Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

45results about How to "Improve the premium rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Bio-organic compound fertilizer

InactiveCN101781149AImprove fat retention capacityImprove buffering effectFertilizer mixturesPotassiumOrganic compound

The invention relates to a bio-organic compound fertilizer, which comprises the following components in part by weight: 10 to 30 parts of organic matter, 2 to 10 parts of compound microbial inoculants, 5 to 20 parts of humic acid, 5 to 20 parts of amino acid, 4 to 10 parts of chitin, 1 to 5 parts of polypeptide, 530 parts of nitrogen, phosphorus and potassium, 5 to 10 parts of secondary and trace elements, 5 to 15 parts of algae fertilizer, 5 to 10 parts of zeolite powder and 1 to 5 parts of synergistic agent. Through the scientific and rational formula, the bio-organic compound fertilizer achieves nutritive equilibrium and can satisfy the need of crop growth in nutrient. The microbial inoculants are added to quickly degrade natural macromolecular organic compounds into the organic fertilizer and decompose organic pollutants, which effectively improves the capacity of crops in the absorption of nutrient components, reduces the waste of the fertilizer and reduces the damage of the chemical fertilizer to soil to further achieve the nutritive equilibrium, satisfy the need of the crop growth in the nutrient, achieve the aims of low investment and high output value, improve the quality of the crops and improve the economic benefit brought by the crops.

Owner:张钧

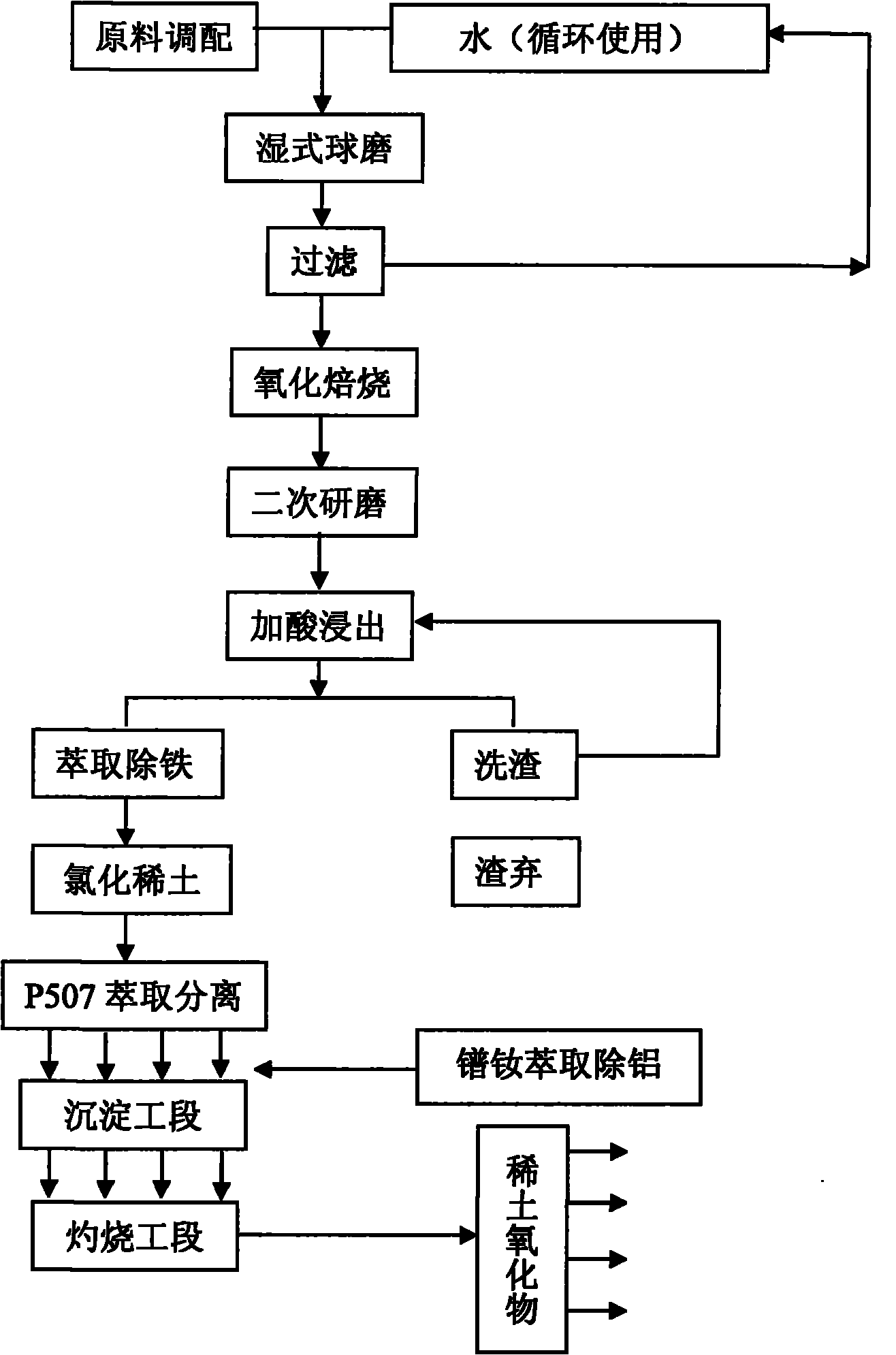

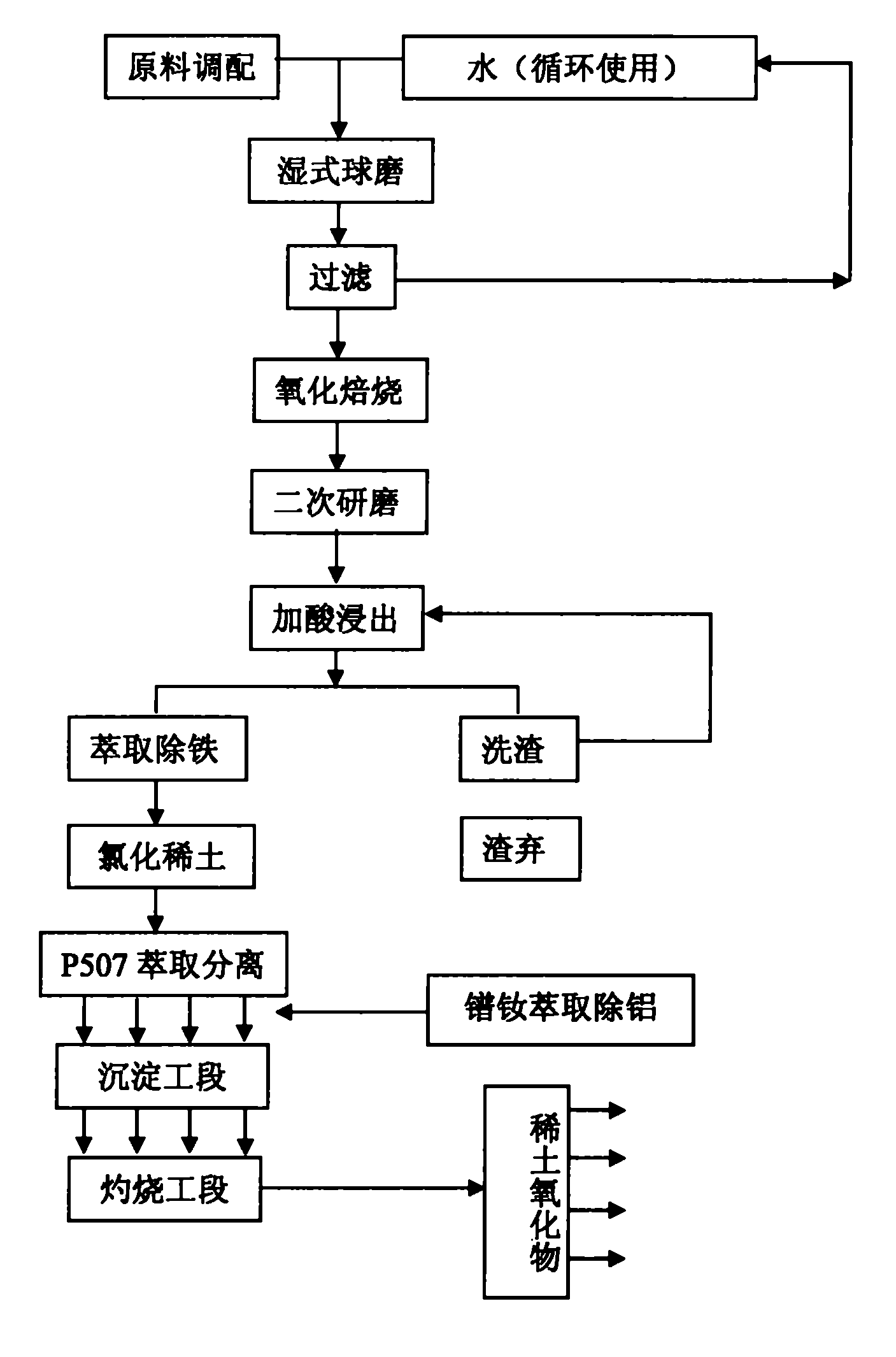

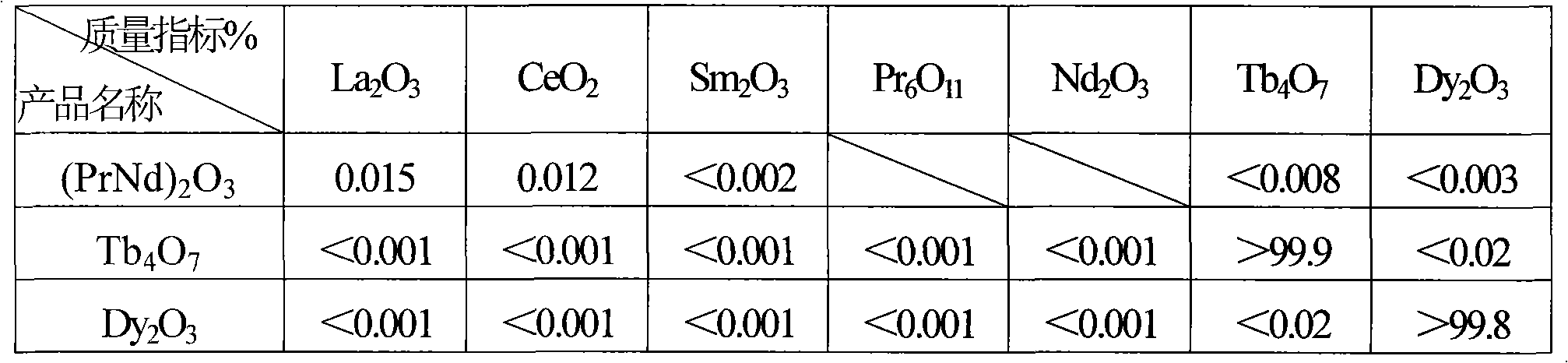

Method for recovering rare earth elements from neodymium-iron-boron wastes

InactiveCN102011020AHigh recovery rateImprove use valueProcess efficiency improvementMischmetalRare-earth element

The invention discloses a method for recovering rare earth elements from neodymium-iron-boron wastes, which comprises the steps of: mixing the neodymium-iron-boron wastes with water and then grinding; oxidizing the ground neodymium-iron-boron wastes; carrying out the secondary grinding for oxidation products; leaching by adding acid; separating solid from liquid; extracting to remove iron; chloridizing rare earth; separating the rare earth by extraction; extracting to remove aluminum; sedimenting; and firing. The method applied to recovery of the rare earth has the beneficial effects that the rare earth recovery rate is increased by 5-8%; the use value of the recovered rare earth is improved so that the production cost of further processing is reduced; the problem of puree fused salt in the electrolysis of single rare earth is solved, and the electrolytic efficiency of the rare earth metal during electrolysis is improved and energy consumption is effectively reduced; and the contents of non rare earth metals, such as C, S, O and the like are reduced.

Owner:BAOTOU XIJUN RARE EARTH

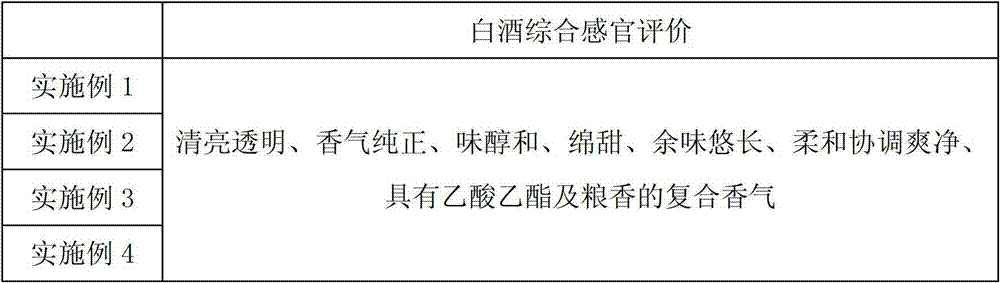

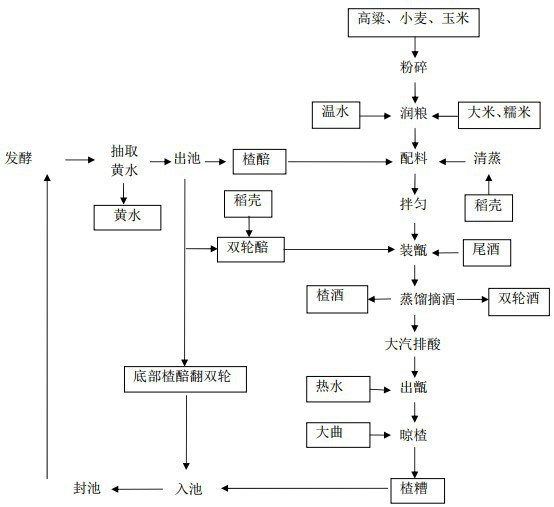

Five-grain fen-flavor liquor and preparation method thereof

ActiveCN102899217AShort fermentation cycleIncrease productivityAlcoholic beverage preparationGluteninDistillation

The invention discloses a five-grain fen-flavor liquor and a preparation method thereof. The five-grain fen-flavor liquor is prepared through diastatic fermentation of brewing raw materials consisting of sorghum, rice, glutinous rice, wheat and corn by using Qingcha Daqu. The preparation method for the liquor comprises the following steps: preparing the Qingcha Daqu; mixing the brewing raw materials with the Qingcha Daqu; carrying out diastatic fermentation; and carrying out distillation. The liquor provided by the invention has pure, mild and mellow taste and satisfies current requirements for taste and health care by drinkers; the flavor of sorghum, sweetness of corn, pureness of rice, sweetness of glutinous rice and unique fragrance generated by fermentation of wheat collagen and glutenin in wheat are combined in the liquor, and deficiency in brewing with only a grain is substantially improved; and the liquor has no special odor, can be used as a base wine for medicinal liquor and functional liquor, is applicable as a flavoring liquor for development of a high-grade liquor and has a good application prospect.

Owner:内蒙古响沙湾酒业有限责任公司

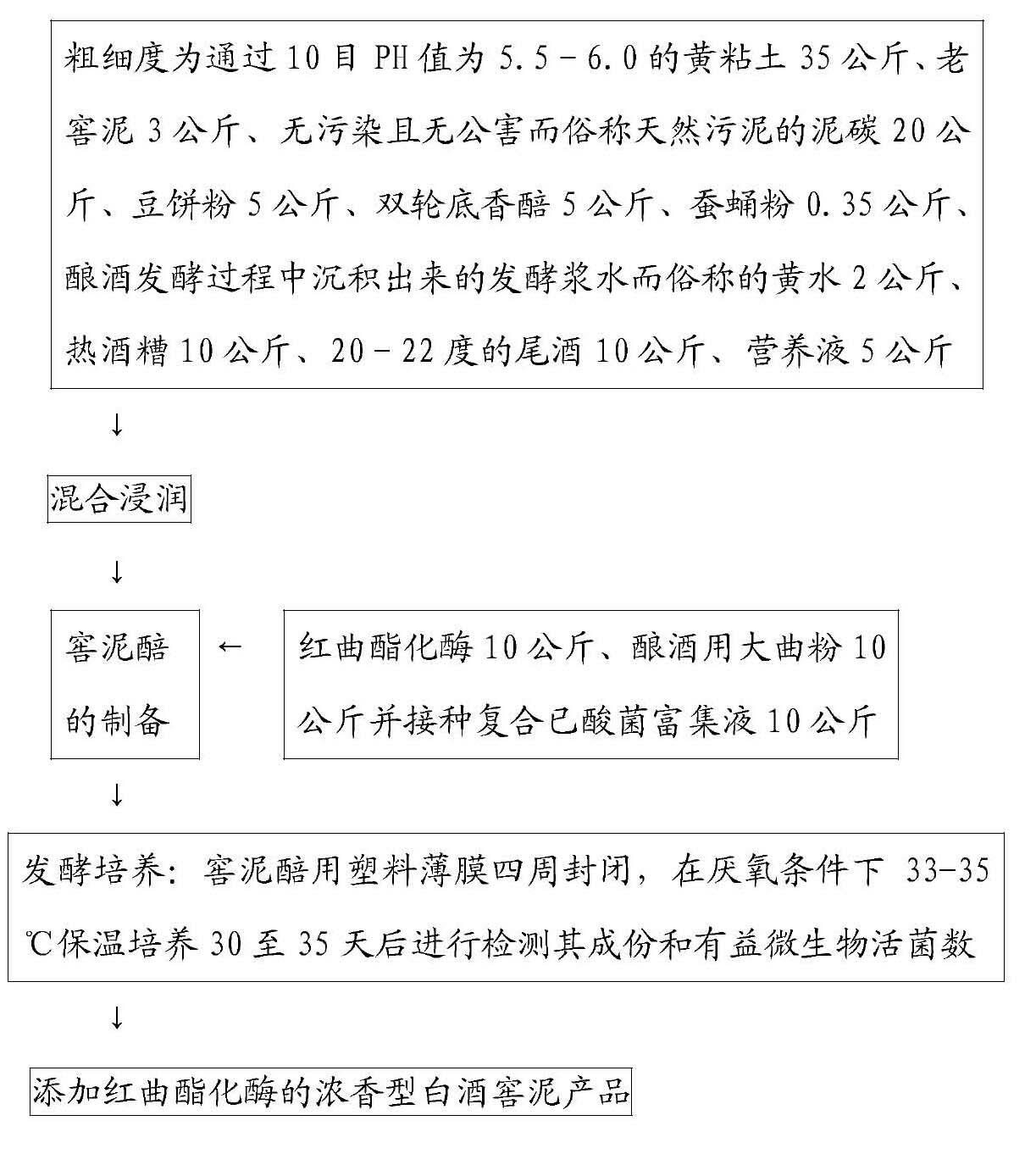

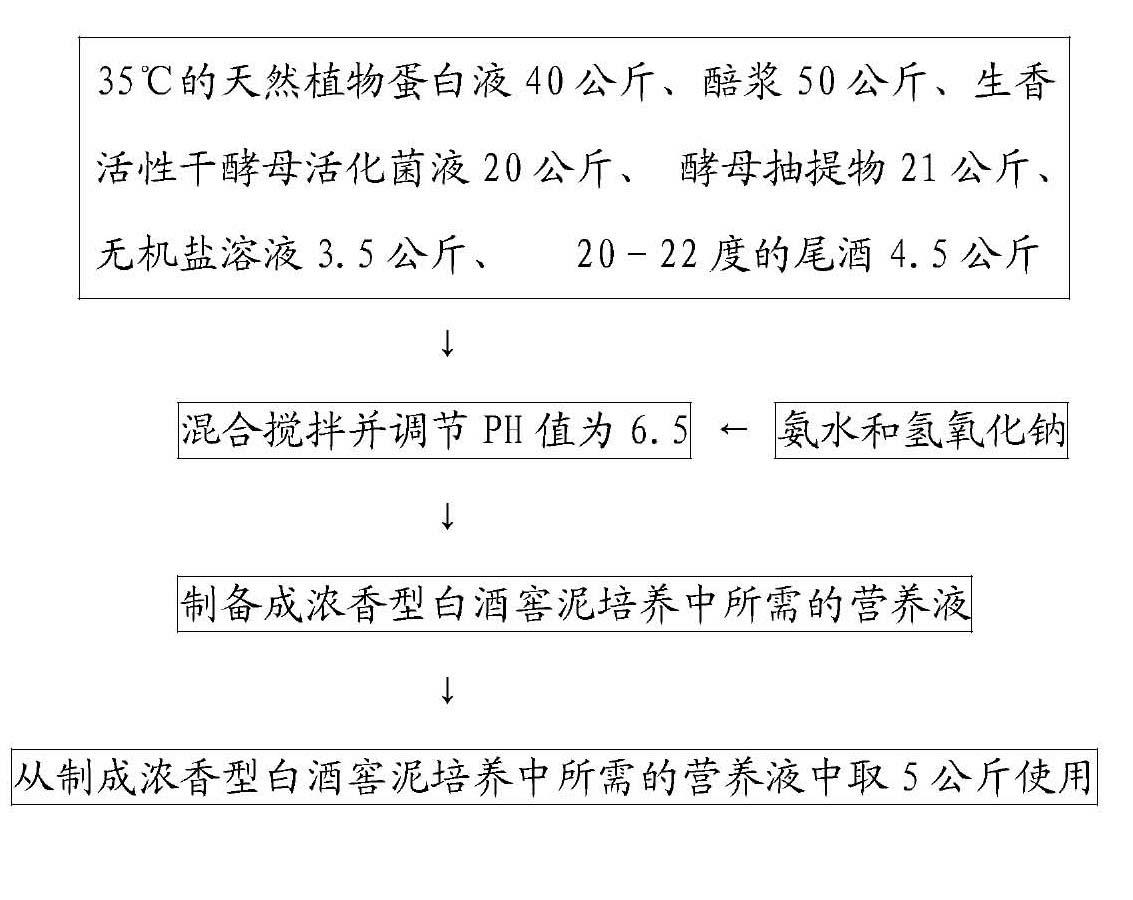

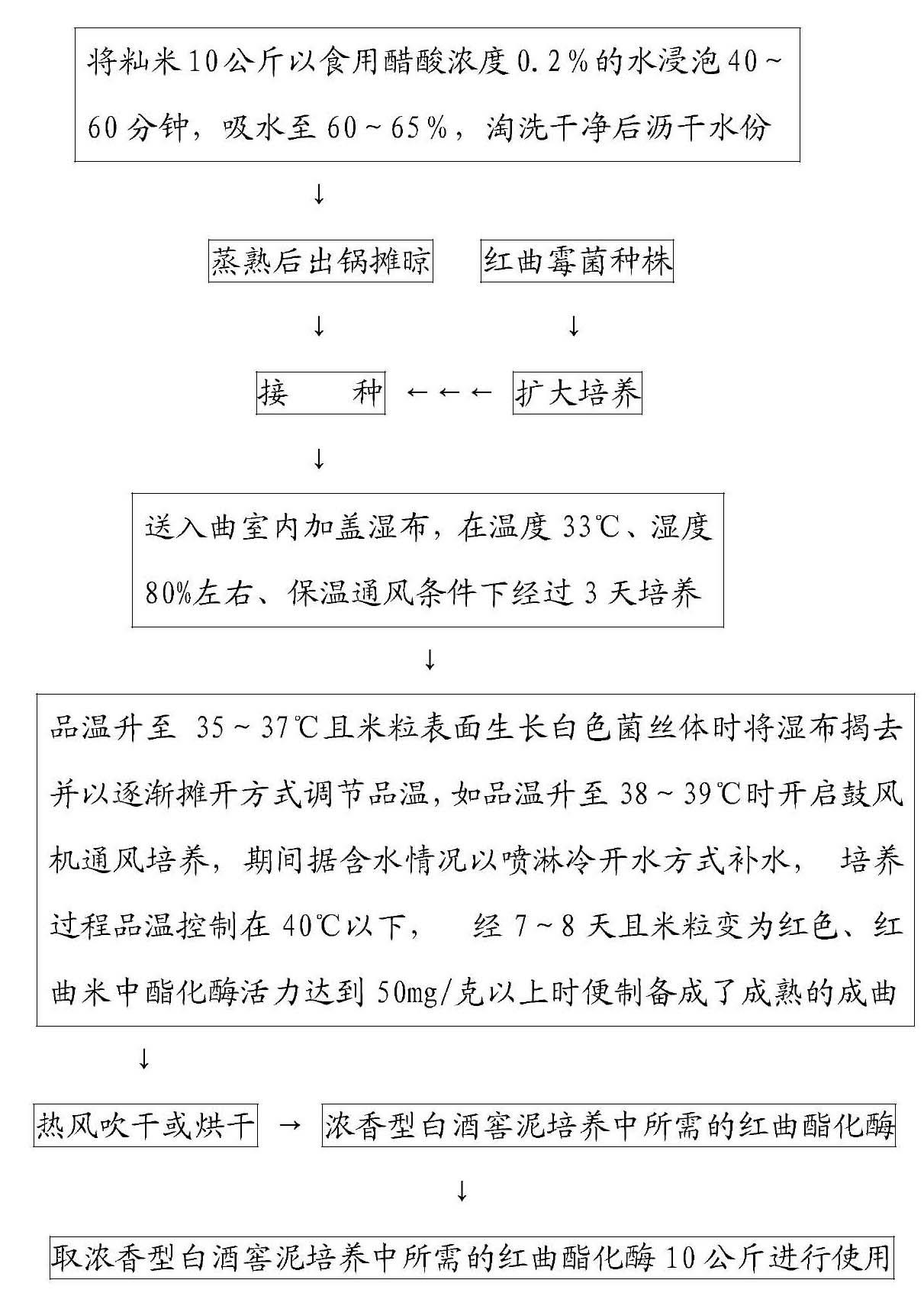

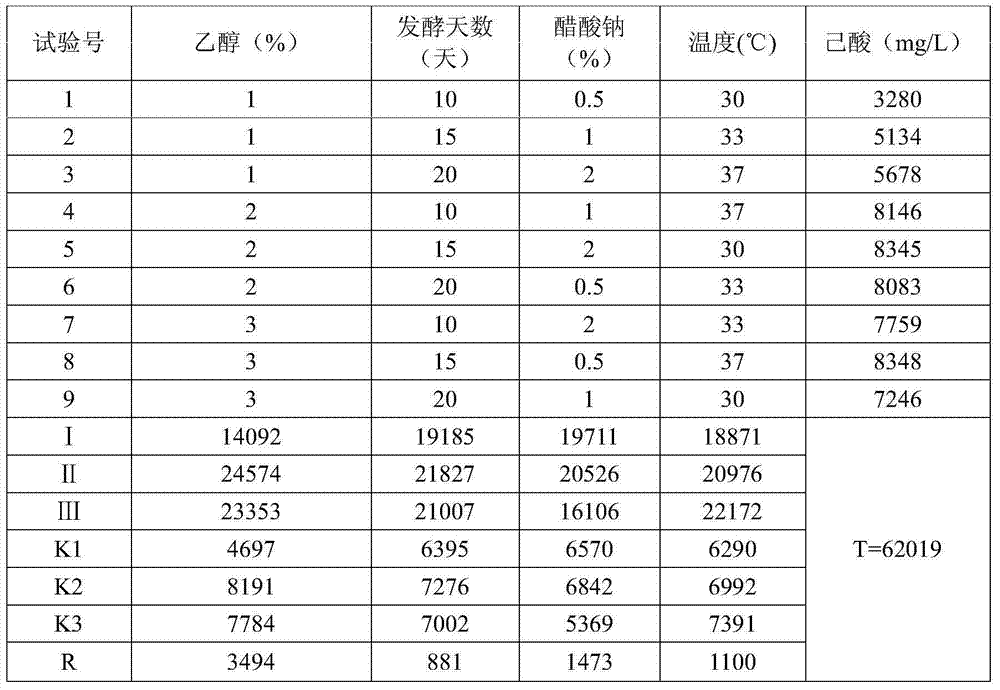

Preparation method of strong aromatic Chinese spirits pit mud by adding red yeast esterified enzyme

InactiveCN102154081AQuality improvementImprove the quality rateAlcoholic beverage preparationYeastTrace element

The invention provides a preparation method of strong aromatic Chinese spirits pit mud by adding red yeast esterified enzyme, and relates to the technical field of spirits making. The preparation method comprises the following steps of: adding 10kg of red yeast esterified enzyme and 10kg of yeast powder into mixed infiltrating body of 35kg of yellow clay, 3kg of old pit mud, 20kg of mud carbon, 5kg of bean cake powder, 5kg of double-wheel bottom flavour grains, 0.35kg of silkworm chrysalis powder, 2kg of yellow water, 10kg of hot vinasse, 10kg of 20 to 22-degree cocktail and 5kg of nutrient solution which respectively can pass a screen mesh of 10 and have the pH value of 5.5-6.0; vaccinating 10kg of compound hexanoic acid bacteria-enriched liquid, stirring and mixing to prepare pit mud grains; sealing the periphery of the pit mud grains by a plastic film; and cultivating for 30-35 days under the anaerobic condition at the temperature of 33-35 DEG C, and detecting the components and the beneficial microbe bacterial counts of the pit mud to obtain the strong aromatic Chinese spirits pit mud by adding the red yeast esterified enzyme. The preparation method is used for cultivating the pit mud in a strong aromatic Chinese spirits preparation technology. The preparation highlights a nitrogen source, trace element and the red yeast esterified enzyme which influences aroma-producing substances and flavor-producing substances of the Chinese spirits.

Owner:湖北黄山头酒业有限公司

Clostridium sporogenes and purpose thereof

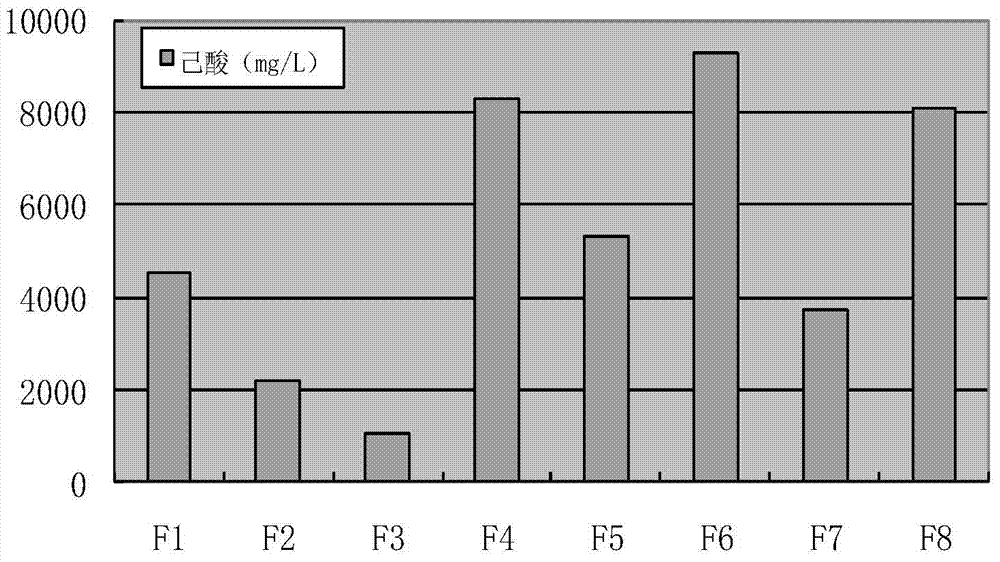

ActiveCN103525743AIncreased ethyl caproate contentAccelerated agingBacteriaMicroorganism based processesMicroorganismMicrobiology

The invention belongs to the technical field of wine brewing, and relates to clostridium sporogenes and the purpose of the clostridium sporogenes. According to the technical problem to be solved, a new bacterial strain with strong caproic acid producing capacity is provided. According to the technical scheme, the bacterial strain of the clostridium sporogenes is preserved in the CGMCC on February 1, 2012, the preservation number is CGMCC No. 5741, the preservation address is Institute of Microbiology of Chinese Academy of Sciences, No. 3, yard No. 1, Beichen West Road, Chaoyang District, Beijing, and the postcode is 10010. The caproic acid producing capacity of the clostridium sporogenes can reach 9000mg / L, and is the new bacterial strain with a high caproic acid yield. A new choice is provided for the caproic acid production.

Owner:四川绵竹剑南春酒厂有限公司

Hybrid intelligent soft-measurement method of Mooney viscosity of rubber

InactiveCN101650290ASolve the problem of online measurement and online forecastImprove robustnessFlow propertiesBiological neural network modelsRobustificationModel method

The invention relates to a hybrid intelligent soft-measurement method of Mooney viscosity of rubber, comprising the steps of collecting the technological parameters that affect Mooney viscosity in thefield at first, then analyzing the principle component and determining the necessary auxiliary variable to normalize; establishing hybrid intelligent algorithm model formed by combining mechanical analysis, wavelet neural network and least squares support vector machine, then collecting data in real time, and calculating input data through the established model to obtain real time predicted valueof Mooney viscosity. With the advantages of a plurality of modeling methods, not only predictive effect is better than the single soft-measurement method, but also the model has good robustness and generalization ability suitable for different working conditions. Computation speed and precision of the soft-measurement predicted model meet the production requirement, and are beneficial to stabilize production, guide operation and promote the quality of the products.

Owner:MAOMING COLLEGE

Biological composite fertilizer

InactiveCN104591847APromote photosynthesisImprove qualityOrganic fertilisersFertilizer mixturesOrganic compoundAmino acid

The invention relates to a biological composite fertilizer, and concretely relates to a biological composite fertilizer. The biological composite fertilizer is characterized by being composed of the following raw materials: 7-9 parts of a microbial composite inoculant, 3-5 parts of nitrogen-fixing bacteria, 3-5 parts of phosphobacteria, 3-5 parts of potassium bacteria, 5-15 parts of humic acid, 10-20 parts of amino acids, 4-6 parts of chitin, 1-3 parts of polypeptide, 5-15 parts of medium and trace elements, 5-15 parts of an algae fertilizer, 8-10 parts of zeolite powder, and 1-3 parts of a synergist. The fertilizer is capable of obviously improving soil fertility and microbial environment in soil, and has effects of resisting insect diseases. The fertilizer is low in cost, simple in production technology, long in fertilizer efficiency and free of pollution. Nutrition balance is reached through scientific reasonable formula, nutrients demanded by crop growth are satisfied, large-molecular natural organic compounds are accelerated to be decomposed into an organic fertilizer by adding the inoculants, organic pollutants are decomposed, the capability of crop absorbing nutrients is effectively improved, fertilizer waste is reduced, damage of chemical fertilizers to soil is reduced, and thus nutrition balance is realized, nutrients demanded by crops are satisfied, and economic benefit of crops is improved.

Owner:YANTAI NAKE ENVIRONMENTAL PROTECTION TECH

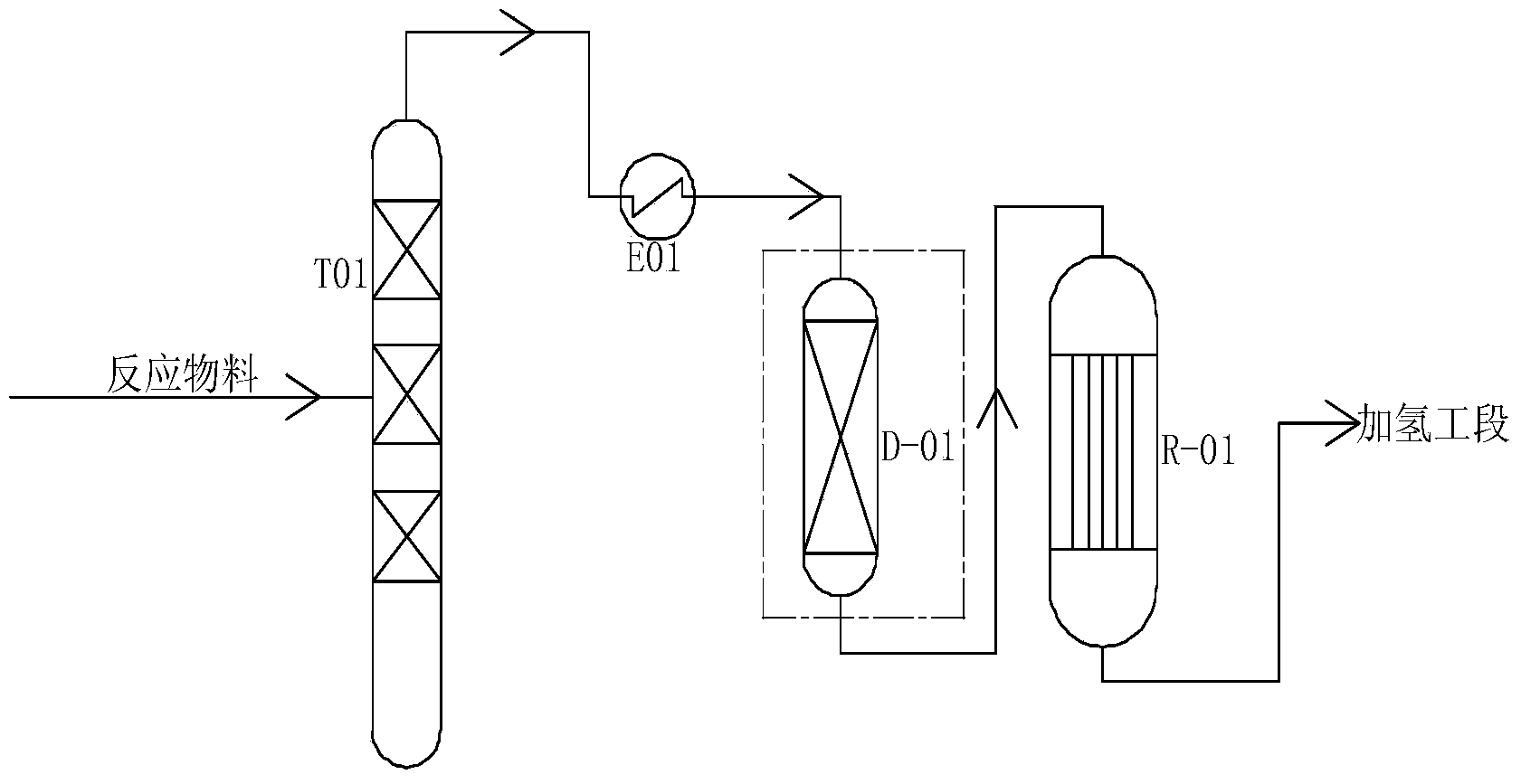

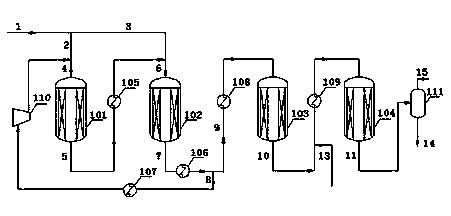

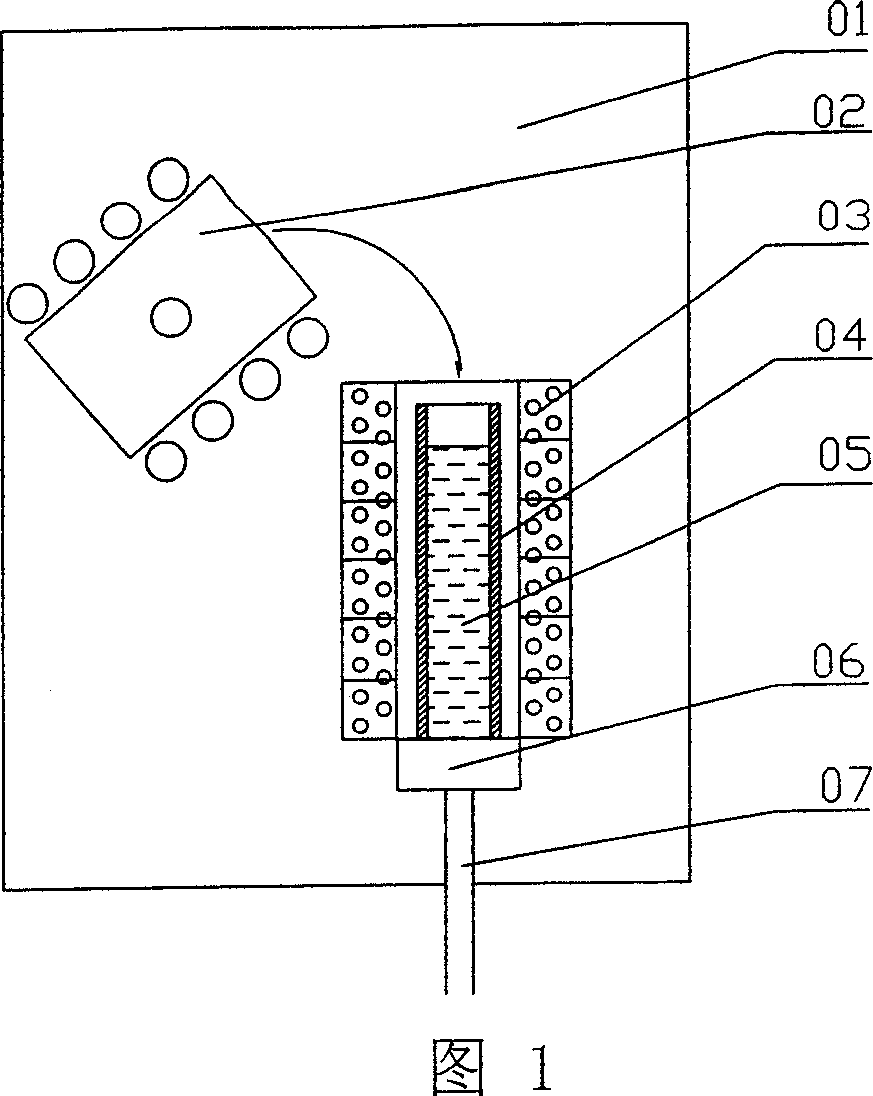

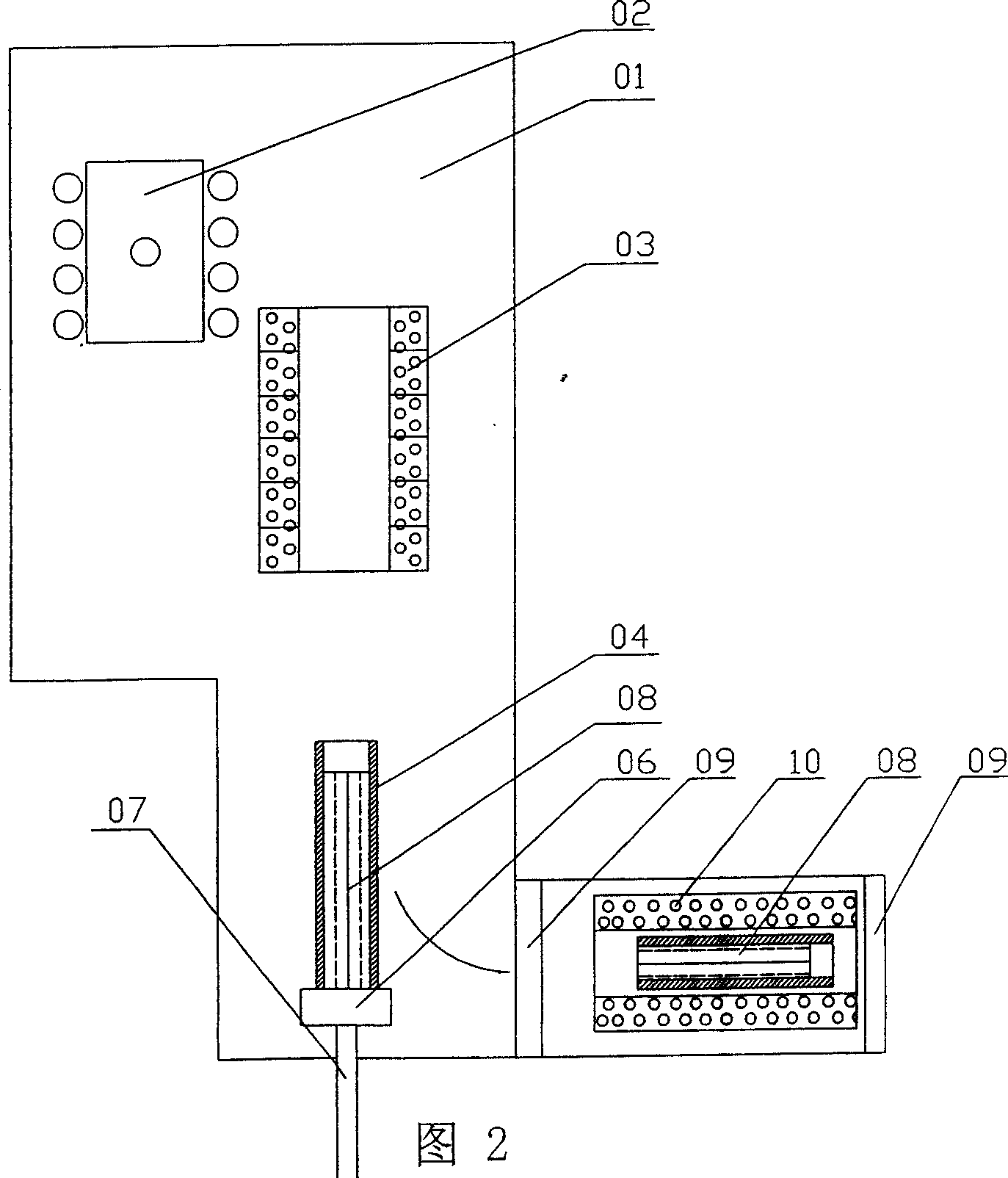

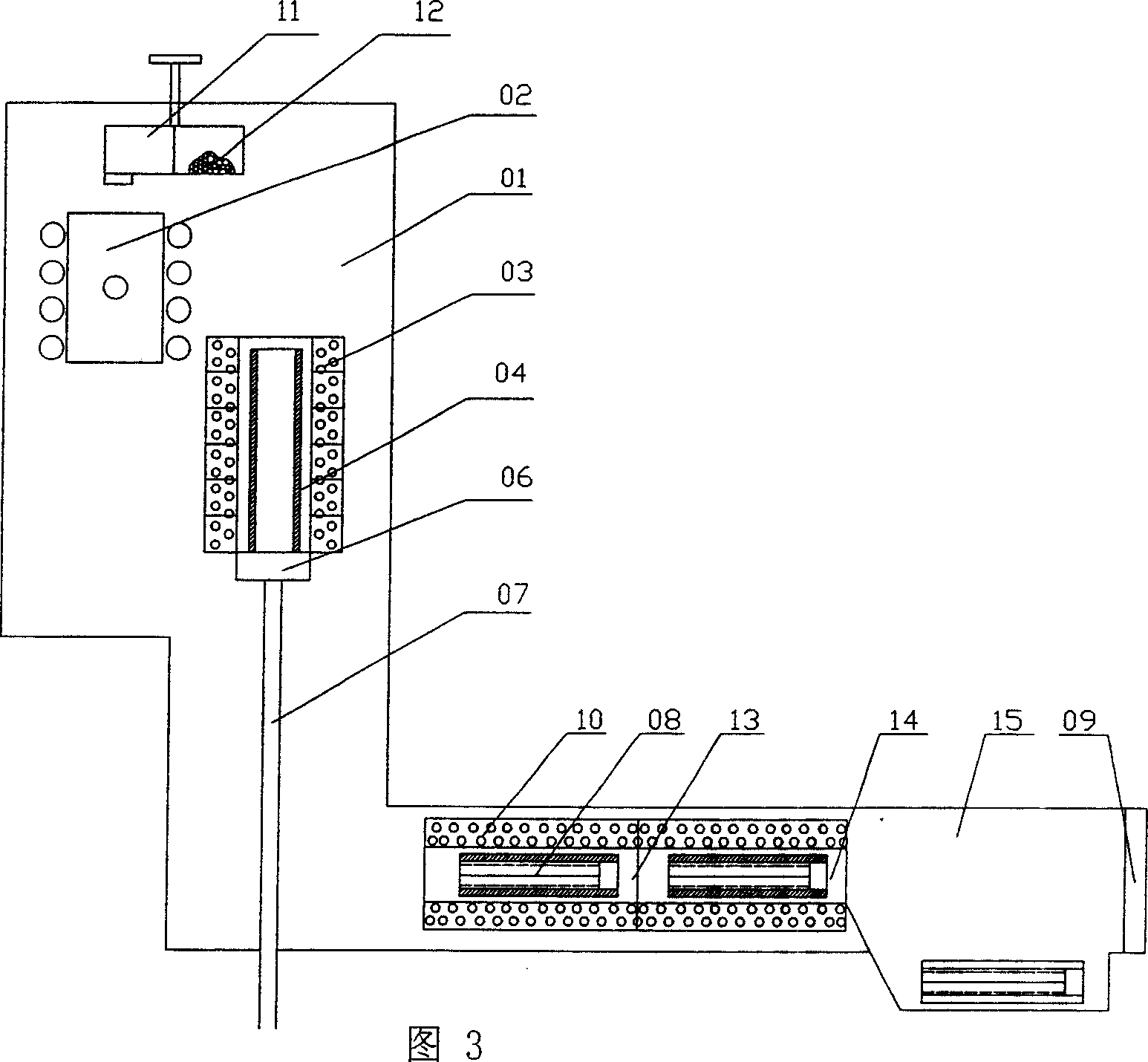

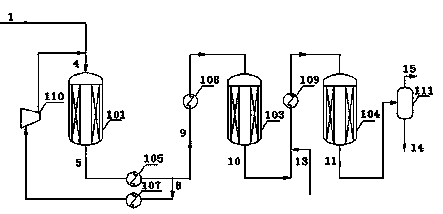

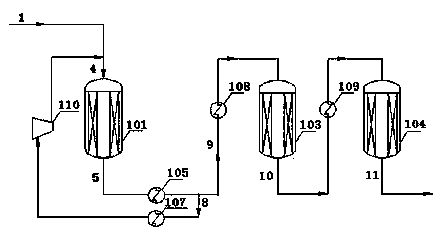

Method and device for producing and synthesizing ethylene glycol by using coal as raw material

ActiveCN103483150AAvoid enrichmentImprove the premium rateOrganic compound preparationHydroxy compound preparationChemistryCorrosion

The invention relates to a method for producing and synthesizing ethylene glycol by using coal as a raw material, which comprises an oxidation and esterification procedure, a carbonylation procedure and a procedure of ethylene glycol preparation through dimethyl oxalate hydrogenation, and further comprises a drying and purifying apparatus, wherein the drying and purifying apparatus is used for drying saturated water in process gas coming out from an oxidation and esterification tower before the process gas enters a carbonylation reactor. The method avoids enrichment of methyl nitrite (MN) in the process gas in an adsorption tower in the regeneration process and harmful emission of regeneration gas, avoids apparatus corrosion caused by oxalic acid formed by hydrolysis of the carbonylation reaction product dimethyl oxalate (DMO), provides a guarantee for long-period operation of the apparatus and improves the high-quality product rate of the final product ethylene glycol.

Owner:PUJING CHEM IND SHA

Method for producing sesame flavored white spirit high in tetramethylpyrazine content

ActiveCN102978073AIncrease softnessImprove comfortAlcoholic beverage preparationMicroorganism based processesTetramethyl pyrazineBran

The invention discloses a method for producing sesame flavored white spirit high in tetramethylpyrazine content, comprising the following steps of: crushing 800-900 parts of broomcorn and 100-200 parts of wheat, blending 50-100 parts of bran and 200-300 parts of stillage obtained through the previous round of steaming with starch solution evenly, and steaming the mixture in a rice steamer, thereby obtaining fermented grains; blending the obtained fermented grains with the stillage obtained through the previous round of steaming in the ratio of 1: (5-5.5) and performing aeration cooling; adding 150-200 parts of sesame flavored yeast and 200-250 parts of bran to the mixture and supplementing the starch solution, and then gathering and stacking for 2-3 days, thereby obtaining fermented residues; performing aeration cooling on the fermented residues so that the temperature thereof reaches 28-32 DEG C; sealing and fermenting in a pit for 50-60 days; and mixing 1000-1200 parts of fermented grains with 150-180 parts of steamed rice husk in the rice steamer for steaming, thereby obtaining the sesame flavored white spirit. The sesame flavored white spirit through the production process provided by the invention is obviously improved in quiet and tasteful degree, softness and comfort in contrast with the wine produced through the existing process; and the premium grade rate of the sesame flavored white spirit is improved by more than 20% in contrast with the existing process, while the content tetramethylpyrazine thereof beneficial for human body health is increased to 3000-4000 ug / L from 300-800 ug / L.

Owner:山东景芝白酒有限公司

Intensified baijiu daqu and production method and application thereof

ActiveCN111235067AMinimal ingredients addedAdd trace ingredientsBacteriaMicroorganism based processesMicroorganismHordeum vulgare

The invention discloses intensified baijiu daqu and a production method and application thereof. The intensified baijiu daqu is produced from the following raw materials in parts by weight: 100 partsof main raw materials, 4-5 parts of an accessory, 2-3 parts of a functional bacterial intensifier and 2-3 parts of mother qu; and the main raw materials are composed of wheat, barley and peas with a weight ratio ranging from 15:1:1 to 20:3:1, the accessory is distiller's dried grains, and the functional bacterial intensifier is produced by mixing bacillus velezensis, acinetobacter and sporosarcinaaccording to a weight ratio ranging from 1.0:0.5:0.5 to 1.0:1.0:1.0. In the intensified baijiu daqu, the microorganisms are diversified and high in content, and the quality of obtained baijiu is excellent.

Owner:HENAN YANGSHAO LIQUOR IND CO LTD +1

Method for producing high-purity micro-silica plastics anti-block agent

InactiveCN101423216AImprove the premium rateIncreased tensile yield strengthSilicon compoundsSilicic acidSilica gel

The invention provides a production method of a high-purity micro-powder silica plastic anti-block agent; high-purity water glass reacts with sulfuric acid to gain sodium sulfate and silicic acid; the sodium sulfate is washed by water to gain silicious colloid which is centrifugally dehydrated, and dried by micro-wave to gain pure SiO2 powder which is crushed by an airflow crusher to gain the high-purity micro-powder silica plastic anti-block agent. The production method of the high-purity micro-powder silica plastic anti-block agent has simple process, high purity and small particle size of the gained products, is suitable for the production and use of top-class plastic films, can obviously improve the top-grade product rate, reduces the cost of the product, improves the tensile yielding strength of the film to 13.5-14.5MPa generally, improves the tensile breaking elongation rate of the film to about 1400 percent, and obviously reduces the fish eye number of the film.

Owner:山西天一纳米科技股份有限公司

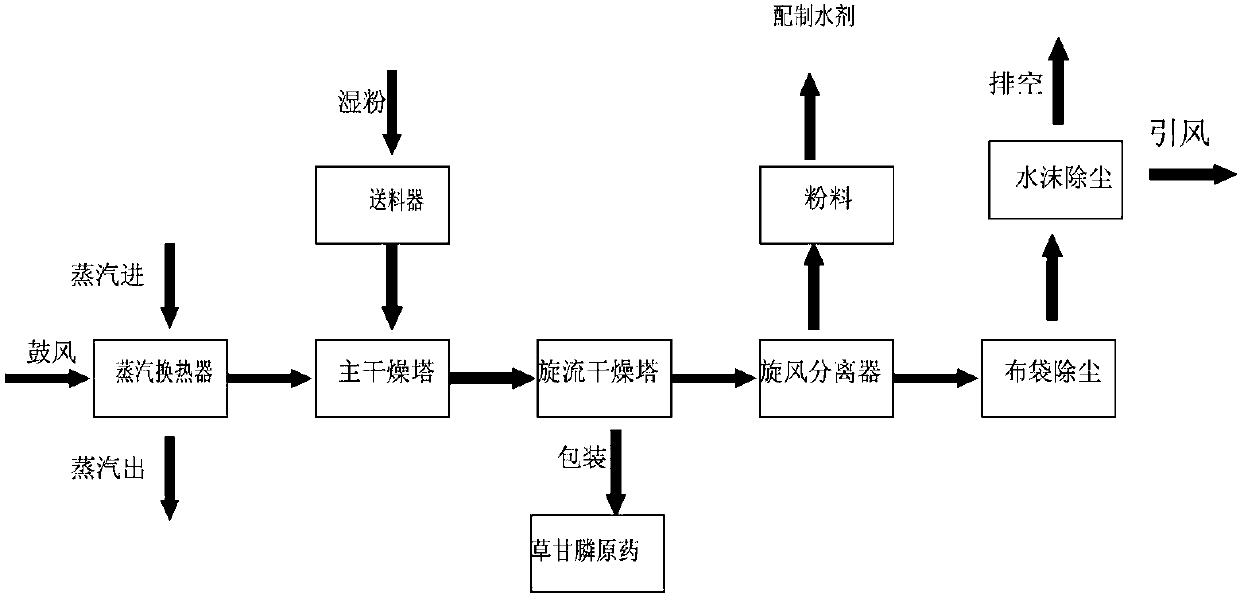

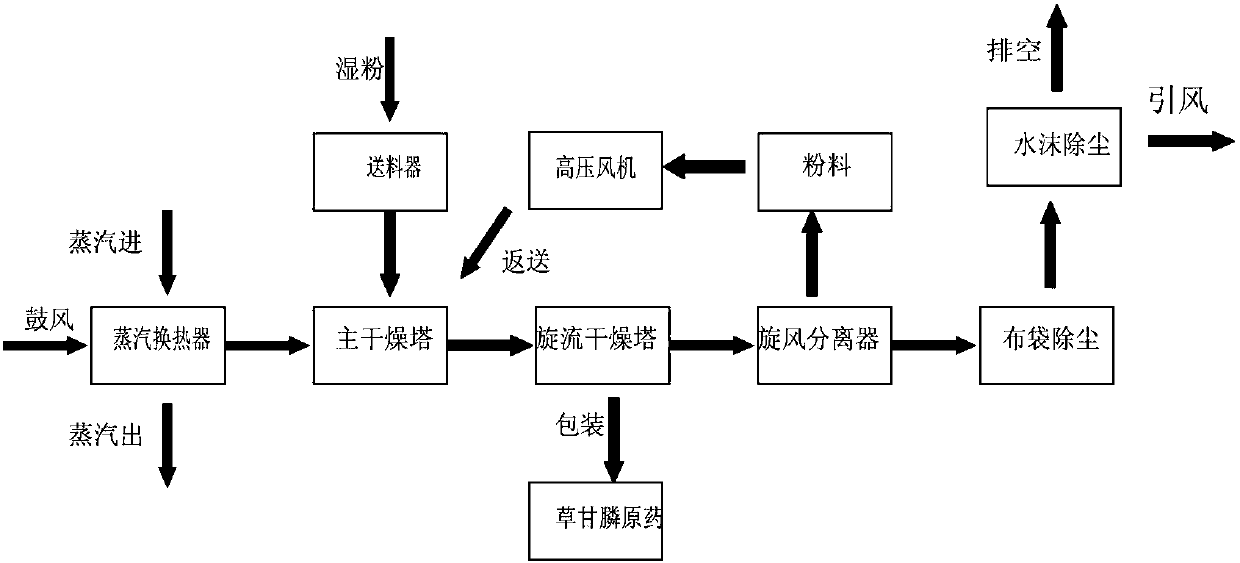

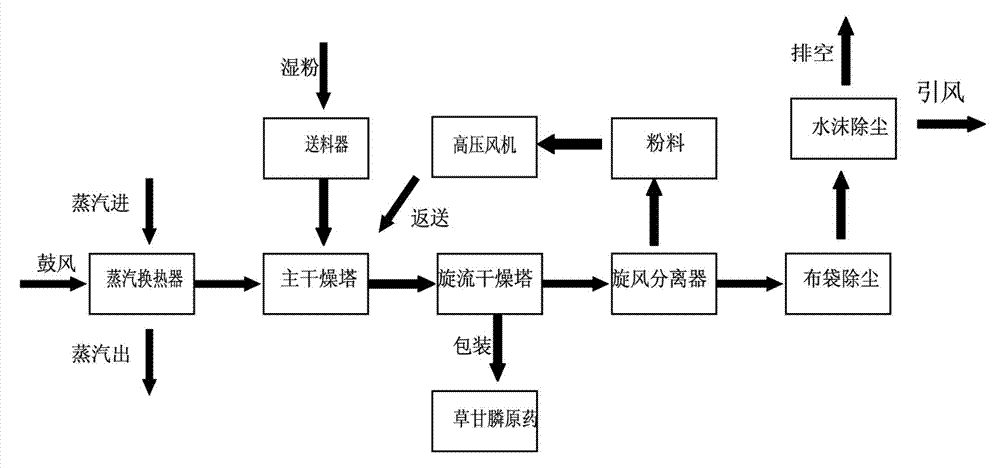

Recovery method for sending glyphosate original chemical back automatically

InactiveCN103344095AImprove the premium rateReduce generationDrying solid materials with heatHearth type furnacesRecovery methodGlyphosate

The invention relates to a recovery method for sending glyphosate original chemical back automatically. The recovery method is combined with aerodynamics, low-content and high premium grade powder chemical is sent back to a drying tower through a high-pressure draught fan and a stainless steel tube, the powder chemical is mixed with wet powder and is dried in the drying tower, and thus the powder chemical is mixed in the glyphosate original chemical uniformly and is packed. According to the technical scheme, the premium grade of the glyphosate original chemical is improved by 2%, the recovery rate of the original chemical reaches more than 99.9%, powder production is reduced greatly, production environment is optimized, steam loss and other losses are decreased by 20% year on year, equipment is guaranteed to work stably, production efficiency and economic benefits are improved, and cost is controlled notably.

Owner:HUBEI TAISHENG CHEM

Ceramic tile made of simulated sandstone and preparation process of ceramic tile

The invention discloses a ceramic tile made of simulated sandstone and a preparation process of the ceramic tile. The ceramic tile comprises a ceramic tile green body and an enamel layer on the surface of the ceramic tile green body. The ceramic tile is characterized in that stone-shaped stripes and ink jet coarse sandstone patterns are printed on the surface of the enamel layer, the enamel layer sequentially comprises a bottom enamel layer, a surface enamel layer, a first-time dot enamel layer, a second-time dot enamel layer, a protection enamel layer and a dry granular enamel layer, an area of the first-time dot enamel layer accounts for 95-99.9% that of the surface of the ceramic tile, and an area of the second-time dot enamel layer accounts for 70-90% of that of the ceramic tile. Processes of repeated enameling and distributing, drum, ink jet, dry granule distributing and single-roller letterpress printing are adopted, multilayer texture and multilayer enamel color are formed, and an effect like natural real sandstone formed by nature is completely realized.

Owner:白刚

Method of producing substitute natural gas by methanation of synthesis gas

The invention relates to a method of producing substitute natural gas by methanation of synthesis gas, mainly solving problems, namely large using amount of recycle gas, high energy consumption of compressors, and excess of the H2 component or the CO2 component in substitute natural gas products, of high-temperature methanation reactions in the prior art. According to the technical scheme adopted by the method, the method comprises: a) a step of providing a high-temperature methanation reaction zone including n-stage series-connected reactors; b) a step of dividing the synthesis gas raw materials into n sections and respectively feeding the n sections of the synthesis gas raw materials into inlets of the reactors at all stages in the high-temperature methanation reaction zone, wherein the stream Vn flowing out from the reactor at the final stage is divided into Vn' and Vn'' and the stream Vn' is condensed and circulated to the inlet of the reactor at the first stage; c) a step of providing a low-temperature methanation reaction zone including m-stage series-connected reactors; and d) a step of supplementing a stream I containing CO2 to a reactor at any stage in the low-temperature methanation reaction zone, and a substitute natural gas product is obtained after the reaction. By the technical scheme, the problems are solved well and the method can be used in industrial production of the substitute natural gas from the synthesis gas.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for producing substitute natural gas

The invention relates to a method for producing substitute natural gas. The problems of large using amount of high-temperature methanation reaction circulating gas, high energy consumption of a compressor and excess of an H2 or CO2 component in a substitute natural gas product in the prior art are mainly solved. According to the technical scheme, the method comprises the following steps: (a) proving a high-temperature methanation reaction area, wherein the high-temperature methanation reaction area comprises an n stages of cascaded reactors; (b) dividing synthesis gas raw materials into n sections, causing the n sections of synthesis gas raw materials to enter an inlet of a reactor in each stage in the high-temperature methanation reaction area, dividing a material flow Vn flowing out of an outlet of the reactor in a final stage into Vn' and Vn', and compressing and circulating the material flow Vn to an inlet of the reactor in the first stage; (c) providing a low-temperature methanation reaction area, wherein the low-temperature methanation reaction area comprises m stages of reactors which are connected in series; (d) supplementing an H2-containing material flow I into the reactor in any stage of a low-temperature methanation unit, and performing reaction to obtain the substitute natural gas product. According to the method, the problems are well solved; the method can be used for industrial production of preparing the substitute natural gas with synthesis gas.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method of producing major diameter TbDyFe-base alloy directionally solidified crystal

InactiveCN1920117ANo coupling mismatch issuesGuaranteed continuityFrom frozen solutionsCrucibleAlloy

The invention relates the technology for producing directional freeze TbDyFe magnetostriction alloy, comprising the following steps: smelting master alloy with copper cold-crucible in vacuum induction suspending smelting furnace; installing ring heater out of die, every heater being a ring heating layer, the temperature being controlled and measured separately, opening heaters, making the temperature above the fusing point of alloy; putting the molten liquid into tubular die, bottom-up reducing the temperature of heater, making the alloy liquid freeze, and then carrying out heat treatment at the cooling course. The invention has the advantages of high productivity, low cost and mass production.

Owner:李碚

Method for liquid brewing of Chinese strong aromatic spirits

PendingCN109517694ASweet and elegant wineIncrease profitAlcoholic beverage preparationDistillationSlurry

The invention relates to the technical field of liquor brewing, and particularly discloses a method for liquid brewing of Chinese strong aromatic spirits. The method comprises the following steps thatunprocessed grain and auxiliary materials are weighed, the unprocessed grain is crushed, and thus unprocessed grain flour is obtained; the unprocessed grain flour and water are mixed, thus unprocessed grain slurry is obtained, and after gelatinization, liquefaction and saccharification treatment is conducted, saccharified mash is obtained; the auxiliary materials are added for alcoholic fermentation, acid production and esterification fermentation; and fermented and ripened mash is filtered, filtrate is distilled in a distillation kettle, and the liquor is taken. According to the method, mechanical continuous production can be conducted, the production cycle is shortened, the unprocessed grain starch utilization rate is increased, the liquor yield is increased, the top-grade product rateof a liquor body is increased, the liquor body style is more elegant, and the taste is more sweet and purer.

Owner:河北山庄老酒股份有限公司

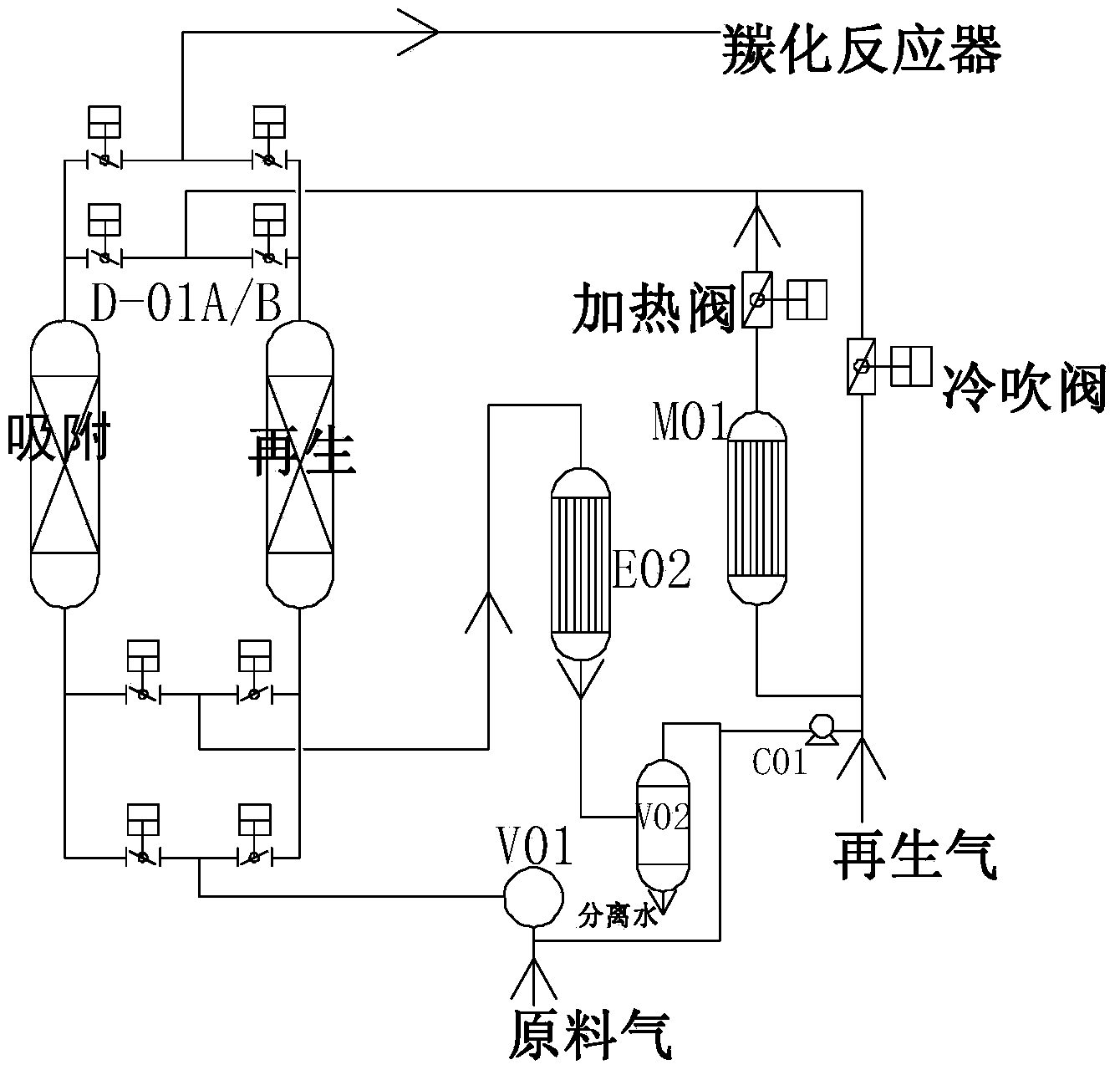

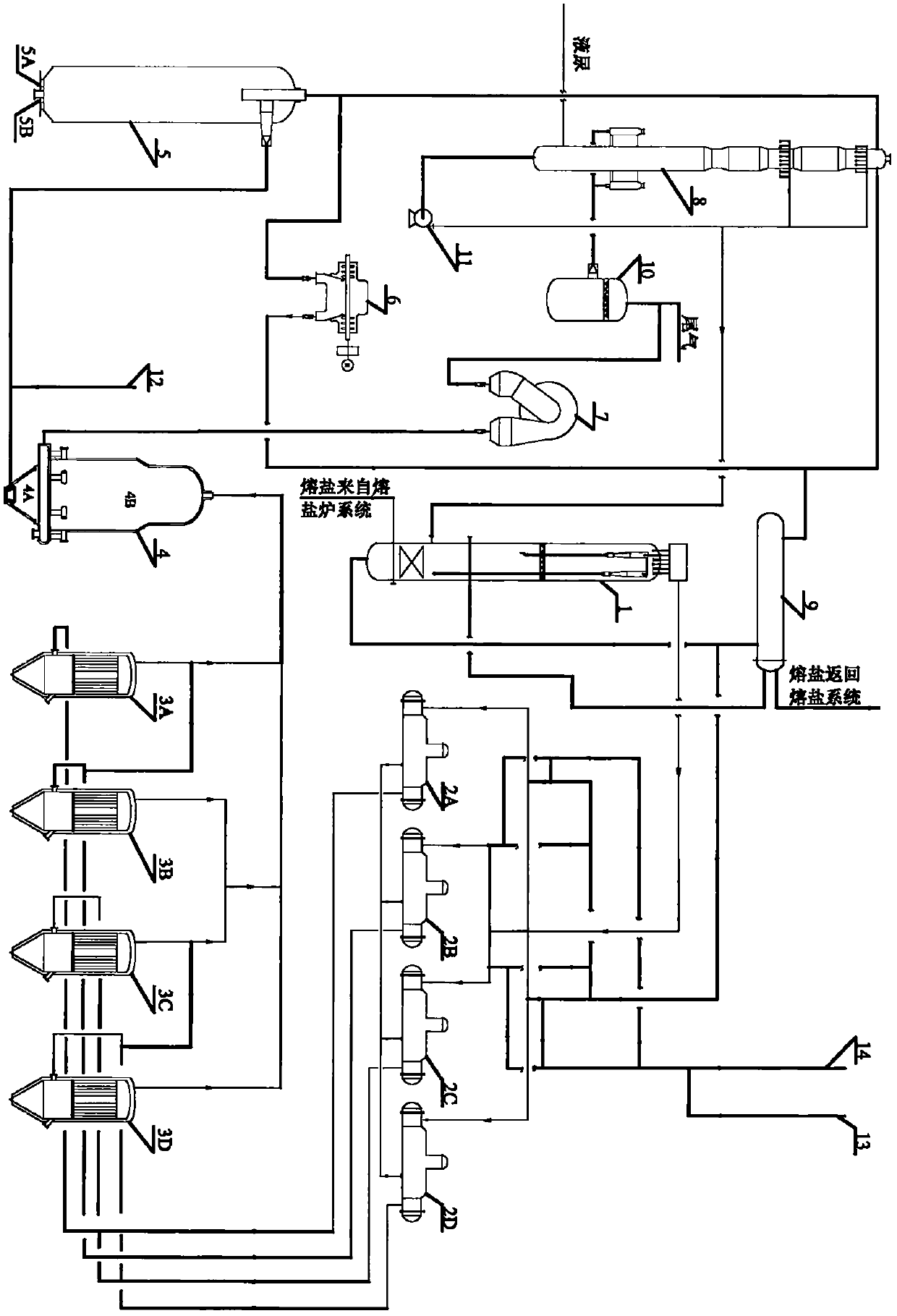

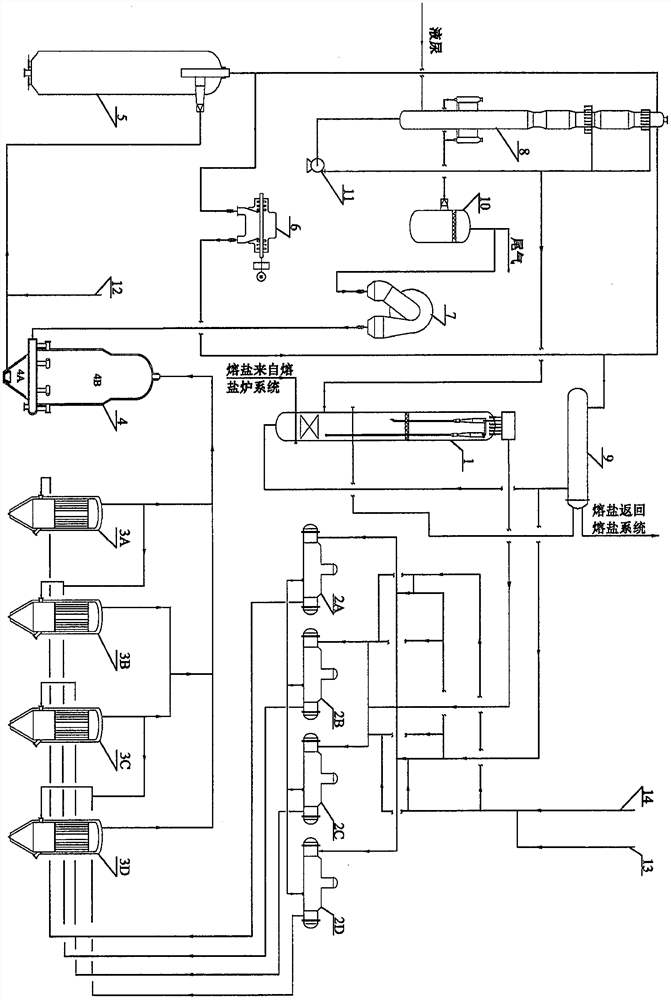

Energy-saving low-pressure cold-brew melamine production technology

ActiveCN107778261ASolve the problem of blocked discharge pipelineEliminates scarring problemsOrganic chemistryChemical industryGas heaterGas compressor

The invention provides an energy-saving low-pressure cold-brew melamine production technology which comprises a melamine reactor, hot-gas coolers, filters, a crystallizer, a trap, a carrier gas compressor, a cool gas fan, a urine washer, a carrier gas heater and the like. The crystallizer is provided with a double-layer cool gas circular canal at the upper part, and a rotary material scraper at the lower part; gas inlets of the carrier gas compressor and the cool gas fan are separated, the gas inlet of the carrier gas compressor adopts hot process gas, and the gas inlet of the cool gas fan adopts cool process gas; a path of hot process gas is lead out from the carrier gas heater, and is matched with hot ammonia gas or superheated vapor, and the mixture gas enters the hot-gas coolers and the filters; the filters are arranged in series or in parallel. The device of the energy-saving low-pressure cold-brew melamine production technology is low in construction investment, low in consumption, and high in operating flexibility, the premium grade rate can reach 95%, and the continuous operation cycle of the device can be 4-6 months or more.

Owner:王庆锋

Method for recovering condensed fluid of glyphosate synthesis solution

InactiveCN102967136AImprove the premium rateReduce generationDrying solid materialsRecovery methodCyclone

The invention discloses a method for recovering a condensed fluid of a glyphosate synthesis solution. Glyphosate technical wet powder enters into a main drying tower for drying through a feeding device and enters into a cyclone drying tower for drying to obtain qualified glyphosate technical. The method is characterized in that the material from the cyclone drying tower enters into a cyclone separator, the powder separated by the cyclone separator reenters into the main drying tower under the action of a fan to be mixed with the glyphosate technical wet powder in the main drying tower, and the mixture is dried. According to the method, the low-content powder with high premium grade rate is returned into the main drying tower to be mixed with the wet powder and the mixture is dried by adopting the high-pressure fan and a stainless steel air pipe, so that the powder is uniformly dispersed in the glyphosate technical for packaging. Therefore, the premium grade rate of the glyphosate technical is increased by 2%, the recovery rate of the technical is more than 99.9%, the powder is greatly reduced, the production environment is optimized, and the loss of steam and the like is reduced by 20% year on year.

Owner:HUBEI TAISHENG CHEM

Method of producing substitute natural gas from synthesis gas

InactiveCN103740424ASensitive control of contentAlternative stabilityGaseous fuelsMethanationSubstitute natural gas

The invention relates to a method of producing substitute natural gas from synthesis gas, mainly solving a problem of excess of the H2 component or the CO2 component in substitute natural gas (SNG) which is a technical product in the prior art. According to the technical scheme adopted by the method, the method comprises: a) a step of feeding synthesis gas raw materials containing H2, CO, CO2 and H2O into an inlet of a high-temperature methanation reactor, wherein the reacted stream V is divided into V' and V'' and the V' stream is compressed and circulated to the inlet of the high-temperature methanation reactor; b) a step of feeding the stream V'' into a low-temperature methanation unit including m-stage series-connected reactors with the m being not less than 2; and c) a step of supplementing a stream I containing CO2 to a reactor at any stage in the low-temperature methanation unit; a substitute natural gas product is obtained after the reaction, wherein the stream I comprises 40-100% in volume of the CO2, 0-60% in volume of H2 and 0-20% in volume of CO. By the technical scheme, the problem is solved well and the method can be used in industrial production of the substitute natural gas from the synthesis gas.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for reducing content of ethyl acetate in strong aromatic wine under mechanized production conditions

PendingCN111763588AHigh yieldReduce generationAlcoholic beverage preparationCellar toolsBiotechnologyWarm water

The invention discloses a method for reducing the content of ethyl acetate in strong aromatic wine under mechanized production conditions. The method comprises the steps of starting to pump yellow water five days before taking out of a cellar, taking 9900-12000 parts of hawthorn fermented grains in the cellar, mixing 2700-3300 parts of crushed unprocessed grains, adding warm water, uniformly stirring the warm water, adding 720-780 parts of steamed rice husk, and uniformly stirring the rice husk to obtain large hawthorn grains; adding 30-60 parts of steamed rice husk into 2000-2200 parts of fermented grains obtained after fermentation, and uniformly stirring the steamed rice husk to obtain double-round grains; firstly adding 50-100 parts of tail wine into a steaming bucket, then scatteringa small amount of steamed rice hulls at the bottom of the steaming bucket, and then putting large hawthorn grains or double-wheel grains into the steaming bucket; carrying out liquor steaming on the loaded large hawthorn grains so that the liquor steaming steam pressure is 4-10 Kpa and the liquor flowing speed is 3-4 Kg / min, removing the head and the tail, picking liquor according to the quality,and picking strong-aroma large hawthorn raw liquor; and steaming the loaded double-round grains, and performing picking to obtain the strong-flavor double-round raw wine. The ethyl acetate content ofthe raw wine is reduced to 400 mg / l or below, the superior product rate of the strong aromatic wine is increased by 15% or above, the cellar aroma is prominent, the wine tastes mellow, sweet and full,the aftertaste is fresh and clean, and the style is typical.

Owner:山东景芝白酒有限公司

Drafting roller for special polyethylene fibers, drafting machine and drafting device

PendingCN108425157ANo disturbanceDry evenlyFilament manufactureArtificial filament washing/dryingProduction rateFiber

The invention discloses a drafting roller for special polyethylene fibers, a drafting machine and a drafting device. The drafting roller comprises a rotating shaft, a roller body, a jacket roller anda heat-conduction medium tube; the rotating shaft is internally provided with a first channel and a second channel; the roller body is fixedly connected with the rotating shaft; the jacket roller is provided with a medium inlet, a medium outlet and a hollow medium flow cavity, the medium flow cavity is communicated with the first channel through the medium inlet, and the medium flow cavity is communicated with the second channel through the medium outlet. The drafting roller has the advantages that the thermal efficiency is high, no disturbance is caused to the fibers, the drafting roller canuniformly dry, evenly heat and highly draft the nascent fibers in a stable and tensioned state without leakage, and an extraction agent is efficiently recycled. A drying box, a seven-roller drafting machine and a drafting hot box in the prior art are replaced, the overall centralized intelligent control over after-spinning of the high-strength and high-modulus polyethylene fibers is achieved, theproduct quality is improved, the energy consumption is reduced, the production rate and the premium grade rate are increased, and the number of workers and the labor intensity are reduced.

Owner:河北和泰航天科技有限公司 +1

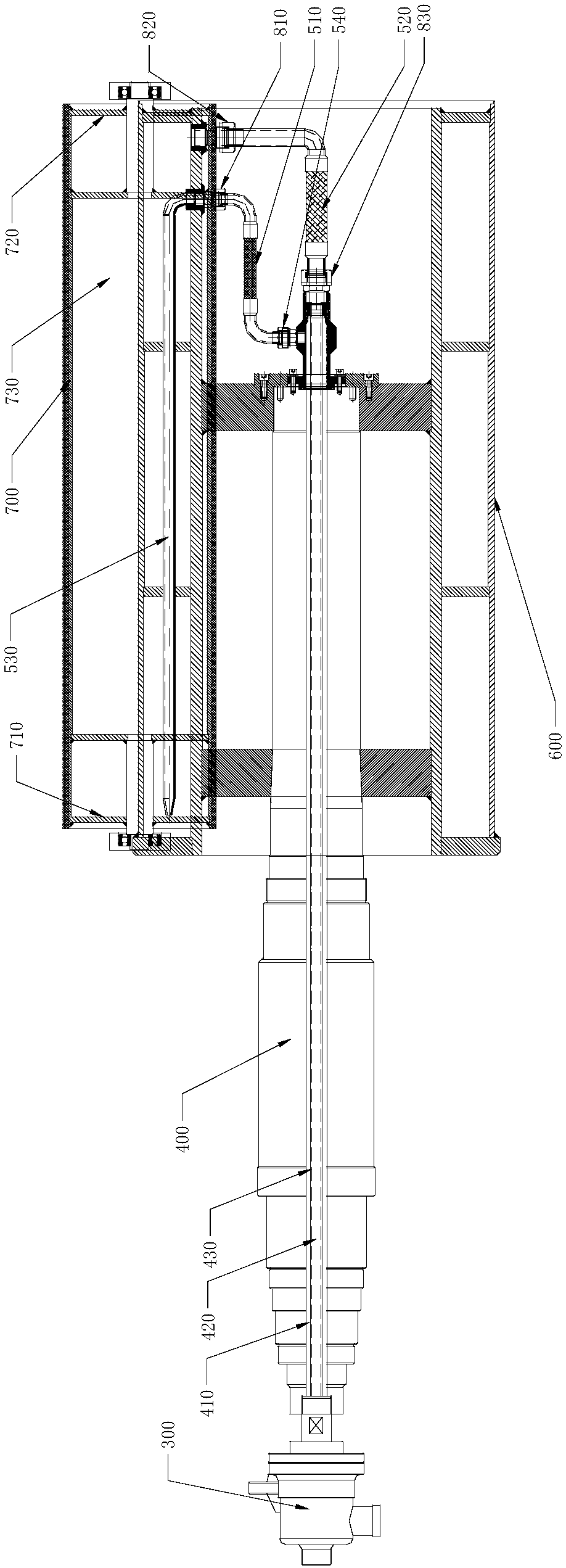

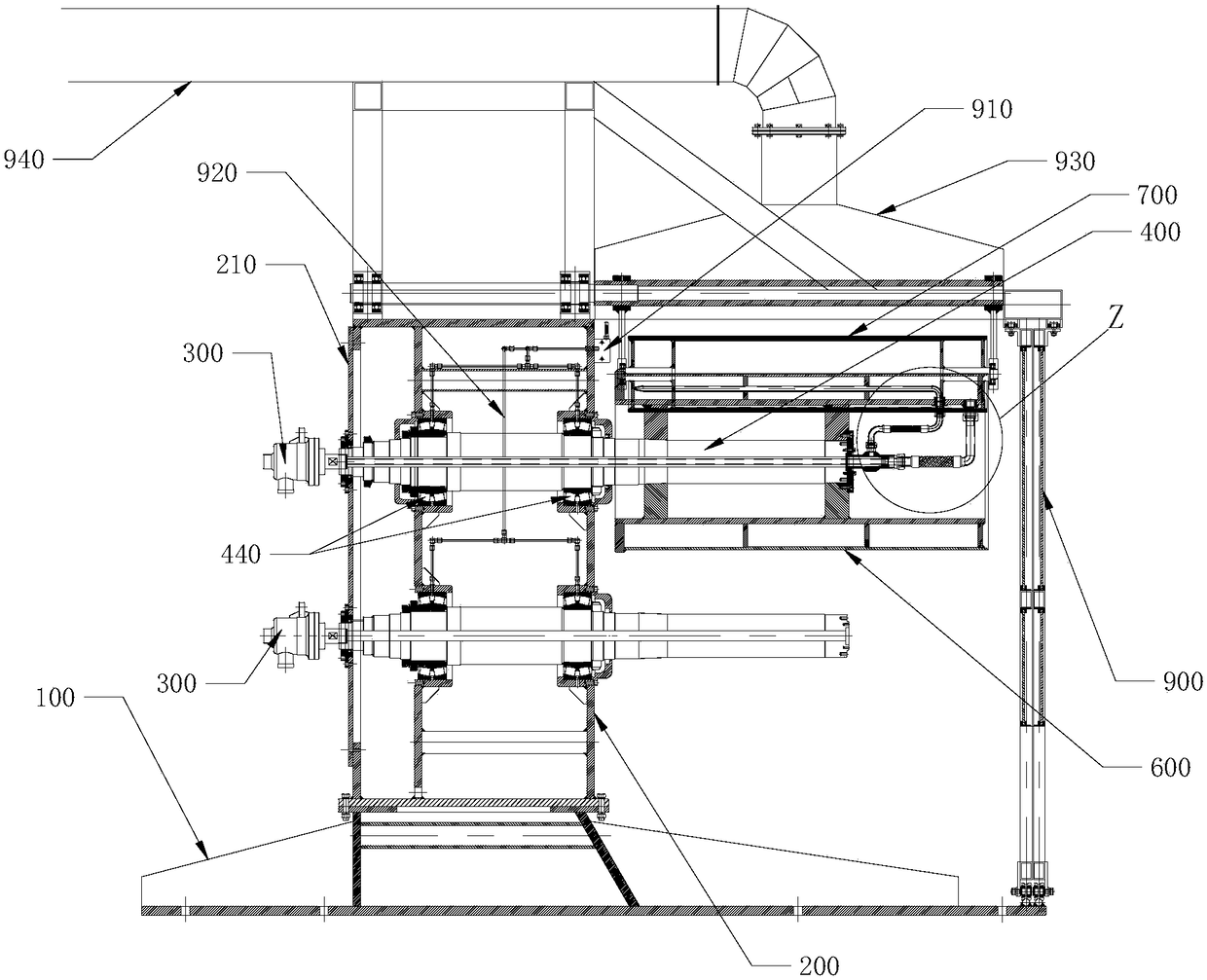

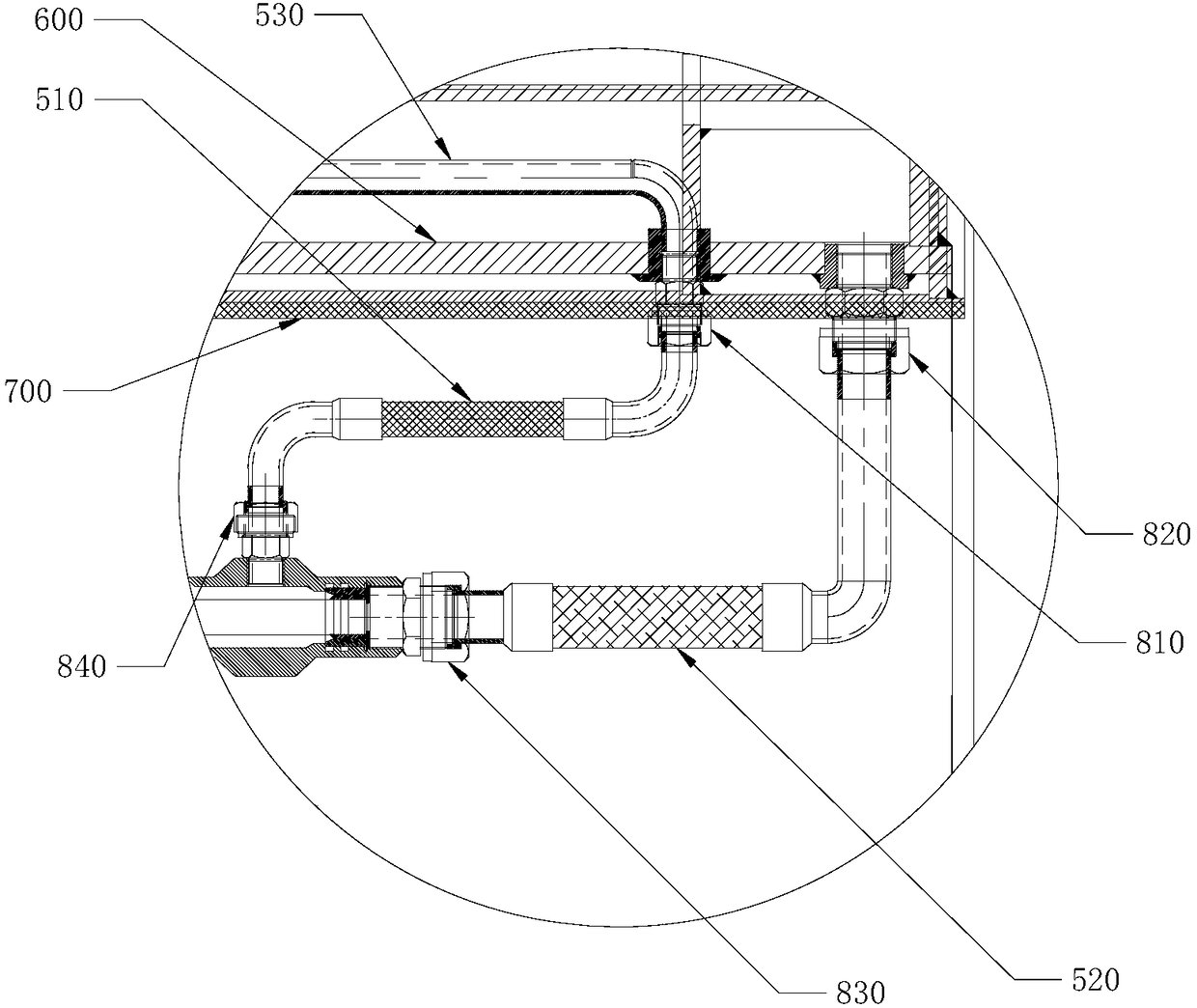

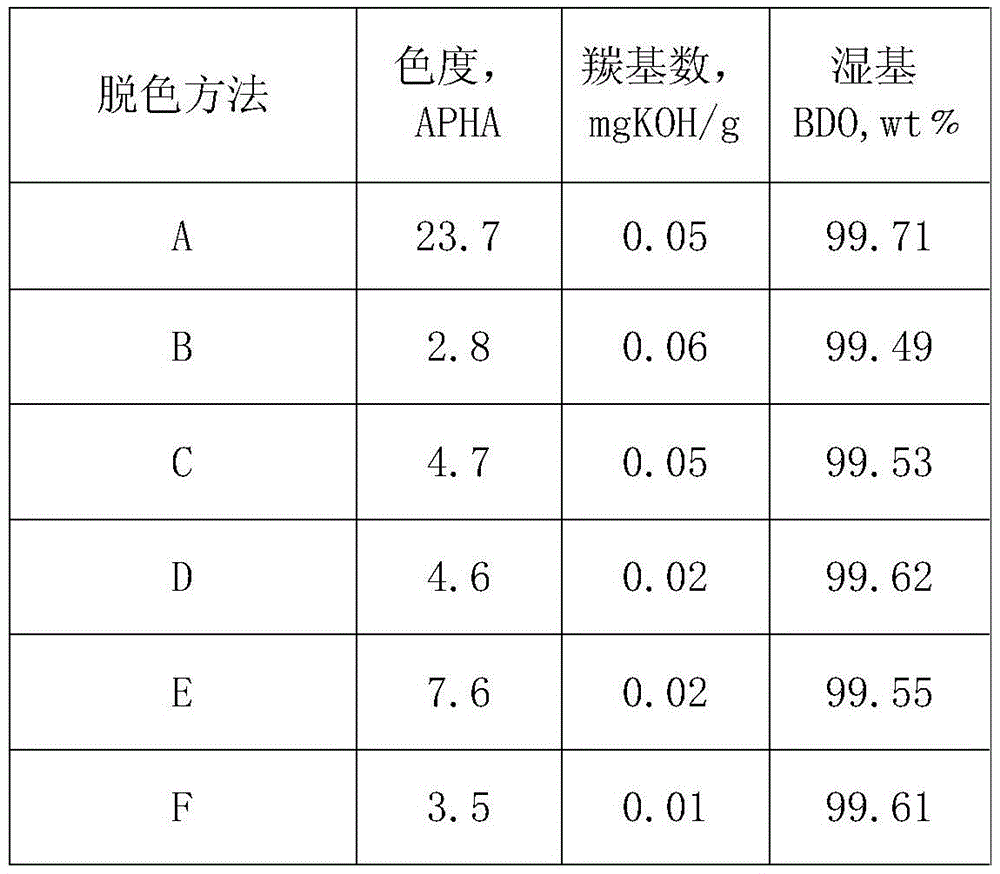

Catalytic hydrogenation and decoloration method of 1,4-butanediol

InactiveCN105418371AImprove product qualityThe method is simple and reliableOrganic compound preparationHydroxy compound preparation1,4-ButanediolHydrogen

The invention relates to a catalytic hydrogenation and decoloration method of 1,4-butanediol. The catalytic hydrogenation and decoloration method of the 1,4-butanediol comprises the following process steps that a catalyst and a 1,4-butanediol solution are added to a reaction container, hydrogen gas is led into the container, reaction is performed under the conditions of the pressure of 0.1-20 MPa and the temperature of 30-180 DEG C, and then filtering is performed. The method adopting the carrier-supported precious metal catalyst to perform catalytic BDO hydrogenation is used for decoloration treatment of the 1,4-butanediol, and the method is simple and reliable. By utilizing the method, the chromaticity of BDO products can be effectively reduced, the quality of the BDO products can be improved, the premium grade rate of the products can be improved, the products can be popularized to the high-end application field of TPU and the like after the BDO chromaticity is reduced, the added value of the products can be increased, and the economic benefits can be improved.

Owner:SINOPEC CHANGCHENG ENERGY CHEM NINGXIA CO LTD

Pp melt-blown material and preparation method thereof

PendingCN112662063AIncrease the melting numberImprove the premium rateMonocomponent polyolefin artificial filamentArtifical filament manufactureMasterbatchPolypropylene

The invention relates to the technical field of melt-blown raw materials, in particular to a pp melt-blown material and a preparation method thereof. The pp melt-blown material is prepared from the following raw materials: polypropylene, a cooling master batch, melt-blown powder, an auxiliary agent and a stabilizer. The peroxide content concentration of the pp melt-blown material is 6000 ppm to 7500 ppm. The pp melt-blown material has the beneficial effects that the cooling master batch, the melt-blown powder and the auxiliaries are adopted according to the proportion, so that the melting number of the polypropylene material is greatly increased, the pp melt-blown material with high melt index and low ash content can be prepared, the processing temperature can be reduced, the requirements of energy conservation and environmental protection are met, and the PP melt-blown material prepared by the method is safe and harmless to human bodies. The pp melt-blown material prepared by the preparation method disclosed by the invention is stable in gram weight, environment-friendly, pollution-free and high in superior product rate, and the melt-blown fabric prepared from the pp melt-blown material disclosed by the invention has high uniformity and consistency and cannot be broken in a filamentation process.

Owner:汕头市格派环保科技有限公司

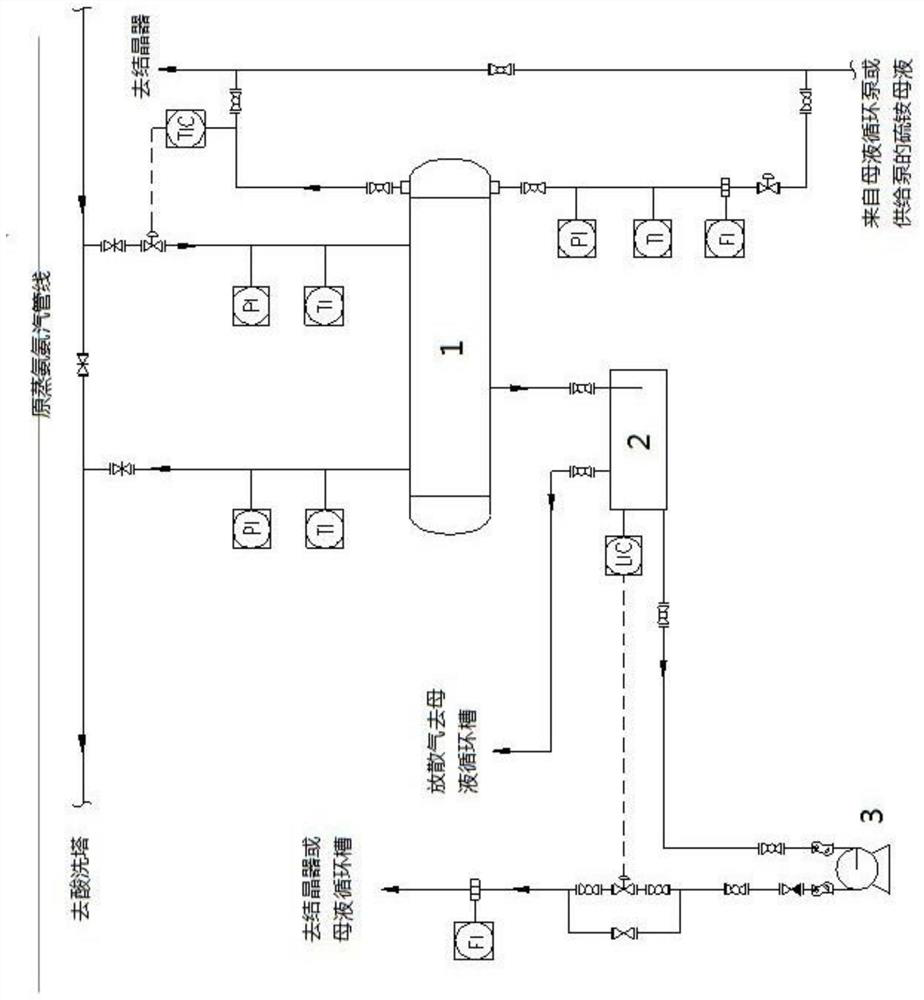

Ammonia steam waste heat utilization device for ammonia distillation

PendingCN112978761AReduce consumptionReduce adhesionEnergy inputSolution crystallizationThermodynamicsProcess engineering

The invention relates to an ammonia steam waste heat utilization device for ammonia distillation, which comprises an ammonium sulfate mother liquor heat exchanger, an ammonia condensate tank and an ammonia condensate pump, the ammonium sulfate mother liquor heat exchanger and the ammonia condensate pump are provided with the ammonia condensate tank, and the ammonia condensate tank is connected with the ammonium sulfate mother liquor heat exchanger and the ammonia condensate pump through a pipeline. The ammonium sulfate mother liquor heat exchanger is provided with an ammonia steam inlet, an ammonia steam outlet, a mother liquor inlet and a mother liquor outlet, an adjusting valve is arranged on a mother liquor inlet pipeline, the flow of mother liquor entering the heat exchanger is controlled through the opening degree of the adjusting valve, an adjusting valve is arranged on an ammonia steam inlet pipeline, and the opening degree of the adjusting valve is automatically adjusted according to the temperature of mother liquor in a mother liquor outlet pipeline.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

High-temperature surface carbon retaining isolation agent for medium-high-carbon steel and application method of high-temperature surface carbon retaining isolation agent

InactiveCN109022723AStop the spreadRealize carbon preservation and carbon increaseCarbon layerHigh carbon

The invention relates to a high-temperature surface carbon retaining isolation agent for medium-high-carbon steel and an application method of the high-temperature surface carbon retaining isolation agent. The high-temperature surface carbon retaining isolation agent comprises components including, by weight percent, 60%-85% of diopside, 1%-5% of nano silicon nitride, 1%-5% of nano chromium carbide, 5%-15% of aluminum ash powder, 6%-25% of potash water glass and 0.1%-0.5% of polyacrylamide, wherein the granularity of the nano silicon nitride and the granularity of the nano chromium carbide are100-500 nm, and the added water volume accounts for 60%-90% of the total weight. The above components are evenly mixed according to a mechanical grinding and mixing method to prepare the isolation agent with the granularity smaller than 100 microns. The isolation agent is suitable for high-temperature protection when a steel blank is heated at the temperature of 900-1,150 DEG C for 1-10 h, the isolation agent is sprayed to the surface of the normal-temperature steel blank, the thickness of the isolation agent ranges from 200 microns to 500 microns, a glass base protection film is formed in the temperature rise process of the isolation agent, and carbon oxygen mutual permeation of the surface of the base body is protected. After the protected steel blank is heated, the isolation agent andthe steel blank surface scales can be completely removed through high-pressure water descaling, the isolation agent achieves the function of carbon retaining, the rolled material surface decarburization layer depth is effectively reduced, the rolled material surface quality is improved, and the usage cost is low.

Owner:晋江市钫淦新材料科技有限公司

Ultrahigh-power graphite electrode contact and preparation process thereof

PendingCN112457014AHigh bulk densityImprove flexural strengthElectric discharge heatingGraphite electrodeMethyl benzene

The invention discloses an ultrahigh-power graphite electrode joint and a preparation process thereof, belongs to the technical field of graphite electrode joints, and solves the technical problems oflow breaking strength, insufficient physicochemical indexes, low superior product rate and the like of the conventional ultrahigh-power graphite electrode joint. According to the technical scheme, the ultrahigh-power graphite electrode contact is prepared from the following raw materials in parts by weight: 45 parts of needle coke, 55 parts of calcined coke powder, 25 parts of asphalt binder and0.5 part of a Fe2O3 additive, wherein methylbenzaldehyde and p-toluenesulfonic acid are added into the asphalt binder. The process comprises the following steps: 1, burdening; 2, mixing and kneading to prepare paste; 3, performing extrusion molding; 4, performing primary roasting; 5, performing primary dipping; 6, performing secondary roasting; 7, carrying out secondary impregnation; 8, roasting for the third time; 9, performing graphitization treatment; and 10, machining. According to the invention, the volume density and breaking strength are improved, various physicochemical indexes are superior to those of the original product, and the production cost is greatly reduced.

Owner:DATONG YULINDE CARBON MATERIALS TECH

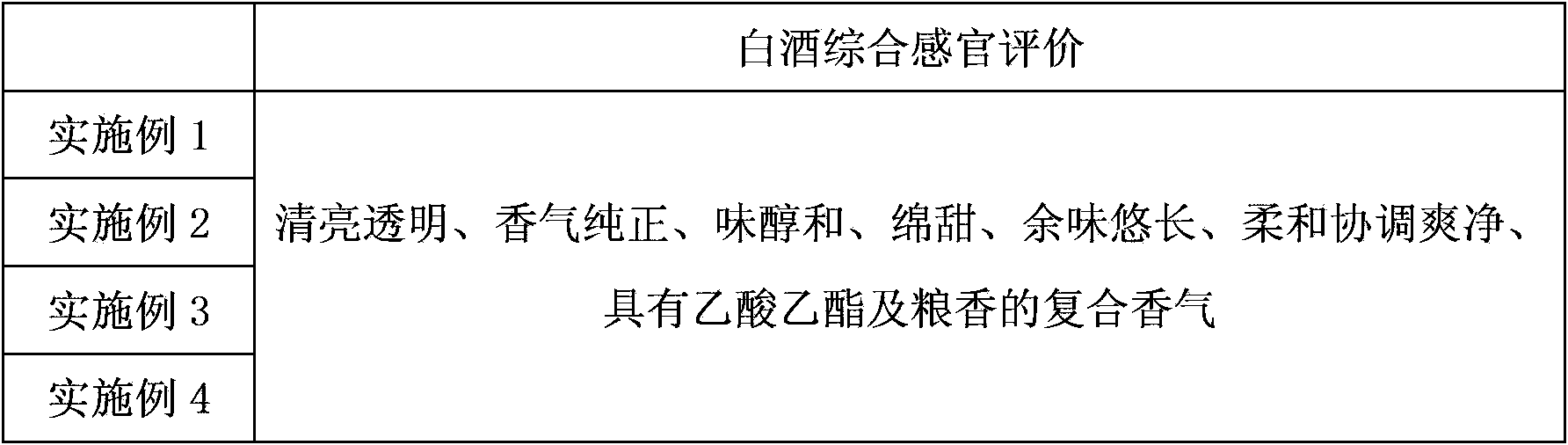

Five-grain fen-flavor liquor and preparation method thereof

ActiveCN102899217BShort fermentation cycleIncrease productivityAlcoholic beverage preparationBiotechnologyChaptalization

The invention discloses a five-grain fen-flavor liquor and a preparation method thereof. The five-grain fen-flavor liquor is prepared through diastatic fermentation of brewing raw materials consisting of sorghum, rice, glutinous rice, wheat and corn by using Qingcha Daqu. The preparation method for the liquor comprises the following steps: preparing the Qingcha Daqu; mixing the brewing raw materials with the Qingcha Daqu; carrying out diastatic fermentation; and carrying out distillation. The liquor provided by the invention has pure, mild and mellow taste and satisfies current requirements for taste and health care by drinkers; the flavor of sorghum, sweetness of corn, pureness of rice, sweetness of glutinous rice and unique fragrance generated by fermentation of wheat collagen and glutenin in wheat are combined in the liquor, and deficiency in brewing with only a grain is substantially improved; and the liquor has no special odor, can be used as a base wine for medicinal liquor and functional liquor, is applicable as a flavoring liquor for development of a high-grade liquor and has a good application prospect.

Owner:内蒙古响沙湾酒业有限责任公司

Energy-saving low-pressure extraction cold melamine production process

ActiveCN107778261BSolve the problem of blocked discharge pipelineEliminates scarring problemsOrganic chemistryChemical industryCold airGas heater

The invention provides an energy-saving low-pressure extraction and cooling melamine production process, including a melamine reactor, a hot air cooler, a filter, a crystallizer, a trap, a carrier gas compressor, a cold air fan, a urine scrubber, a carrier gas heater, etc. . The upper part of the crystallizer has a double-layer cold air ring pipe, and the lower part of the crystallizer has a rotary scraper; the air intake of the carrier gas compressor and the air-conditioning fan are separated, the air intake of the air-conditioning compressor adopts hot process air, and the air intake of the air-conditioning fan adopts cold process air; From the outlet of the carrier gas preheater, a hot process gas is led out to distribute hot ammonia gas or superheated steam into the hot gas cooler and filter; the filters are set in series and parallel. The low-pressure extraction and cooling melamine production process device of the present invention has less construction investment, low consumption, high operating flexibility, high-grade product rate can reach 95%, and the continuous operation period of the device can reach more than 4 to 6 months.

Owner:王庆锋

Cooling method of bulk PVC resin polymerization

The invention discloses a method for cooling down polymerization system in the polymerization process of PVC resin, which comprises letting normal temperature recirculated water into polymerization still jacket and still top condenser, then cooling down the polymerization system with circulated water, and letting 5-15 deg C circulate chilled water into the polymerization stirrer. The invention can substantially improve the heat-transfer capability for polymerization agitation.

Owner:YIBIN TIANYUAN GRP CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com