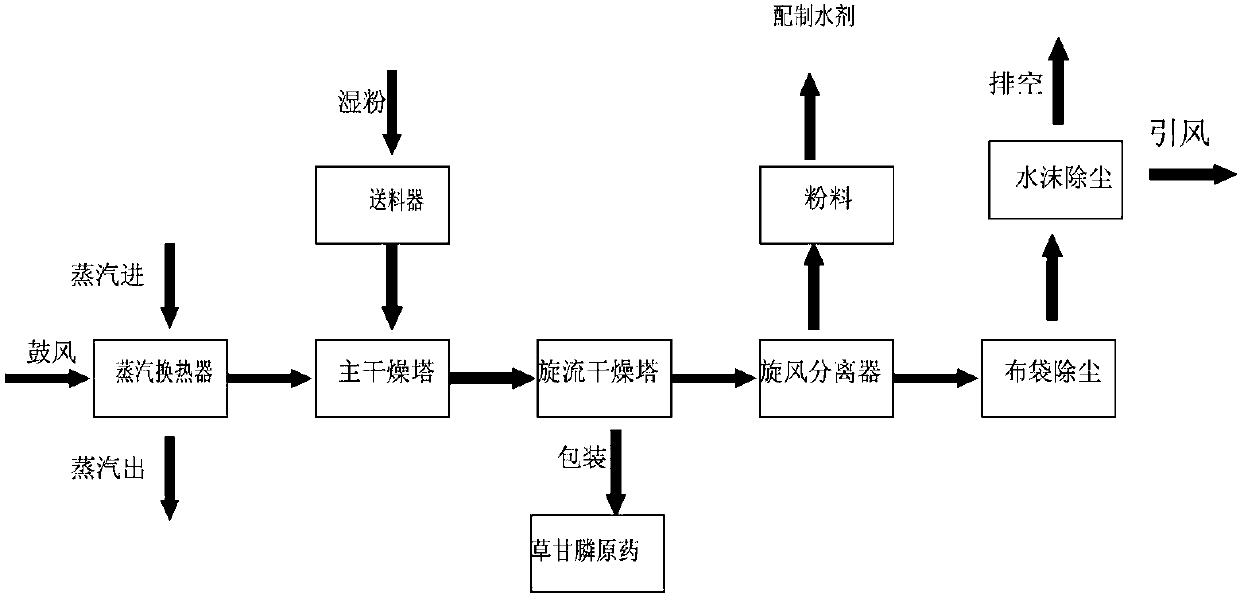

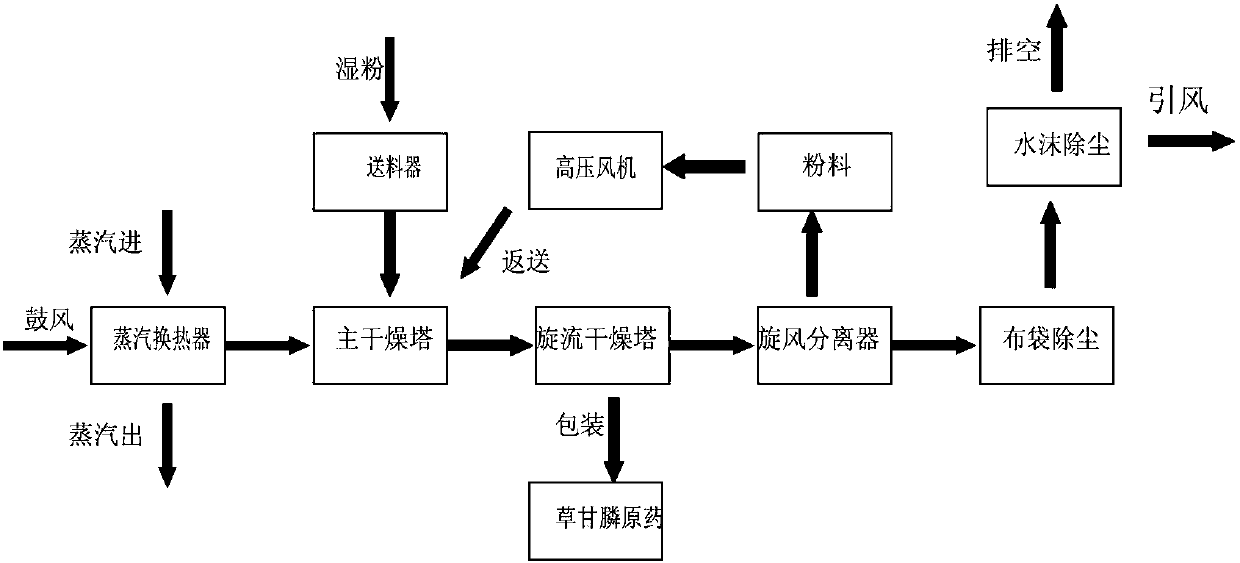

Recovery method for sending glyphosate original chemical back automatically

A recovery method and technology of glyphosate, applied in the direction of drying solid materials, heating to dry solid materials, drying, etc., can solve the problems of meager benefits, environmental pollution, waste of powder materials, etc. The effect of optimizing the production environment and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] In the recovery method of glyphosate raw material drying and automatic return, the glyphosate wet powder is sent into the drying tower, the steam heat exchanger is used to exchange air, and the hot air is blown into the drying tower through the blower, and the glyphosate wet powder The powder is blown into the cyclone drying tower by the hot cyclone in the drying tower, and the qualified glyphosate powder is obtained by discharging the material at the bottom of the cyclone drying tower, and the powder at the top of the cyclone drying tower is sucked in by the hot cyclone In the cyclone separator, the hot cyclone at the top of the cyclone separator brings a very small amount of glyphosate dust into the bag filter for filtration and recovery, and then enters the water foam dust collector for washing and then vents. The powder recovered at the bottom of the cyclone separator The material is sent back to the drying tower through a high-pressure fan and a stainless steel air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com