Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

67results about How to "Non-toxic and tasteless" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Bicomponent platinum catalyst vulcanizer and its preparation method

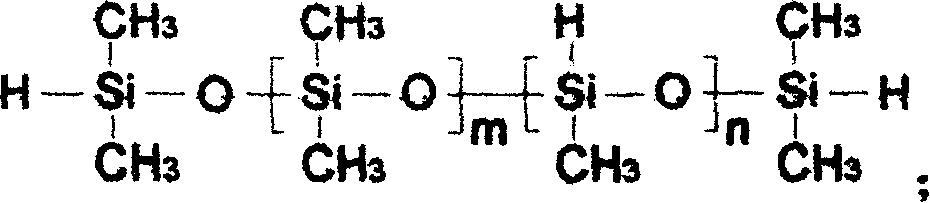

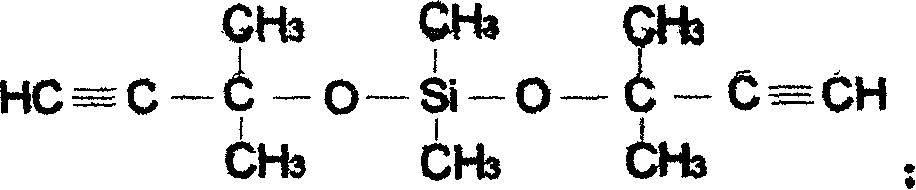

The present invention relates to a double-component platinum catalyst curing agent. It includes agent A and agent B which can be uniformly mixed when they are used, in which the agent A is mixture of vinyl raw rubber, gas phase white carbon black and platinum complex, and the agent B is mixture of vinyl raw rubber, gas phase white carbon black, silicon oil whose end contains hydrogen and inhibitor. When the agent A and agent B are mixed, their mass ratio is agent A: agent B = (0.8-1.0)(1.0-1.5). Said invention also provides the preparation method of said double-component platinum catalyst curing agent.

Owner:SHENZHEN ANPIN SILICONE MATERIAL

Environment-friendly PVC (polyvinyl chloride) decorative film and preparation method thereof

ActiveCN105482548ANon-toxic and tastelessImprove thermal stabilitySynthetic resin layered productsLaminationPolymer sciencePolyvinyl chloride

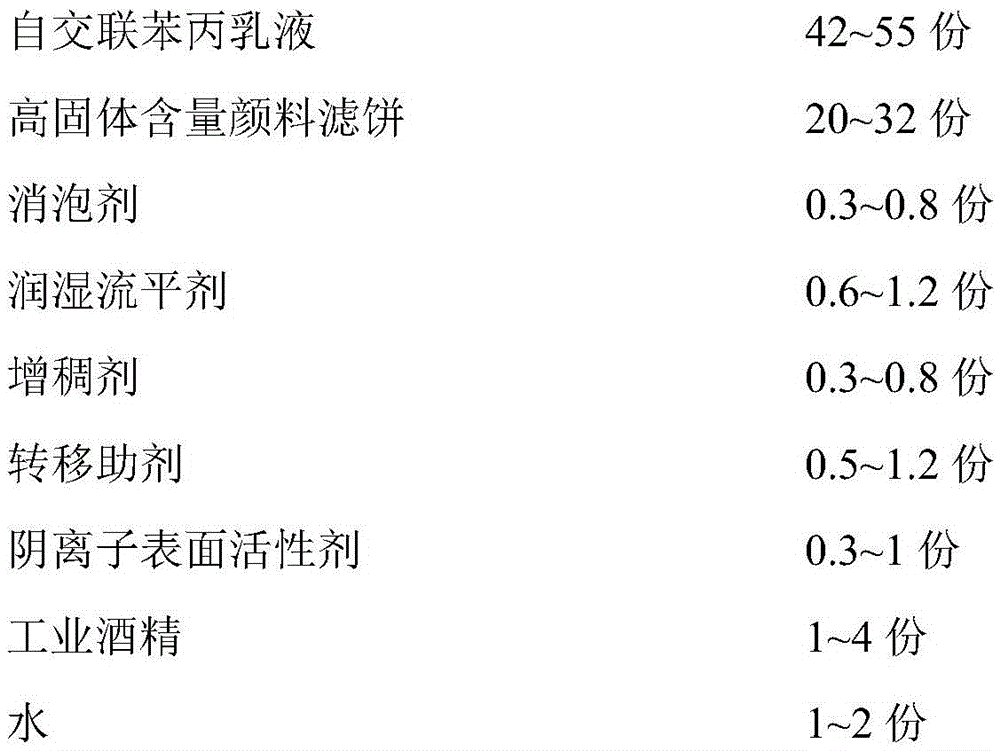

The invention discloses an environment-friendly PVC (polyvinyl chloride) decorative film which comprises an environment-friendly PVC substrate, a water-based ink printing layer printed on the environment-friendly PVC substrate, and an environment-friendly PVC mask attached to the water-based ink printing layer. The water-based ink is an inorganic nano modified acrylate composite paint which is mainly prepared from 18-22 parts of nano silicon dioxide acrylate composite emulsion, 42-55 parts of self-crosslinked styrene-acrylic emulsion, 20-32 parts of high-solid-content pigment filter cake, 0.3-1 part of anionic surfactant and the like. The environment-friendly PVC decorative film has the advantages of favorable staining power, high drying speed, favorable film forming property, high adhesive force, no toxicity or smell, favorable heat stability and the like. The invention also discloses a preparation method of the environment-friendly PVC decorative film. The preparation method has the advantages of simple production technique and high practicality, and is beneficial to industrial production.

Owner:GUANGDONG T&H NEW MATERIALS CO LTD +2

Inorganic anti-radiation coating for lining of radiation chamber of ethylene cracking furnace and preparation method of inorganic anti-radiation coating

InactiveCN104109407AGood thermal shock resistanceImprove efficiencyChemical industryReflecting/signal paintsCobalt oxideSodium silicate

The invention discloses an inorganic anti-radiation coating for a lining of a radiation chamber of an ethylene cracking furnace. The inorganic anti-radiation coating comprises the following components in parts by weight: 15-20 parts of cobalt oxide, 1-10 parts of zirconium oxide, 3-10 parts of aluminum oxide, 1-5 parts of silica powder, 8-12 parts of silicon carbide, 3-7 parts of chromium oxide, 0-8 parts of manganese oxide, 0-5 parts of carborundum, 2-10 parts of sodium silicate, 5-8 parts of aluminum dihydrogen phosphate, 1-5 parts of quartz powder, 1-5 parts of feldspar powder, 10-15 parts of phosphorus pentoxide, 0-3 parts of chrome iron ores, 0-2 parts of zircon sand, 0-1 part of cerium oxide, 1-4 parts of graphite powder, 0.5-1.0 part of boron oxide and 0.1-0.5 part of carclazyte, wherein the particle of each solid component is not smaller than 350 meshes. The invention also discloses a preparation method of the inorganic anti-radiation coating for the lining of the radiation chamber of the ethylene cracking furnace. By using the inorganic anti-radiation coating disclosed by the invention, the high temperature resistance and thermal shock resistance of the coating can be effectively improved, the utilization ratio of radiant energy can be increased, and the binding force of the coating and the lining material of the cracking furnace can be enhanced.

Owner:上海乐恒石油化工集团有限公司

Water-proofing soy protein trademark glue for liquor drink bottle trademark pasting and preparing method of water-proofing soy protein trademark glue

ActiveCN105018005AExcellent adhesionHigh solid contentNon-macromolecular adhesive additivesProtein adhesivesEmulsionTrademark

The invention provides water-proofing soy protein trademark glue for liquor drink bottle trademark pasting and a preparing method of the water-proofing soy protein trademark glue. Soy protein is used for replacing casein, the problem of resource shortage is solved, and the preparing cost of the trademark glue is reduced. Other auxiliary raw materials are adopted, and the initial pasting performance, the water resistance and the fluidity of the trademark glue are improved. The water-proofing soy protein trademark glue comprises, by weight, 5-6 % of soy protein, 20-25% of urea, 2-3% of modified corn starch, 0.2-0.4% of antifoaming agent, 25-28% of modified acrylic emulsion, 0.5-0.8% of caustic soda flake, 1.8-2.5% of water repellent agent, 0.11-0.15% of cross-linking agent and 30-50% of water. The water-proofing soy protein trademark glue has the advantages of being fast in drying, resistant to water, free of mildew, good in initial pasting performance, free of toxin and smells, low in cost and the like. The physicochemical indexes of the water-proofing soy protein trademark glue are superior to the physicochemical indexes of products of the same kind at home and abroad. The water-proofing soy protein trademark glue is suitable for domestic and imported trademark pasting machines. The water-proofing soy protein trademark glue for liquor drink bottle trademark pasting and the preparing method of the water-proofing soy protein trademark glue are suitable for trademark pasting of aluminum foil and copper plate paper labels of beer bottles or beverage bottles or other glass bottles in the industries of beverages and food, have a large trademark pasting application range and are suitable for trademark pasting machines for conducting trademark pasting on 20,000-60,000 bottles per hour.

Owner:烟台世能科技有限公司

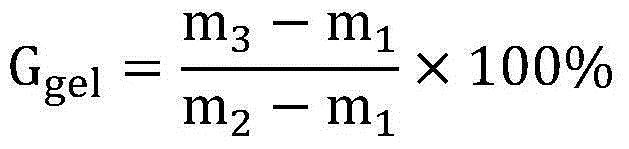

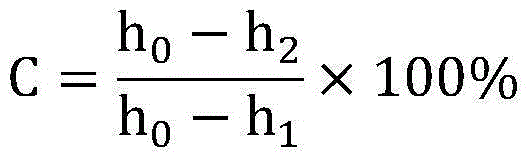

Cross-linked polypropylene microcellular foam material and production method thereof

The invention relates to a cross-linked polypropylene microcellular foam material. The cross-linked polypropylene microcellular foam material comprises the following raw materials in parts by weight: 99-100 parts of polypropylene resin, 0.1-2 parts of irradiation sensitizer and 0.1-3 parts of antioxidant and is produced through the following steps: mixing the raw materials; dipping a substrate with CO2 gas; foaming the substrate; performing irradiation treatment on the foam material; performing high-temperature annealing; detecting the foam material. The cross-linked polypropylene microcellular foam material has the advantages that the polypropylene resin, the irradiation sensitizer and the antioxidant are subjected to the steps of mixing the raw materials, dipping the substrate with CO2 gas, foaming the substrate, performing irradiation treatment on the foam material, performing high-temperature annealing and detecting the foam material in sequence to obtain a high-resilience polypropylene microcellular foam product with small cell size and high cell density; the cross-linked polypropylene microcellular foam material prepared by the method has the characteristics of good resilience, fine handfeel, no toxicity and no smell, and can be widely applied to the fields with high requirements on the resilience and the sanitation level of the foam material.

Owner:浙江新恒泰新材料股份有限公司

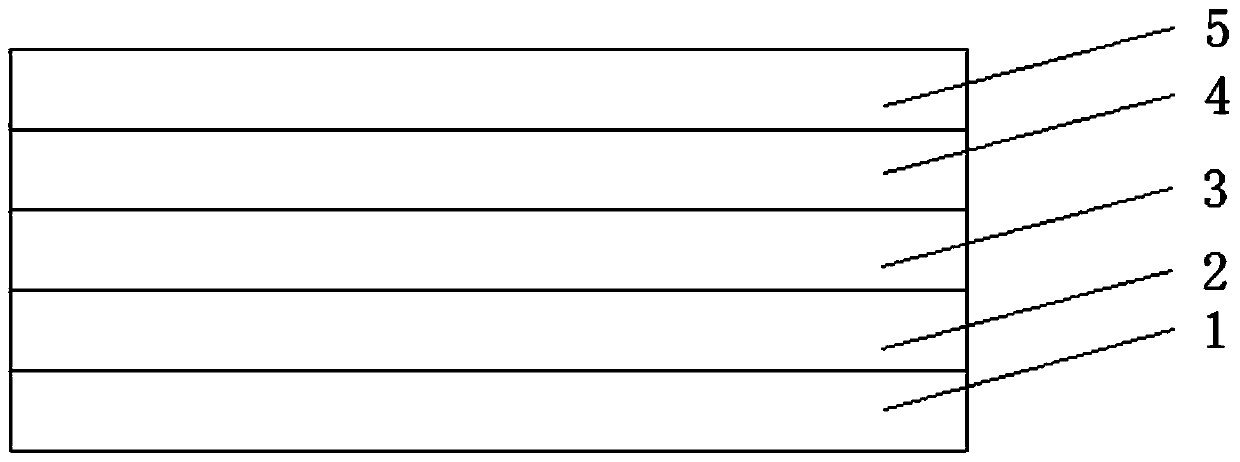

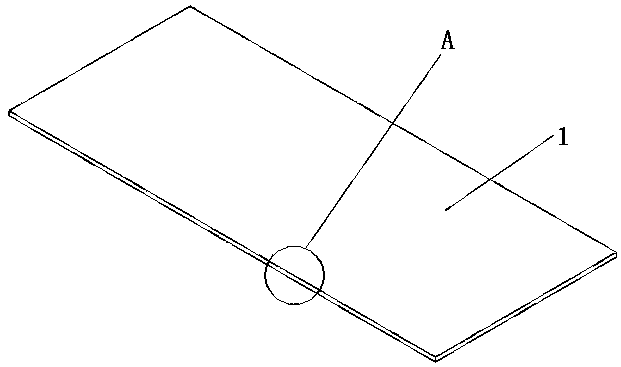

Environment-friendly polypropylene floor

InactiveCN109986858ARegular structureNon-toxic and tastelessSynthetic resin layered productsConstructions elementsToxic gasPolymer science

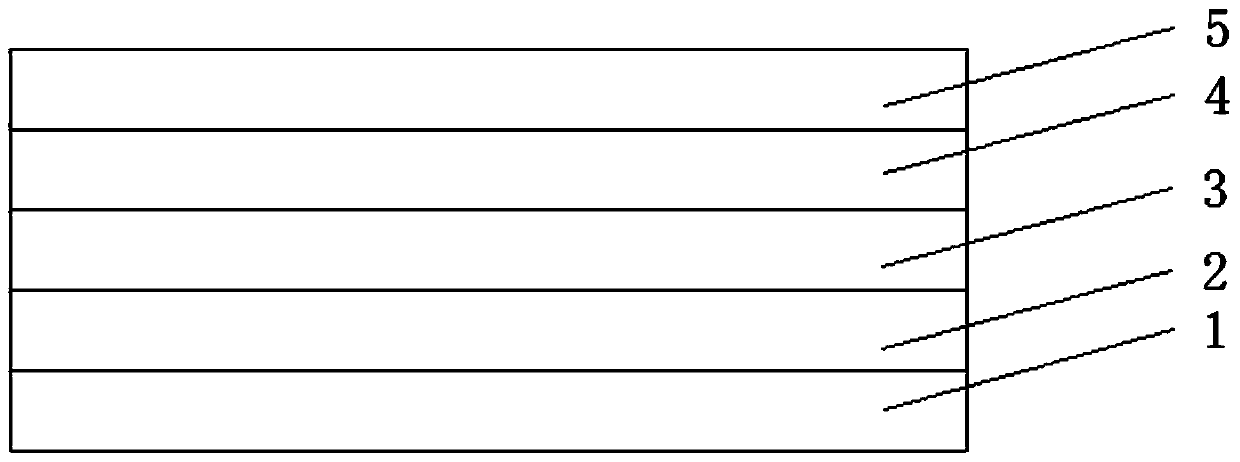

The invention relates to an environment-friendly polypropylene floor. The environment-friendly polypropylene floor comprises a balance layer, a base board layer, a decorative layer, a wear-resistant layer and a scratch-resistant layer from bottom to top, through hot-press, a compound semi-finished product is produced, then the scratch-resistant layer is subjected to roller coating, then through tempering, board cutting and slotting or edge chipping, the environment-friendly polypropylene floor is produced, and the balance layer is produced by adopting the following materials of, in percentageby weight, 20-80% of polypropylene A with a melt index of 0.5-20 g / 10min, 1-20% of polypropylene B, 0-20% of calcium carbonate, 0.1-5% of an antioxidant, 0.05-5% of a flame retardant and 0.1-5% of toner; the base board layer is produced by adopting the following materials of, in percentage by weight, 20-60% of polypropylene A, 1-20% of polypropylene B, 20-80% of calcium carbonate, 0.1-5% of an antioxidant, 0.05-5% of a flame retardant, 10-70% of talcum powder, 0.5-3% of a coupling agent and 0.1-5% of toner; and the wear-resistant layer is produced by adopting the following materials of, in percentage by weight, 90-98% of polypropylene B, 0.1-1.0% of a transparent agent, 0.5-5% of an antioxidant, 0.1-0.5% of a light stabilizer and 0.05-5% of a flame retardant. The environment-friendly polypropylene floor is environmentally friendly, and is not liable to generate toxic gas.

Owner:JIANGSU BEIER DECORATION MATERIALS CO LTD

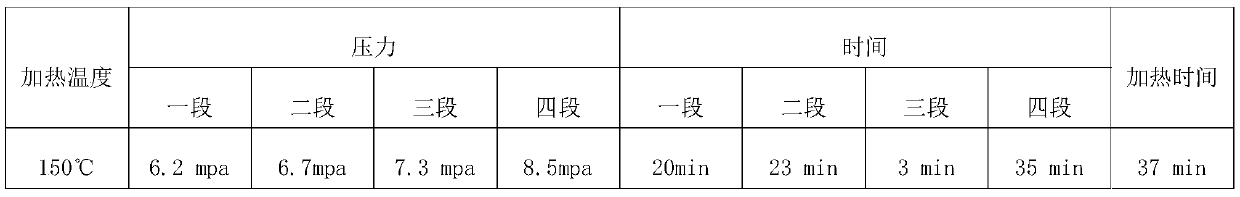

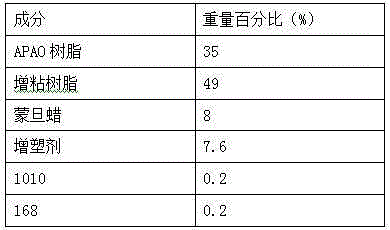

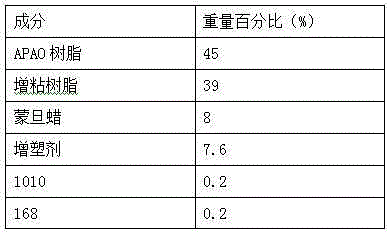

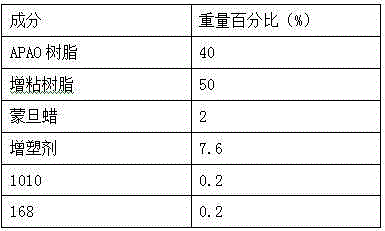

Tissue paper compounding hot melt adhesive and preparation method thereof

InactiveCN105219299AHigh active ingredientFast curingMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesPlasticizerPetroleum resin

The invention relates to a tissue paper compounding hot melt adhesive which is composed of, by mass, 20-45% of APAO resin, 30-60% of tackifying resin, 2-15% of a plasticizer, 1-15% of montan wax and 0.2-0.8% of an antioxidant. The APAO resin has a propylene content of 60-75%, a glass transition temperature of -40 DEG C to -20 DEG C, and a viscosity of 3000-10000cps under a temperature of 190 DEG C. The tackifying resin is hydrogenated petroleum resin with a softening point of 60-90 DEG C. the tissue paper compounding hot melt adhesive provided by the invention does not contain water, such that no water penetrates into the tissue paper during a tissue paper production process. Therefore, tissue paper performances such as hand feeling, strength and comfortableness can be ensured, and paper quality decrease caused by water penetration can be avoided. The adhesive also has the advantages of high curing speed, excellent strippability, long exposure time, good fluidity, good safety, good environment friendliness, no toxicity, and no odor. The adhesive has a good application prospect.

Owner:熊红兵

Hard PVC floor production technology

The invention discloses a hard PVC floor production process, which comprises the following steps: 1) mixing materials; 2) banburying; 3) opening practice; 4) cutting; 5) hot pressing; Fire; 8) health preservation; 9) cutting board slotting; 10) health preservation; 11) packaging. In the hard PVC floor production process of the present invention, the PVC base plate is made of hard PVC foam material, which can effectively prevent deformation, increase strength and prevent collapse while effectively controlling the shrinkage rate.

Owner:JIANGSU RUISHENG NEW MATERIALS CO LTD

Shock-absorbing electric toothbrush

The invention provides a shock-absorbing electric toothbrush. The shock-absorbing electric toothbrush comprises a shell; the shell is provided with a motor bracket, a motor shock-absorbing seat, a motor and a shock-absorbing mechanism; the tail end of the motor is connected with the motor bracket by the motor shock-absorbing seat; the motor is sleeved by a motor shock-absorbing casing; the motor shock-absorbing casing is provided with a first through hole; one end of the shell is provided with a second through hole; the motor shaft of the motor successively passes through the first through hole and the second through hole; and the shock-absorbing mechanism abuts against the inner wall of the shell and is connected with the motor shaft. With such a technical scheme, collision among the motor, the motor bracket and the shell of the shock-absorbing electric toothbrush is reduced, the noise of the motor is decreased, and the motor is prevented from loosening and damage due to long-term vibration; the shock-absorbing mechanism is connected with the motor shaft and abuts against the inner wall of the shell, so vibration between the motor shaft and the shell is reduced, and noise generated during forward and backward rapid rotation of the motor shaft is further reduced, and thus, noise generated during working of the electric toothbrush is reduced.

Owner:GUANGDONG XUEJIE DAILY NECESSITIES

Biological liquid fertilizer

InactiveCN101284738AIncrease brightnessReliable performanceSuperphosphatesOrganic fertilisersChemistryPesticide

The invention belongs to the biotechnology field, and relates to a drug potentiator biological liquid flushing fertilizer, which is composed of materials by weight parts as follows: water 20kg, soybean 6kg, fish meal 3kg, bone meal 4kg, brown sugar 2kg, ferment enlargement fungi 1.5kg, calcium superphosphate 3kg, ferrous sulfate 300g and borax 60g. The soybean is put in a pot to be boiled for 10 minutes, water is added into a vat, and the soybean is poured into the vat; the fish meal of 3kg, the bone meal of 4kg, the brown sugar of 2kg, the calcium superphosphate of 3kg, the ferrous sulfate of 300g and the borax of 60g are put into the vat; then, the enlargement fungi of 1.5kg is put into the vat, and is stirred by a wooden staff once a day, until the solution is fermented. The fertilizer used together with acid pesticides not only serves as the fertilizer, but also is a drug potentiator. The fertilizer can prevent the plant from being damaged by various epiphytes and bacteria and can prevent diseases and insect pests, such as powdery mildew, acarid, red spider, etc. Furthermore, the fertilizer has the advantages of safe and reliable performance, no side effects, no pollution and no damage to human bodies, and can be sprayed and flushed.

Owner:庞纯凯

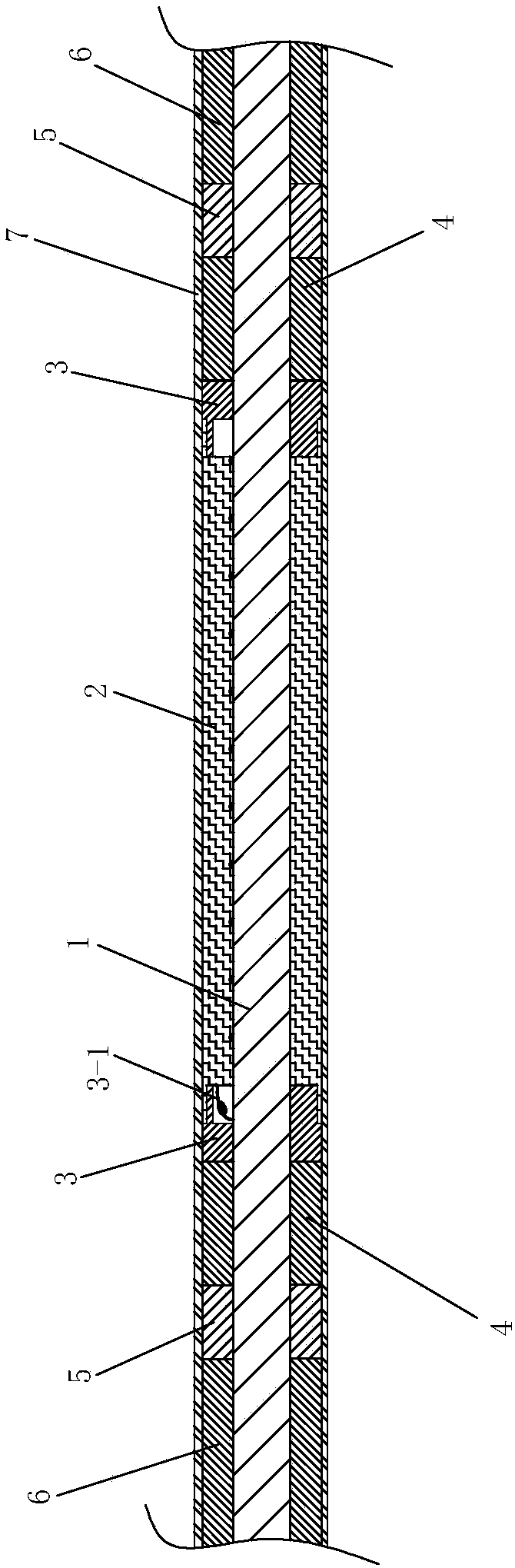

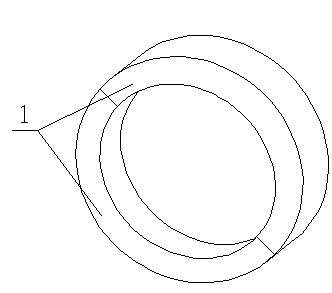

Solid towline with good dragging performance for marine seismic exploration

InactiveCN108447591AMaintain pressure resistanceWith impact resistanceNon-insulated conductorsFloating cablesYarnRubber material

The invention discloses a solid towline with good dragging performance for marine seismic exploration. The solid towline is characterized in that the solid towline comprises a main cable, hydrophones,buoyancy sleeves and an outer sheath. The hydrophones are fixedly arranged on the main cable with an equal interval. The hydrophones are electrically connected to corresponding wire cores in the maincable. Each of the buoyancy sleeves is made of a foamed polyethylene material, and foamed polyethylene is extruded on the main cable. The main cable includes the transmission wire cores, a tensile fiber layer and a conductive wire layer. The tensile fiber layer is formed by weaving aramid yarn and / or polyester yarn outside the transmission wire cores. The conductive wire layer includes a set of power lines and a set of signal lines. The power lines and the signal lines are orderly arranged with an equal interval along the circumferential direction of the main cable outside the tensile fiber layer to form the corresponding wire layer. The buoyancy sleeves are fixedly arranged on the main cable with an equal interval, and each of the buoyancy sleeves is between two adjacent hydrophones. Theouter sheath is made of a thermoplastic polyurethane elastomer rubber material and is extruded outside the hydrophones, positioning ends and the buoyancy sleeves, and the outer sheath is seamlessly bonded to the hydrophones.

Owner:CHANGZHOU MARINE CABLE

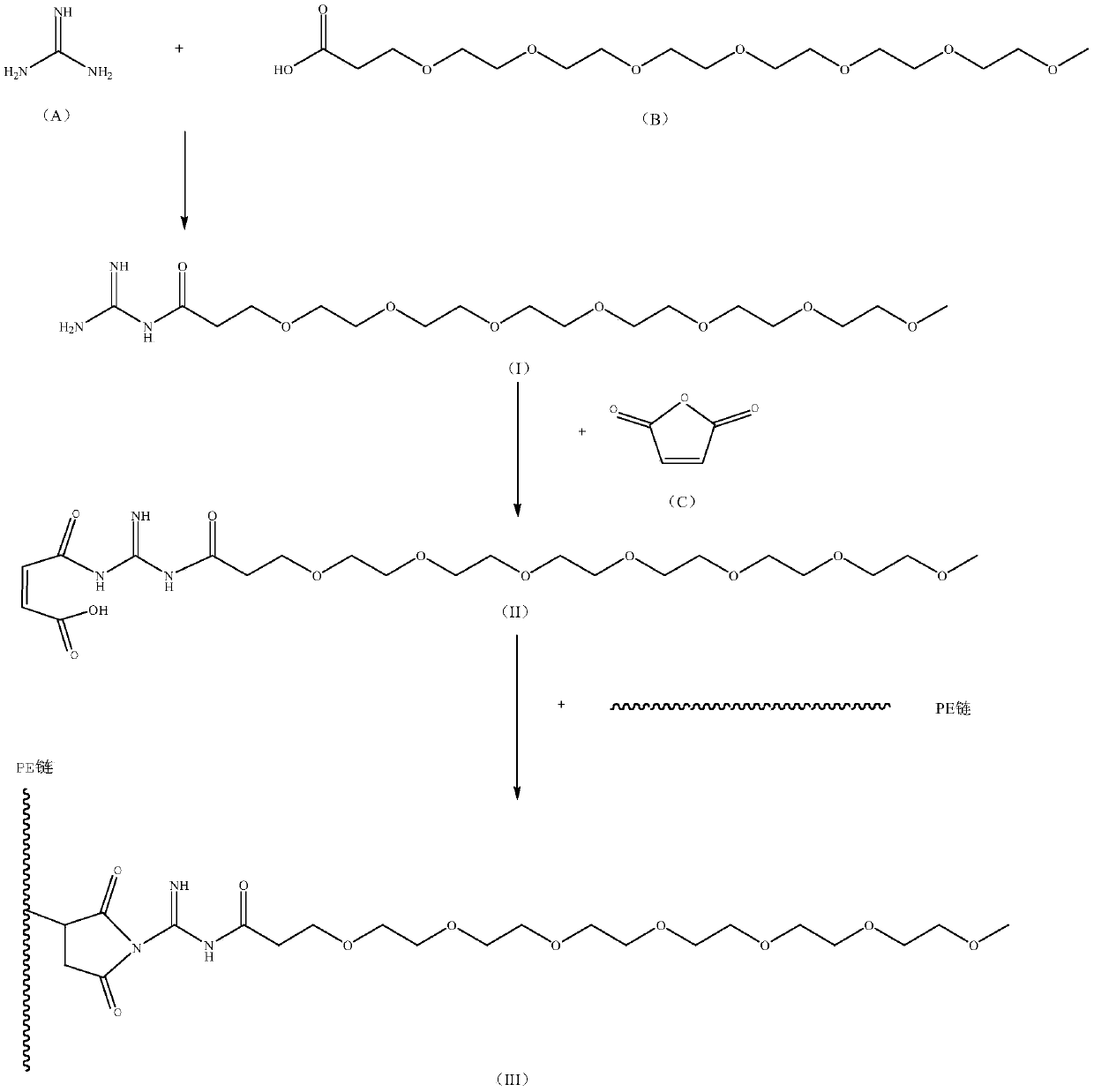

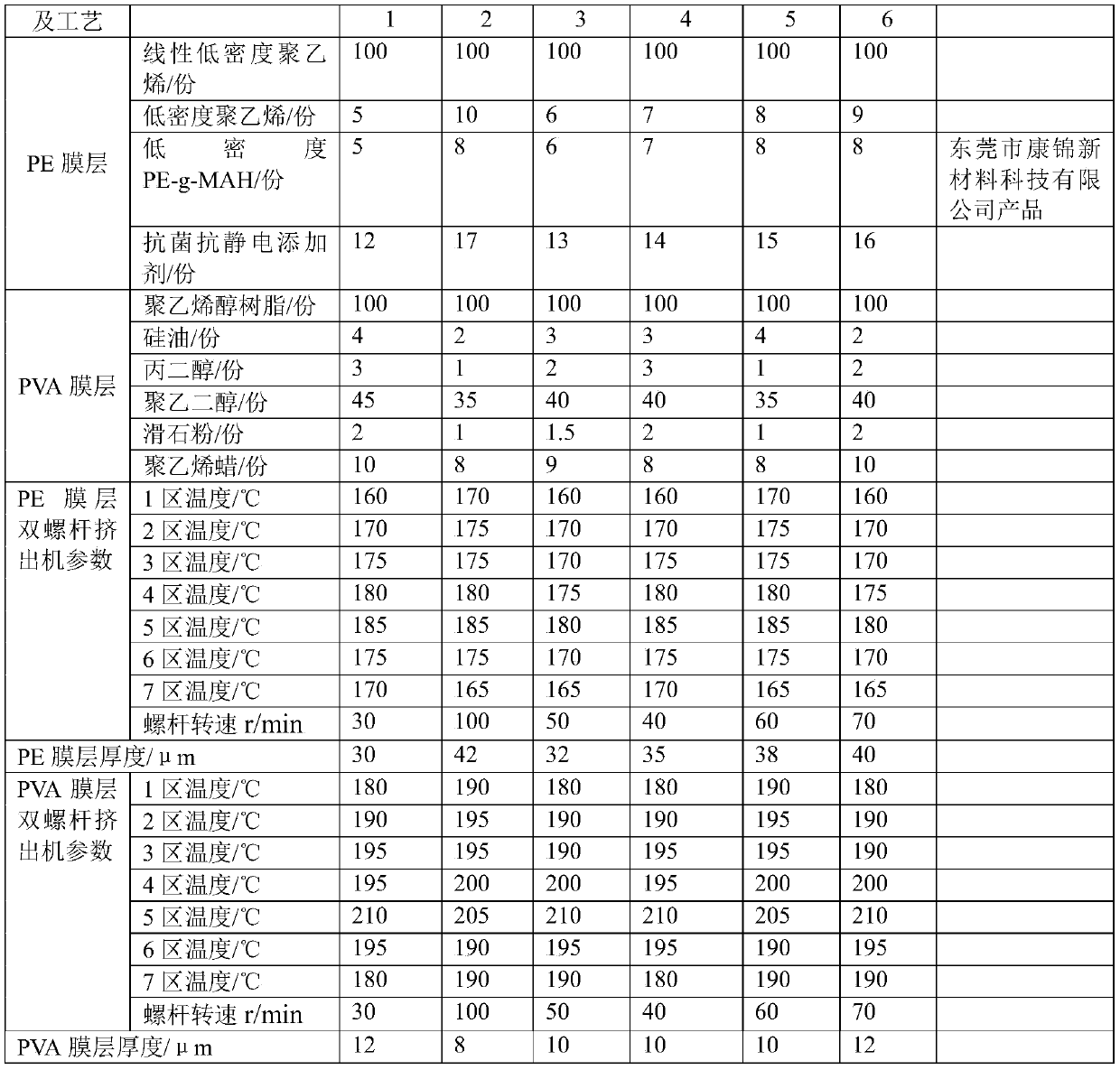

Antibacterial high-oxygen barrier PE composite film and preparation method thereof

The invention belongs to the field of packaging materials, and particularly relates to an antibacterial high-oxygen barrier PE composite film and a preparation method thereof. The antibacterial high-oxygen barrier PE composite film sequentially comprises a PE film layer, a PVA film layer and a PE film layer from outside to inside and is prepared through three-layer co-extrusion compounding. The antibacterial high-oxygen barrier PE composite film has excellent antibacterial and antistatic properties while effectively improving the poor moisture resistance, oxygen barrier property and film interlayer binding force of an existing PE composite film, has the advantage of good comprehensive performance, has wide application space, and is especially suitable for food packaging and medical treatment.

Owner:山东亚新塑料包装有限公司

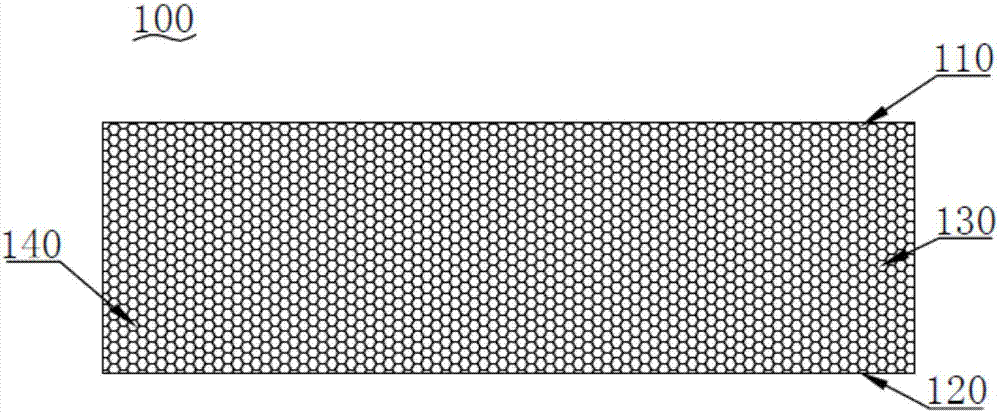

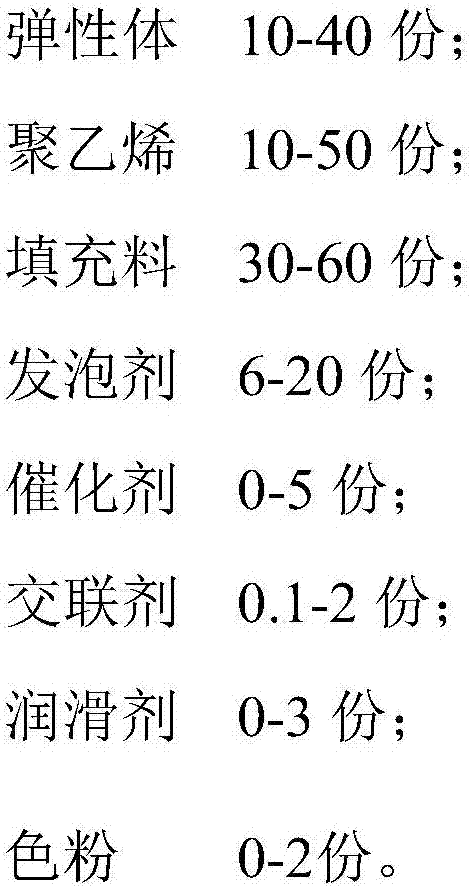

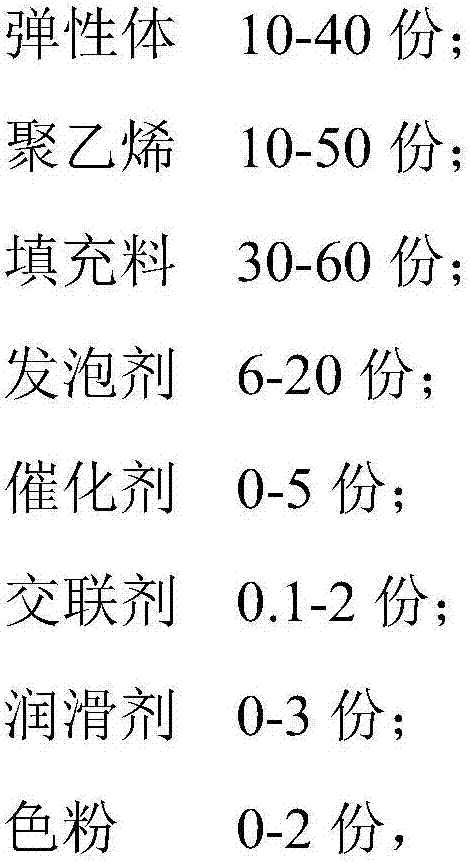

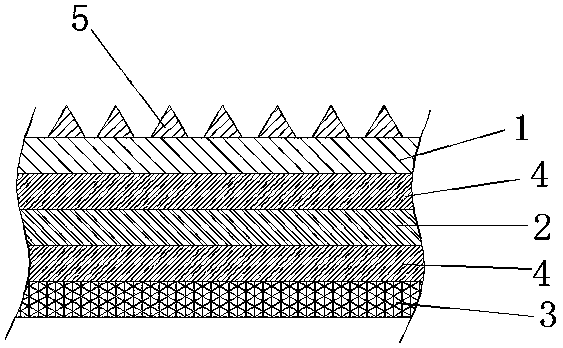

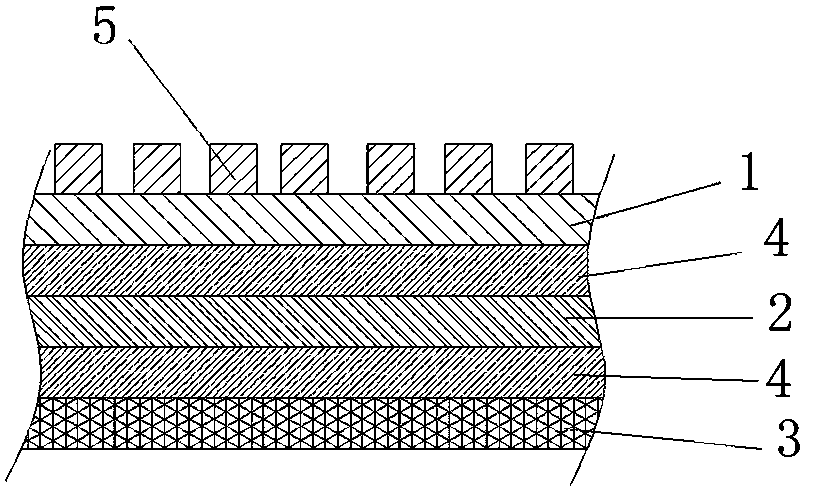

Closed-cell foaming material as well as manufacturing formula and manufacturing method thereof

PendingCN107379695AIncrease foam densityLow costSynthetic resin layered productsElastomerPolymer science

The invention relates to the technical field of foaming materials, and in particular relates to a closed-cell foaming material as well as a manufacturing formula and a manufacturing method thereof. The closed-cell foaming material comprises a body, wherein the body is integrally molded through continuous foaming; the body comprises an upper surface skin, a middle core layer and a lower surface skin; the upper surface skin, the middle core layer and the lower surface skin are integrally molded through continuous closed-cell foaming; a formula of the foaming material comprises 10 to 40 parts of elastomers (including EVA (Ethylene-vinyl Acetate copolymer), POE (Polyolefin Elastomer), TPE (Thermoplastic Elastomer), TPR (Thermoplastic Rubber) and MPP (Modified Polypropylene)), 10 to 50 parts of polyethylene, 30 to 60 parts of a filling material, 6 to 20 parts of a foaming agent, 0 to 5 parts of a catalyst, 0.1 to 2 parts of a cross-linking agent, 0 to 3 parts of a lubricant and 0 to 2 parts of toner; the manufacturing method of the foaming material comprises the following steps: mixing; extruding; calendering to form a master batch; carrying out primary cooling and winding; adding the master batch into a continuous foaming tunnel furnace and carrying out closed-cell cross-linking foaming under normal pressure; carrying out secondary cooling; printing to obtain a finished product and winding. The method provided by the invention completely meets European Union standards and user requirements especially in the aspect of formamide; the closed-cell foaming material provided by the invention can be used for continuously carrying out chemical cross-linking closed-cell foaming without electron irradiation crosslinking and mould pressing.

Owner:广东富利时实业有限公司

Waterproof and bacteriostatic tarpaulin

InactiveCN107964791ANon-toxic and tastelessImpermeableFibre treatmentETHYLHEXYL SALICYLATESodium Bentonite

The invention discloses a waterproof and bacteriostatic tarpaulin, which comprises a netted sandwich cloth and a functional liquid. The functional liquid is mainly composed of the following componentsby weight: 5-10 parts of chitosan, 5-10 parts of a chitosan oligosaccharide derivative, 2-5 parts of nano titanium dioxide particles, 60-80 parts of polyvinyl chloride paste resin, 2-5 parts of ethylhexyl salicylate, and 10-20 parts of bentonite. The tarpaulin has the characteristics of no toxicity, no odor, osmosis prevention, ageing resistance, bacteriostasis and mold prevention, and is in linewith the provisions of GB-6675. The invention also discloses a preparation method of the waterproof and bacteriostatic tarpaulin, the method is simple, and is easy for industrial production.

Owner:NINGBO TIANDUN WATERPROOF MATERIAL CO LTD

Composite fireproof insulation board and preparation method thereof

InactiveCN105948692AWide range of hardnessImprove shock absorptionSolid waste managementCeramicwareCelluloseInsulation layer

The invention discloses a composite fireproof insulation board and a preparation method thereof. The composite fireproof insulation board can be selected from a two-layer structure including an insulation layer and an inorganic fireproof insulation layer or a three-layer structure including an insulation layer, an inorganic fireproof insulation layer and a mortar protection layer; the insulation layer is selected from one of a polyurethane plate, an extruded plate, an expanded polystyrene plate and a thermosetting polystyrene foamed plastic; the inorganic fireproof insulation layer is prepared by selecting 80 parts by mass of magnesium oxide, 60 parts by mass of magnesium chloride, 40 parts by mass of water, 80 parts by mass of a mineral powder, 1 part by mass of a modifier, 8 parts by mass of a hydrophobic agent, 2 parts by mass of a hydrophobic powder, 8-10 parts by mass of expanded polystyrene particles, and 25 parts by mass of a foaming agent and water; the mortar protection layer is prepared from 350 parts by mass of cement, 650 parts by mass of quartz sand or washed-out sand, 1 part by mass of hydroxypropyl methyl cellulose, 1 part by mass of cellulose ether, 20 parts by mass of a rubber powder, and 7 parts by mass of a hydrophobic agent. The composite fireproof insulation layer provided by the invention has the advantages of fire prevention, thermal insulation, environmental friendliness and the like.

Owner:曹芳芹

Concrete demolding agent

InactiveCN104450036ANon-toxic and tastelessGood release effectCeramic shaping apparatusLubricant compositionCellulosePolyester

The invention discloses a concrete demolding agent prepared from the following raw materials in parts by weight: 9-15 parts of polyvinyl alcohol, 3-9 parts of solid paraffin, 7-11 parts of nonylphenol polyoxyethylene ether, 2-6 parts of molasses, 5-9 parts of rosin pyrolytic polymer, 7-10 parts of sepiolite fabric, 3-8 parts of polyisobutylene succinimide, 3-5 parts of polyanionic cellulose, 6-9 parts of graphene oxide, 3-8 parts of polyester rubber powder, 1-5 parts of rosin, 9-16 parts of tributyl phosphate, 0.2-1 part of ammonia water and 2-6 parts of stearic acid. The concrete demolding agent disclosed by the invention has the beneficial effects of being nontoxic and tasteless, having a good demolding effect, and being very good in waterproof and antirust effects and low in cost.

Owner:张桂华

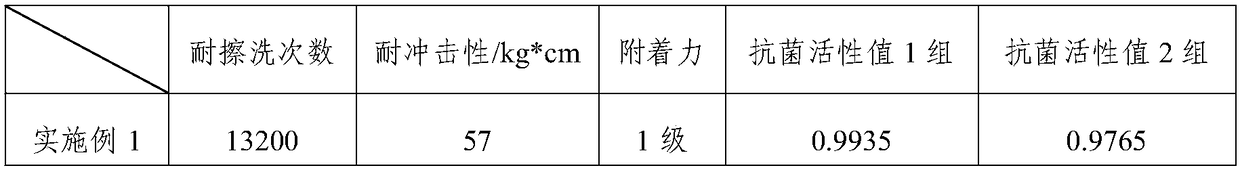

Waterborne antibacterial wood paint as well as preparation method and application thereof

InactiveCN108587428AGood dispersionImprove antibacterial propertiesAntifouling/underwater paintsPaints with biocidesEpoxyShock resistance

The invention discloses waterborne antibacterial wood paint as well as a preparation method and application thereof. The wood paint is prepared from the following components in parts by weight: 35 to50 parts of waterborne polyurethane dispersion resin emulsion, 5 to 10 parts of waterborne o-cresol formaldehyde epoxy resin emulsion, 0.5 to 2 parts of nanometer zinc oxide, 0.2 to 1 part of nanometer silver powder, 1 to 3 parts of isothiazolinone, 1 to 3 parts of nanometer silicon dioxide powder, 1 to 3 parts of a defoamer, 2 to 5 parts of a dispersing agent, 1 to 2 parts of a thickener, 0.5 to1.5 parts of a coalescing agent, 3 to 8 parts of an antifreezing agent, 2 to 4 parts of a preservative, and the balance of water. The waterborne antibacterial wood paint obtained with the preparationmethod not only solves the problem of poor abrasive resistance of waterborne wood paint, but also obviously enhances the shock resistance, water resistance and antibacterial performance, enhances thequality of the waterborne wood paint, and further has the advantage that the wood paint is poisonless, tasteless, pollution-free and the like.

Owner:安徽名士达新材料有限公司

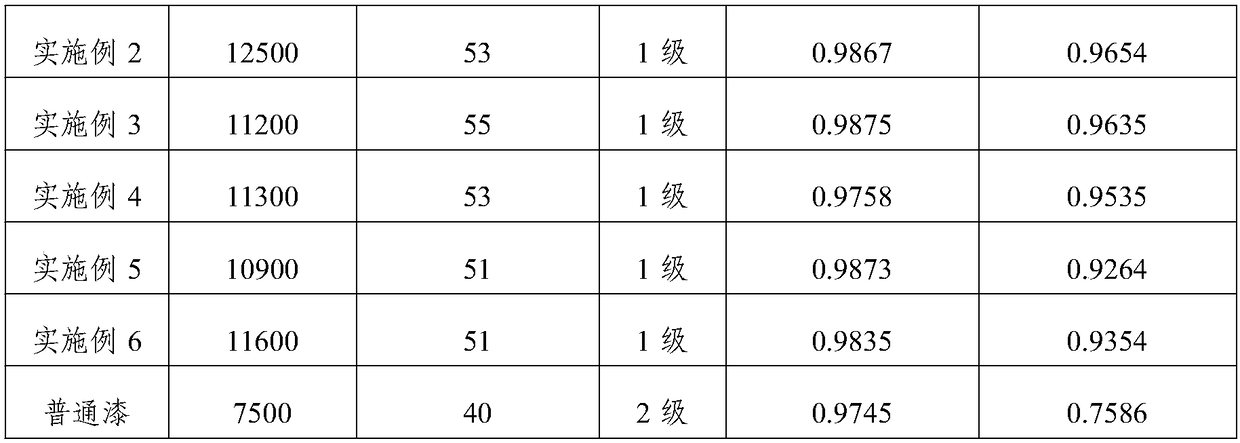

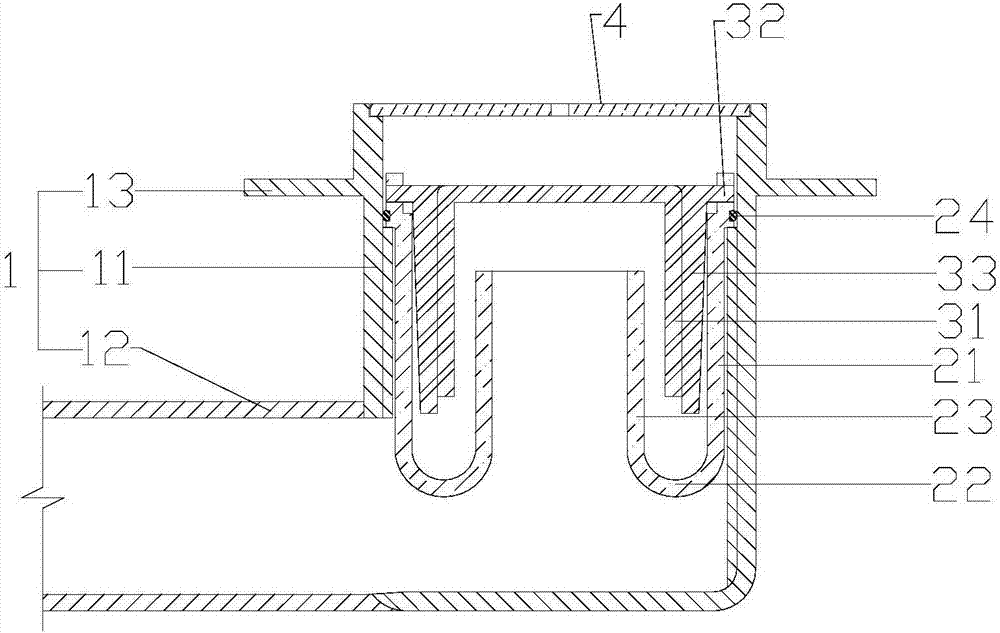

Floor drain of the same floor

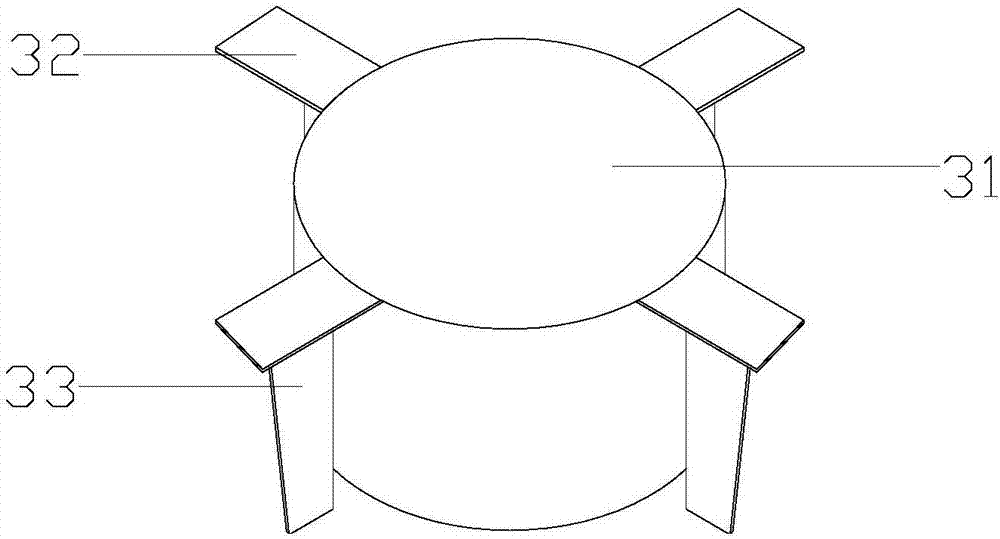

PendingCN106869289ASimple structureIncreased durabilitySewerage structuresClimate change adaptationFloor slabStructural engineering

The invention discloses a floor drain of the same floor, which comprises a floor drain body, a water seal cylinder, a funnel and a cover plate. The floor drain body comprises a cylindrical shell and a short drain pipe, and the height of the floor drain body is smaller than the thickness of a floor. The water seal cylinder is arranged inside the cylindrical shell, and comprises a cylinder wall, an annular groove and a cylinder inner tube, wherein four clasp grooves are uniformly formed in the top surface of the cylinder wall, the outer top of the annular groove is connected with the bottom of the cylinder wall, and the inner top of the annular groove is connected with the bottom of the cylinder inner tube. The funnel is arranged inside the water seal cylinder, and comprises a cylindrical barrel and lap plates, wherein the bottom of the cylindrical barrel is open, the top of the cylindrical barrel is sealed, and the four lap plates are located on the outer side of the top of the cylindrical barrel and clasped in the clasp grooves. The cover plate is provided with a plurality of drain holes, and the cover plate is arranged at the top opening of the cylindrical shell. The floor drain of the same floor has the advantages that the height of the floor drain body is smaller than the thickness of the floor, the floor drain body can be completely embedded into the floor when the floor drain is installed by means of the same-floor water drainage technology, the construction difficulty is small and the production costs are low.

Owner:BIOMEDY LIMITED

A kind of cross-linked polypropylene microporous foam material and its production method

Owner:ZHEJIANG XINHENGTAI ADVANCED MATERIAL

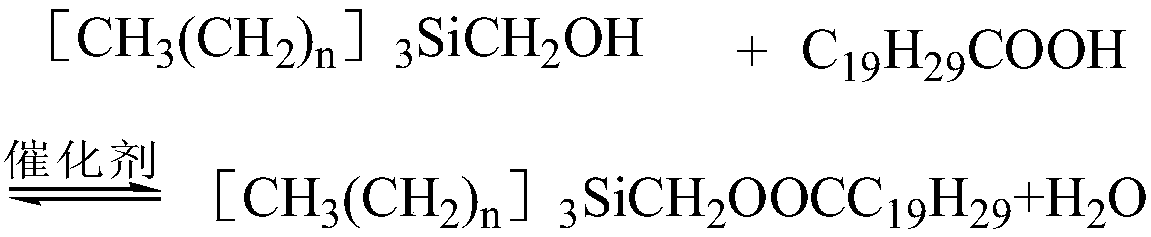

Tackifying resin and preparation method and application thereof

ActiveCN109627984AReduce surface tensionSmall viscosity-temperature coefficientNatural resin chemical modificationRosin adhesivesSurface energyRosin

The invention provides tackifying resin. The tackifying resin is characterized by being prepared from, by weight, 100 parts of rosin resin, 0.1-80 parts of hydroxyl silane, 0-50 parts of alcohol, 0.2-0.4 part of a catalyst and 0.3-0.6 part of an antioxidant. The invention further provides a preparation method and application of the tackifying resin. The preparation method includes the following steps that 1, the raw materials are weighed; 2, the rosin resin is smashed, the antioxidant is added, stirring is conducted to dissolve the rosin resin, and heating is conducted until the rosin resin iscompletely dissolved; 3, the catalyst is added and disperses for 5 minutes, and then alcohol is added to react for 30 minutes; 4, hydroxyl silane is added dropwise to start esterification reaction; 5, when no water is discharged any more, vacuum decompression is conducted to distill off fractions with low boiling points; 6, cooling is conducted to discharge the tackifying resin. The tackifying resin has excellent bonding performance for materials with low surface energy, can independently serve as hot melt adhesive resin, can also be added into other hot melt adhesive systems to serve as a tackifying agent to be in mixed usage and can serve as a compatilizer in the hot melt adhesive systems.

Owner:广东省邦得利新材料技术有限公司

High-strength magnesium steel heat-insulating material, preparation method thereof and heat-insulating block made of high-strength magnesium steel heat-insulating material

InactiveCN102093028AGood support and protectionAging resistantThermal insulationPipe protection by thermal insulationChemical industryThermal insulation

The invention relates to a high-strength magnesium steel heat-insulating material, a preparation method thereof and a heat-insulating block made of the high-strength magnesium steel heat-insulating material, belonging to the technical field of chemical industry. The high-strength magnesium steel heat-insulating material is mainly used for support and heat insulation of pipelines and equipment. The high-strength magnesium steel heat-insulating material is prepared from the following components in parts by weight: 4000-4500 parts of magnesium oxide, 2500-3000 parts of magnesium chloride, 5-10 parts of ferrous sulfate, 5-10 parts of trisodium phosphate, 5-10 parts of oxalic acid and 2800-3300 parts of glass fiber. The invention has favorable functions of supporting and protecting pipelines and equipment, and has the characteristics of low coefficient of heat conductivity, favorable thermal-insulation effect, aging resistance, water resistance, corrosion resistance, heat resistance, fire resistance, no toxicity and no smell.

Owner:陈品山

Aluminum foil package material, and preparation method and application of aluminum foil package material

InactiveCN108611015APuncture resistantHigh temperature resistanceNon-macromolecular adhesive additivesFilm/foil adhesivesPolyesterPack material

The invention provides an aluminum foil package material. A polyester film in the aluminum foil package material serves as an outer layer of the aluminum foil package material and has the advantages of puncture resistance, high and low temperature resistance, and oil resistance, and good toughness, airtightness and fragrance protectiveness; aluminum foil has the advantages of moisture proofing, airtightness, light proofing, corrosion resistance, fragrance protectiveness, nontoxicity and no odor; a polyethylene film is low in moisture permeability and can exert a moisture-proof effect; a firstpolyurethane glue layer and a second polyurethane glue layer formed by polyurethane glue can exert adhesive effects on the polyester film and the aluminum foil that are arranged on the two sides of the first polyurethane glue layer, and the aluminum foil and the polyethylene film that are arranged on the two sides of the second polyurethane glue layer; a hot melt adhesive has strong viscosity; anda hot melt adhesive layer formed by the hot melt adhesive can ensure that the aluminum foil package material has good sealability and an unsealing pull force is not too large at the same time. In addition, expensive raw materials are not required for preparation of the aluminum foil package material, and the production cost is low.

Owner:温州市瑞欣印务包装有限公司

Low temperature-resistant PVC (Polyvinyl Chloride) cable material

InactiveCN108707298AWith high and low temperature resistanceWith electrical insulationPlastic/resin/waxes insulatorsAntioxidantPolyvinyl chloride

The invention relates to a cable material, in particular to a low temperature-resistant PVC (Polyvinyl Chloride) cable material and a preparation method thereof. The low temperature-resistant PVC cable material is prepared from the following components in parts by weight: 100 parts of PVC resin, 20 to 35 parts of organosilicone resin, 30 to 45 parts of silicone oil, 15 to 30 parts of white carbonblack, 20 to 45 parts of nano calcium carbonate, 3 to 8 parts of acid-binding agent, 1 to 3 parts of lubricating agent and 1 to 3 parts of antioxidant. The low temperature-resistant PVC cable materialdisclosed by the invention has the following beneficial effects that (1) through a plasticizing effect of the organosilicone resin and the silicone oil, low temperature resistance of the low temperature-resistant PVC cable material can be effectively improved; (2) a formula and a preparation technology of the low temperature-resistant PVC cable material are simple, are low in cost, are capable ofproducing without changing existing equipment and are suitable for large-scale production; (3) the obtained low temperature-resistant PVC cable material also is good in mechanical property, weather fastness and flame resistance.

Owner:ZHEJIANG WELLSCOM PLASTIC CO LTD

Cpp bottomless silent cold laminating film

ActiveCN109266232AImprove tensile strengthSmooth sealFilm/foil adhesivesCoatingsWater basedWrinkle skin

The invention provides a cpp bottomless silent cold laminating film, comprising: a non-silicon coating, a base film layer and a glue layer, wherein the non-silicon coating is applied on the front surface of the base film layer, one side, away from the front surface of the base film layer, of the non-silicon coating layer is protruded at intervals in a horizontal direction corresponding to the basefilm layer to form ribs, and the back surface of the base film layer is coated with aqueous glue to form the glue layer. During the use process, the tensile resistance of the base film layer can be enhanced by forming the ribs, so that the non-silicon coating is applied on the base film layer smoothly, the wrinkles are avoided, the generation of bubbles is reduced, and the efficiency of the coating is improved. The ribs form a texture, so that the three-dimensional feeling of the cold laminating film of the invention can be increased. A bottom paper layer is eliminated, so that the problems in the prior art that the unevenness of the bottom paper during the laminating process is likely to cause small bubbles in the film, shrinkage, film wrinkles, low speed, occupation of inventory space and the like can be avoided. Therefore, the cold laminating film is light, ultra-transparent, and more environmentally friendly, the production cost is reduced, and since water-based glue is used, thecold laminating film is safe, environmentally friendly, non-toxic and tasteless.

Owner:GUANGDONG YUEHUI TECH CO LTD

Machining process of high strength fire-resistant one-way valve

InactiveCN108998719AHigh strengthAccelerated corrosionFireproof paintsSolid state diffusion coatingAlloyFire retardant

The invention relates a machining process of a high strength fire-resistant one-way valve, and belongs to the technical field of valve devices. The machining process of the high strength fire-resistant one-way valve includes the following steps that (1), material batching is conducted; (2), raw material smelting is conducted; (3), cooling of alloy solution made in the last step and formation of alloy are conducted; (4), secondary smelting of the alloy made in the last step in the smelter and formation of the alloy solution are conducted; (5), forging is conducted; (6), carburizing process is conducted; (7), quenching is conducted; (8), tempering is conducted; (9), grinding and polishing of a valve body are conducted; (10), the surface of the valve body is varnished by fire retardant coating; and (11), a valve plug is put into the valve body varnished with the fire retardant coating, and the high strength fire-resistant one-way valve is produced. The machining process of the high strength fire-resistant one-way valve improves the mechanical strength and the fire resistance performance of the high strength fire-resistant one-way valve through heat treatment process and varnishing ofthe fire retardant coating, and loss and pollution caused by liquid or gas leakage from a pipeline can be prevented when the fire happens.

Owner:JIANGSU HUATAI ELECTRIC POWER ELECTRONICS INSTR

Tea package bag with multi-layer structure

InactiveCN102424175AImprove herbicidal activityBroad-spectrum sterilization and mildew removal abilitySynthetic resin layered productsBagsPolyesterPrinting ink

The invention discloses a tea packaging bag with a multi-layer structure. The tea packaging bag has a layered structure, and comprises an oriented polypropylene (OPP) film, a polyester (PET) laser film, an aluminum foil and a polyurethane (PE) film from outside to inside; and various layers are attached to one another to form the tea packaging bag. The tea packaging bag has the advantages of the OPP, PET, the aluminum foil and the PE, has a better sealing effect, and ensures a better tea preserving effect and long storage time; and printed ink hardly infiltrates the packaging bag, so that tea is more safe and sanitary.

Owner:南安市华辉包装有限公司

Hot-melt pressure-sensitive adhesive

ActiveCN104650783ASolve the shortcomings of high price and non-renewable raw materialsReduce usageNon-macromolecular adhesive additivesNatural resin chemical modificationPetroleumLiquid resin

The invention discloses a hot-melt pressure-sensitive adhesive, relating to the technical fields of chemistry and chemical engineering. The hot-melt pressure-sensitive adhesive comprises the following compositions in parts by weight: 30-40 parts of light-colored liquid resin, 90-100 parts of a styrene-vinylidene segmented copolymer, 4-5 parts of a mixed plasticizer, 2-5 parts of an antioxidant N-dibutylamino zinc dithiocarbamate and 9-10 parts of a filling agent. According to the hot-melt pressure-sensitive adhesive, the light-colored liquid resin is introduced as thickening agent resin, so that the disadvantages that domestic petroleum resin is high in price, and raw materials are not regenerable are solved, the use levels of a softening agent and a viscosity modifier are reduced, and the cost is further saved; furthermore, the preparation process is easily controlled, the emission of pollutant is completely avoided, the safety and the environmental friendliness are guaranteed, a green production idea is realized, and various indexes can meet various performance requirements of the hot-melt pressure-sensitive adhesive in which rosin resin is utilized as the thickening agent.

Owner:GUANGXI ZHONGCHANG RESIN

Epoxy resin base floor coating and preparation method thereof

PendingCN112831243AHigh mechanical strengthNon-toxic and tastelessAnti-corrosive paintsEpoxy resin coatingsPolymer scienceFirming agent

The invention discloses an epoxy resin base floor coating and a preparation method thereof. The preparation method comprises the following steps: firstly, mixing, well mixing a component A and a component B of the coating, uniformly stirring by using a stirrer, adding a component C, uniformly stirring by using the stirrer, carrying out trowel coating, paving the well mixed coating on a prepared floating coat, performing trowel coating construction by using a 5 mm trowel, defoaming, pulling a defoaming roller back and force on the surface of the trowel-coated coating to enable the colored organic aggregate to be uniformly distributed in the coating, finally performing water milling, and after the coating is completely dried, performing water milling by using a 2000-mesh resin abrasive disc to obtain a finished product after the water is completely dried. The component B is a modified alicyclic amine epoxy curing agent, and alicyclic amine has a similar adamantane skeleton structure and has extremely high mechanical strength; and the component C is melamine resin sand, which is non-toxic, odorless, collision-resistant, corrosion-resistant, compact in structure, extremely high in hardness, extremely high in durability, bright in color, very beautiful and excellent in scratch resistance.

Owner:SHENZHEN CAITIAN CHEM

Preparation method of ecological bamboo-wood profile

InactiveCN104448605ANon-toxic and tastelessLow-carbon and environmentally friendlyNon toxicityFoaming agent

The invention provides a preparation method of an ecological bamboo-wood profile. The preparation method comprises the following steps: weighing the raw materials and putting into a mixer, adding an appropriate amount of water, a foaming agent, a regulator, a toner, a plasticizer and a coupling agent, and mixing evenly; next, putting all the materials into a high-temperature furnace, heating to the range of 200 to 260 DEG C and maintaining for 1-2 hours; injecting the heated mixture into a die, performing die-casting molding, and performing cooling, blow-drying, laminating, sizing, cutting and baling on the molded slab. The ecological bamboo-wood profile has the advantages of low carbon and environmental friendliness, non-toxicity and tastelessness, fire protection, water prevention, insect prevention, mildew prevention, protection against termites, acid-base resistance and aging resistance.

Owner:湖南益丰新材料有限公司

New radiation-proof material

The invention relates to a new radiation-proof material. The new radiation-proof material is used to make a TV main board and / or a power board, the TV main board and / or the power board comprises a radiation-proof layer, a bonding layer and a heat dissipation layer in order from inside to outside, and the radiation-proof layer is pasted with the heat dissipation layer into one through the bonding layer. The chemical composition of the radiation-proof layer is: polyvinyl chloride; organosilicon; cis-polybutadiene; silk fiber; a waterborne acrylic emulsion; silver powder; a compatibilizer; a plasticizer; a thermal stabilizer; and an antioxidant, wherein a mass ratio of polyvinyl chloride to the silk fiber to the silver powder is 5-9:1:1-1.5, the antioxidant is a mixture of zinc dialkyl dithiophosphate and zinc dialkyl dithiocarbamate mixed according to 1:1, and a mass ratio of the organosilicon to the cis-polybutadiene to the waterborne acrylic emulsion is 1:1:0.8. The new radiation-proofmaterial can effectively prevent electromagnetic wave radiation, can avoid an excessive thickness of the TV main board and the power board, and at the same time can ensure the strength, so that the performance of the TV main board and the power board is greatly improved.

Owner:苏州韵之秋智能科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com