Antibacterial high-oxygen barrier PE composite film and preparation method thereof

A composite film and high oxygen technology, applied in the field of packaging materials, can solve the problems of moisture resistance of PE composite film and poor adhesion between oxygen barrier films, and achieve the effects of low cost, increased compatibility, and improved processing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] An antibacterial high oxygen barrier PE composite film, comprising a PE film layer and a PVA film layer:

[0044] PE film layer comprises the raw material of following parts by weight:

[0045] 100 parts of linear low density polyethylene;

[0046] 5 parts of low-density polyethylene;

[0047] Low density PE-g-MAH 5 parts;

[0048] 12 parts of antibacterial and antistatic additives.

[0049] PVA film layer comprises the raw material of following parts by weight:

[0050] 100 parts of polyvinyl alcohol resin;

[0051] 4 parts of silicone oil;

[0052] 3 parts of propylene glycol;

[0053] 45 parts of polyethylene glycol;

[0054] 2 parts talcum powder;

[0055] Polyethylene wax 10 parts.

[0056] The materials of the outer PE film layer, the middle PVA film layer and the inner PE film layer are heated and melted by a twin-screw extruder, and the heating temperature of the PE film layer 1-7 is as follows: 160°C, 170°C, 175°C , 180°C, 185°C, 175°C, 170°C, the twin-...

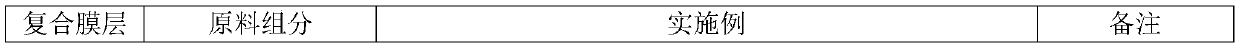

specific Embodiment 2-6

[0057] Specific embodiment 2-6, other are with specific embodiment 1, difference is following table:

[0058]

[0059]

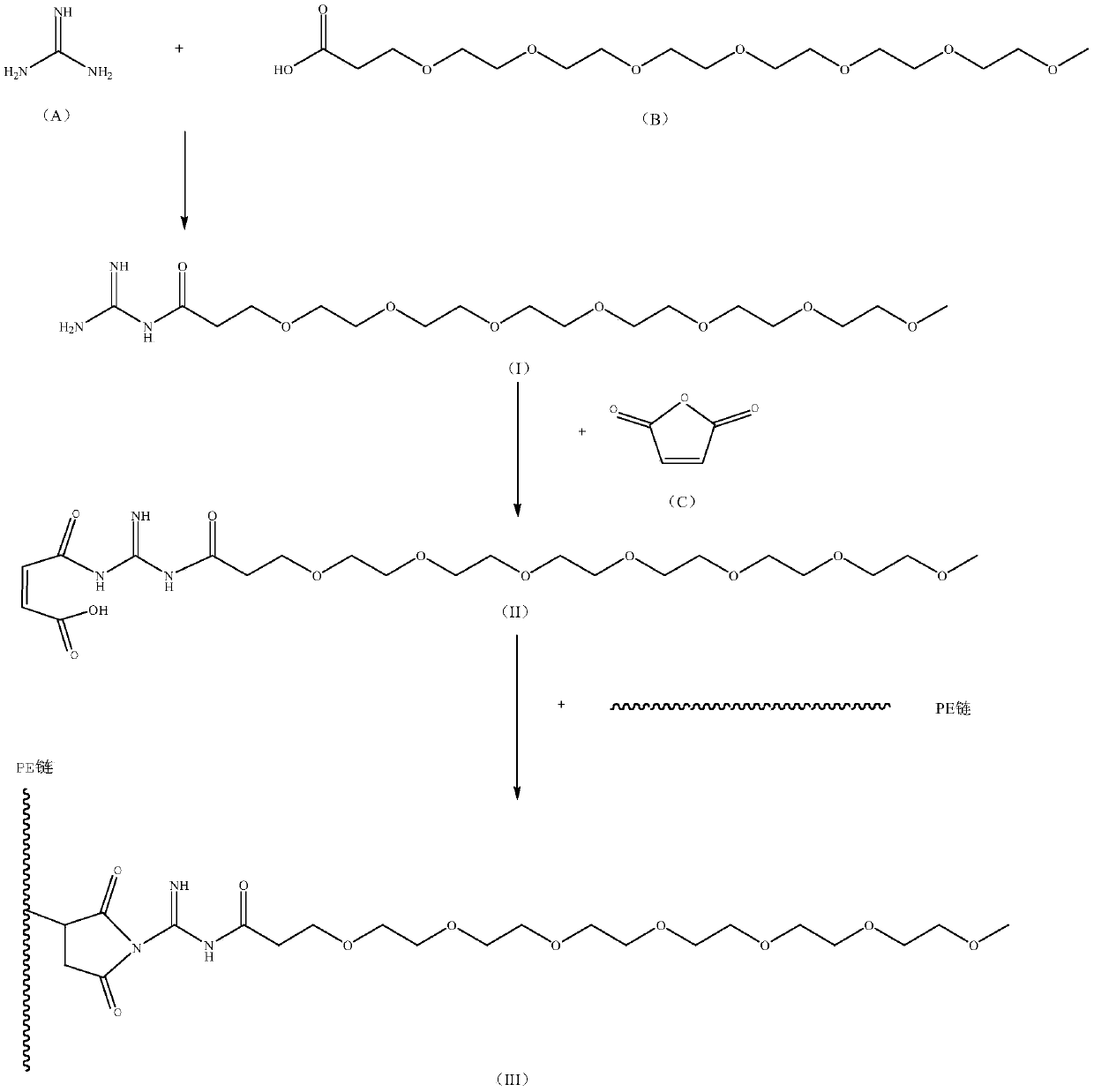

[0060] The antibacterial antistatic additive used in above-mentioned embodiment 1-6 is to prepare by following method:

[0061] (1) Dissolve a mixture of 1.2mol methoxy-heptapolyethylene glycol-propionic acid (B), 1.2mol dicyclohexylcarbodiimide and 2wt% 4-dimethylaminopyridine in 10mol N,N-di Methylformamide was placed in a constant pressure dropping funnel, slowly added dropwise to N,N-dimethylformamide containing 1mol guanidine (A), at room temperature, magnetically stirred for 10h, allowed to stand, filtered, and decompressed Distillation, vacuum drying, to obtain the intermediate product I (IR: 1648cm -1 : the presence of -C=O of the amide bond; 3318cm -1 、1625cm -1 :-NH exists);

[0062] (2) Dissolve 1 mol I and 1.2 mol maleic anhydride (C) in an organic solvent, heat and stir at 40°C for 5 hours, then cool down, distill the reaction product ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com