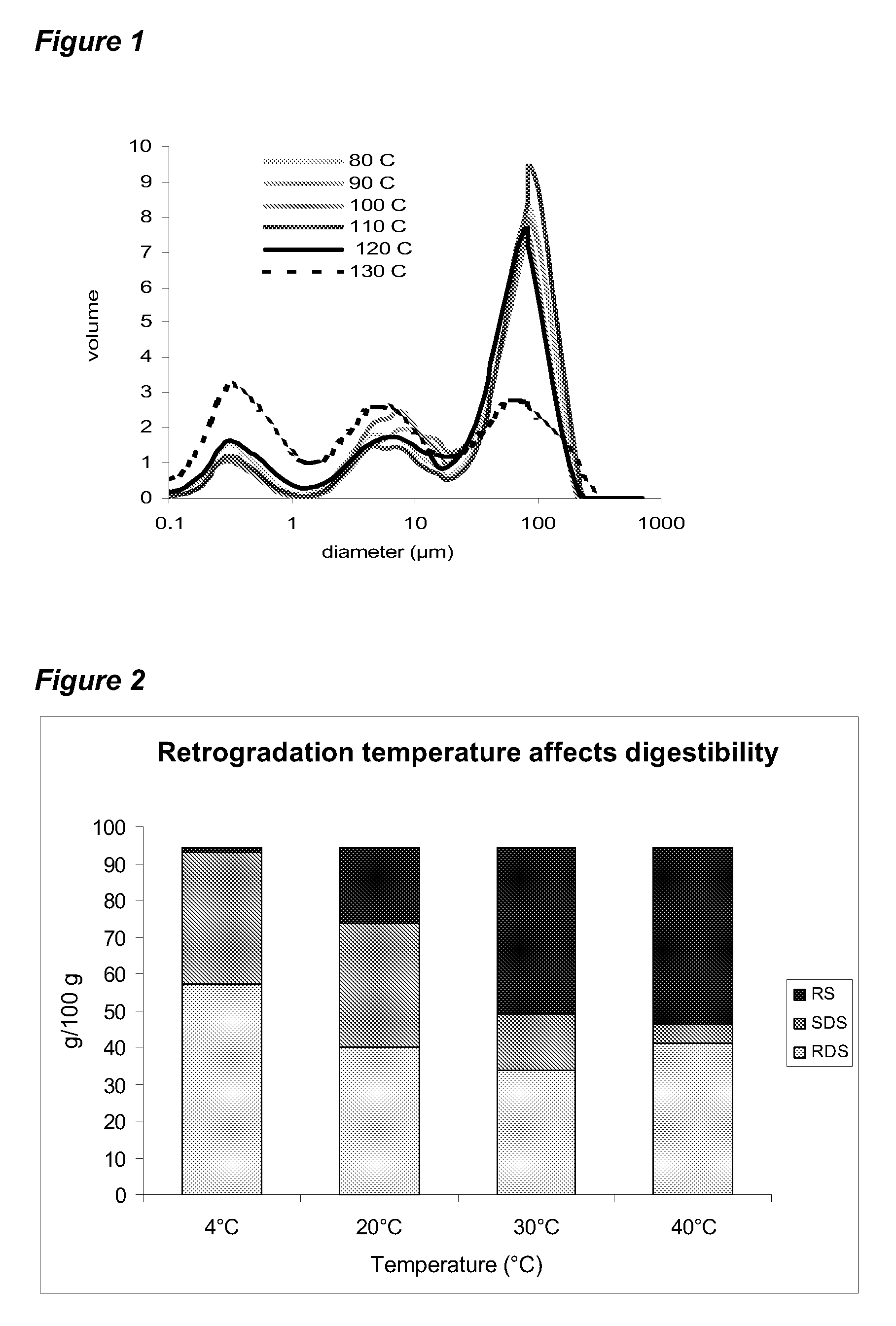

Process for producing slowly digestible starch

InactiveUS20100086668A1Provide quicklyVast supplyFood ingredient functionsFood preparationDigestible starchGlucose polymers

A sterilised food product containing starch, the starch having: (a) an amylose content of at least 60 wt. %; (b) a median particle size of between 1 and 15 &mgr;m, at least 90 wt. % of the starch particles having a particle diameter of less than 50 &mgr;m; and (c) a non-digestible starch content of less than 50 wt. %; and (d) a slowly digestible starch content of 15-75 wt. %. The product is obtained by heating and rapidly cooling the starch product and has a high slowly digestible starch content. It is suitable for use in the treatment of diabetes, obesitas, insulin resistance, or for postprandial glucose response.

Owner:NUTRICIA

Process for producing slowly digestible starch

InactiveUS8642110B2Provide quicklyVast supplyFood ingredient functionsFood preparationDigestible starchGlucose polymers

Owner:NV NUTRICIA

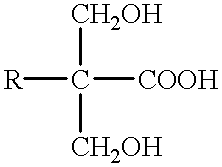

Terminal unsaturated, glycidol-based macromonomers, polymers obtainable therefrom, preparation and use

InactiveUS20120165414A1Lower levelProportion of secondary reactions and by-products should be very lowCosmetic preparationsOrganic compound preparationProtonationEthylene oxide

Process for preparing a macromonomer, in which a starting compound H2C═CR1—C6H4-s(R4)s—R3—OH or H2C═CR2—CO—NH—R3—OH, where R1 and R2 are each H or a linear or branched alkyl radical having from 1 to 4 carbon atoms, R3 is a linear or branched alkylene, aralkylene radical which has from 1 to 20 carbon atoms and can contain one or more hydroxy groups and the radicals R4 are each, independently of one another, a linear or branched alkyl, aralkyl, alkoxy or aralkoxy radical having from 1 to 20 carbon atoms and s=0-4, is, after partial deprotonation, reacted with at least one hydroxy-functional oxirane compound in the presence of an inhibitor of free-radical polymerization with opening of the oxirane ring, where the molar ratio of the molar amounts used n(starting compound):n(oxirane compound) is in the range from 1:100 to 1:1.Macromonomers which can be obtained by the process, polymers which can be obtained therefrom and their use as additives in coating compositions, plastics and cosmetics.

Owner:BYK CHEM GMBH

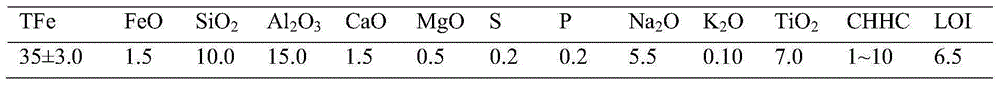

Iron ore pellet iron-rich composite bonder and preparation method and application thereof

ActiveCN104988308AImprove iron gradeReduce manufacturing costCarboxymethyl celluloseCompressive strength

The invention provides an iron ore pellet iron-rich composite bonder and a preparation method and application thereof. The iron ore pellet iron-rich composite bonder comprises iron mud and a tackifier with the mass ratio being 100:1-10. The tackifier is carboxymethyl cellulose. The total iron content in the iron-rich composite bonder is 35-40wt%, and the (SiO2+Al2O3) content is smaller than or equal to 25 wt%. According to the iron-rich composite bonder, the double bonding function of sodium silicate in the iron mud and the tackifier is used for replacing the bonding function of bentonite on iron ore pellets, meanwhile, the (SiO2+Al2O3) content can be reduced, the balling performance of iron ore powder is improved, the falling strength and the comprehensive strength of green balls are improved, and the purpose of improving the quality of finished product balls is achieved. Besides, the total cost of the bonder can be greatly reduced, and meanwhile, the environmental protection problem of the iron mud is solved.

Owner:北京新佰奥科技有限公司

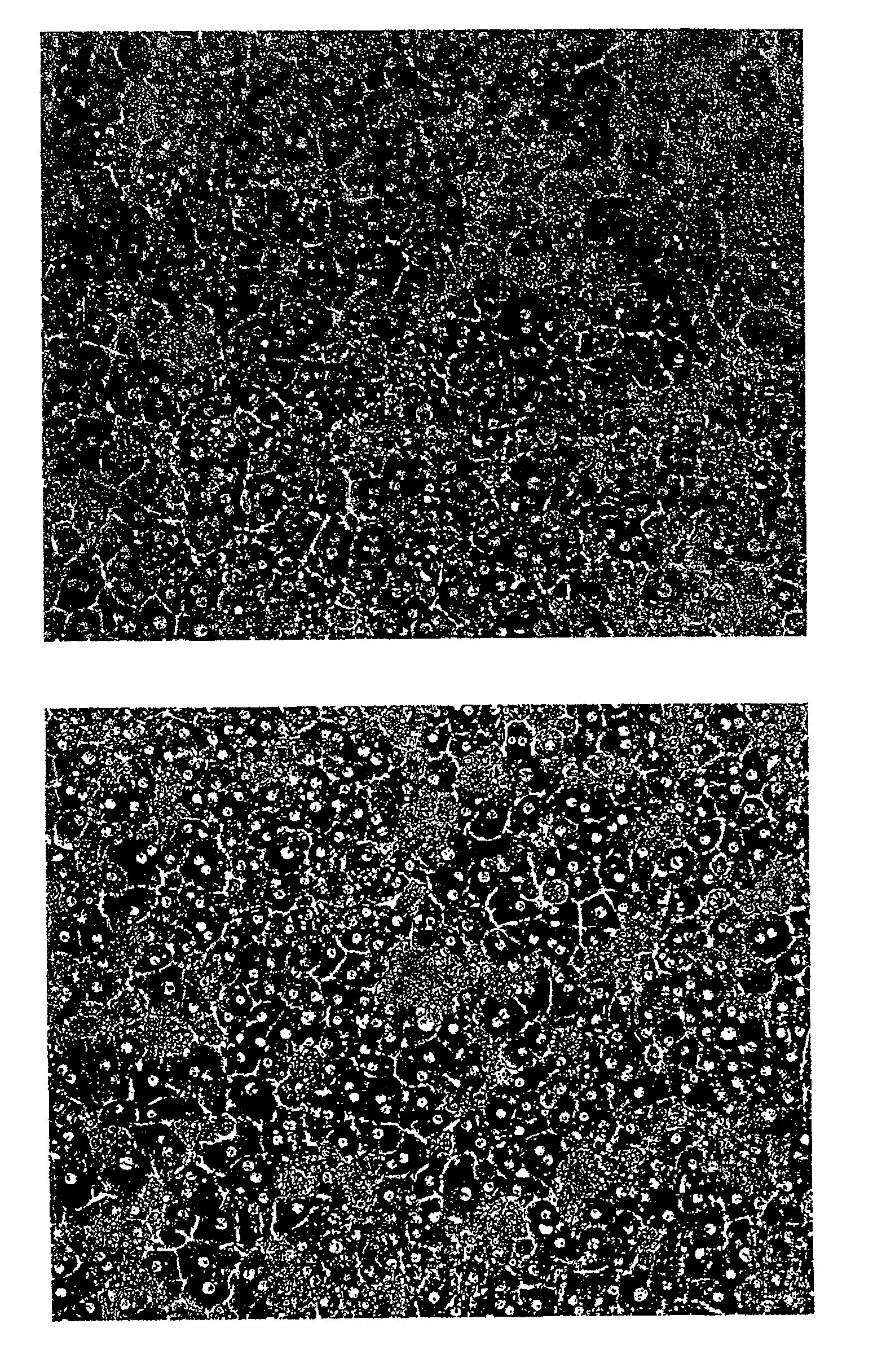

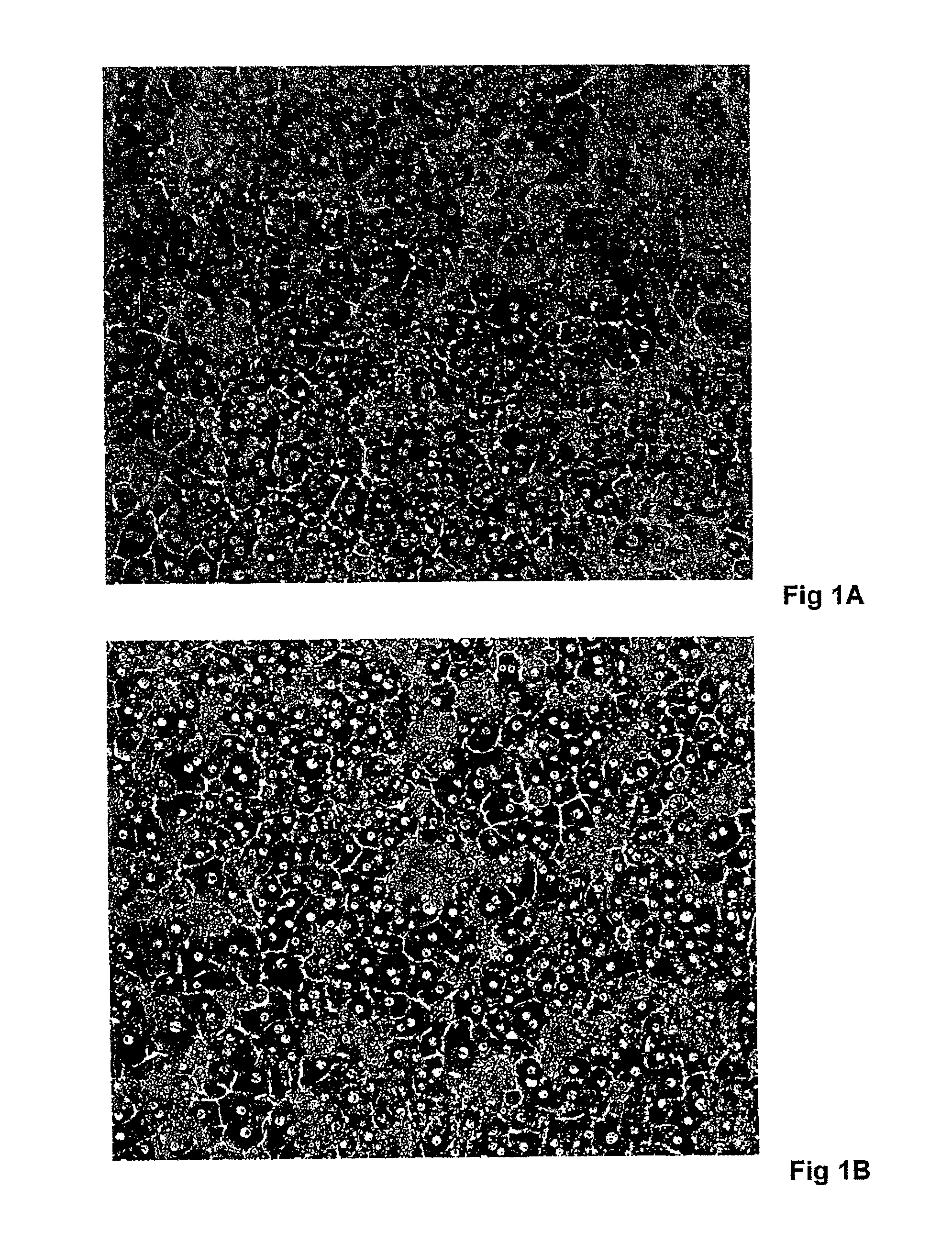

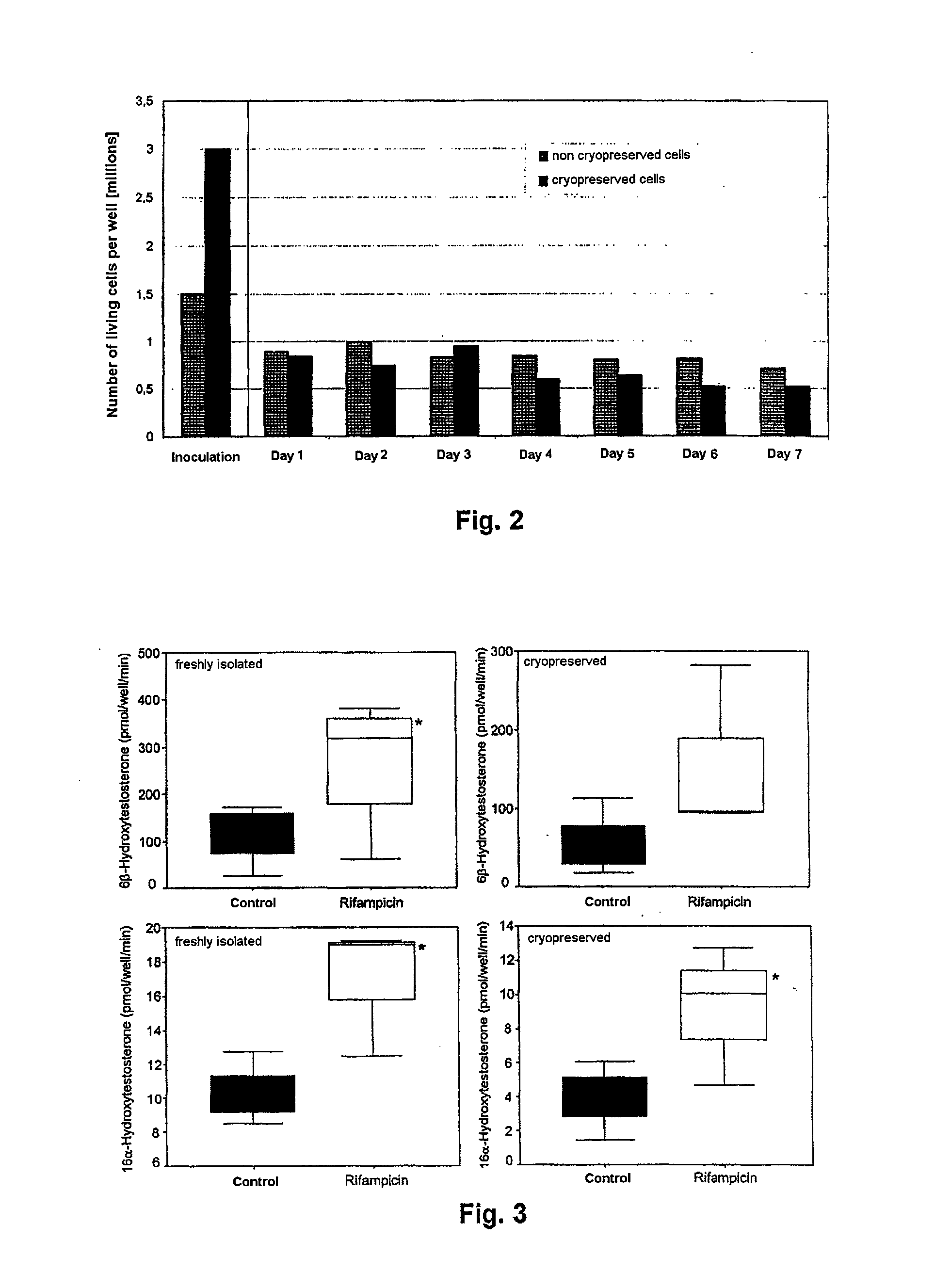

Cryopreservation of Hepatocytes

InactiveUS20080280357A1High vitality rateProportion of nonvital and/or nonadherent cells is very lowVertebrate cellsDead animal preservationCryopreservationBiology

The invention relates to processes for the preparation of liver cells for cryopreservation, processes for cryopreservation of isolated liver cells and processes for the preparation of a culture of cryopreserved isolated liver cells.

Owner:CYTONET

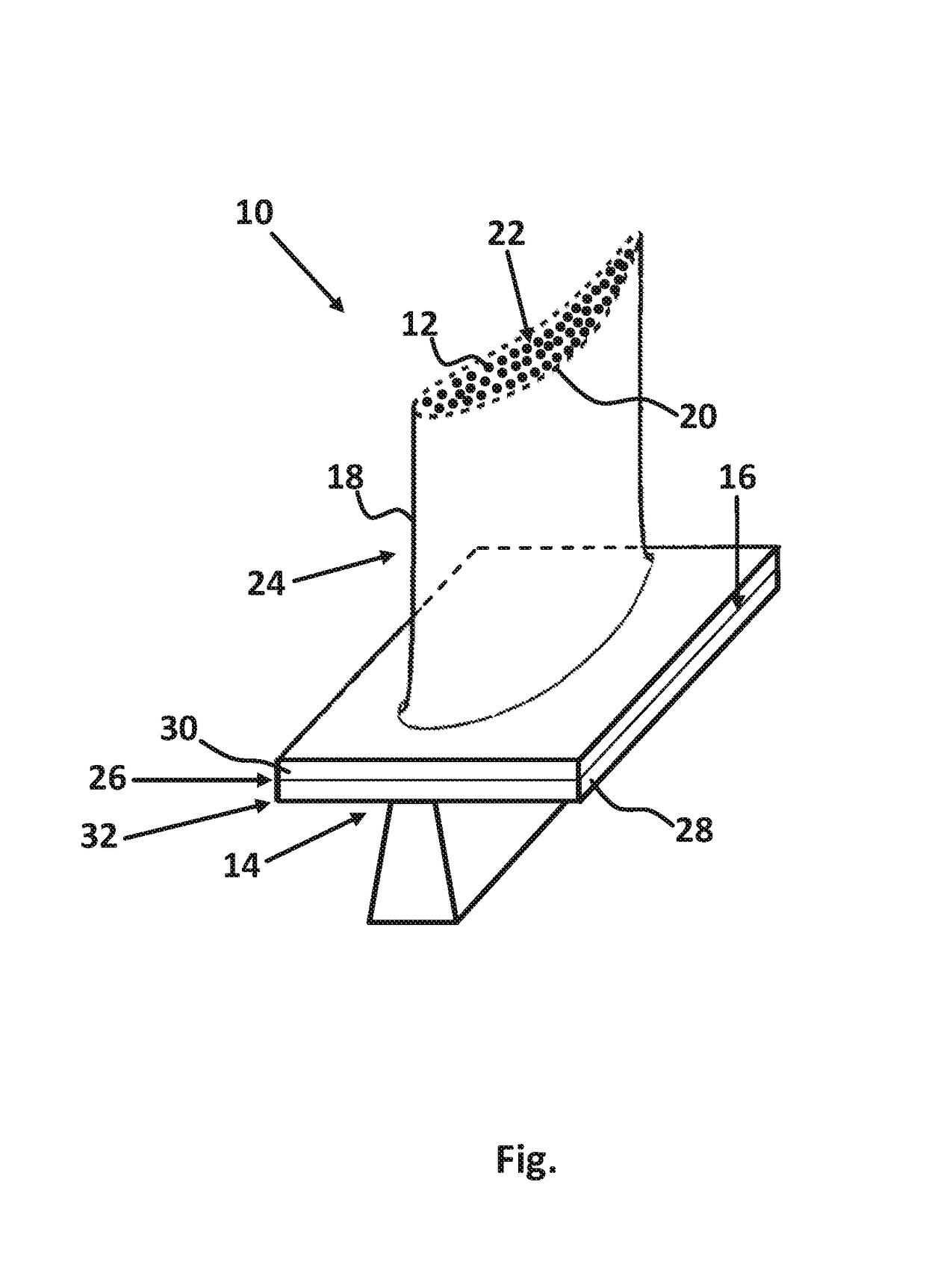

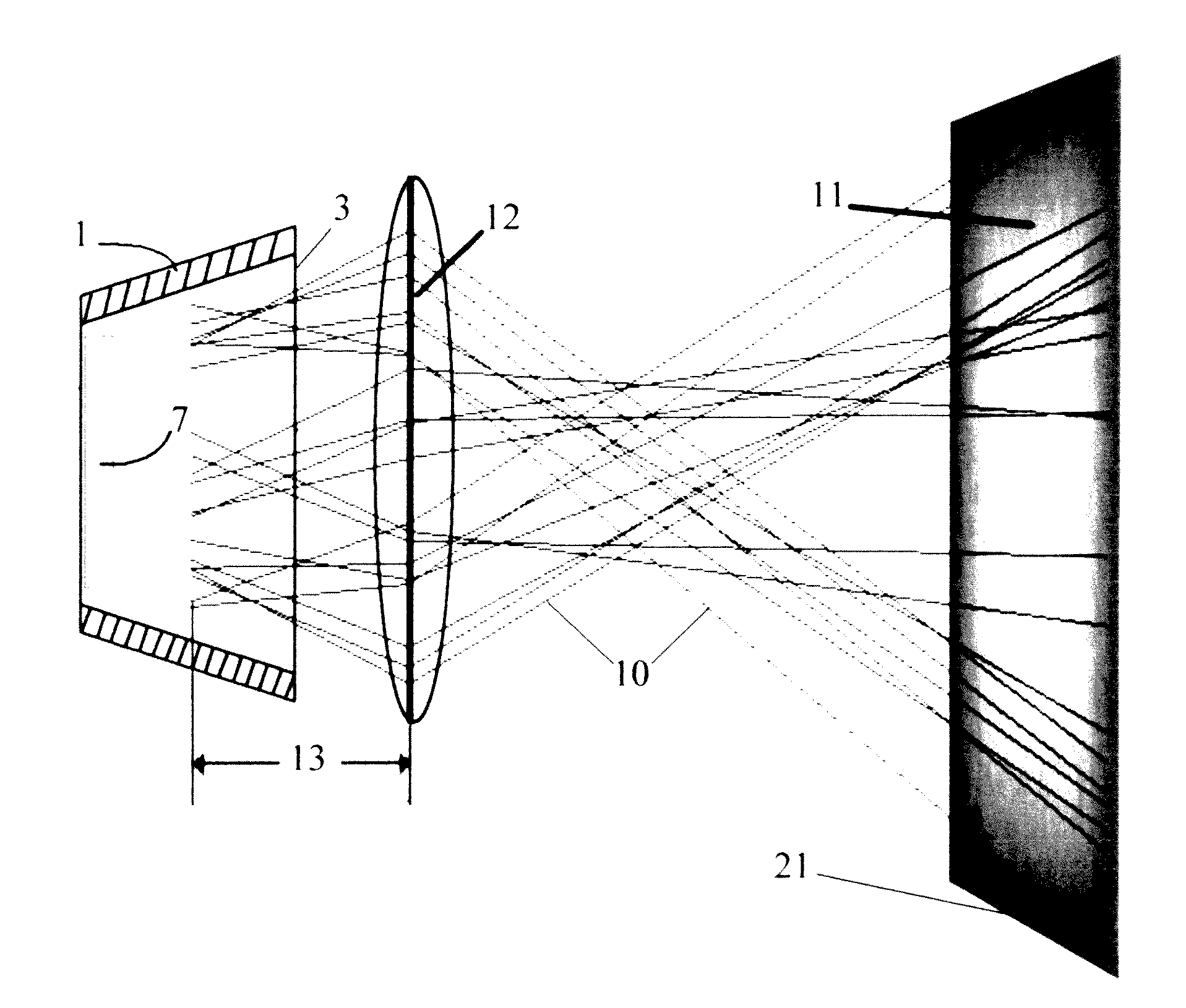

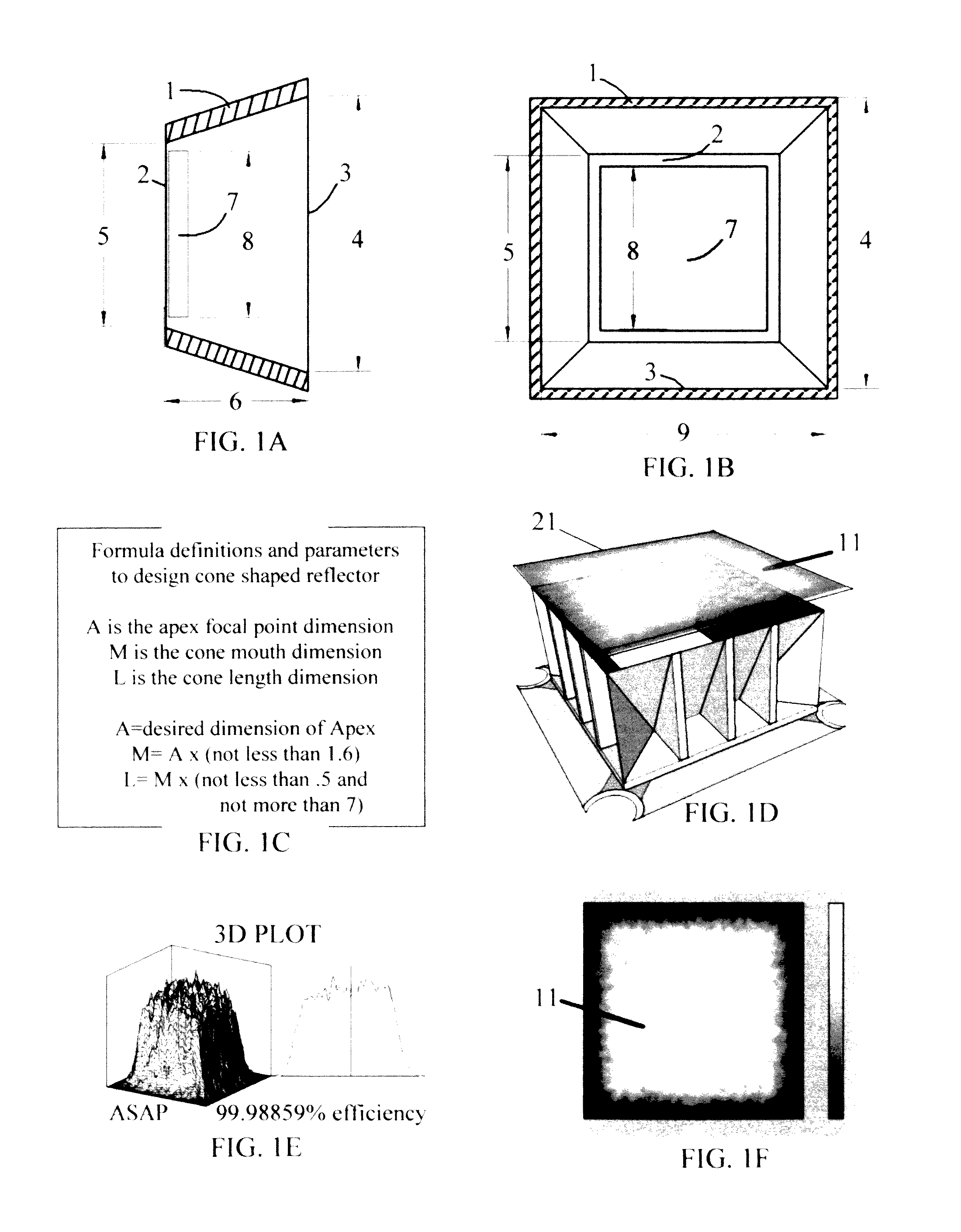

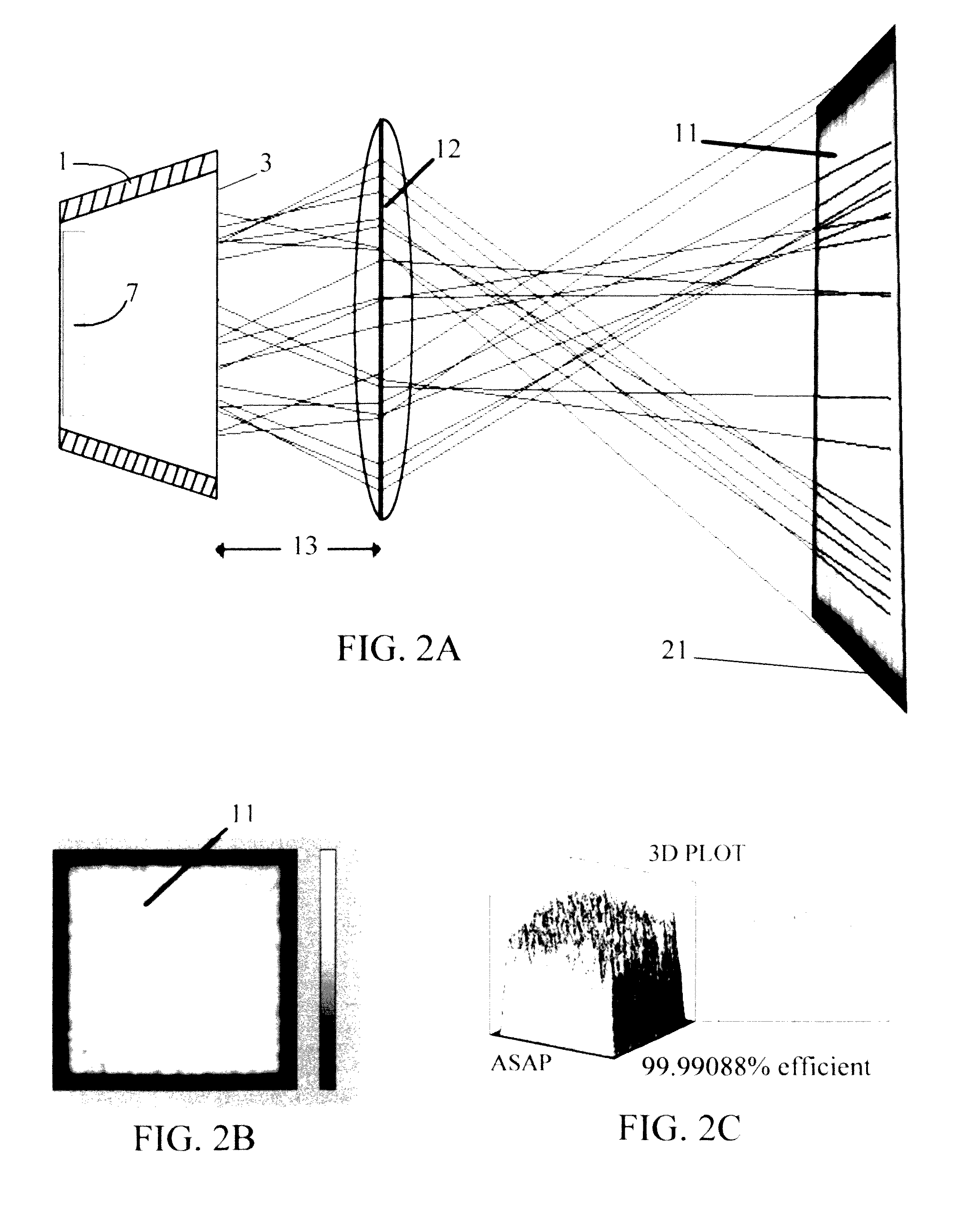

Vortex light projection system, LED lensless primary optics system, and perfectly random LED color mixing system

ActiveUS9512978B1Low proportionImprove cooling effectPoint-like light sourceLighting heating/cooling arrangementsLight beamProjection system

An improved primary optics light projection system comprising a cone shaped reflector designed within specified mathematical parameters and a light source placed near the apex focal point cross sectional area of said reflector is disclosed for projecting a vortex of light rays with a precise shape and an even beam field containing a maximum number of light rays produced by a light source having a small or large diameter or cross section. A reflector near the base of the light source and perpendicular to the cone shaped reflector and one or more lens may be included to increase efficiency. The cone shaped reflector may be made in various cross sectional shapes providing means for using light sources with a square, rectangular, round, oval, or unconventional shape allowing the use of high efficiency light sources such as, but not limited to, light emitting diodes, often used in clusters of multiple LEDs.

Owner:WIMBERLY RANDAL L

Coated printing paper

InactiveUS20090162641A1Good print glossResistanceNon-fibrous pulp additionLayered productsAdhesiveHazardous substance

The present invention aims to provide coated printing paper having good printing quality combined with the property of decomposing hazardous substances upon exposure to light and resistance to fading.Coated printing paper comprising a coating layer containing a pigment and an inorganic adhesive and an organic adhesive on a base paper, wherein the coating layer contains 1-30 parts by weight of titanium dioxide having an average secondary particle diameter of 300-2000 nm per 100 parts by weight of the pigment and the coated paper has a PPS roughness of 0.5-5.0 μm.

Owner:NIPPON PAPER IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com