Cpp bottomless silent cold laminating film

A cold lamination film and silent technology, applied in the direction of film/sheet adhesives, coatings, adhesives, etc., can solve the problems of large waste of resources, high production costs, small air bubbles, etc., to achieve environmental protection production costs and save production Cost, the effect of enhancing the tension resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to have a further understanding and understanding of the structure, features and effects of the present invention, the following preferred embodiments are now given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

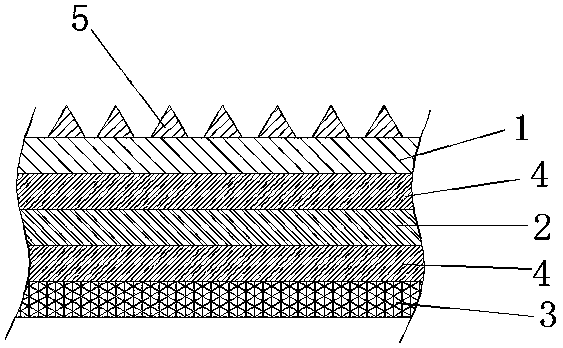

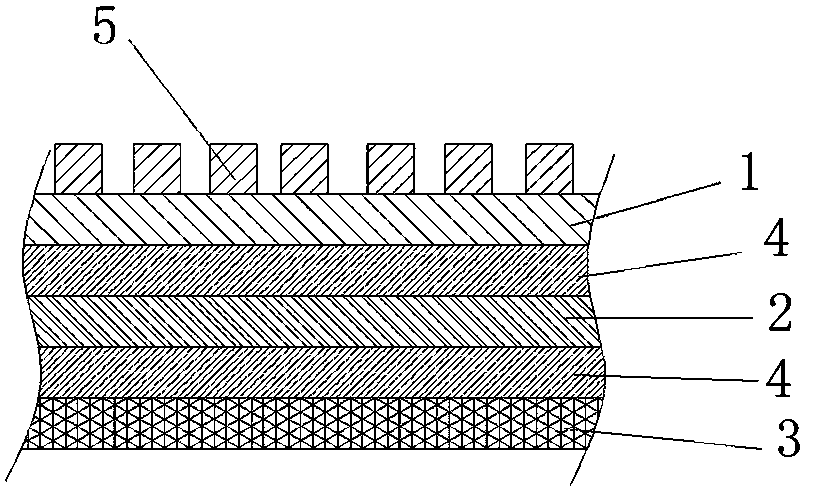

[0030] Such as figure 1 and figure 2 The first embodiment of the cpp bottom-free silent cold lamination film includes the following layers in sequence: non-silicon coating 1, base film layer 2 and glue layer 3, the front and back of the base film layer 2 are corona treated, Form the corona surface 4, the non-silicon coating 1 is coated on the front of the base film layer 2, and the side of the non-silicon coating 1 that is far away from the front of the base film layer 2 is formed at intervals in the lateral direction of the corresponding base film layer 2 The convex strip 5, the back of the base film layer 2 is coated with water-based glue to form the glue layer 3.

[0031] In the first embodiment, the pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| cure temperature | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com