Method for preparing untwisted, highly branched textiles

A textile and polymer technology, applied in textile/flexible product manufacturing, textile and papermaking, equipment configuration for processing textile materials, etc., can solve the problems of non-productivity, high environmental pollution, and high cod

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

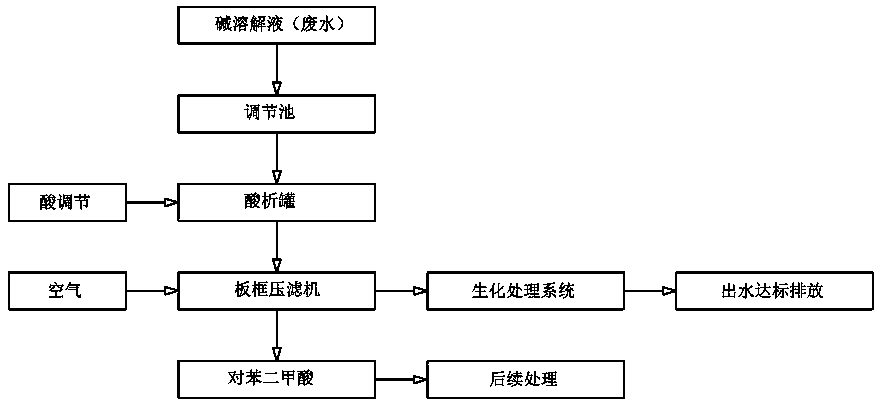

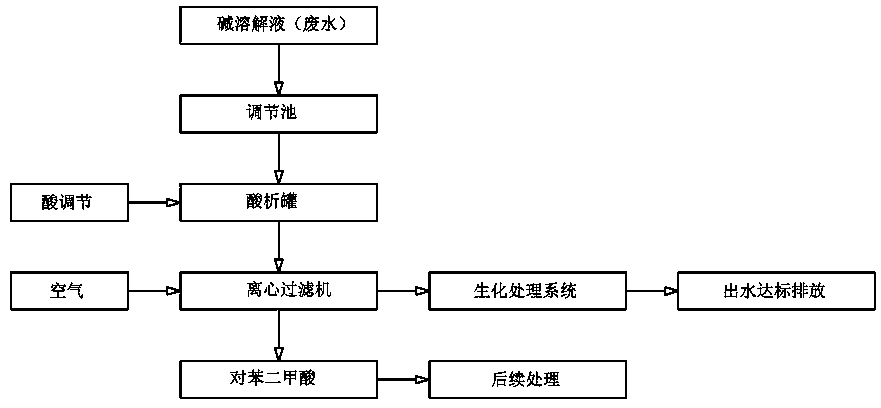

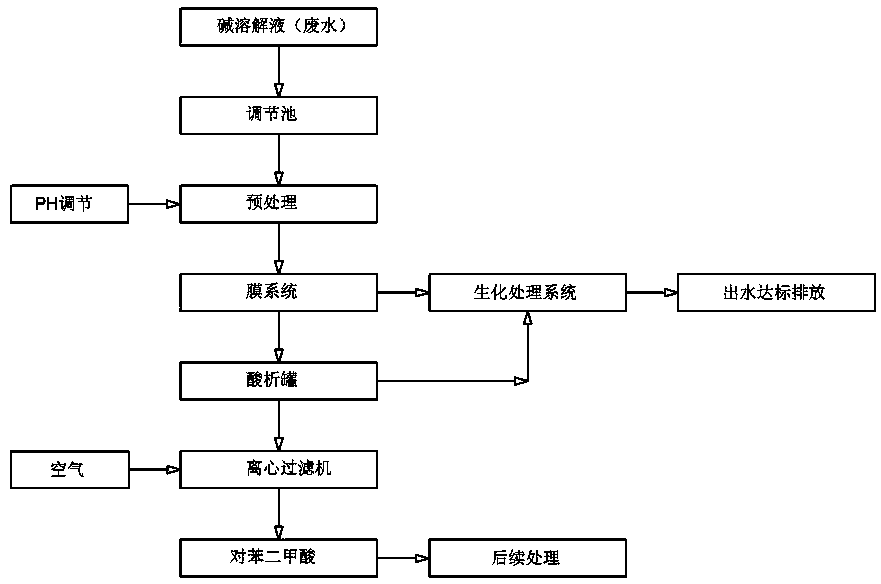

Method used

Image

Examples

Embodiment 1

[0031] A method for preparing a non-twisted textile, which comprises the following process steps, specifically:

[0032] a. Preparation of alkali-degraded slices: During the polymerization of polyester raw materials, 5-sodium sulfonate-polyethylene glycol isophthalate with a total weight of 5% of the polymer and isophthalic acid with a total weight of 5% of the polymer are added. Diformic acid, beat and stir while heating to 230°C; then move to the reactor and add polyethylene glycol with a total weight of 5% of the polymer to dilute and cool down to 210°C; continue to add molecular weight to the reactor Polyethylene glycol is 6000, and polyethylene glycol accounts for 5% of polymer gross weight, adds polyethylene glycol within 50 minutes and stirs simultaneously, is warming up to 230 ℃ under normal pressure and makes mixed material under vacuum state Polymerization, after polymerization, the alkali-degraded slices are cast, cooled, pelletized, dried, and screened sequentially...

Embodiment 2

[0039] A method for preparing hollow textiles, which includes the following process steps, specifically:

[0040] a. Preparation of alkali-degraded slices: During the polymerization of polyester raw materials, add 5-sodium sulfonate-polyethylene glycol isophthalate with a total weight of 4% of the polymer and isophthalic acid with a total weight of 3% of the polymer. Diformic acid, beat and stir while heating to 230°C; then move to the reactor and add polyethylene glycol with a total weight of 5% of the polymer to dilute and cool down to 210°C; continue to add molecular weight to the reactor Polyethylene glycol of 6000, polyethylene glycol accounts for 3% of polymer gross weight, adds polyethylene glycol within 50 minutes and stirs simultaneously, is heated up to 230 ℃ under normal pressure and makes the mixed material under vacuum state Polymerization, the alkali-degraded slices after polymerization are finally cast, cooled, pelletized, dried and screened in sequence, wherein...

Embodiment 3

[0052] The preparation method of hyperbranched textile, it comprises the following processing steps, specifically:

[0053] a. Preparation of alkali-degraded slices: During the polymerization of polyester raw materials, 5-sodium sulfonate-polyethylene glycol isophthalate with a total weight of 3% of the polymer and isophthalic acid with a total weight of 4% of the polymer were added. Diformic acid, beat and stir while heating to 230°C; then move to the reactor and add polyethylene glycol with a total weight of 3% of the polymer to dilute and cool down to 210°C; continue to add molecular weight to the reactor Polyethylene glycol of 6000, polyethylene glycol accounts for 2% of the total weight of the polymer, and the polyethylene glycol is added within 50 minutes while stirring, and the temperature is raised to 230 ° C under normal pressure and the mixture is kept under vacuum. Polymerization, after polymerization, the alkali-degraded slices are cast, cooled, pelletized, dried, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| fineness modulus | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com