Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

37results about How to "Less porous" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

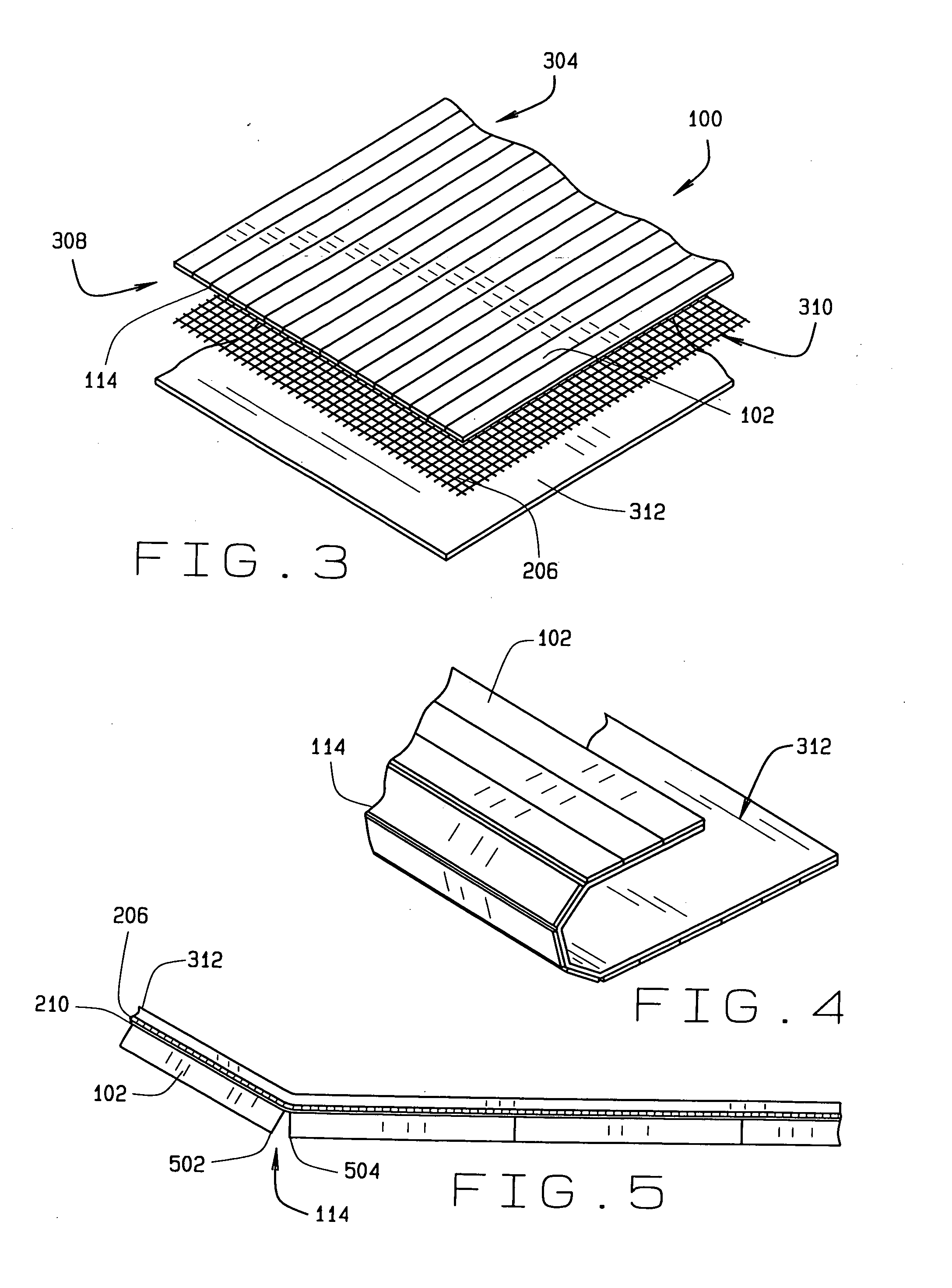

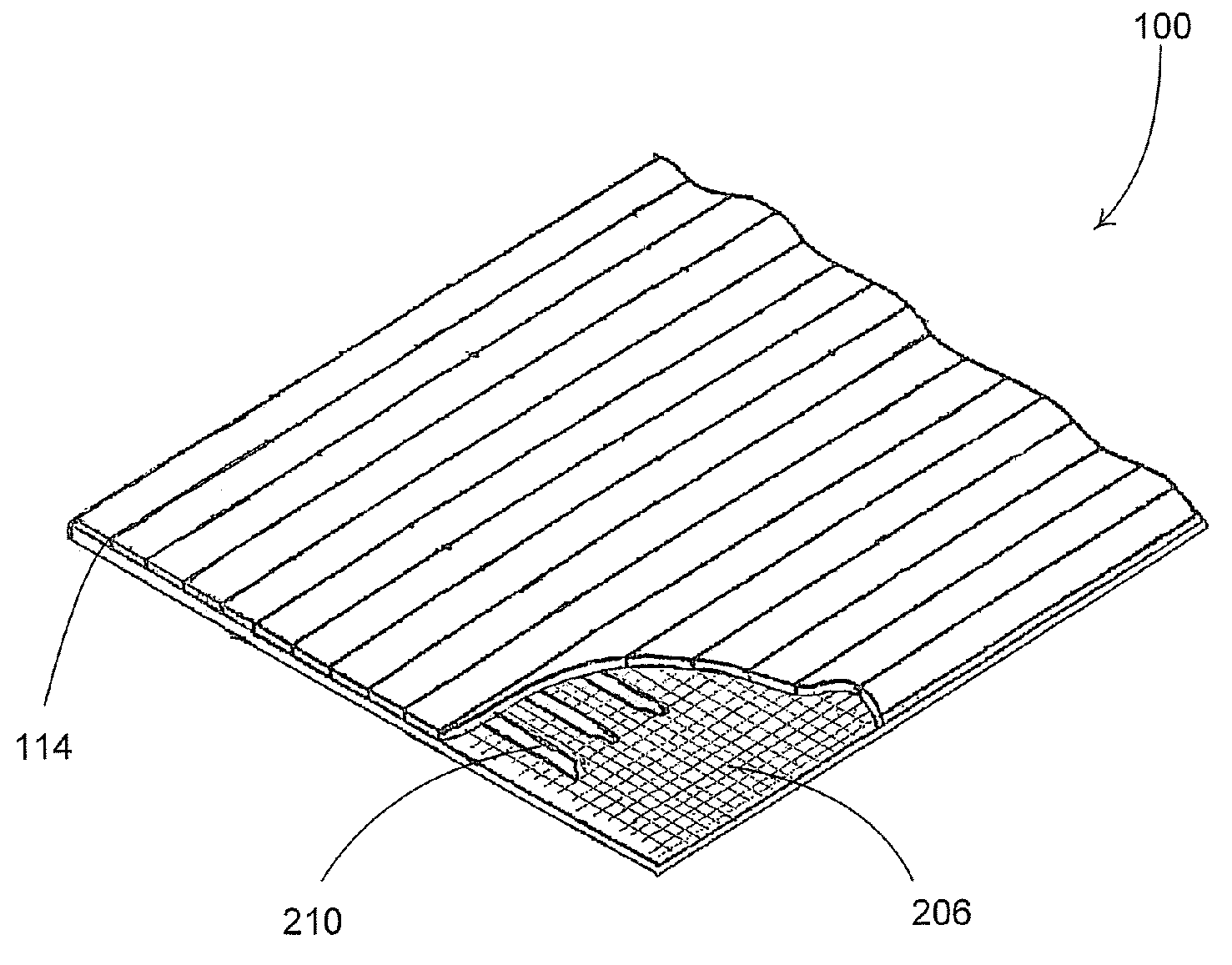

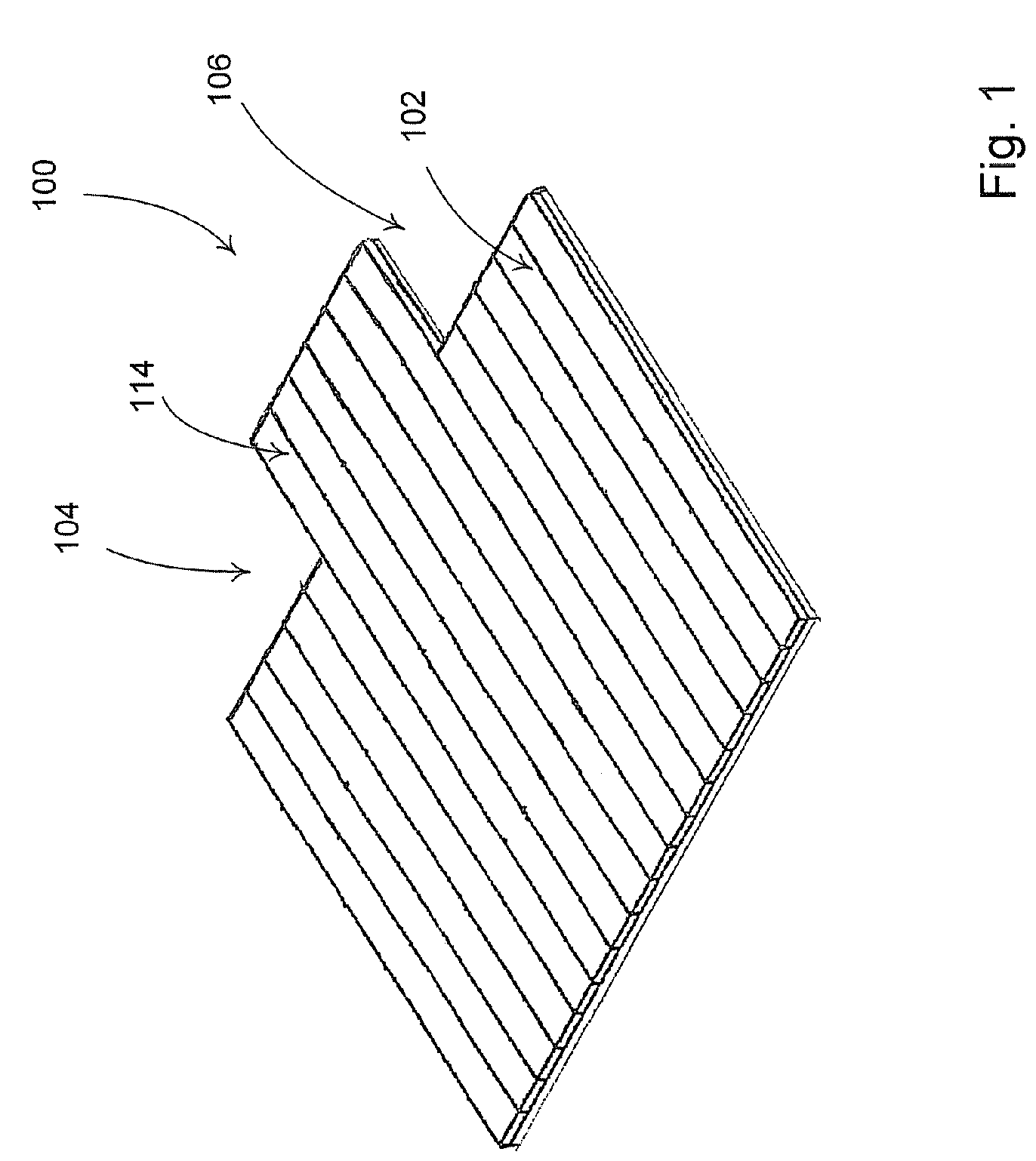

Compositions and methods for manufacturing starch-based compositions

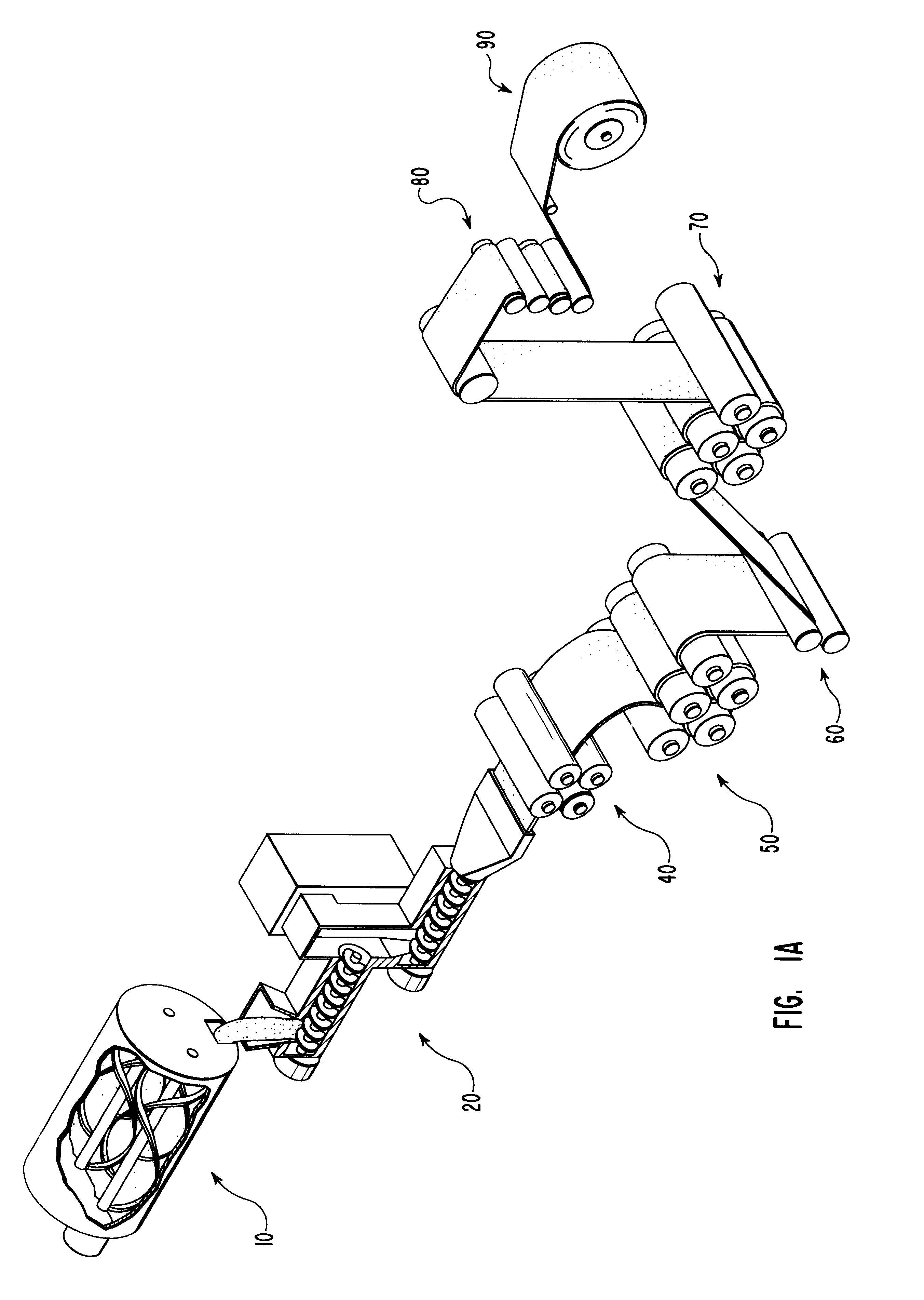

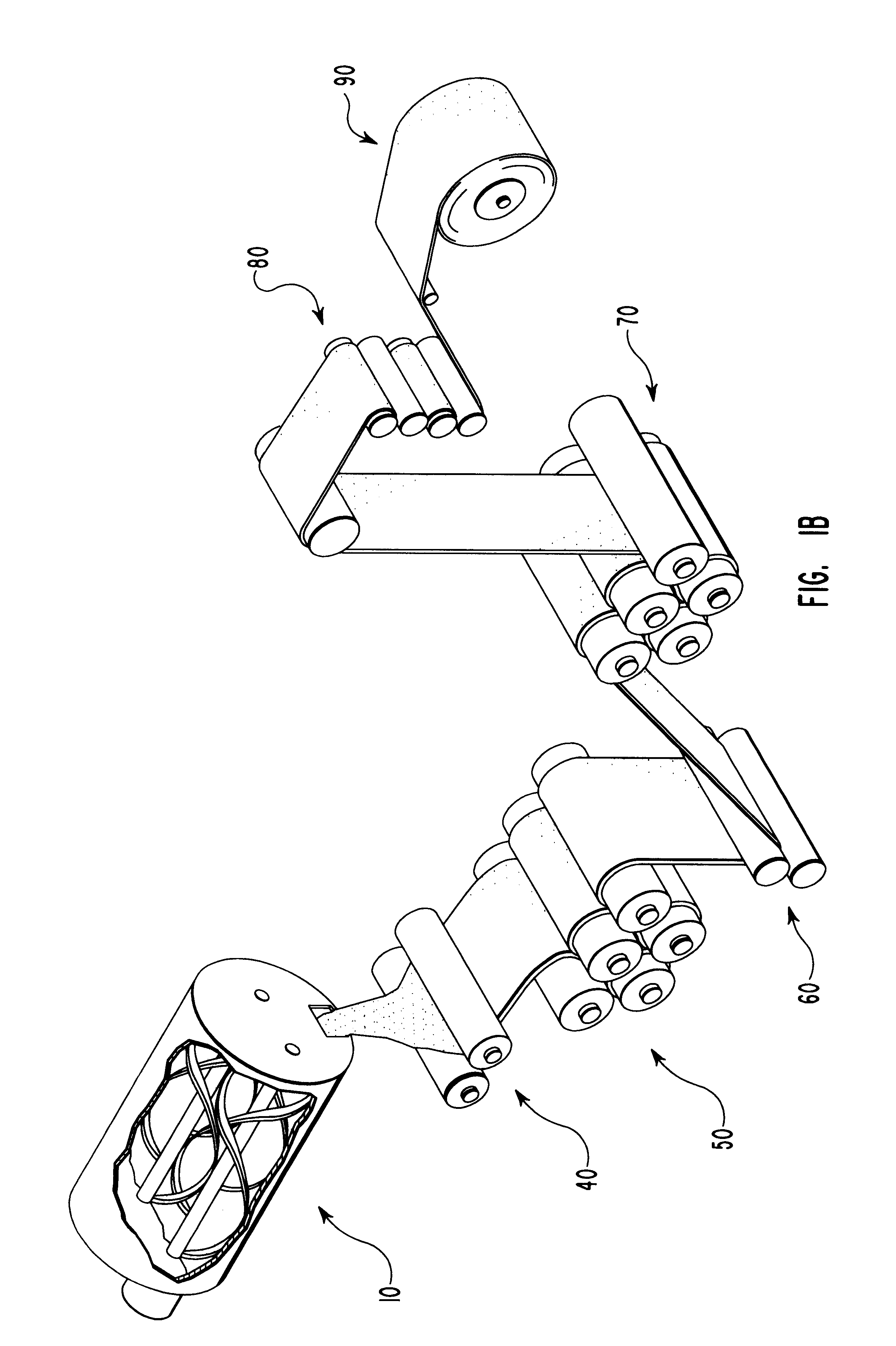

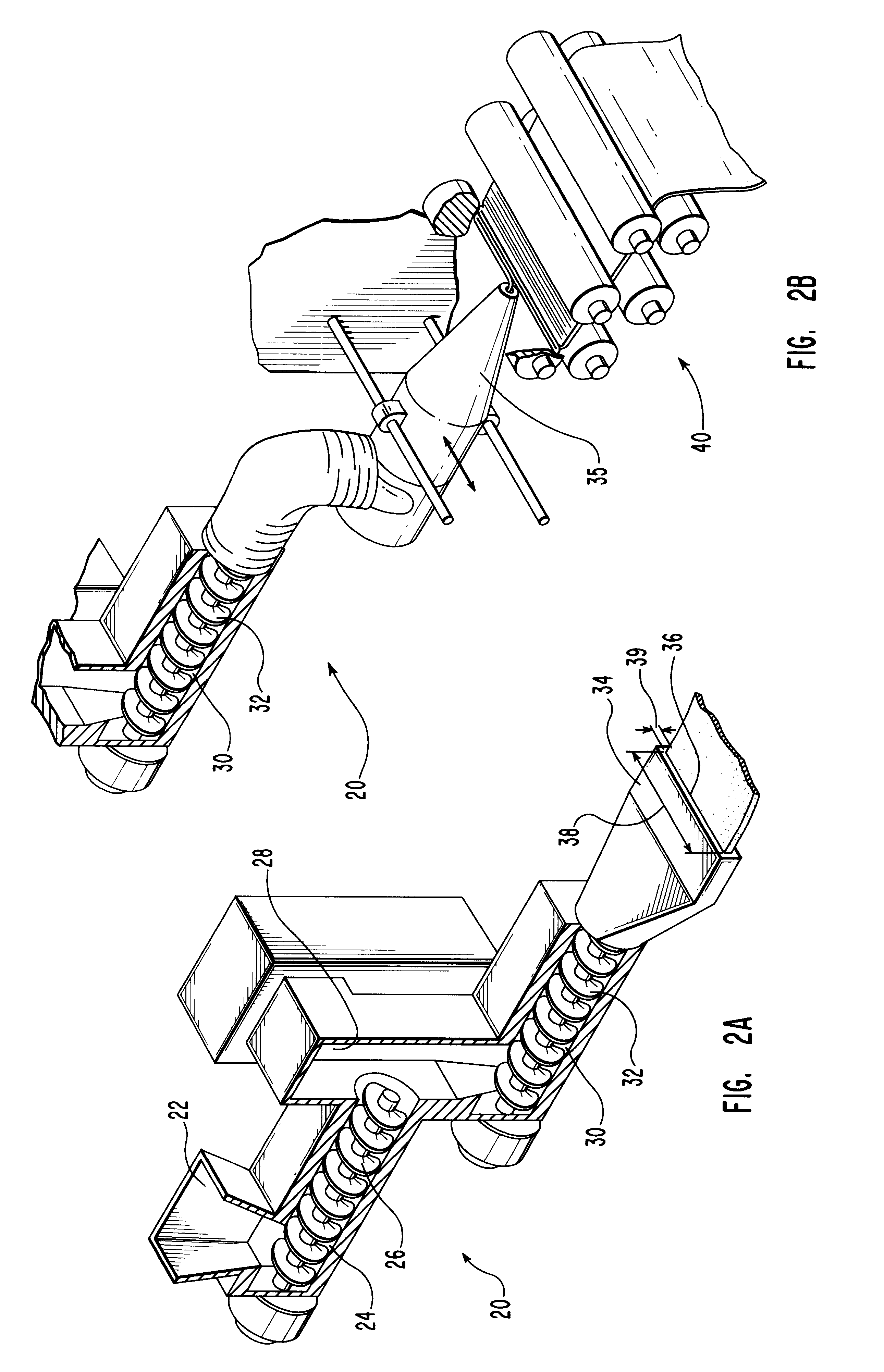

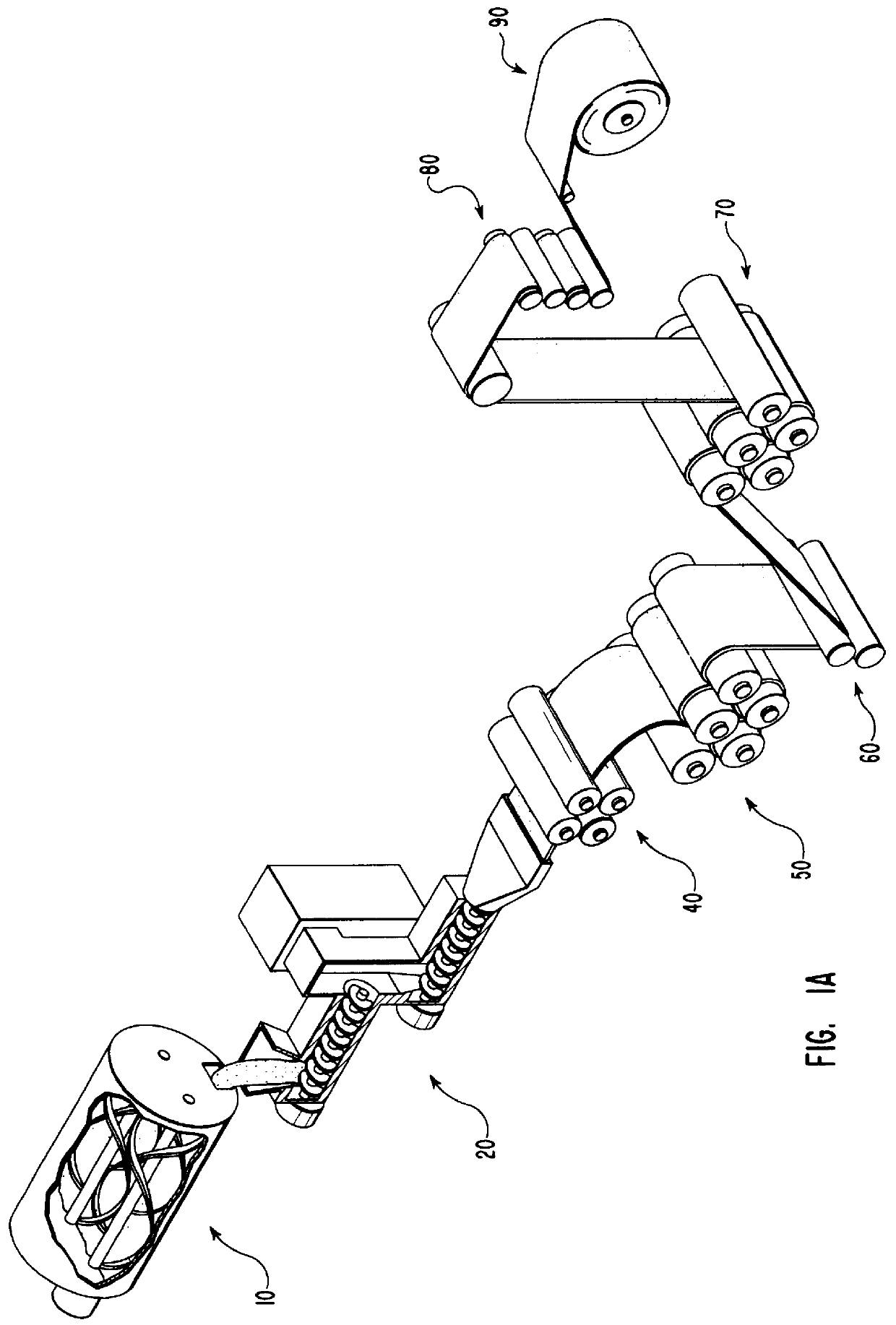

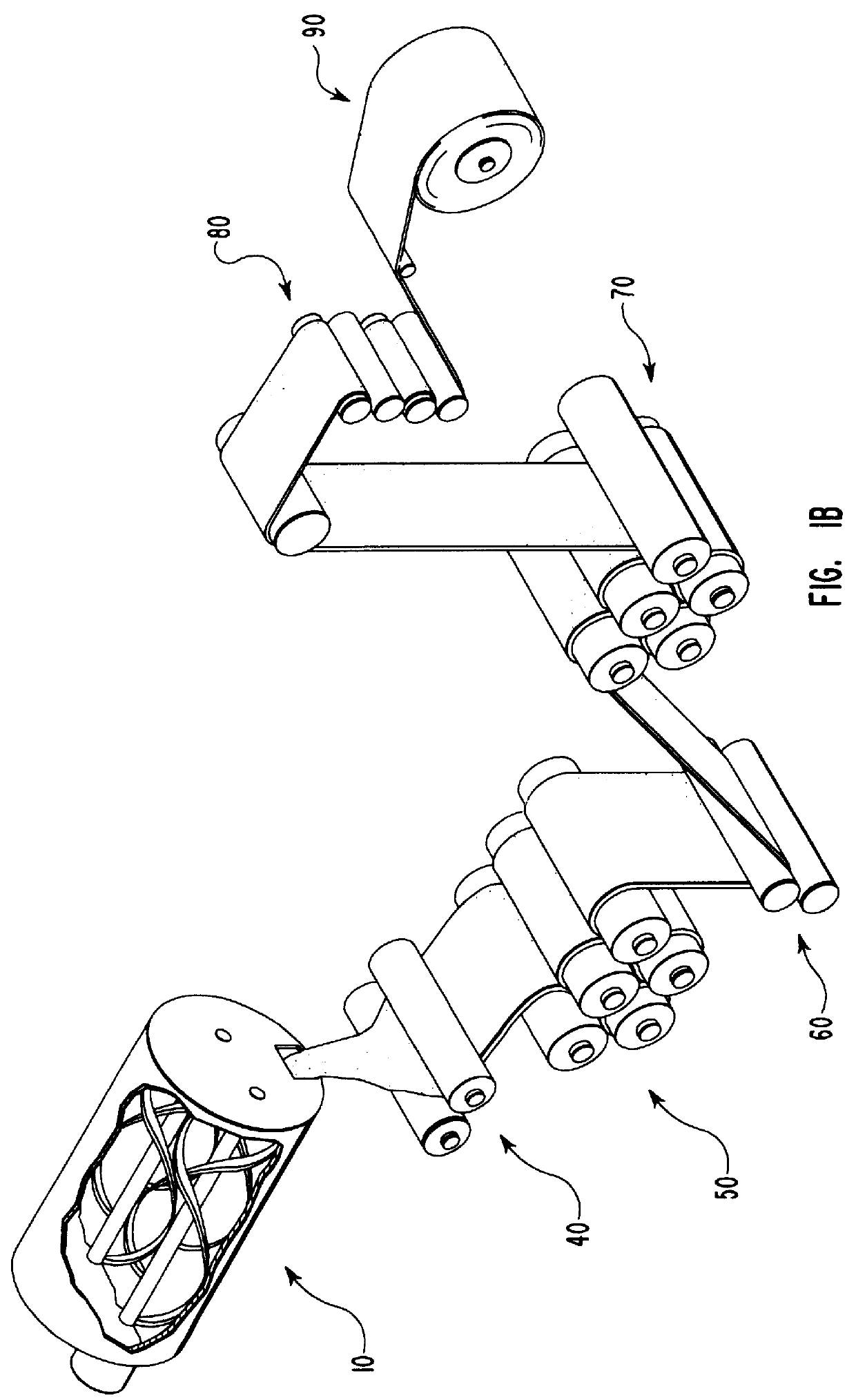

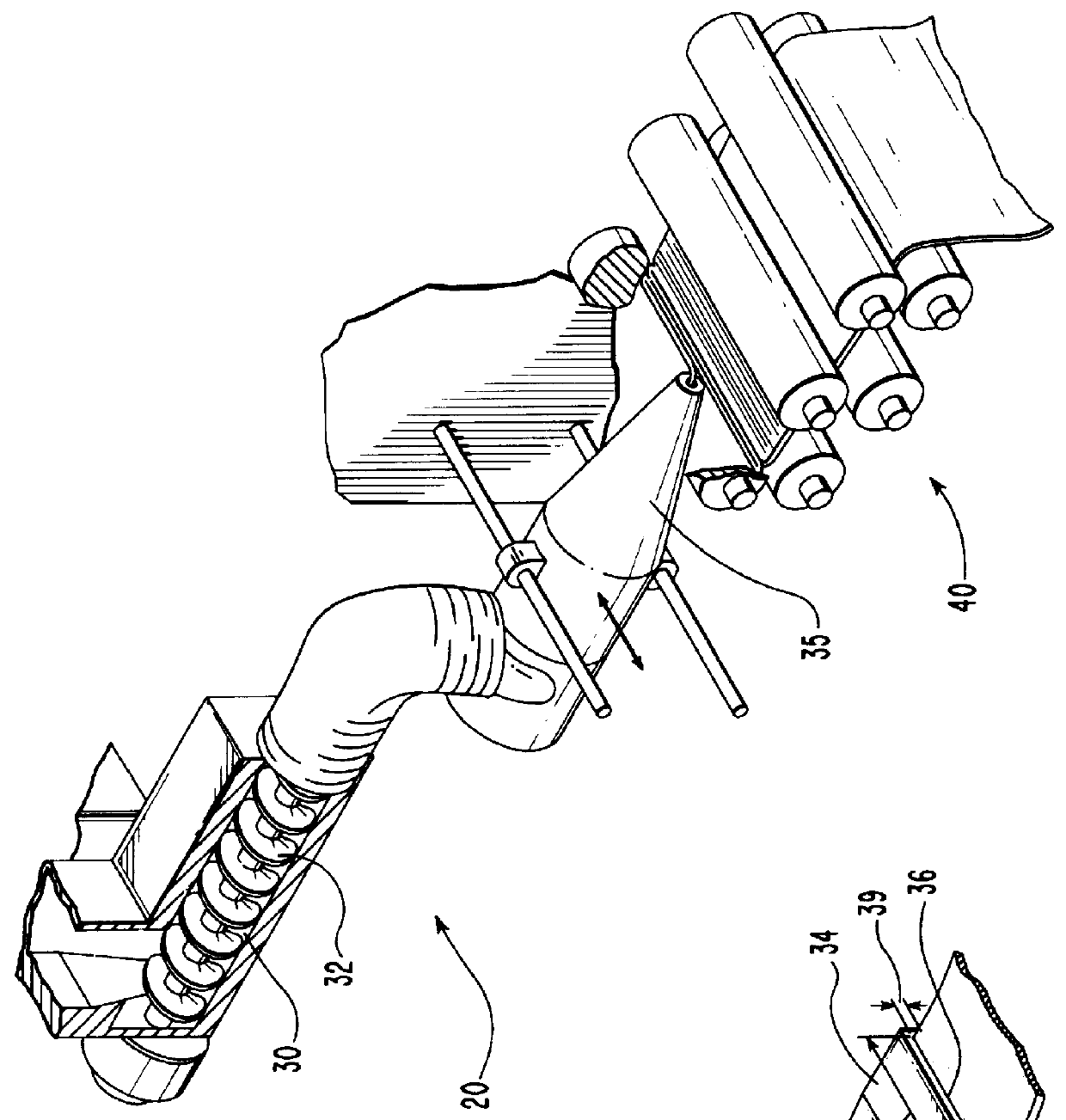

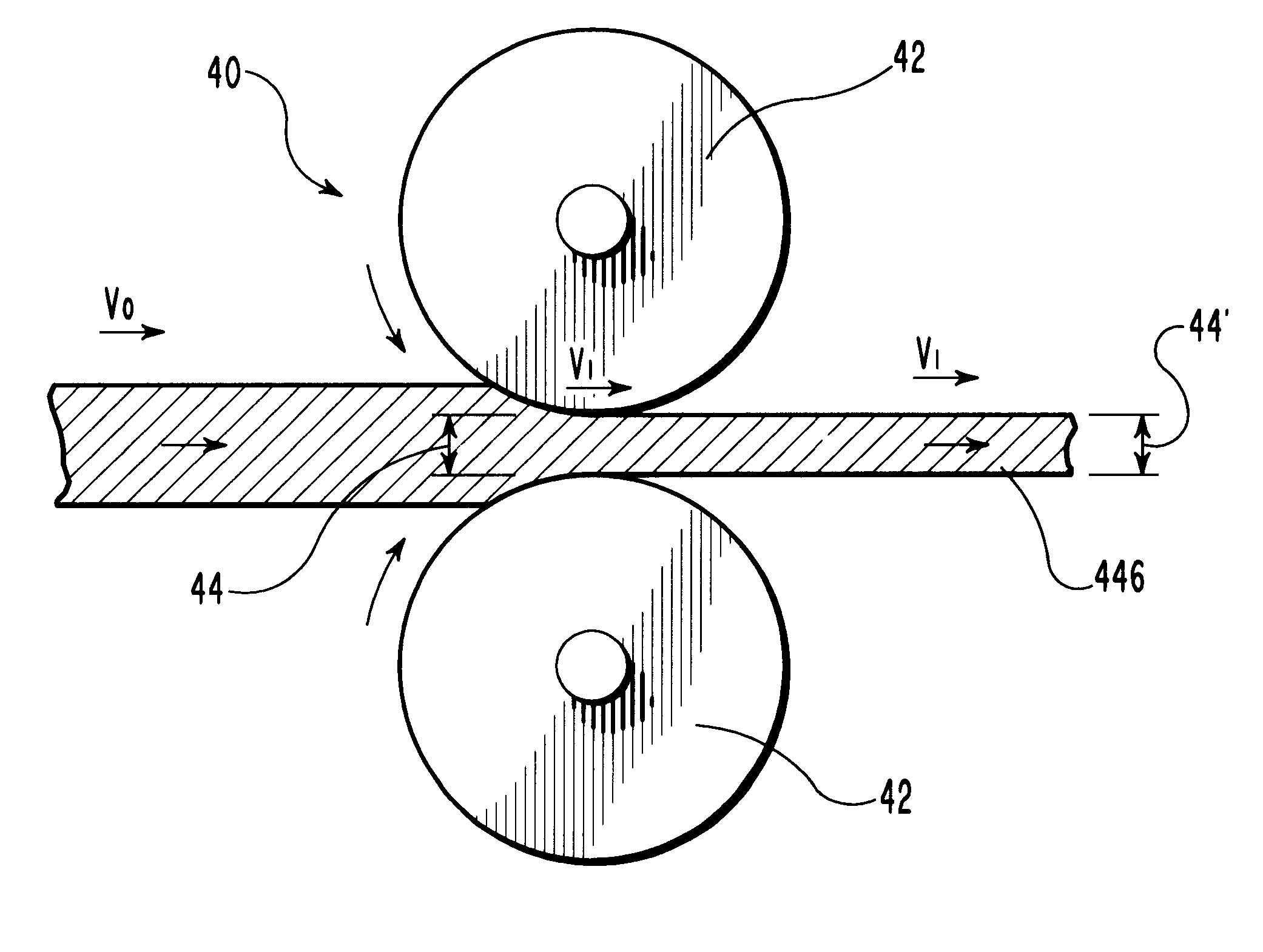

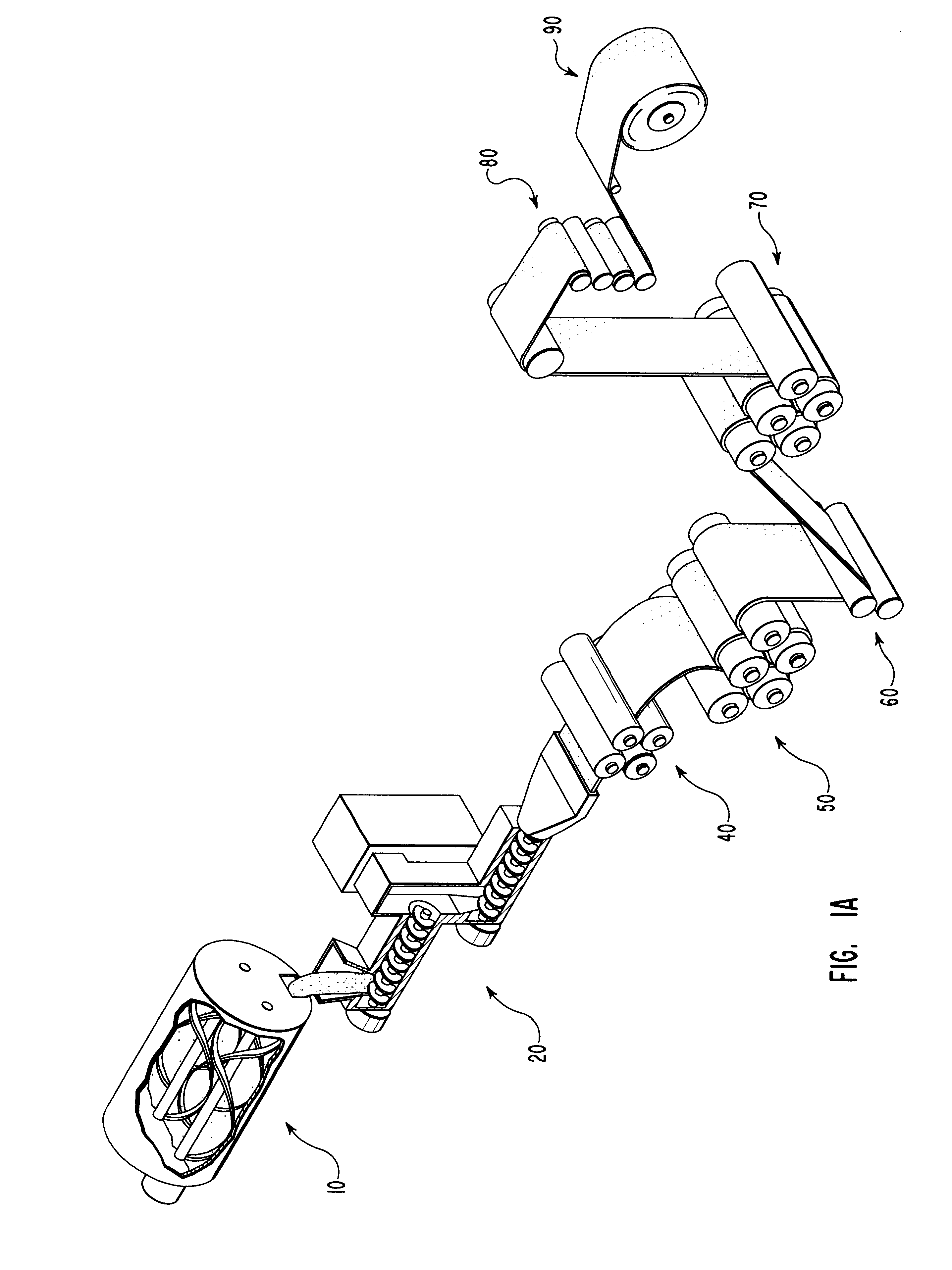

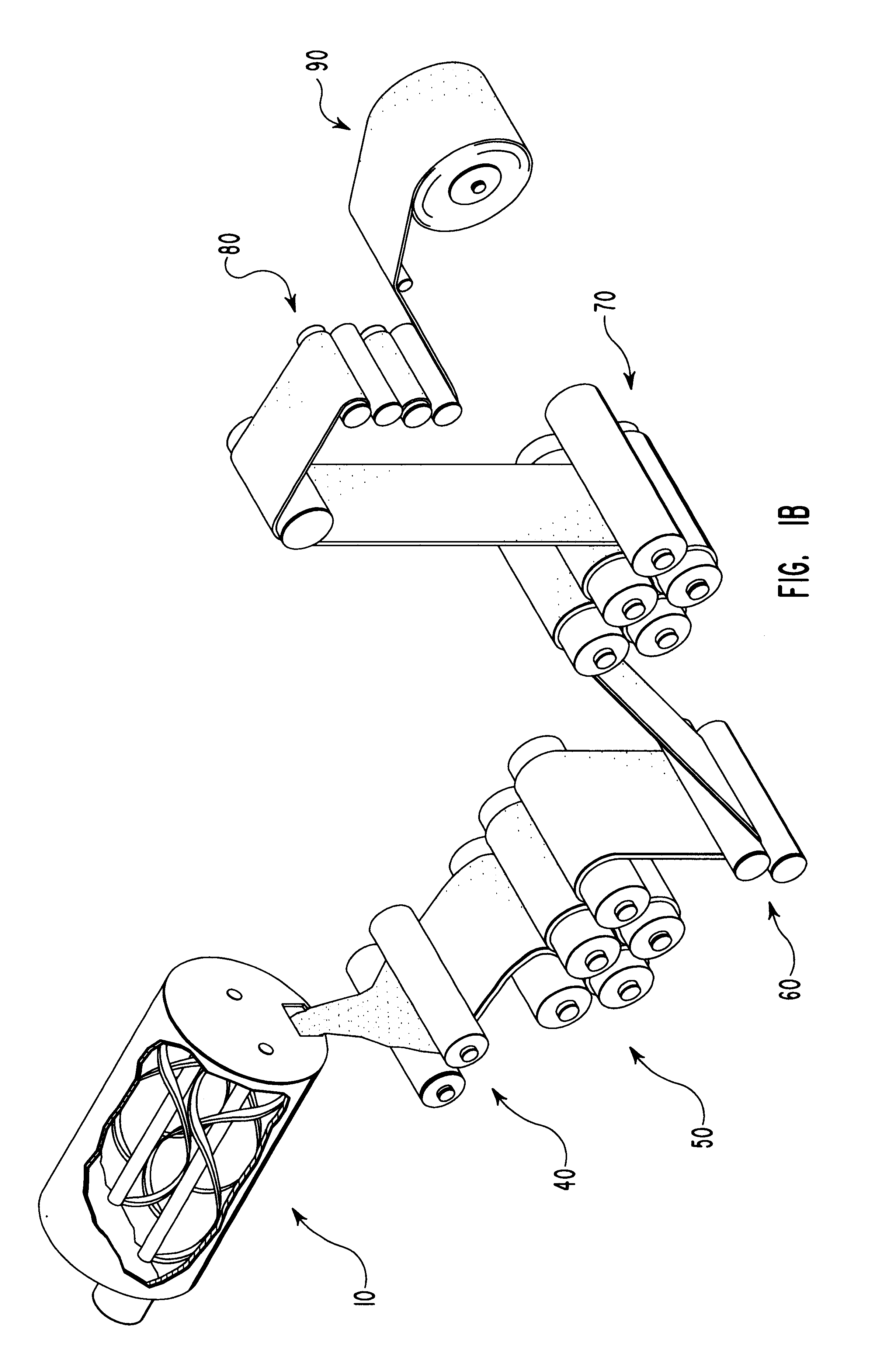

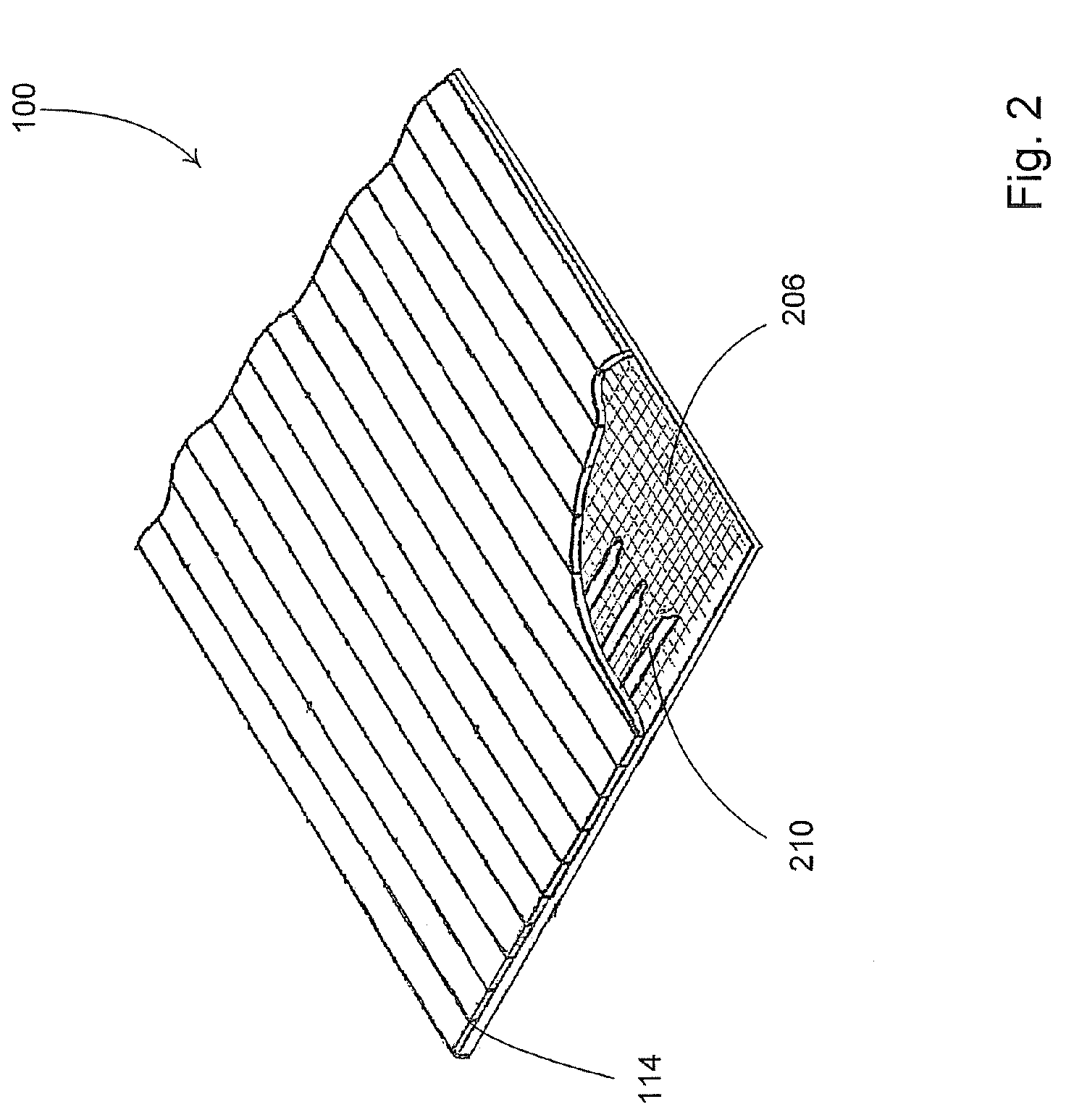

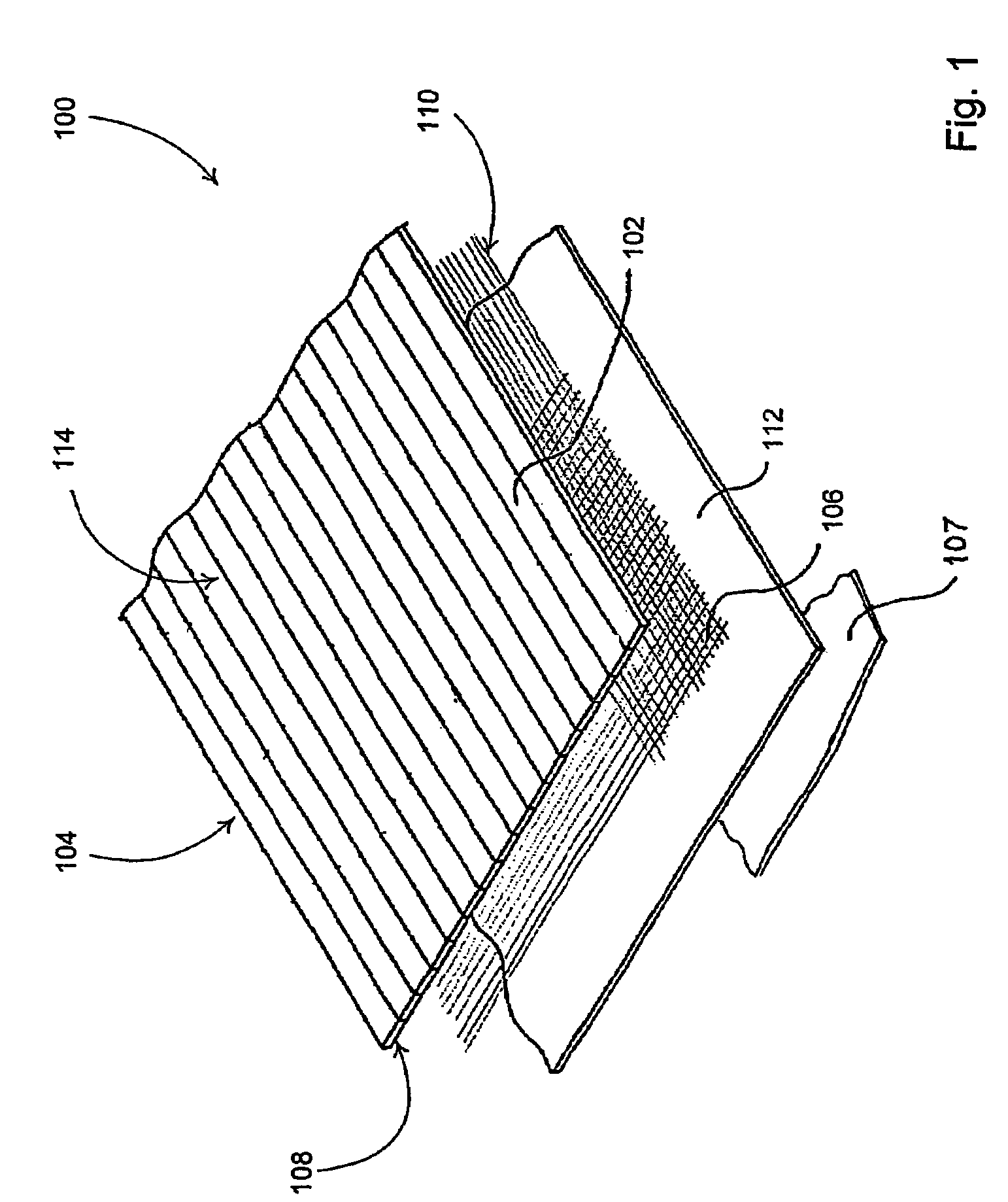

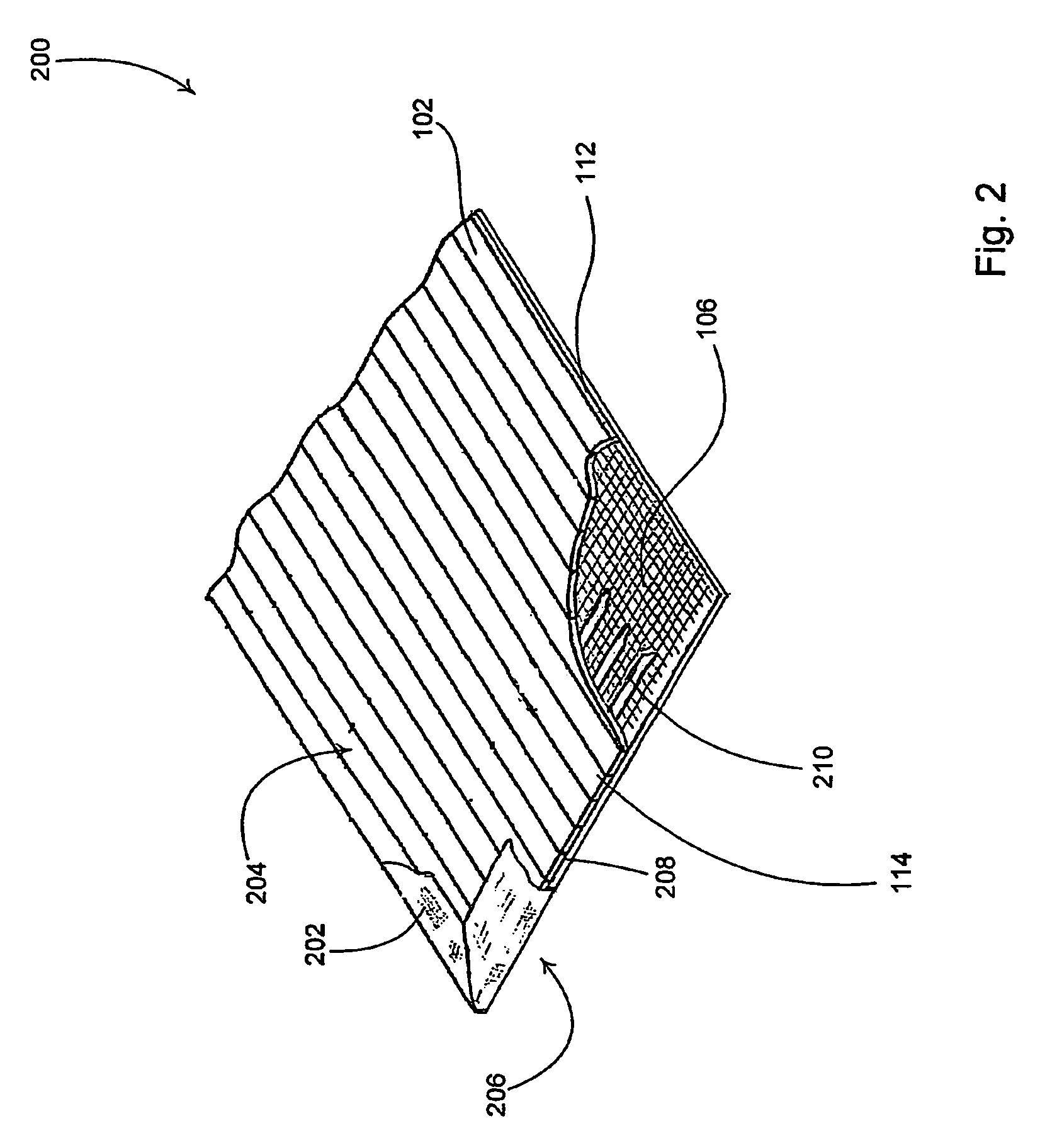

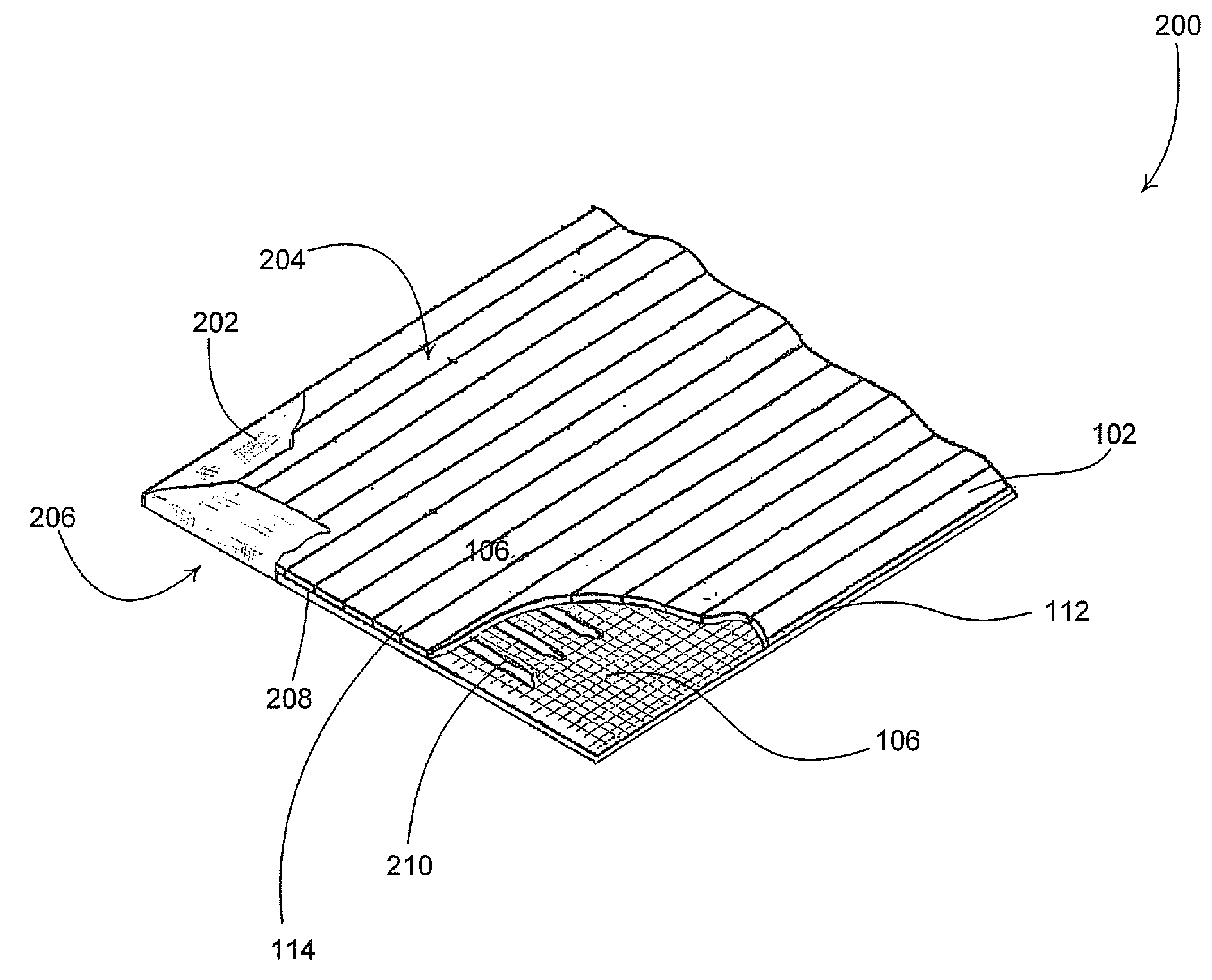

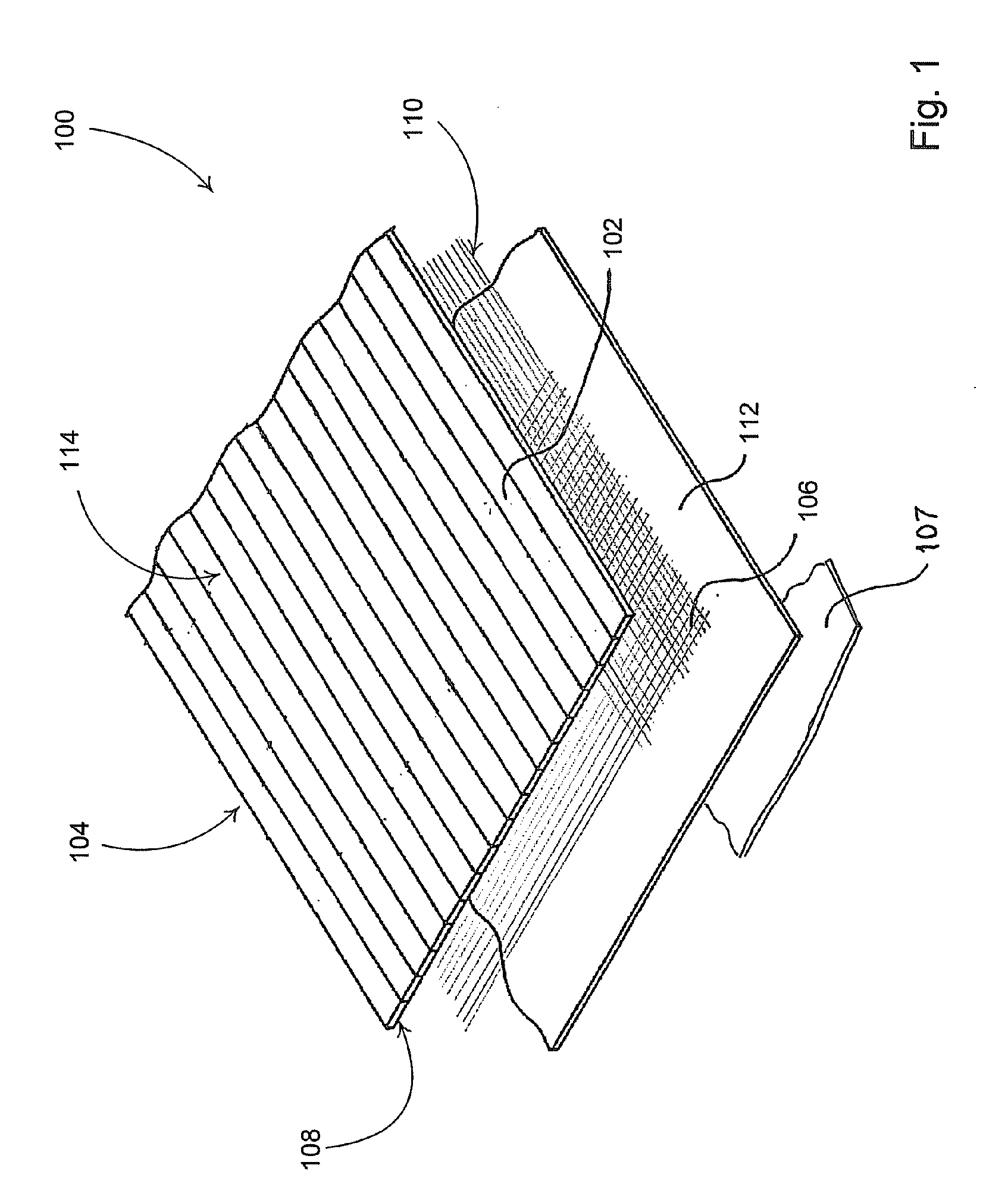

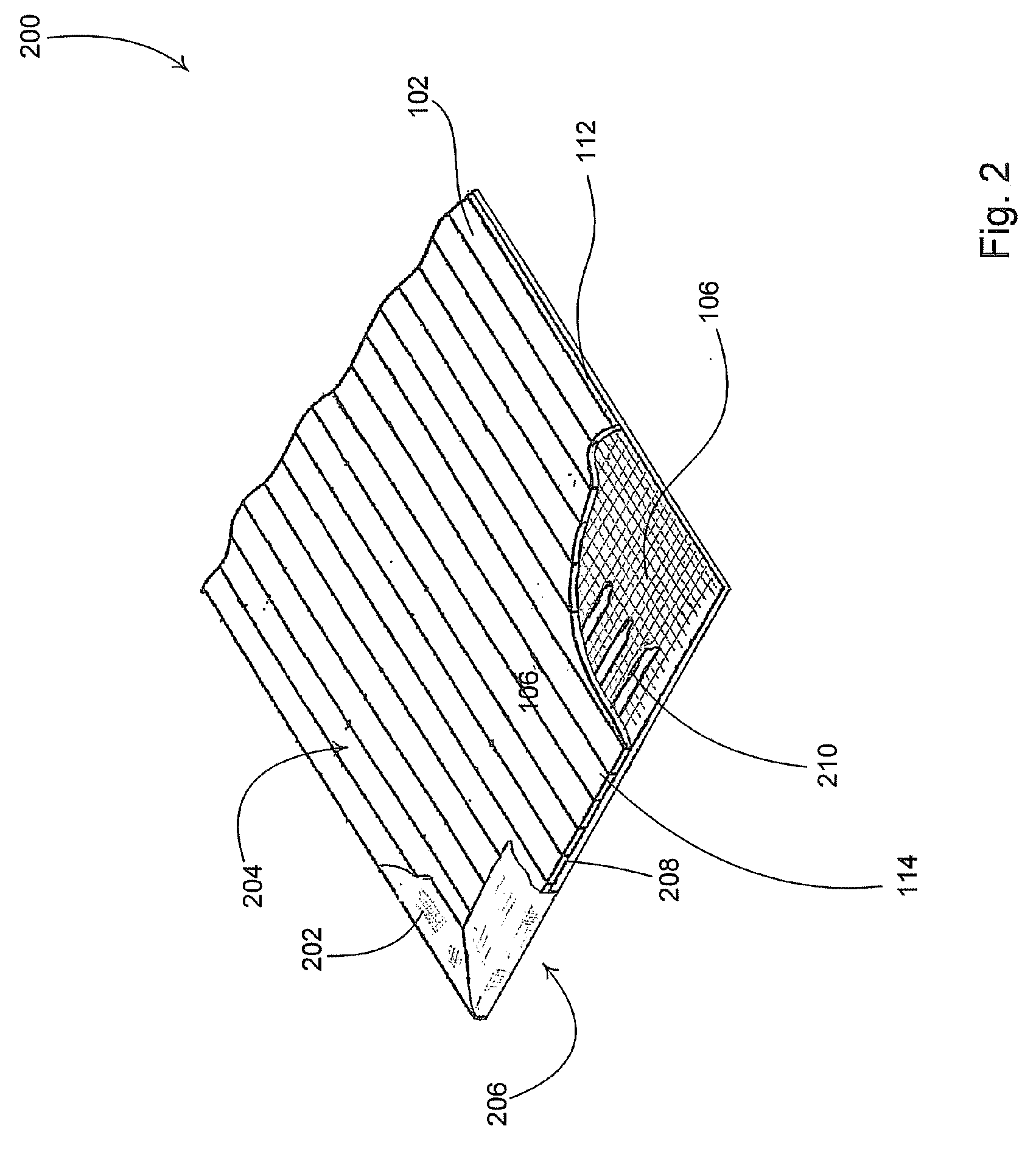

Compositions and methods for manufacturing sheets having a starch-bound matrix reinforced with fibers and optionally including an inorganic mineral filler. Suitable mixtures for forming the sheets are prepared by mixing together water, unmodified and ungelatinized starch granules, an auxiliary water-dispersible organic polymer, fibers, and optionally an inorganic mineral filler in the correct proportions to form a sheet having desired properties. The mixtures are formed into sheets by passing them between one or more sets of heated rollers to form green sheets. The heated rollers cause the auxiliary polymer to form a skin on the outer surfaces of the sheet that prevents the starch granules from causing the sheet to adhere to the rollers upon gelation of the starch. The green sheets are passed between heated rollers to gelatinize the starch granules, and then to dry the sheet by removing a substantial portion of the water by evaporation. The starch and auxiliary polymer form the binding matrix of the sheets with the fibers and optional inorganic filler dispersed throughout the binding matrix. The starch-bound sheets can be cut, rolled, pressed, scored, perforated, folded, and glued to fashion articles from the sheets much like paper or paperboard. The sheets are particularly useful in the mass production of containers, such as food and beverage containers.

Owner:E KHASHOGGI INDS

Sheets having a starch-based binding matrix

Compositions and methods for manufacturing sheets having a starch-bound matrix, optionally reinforced with fibers and optionally including an inorganic mineral filler. Suitable mixtures for forming the sheets are prepared by mixing together water, unmodified and ungelatinized starch granules, a cellulosic ether, optionally fibers, and optionally an inorganic mineral filler in the correct proportions to form a sheet having desired properties. The mixtures are formed into sheets by passing them between one or more sets of heated rollers to form green sheets. The heated rollers cause the cellulosic ether to form a skin on the outer surfaces of the sheet that prevents the starch granules from causing the sheet to adhere to the rollers upon gelation of the starch. The green sheets are passed between heated rollers to gelatinize the starch granules, and then to dry the sheet by removing a substantial portion of the water by evaporation. The starch and cellulosic ether form the binding matrix of the sheets with the fibers and optional inorganic filler dispersed throughout the binding matrix. The starch-bound sheets can be cut, rolled, pressed, scored, perforated, folded, and glued to fashion articles from the sheets much like paper or paperboard. The sheets are particularly useful in the mass production of containers, such as food and beverage containers.

Owner:E KHASHOGGI INDS

Compositions and methods for manufacturing starch-based sheets

Compositions and methods for manufacturing sheets having a starch-bound matrix reinforced with fibers and optionally including an inorganic mineral filler. Suitable mixtures for forming the sheets are prepared by mixing together water, unmodified and ungelatinized starch granules, an auxiliary water-dispersible organic polymer, fibers, and optionally an inorganic mineral filler in the correct proportions to form a sheet having desired properties. The mixtures are formed into sheets by passing them between one or more sets of heated rollers to form green sheets. The heated rollers cause the auxiliary polymer to form a skin on the outer surfaces of the sheet that prevents the starch granules from causing the sheet to adhere to the rollers upon gelation of the starch. The green sheets are passed between heated rollers to gelatinize the starch granules, and then to dry the sheet by removing a substantial portion of the water by evaporation. The starch and auxiliary polymer form the binding matrix of the sheets with the fibers and optional inorganic filler dispersed throughout the binding matrix. The starch-bound sheets can be cut, rolled, pressed, scored, perforated, folded, and glued to fashion articles from the sheets much like paper or paperboard. The sheets are particularly useful in the mass production of containers, such as food and beverage containers.

Owner:E KHASHOGGI INDS

Wear resistant coating for brush seal applications

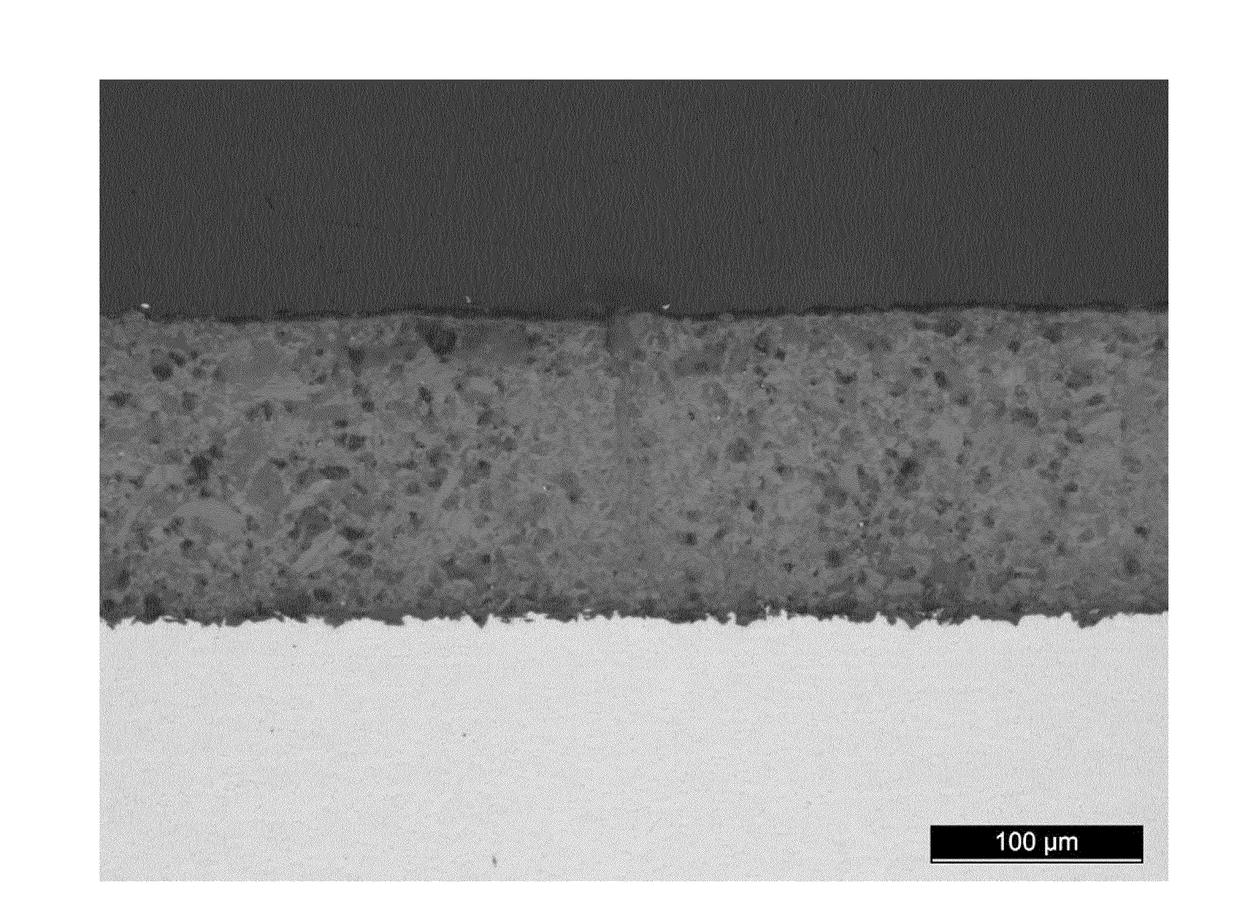

InactiveUS6186508B1Less stressReduced tendency to crackEngine sealsMolten spray coatingWear resistantCarbide

A metallic coating containing hard carbide particles is described. The coating is applied by an HVOF process using powder particles whose size ranges from about 15 to about 44 microns. The carbide particles are held in a 80% nickel-20% chromium matrix. The coating has a reduced tensile compressive stress relative to similar plasma sprayed coatings and exhibits a high strain to cracking value.

Owner:UNITED TECH CORP

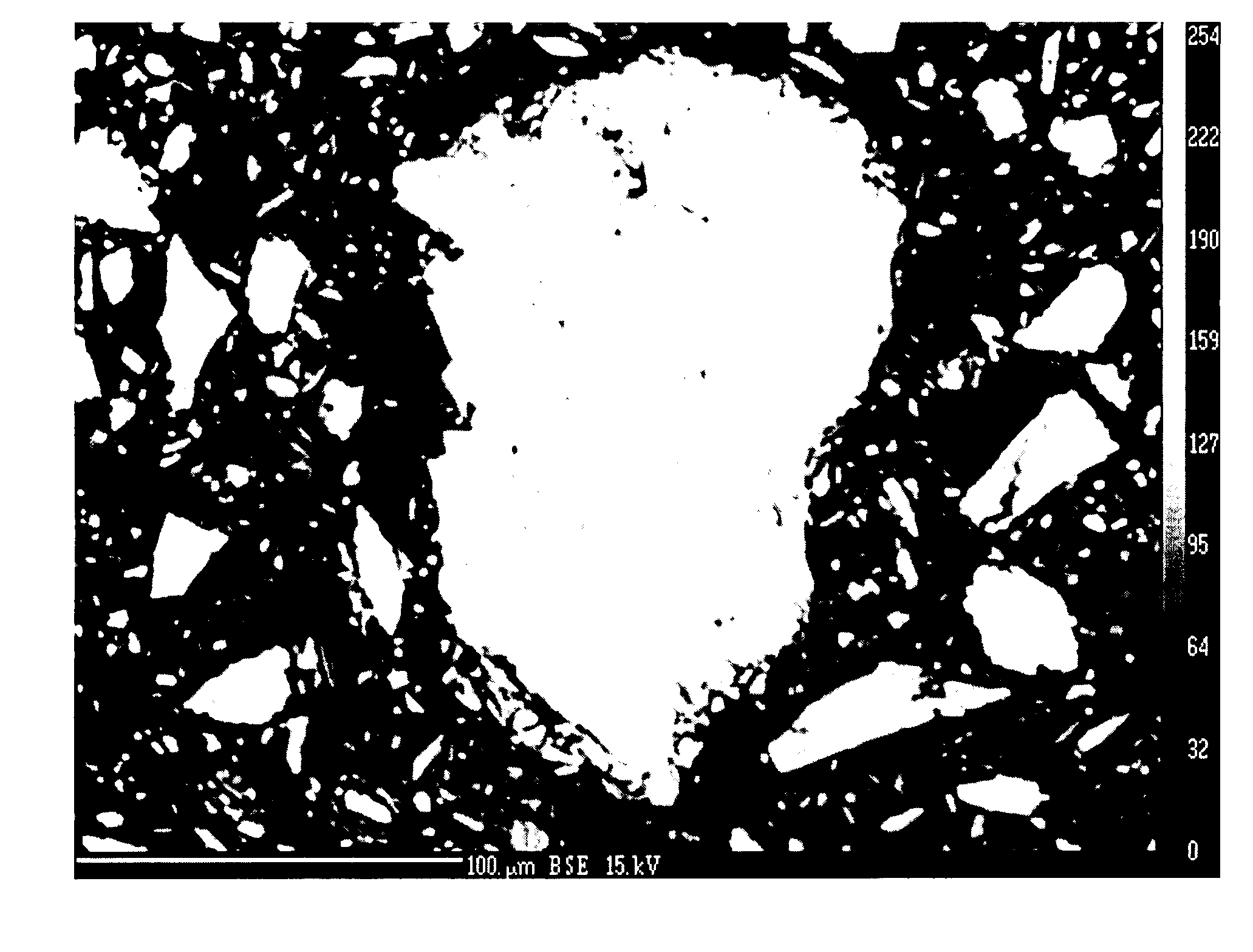

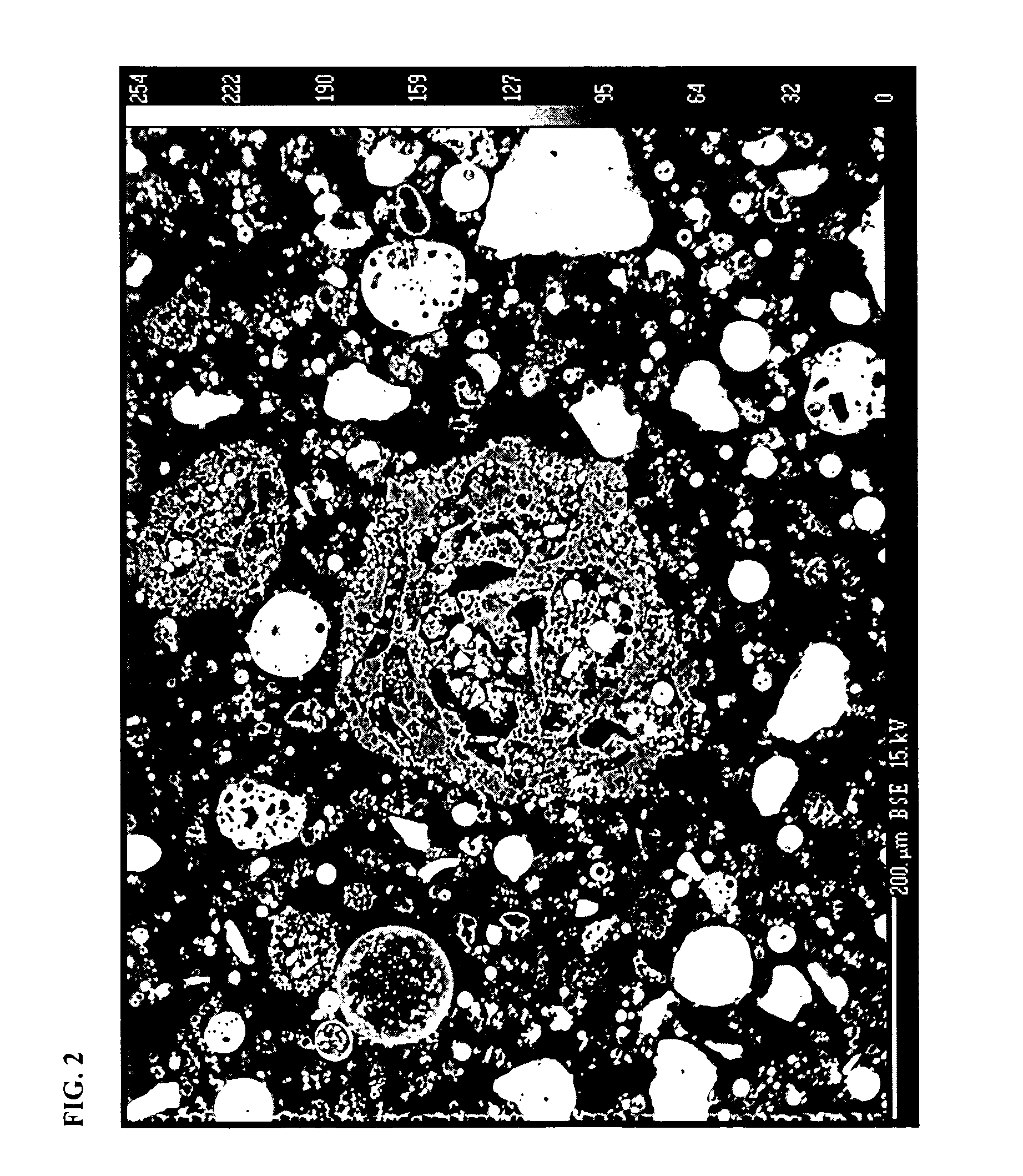

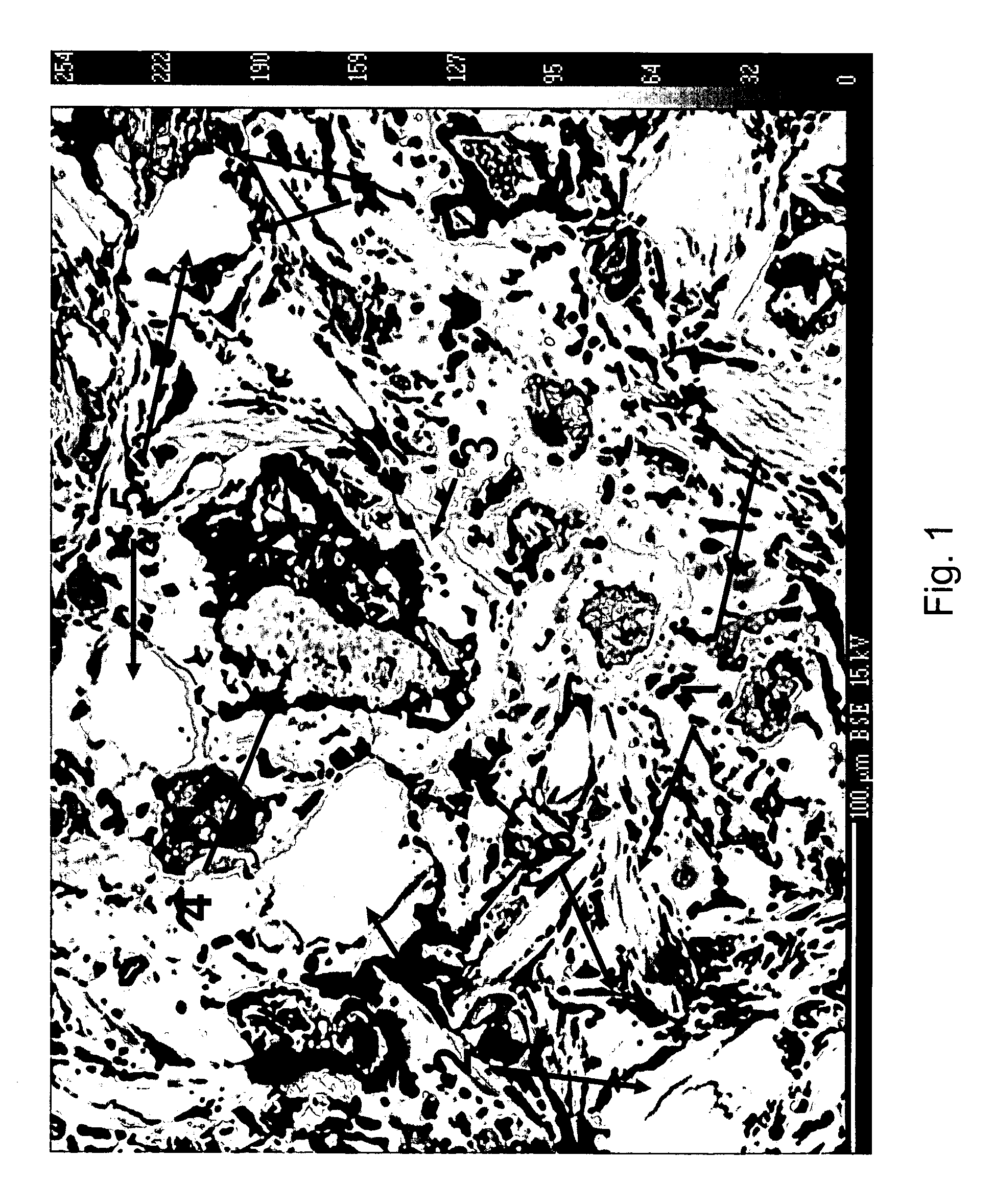

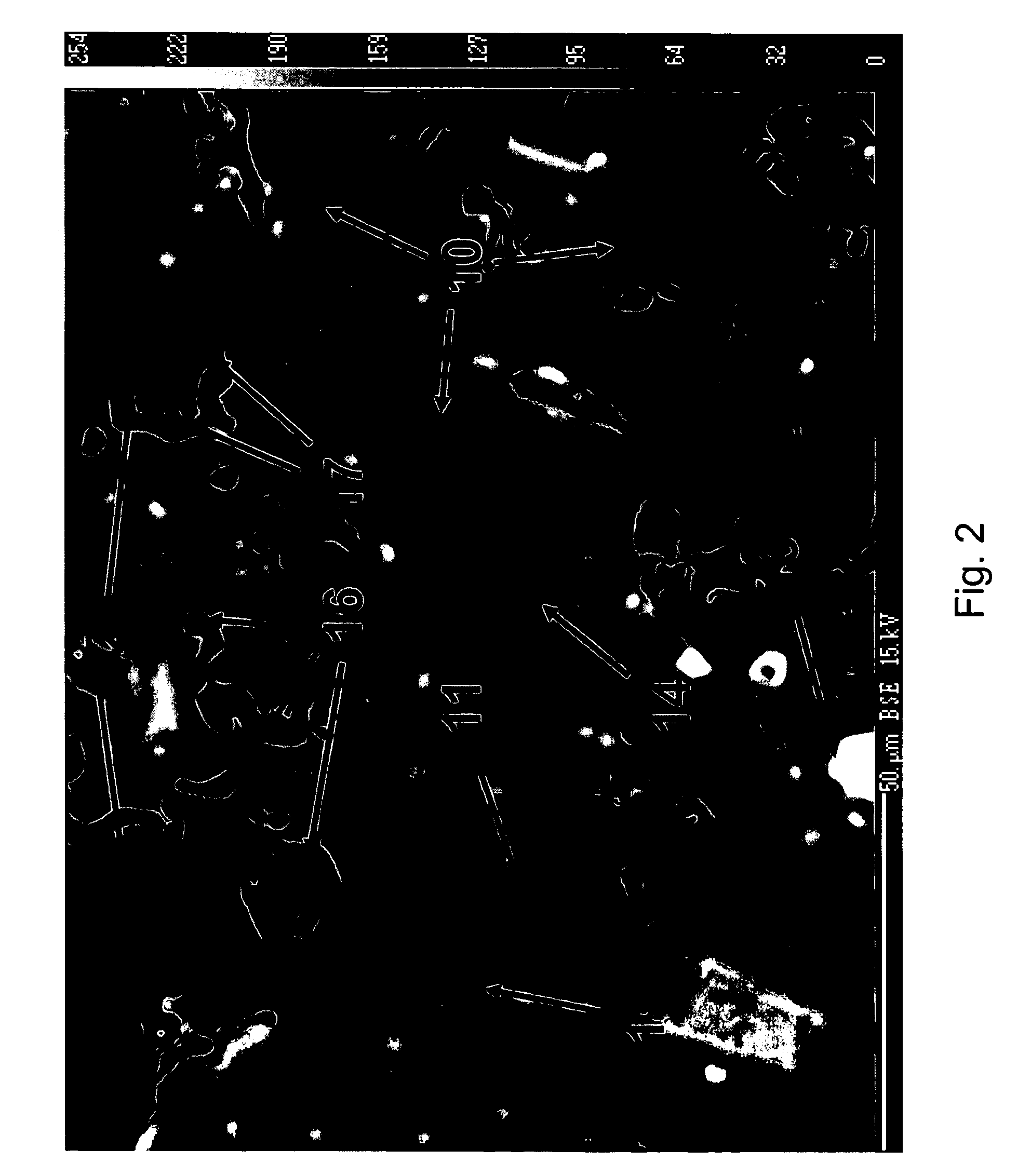

Synthesized hybrid rock composition, method, and article formed by the method

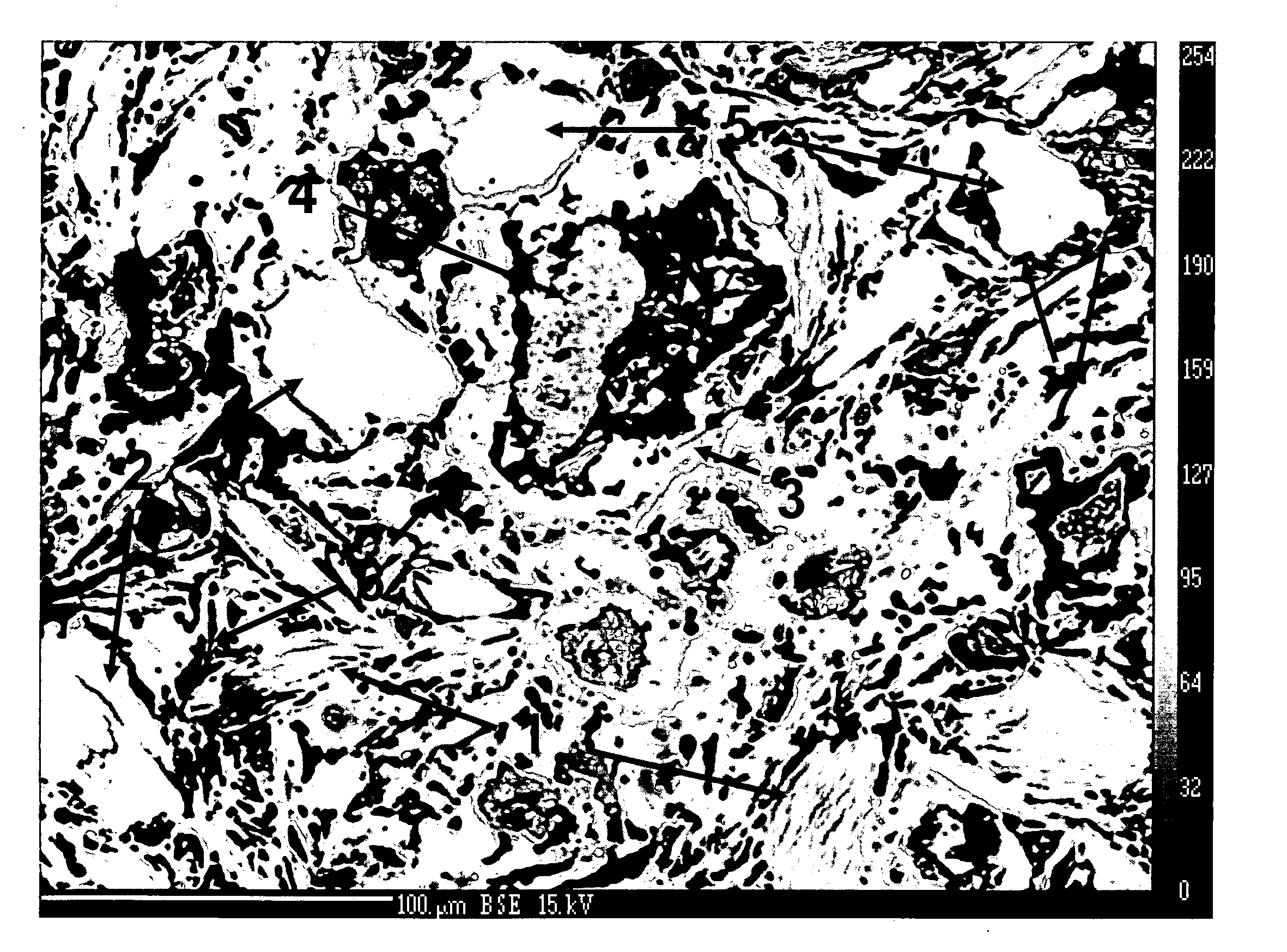

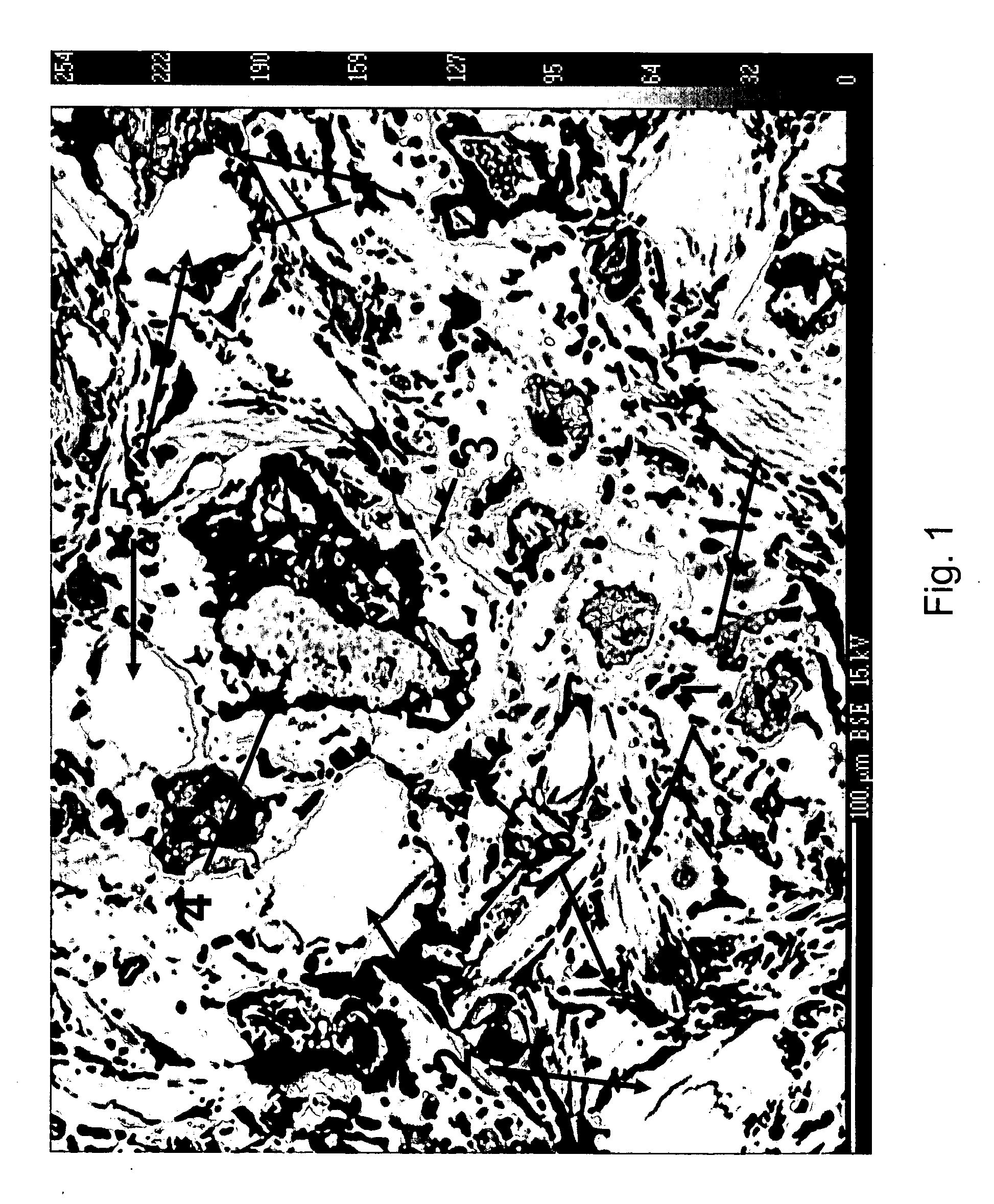

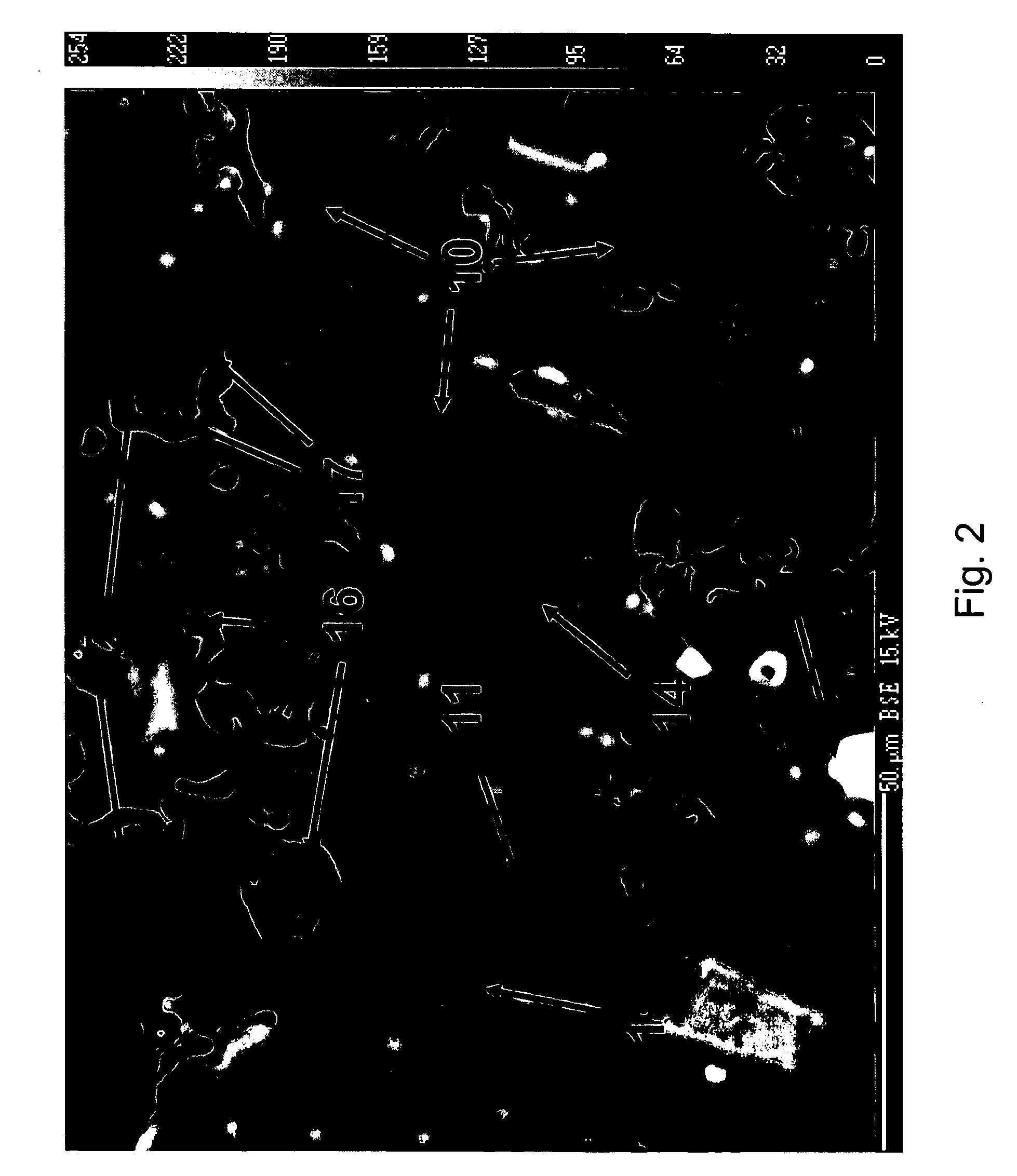

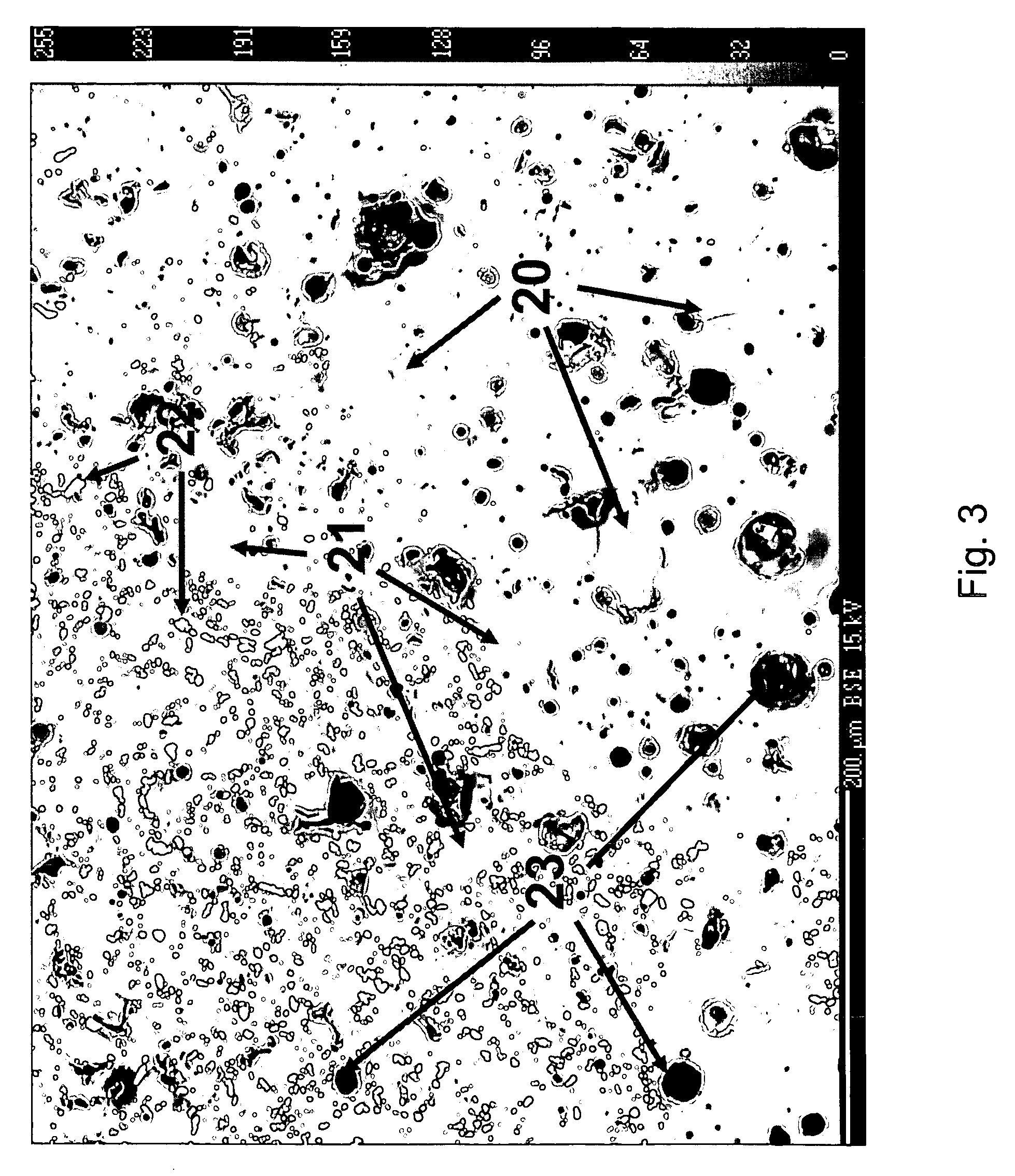

ActiveUS20070049487A1Less porousLight weightSolid waste managementTransportation and packagingSlagScrap

The invention relates to synthetic hybrid rock compositions, articles of manufacture and related processes employing mineral waste starting materials such as mine tailings, mine development rock, ash, slag, quarry fines, and slimes, to produce valuable articles of manufacture and products, which are characterized by superior physical and structural characteristics, including low porosity, low absorption, increased strength and durability, and retained plasticity. The resulting materials are compositionally and chemically distinct from conventional synthetic rock materials as demonstrated by scanning electron microprobe analysis, and are useful in a wide variety of applications, particularly with respect to commercial and residential construction.

Owner:CERAMEXT LLC

Wear resistant coating for brush seal applications

InactiveUS6815099B1Less stressReduced tendency to crackEngine sealsMolten spray coatingWear resistantCarbide

A metallic coating containing hard carbide particles is described. The coating is applied by an HVOF process using powder particles whose size ranges from about 15 to about 44 microns. The carbide particles are held in a 80% nickel-20% chromium matrix. The coating has a reduced tensile compressive stress relative to similar plasma sprayed coatings and exhibits a high strain to cracking value.

Owner:UNITED TECH CORP

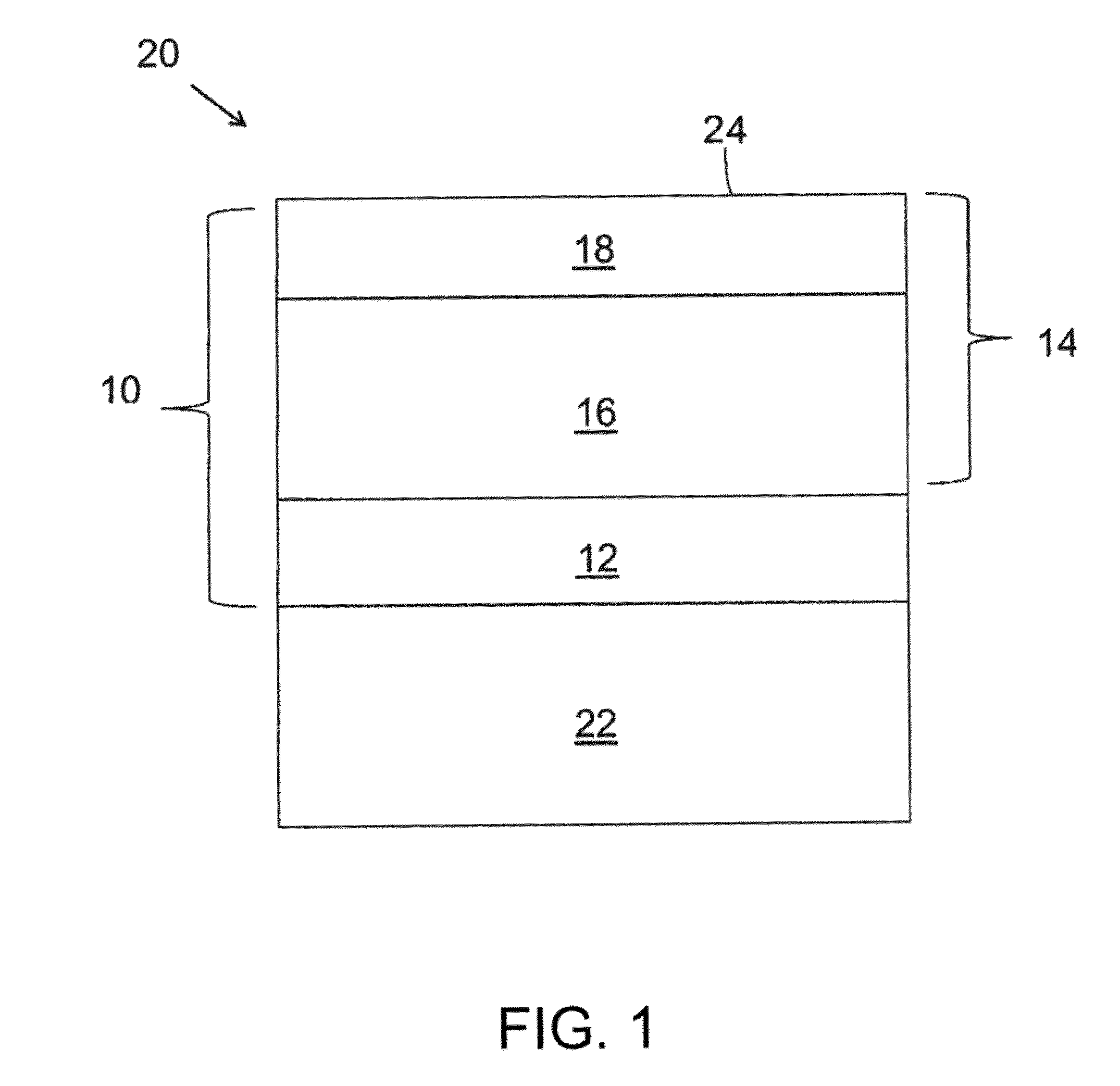

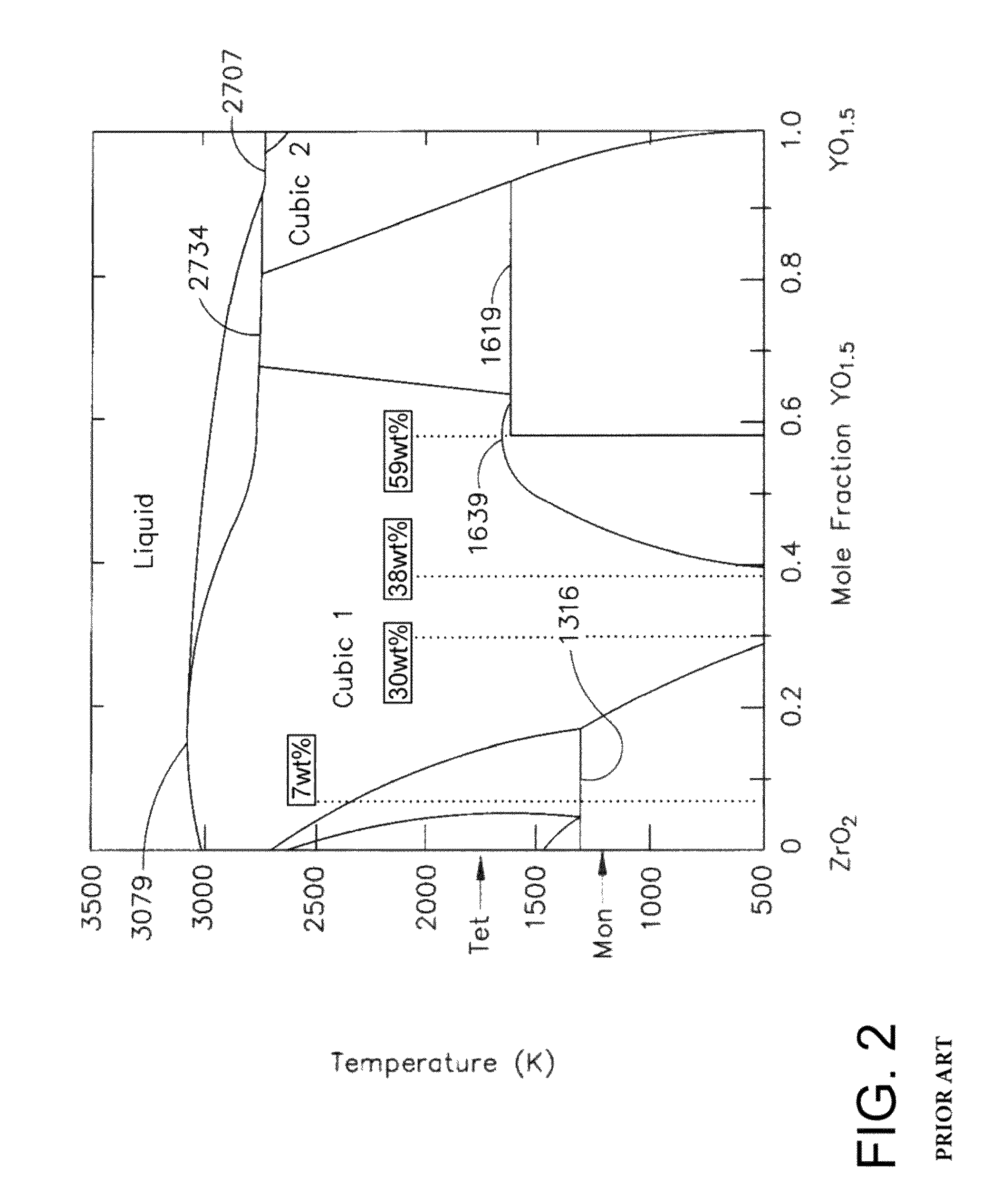

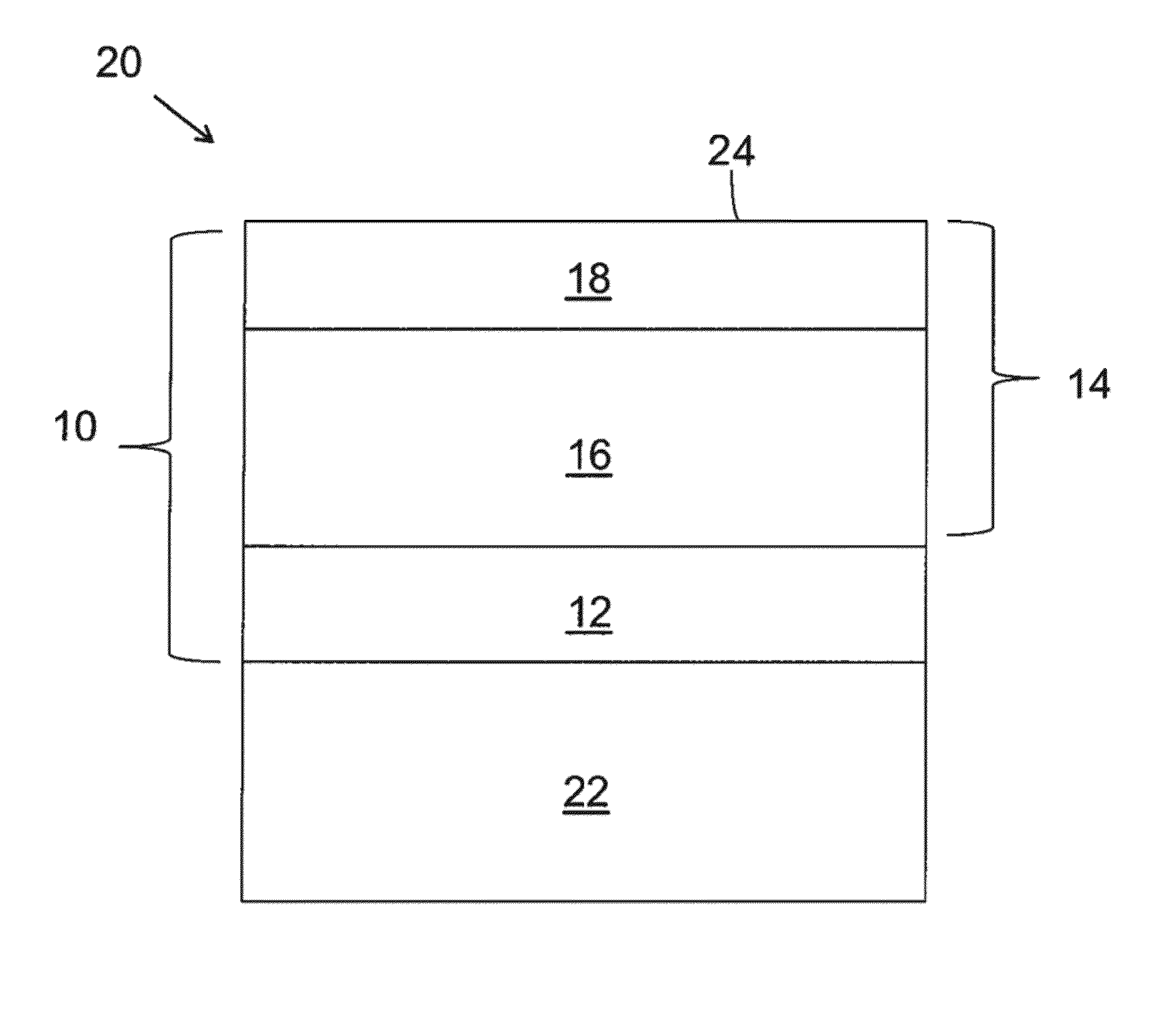

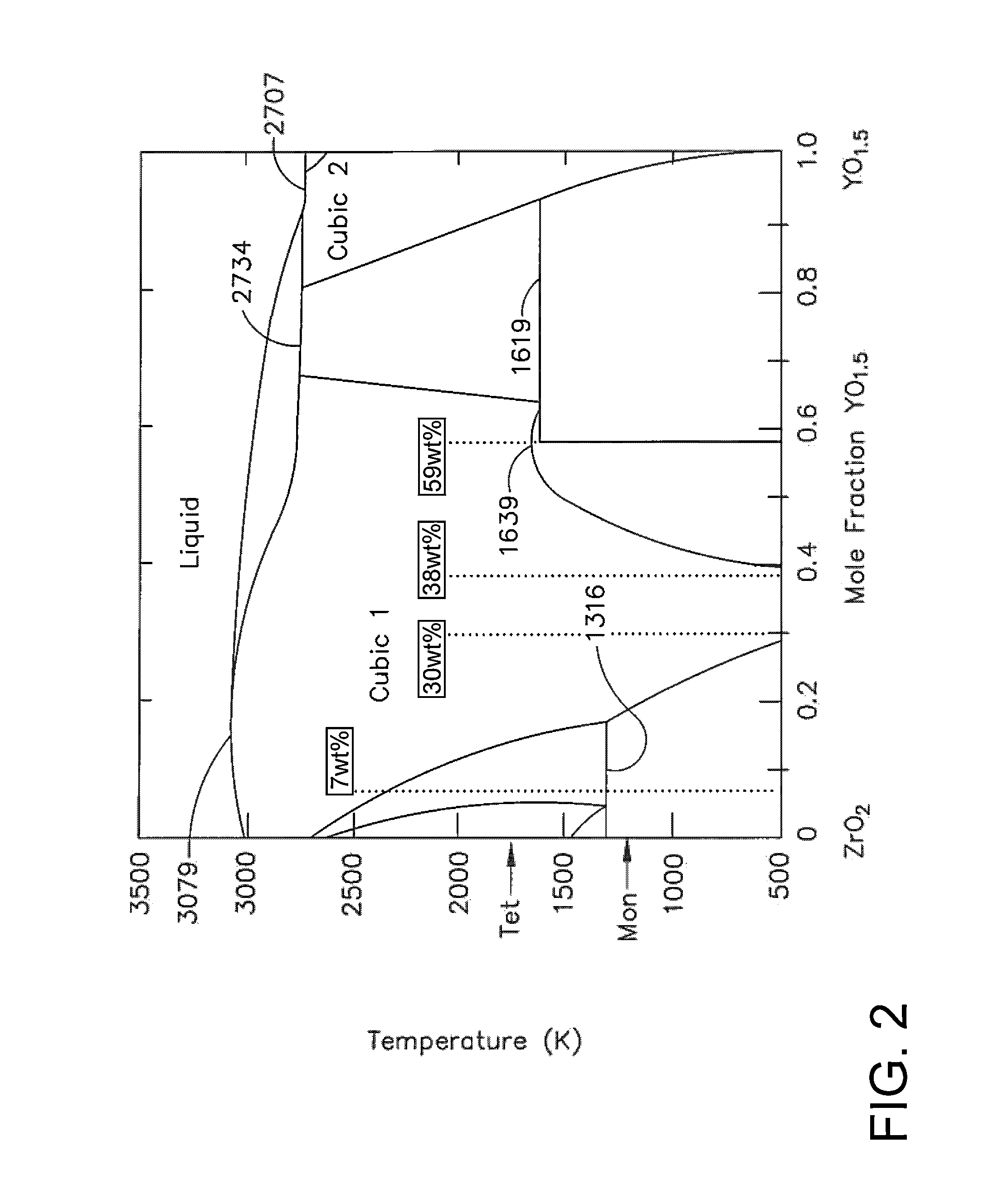

Thermal barrier coating systems and processes therefor

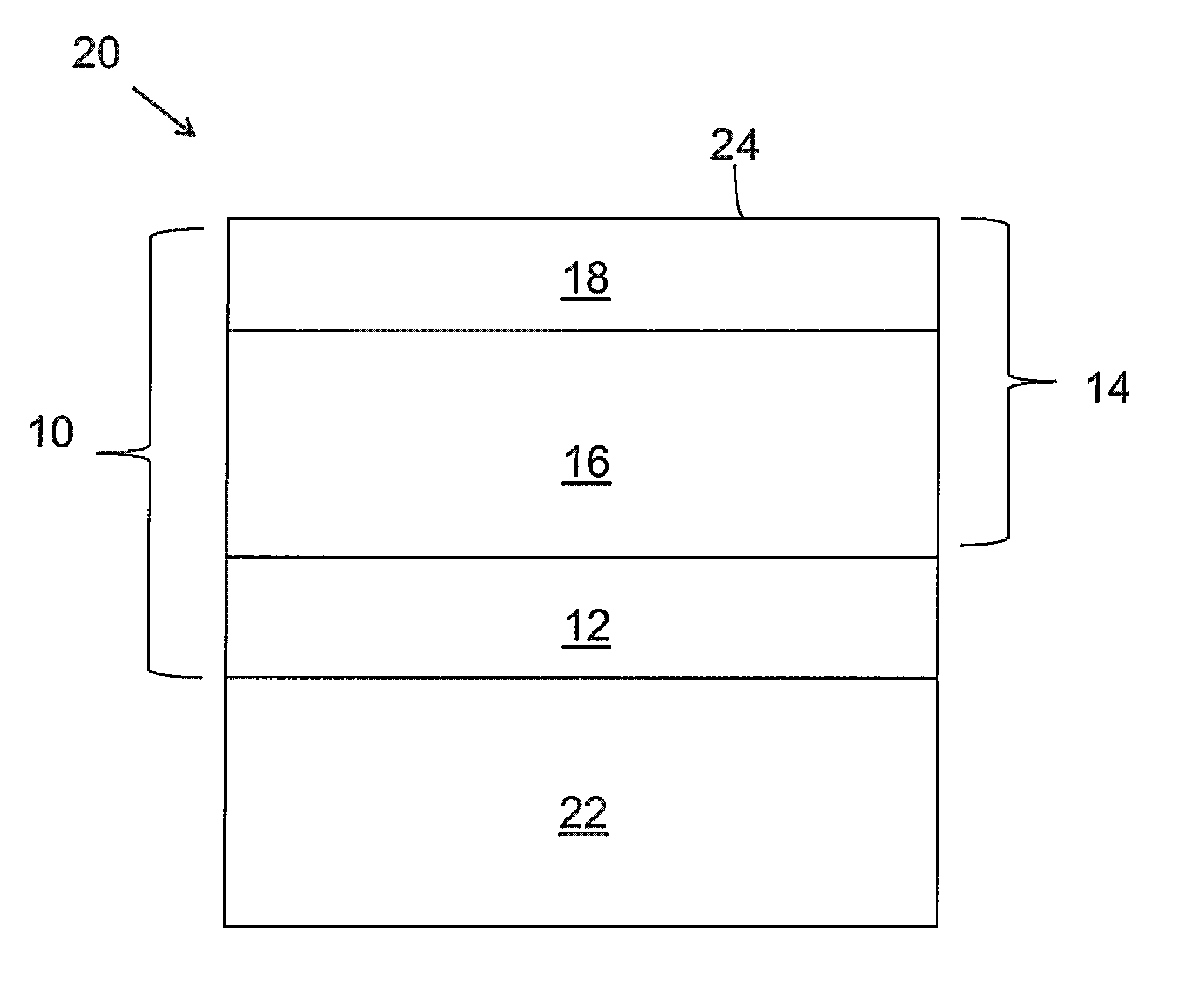

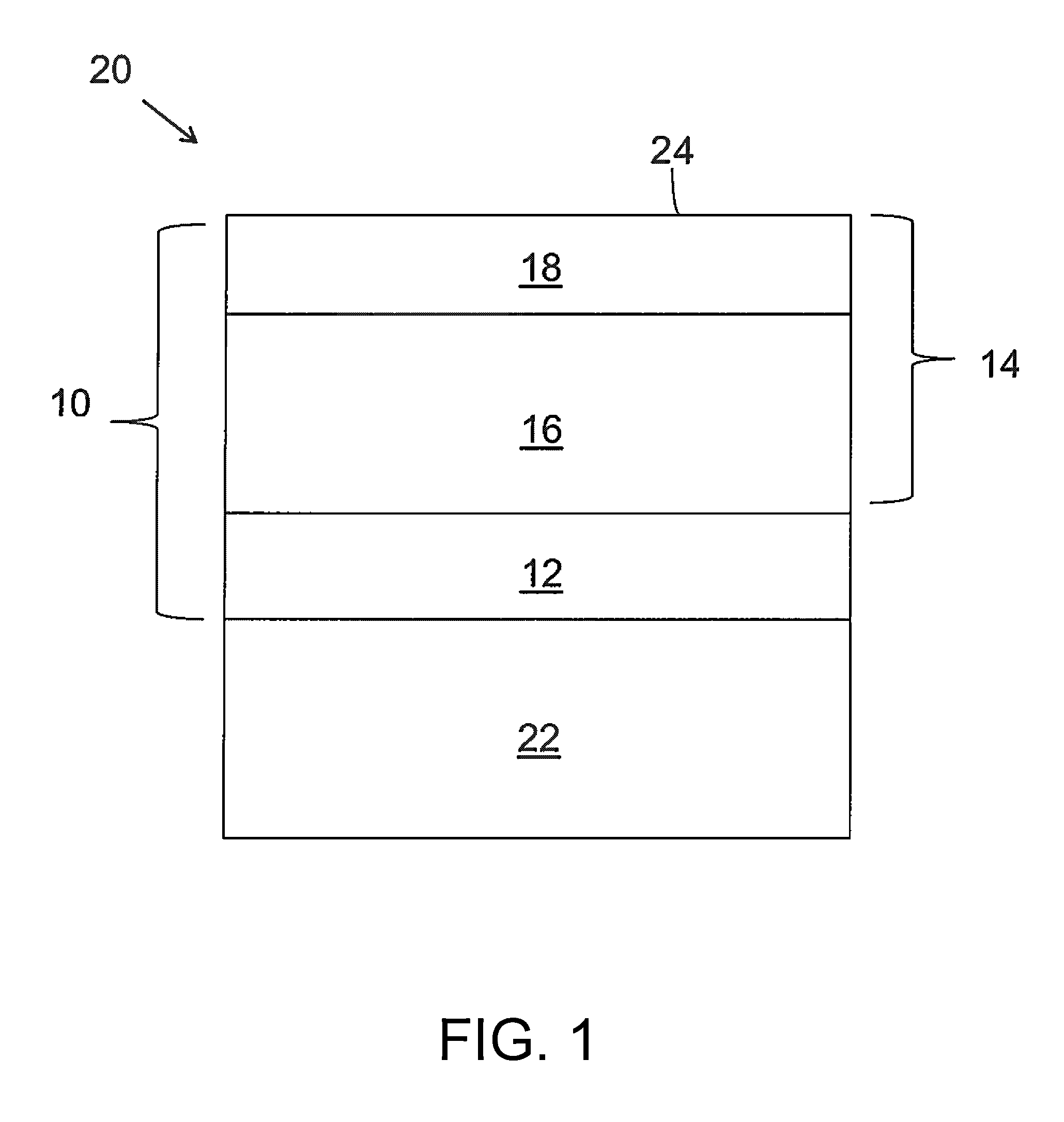

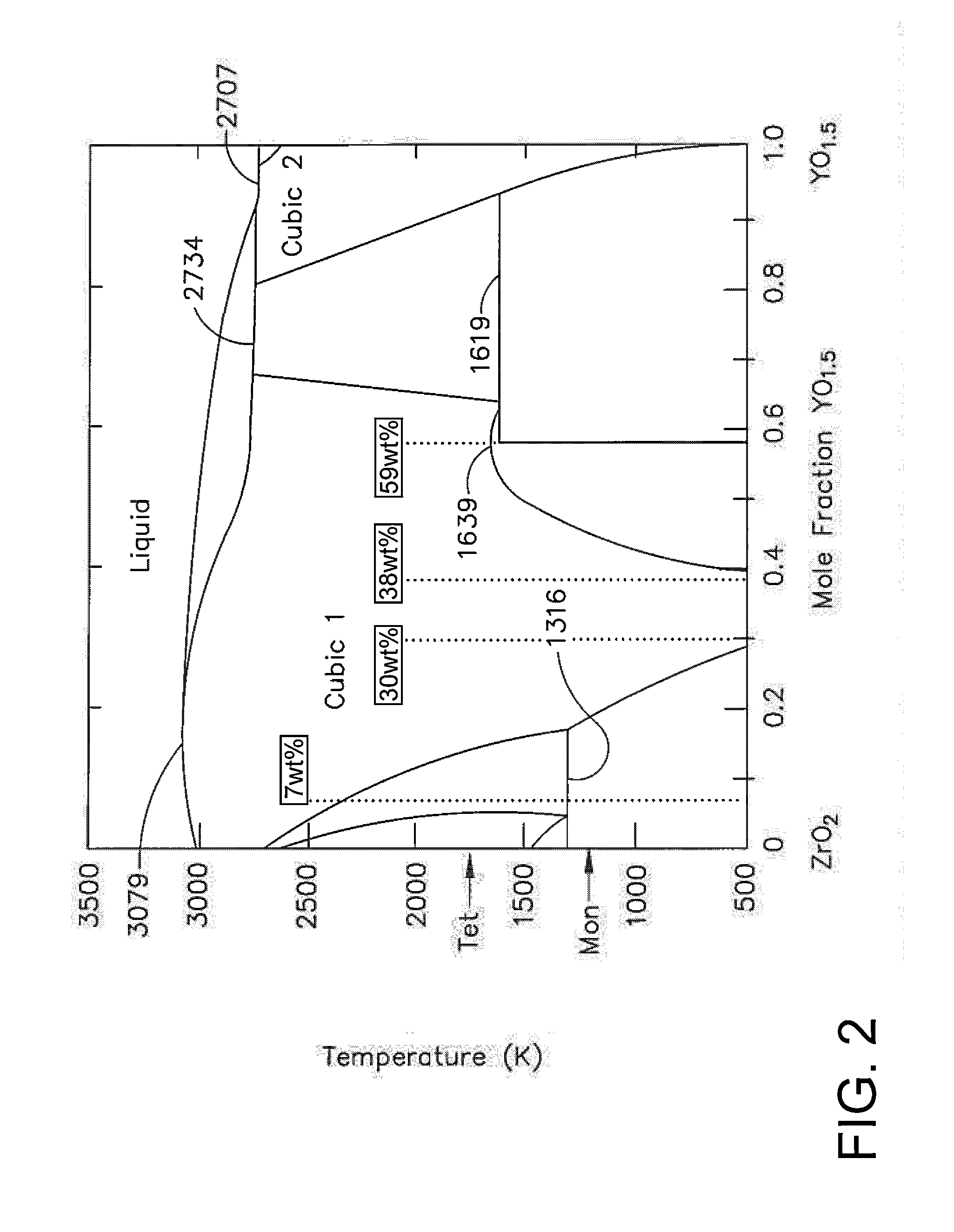

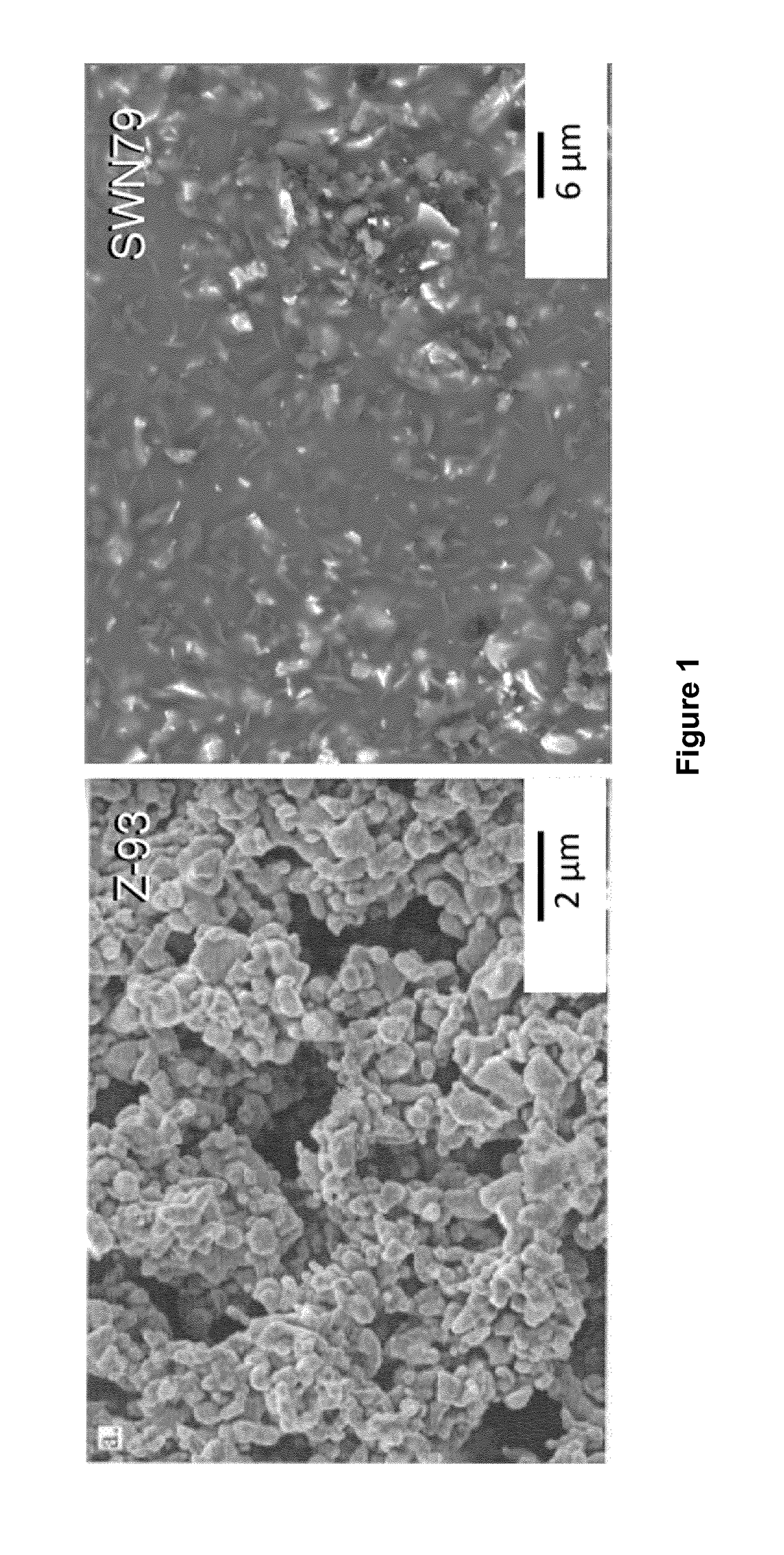

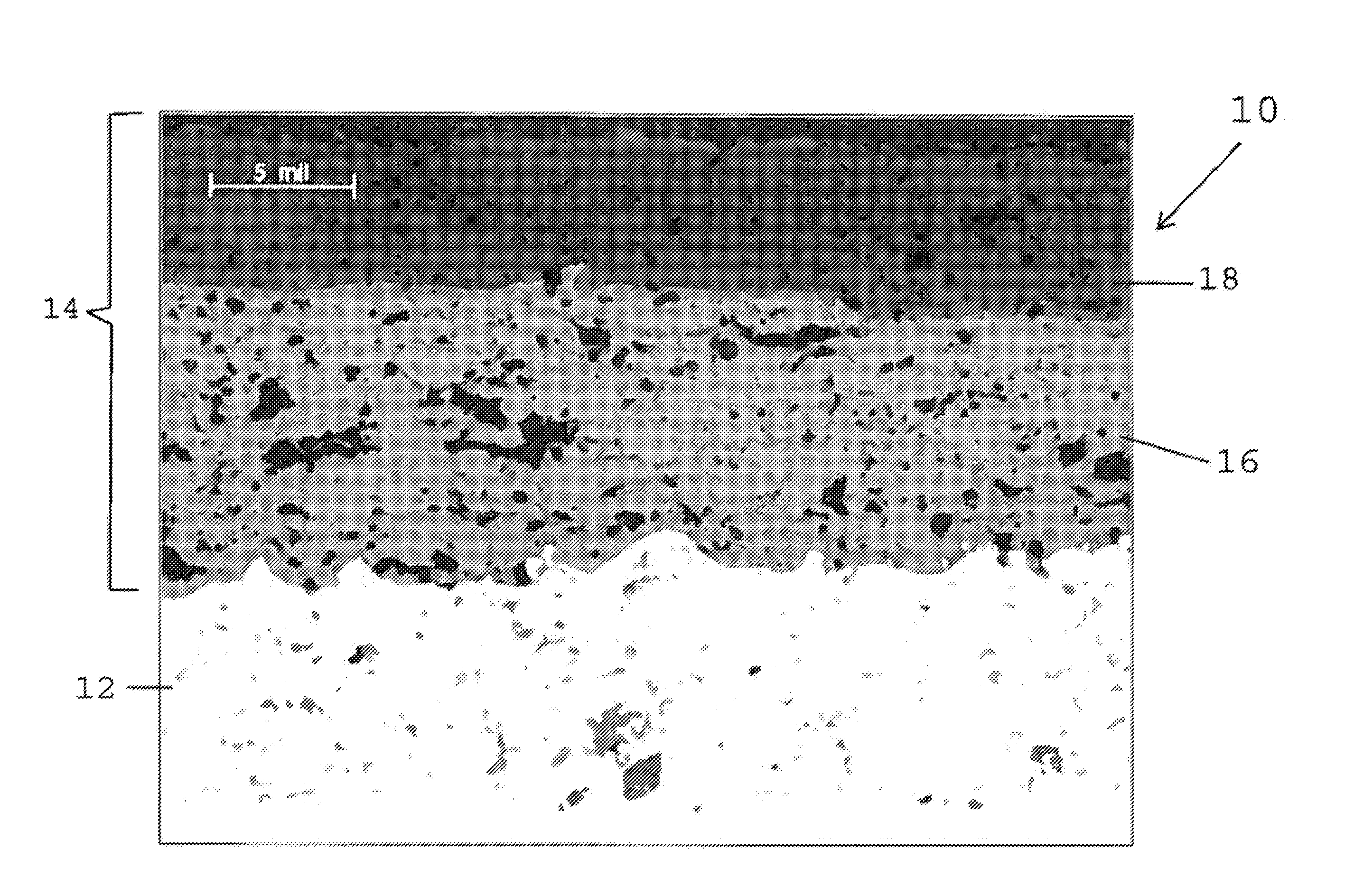

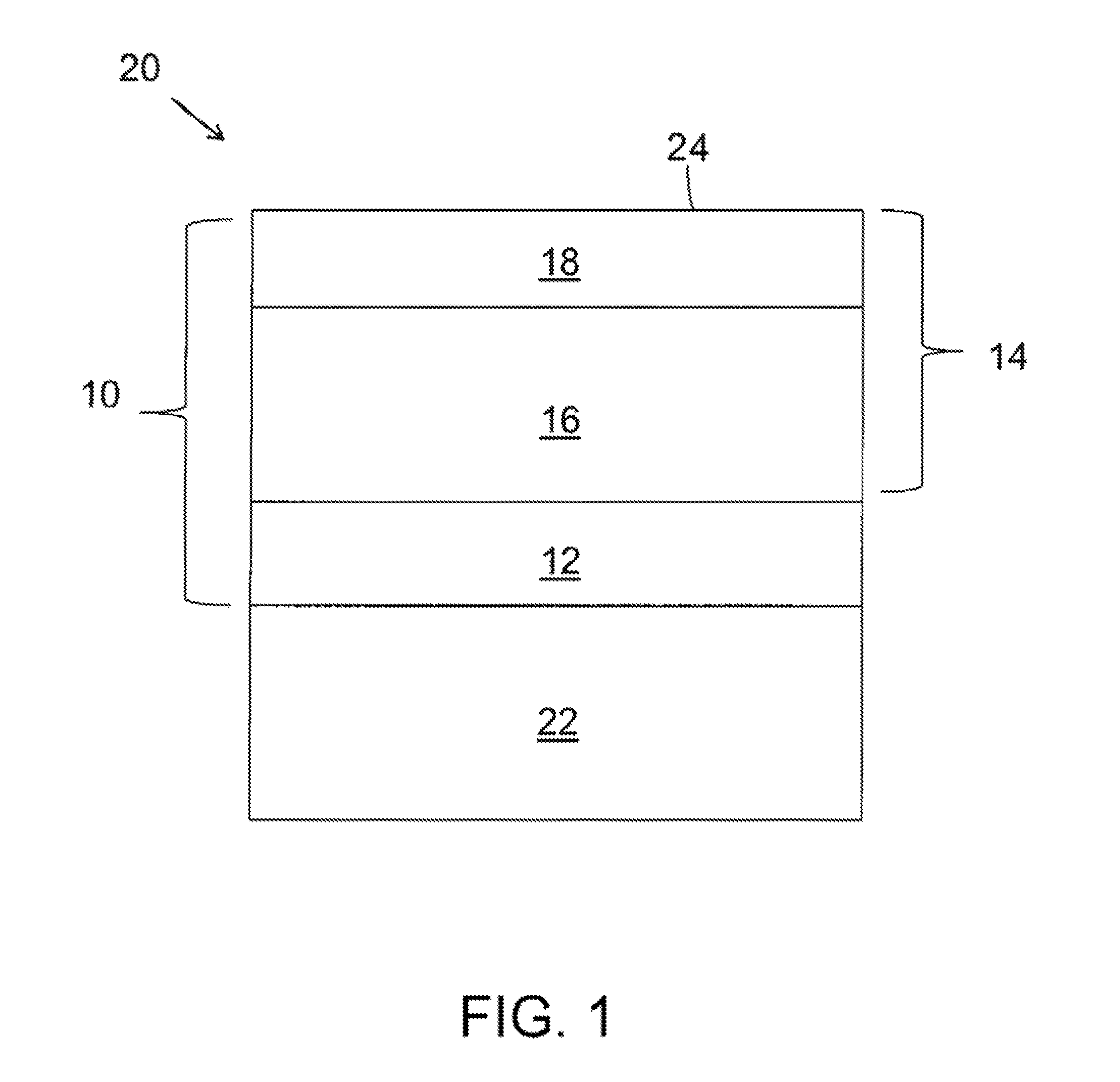

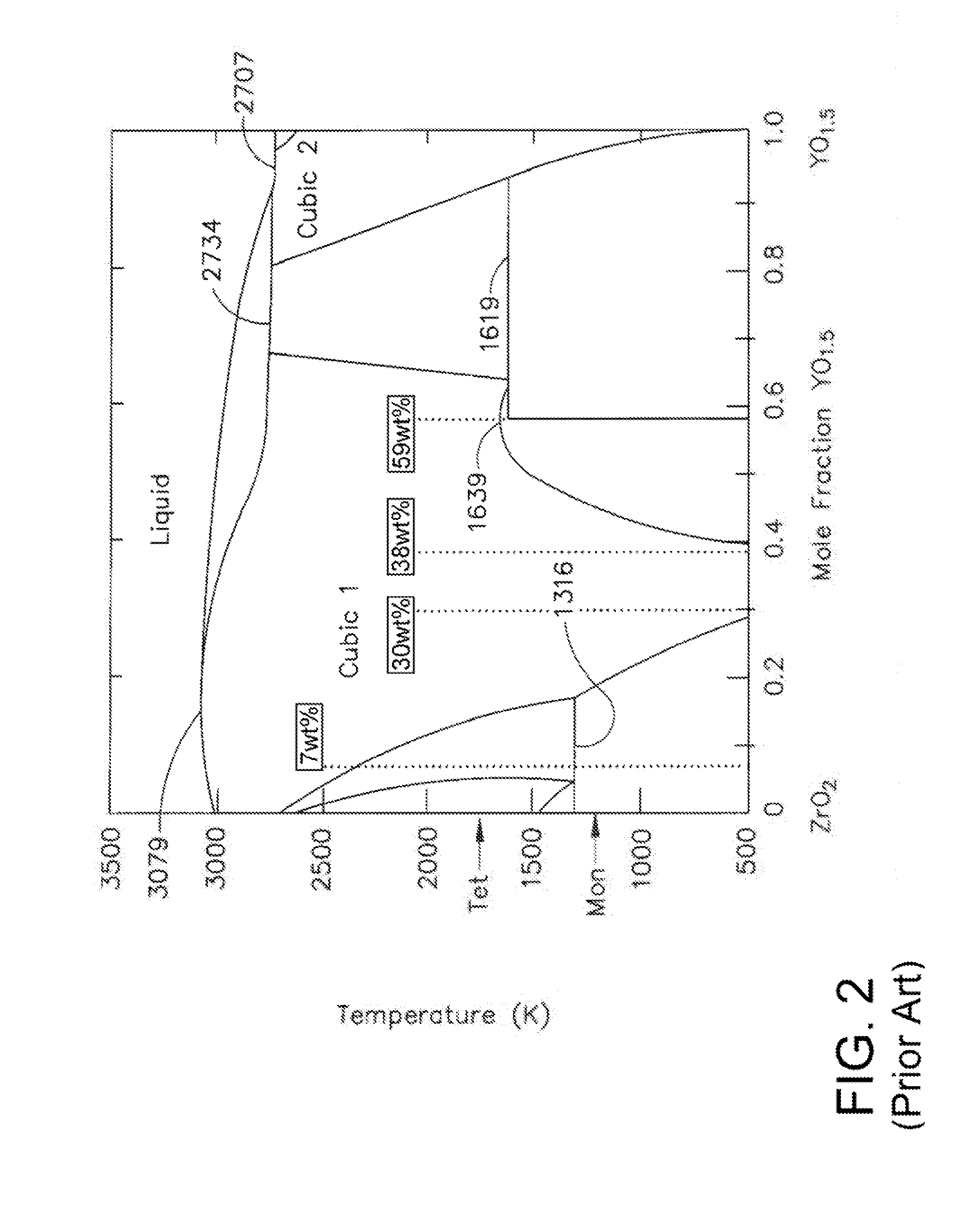

ActiveUS20130095344A1Enhances spallation resistanceLess porousLiquid surface applicatorsMolten spray coatingPorosityCoating system

Coating systems and processes by which the coating systems can be deposited to be resistant to contaminants, and particularly resistant to infiltration and damage caused by CMAS. The coating systems include inner and outer ceramic layers, each having a microstructure characterized by splats and horizontal porosity. The inner ceramic layer consists essentially of zirconia stabilized by about 6 to about 9 weight percent yttria. The outer ceramic layer overlies and contacts the inner ceramic layer to define the outermost surface of the coating system. The outer ceramic layer consists essentially of zirconia stabilized by about 25 to about 75 weight percent yttria, has a thickness that is less than the thickness of the inner ceramic layer, and has a porosity level that is lower than that of the inner ceramic layer.

Owner:GENERAL ELECTRIC CO

Thermal barrier coating systems and processes therefor

ActiveUS9034479B2High melting pointImprove sintering resistanceMolten spray coatingBlade accessoriesPorosityCoating system

Coating systems and processes by which the coating systems can be deposited to be resistant to contaminants, and particularly resistant to infiltration and damage caused by CMAS. The coating systems include inner and outer ceramic layers. The inner ceramic layer consists essentially of zirconia stabilized by about 6 to about 9 weight percent yttria and optionally contains greater than 0.5 to 10 weight percent hafnium oxide. The outer ceramic layer overlies and contacts the inner ceramic layer to define the outermost surface of the coating system. The outer ceramic layer consists essentially of zirconia stabilized by about 25 to about 75 weight percent yttria, has a thickness that is less than the thickness of the inner ceramic layer and further contains greater than 0.5 to 10 weight percent hafnium oxide and optionally 1 to 10 weight percent tantalum oxide. The outer ceramic layer has a porosity level that is lower than that of the inner ceramic layer.

Owner:GENERAL ELECTRIC CO

Thermal barrier coating systems and processes therefor

ActiveUS9023486B2Enhances spallation resistanceLess porousPropellersMolten spray coatingPorosityCoating system

Coating systems and processes by which the coating systems can be deposited to be resistant to contaminants, and particularly resistant to infiltration and damage caused by CMAS. The coating systems include inner and outer ceramic layers, each having a microstructure characterized by splats and horizontal porosity. The inner ceramic layer consists essentially of zirconia stabilized by about 6 to about 9 weight percent yttria. The outer ceramic layer overlies and contacts the inner ceramic layer to define the outermost surface of the coating system. The outer ceramic layer consists essentially of zirconia stabilized by about 25 to about 75 weight percent yttria, has a thickness that is less than the thickness of the inner ceramic layer, and has a porosity level that is lower than that of the inner ceramic layer.

Owner:GENERAL ELECTRIC CO

Flexible bamboo chair pad

ActiveUS20060165948A1Avoid insufficient thicknessImprove the immunityDomestic upholsterySynthetic resin layered productsFiberNatural factor

A bamboo Chair pad that can be manufactured from 100% Anji Mountain bamboo from China. The bamboo is all treated with various protective coatings to add resistance to natural factors including water, sun and dirt. All bamboo chair pads can be manufactured from the harder portions of the bamboo trunk. (Some bamboo are manufactured from the softer fibers of the inside of the bamboo trunk). This portion of the bamboo trunk is not utilized for this invention. The bamboo utilized in the present invention is taken from the harder part of the bamboo trunk to assure maximum endurance and longevity. The lower trunk portion of the bamboo plant is harder and less porous.

Owner:GFH ENTERPRISES

Flexible bamboo chair pad

ActiveUS20110183136A1Avoid insufficient thicknessImprove the immunityCovering/liningsMedical patchesFiberNatural factor

A bamboo Chair pad that can be manufactured from 100% Anji Mountain bamboo from China. The bamboo is all treated with various protective coatings to add resistance to natural factors including water, sun and dirt. All bamboo chair pads can be manufactured from the harder portions of the bamboo trunk. (Some bamboo is manufactured from the softer fibers of the inside of the bamboo trunk). This portion of the bamboo trunk is not utilized for this invention. The bamboo utilized in the present inventions is taken from the harder part of the bamboo trunk to assure maximum endurance and longevity. The lower trunk portion of the bamboo plant is harder and less porous.

Owner:GFH ENTERPRISES

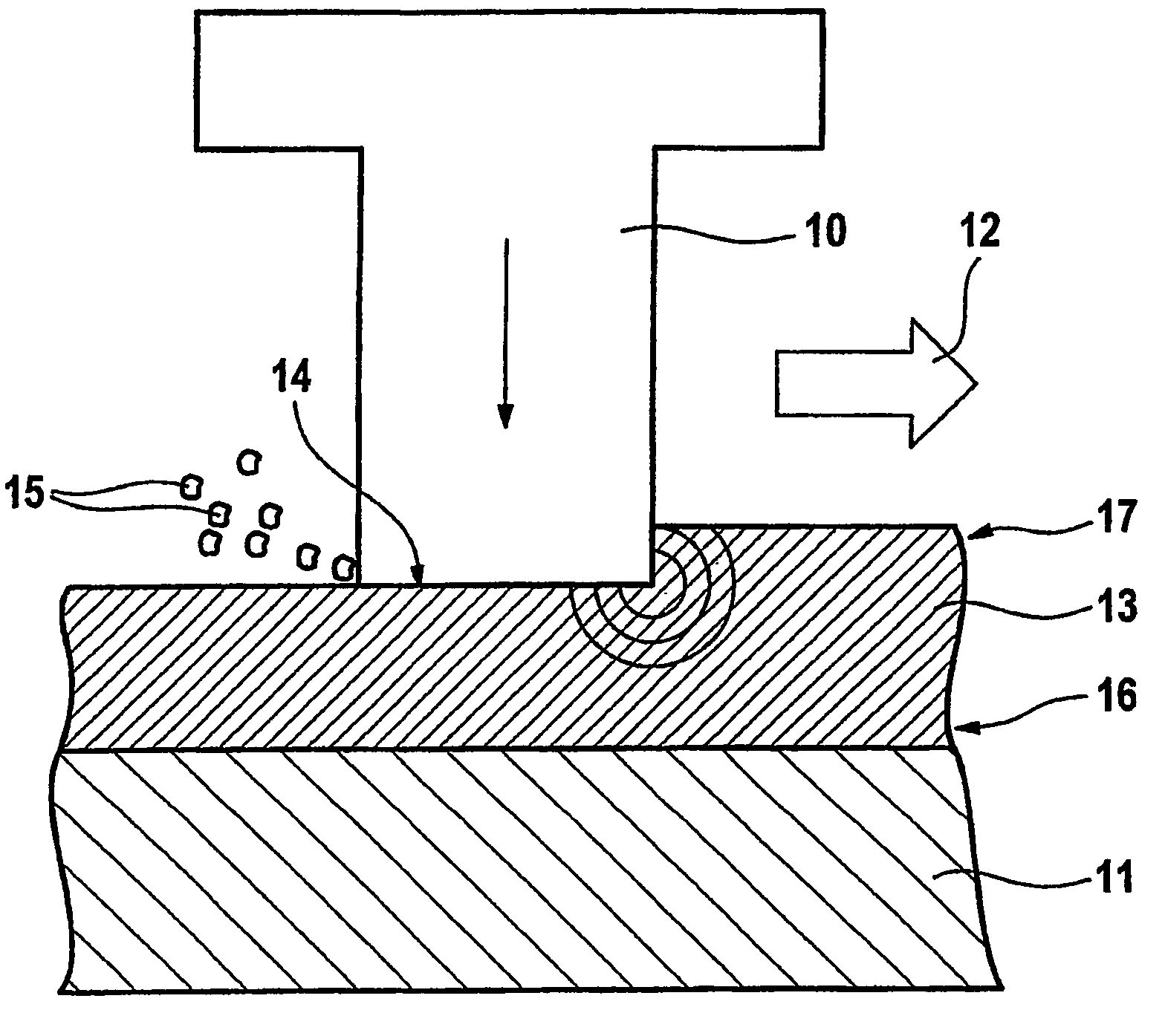

Process and apparatus for hot-forging synthetic ceramic

InactiveUS20080090720A1Less porous and more impermeableLight weightPolycrystalline material growthCeramic materials productionCeramicCrystallization

The embodiments of the invention are directed to a synthetic ceramic comprising pyroxene-containing crystalline phase, a clast, and a glass phase, wherein at least a portion of the synthetic ceramic is plastically deformable in a certain temperature range. Other embodiments of the invention relate to a method of making a synthetic ceramic, comprising heating a green ceramic material to 900-1400° C., to a temperature sufficient to initiate partial melting of at least a portion of the green ceramic material, transferring the heated green ceramic material to a press, pressing the heated green ceramic material in a die at 1,000 to 10,000 psi, and transferring the heated, pressed green ceramic material to a furnace for cooling to form the synthetic ceramic.

Owner:CERAMEXT LLC

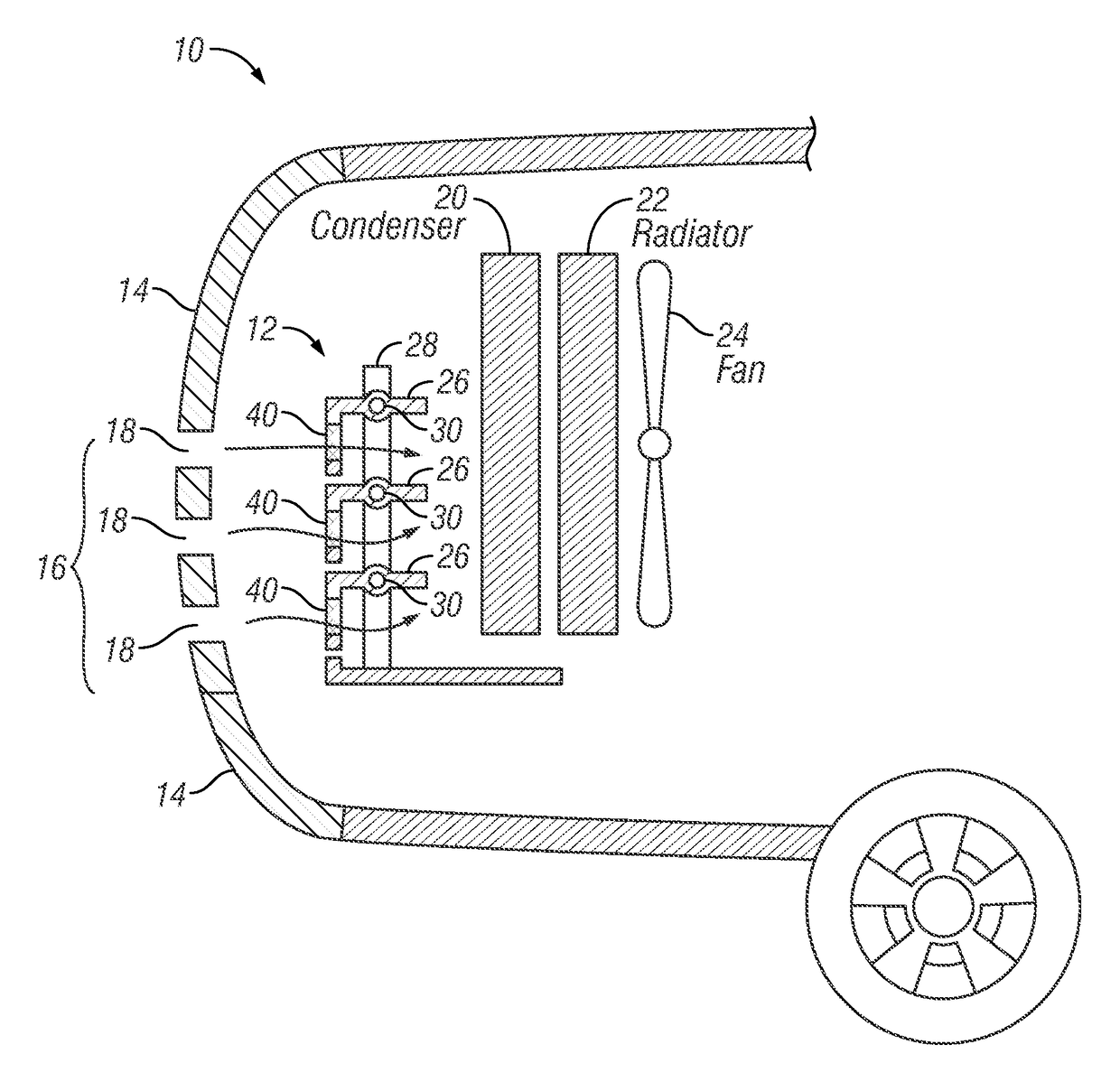

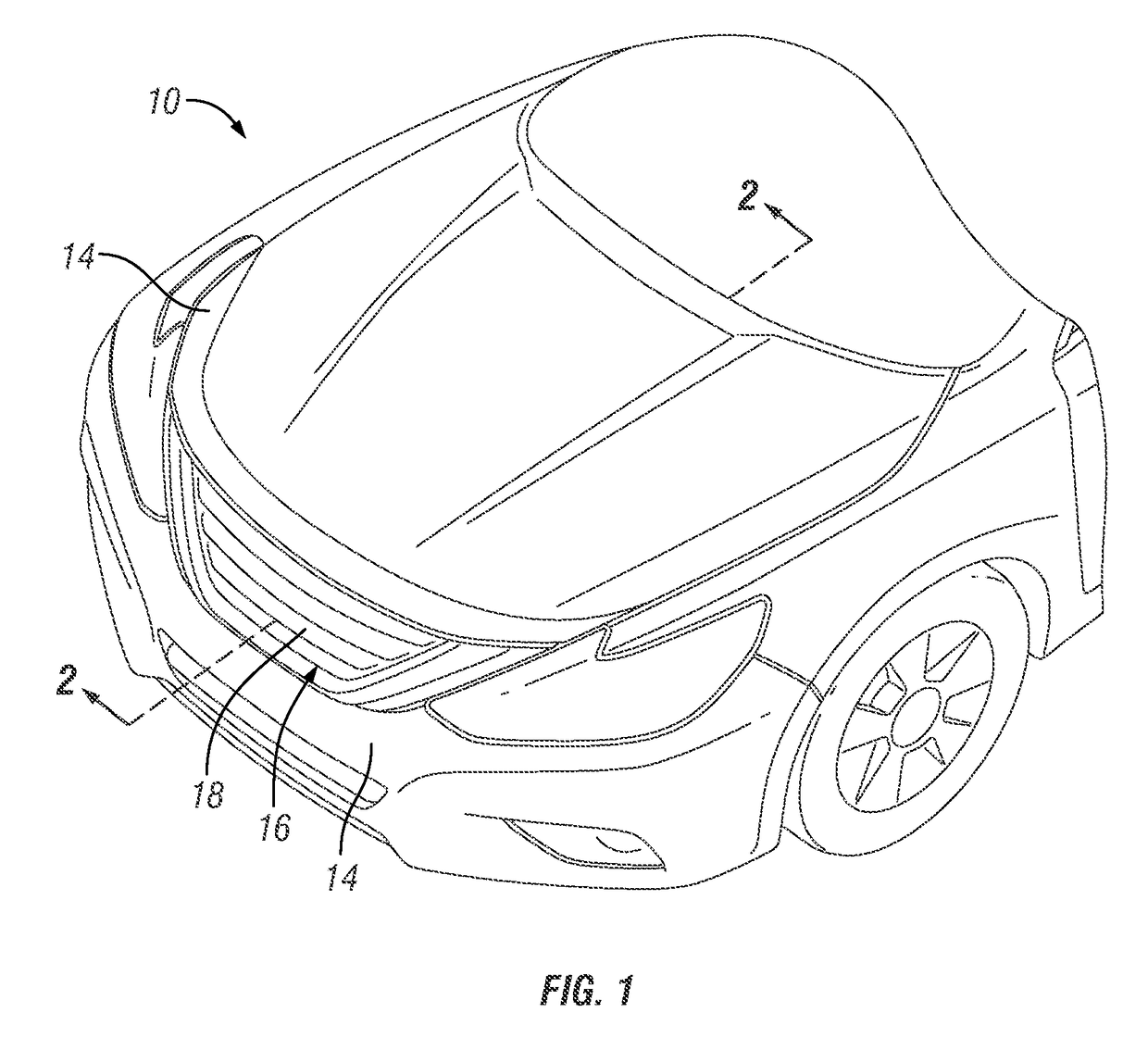

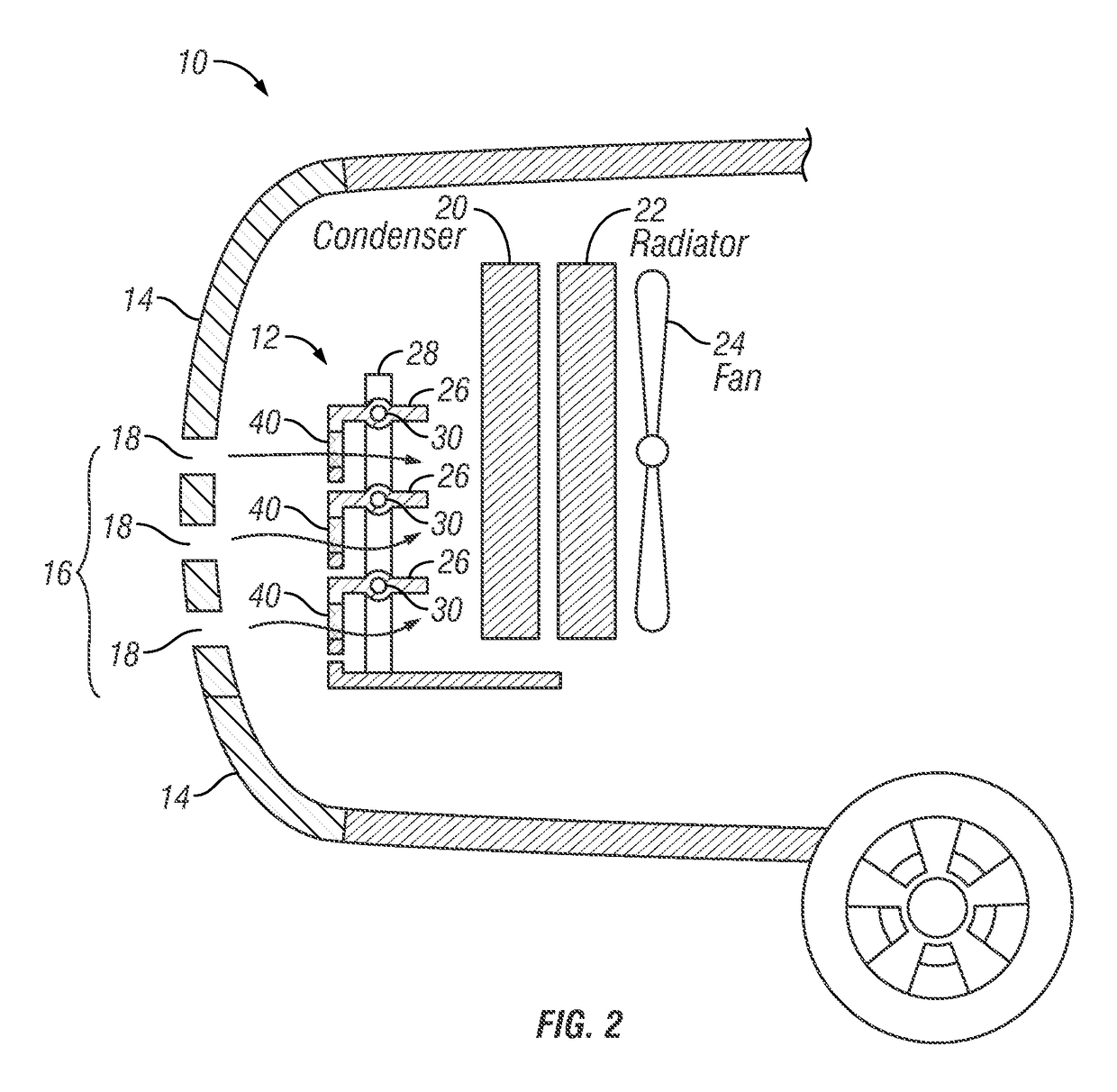

Vehicle grill shutter system

A vehicle grill shutter system comprising at least one grill shutter and a controller. The grill shutter is movably coupled to a vehicle at a location forward of a radiator of the vehicle. The grill shutter comprises first and second portions. The first portion has a first surface and includes a first material having a first porosity, and the second portion has a second surface and includes a second material having a second porosity which is less porous than the first porosity. The controller is configured to operate the grill shutter, in response to a detected vehicle condition pertaining to the vehicle, to move between a first position at which the first surface is oriented transverse to a flow direction of air entering a grill of the vehicle toward the radiator and a second position at which the second surface is oriented transverse to the flow direction.

Owner:NISSAN MOTOR CO LTD

Flexible bamboo chair pad

ActiveUS7402536B2Avoid insufficient thicknessImprove the immunityDomestic upholsterySynthetic resin layered productsNatural factorFiber

A bamboo Chair pad that can be manufactured from 100% Anji Mountain bamboo from China. The bamboo is all treated with various protective coatings to add resistance to natural factors including water, sun and dirt. All bamboo chair pads can be manufactured from the harder portions of the bamboo trunk. (Some bamboo are manufactured from the softer fibers of the inside of the bamboo trunk). This portion of the bamboo trunk is not utilized for this invention. The bamboo utilized in the present invention is taken from the harder part of the bamboo trunk to assure maximum endurance and longevity. The lower trunk portion of the bamboo plant is harder and less porous.

Owner:GFH ENTERPRISES

Indoor and outdoor bamboo area rug

InactiveUS7361616B2Improve the immunityMaximum longevitySynthetic resin layered productsFurniture partsFiberNatural factor

Owner:GFH ENTERPRISES

Indoor and outdoor bamboo area rug

InactiveUS20060165937A1Improve the immunityAssure maximum enduranceSynthetic resin layered productsFurniture partsFiberOutdoor area

A bamboo Indoor / Outdoor Area Rug that is manufactured from 100% Anji Mountain bamboo from China. The bamboo is all treated with various protective coatings to add resistance to natural factors including water, sun and dirt. All bamboo rugs manufactured for outdoor / indoor use are made from the harder portions of the bamboo trunk. (Some bamboo used for indoor purposes only are manufactured from the softer fibers of the inside of the bamboo trunk). This portion of the bamboo trunk is not utilized for this invention. The bamboo utilized in the present invention is taken from the harder part of the bamboo trunk to assure maximum endurance and longevity. The lower trunk portion of the bamboo plant is harder and less porous.

Owner:GFH ENTERPRISES

Synthesized hybrid rock composition, method, and article formed by the method

ActiveUS7704907B2Zero open porosityLess porousSolid waste managementTransportation and packagingPorosityElectron probe microanalysis

The invention relates to synthetic hybrid rock compositions, articles of manufacture and related processes employing mineral waste starting materials such as mine tailings, mine development rock, ash, slag, quarry fines, and slimes, to produce valuable articles of manufacture and products, which are characterized by superior physical and structural characteristics, including low porosity, low absorption, increased strength and durability, and retained plasticity. The resulting materials are compositionally and chemically distinct from conventional synthetic rock materials as demonstrated by scanning electron microprobe analysis, and are useful in a wide variety of applications, particularly with respect to commercial and residential construction.

Owner:CERAMEXT LLC

Thermal control coatings

ActiveUS20170204273A1Accelerated degradation of materialDamage to deviceAlkali metal silicate coatingsRadiation-absorbing paintsMagnesium phosphateThermochromism

A curable coating composition comprising: (a) a silicate, such as sodium silicate, potassium silicate or lithium silicate; (b) a phosphate, such calcium phosphate, magnesium phosphate or sodium phosphate; and (c) a metal oxide, such as magnesium oxide, aluminium (III) oxide, scandium (III) oxide, yttrium (III) oxide, or zirconium oxide. Such curable coating compositions may be used as non-thermochromic (tailored based on expected operating environment) thermal control coating compositions for application to spacecraft and components thereof. As an alternative metal oxide component, for use in lower temperature applications, or in applications for which thermochromism at elevated temperatures is not a concern, the metal oxide may comprise zinc oxide. Also provided is a curable coating composition comprising: (a) a silicate (e.g. as above); (b) a phosphate (e.g. as above); and (c) a metal sulphate, such as a barium sulphate. Cured coatings are also provided, as are thermal control coatings, thermal control paints, and processes for making coated substrates.

Owner:UNIV COLLEGE DUBLIN NAT UNIV OF IRELAND DUBLIN

Indoor and outdoor bamboo area rug

InactiveUS20080280092A1Improve the immunityAssure maximum enduranceLayered productsCarpetsFiberOutdoor area

A bamboo Indoor / Outdoor Area Rug that is manufactured from 100% Anji Mountain bamboo from China. The bamboo is all treated with various protective coatings to add resistance to natural factors including water, sun and dirt. All bamboo rugs manufactured for outdoor / indoor use are made from the harder portions of the bamboo trunk. (Some bamboo used for indoor purposes only are manufactured from the softer fibers of the inside of the bamboo trunk). This portion of the bamboo trunk is not utilized for this invention. The bamboo utilized in the present invention is taken from the harder part of the bamboo trunk to assure maximum endurance and longevity. The lower trunk portion of the bamboo plant is harder and less porous.

Owner:GOLD DARRYL S

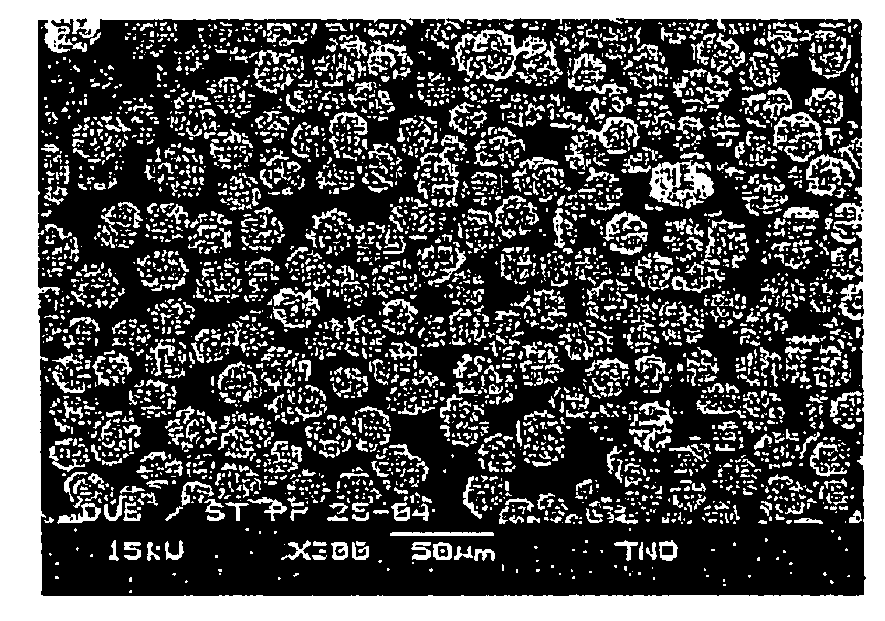

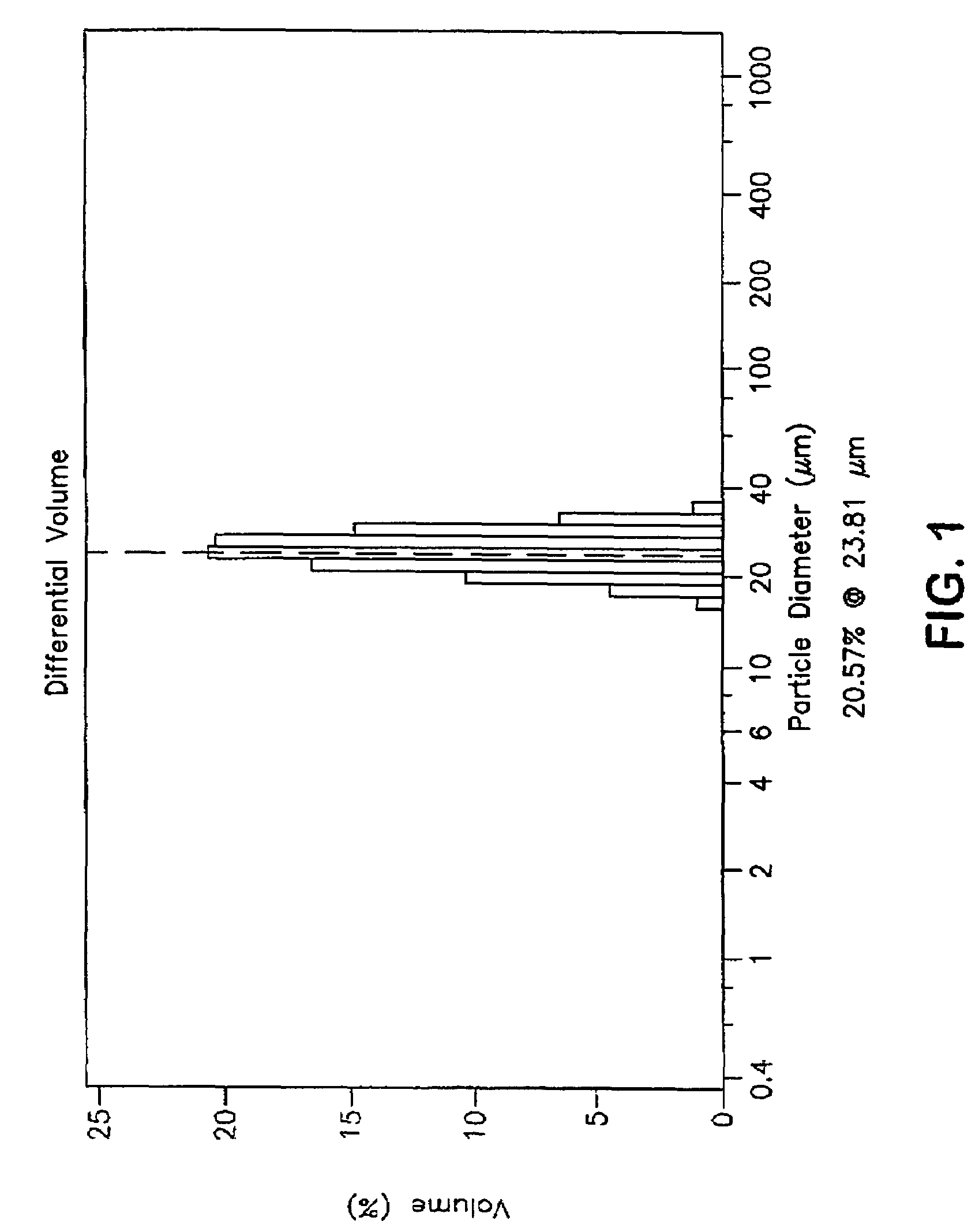

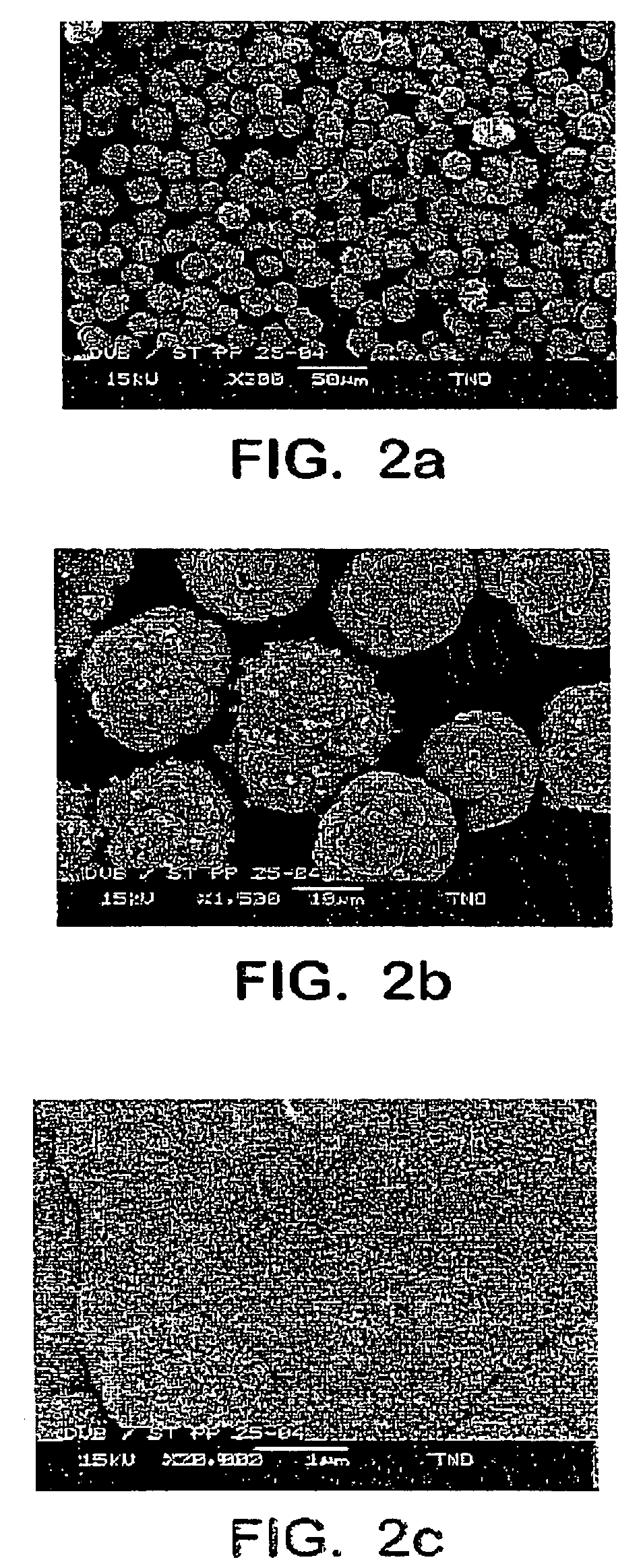

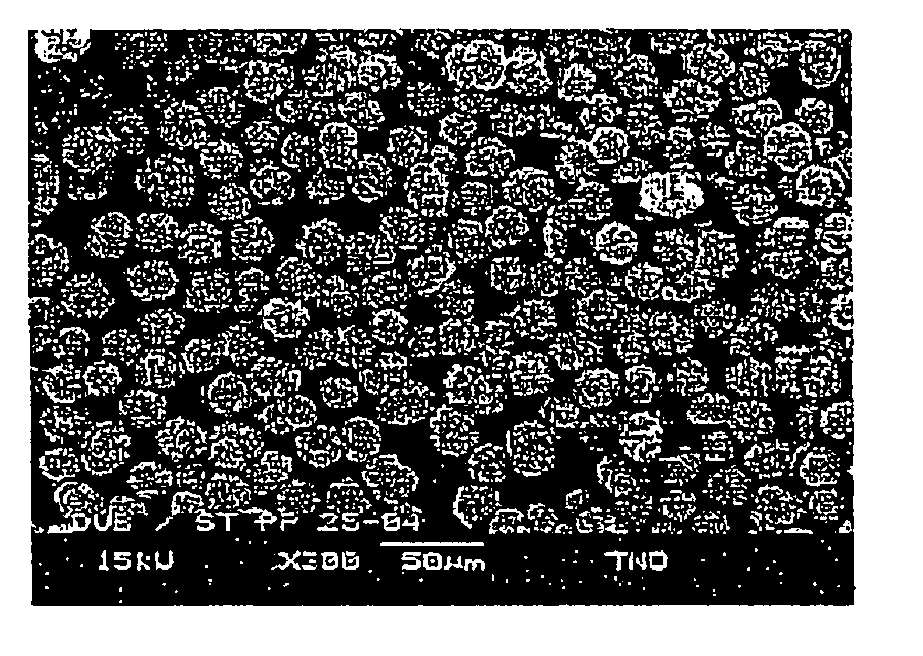

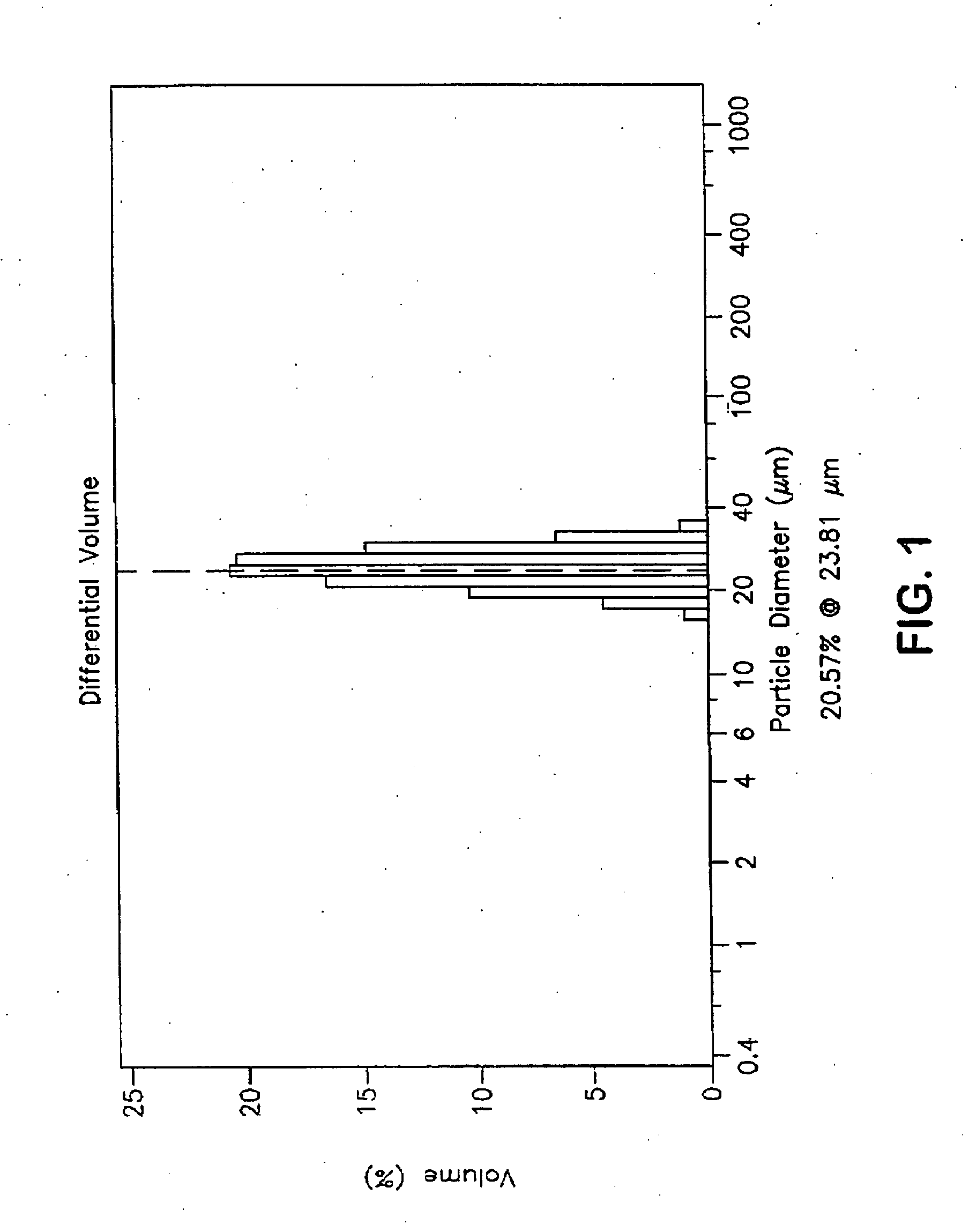

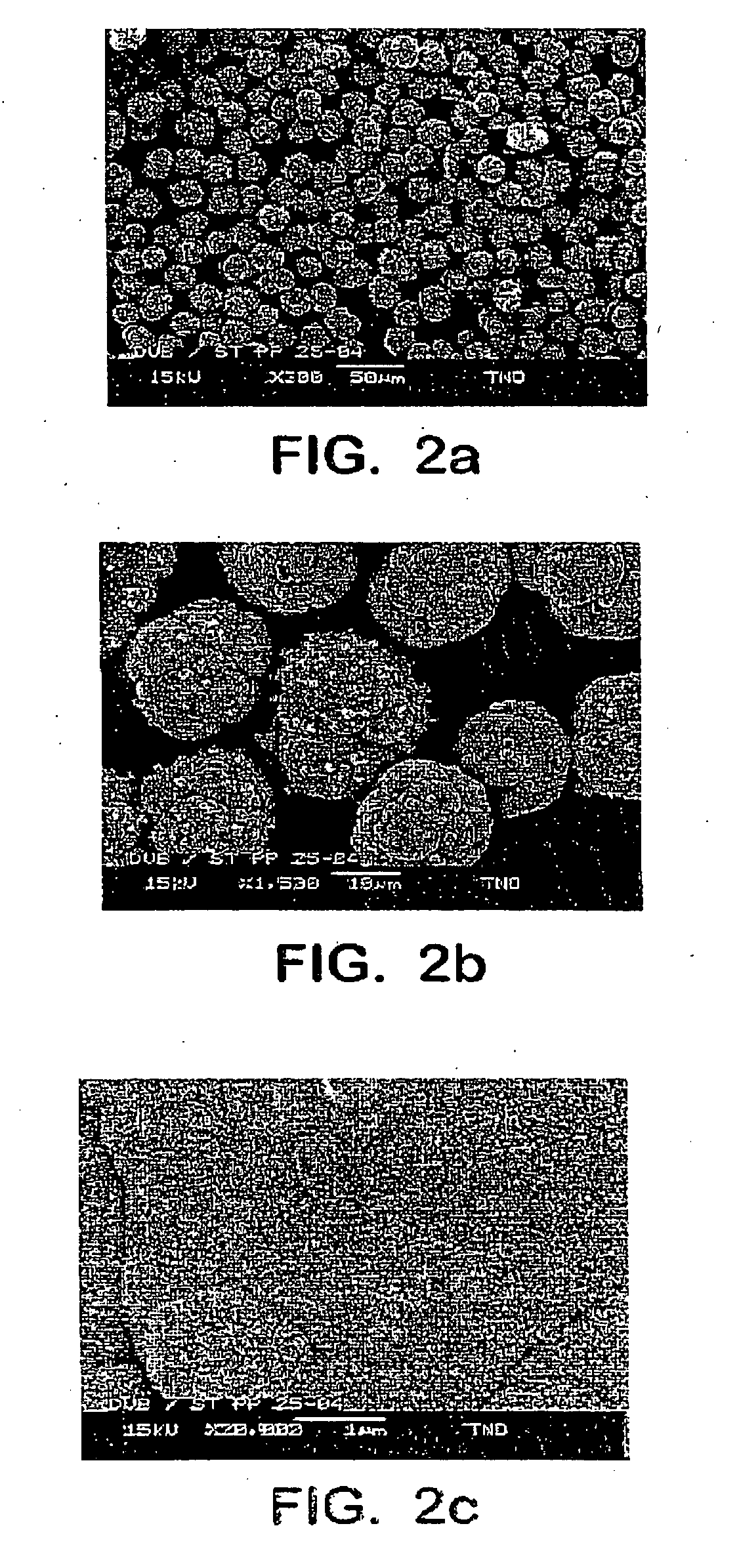

Method of preparing spheroid polymer particles having a narrow size distribution by dispersion polymerization, particles obtainable by the method and use of these particles

ActiveUS7540962B2Less complicatedMore “fines”Ion-exchange process apparatusCation exchanger materialsOrganic solventEmulsion polymerization

The invention relates to a method of preparing spheroid polymer particles having a narrow size distribution by dispersion polymerization. This method comprises the steps of: providing a two-phase system in the form of a dispersion comprising an organic phase of droplets dispersed in an aqueous medium, mixing said organic phase in said aqueous medium under agitation without using a dispersion stabilizing agent to stabilize the dispersion, wherein the organic phase comprises at least a crosslinkable monomer, a polymerization initiator and an organic solvent for said monomer, and allowing the crosslinkable monomers to polymerize, while the two-phase system is agitated.

Owner:AGILENT TECH INC

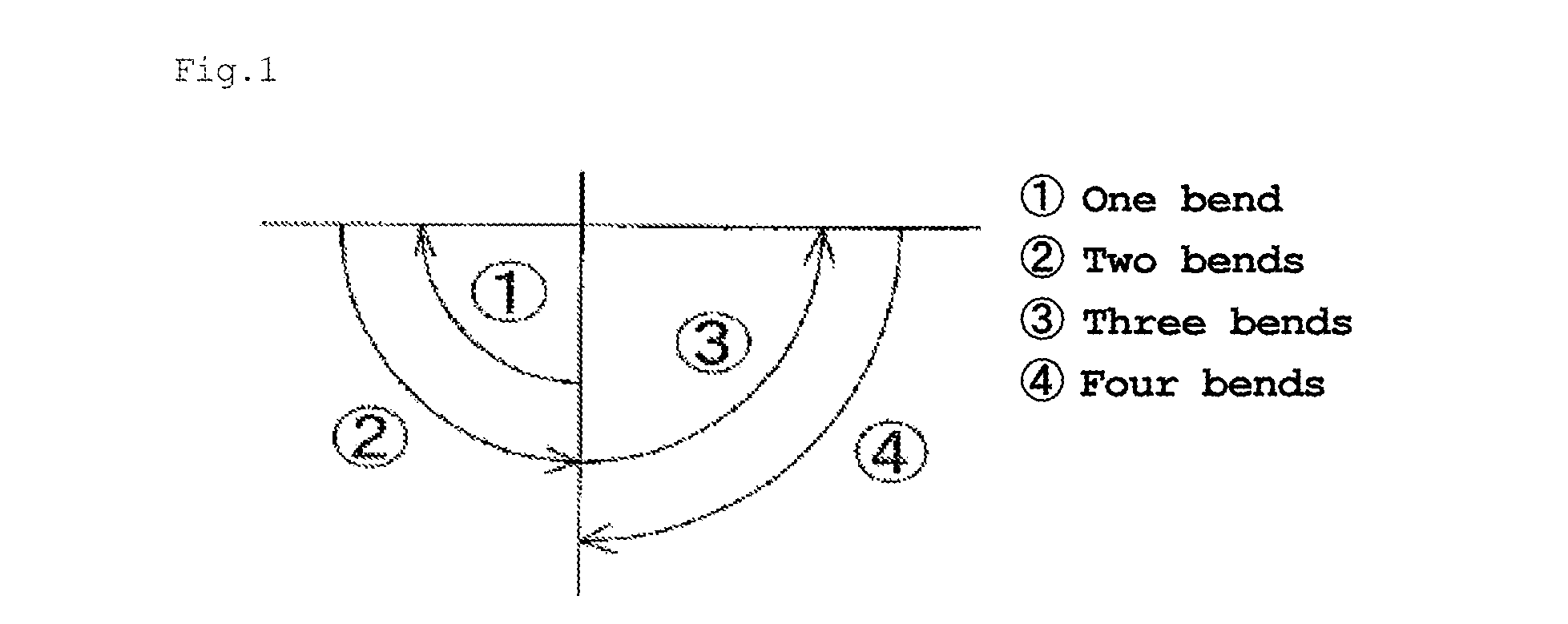

Electrode material for aluminum electrolytic capacitor, and method for producing same

ActiveUS20140211375A1Improve volumetric efficiencyImprove bending strengthCoatingsSpecial surfacesPorosityAluminum foil

An electrode material for an aluminum electrolytic capacitor, comprising, as constituent elements, sintered body of a powder of at least one member selected from the group consisting of aluminum and aluminum alloys, and an aluminum foil substrate supporting the sintered body thereon, wherein (1) the powder has an average particle size D50 of 0.5 to 100 μm, (2) the sintered body is formed on one surface or both surfaces of the aluminum foil substrate and has a total thickness of 10 to 1,000 μm, (3) the porosity of the sintered body is 35 to 49% by volume, and (4) the sintered body is obtained by applying a rolling process to a film made from a composition comprising a powder of at least one member selected from the group consisting of aluminum and aluminum alloys, and subsequently sintering the film.

Owner:TOYO ALUMINIUM KK

Thermal barrier coating systems and processes therefor

InactiveUS20140377473A1Enhances spallation resistanceLess porousLiquid surface applicatorsMolten spray coatingPorosityCoating system

Owner:GENERAL ELECTRIC CO

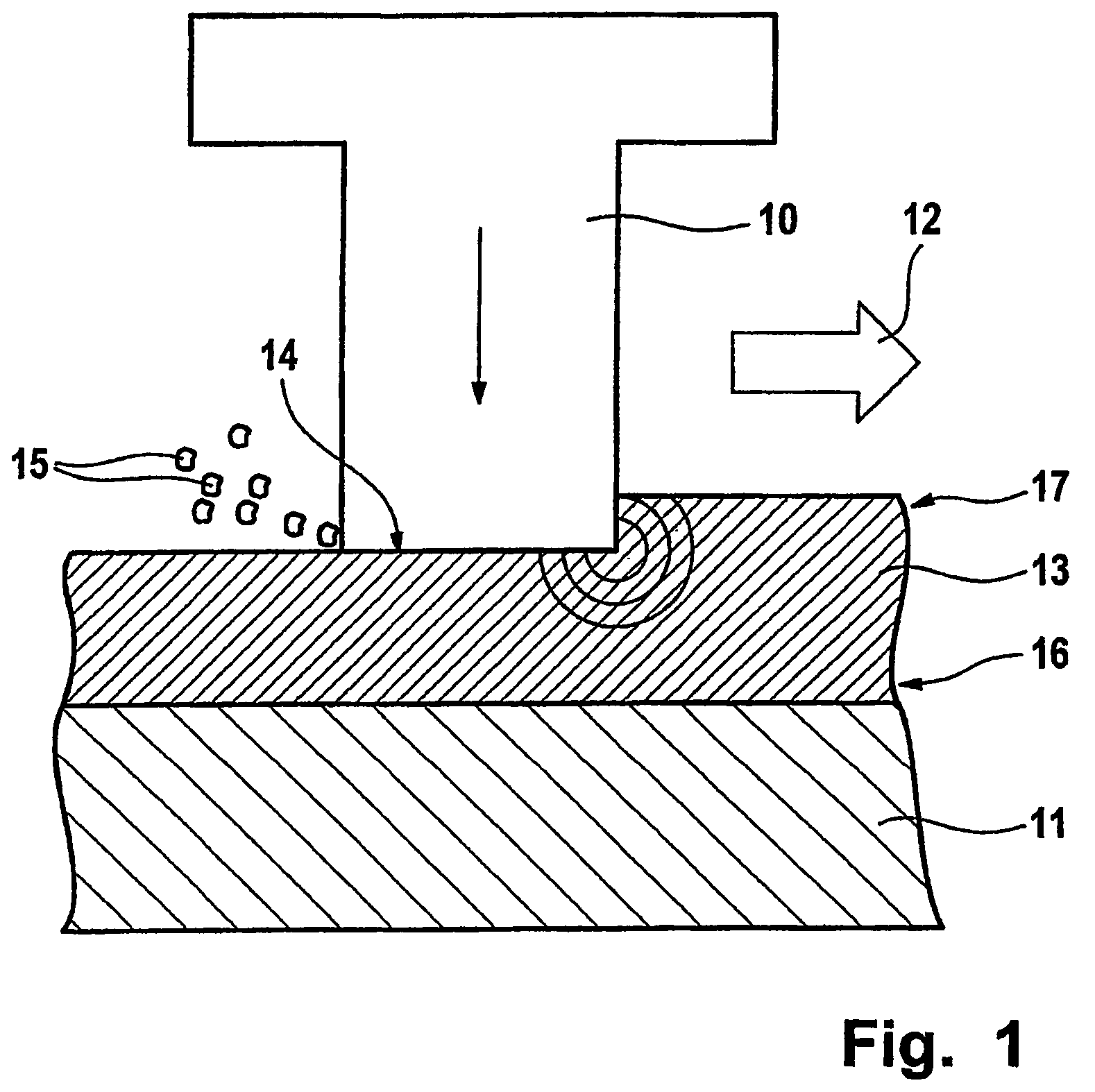

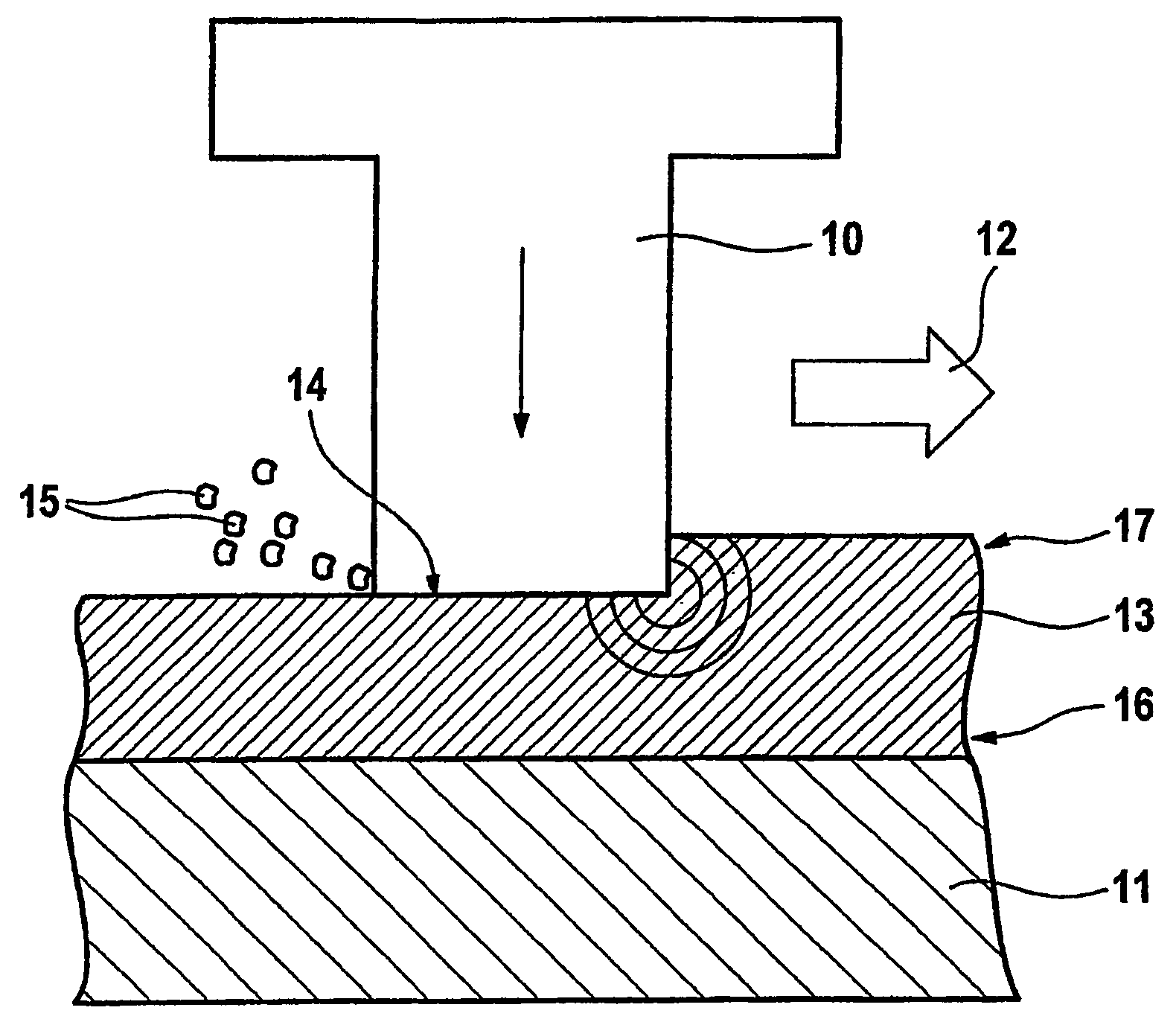

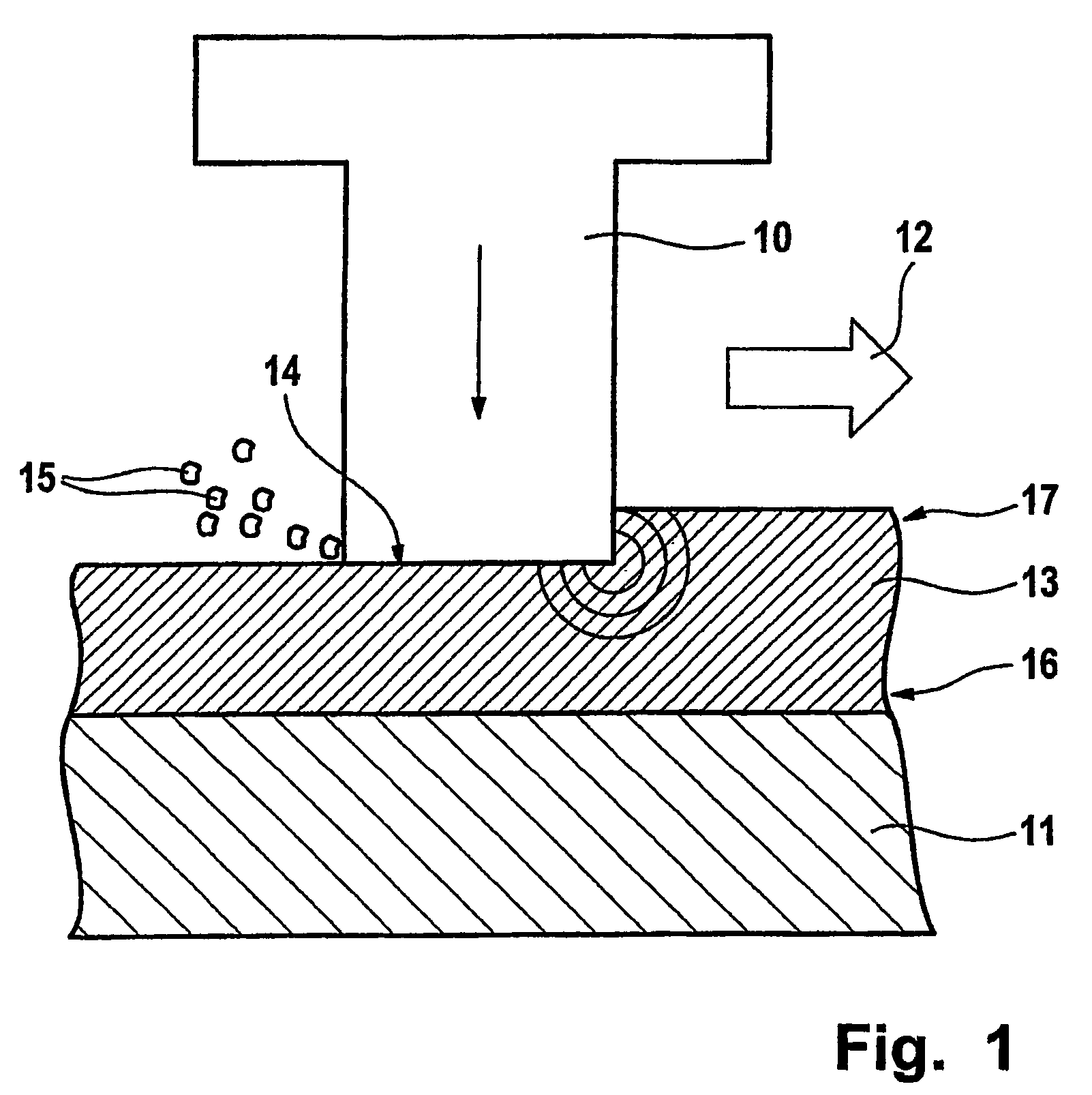

Run-in coating for gas turbines and method for producing same

A run-in coating is for gas turbines. The run-in coating is used for sealing a radial gap between a housing of the gas turbine and rotating rotor blades of same, the run-in coating being applied onto the housing. The run-in coating is made of an intermetallic titanium-aluminum material.

Owner:MTU AERO ENGINES GMBH

Run-in coating for gas turbines and method for producing same

A run-in coating is for gas turbines. The run-in coating is used for sealing a radial gap between a housing of the gas turbine and rotating rotor blades of same, the run-in coating being applied onto the housing. The run-in coating is made of an intermetallic titanium-aluminum material.

Owner:MTU AERO ENGINES GMBH

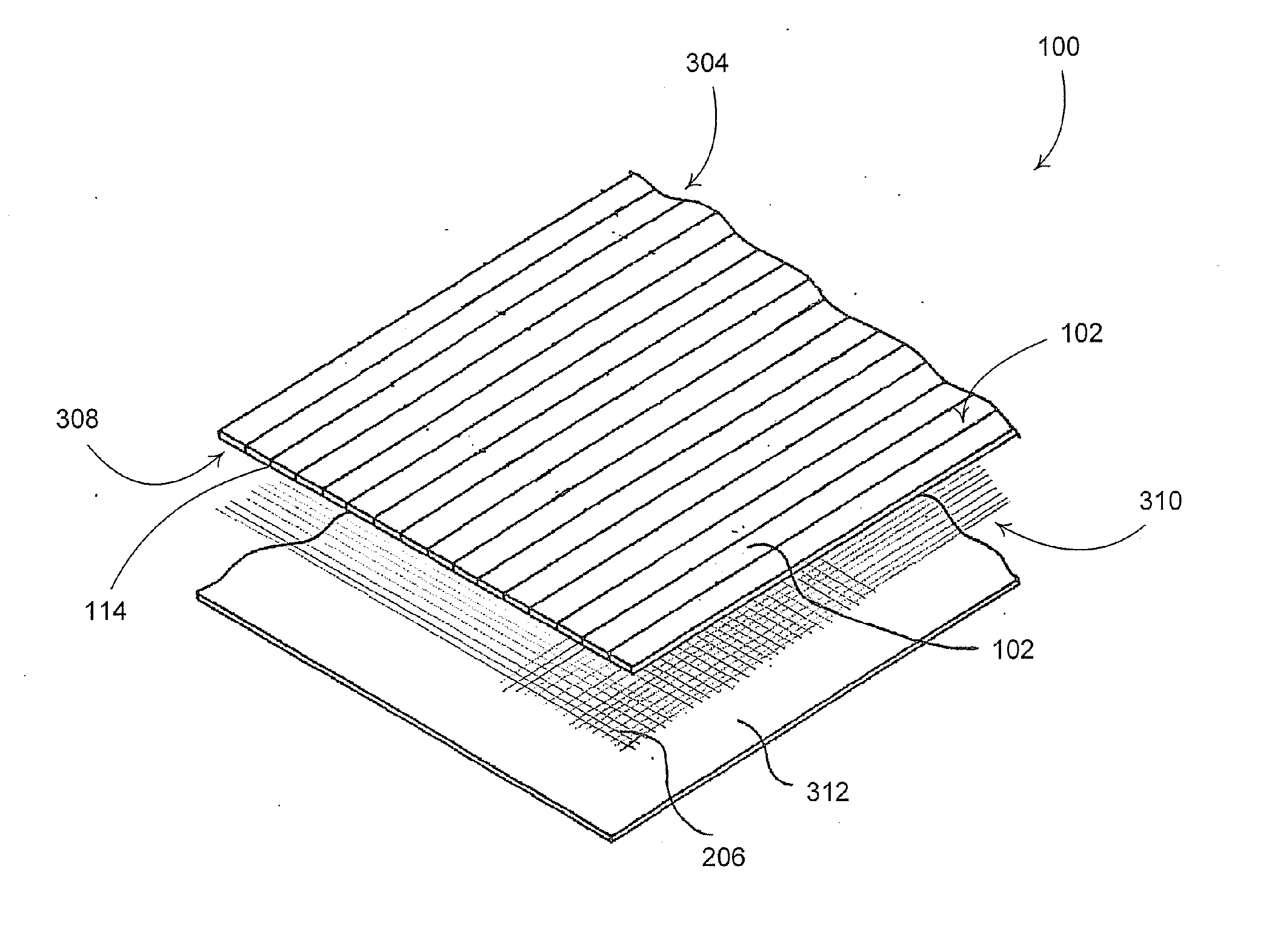

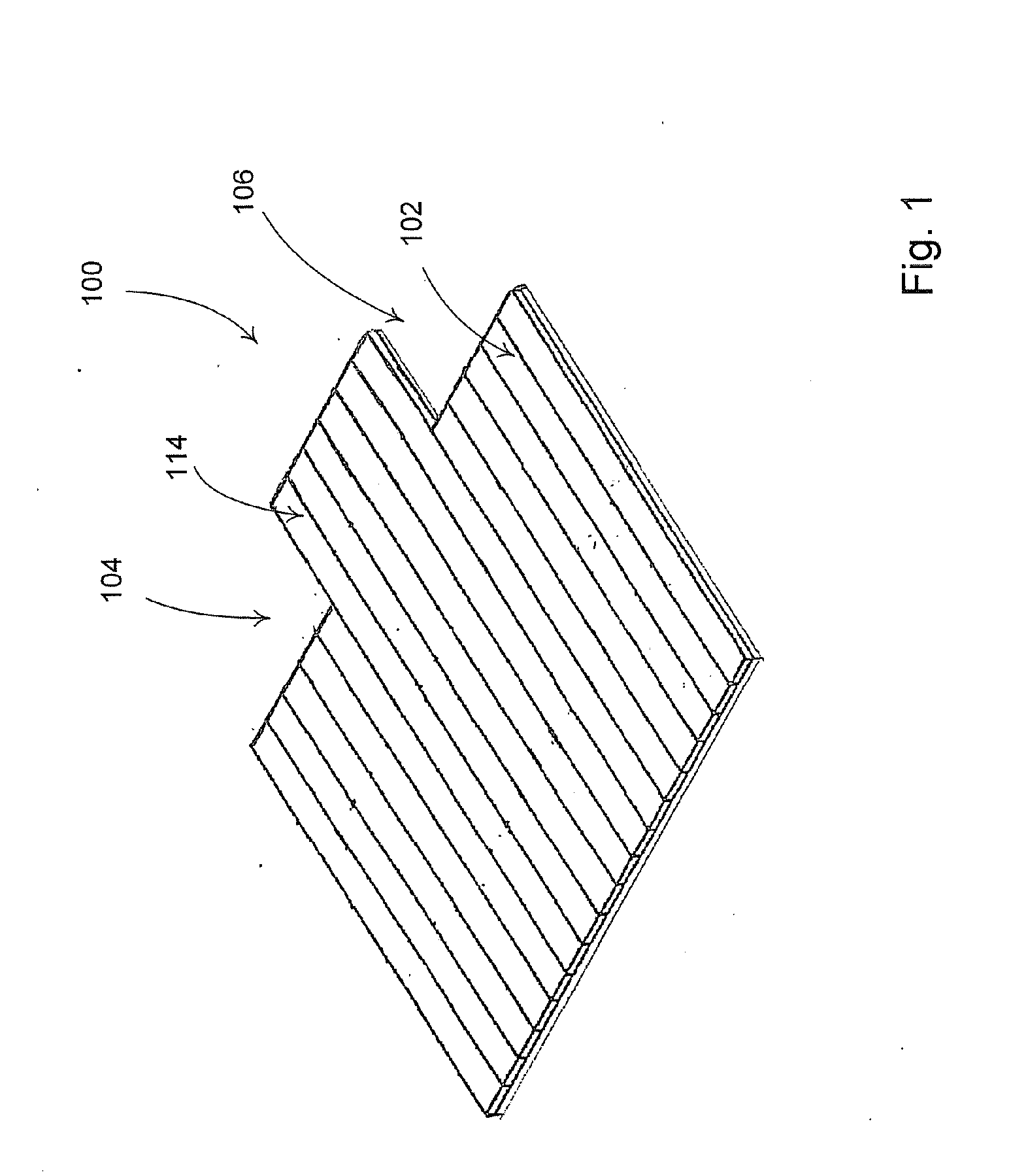

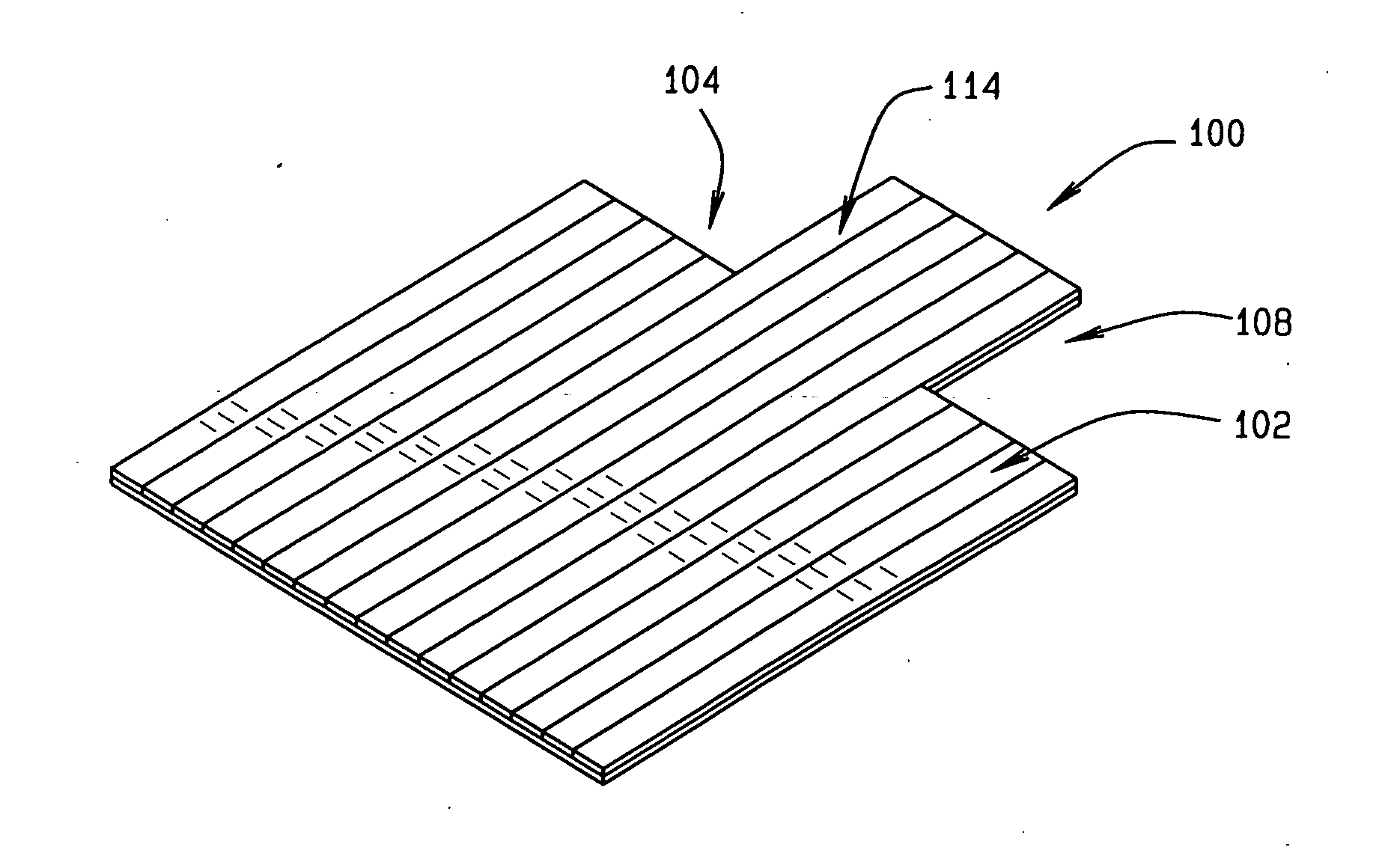

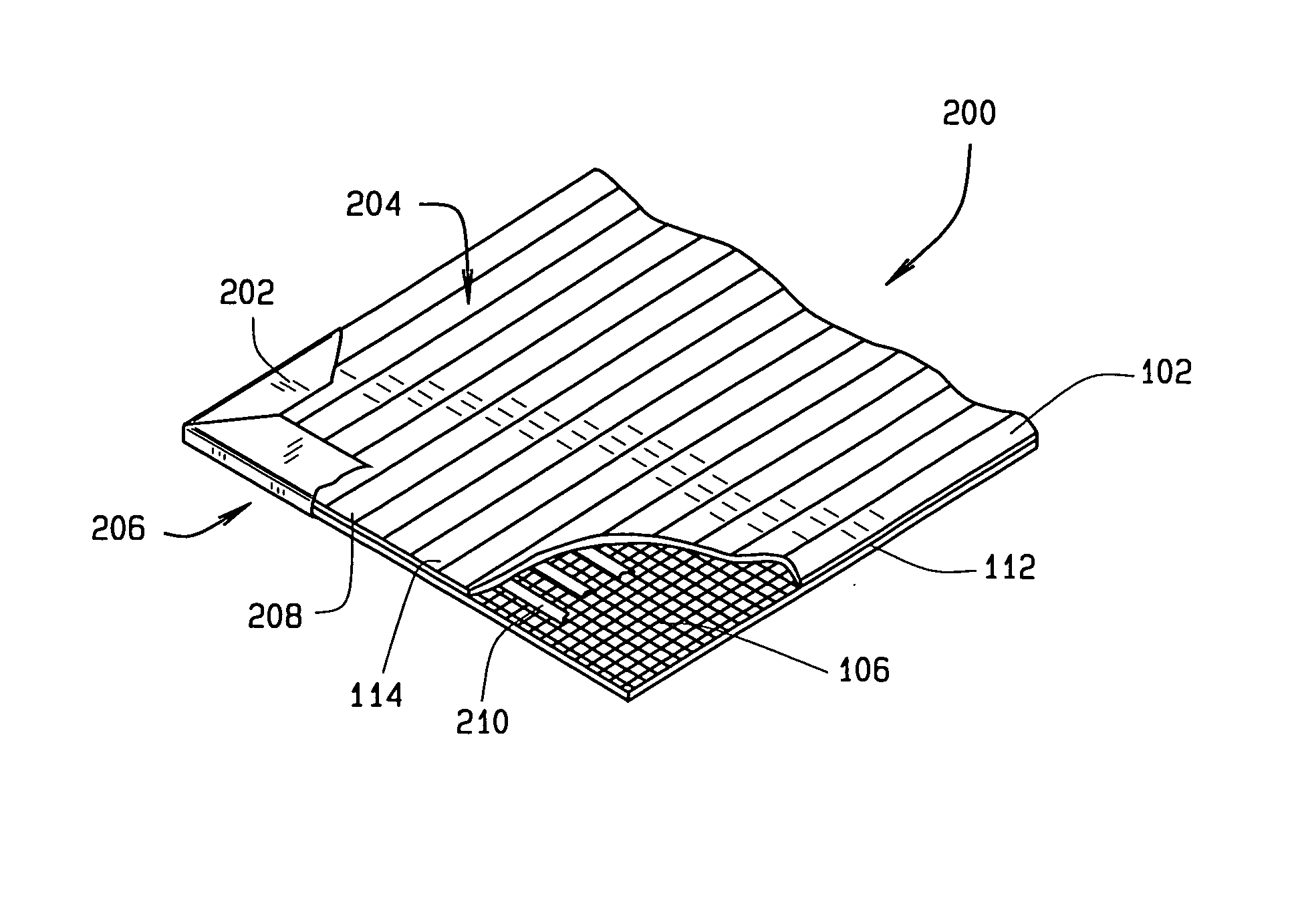

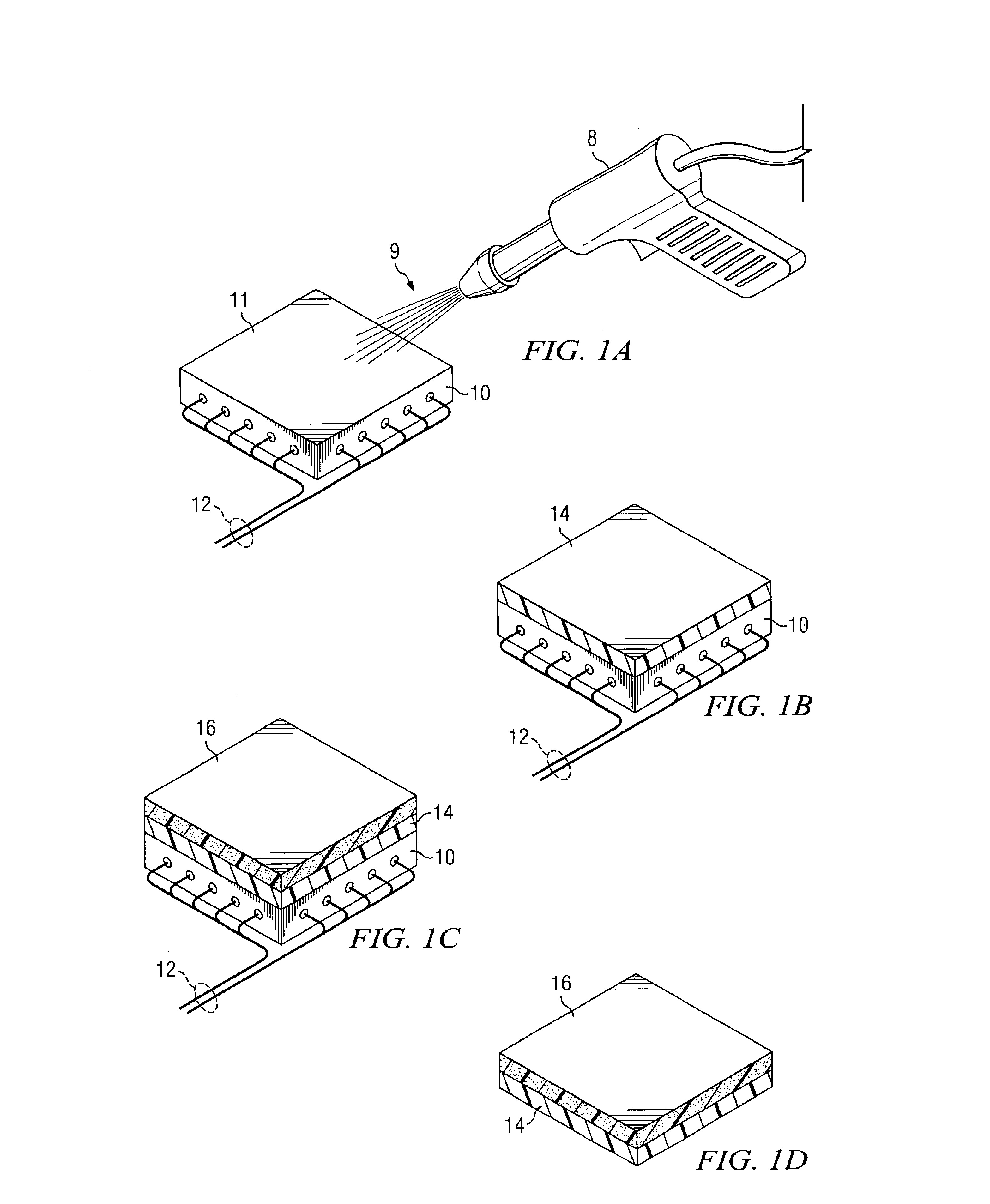

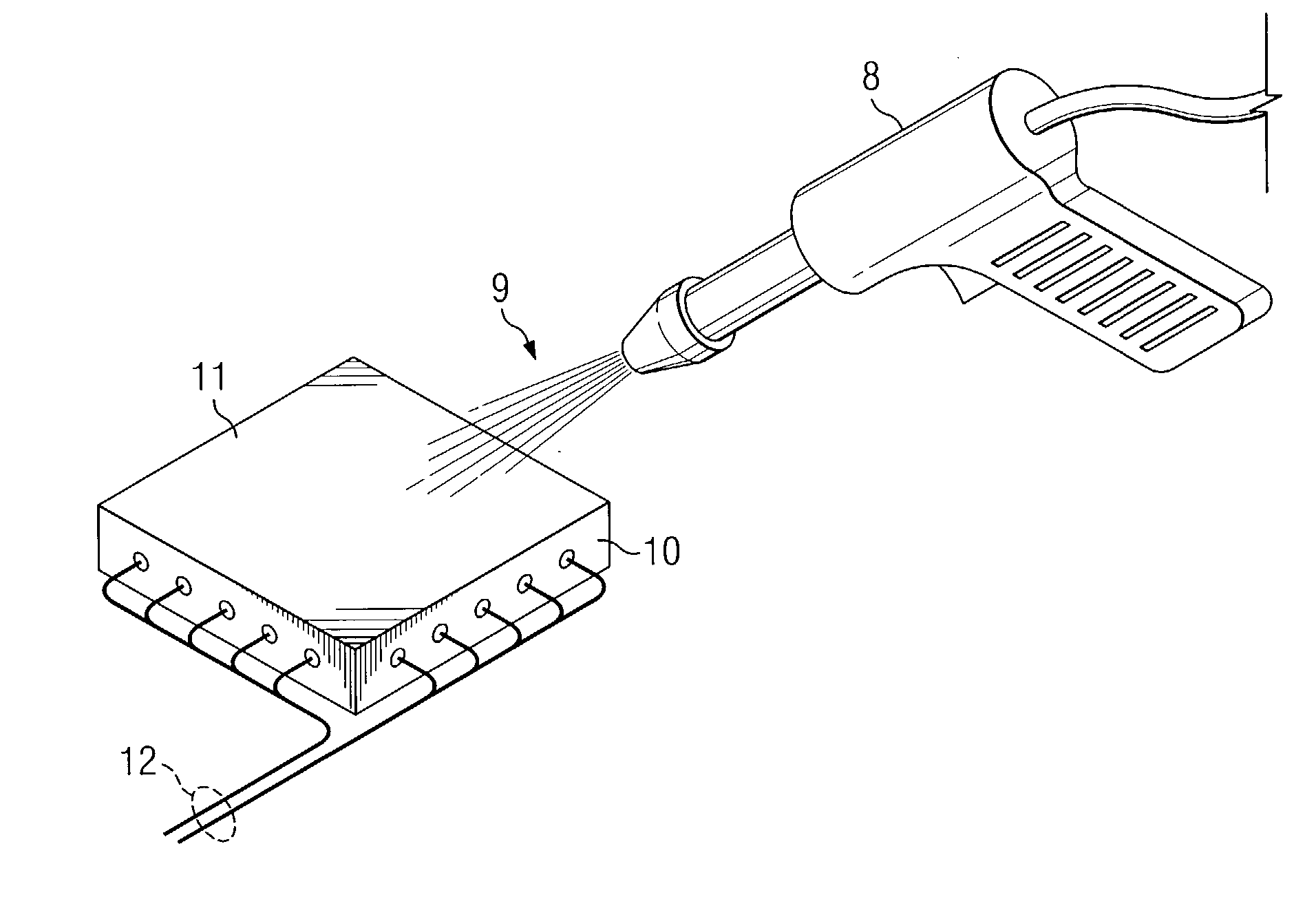

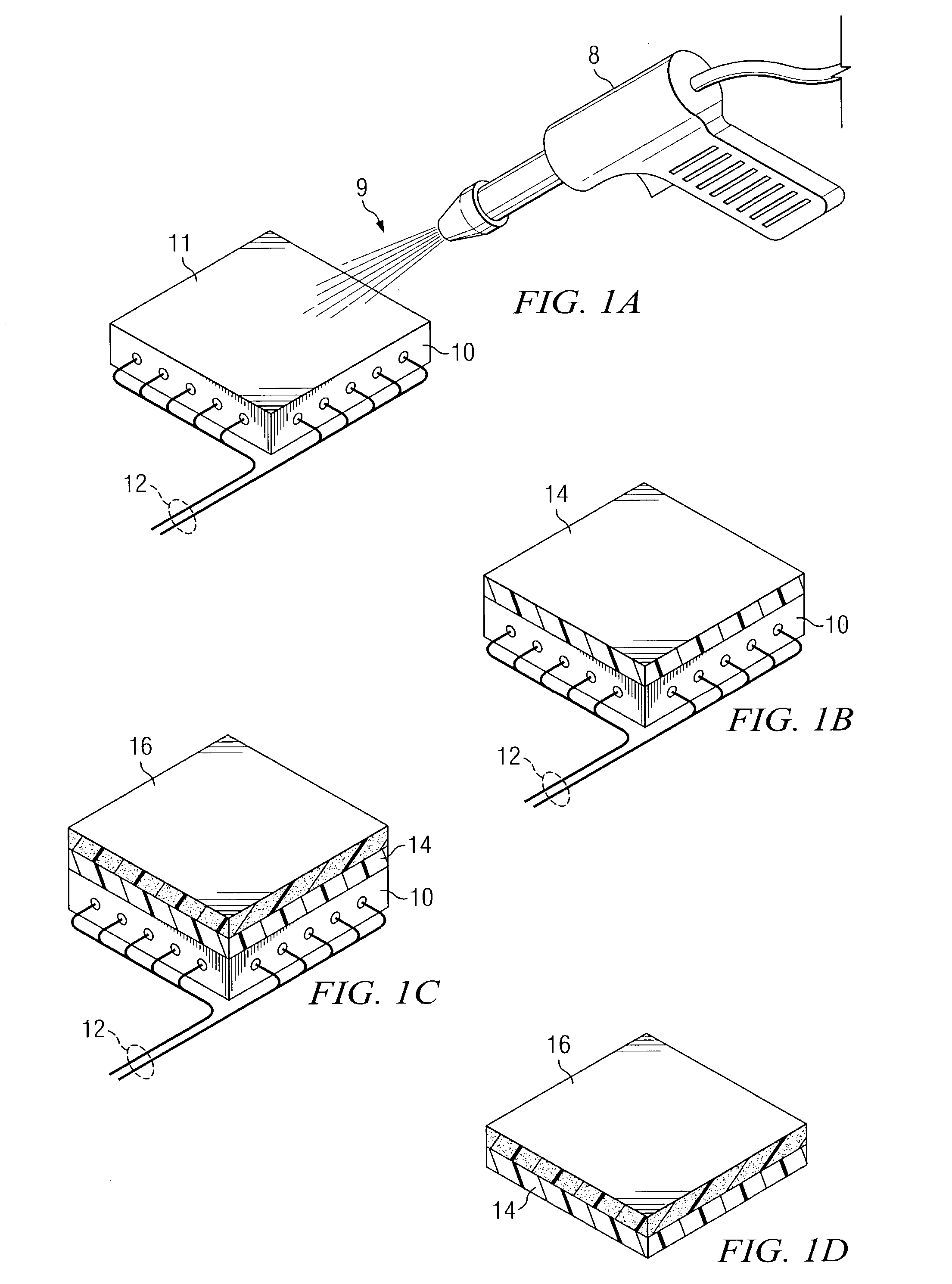

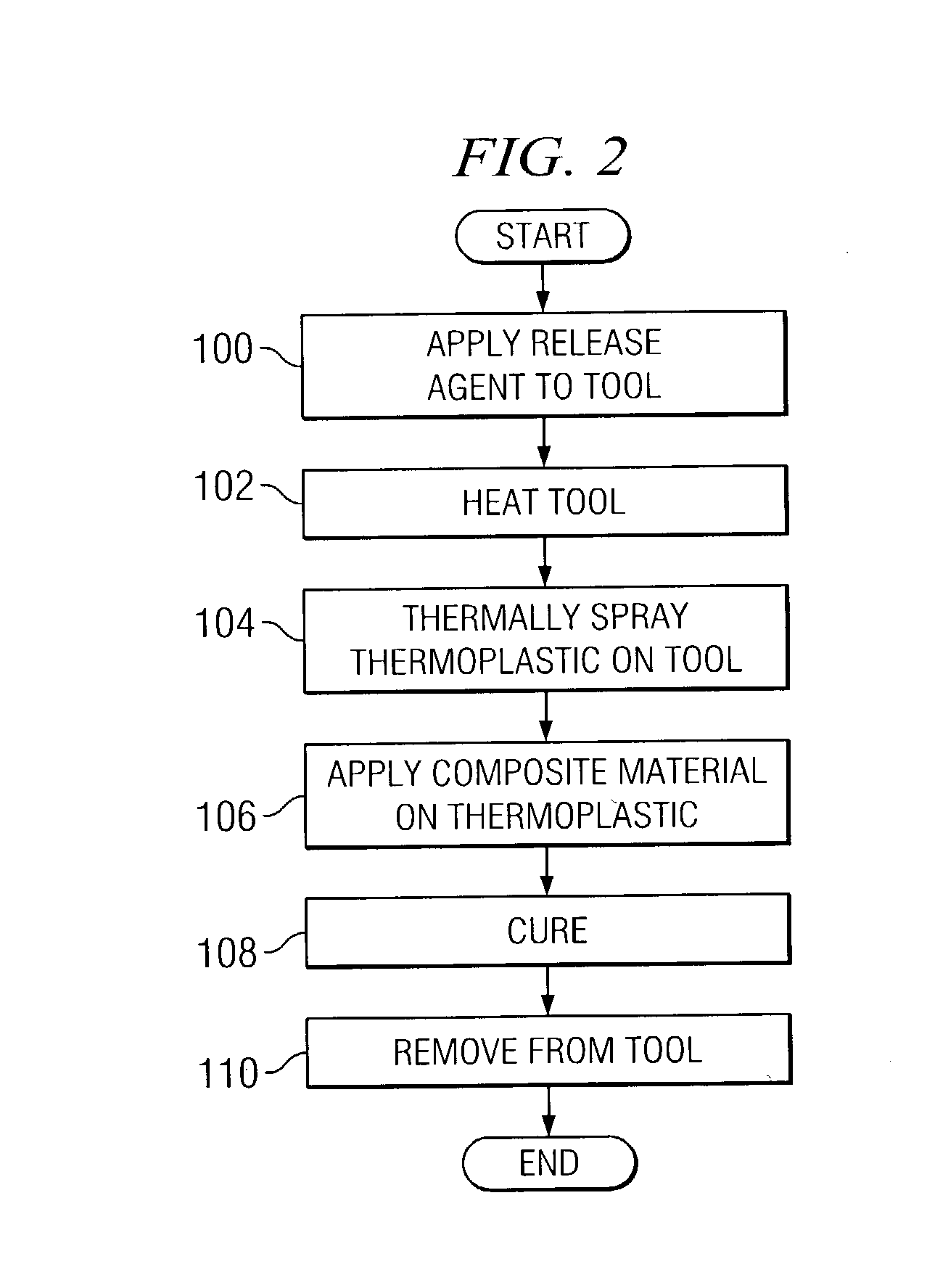

Thermoplastic coating for composite structures

ActiveUS6974606B2Uniform thicknessLess permeableMolten spray coatingLaminationThermoplasticThermal spraying

Owner:NORTHROP GRUMMAN SYST CORP

Magnesium anodisation methods

This invention relates to a method of anodising magnesium material which includes anodising the magnesium while it is immersed in an aqueous electrolyte solution having a pH above 7, and in the presence of a phosphate, the electrolyte solution also containing a sequestering agent. The method may further include the provision of a plasma suppressing substance within the electrolyte solution. Furthermore, the electrolyte solution may also preferably include a tertiary amine such a TEA, and the current passed through the electrolyte solution may preferably be a straight DC current.

Owner:KERONITE INT LTD

Method of preparing spheroid polymer particles having a narrow size distribution by dispersion polymerization, particles obtainable by the method and use of these particles

ActiveUS20070295655A1Easy to prepareLow costIon-exchange process apparatusCation exchanger materialsOrganic solventPolymer science

The invention relates to a method of preparing spheroid polymer particles having a narrow size distribution by dispersion polymerization. This method comprises the steps of: providing a two-phase system in the form of a dispersion comprising an organic phase of droplets dispersed in an aqueous medium, mixing said organic phase in said aqueous medium under agitation without using a dispersion stabilizing agent to stabilize the dispersion, wherein the organic phase comprises at least a crosslinkable monomer, a polymerization initiator and an organic solvent for said monomer, and allowing the crosslinkable monomers to polymerize, while the two-phase system is agitated.

Owner:AGILENT TECH INC

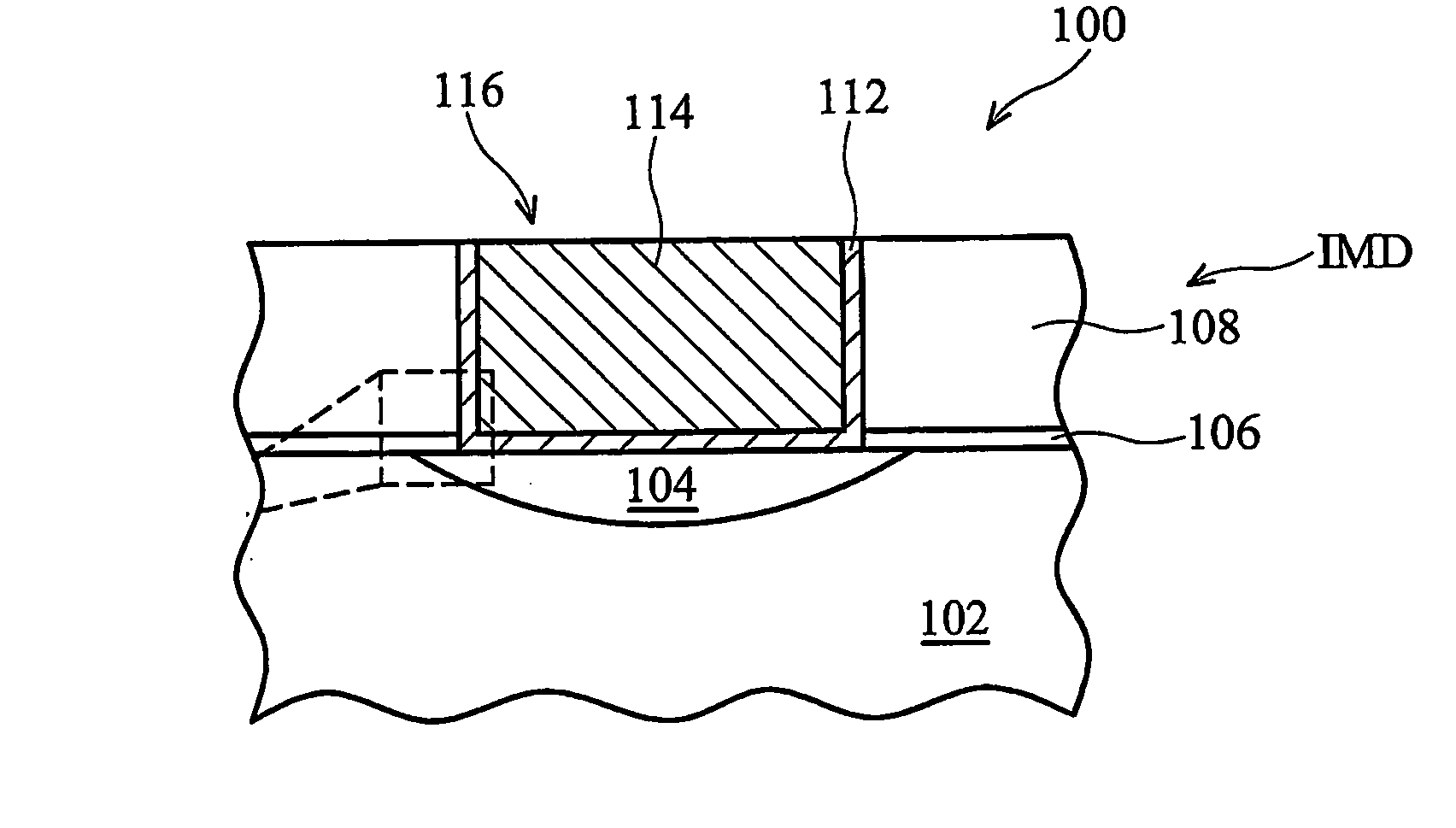

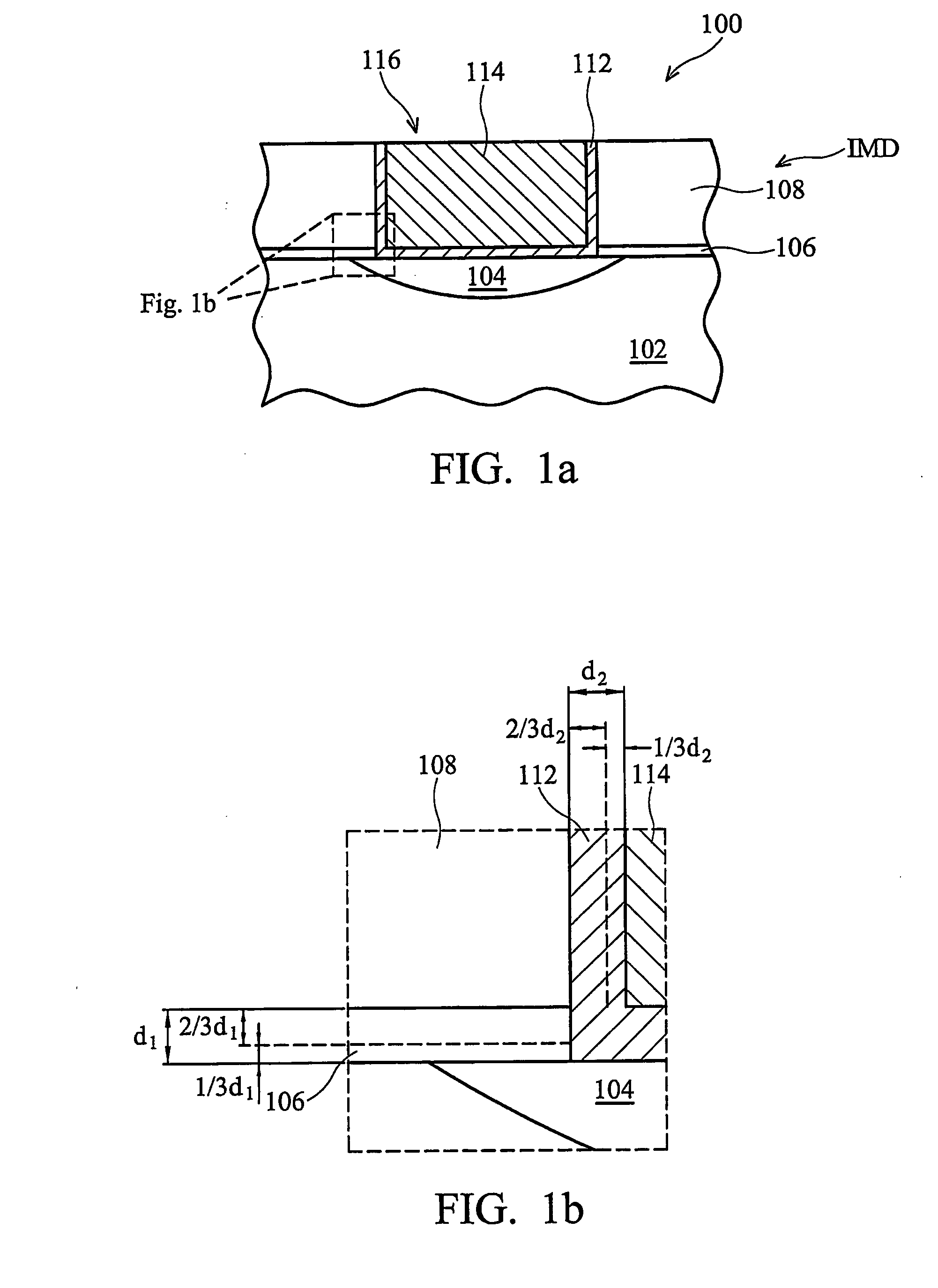

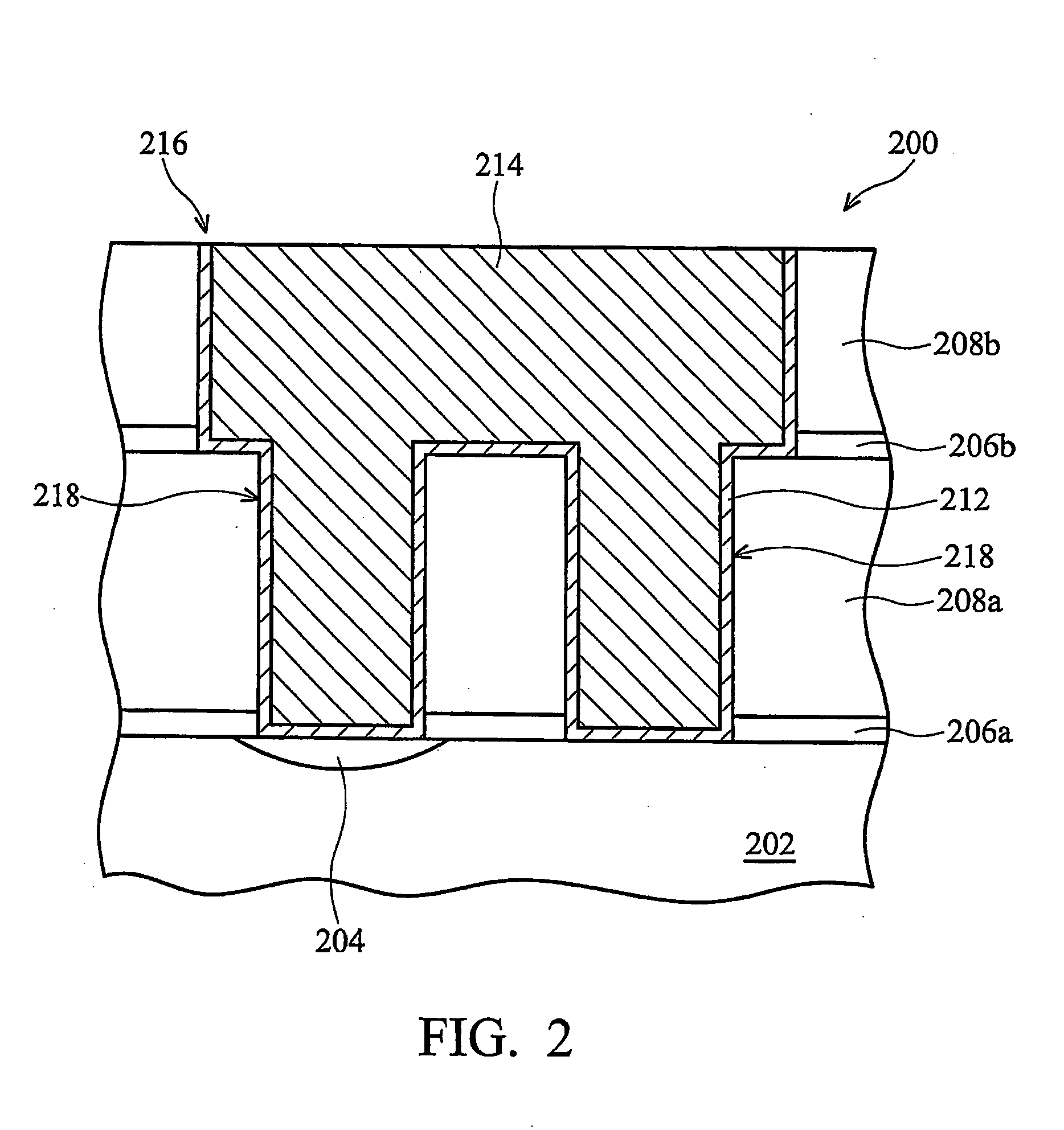

Robust fluorine containing Silica Glass (FSG) Film with less free fluorine

InactiveUS20060017166A1Less free FImprove film qualitySemiconductor/solid-state device detailsSolid-state devicesPorosityDielectric

A semiconductor device and method of manufacture thereof having a less free fluorine (F) fluorine containing Silica Glass (FSG) dielectric film formed thereon. The FSG dielectric film includes about 25% or less free F, has a porosity of about 5% or less and has a dielectric constant of about 3.8 or less. A first barrier layer may be disposed between a workpiece and the FSG dielectric film, and a second barrier layer may be disposed between the FSG dielectric film and at least one conductive line formed in the FSG dielectric film. The FSG dielectric film is formed by introducing SiF4:SiH4 at a reaction condition ratio of about 2.5 or less at a pressure of about 3 Torr or less and at an RF of about 500 watts to 5000 watts.

Owner:TAIWAN SEMICON MFG CO LTD

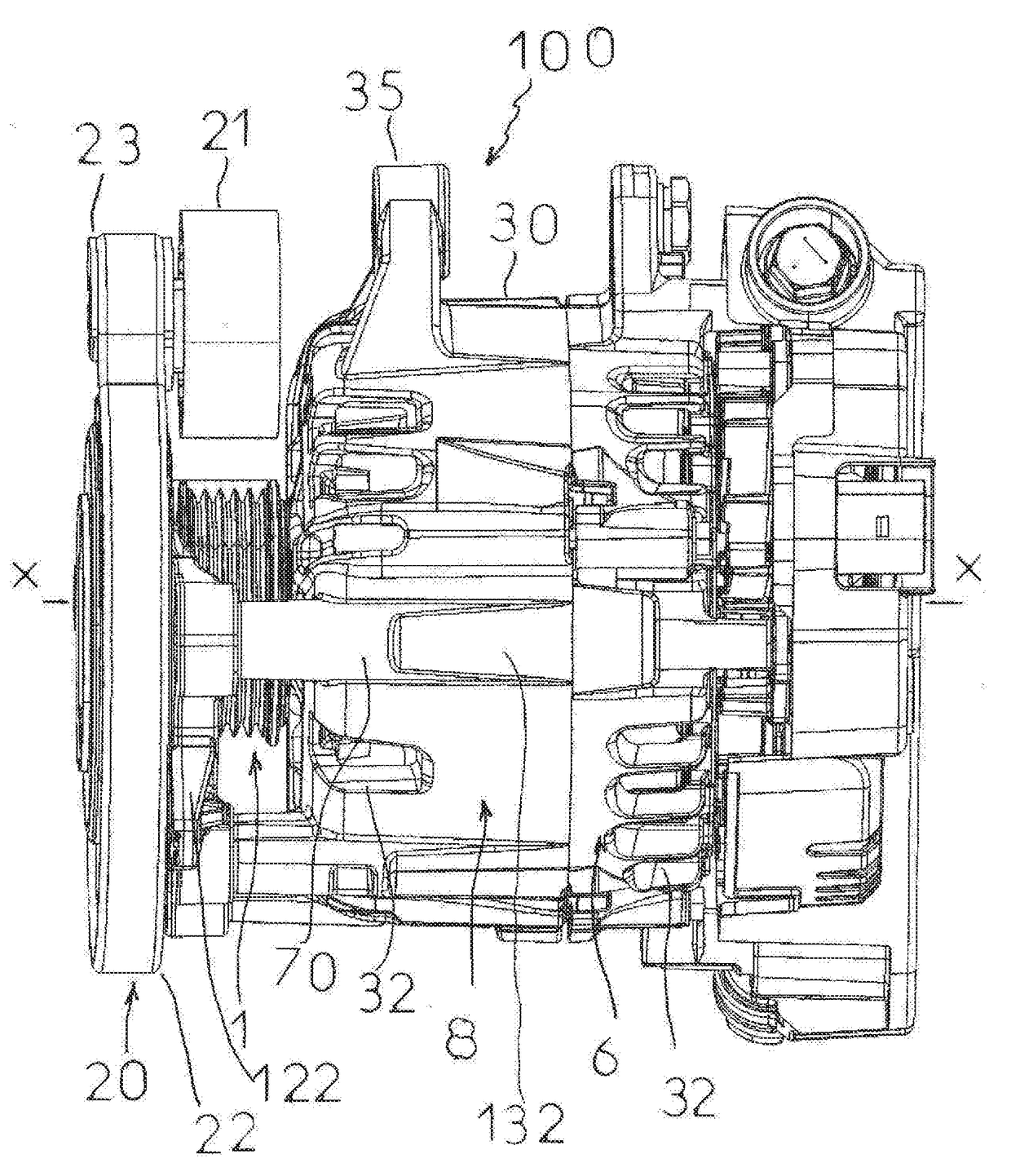

Front flange of a rotary electrical machine, and rotary electrical machine comprising a flange of this type

InactiveUS20170288496A1Brace robustPromote circulationMechanical energy handlingSupports/enclosures/casingsFlangePulley

The front flange made of mouldable material of a rotary electrical machine with a pulley (1) for receipt of a belt comprises at least two projecting braces (70) with axial orientation obtained by moulding of its outer periphery, and designed for securing of a support of at least one body, such as a belt tensioning roller, the braces (70) each comprising laterally at least one hollow (71).

Owner:VALEO EQUIP ELECTRIC MOTEUR

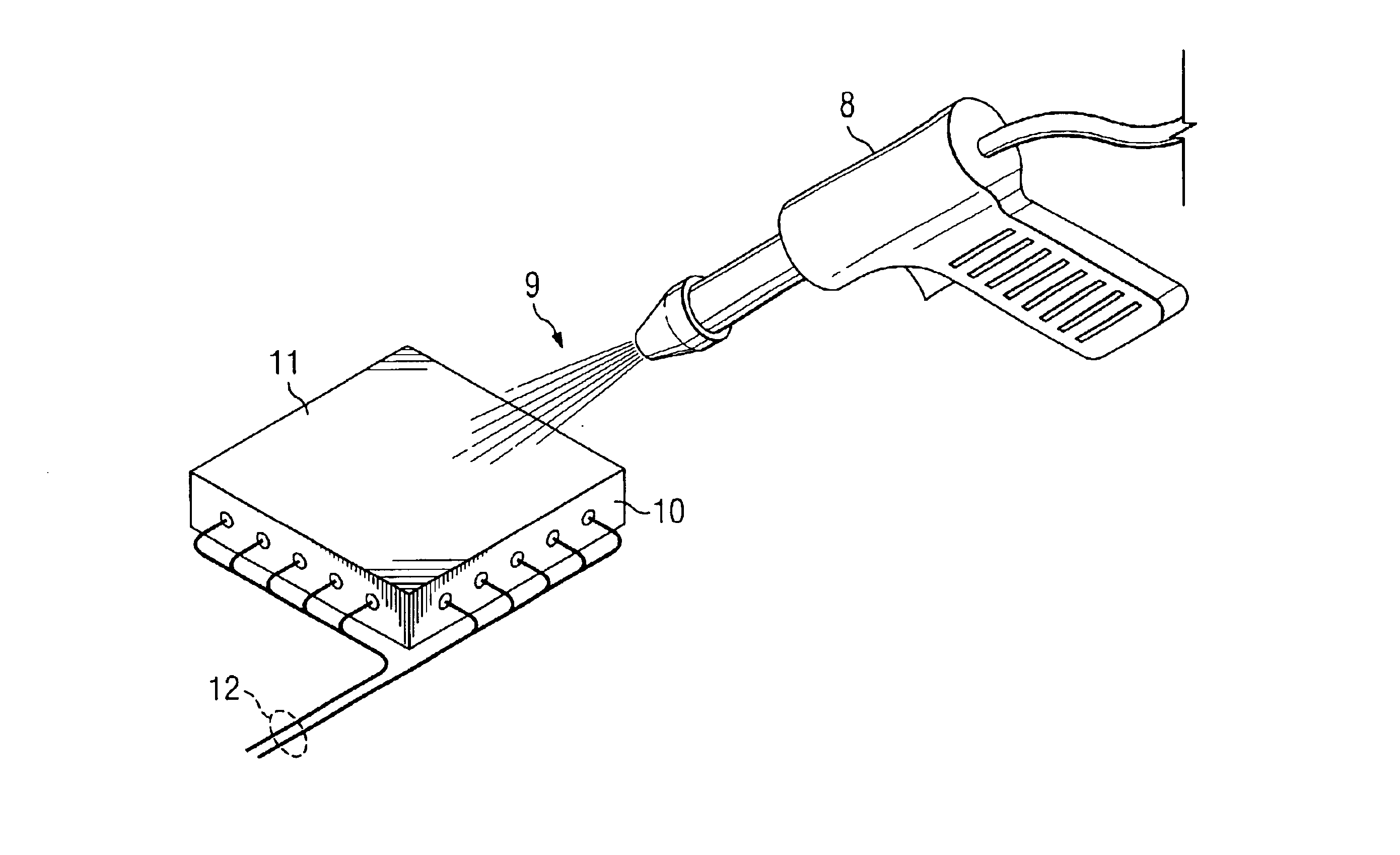

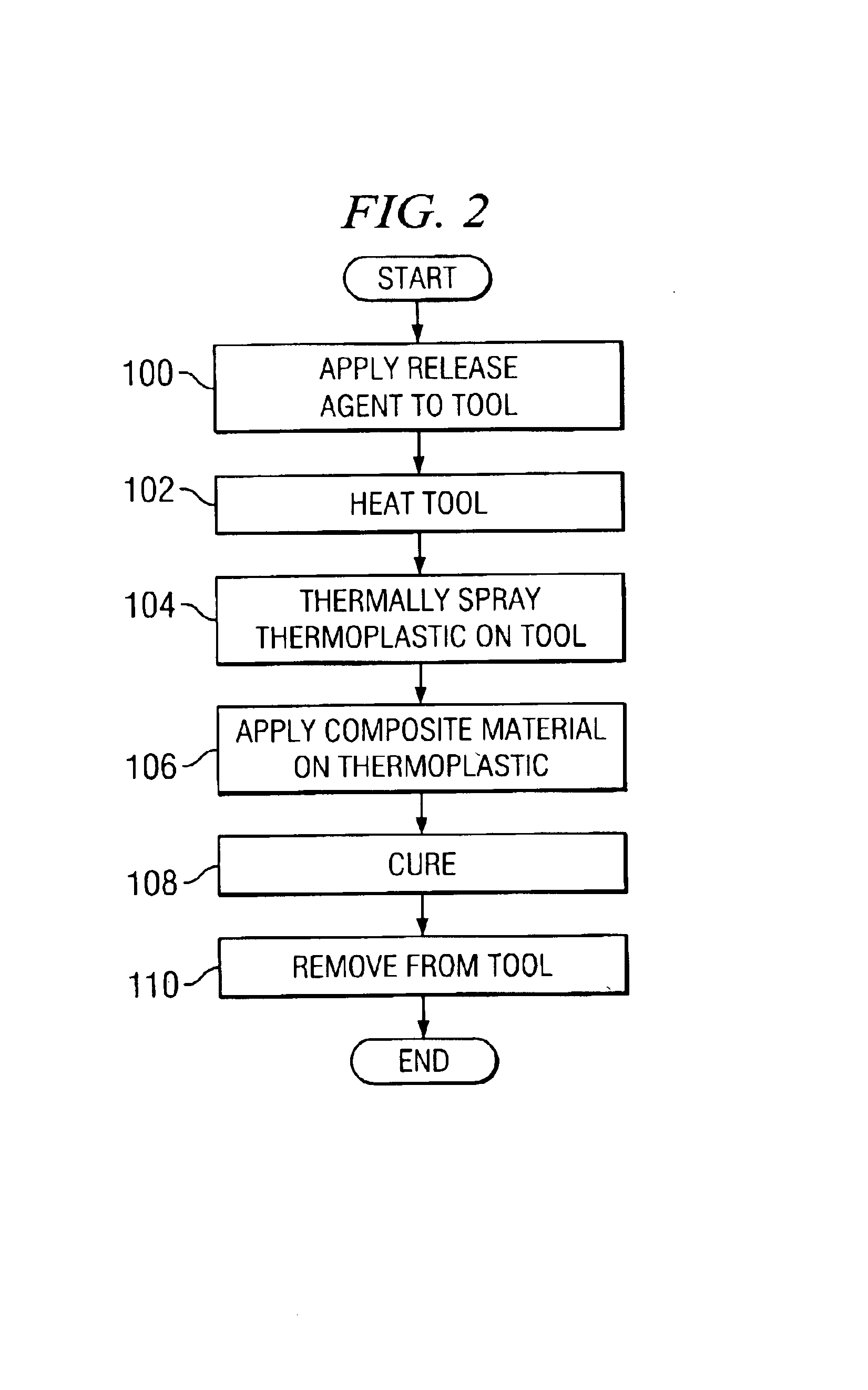

Thermoplastic coating for composite structures

ActiveUS20050019501A1Uniform thicknessUniform morphologyLaminationPretreated surfacesThermoplasticThermal spraying

A method of thermoplastic coating composite structures includes heating a tool. A thermoplastic layer is deposited onto the heated tool by thermal spraying a thermoplastic on the heated tool. Composite material is applied onto the thermoplastic layer. The thermoplastic layer and the composite material are then cured.

Owner:NORTHROP GRUMMAN SYST CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com