Prevention device and prevention method used for blasting air shock waves in drilling and blasting tunnel

A technology of air shock wave and shock wave, which is applied in the field of prevention devices for construction blasting shock waves in tunnels, and can solve problems such as shock wave hazards, natural environment damage, and human settlement environment interference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with specific embodiments.

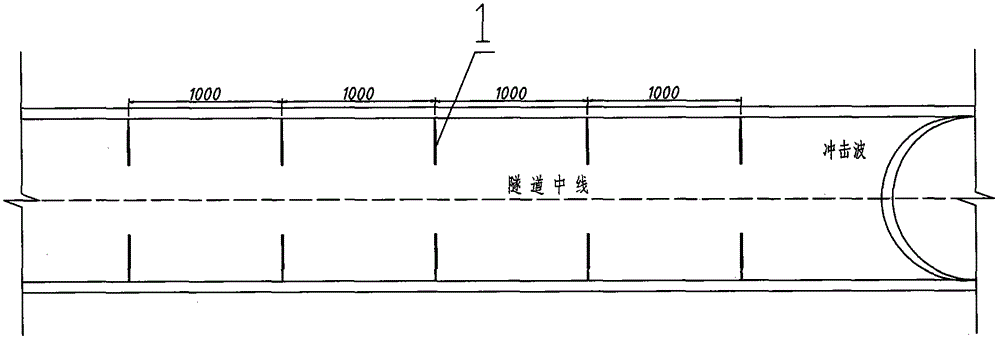

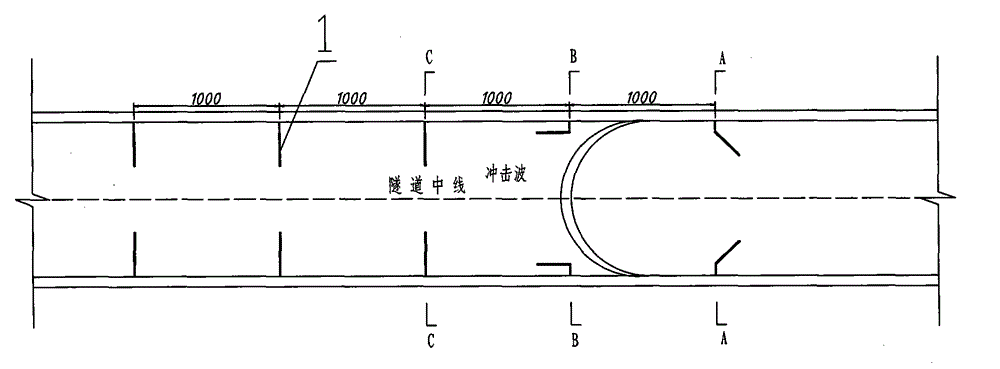

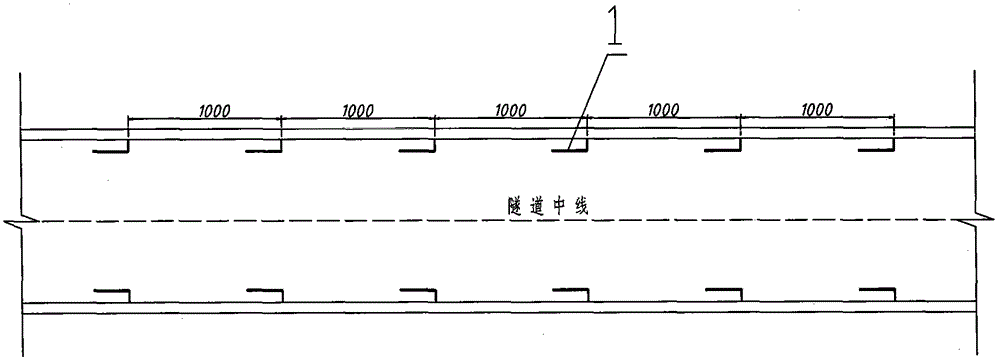

[0024] refer to Figure 1 to Figure 5 , the preventive device for blasting air shock wave in the drilling and blasting tunnel hole of the present invention includes a plurality of baffle units installed on the side wall of the tunnel, the baffle units are symmetrically installed on the side wall of the tunnel, and the baffle units include shock-resistant and high-temperature-resistant The baffle is fixed on the side wall of the tunnel through the switch hinge. The baffle can rotate around the shaft of the switch hinge. Three dampers are set on the shaft to provide damping for the rotation of the baffle. The switch hinge adopts standard hinges. Page, welded on the baffle plate of the present invention, the installation of the damper is specifically determined according to the type of the damper, the baffle plate is 10cm thick, long 300cm, and wide 200cm. The interior spac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com