Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

37results about How to "Easily oxidizable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thermally stable jet prepared from highly paraffinic distillate fuel component and conventional distillate fuel component

InactiveUS6846402B2Improve stabilityReduced deposit formationLiquid organic insulatorsHydrocarbon purification/separationTurbinePetroleum

A stable distillate fuel blend useful as a fuel or as a blending component of a fuel that is suitable for use in turbine engine, said fuel blend prepared from at least one highly paraffinic distillate fuel component having low to moderate branching and at least one conventional petroleum-derived distillate fuel component and a process for preparing same involving the blending of at least two components having antagonistic properties with respect to one another.

Owner:CHEVROU USA INC

Encapsulation of readily oxidizable components

ActiveUS20070098853A1Prevent oxidationAvoids possible deleterious interactionDough treatmentFatty substance preservation using additivesControlled releasePlasticizer

A stabilized emulsion is employed to produce shelf stable, controlled release, discrete, solid particles or pellets which contain an encapsulated and / or embedded component, such as a readily oxidizable component, such as omega-3 fatty acids. An oil encapsulant component which contains an active, sensitive encapsulant, dissolved and / or dispersed in an oil is admixed with an aqueous component and a film-forming component, such as a protein, to form an emulsion. The emulsion is admixed with a matrix material for obtaining a formable mixture or dough. An acidic antioxidant for prevention of oxidation of the active, sensitive encapsulant, and a plasticizer which solubilizes the acidic antioxidant are included in the matrix material which encapsulates film-coated oil droplets containing the readily oxidizable component. The plasticizer, such as glycerol, provides mobility for the acidic antioxidant within the matrix material of the pellets for reaction with any ambient oxygen and malodorous amines.

Owner:GENERAL MILLS INC

Thermally stable blends of highly paraffinic distillate fuel component with conventional distillate fuel component

InactiveUS20060049080A1Minimize deposit formationHigh aromatic contentLiquid organic insulatorsHydrocarbon purification/separationProcess engineeringInternal combustion engine

A stable distillate fuel blend useful as a fuel or as a blending component of a fuel that is suitable for use in an internal combustion engine, said fuel blend prepared from at least one highly paraffinic distillate fuel component and at least one highly aromatic petroleum-derived distillate fuel component and a process for preparing same involving the blending of at least two components having antagonistic properties with respect to one another.

Owner:CHEVROU USA INC

Encapsulation of sensitive components using pre-emulsification

ActiveUS7431986B2Increase stabilityIncrease bioavailabilityPowder deliveryLiquid surface applicatorsWater contentOmega 3 fatty acid

A stabilized emulsion is employed to produce shelf stable, controlled release, discrete, solid particles or pellets which contain an encapsulated and / or embedded component, such as a readily oxidizable component, such as omega-3 fatty acids. An oil encapsulant component which contains an active, sensitive encapsulant, dissolved and / or dispersed in an oil is admixed with an aqueous component and a film-forming component to form an emulsion. An antioxidant for prevention of oxidation of the active, sensitive encapsulant, and a film-softening component or plasticizer for the film-forming component may be included in the emulsion. The emulsion is stabilized by subjecting it to homogenization. The pellets are produced by first reducing the water content of the stabilized emulsion so that the film-forming component forms a film around the oil droplets and encapsulates the encapsulant. In embodiments of the invention, the water content of the homogenized emulsion may be reduced by spray-drying to produce a powder. In other embodiments of the invention, after homogenization, the water content of the emulsion may be reduced by admixing the emulsion with at least one matrix material to thereby encapsulate the film-coated oil droplets within the matrix material. After the water content of the emulsion is reduced, a protective coating is applied on the film-coated oil droplets to obtain pellets.

Owner:GENERAL MILLS INC

Oxygen scavenger composition

InactiveUS20060163534A1Large oxygen-absorbing abilitySmall sizeHydrogenOther chemical processesCalcium silicateContamination

The oxygen-absorbing composition of the invention comprises 100 parts by weight of a carrier and an easily oxidizable organic composition that is carried on the carrier in an amount exceeding 210 parts by weight. The carrier comprises a calcium silicate compound represented by the following formula: CaO.mSiO2.nH2O wherein m is a number from 1.6 to 6.5 and n is a positive number, and has crystal structures constituted by aggregates of curved plate crystals comprising gyrolite calcium silicate and amorphous silicon dioxide. Because of a high flowability, the oxygen-absorbing composition of the invention is excellent in the productivity of the oxygen-absorbing packages. In addition, because of a large oxygen absorption per unit volume, the oxygen-absorbing package can be made compact in its shape. The oxygen-absorbing package is not detected by a metal detector because the contamination with iron components as impurities can be prevented.

Owner:MITSUBISHI GAS CHEM CO INC

Encapsulation of readily oxidizable components

ActiveUS20110020520A1Prevent oxidationAvoids possible deleterious interactionEdible oils/fats ingredientsLiquid surface applicatorsControl releasePlasticizer

A stabilized emulsion is mixed with plasticizable matrix material to produce shelf stable, controlled release, discrete, solid particles or pellets which contain an encapsulated and / or embedded component, such as a readily oxidizable component, such as omega-3 fatty acids. An oil encapsulant component which contains an active, sensitive encapsulant, dissolved and / or dispersed in an oil is admixed with an aqueous component and a film-forming component, such as a protein, to form an emulsion. The emulsion is admixed with a matrix material for obtaining a formable mixture or dough. An acidic antioxidant for prevention of oxidation of the active, sensitive encapsulant, and a plasticizer which solubilizes the acidic antioxidant are included in the matrix material which encapsulates film-coated oil droplets containing the readily oxidizable component. The plasticizer, such as glycerol, provides mobility for the acidic antioxidant within the matrix material of the pellets for reaction with any ambient oxygen and malodorous amines.

Owner:GENERAL MILLS INC

Encapsulation of readily oxidizable components

ActiveUS7803414B2Prevent oxidationAvoids possible deleterious interactionDough treatmentFatty substance preservation using additivesControlled releaseAntioxidant

A stabilized emulsion is mixed with plasticizable matrix material to produce shelf stable, controlled release, discrete, solid particles or pellets which contain an encapsulated and / or embedded component, such as a readily oxidizable component, such as omega-3 fatty acids. An oil encapsulant component which contains an active, sensitive encapsulant, dissolved and / or dispersed in an oil is admixed with an aqueous component and a film-forming component, such as a protein, to form an emulsion. The emulsion is admixed with a matrix material for obtaining a formable mixture or dough. An acidic antioxidant for prevention of oxidation of the active, sensitive encapsulant, and a plasticizer which solubilizes the acidic antioxidant are included in the matrix material which encapsulates film-coated oil droplets containing the readily oxidizable component. The plasticizer, such as glycerol, provides mobility for the acidic antioxidant within the matrix material of the pellets for reaction with any ambient oxygen and malodorous amines.

Owner:GENERAL MILLS INC

Encapsulation of readily oxidizable components

ActiveUS7803413B2Prevent oxidationAvoids possible deleterious interactionDough treatmentFatty substance preservation using additivesControlled releasePlasticizer

A stabilized emulsion is employed to produce shelf stable, controlled release, discrete, solid particles or pellets which contain an encapsulated and / or embedded component, such as a readily oxidizable component, such as omega-3 fatty acids. An oil encapsulant component which contains an active, sensitive encapsulant, dissolved and / or dispersed in an oil is admixed with an aqueous component and a film-forming component, such as a protein, to form an emulsion. The emulsion is admixed with a matrix material for obtaining a formable mixture or dough. An acidic antioxidant for prevention of oxidation of the active, sensitive encapsulant, and a plasticizer which solubilizes the acidic antioxidant are included in the matrix material which encapsulates film-coated oil droplets containing the readily oxidizable component. The plasticizer, such as glycerol, provides mobility for the acidic antioxidant within the matrix material of the pellets for reaction with any ambient oxygen and malodorous amines.

Owner:GENERAL MILLS INC

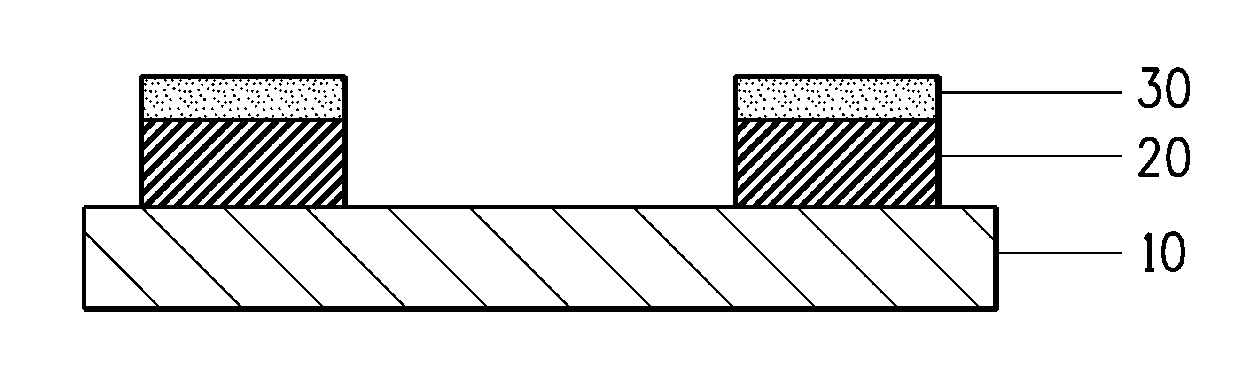

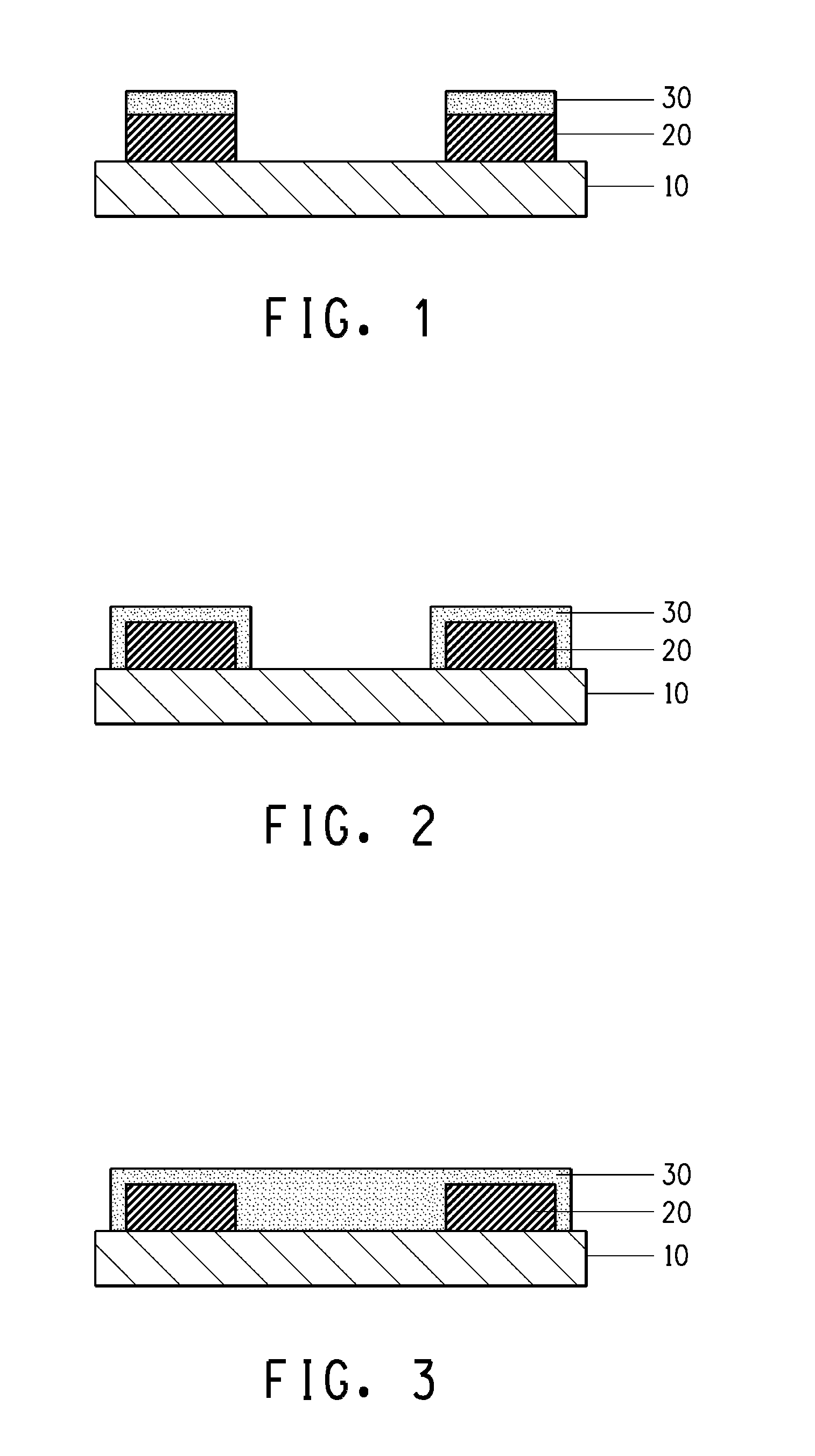

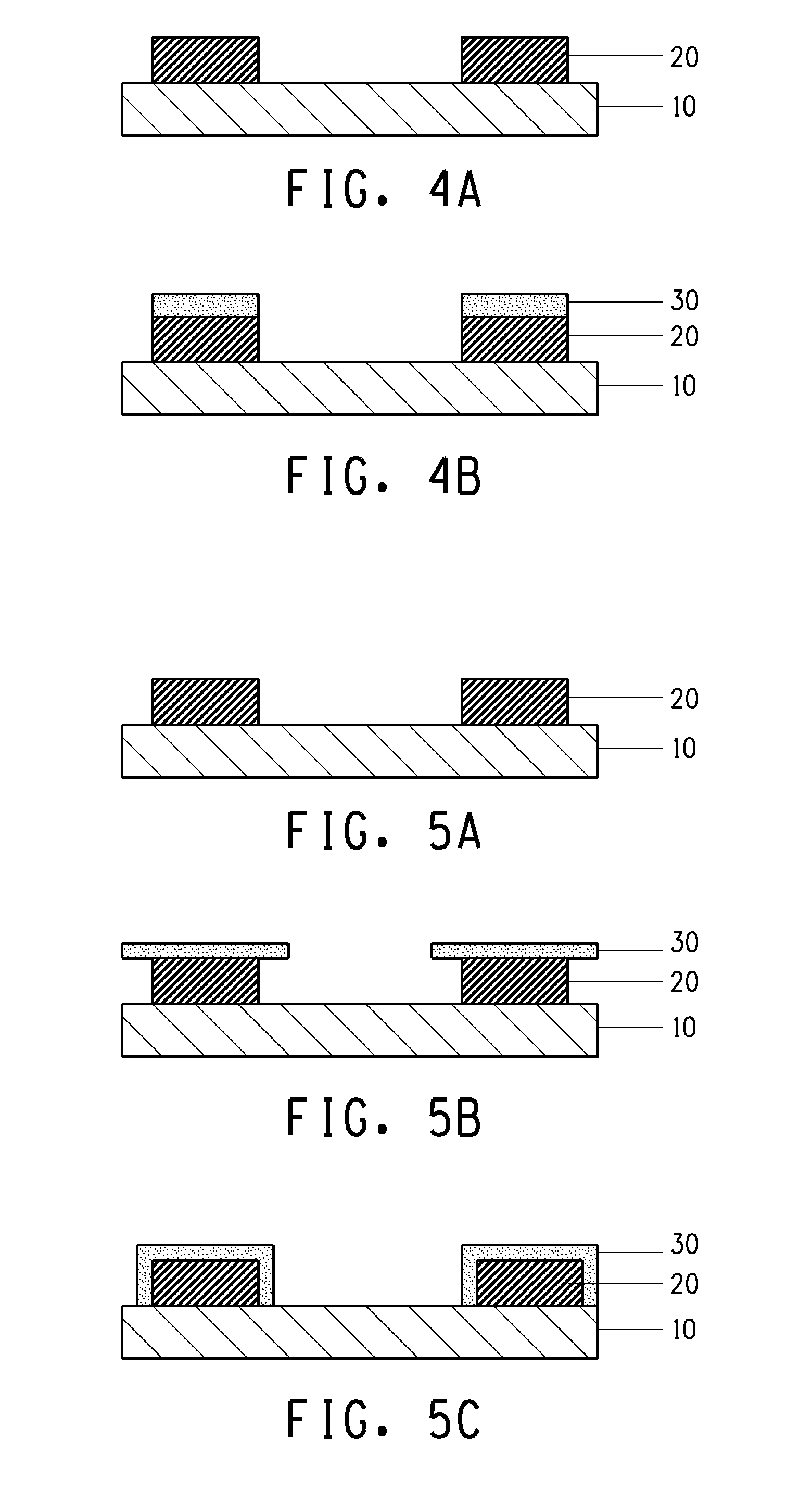

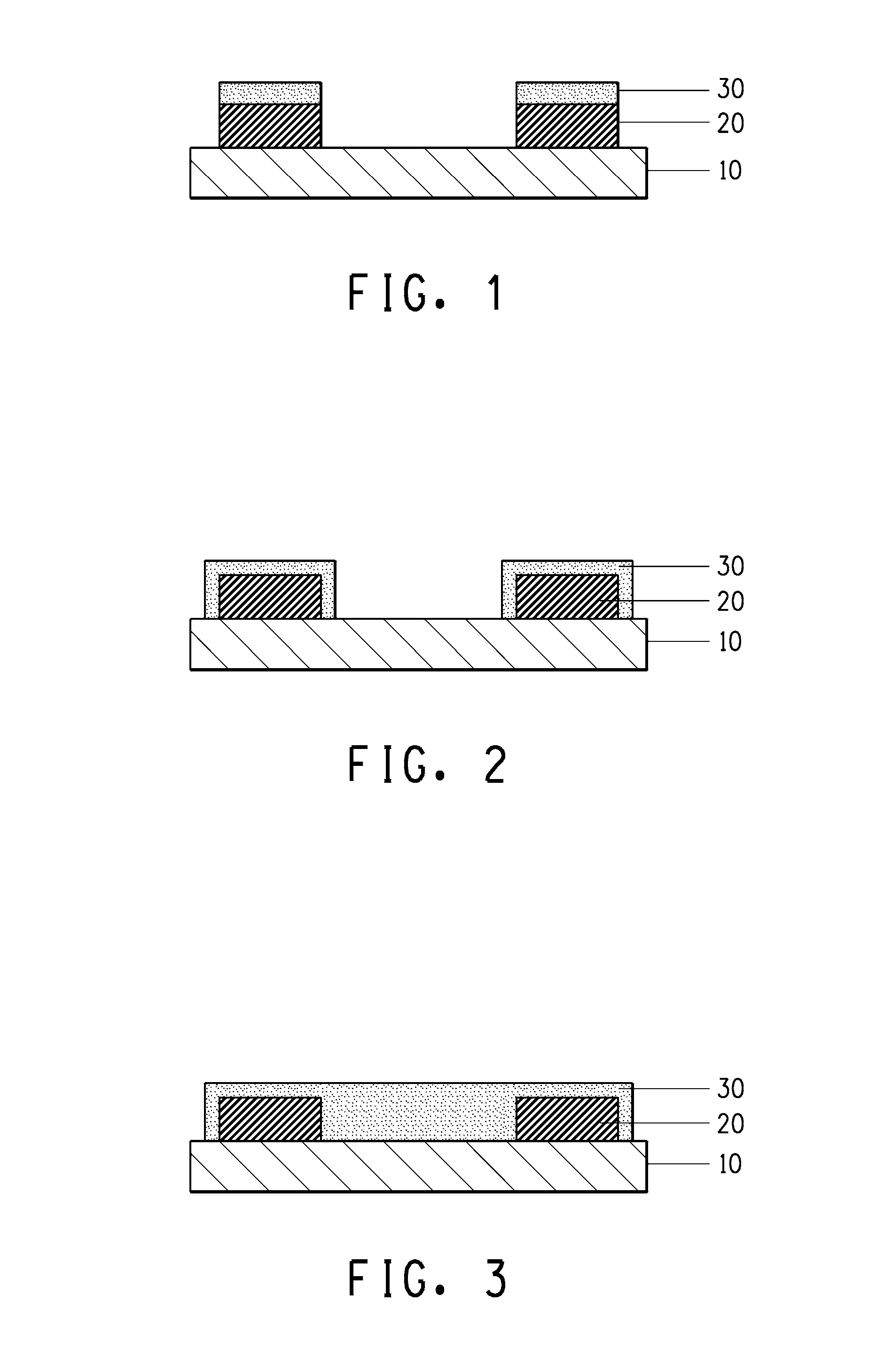

Electrode and method for manufacturing the same

InactiveUS20110083874A1Low costEasily oxidizableElectric discharge tubesPhotomechanical apparatusAlloyOptoelectronics

Disclosed is an electrode, including a conductive layer containing a conductive component selected from the group consisting of copper, nickel, iron, cobalt, titanium, lead, aluminum, tin, and alloys comprising one of these metals as the principal ingredient thereof, and an oxidation protection layer containing boron oxide, said oxidation protection layer covering the top surface of the conductive layer, or covering both the top surface and the sides of the conductive layer, or covering all locations where the conductive layer has been formed; the electrode being formed by air firing the conductive layer and the oxidation protection layer simultaneously.

Owner:EI DU PONT DE NEMOURS & CO

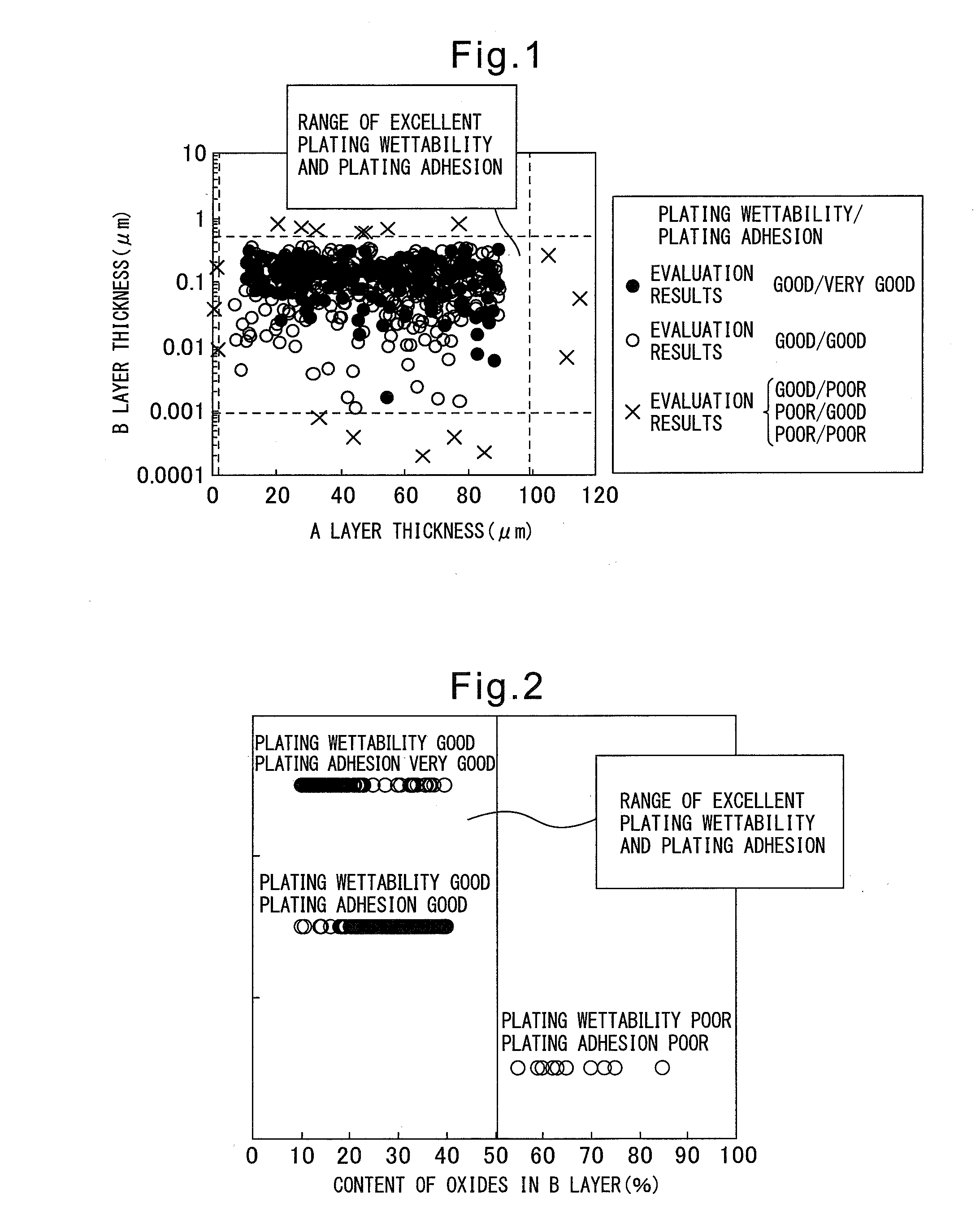

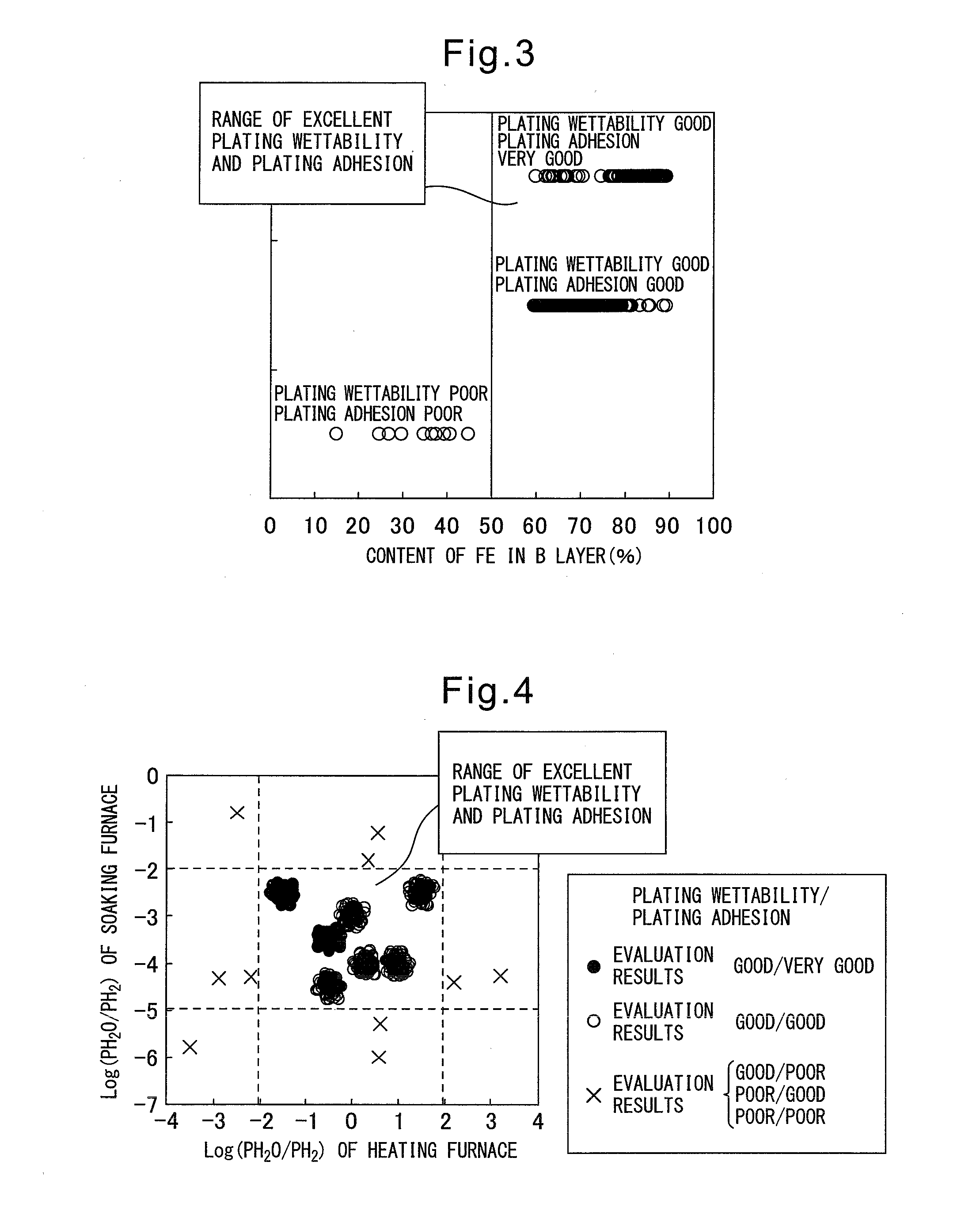

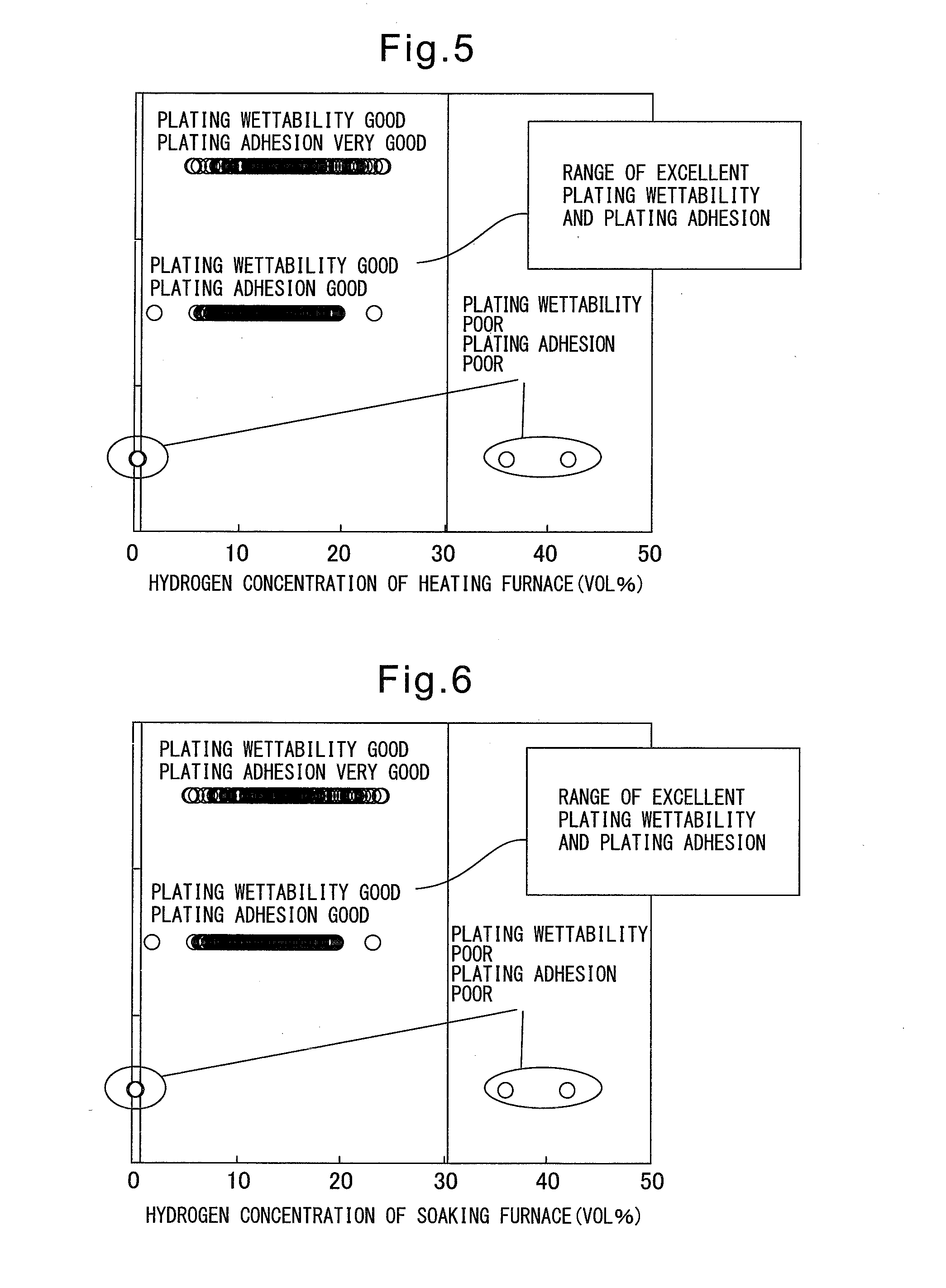

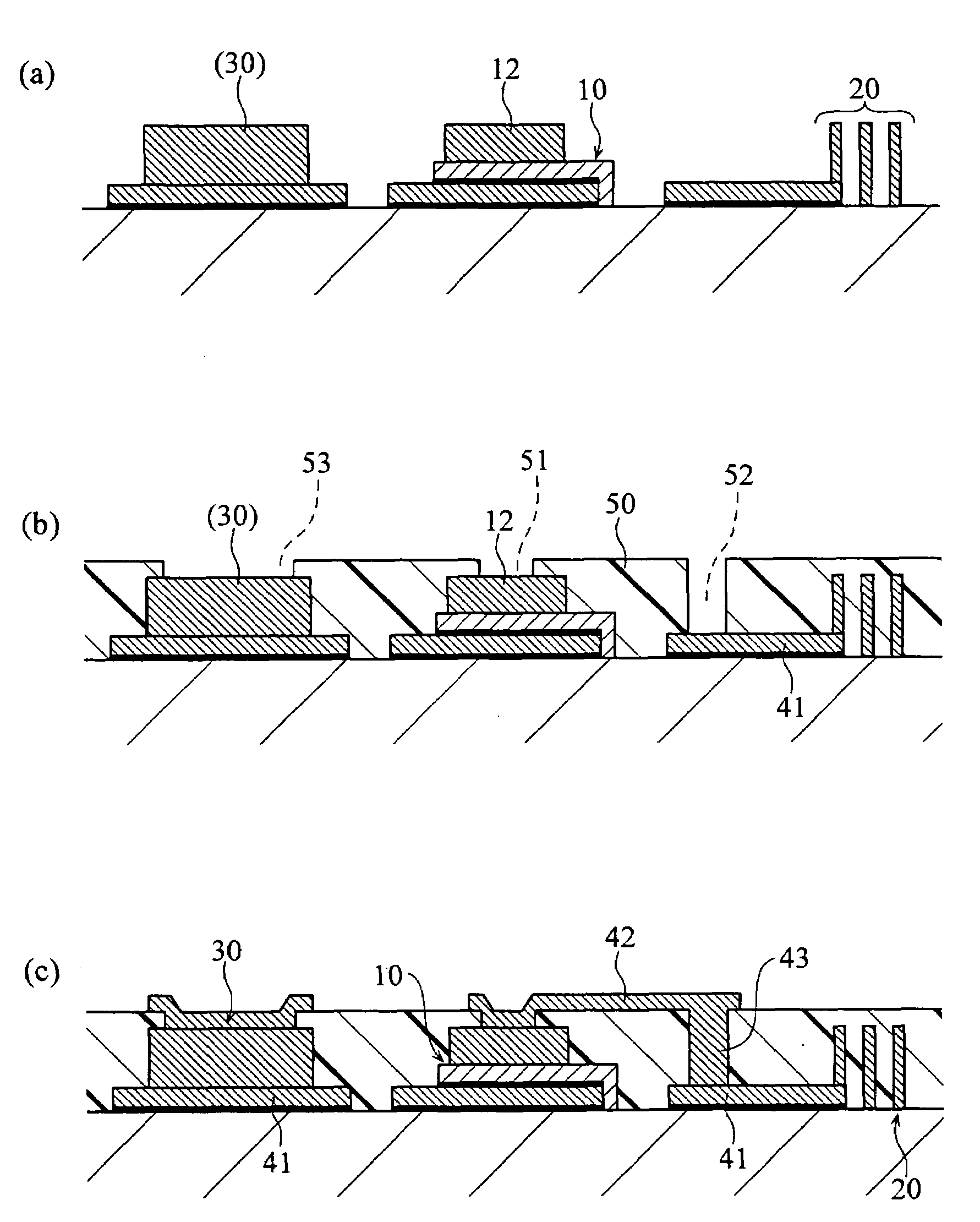

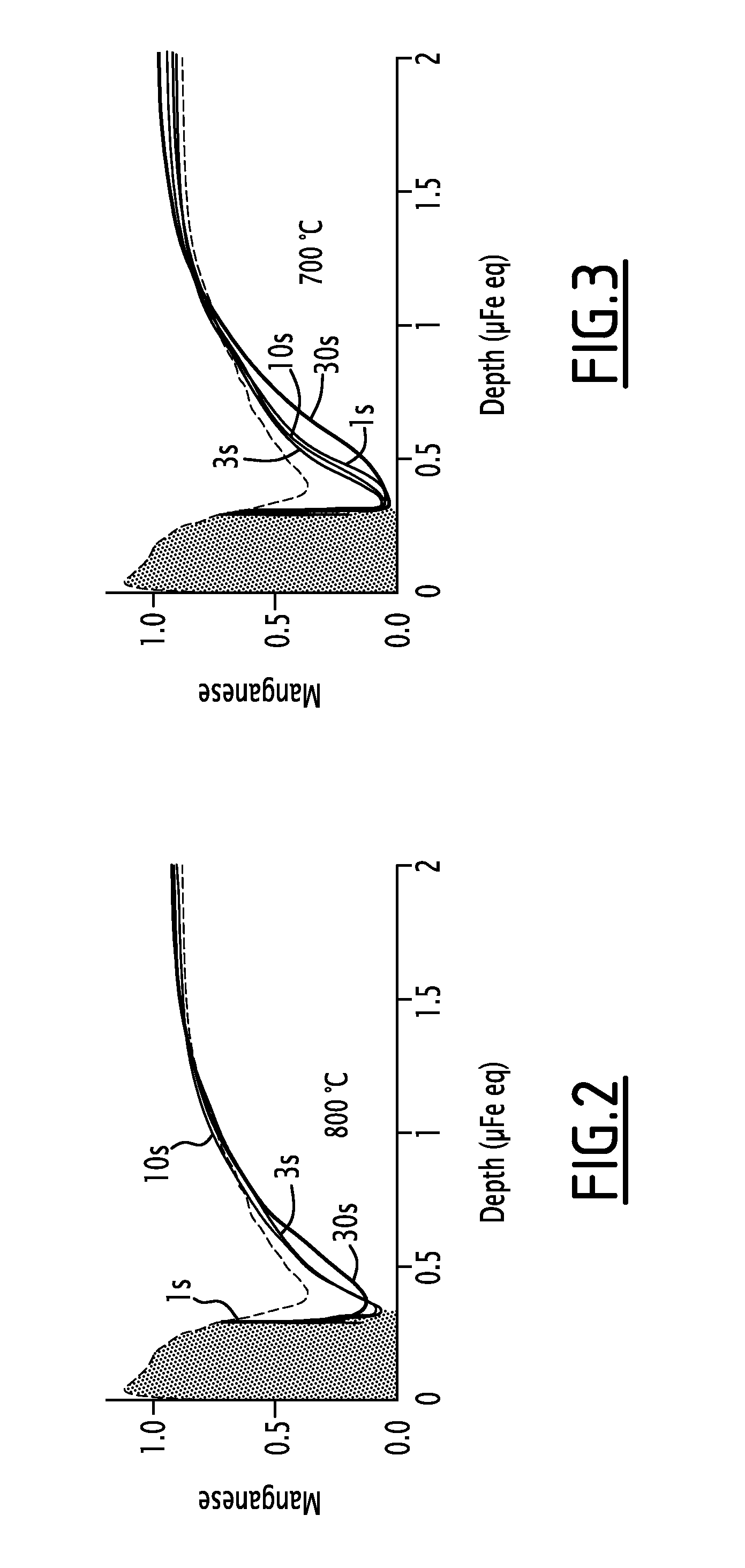

Steel sheet provided with hot dip galvanized layer excellent in plating wettability and plating adhesion and method of production of same

ActiveUS20140234656A1Improve adhesionImprove wettabilityHot-dipping/immersion processesFurnace typesMaterials scienceHot-dip galvanization

A steel sheet which uses steel sheet which contains the easily oxidizable elements Si and Mn as a base material and which is provided with a hot dip galvanized layer which is excellent in plating wettability and plating adhesion and a method of production of the same are provided. A hot dip galvanized steel sheet which is comprised of a steel sheet having a hot dip galvanized layer A on the surface of the steel sheet, characterized by having the following B layer right under the steel sheet surface and in the steel sheet:B layer: Layer which has thickness of 0.001 μm to 0.5 μm, which contains, based on mass of the B layer, one or more of Fe, Si, Mn, P, S, and Al oxides in a total of less than 50 mass %, which contains C, Si, Mn, P, S, and Al not in oxides in C: less than 0.05 mass %, Si: less than 0.1 mass %, Mn: less than 0.5 mass %, P: less than 0.001 mass %, S: less than 0.001 mass %, and Al: less than 0.005 mass % and which contains Fe not in oxides in 50 mass % or more.

Owner:NIPPON STEEL CORP

Thermally stable blends of highly paraffinic distillate fuel component with conventional distillate fuel component

InactiveUS7033484B2Minimize deposit formationHigh aromatic contentLiquid organic insulatorsHydrocarbon purification/separationEngineeringInternal combustion engine

A stable distillate fuel blend useful as a fuel or as a blending component of a fuel that is suitable for use in an internal combustion engine, said fuel blend prepared from at least one highly paraffinic distillate fuel component and at least one highly aromatic petroleum-derived distillate fuel component and a process for preparing same involving the blending of at least two components having antagonistic properties with respect to one another.

Owner:CHEVROU USA INC

Fruit products containing omega-3 fatty acids

InactiveUS20100021607A1Prevent oxidationProvide mobilityFood ingredient as antioxidantFood ingredient as viscosity modification agentPolyolAntioxidant

A fruit product containing a readily oxidizable polyunsaturated fatty acid, such as omega-3 fatty acids, may be prepared by cooking a fruit base composition to obtain a cooked fruit base composition, cooling the cooked fruit base composition, admixing the fruit base composition with an oil which contains at least one readily oxidizable polyunsaturated fatty acid. Additionally, an acidic antioxidant for preventing oxidation of the at least one polyunsaturated fatty acid; and at least one polyol for providing mobility for the acidic antioxidant is admixed with the cooked fruit base composition to obtain an at least substantially homogeneous mixture, which may be formed into pieces.

Owner:GENERAL MILLS INC

Electronic component

InactiveUS20070158848A1Improve pressure resistanceSolve the lack of adhesionThin/thick film capacitorFixed capacitor electrodesOptoelectronicsElectronic component

An electronic component includes a substrate, and a capacitor unit on the substrate. The capacitor unit has a laminate structure including a first electrode layer provided on the substrate, a second electrode layer opposed to the first electrode layer, and a dielectric layer disposed between the first and the second electrode layers. The first electrode layer has a multilayer structure including an adhesion metal layer joined to the dielectric layer. The adhesion metal layer is provided with an oxide coating on a side of the dielectric layer.

Owner:FUJITSU LTD

Thermally stable jet prepared from highly paraffinic distillate fuel component and conventional distillate fuel component

InactiveUS20070278133A1Reduced deposit formationEasily oxidizableLiquid organic insulatorsLiquid carbonaceous fuelsProcess engineeringTurbine

Owner:CHEVROU USA INC

Devices containing lipid emulsions

InactiveUS20080031826A1Easily oxidizablePrevent oxidationBiocideSugar food ingredientsLipid formationChemistry

The present invention relates to compositions and methods for the storage and consumption of a lipid emulsion. In particular, the present invention relates to the storage of an omega-3 lipid emulsion for consumption in a container under non-oxidizing conditions.

Owner:AKER BIOMARINE ASA

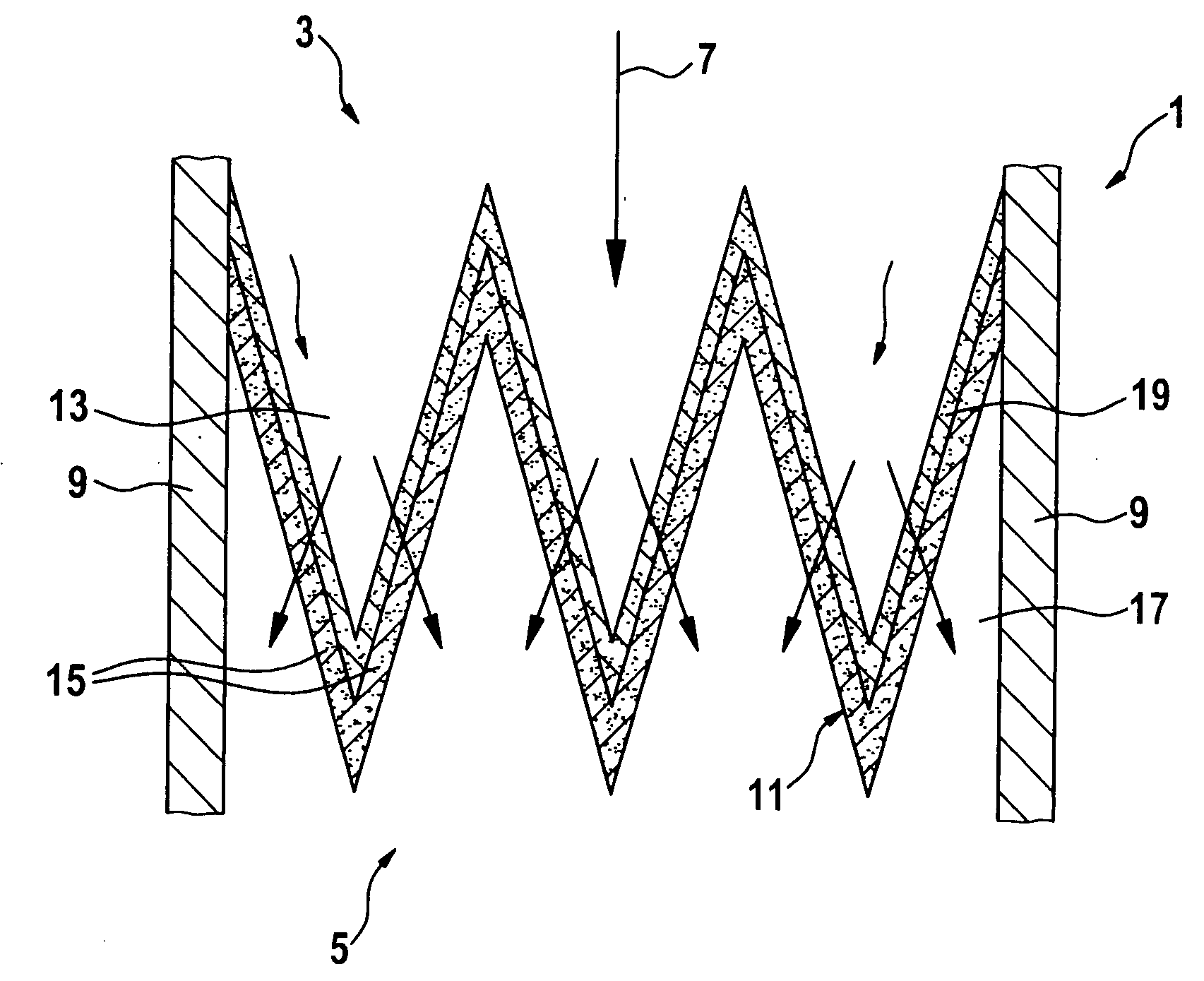

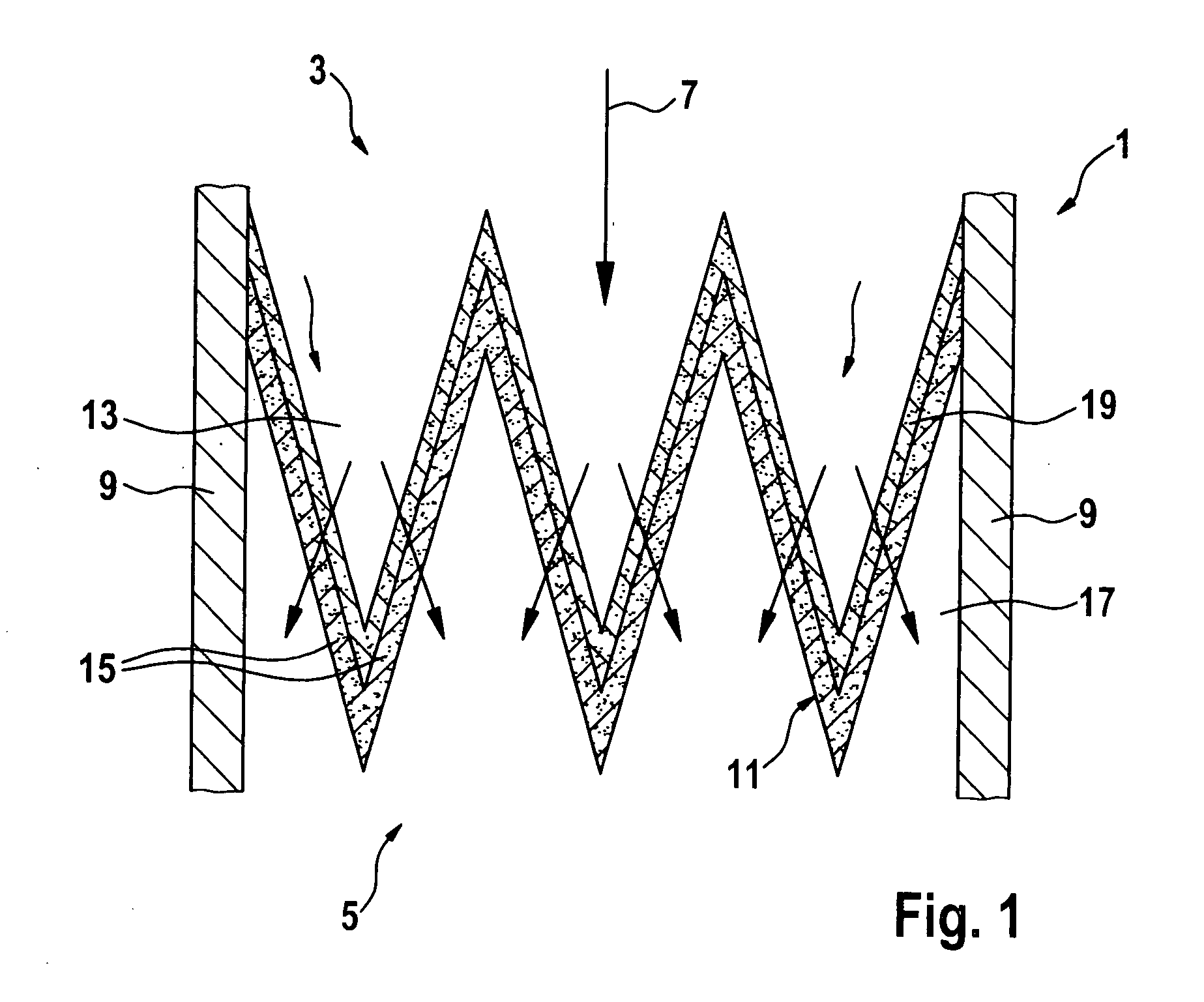

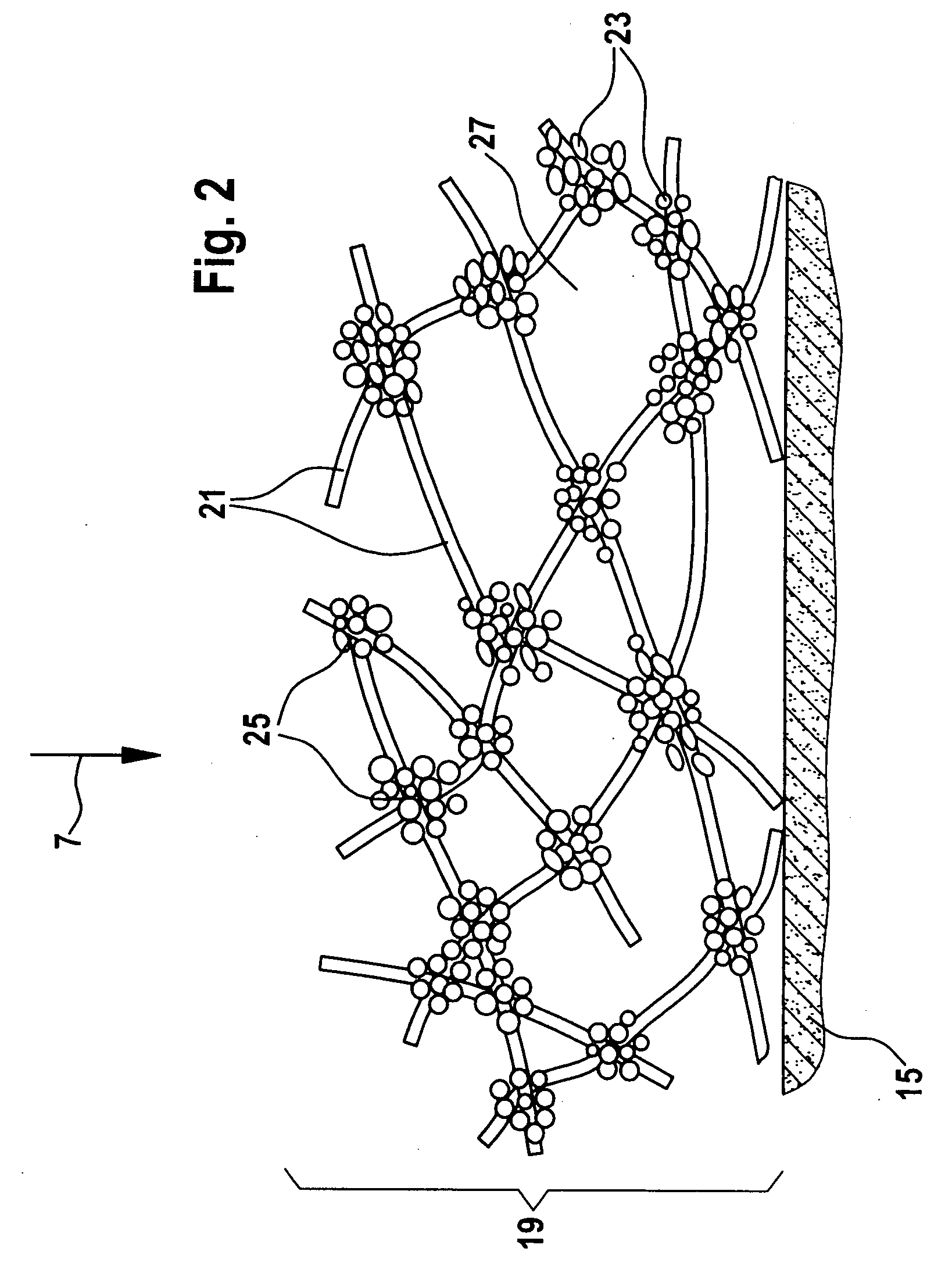

Filter for purifying gas mixtures and method for its manufacture

InactiveUS20070289270A1Increase capacityImprove mutual adhesionCombination devicesGas treatmentFiberParticulates

A filter for purifying gas mixtures containing particulates, in particular exhaust gases of internal combustion engines containing soot. The filter has a porous wall made of a filter base material through which the gas mixture to be purified flows. A surface coating of ceramic fibers is applied to the surface of the wall which is exposed to the flow of the gas mixture to be purified. The ceramic fibers are coated with nanoparticles. Furthermore, a method for manufacturing such a filter.

Owner:ROBERT BOSCH GMBH

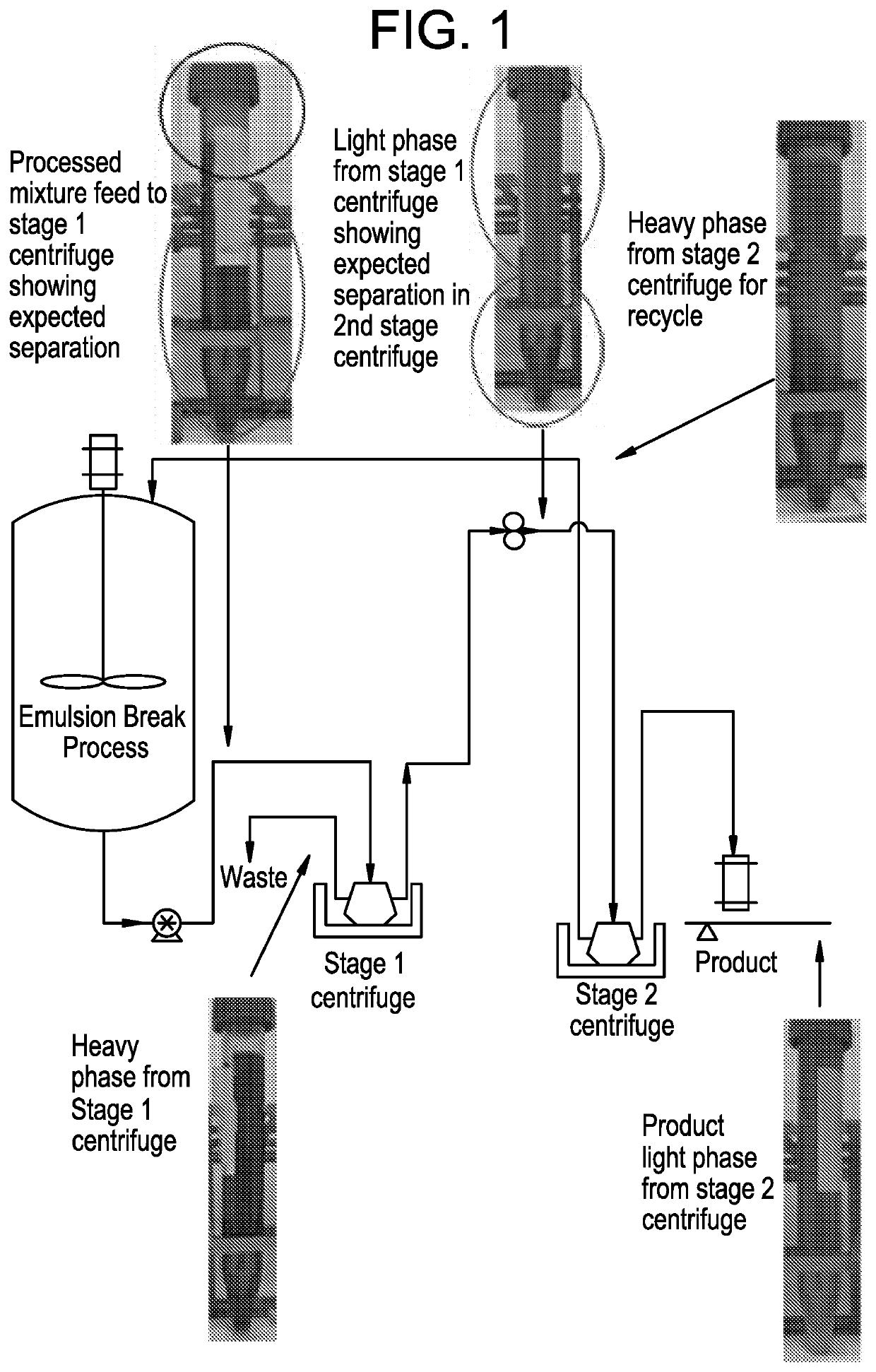

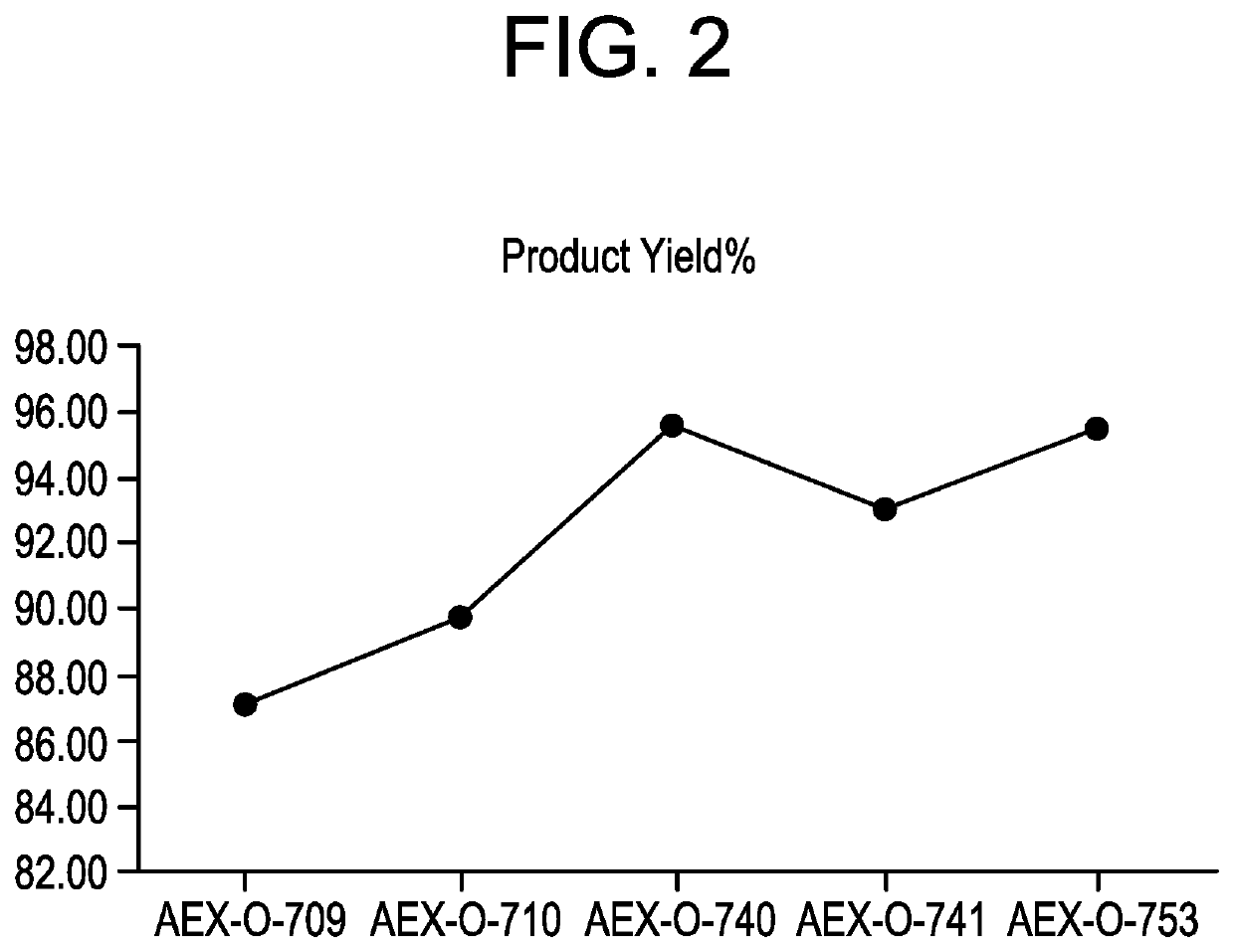

Double centrifugation process for nutritive oil purification

PendingUS20200362373A1Quality improvementLosing on oil yieldCentrifugal force sediment separationFermentationFermentation brothBiotechnology

This invention relates to a method of using a two-step serial centrifugation process in extracting nutritive oil from a fermentation broth, this novel method prevents oil yield losses while preserving product quality.

Owner:EVONIK OPERATIONS GMBH +1

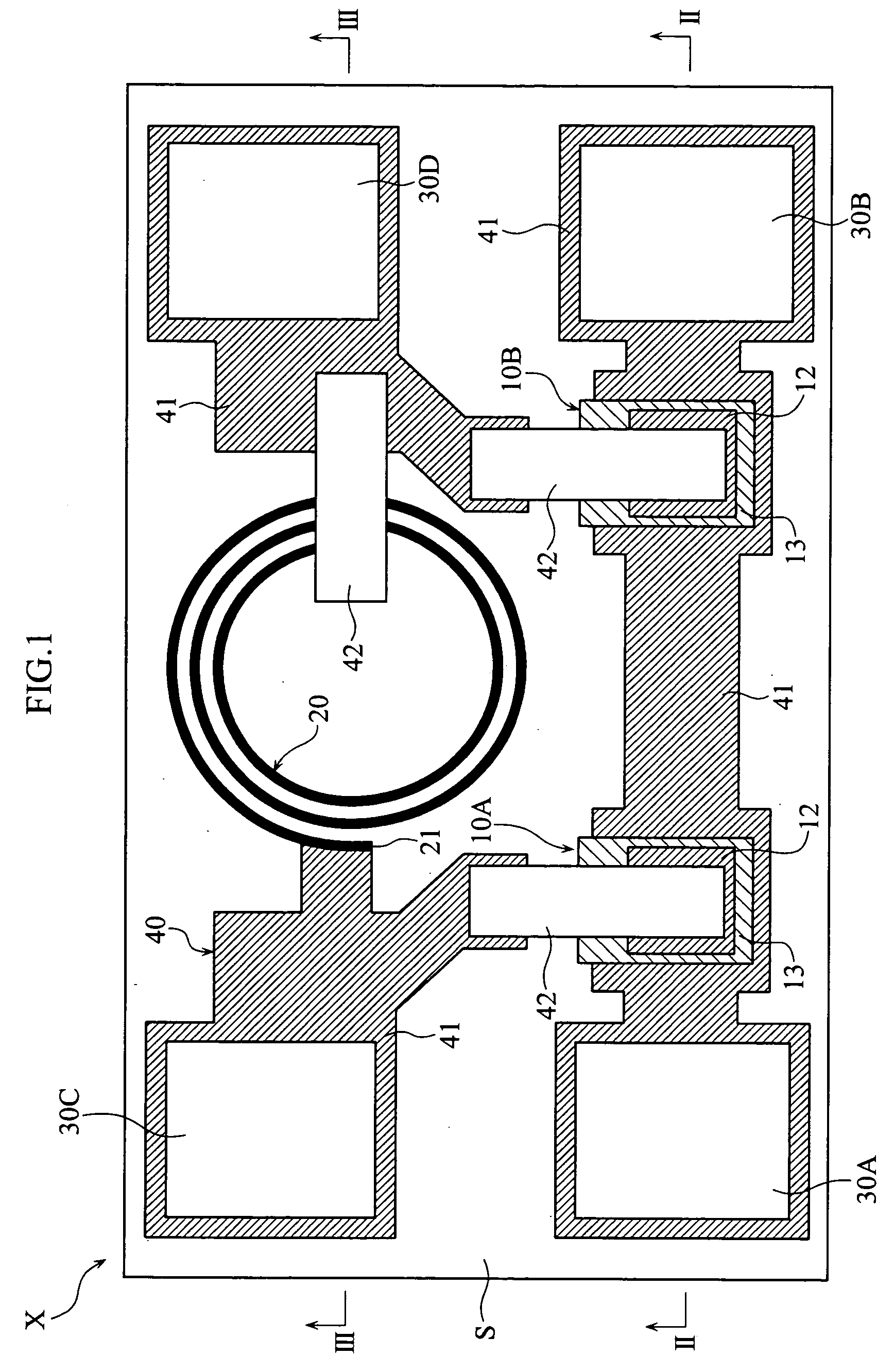

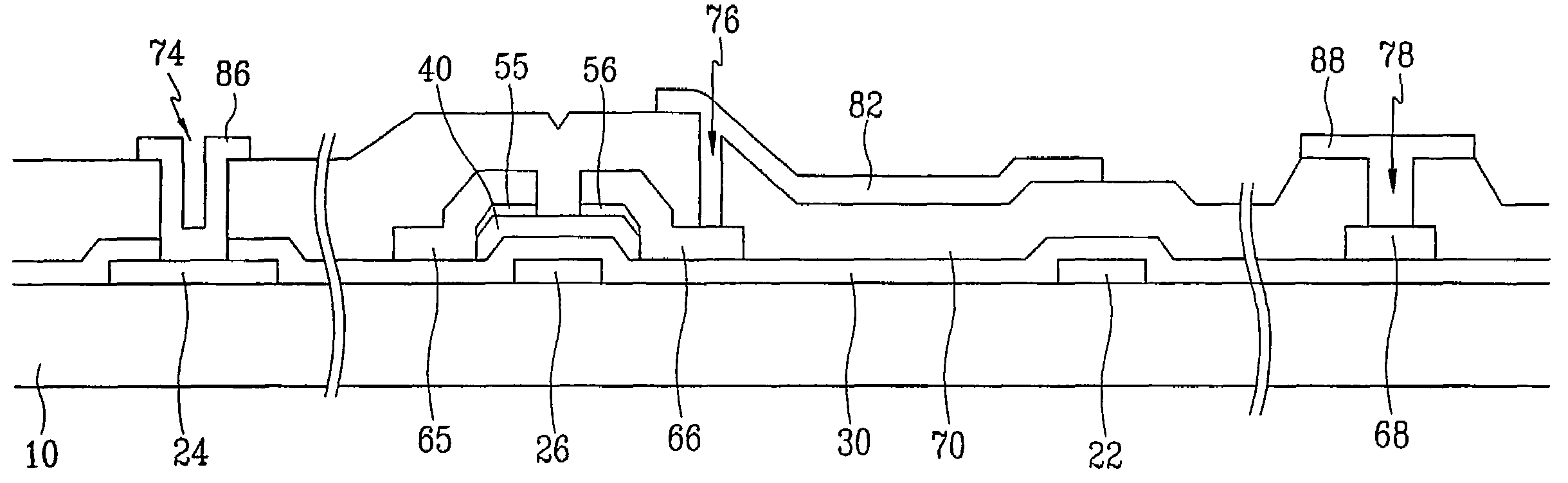

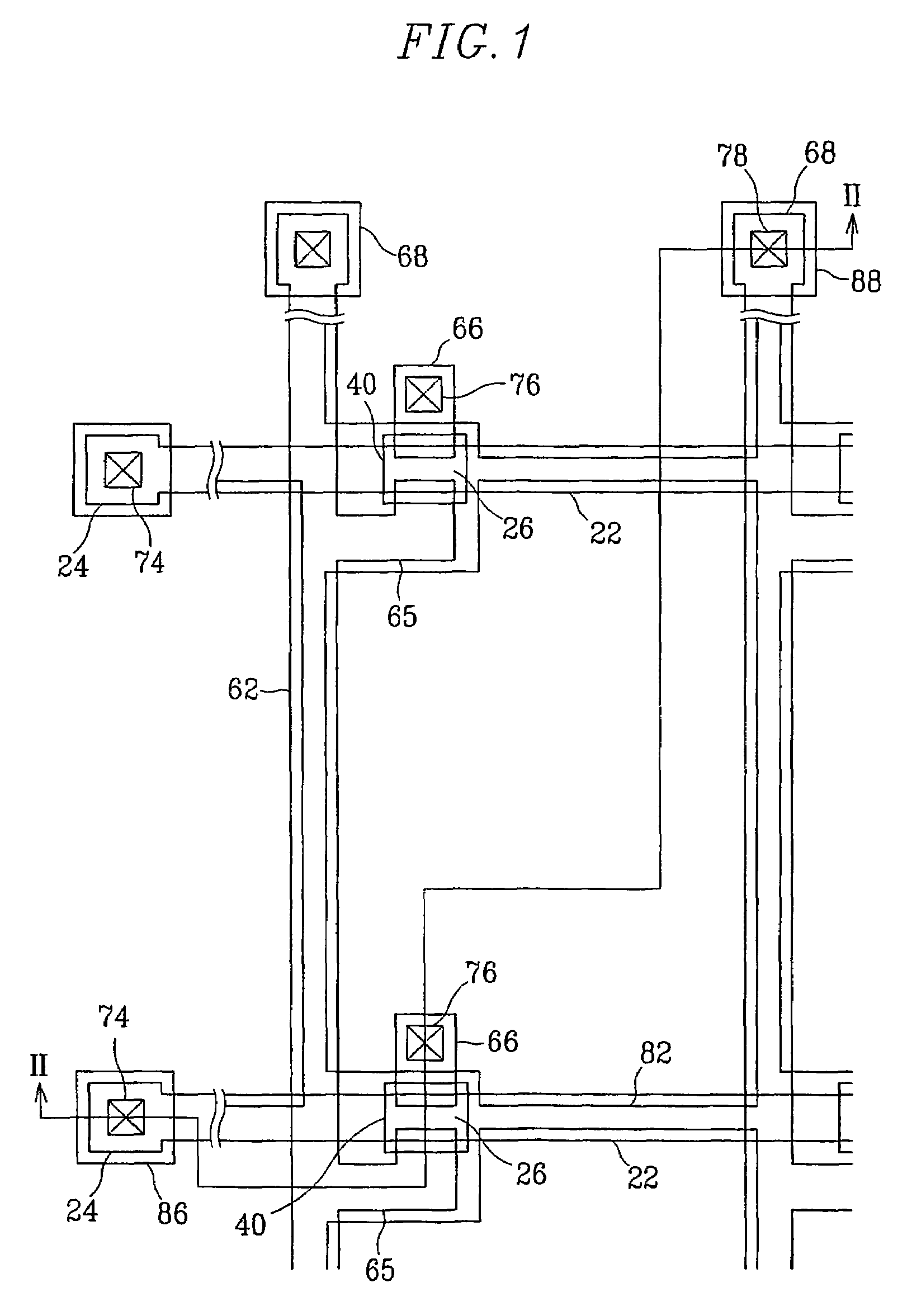

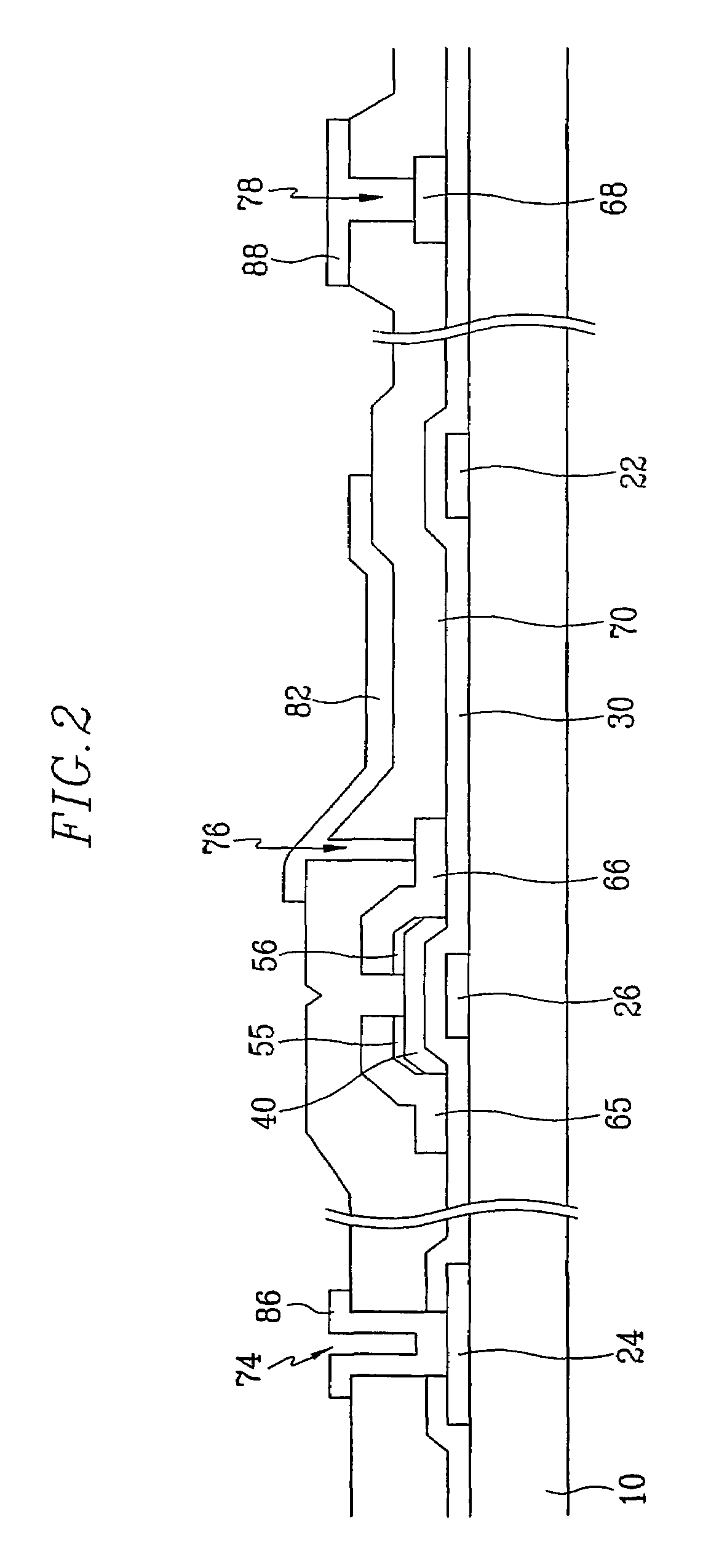

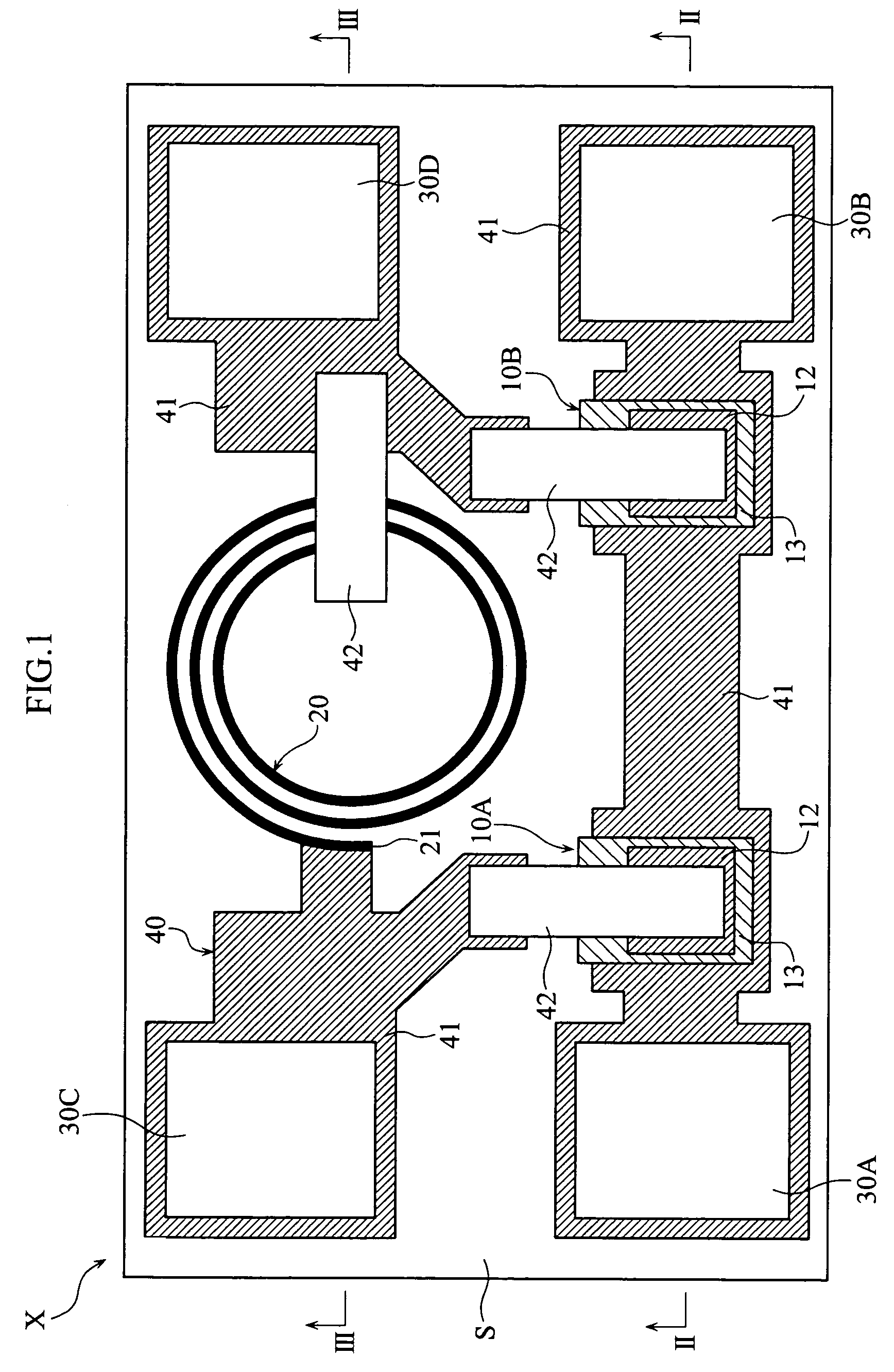

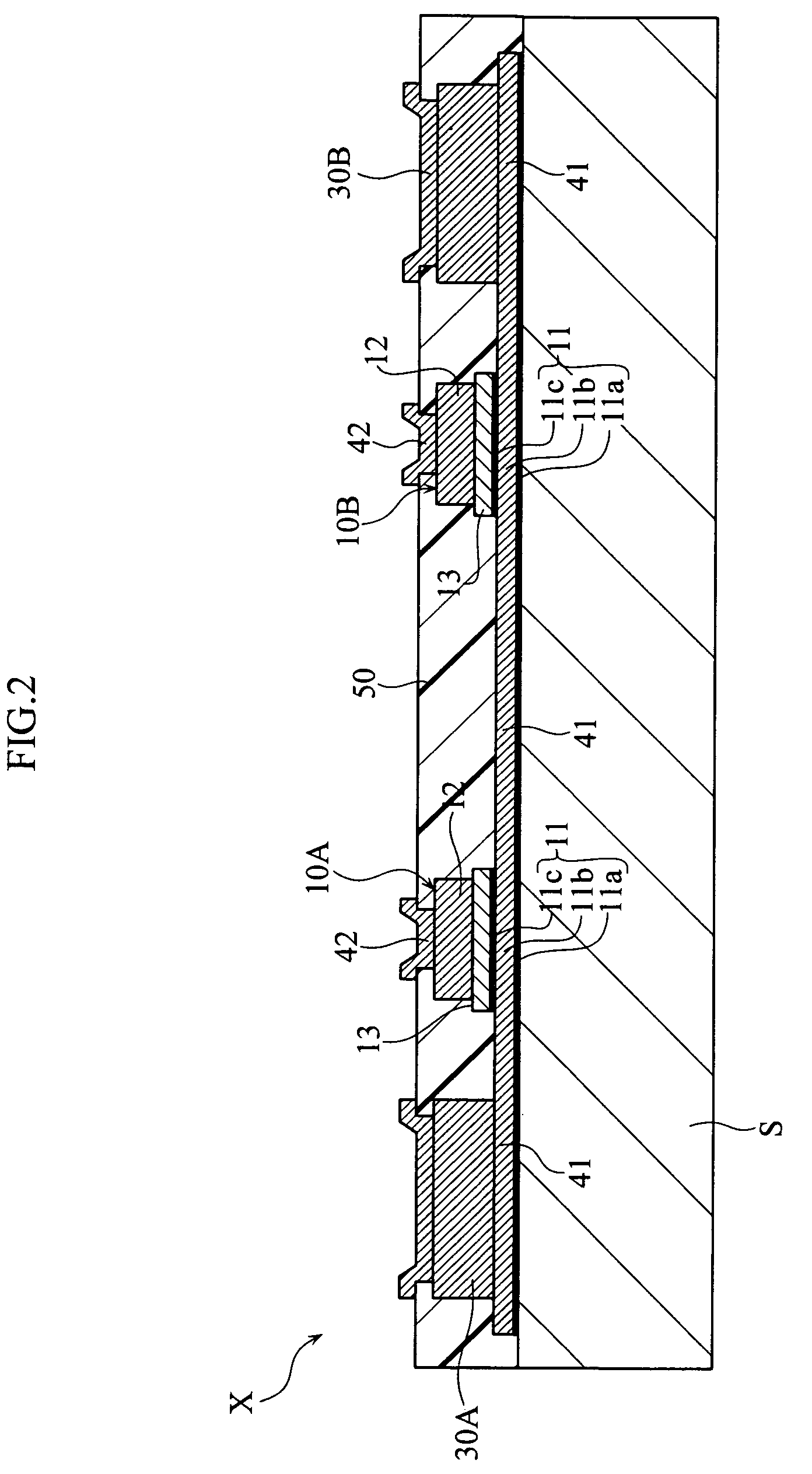

Thin film transistor array panel

InactiveUS7375373B2Low resistivityImprove reliabilityTransistorSemiconductor/solid-state device detailsProtection layerSemiconductor

A thin film transistor array panel includes an insulating substrate, a gate wire formed on the insulating substrate. A gate insulating layer covers the gate wire. A semiconductor pattern is formed on the gate insulating layer. A data wire having source electrodes, drain electrodes and data lines is formed on the gate insulating layer and the semiconductor pattern. A protective layer is formed on the data wire. Pixel electrodes connected to the drain electrode via contact holes are formed on the protective layer. The gate wire and the data wire are made of Ag alloy containing Ag and an additive including at least one selected from Zn, In, Sn and Cr.

Owner:SAMSUNG DISPLAY CO LTD

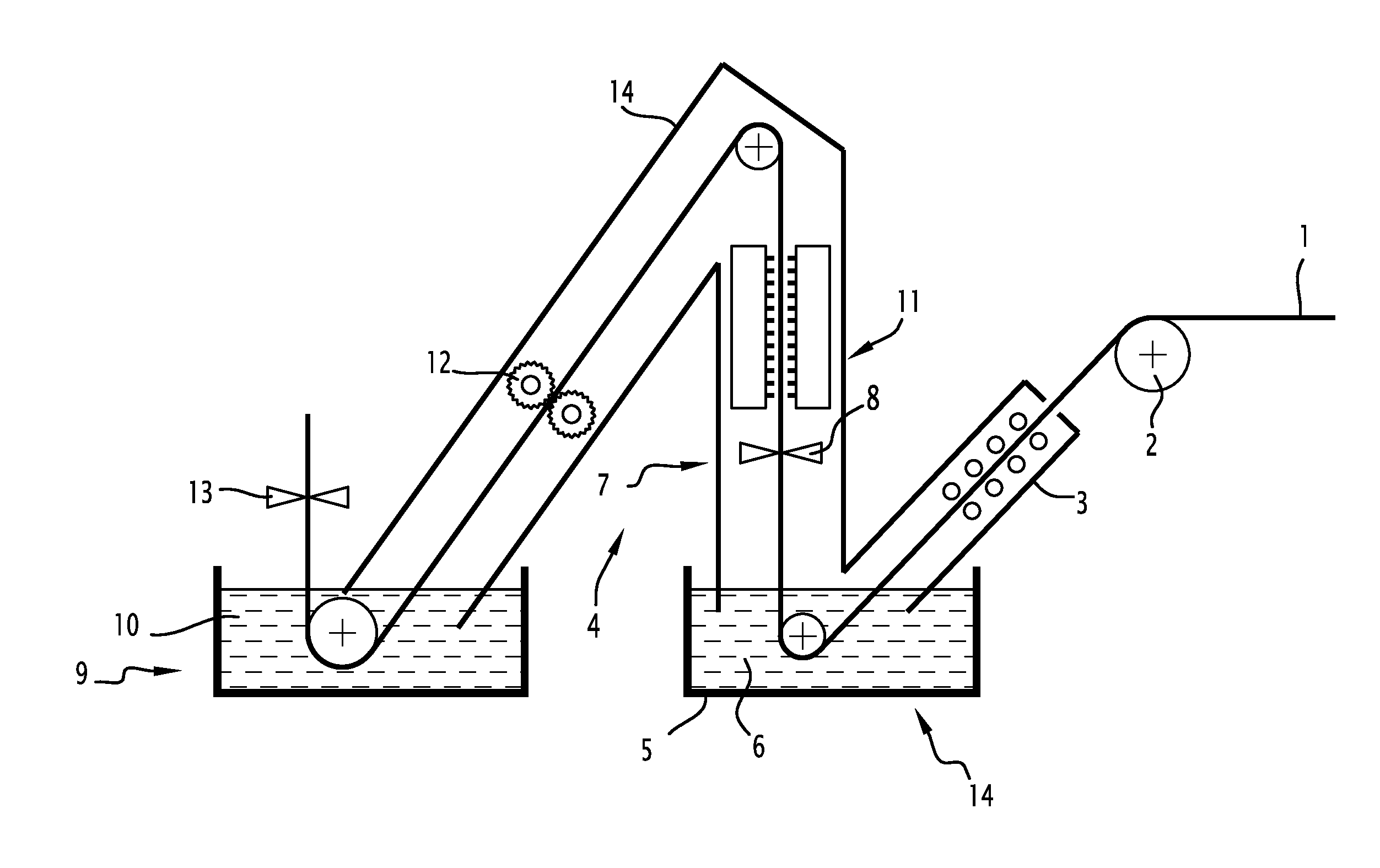

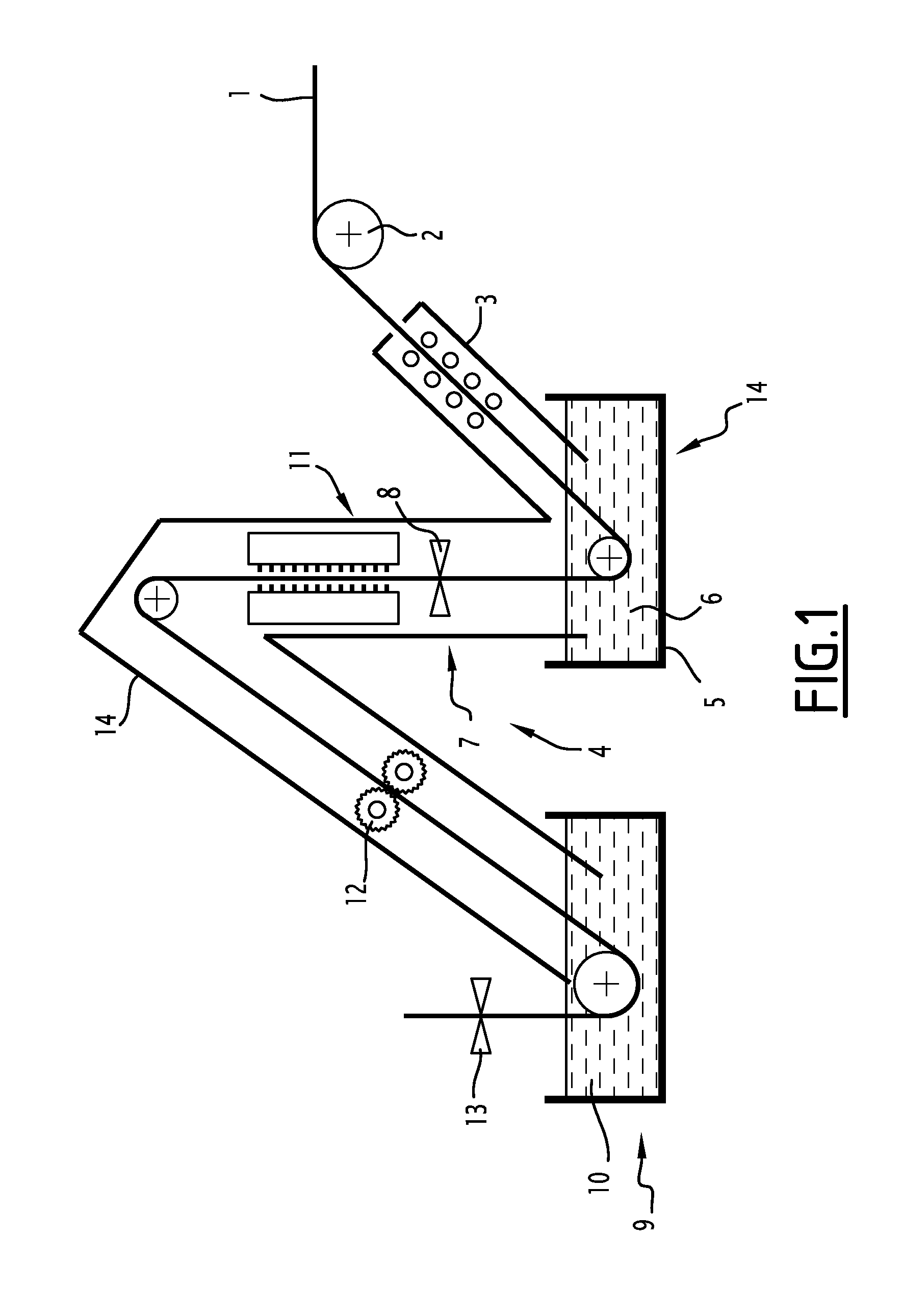

Method of treatment of a running ferrous alloy sheet and treatment line for its implementation

ActiveUS20150368730A1Good metal adhesionEasily oxidizableHot-dipping/immersion processesFurnace typesAlloyResidence time

A method of treatment of a running ferrous alloy sheet containing at least one easily oxidized element is provided. The method includes a step of immersion of the sheet in a molten oxides bath.The molten oxides bath has a viscosity between 0.3.10−3 Pa·s and 3.10−1 Pa·s, the surface of the bath is contact with a non-oxidizing atmosphere, and the molten oxides are inert towards iron. The residence time of the running sheet in the bath is at least 1 s and the residues of oxides remaining on the surfaces of the sheet at the exit of the bath are eliminated.A treatment line of a ferrous alloy sheet for implementing the method, is provided. The treatment line includes a molten oxides bath having a viscosity between 0.3.10−3 and 3.10−1 Pa·s. The surface of the bath is contact with a non-oxidizing atmosphere, and the molten oxides are inert towards iron.Mechanical devices for eliminating the residues of molten oxides remaining on the surfaces of the ferrous alloy sheet are at the exit of the molten oxides bath.

Owner:ARCELORMITTAL INVESTIGACION Y DESARROLLO SL

Process for producing polyester ether poly- or mono-ol

To provide a process for producing a polyester ether poly- or mono-ol having a narrow molecular weight distribution, which is obtained by copolymerizing an initiator having hydroxyl groups with a cyclic ester compound and an alkylene oxide.It is possible to produce a polyester ether poly- or mono-ol having a molecular distribution (Mw / Mn) of from 1.02 to 1.4 by copolymerizing a cyclic ester compound which carbon number is from 3 to 9 and an alkylene oxide which carbon number is from 2 to 20 with an initiator having from 1 to 12 hydroxyl groups and having a number average molecular weight (Mn) of from 18 to 20,000 in the presence of a double-metal cyanide complex catalyst is having tert-butyl alcohol as at least a part of an organic ligand.

Owner:ASAHI GLASS CO LTD

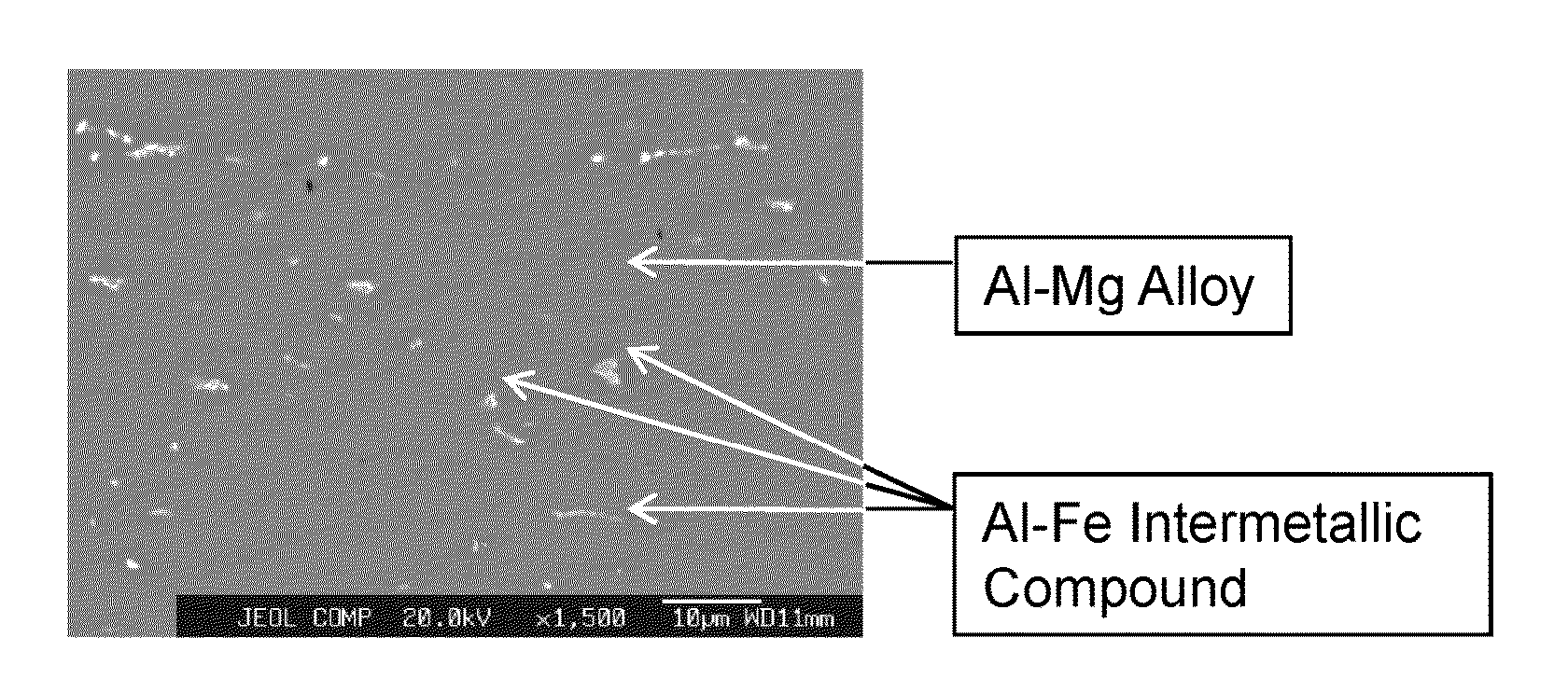

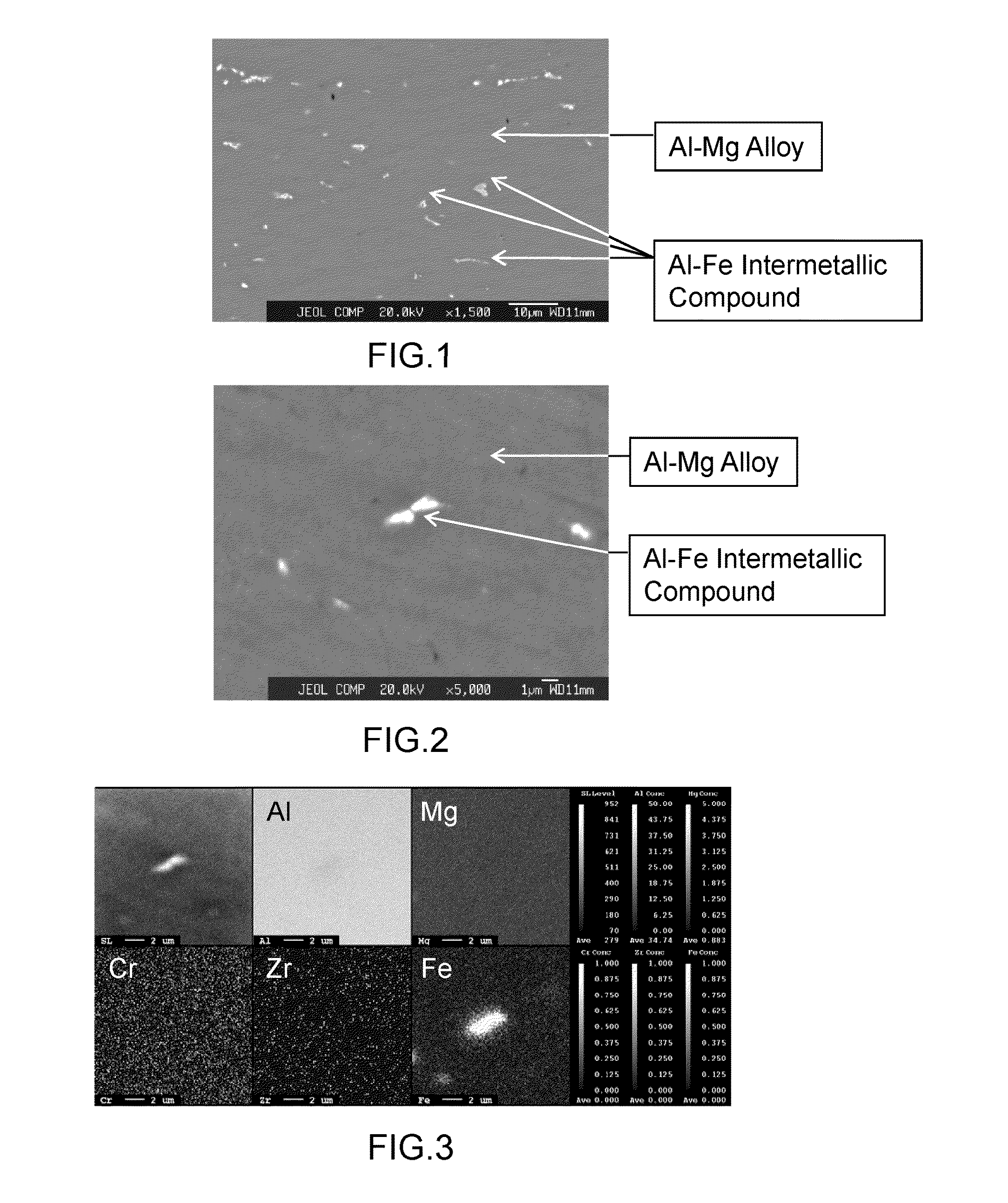

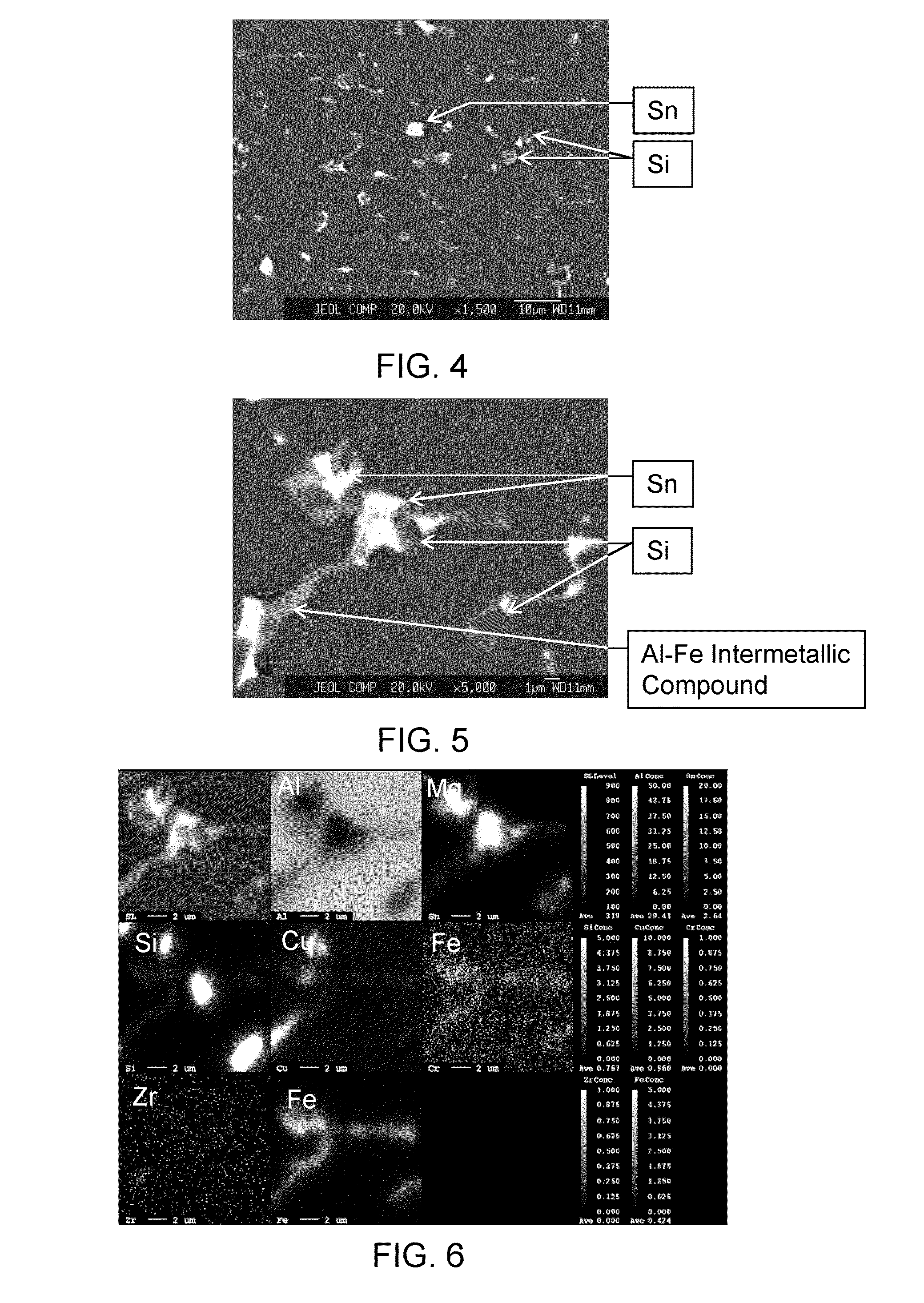

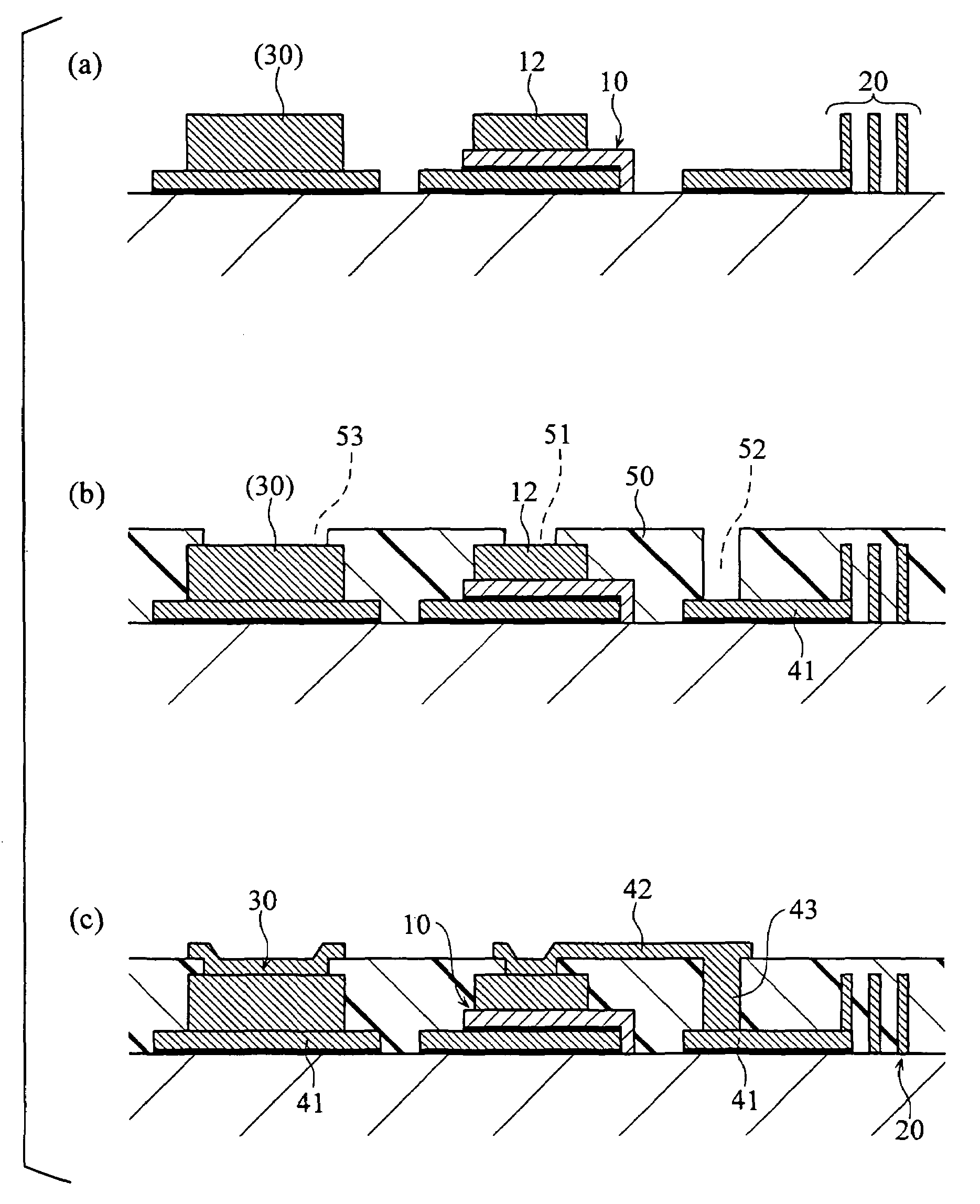

Aluminum alloy for plain bearing, plain bearing and production method for the bearing

ActiveUS20130022301A1High tensile strengthReduce the weakening of strengthShaftsPretreated surfacesUltimate tensile strengthImpurity

With regard to an Al—Cr—Zr based alloy having annealing temper, a high temperature strength at 180 to 200 degrees C. is ensured. An aluminum alloy for a plain bearing having improved fatigue resistance is to be provided. An aluminum alloy for a plain bearing solving the problems has a composition of 3 to 7 mass % Mg, 0.1 to 0.3 mass % Cr, and 0.1 to 0.3 mass % Zr, with the balance being Al and inevitable impurities. A principal structure of the aluminum alloy consist of an Al matrix containing solute Mg, minute particles of Cr, and Zr.

Owner:TAIHO INDUSTRIES CO LTD

Antioxidant Fat or Oil Composition Containing Long-Chain Highly Unsaturated Fatty Acid

InactiveUS20080026125A1Great tasteEasily oxidizableFatty acid esterificationFatty substance preservation using additivesFish oilUnsaturated fat

The purpose of the present invention is to provide a fat or oil composition that can be protected from the off-flavor of the fish oil for a long period of time, and can be used in usual cooking without any problems.Thus, the present invention is related to a fat or oil composition comprising oleic acid of 3˜9 parts by weight, preferably 3˜7 parts by weight, linolic acid of 5˜15 parts by weight, preferably 6˜10 parts by weight and linolenic acid of 0.1˜1.5 parts by weight, preferably 0.5˜1.5 parts by weight per one part by weight of long-chain highly unsaturated fatty acids, and to a fat or oil composition comprising oleic acid of 5˜40 parts by weight, preferably 8˜35 parts by weight, linolic acid of 10˜60 parts by weight, preferably 12˜45 parts by weight and linolenic acid of 0.1˜4 parts by weight, preferably 0.2˜3 parts by weight per one part by weight of long-chain highly unsaturated fatty acids.

Owner:J OIL MILLS INC

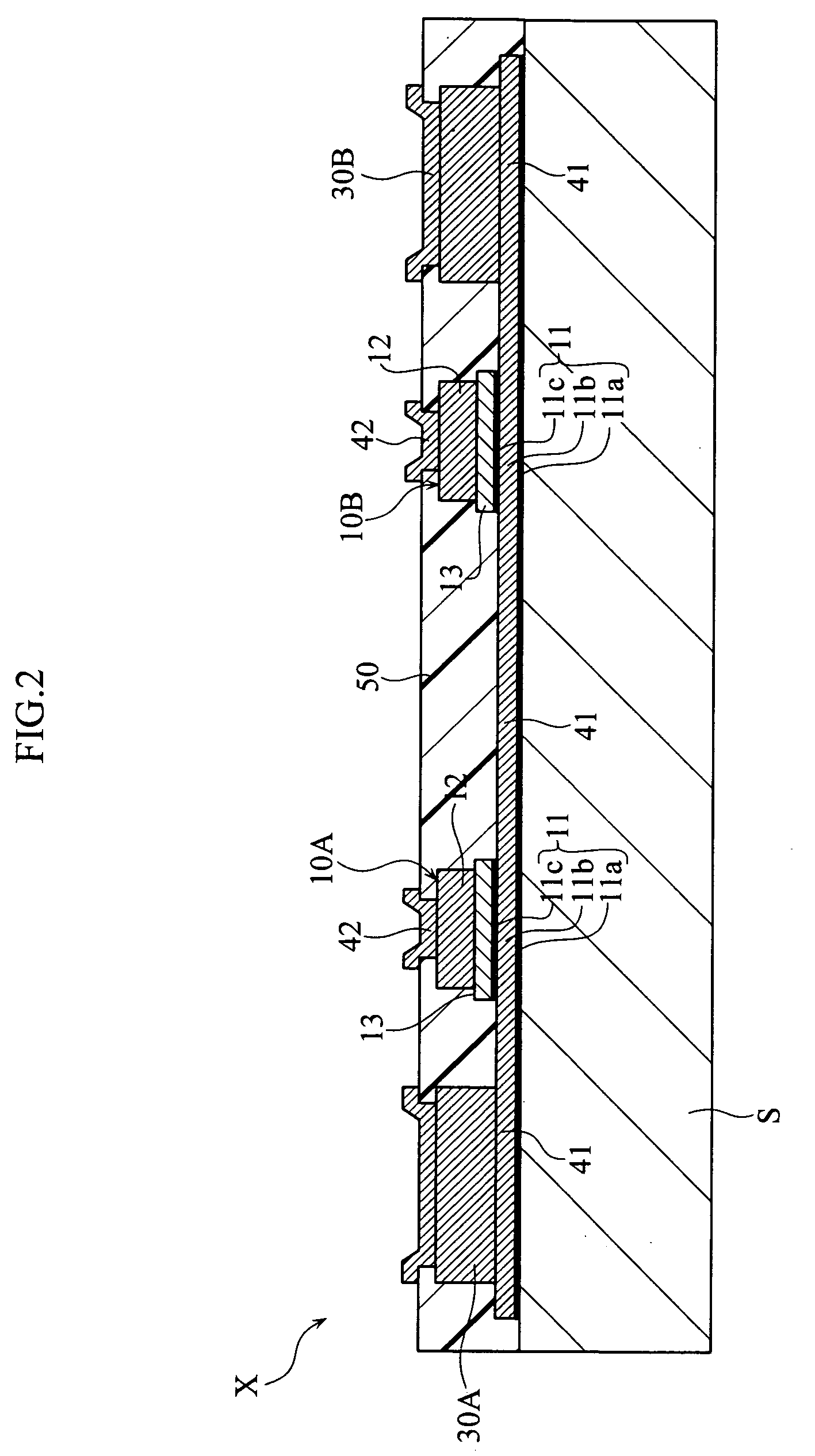

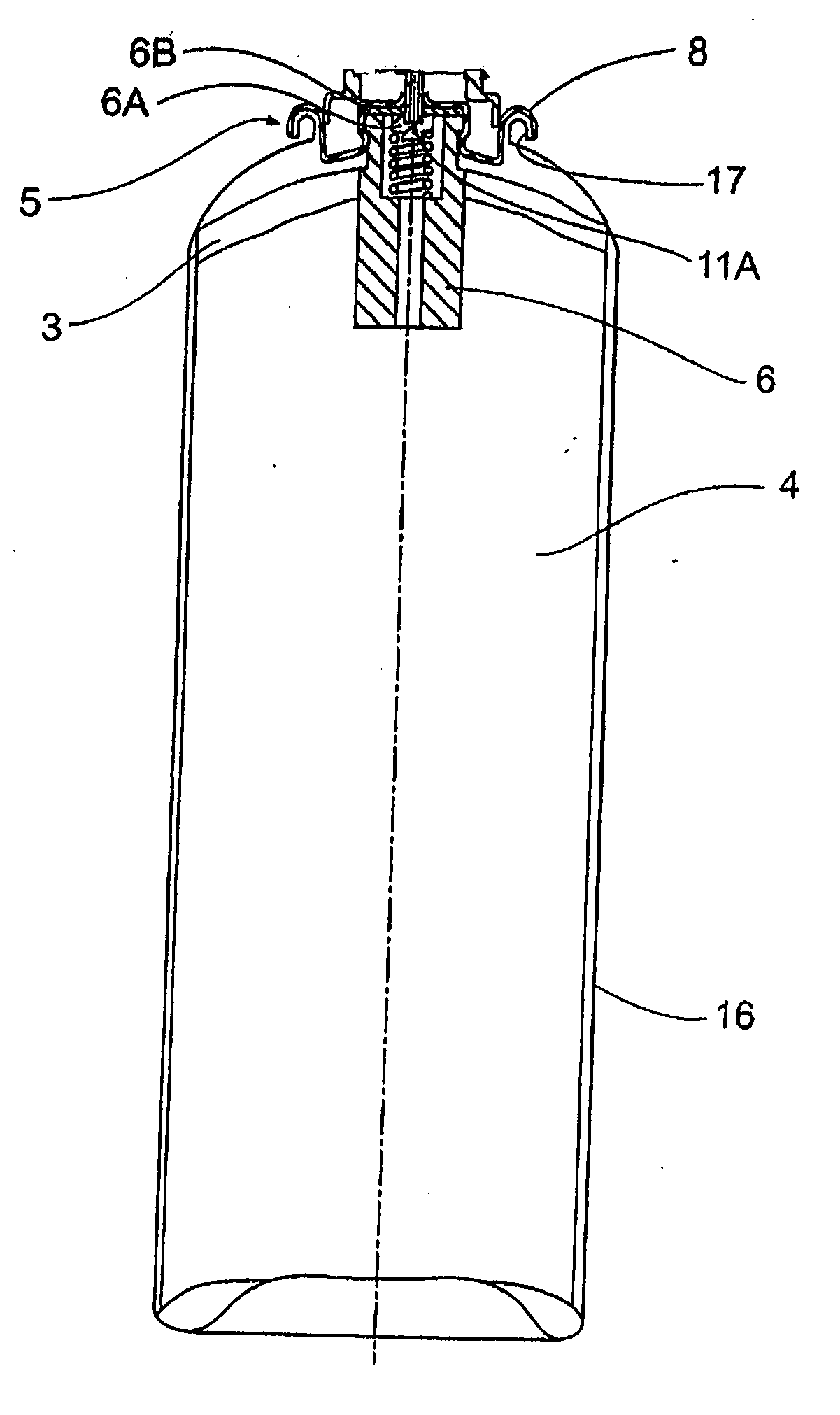

Packaged article of oxygen absorbing multilayer body and method for storing oxygen absorbing multilayer body

InactiveUS20150353251A1Excellent oxygen absorption performanceEfficient oxygen permeabilityWrappersDomestic containersHermetic sealIsolation layer

There are provided a packaged article and a storage method that can maintain the oxygen absorption performance of an oxygen absorbing multilayer body containing an easily oxidizable thermoplastic resin and a transition metal catalyst during long-term storage, and the like. The packaged article of an oxygen absorbing multilayer body of the present invention is obtained by hermetically sealing in a gas barrier container (A) an oxygen absorbing multilayer body comprising at least two layers, an isolation layer comprising a thermoplastic resin and an oxygen absorption layer comprising an oxygen absorbing resin composition comprising an easily oxidizable thermoplastic resin and a transition metal catalyst, and (B) a gas having a carbon dioxide concentration of 0.1 to 100% by volume.

Owner:MITSUBISHI GAS CHEM CO INC

Electronic component

InactiveUS7855458B2Solve the lack of adhesionImprove pressure resistanceFixed capacitor electrodesThin/thick film capacitorOptoelectronicsElectronic component

An electronic component includes a substrate, and a capacitor unit on the substrate. The capacitor unit has a laminate structure including a first electrode layer provided on the substrate, a second electrode layer opposed to the first electrode layer, and a dielectric layer disposed between the first and the second electrode layers. The first electrode layer has a multilayer structure including an adhesion metal layer joined to the dielectric layer. The adhesion metal layer is provided with an oxide coating on a side of the dielectric layer.

Owner:FUJITSU LTD

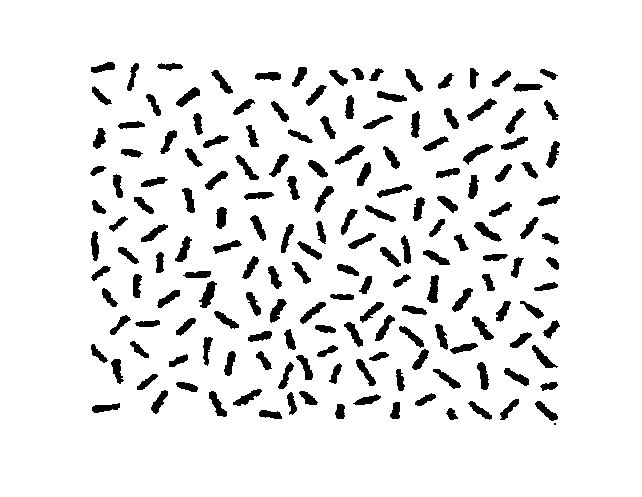

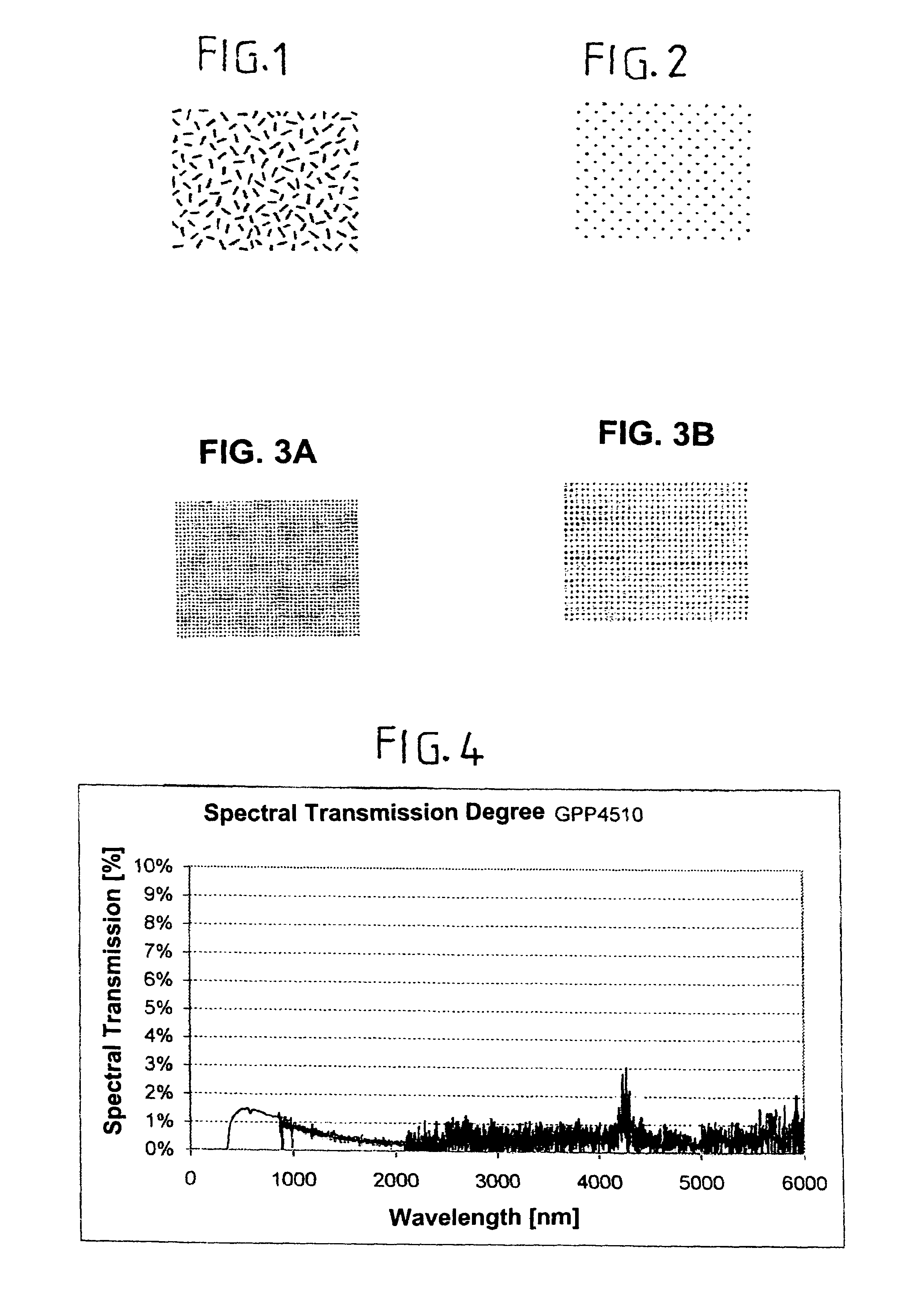

Glass ceramic plate providing a cooking surface for a cooking apparatus and having a coating on an underside thereof and coating process for making same

InactiveUS7638208B2Good chemical resistanceEasily oxidizableConductive materialHot plates heating arrangementsSpectral transmissionAsymmetric distribution

The glass ceramic plate for a cooking apparatus is transparent to visible light and IR radiation and has a noble metal film on its underside. The noble metal film is composed of an alloy of gold, platinum and / or palladium, which imparts a reflective property to it. It contains from 0 to 5 percent by weight, in relation to a total metal content, of silver, copper, silicon, bismuth and other metals that are not noble metals. The glass ceramic plate coated with the noble metal film has a spectral transmission of 0 to 12% in the infrared region of the spectrum. When a decoration consisting of a grid of unsymmetrically distributed elements is provided on the topside of the glass ceramic plate, defects in the glass ceramic material can be concealed. The invention also includes a method of coating.

Owner:SCHOTT AG

Coating composition

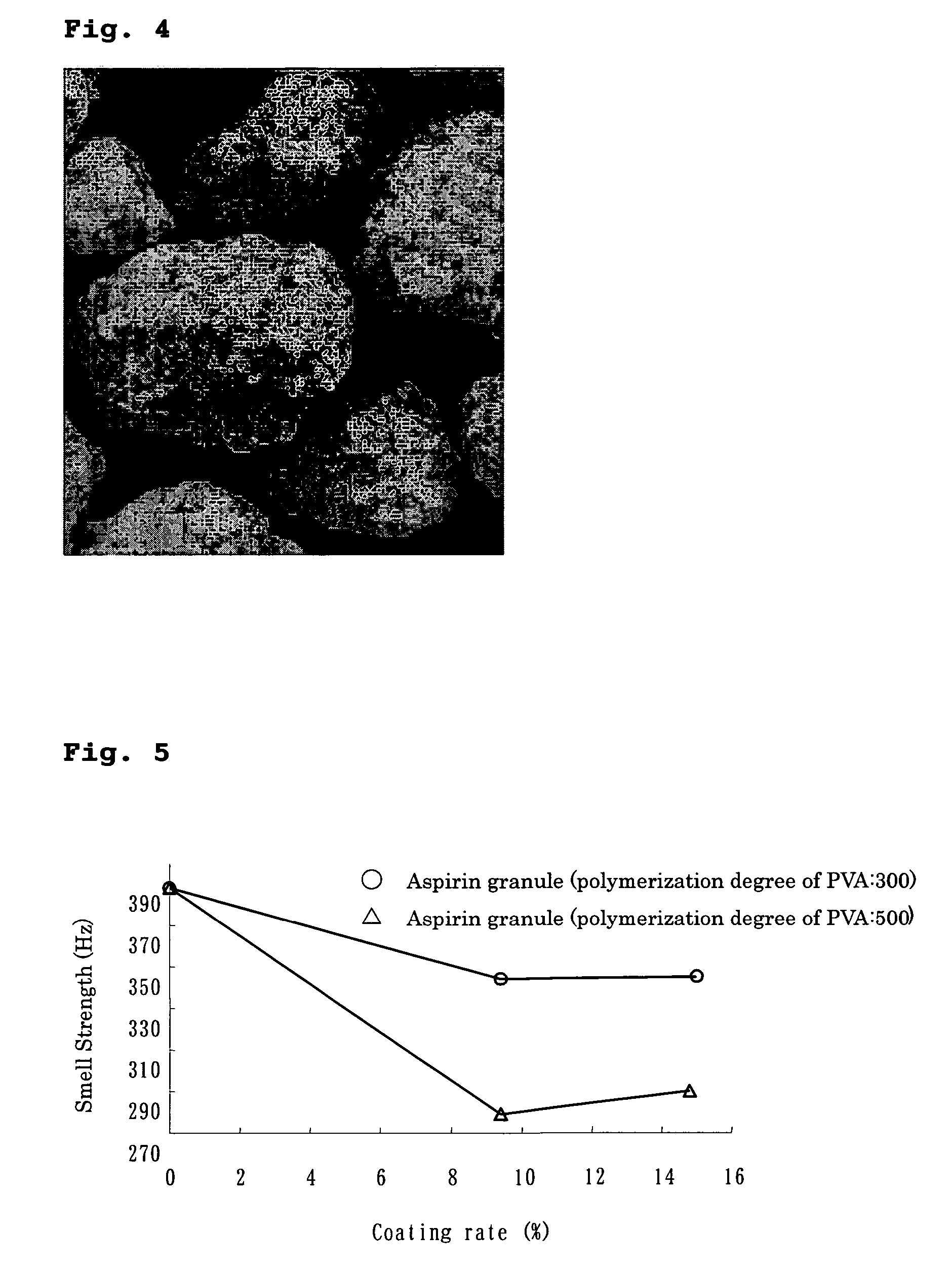

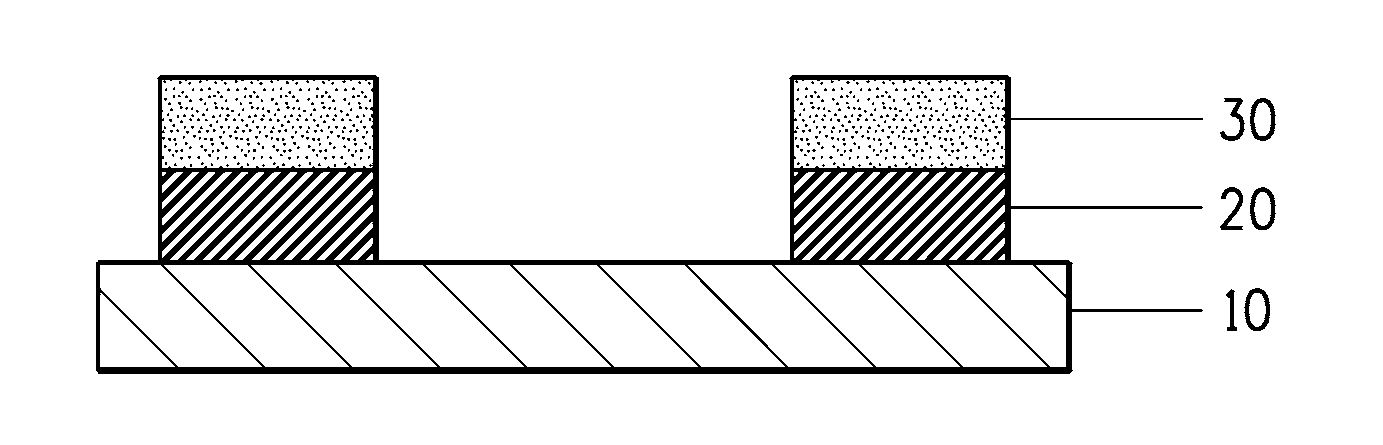

ActiveUS8277844B2Prevent oxidationAvoid changeAntipyreticAnalgesicsPVA - Polyvinyl alcoholPolymer chemistry

The present invention relates to a novel resin composition useful as a coating agent or a binder for medicines, drugs for animals, agricultural chemicals, fertilizers, foods or the like, which contains a polyvinyl alcohol copolymer as a main component. More particularly, the present invention relates to a resin composition, characterized in that the composition is obtained by copolymerizing a polyvinyl alcohol having an average polymerization degree of 1300 or less, and at least one polymerizable vinyl monomer in a weight ratio of 6:4 to 9:1.

Owner:SHIONOGI & CO LTD +2

Electrode and method for manufacturing the same

InactiveUS20120255765A1Easily oxidizableLow costElectric discharge tubesPretreated surfacesAdditive ingredientAlloy

Disclosed is an electrode, including a conductive layer containing a conductive component selected from the group consisting of copper, nickel, iron, cobalt, titanium, lead, aluminum, tin, and alloys comprising one of these metals as the principal ingredient thereof, and an oxidation protection layer containing boron oxide, said oxidation protection layer covering the top surface of the conductive layer, or covering both the top surface and the sides of the conductive layer, or covering all locations where the conductive layer has been formed; the electrode being formed by air firing the conductive layer and the oxidation protection layer simultaneously.

Owner:EI DU PONT DE NEMOURS & CO

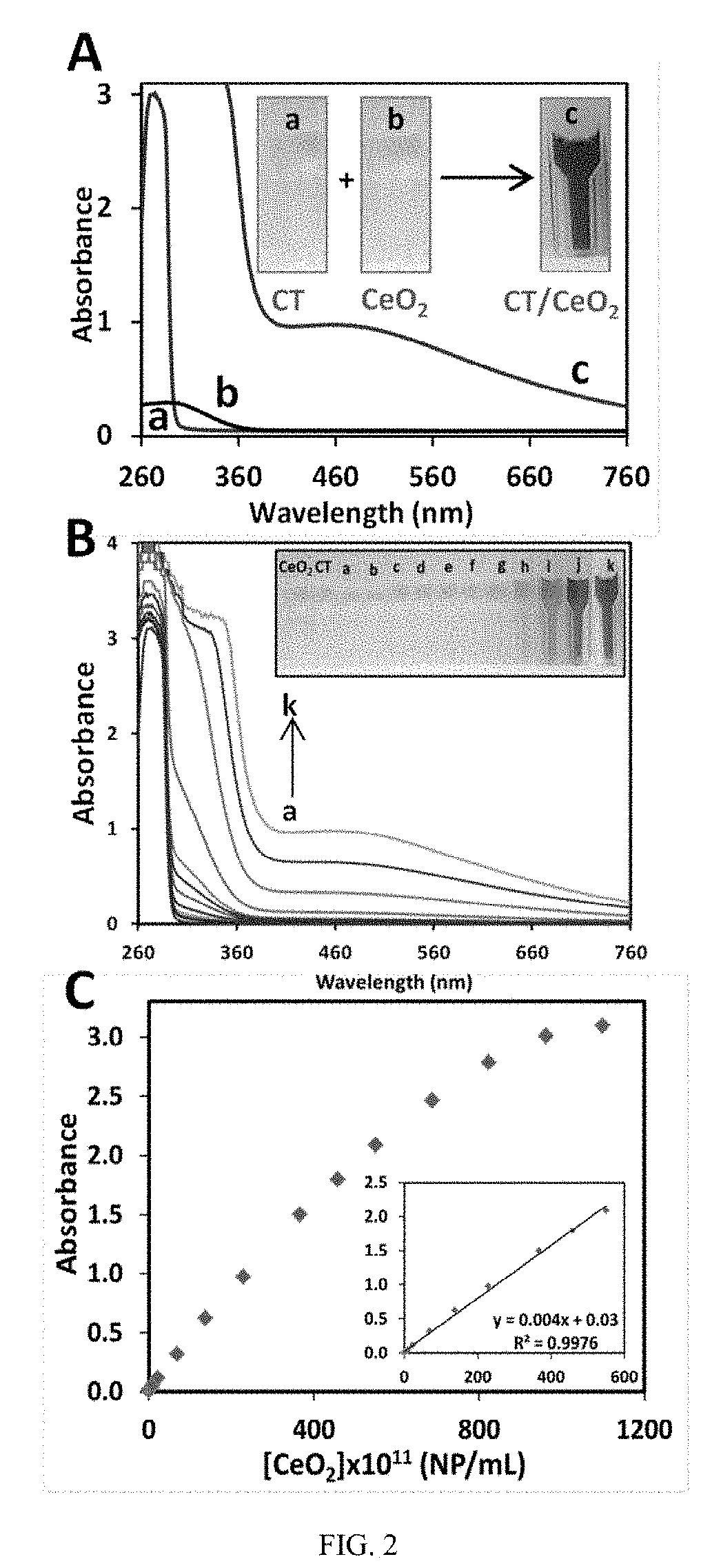

Functional Platform for Rapid Capture and Removal of Nanoparticles

ActiveUS20180022604A1Facilitate rapid assessmentEasy to measureWater treatment parameter controlWater treatment compoundsBinding siteBiochemical engineering

Device, method, and system for nanoparticle capture, tracking, and / or detection. A functional paper-based platform is modified with capture ligands to create binding sites for nanoparticles. According to an embodiment, nanoparticle binding produces visual images of the particle content and distribution on the modified sensing surface, which provides capabilities for both NP sequestration and real-time detection. According to an embodiment the system may be utilized for environmental decontamination, fabrication of personal protective equipment, field monitoring, and epidemiological studies. The availability of inexpensive and easy-to-use quantitative methods can facilitate rapid assessment and measurement of NPs concentration and the level of exposure for large scale toxicological and epidemiological testing

Owner:CLARKSON UNIVERSITY

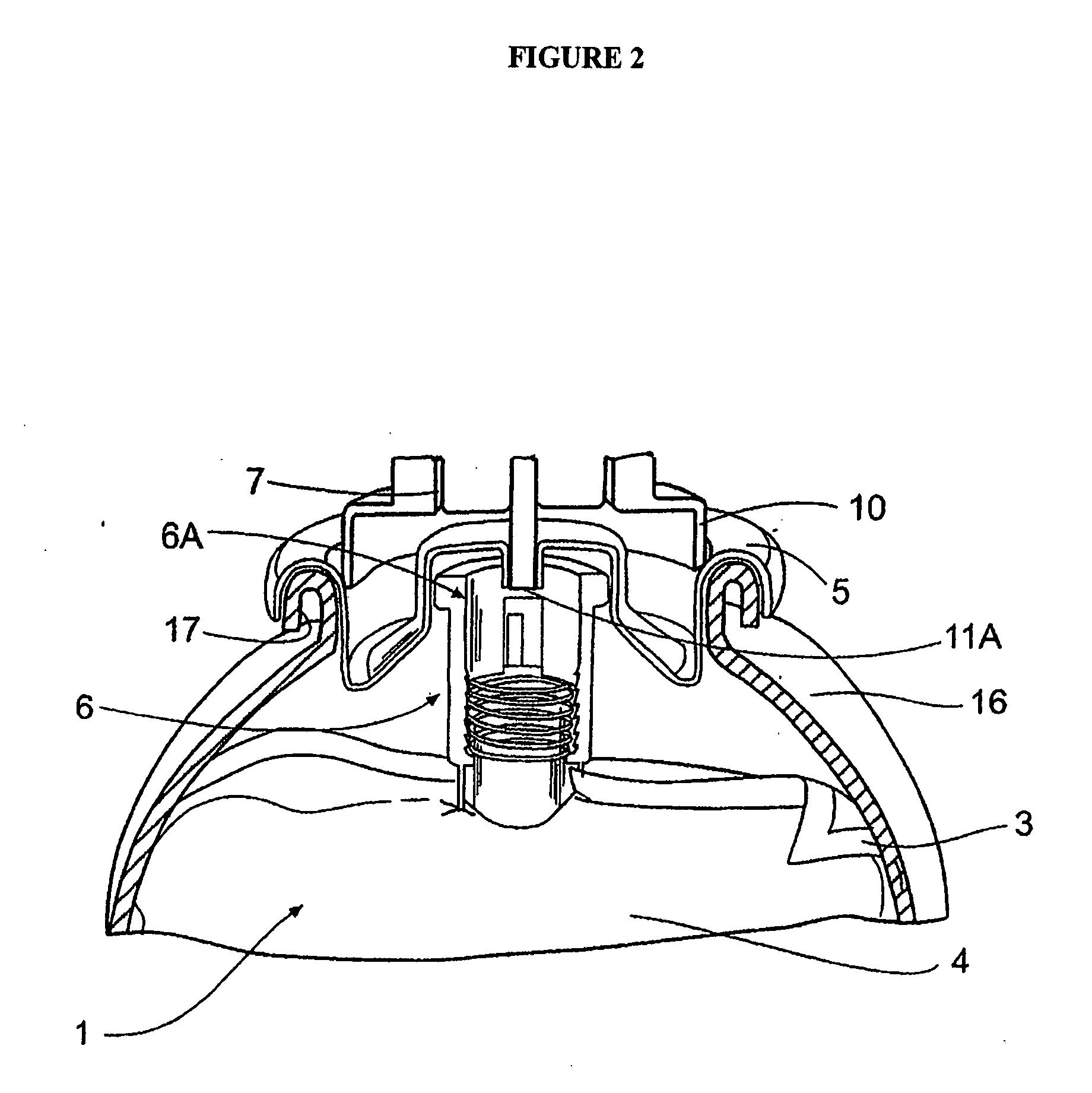

Probe for determination of oxygen activity in metal melts and methods for its production

InactiveUS7578913B2Reduce measurement errorReduce errorsMaterial analysis by electric/magnetic meansTesting metalsOxygen ionsMethods of production

The invention relates to a probe (100, 200, 300, 400, 500, 600) for the measurement of the oxygen activity of metal melts, in particular steel melts, comprising a reference substance (2) of known oxygen activity in electrically conducting contact (3) with a measuring device; and comprising a solid electrolyte predominantly oxygen ion conducting and negligibly electron conducting at high temperatures and separating the reference substance (2) from the metal melt and having an entry surface (4) for oxygen ions which is in contact with the metal melt, wherein the entry surface (4) of the probe ready for operation is covered by a functional foil arrangement (10,20) in close contact to the entry surface (4).

Owner:SPECIALITY MINERALS (MICHIGAN) INC

Distributed feedback semiconductor laser and method for manufacturing the same

InactiveUS20060109884A1Easy to manufactureEasily oxidizableOptical resonator shape and constructionSemiconductor lasersSemiconductor materialsGain coefficient

A distributed feedback semiconductor laser oscillating in a single mode and a method for manufacturing the same is disclosed. The distributed feedback semiconductor laser includes an active layer; a clad layer formed adjacent to the active layer; and diffraction gratings periodically formed in the clad layer and separated from each other by a predetermined distance. The diffraction gratings are formed of a nonconductor so that a current injected into the active layer is partially blocked and distribution of gain coefficient is varied. The nonconductor is an oxidized semiconductor material.

Owner:SAMSUNG ELECTRONICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com