Environment-friendly polypropylene floor

A polypropylene, environmentally friendly technology, applied in coatings, building components, layered products, etc., can solve the problems of poor environmental protection, toxicity, and impact on health of PVC flooring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

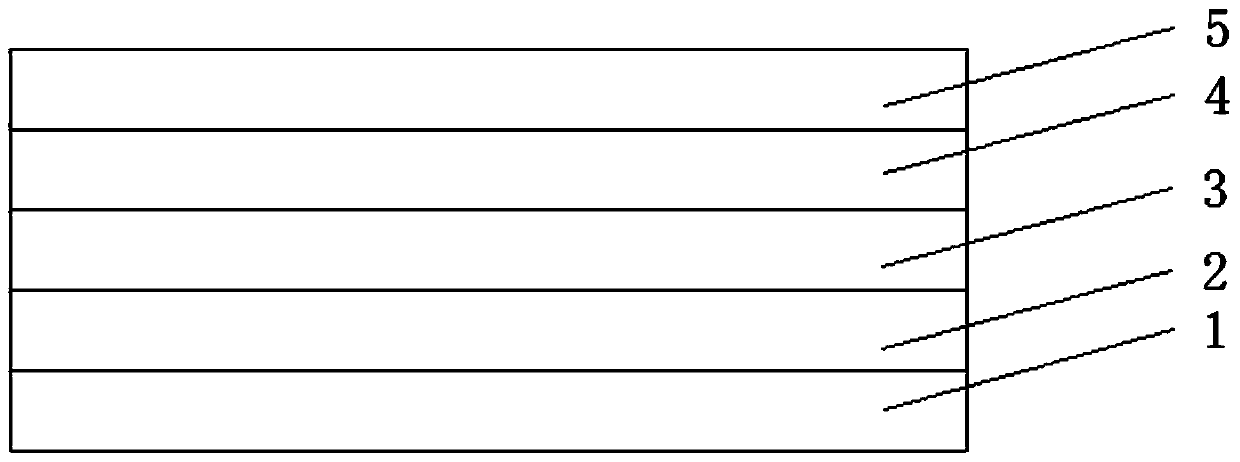

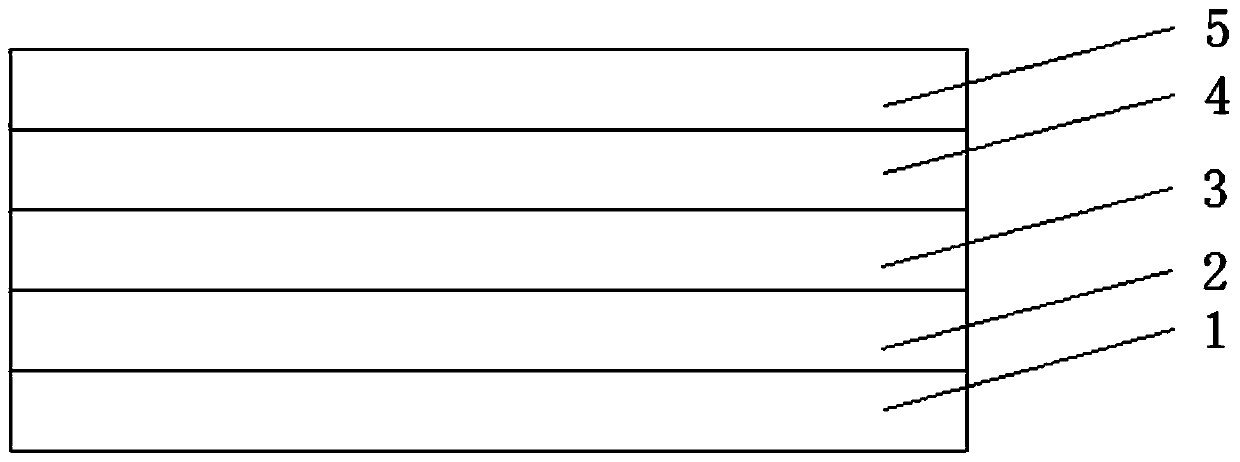

[0020] Embodiment one: see figure 1 As shown, an environment-friendly polypropylene flooring consists of balance layer 1, substrate layer 2, decorative layer 3, wear-resistant layer 4 and scratch-resistant layer 5 from bottom to top, which are made into composite semi-finished products by hot pressing, and then rolled The scratch-resistant layer 5 is made by tempering, sawing, grooving or chamfering,

[0021] The balance layer 1 is made of the following materials by weight: 80% polypropylene with a melt index of 3g / 10min; 5% polypropylene with a melt index of 20g / 10min; 8% calcium carbonate; 1.8% anti Oxygen agent; 5% flame retardant; 0.2% toner.

[0022] The substrate layer 2 is made of materials with the following weight ratio: 30% polypropylene with a melt index of 3g / 10min; 3% polypropylene with a melt index of 20g / 10min; 50% calcium carbonate; 1.8% anti Oxygen agent; 4% flame retardant; 10% talcum powder; 1% coupling agent 0.2% toner.

[0023] The wear-resistant layer ...

Embodiment 2

[0031] Embodiment two: see figure 1 As shown, an environment-friendly polypropylene flooring consists of balance layer 1, substrate layer 2, decorative layer 3, wear-resistant layer 4 and scratch-resistant layer 5 from bottom to top, which are made into composite semi-finished products by hot pressing, and then rolled The scratch-resistant layer 5 is made by tempering, sawing, grooving or chamfering,

[0032] The balance layer 1 is made of materials with the following weight ratio: the balance layer 1 is made of materials with the following weight ratio: 60% polypropylene with a melt index of 3g / 10min; 15% polypropylene with a melt index of 20g / 10min; 20% calcium carbonate; 1.5% antioxidant; 3.3% flame retardant; 0.2% toner.

[0033] The substrate layer 2 is made of materials with the following weight ratio: 25% polypropylene with a melt index of 3g / 10min; 8% polypropylene with a melt index of 20g / 10min; 45% calcium carbonate; 1.8% anti Oxygen agent; 3.5% flame retardant; 15...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com