Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

392results about How to "Conducive to cost control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

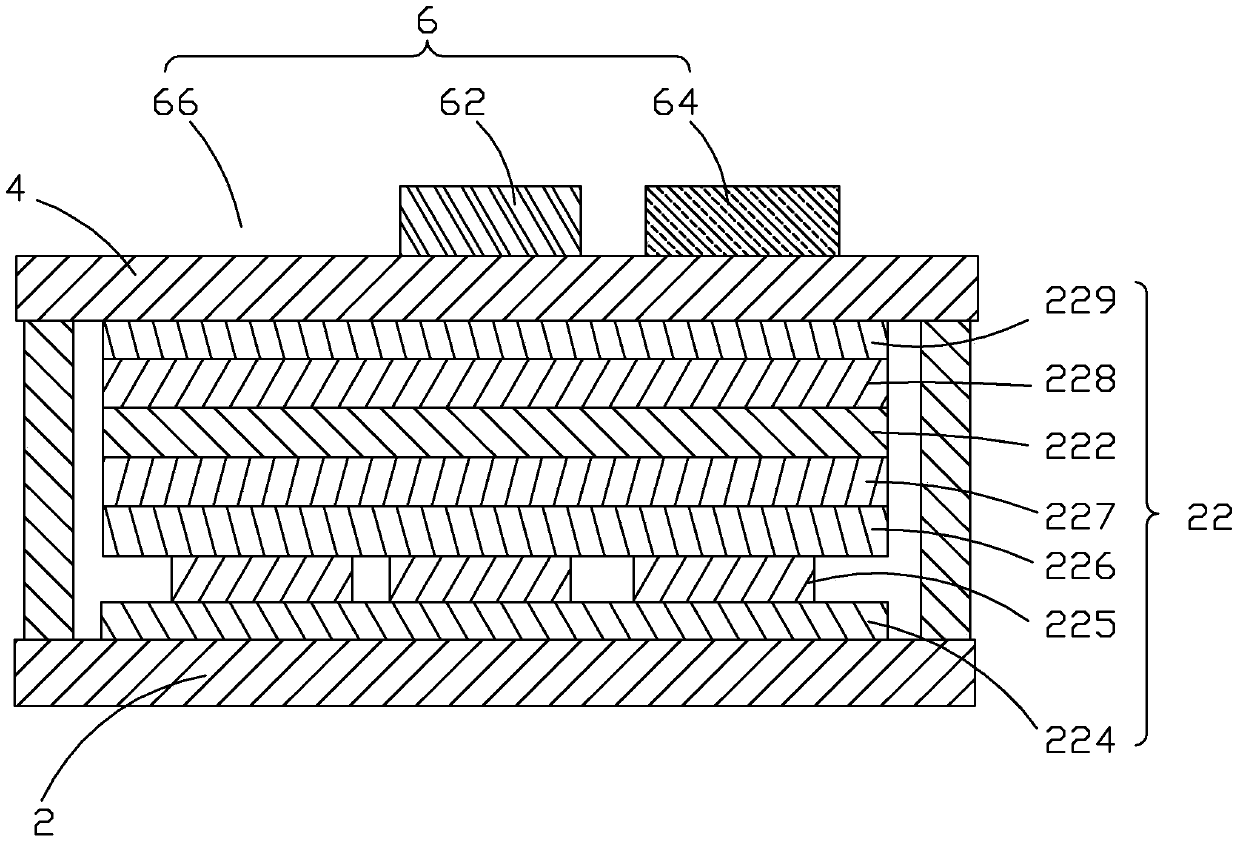

Colored OLED device and manufacturing method thereof

InactiveCN103474451AExtended service lifeSimple processSolid-state devicesSemiconductor/solid-state device manufacturingQuantum dotEngineering

The invention provides a colored OLED device and a manufacturing method thereof. The device comprises an OLED substrate (2), an OLED cover plate (4) attached to the OLED substrate (2), and a color conversion layer (6) formed on the OLED cover plate (4), wherein an OLED element (22) is formed on the OLED substrate (2), the OLED element (22) comprises a light-emitting layer (222), the color conversion layer (6) comprises a plurality of quantum dot units, and light emitted by the light-emitting layer (222) is converted through the quantum dot units of the color conversion layer (6) to achieve colorization. According to the colored OLED device and the manufacturing method, colorization display is achieved through the light-emitting layer and the quantum dot units, the thickness of the light-emitting layer is reduced, and then the thickness of the whole colored OLED device is reduced; besides, quantum dots further have the advantages of being good in stability, long in service life, good in color purity and the like, so the service life of the colored OLED device is prolonged, and color purity is improved; meanwhile, the colored OLED device is simple in manufacturing process and low in cost.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

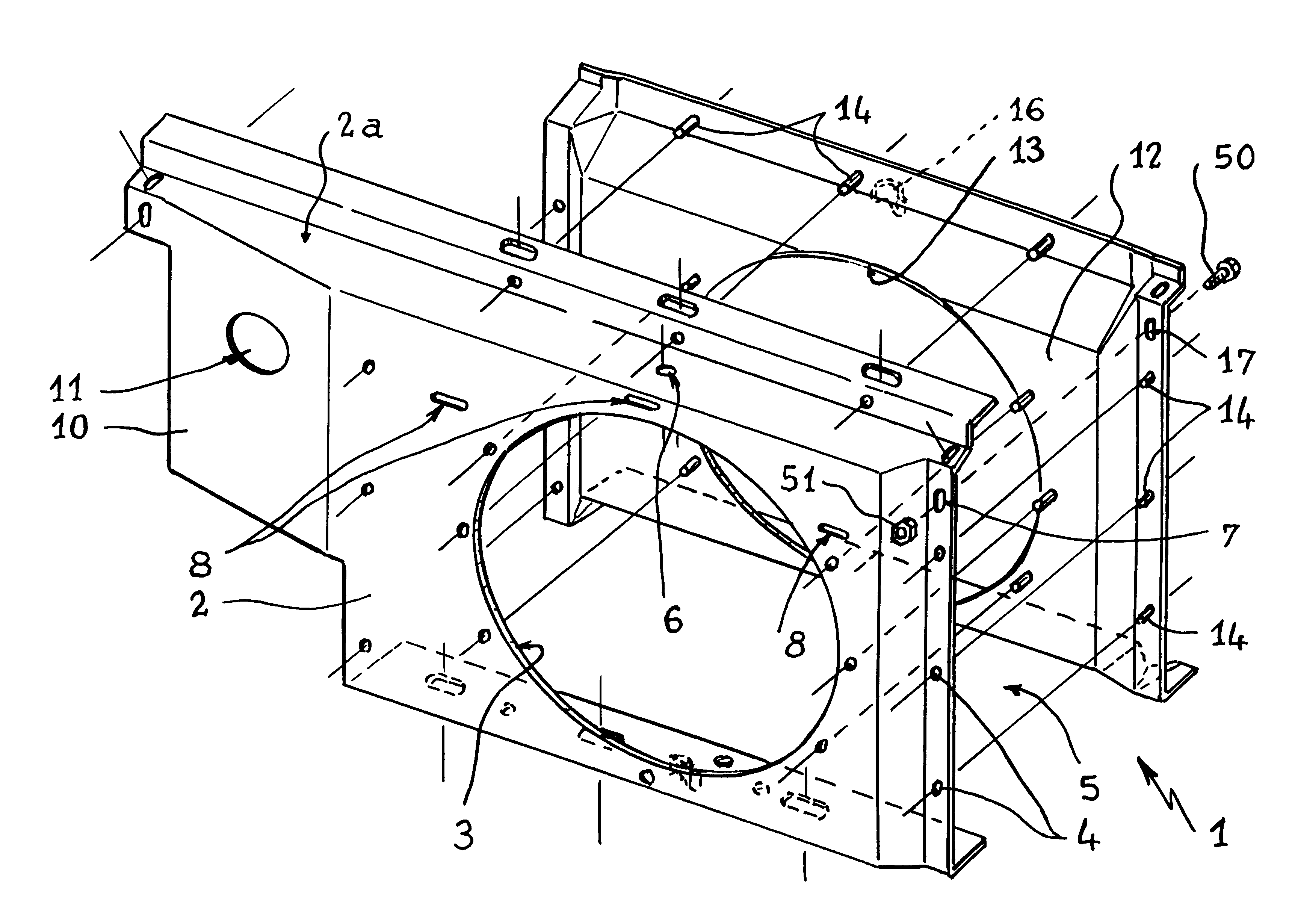

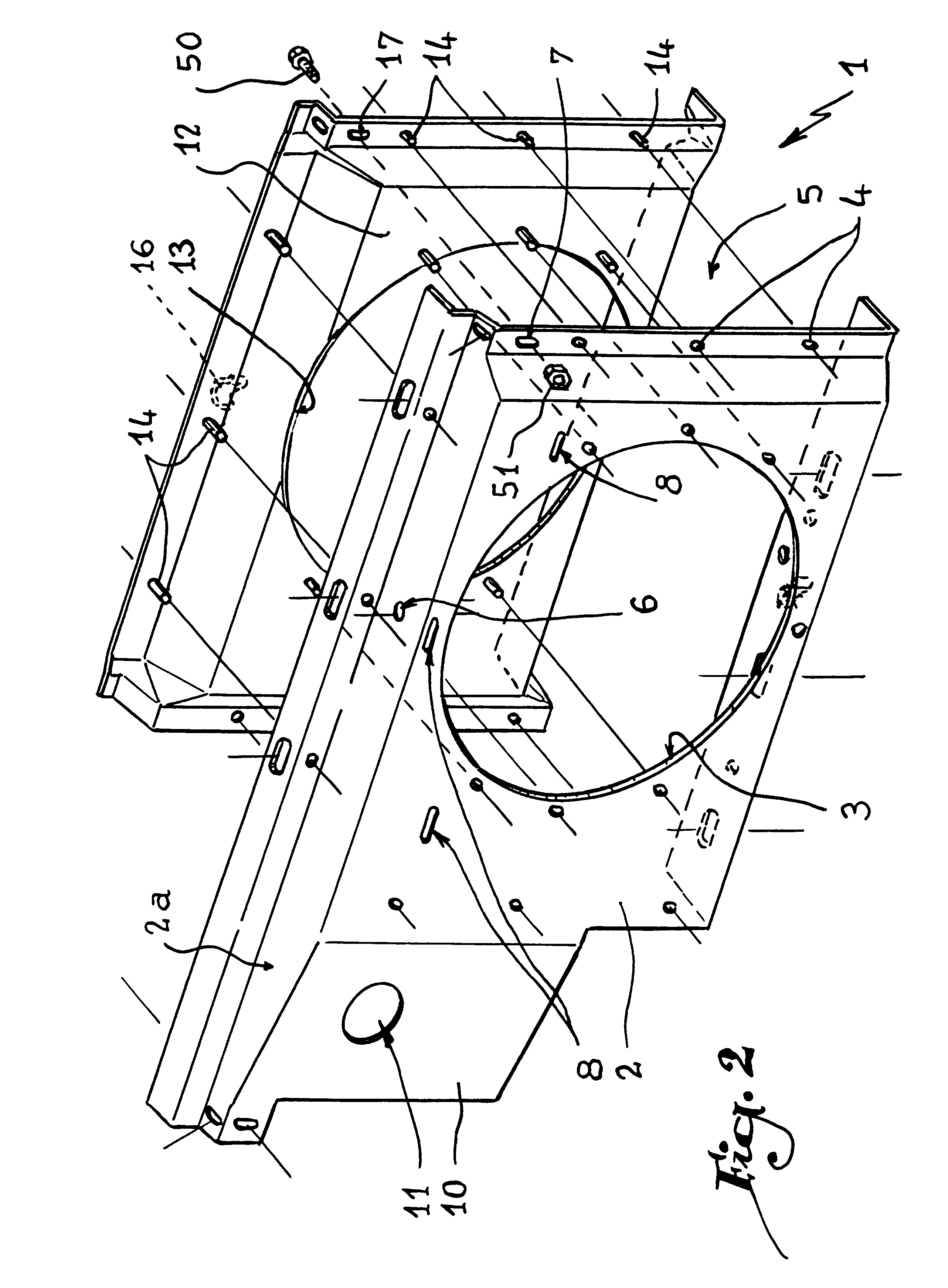

Front panel bodywork element for an automobile including a reinforcing element

InactiveUS6186583B1Conducive to cost controlImprove assembly rigidityVehicle seatsSuperstructure subunitsMobile vehicleEngineering

A composite front panel bodywork element for an automotive vehicle which includes a stamped metal reinforcement defining a cavity in which is seated a portion of a plastic support structure for mounting functional elements associated with the vehicle thereto. The plastic support structure is mounted relative to the metallic reinforcement so as to define open channels therebetween.

Owner:INOPLAST

Anti-sliding glaze, anti-sliding brick and preparation method thereof

The invention discloses an anti-sliding glaze which contains the following chemical components by weight percent: 42.8%-48.5% of SiO2, 19.1%-22.8% of Al2O3, 0.1%-0.2% of Fe2O3, 7.0%-9.5% of CaO, 2.5%-5.2% of MgO, 2.1%-8.6% of Na2O, 0.9%-4.1% of K2O, 1.1%-3.3% of ZnO and 2.8%-6.2% of ZrO2. The invention also discloses an anti-sliding ceramic tile and a preparation method for the anti-sliding ceramic tile. The anti-sliding ceramic tile disclosed by the invention can achieve an excellent anti-sliding effect after a layer of anti-sliding glaze is applied to the surface of the anti-sliding ceramic tile, the technology is simple and the cost is low.

Owner:DONGGUAN CITY WONDERFUL CERAMICS IND PARK

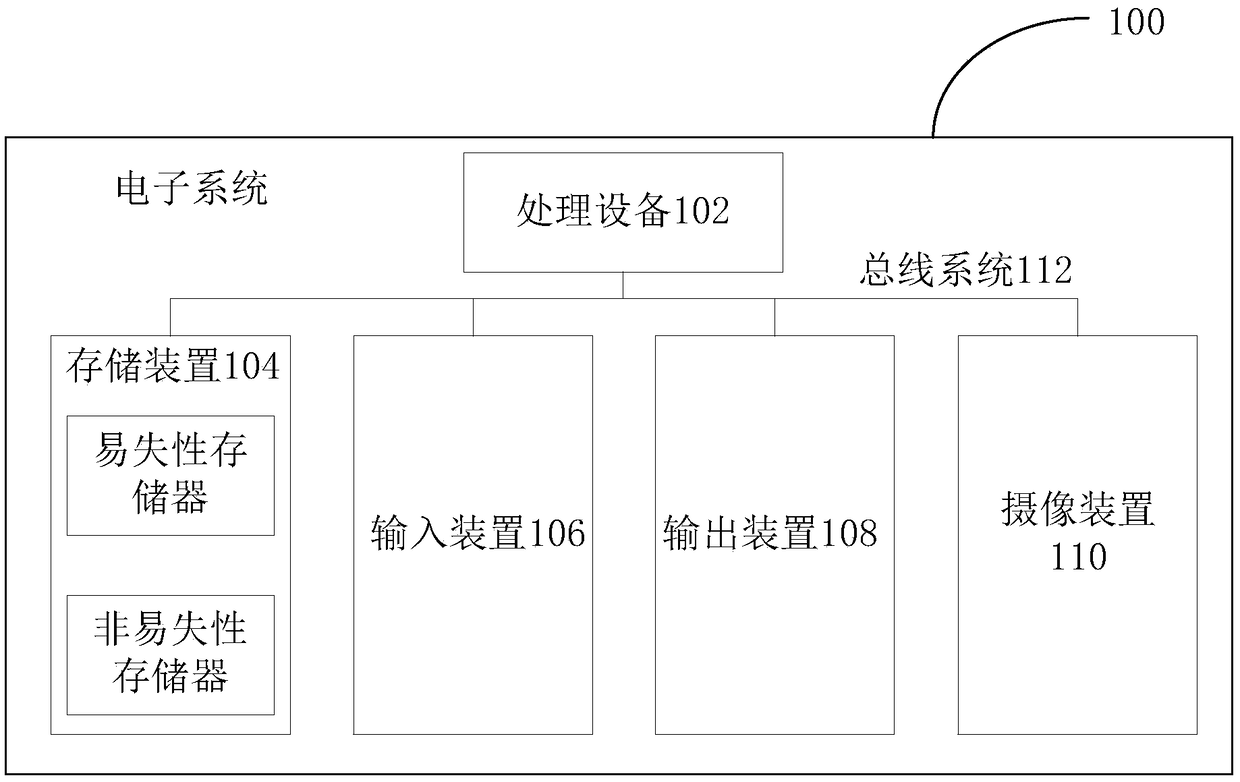

Information correlating method, device thereof and system

The invention provides an information correlating method, a device thereof and a system, wherein the method, the device thereof and the system relate to the field of intelligent recognition technology. The method comprises the steps of acquiring a plurality of video frame images in a target area; recognizing an object processing action track of a target object in a preset position range in the plurality of video frame images; if the object processing action track comprises a preset processing action, acquiring the object information of the object which corresponds with the processing action; and correlating the object information with the target object. The information correlating method, the device thereof and the system have advantages of realizing relatively comprehensive understandingof the interested object of a customer, improving customer shopping behavior analysis accuracy and realizing relatively low realization cost.

Owner:BEIJING KUANGSHI TECH

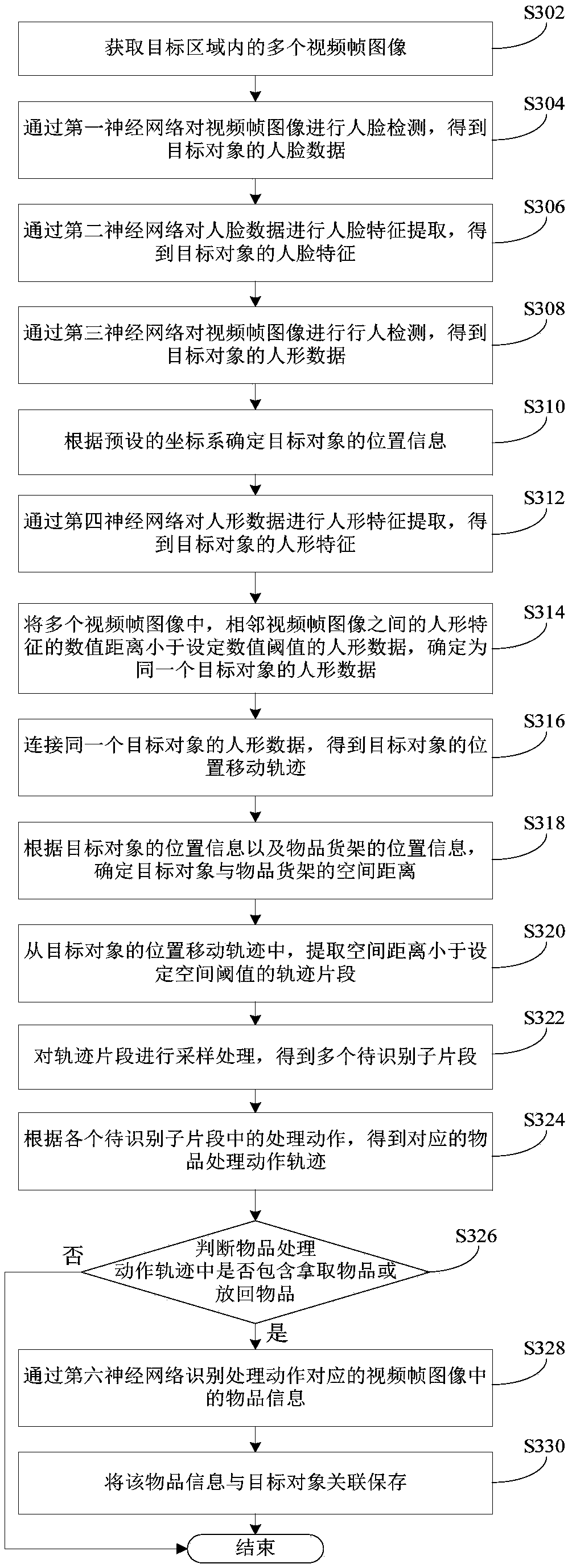

Human face recognition wireless video monitoring system based on cloud computing platform

InactiveCN102497531AGuaranteed uptimeReduce labor intensityCharacter and pattern recognitionClosed circuit television systemsVideo monitoringWireless transmission

A human face recognition wireless video monitoring system based on a cloud computing platform is characterized by consisting of the cloud computing platform (6), a monitoring server (5) and a wireless monitoring terminal (4). A wireless transmission module (1), a monitoring camera (2) and a smart encrypted TF (transflash) card (3) are installed on the wireless monitoring terminal (4). By the aid of human face recognition and encrypting authentication, safety running and working of the wireless video monitoring system are guaranteed, cost is saved and efficiency is improved. All wireless apparatuses are managed unitively clearly, full real-time monitoring can be realized, labor intensity of safety monitor personnel is reduced, wiring and wire modifying projects are convenient, building, installing, managing, position change and maintenance of the system are convenient and cost can be controlled easily.

Owner:SHANGHAI QINGLONG COMM TECH

Standardized construction method for hydraulic prefabricated member based on BIM (Building Information Modeling)

InactiveCN106326536APrecise layoutFast, accurate and reasonable arrangementDesign optimisation/simulationSpecial data processing applicationsEngineeringControl parameters

The invention provides a standardized construction method for a hydraulic prefabricated member based on BIM (Building Information Modeling). The standardized construction method comprises the following steps: S1, modeling a three-dimensional parameterization model by using a BIM modeling tool, and further implementing the design of three-dimension drawing according to the model; S2, dividing and classifying project units according to different members; S3, deploying corresponding members in a three-dimensional model of a specific project; S4, exporting to obtain an arrangement drawing, a detail table and control parameters of the members, and counting the project quantity of the members; S5, performing BIM on a prefabricated field, and guiding capital construction of the prefabricated field based on the BIM; S6, exporting the three-dimensional parameterization model, thereby performing specific three-dimension design and structure operation on the members; S7, simulating all stages of field operation for prefabricating the members; S8, implementing field prefabrication of the members; S9, prefabricating the members and implanting chips containing traceable prefabrication quality information of the members into the members; S10, after prefabrication of the members is finished, performing hanging safe construction on the members.

Owner:上海交通建设总承包有限公司

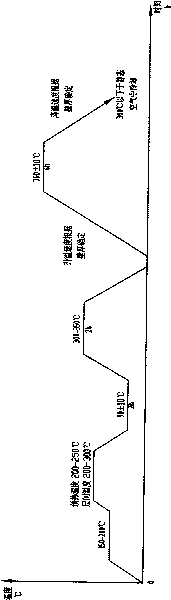

Continuous casting method for improving central shrinkage cavity of small high-carbon steel square billet

ActiveCN103506586AConducive to cost controlSimplified means of operationElectromagnetic stirringSteel square

The invention discloses a continuous casting method for improving a central shrinkage cavity of a small high-carbon steel square billet. According to the continuous casting method for improving the central shrinkage cavity of the small high-carbon steel square billet, the degree of superheat, the amount of blown argon of a submersed nozzle and full-protection casting are controlled, the cooling specific water flow for secondary cooling and casting speed are adjusted, and soft reduction of the final stage of electromagnetic stirring and solidification of each crystallizer is carried out. The specific technological parameters are that the amount of blown argon of the submersed nozzle is controlled to be 15-20L / min under the condition that the full-protection casting is adopted, the average casting speed of a casting blank corresponding to each crystallizer is 2.6-3.0m / min, the cooling specific water flow of cooling water in the secondary cooling section of each crystallizer is 0.8-1.2L / kg, and aerosol cooling is carried out; casting with the low degree of superheat is adopted in the whole process, the degree of superheat is 20-40 DEC C, and soft reduction of the final stage of the crystallizer electromagnetic stirring under the condition of 460-480 A and 5-7Hz and solidification under the 0.4-4.5m condition is adopted. The continuous casting method for improving the central shrinkage cavity of the small high-carbon steel square billet has the advantages that the flow of the inlet gas and the specific water flow can be accurately controlled, cost is reduced, and products meeting all specifications are produced through adjustment of all parameters.

Owner:ANGANG STEEL CO LTD

Model of mouth cavity biomembrane and method for forming mouth cavity biomembrane

InactiveCN1480110AVerify Application PerformanceSimple working processBioreactor/fermenter combinationsBiological substance pretreatmentsBottleBiological membrane

An oral biomembrane model equipment is composed of alkali solution container, culture medium container, fermentor, constant-current culture chambers and sample bottle. A process for forming the oral biomembrane includes aseptic connection of said equipment, inoculating experimental bacterial strain into fermentator, continuous culture, regulating pH=7.0, adding artificial saliva as culture medium, culturing, continuing to culture in parallel constant-current culture chambers, and mediating it on hydroxyphosphorite sheet to obtain oral biomembrane.

Owner:SICHUAN UNIV

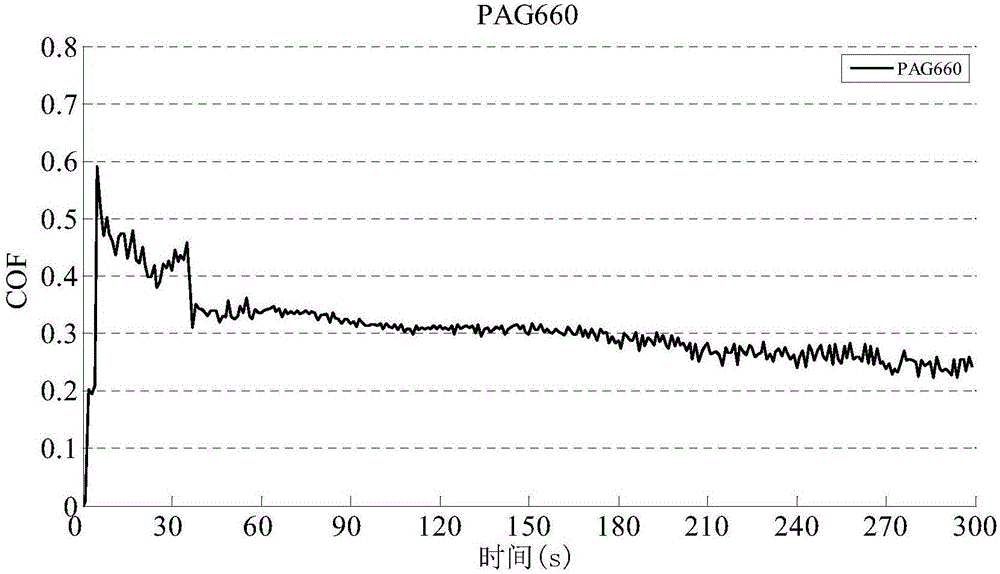

Water-based fully-synthetic titanium alloy cutting fluid

ActiveCN106479657ANot prone to corruptionExtended service lifeLubricant compositionWater basedNitrite

The invention relates to a water-based fully-synthetic titanium alloy cutting fluid. The titanium alloy cutting fluid is prepared from components in percentage by weight as follows: 1%-20% of a main lubricating agent, 1%-10% of an auxiliary lubricating agent and the balance of water. The titanium alloy cutting fluid belongs to a water-based fully-synthetic metal machining fluid, doesn't contain oily ingredients such as mineral oil, plant oil and the like, doesn't contain nitrite, secondary amine, formaldehyde, formaldehyde releasing substances, chlorine, chromium or other elements, is friendly to the environment and human bodies, doesn't easily decay and is long in service life.

Owner:超滑科技(佛山)有限责任公司

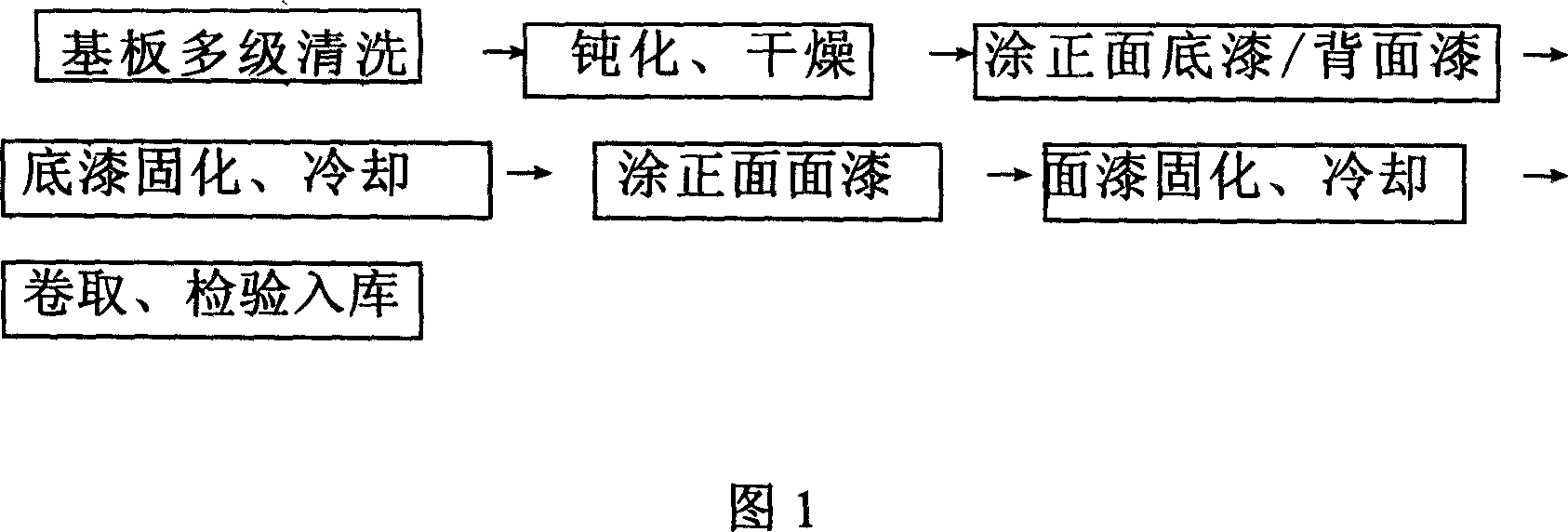

Multi purpose color coating boards, and preparation method

ActiveCN1958284AMeet different performance requirementsEasy to useSynthetic resin layered productsSpecial ornamental structuresEpoxyPollution

A multi-purpose coated color plate used to prepare corrugated plate or sandwich plate is composed of a coated layer on front surface, a basic plate, and a coated layer on back, which uses high-purity (90-99%) epoxy resin as its filming resin. Its preparing process is also disclosed, which features that the Ti-Ni pigments are used to replace Cr-Sr yellow pigment for improving its corrosion resistance and decreasing environmental pollution.

Owner:MAANSHAN IRON & STEEL CO LTD

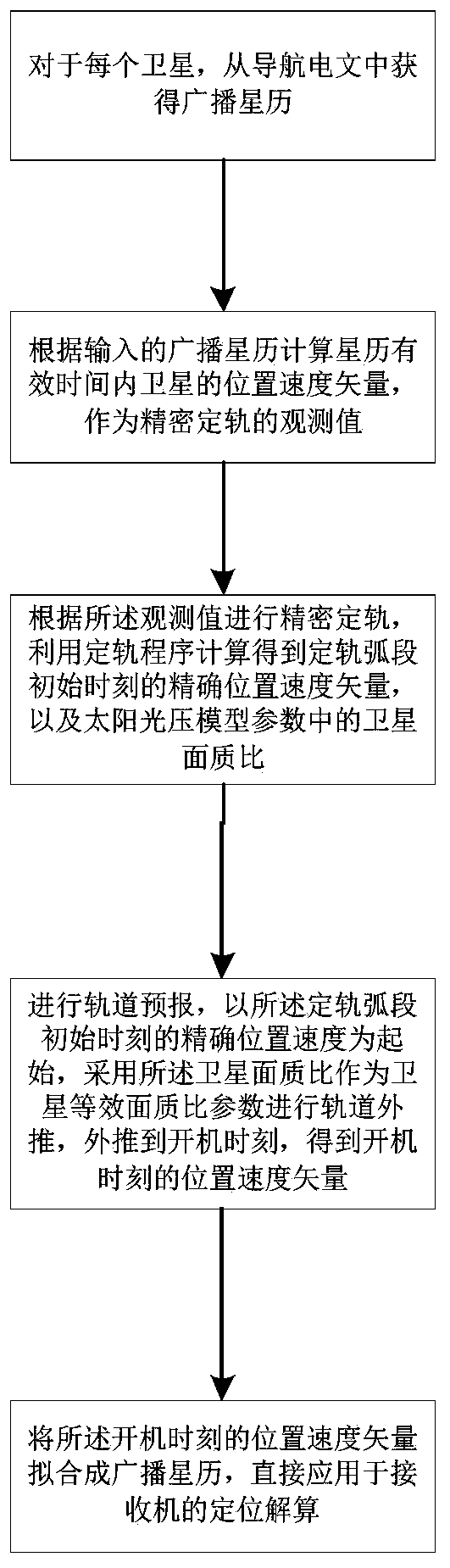

Method for autonomous ephemeris prediction of GPS receiver

ActiveCN109738919AReduce storage space requirementsConducive to cost controlSatellite radio beaconingMass ratioCost Controls

The invention discloses a method for autonomous ephemeris prediction of a GPS receiver. The method comprises the following steps: step one, computing a location speed vector of a satellite in ephemeris effective time according to input broadcast ephemeris as an observation value of precise orbital determination; step two, performing precise orbital determination according to the observation value,computing by utilizing an orbital determination program to obtain a precise location speed vector at initial moment of an orbital determination segmental arc, and a satellite area-mass ratio in a solar radiation pressure model parameter; step three, performing orbital forecast, taking the precise location speed at the initial moment of the orbital determination segmental arc as the starting, taking the satellite area-mass ratio as the satellite equivalent area-mass ratio parameter to perform orbit extrapolation, and extrapolating to turn-on moment; and step four, fitting the location speed quantity at the turn-on moment as the broadcast ephemeris to give out the forecast ephemeris, and directly applying the forecast ephemeris to positioning resolution of a receiver location. The first positioning duration of the receiver not in warm start is greatly shortened, a requirement on a chip storage space is reduced, and the cost control of the chip is convenient.

Owner:西安开阳微电子有限公司

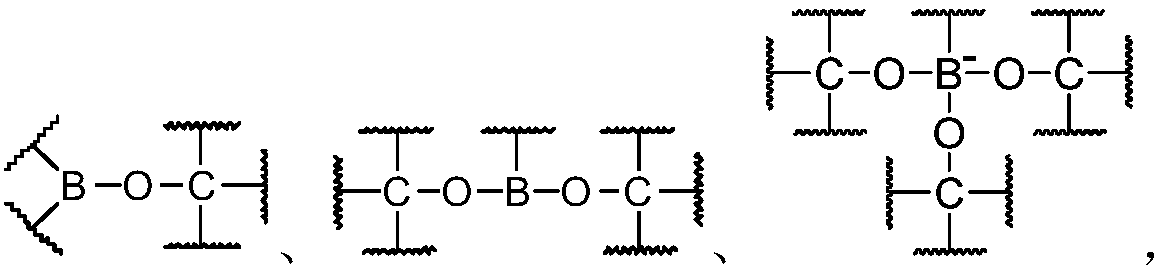

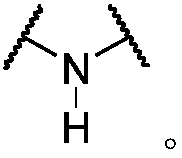

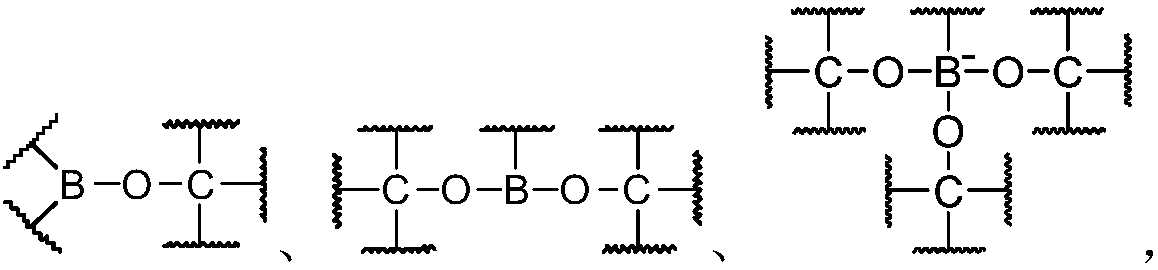

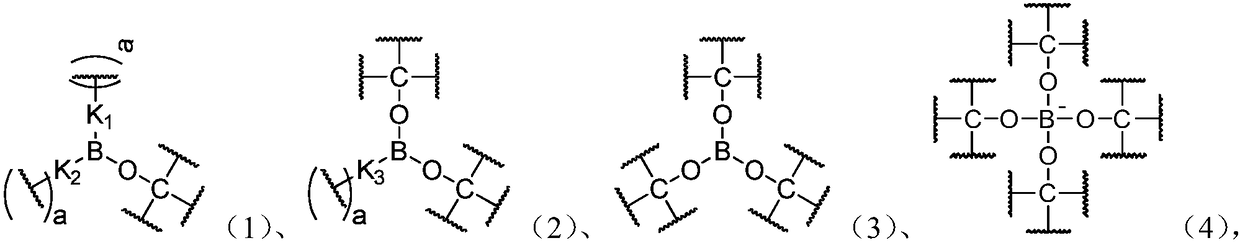

Dynamic polymer with hybrid cross-linked network and application thereof

The invention discloses a dynamic polymer with a hybrid cross-linked network. The dynamic polymer contains common covalent cross-linking and dynamic covalent organic borate bonds. The dynamic polymerintegrates the respective advantages of the dynamic covalent organic borate bonds and the common covalent cross-linking, and polymeric materials of abundant structures and with diversified propertiescan be prepared by regulating the structures of reactants. The high dynamic reversibility of the dynamic covalent organic borate bonds in the dynamic polymer allows the polymer to present the functional characteristics of stimulation responsiveness, self repair performance; the common covalent cross-linking endows the dynamic polymer with certain strength and stability; moreover, based on the dynamic nature of the dynamic organic borate bonds, the dynamic polymer has the characteristics of energy dissipation and energy absorption and the good functions of damping, shock absorption, sound insulation, impact resistance, high toughness and the like. The dynamic polymer can be used for preparing damping and buffering materials, anti-impact protection materials, self-repairing materials, toughmaterials, force transducers, etc.

Owner:厦门天策材料科技有限公司

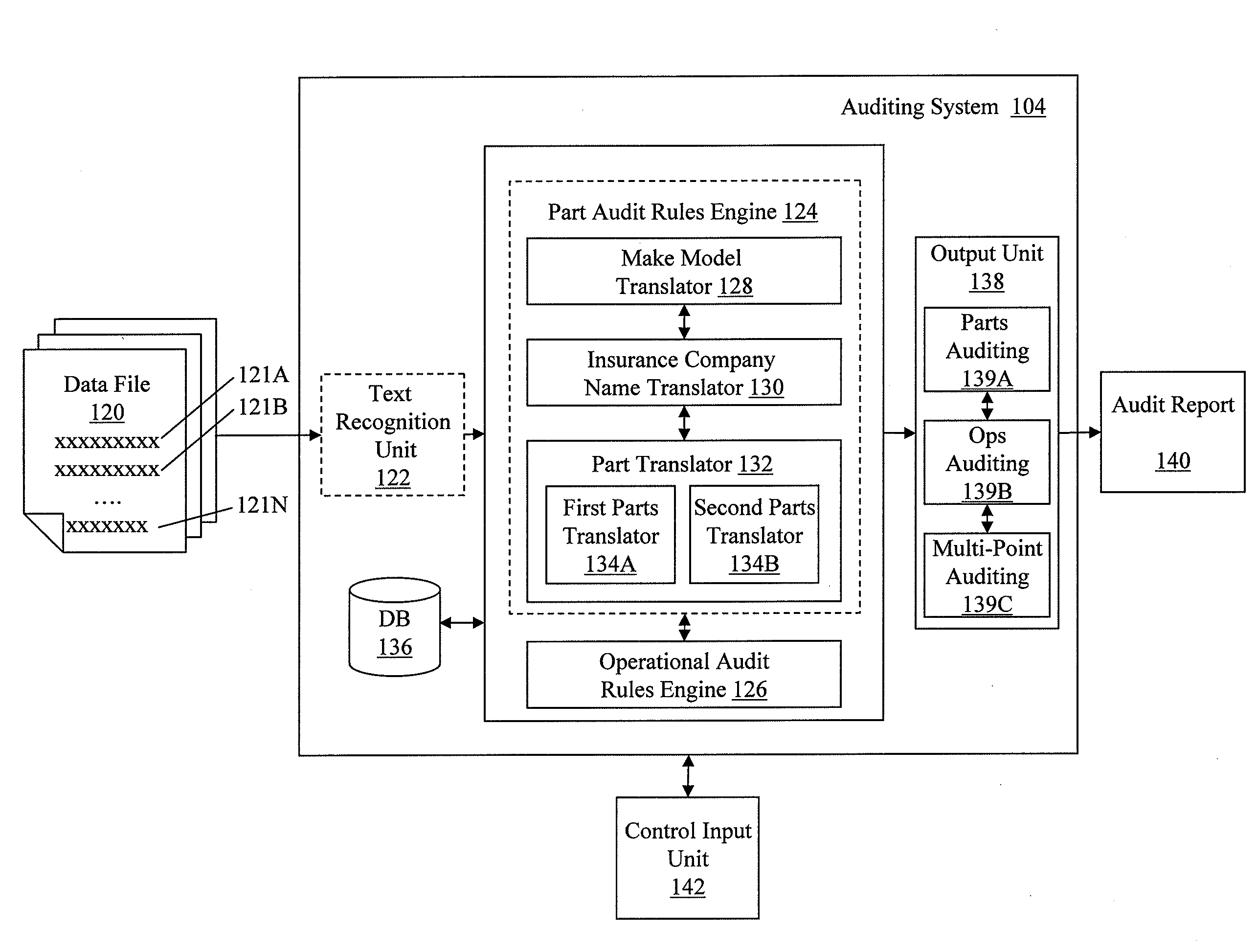

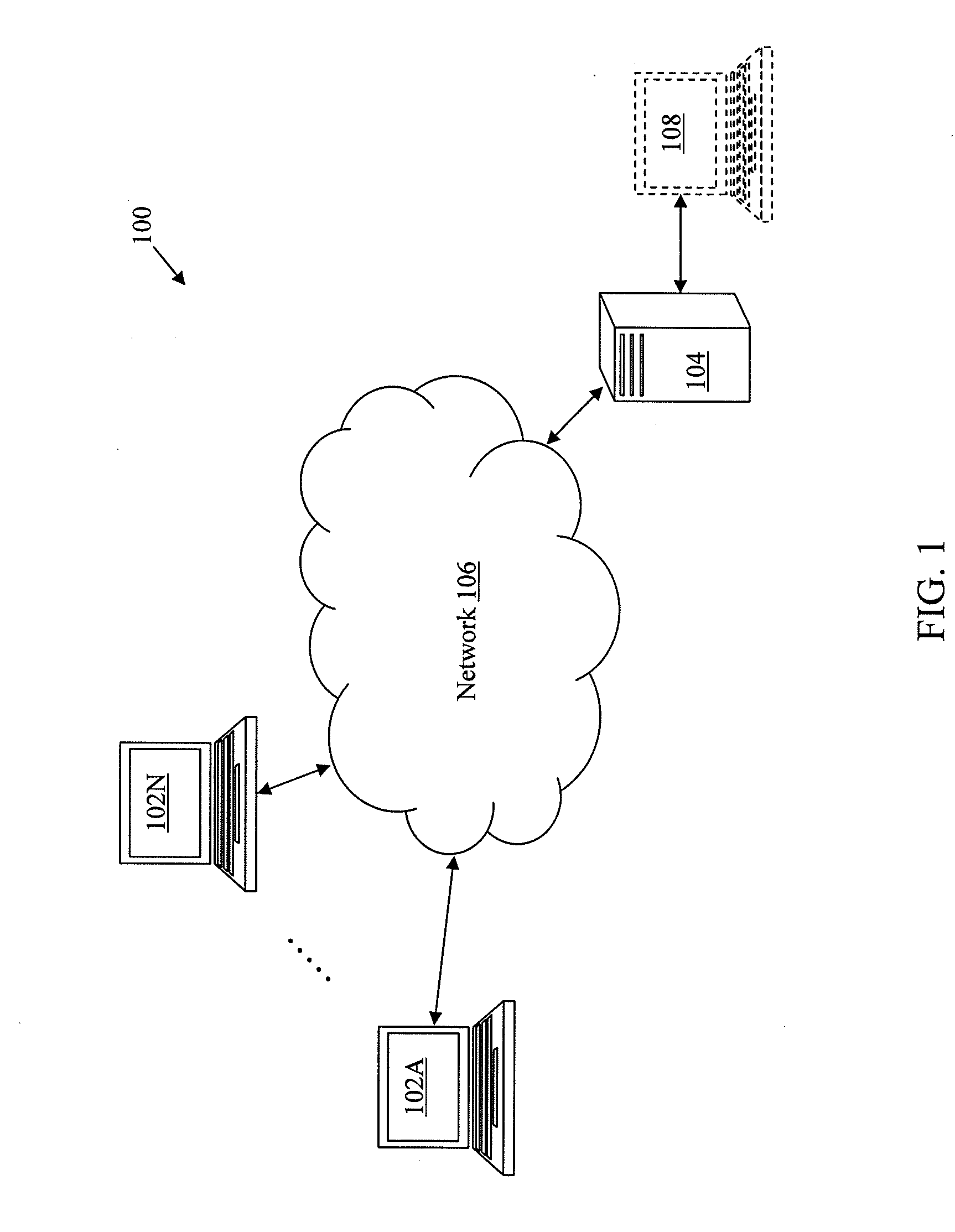

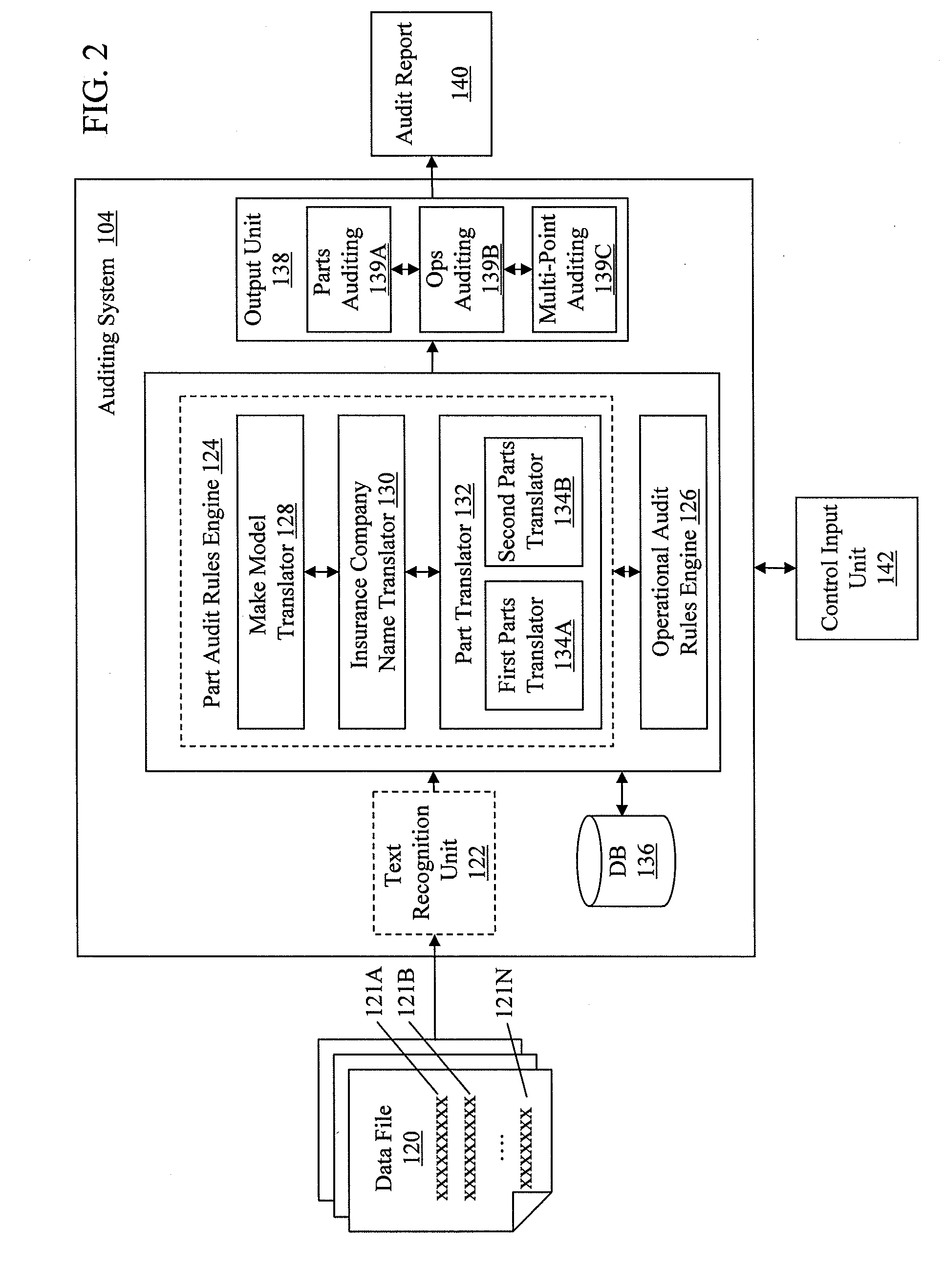

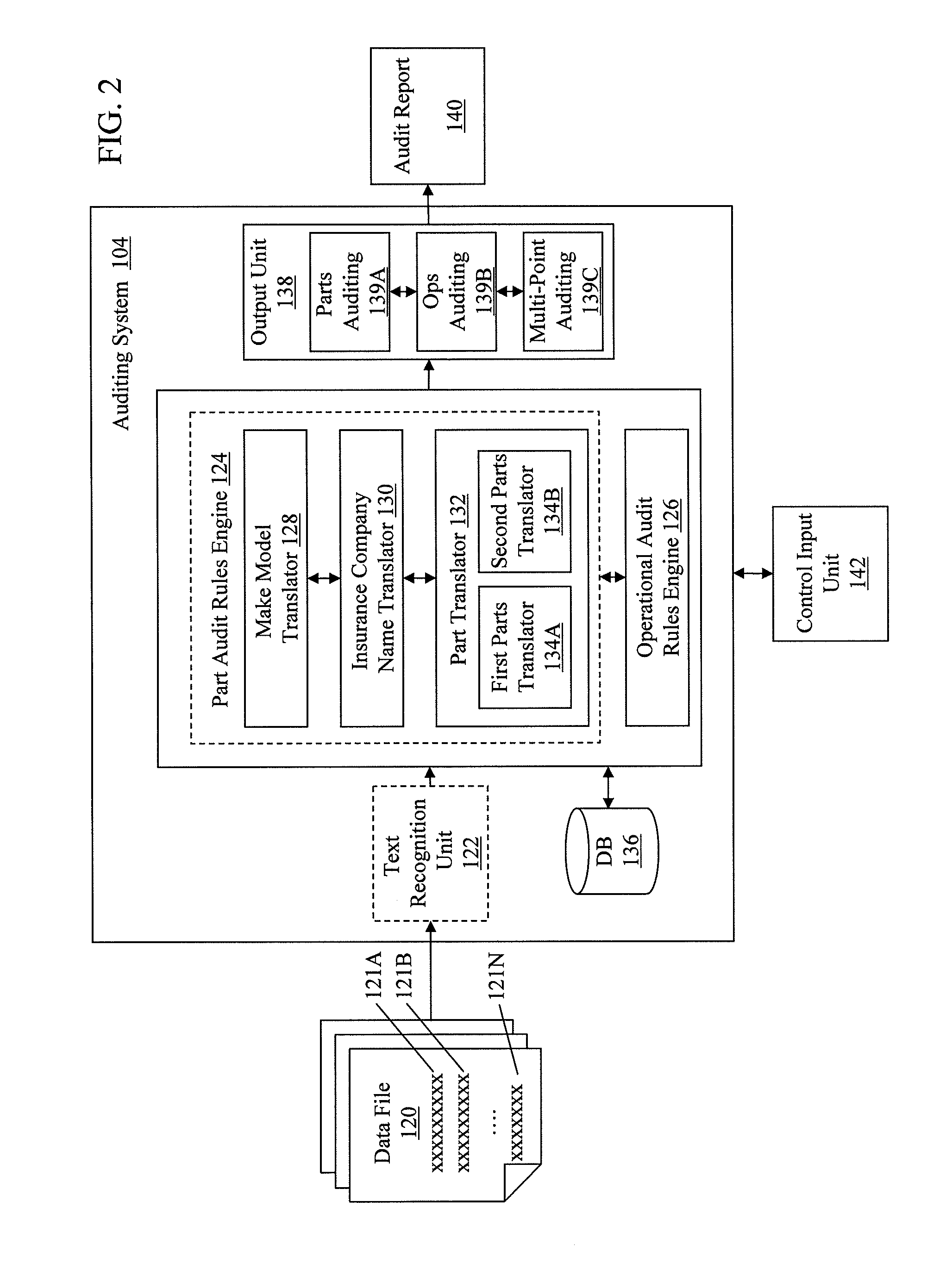

Automation of auditing claims

Described are computer-based methods and apparatuses, including computer program products, for automation of auditing claims. A data file comprising make model information, insurance company information, and one or more auditable items, each auditable item comprising a word string having one or more words. The make model information is automatically translated into a vehicle identifier. The insurance company information is automatically translated into an insurance company identifier. The one or more auditable items are automatically translated into one or more groups of identifiers, wherein the one or more groups of identifiers comprises one or more part item identifiers, one or more operational item identifiers, or both. A parts audit report is automatically generated based on the one or more groups of identifiers. An operational audit report is automatically generated. A multi-point estimate is automatically generated based on the parts audit report data and the operational audit report data.

Owner:HYPERQUEST

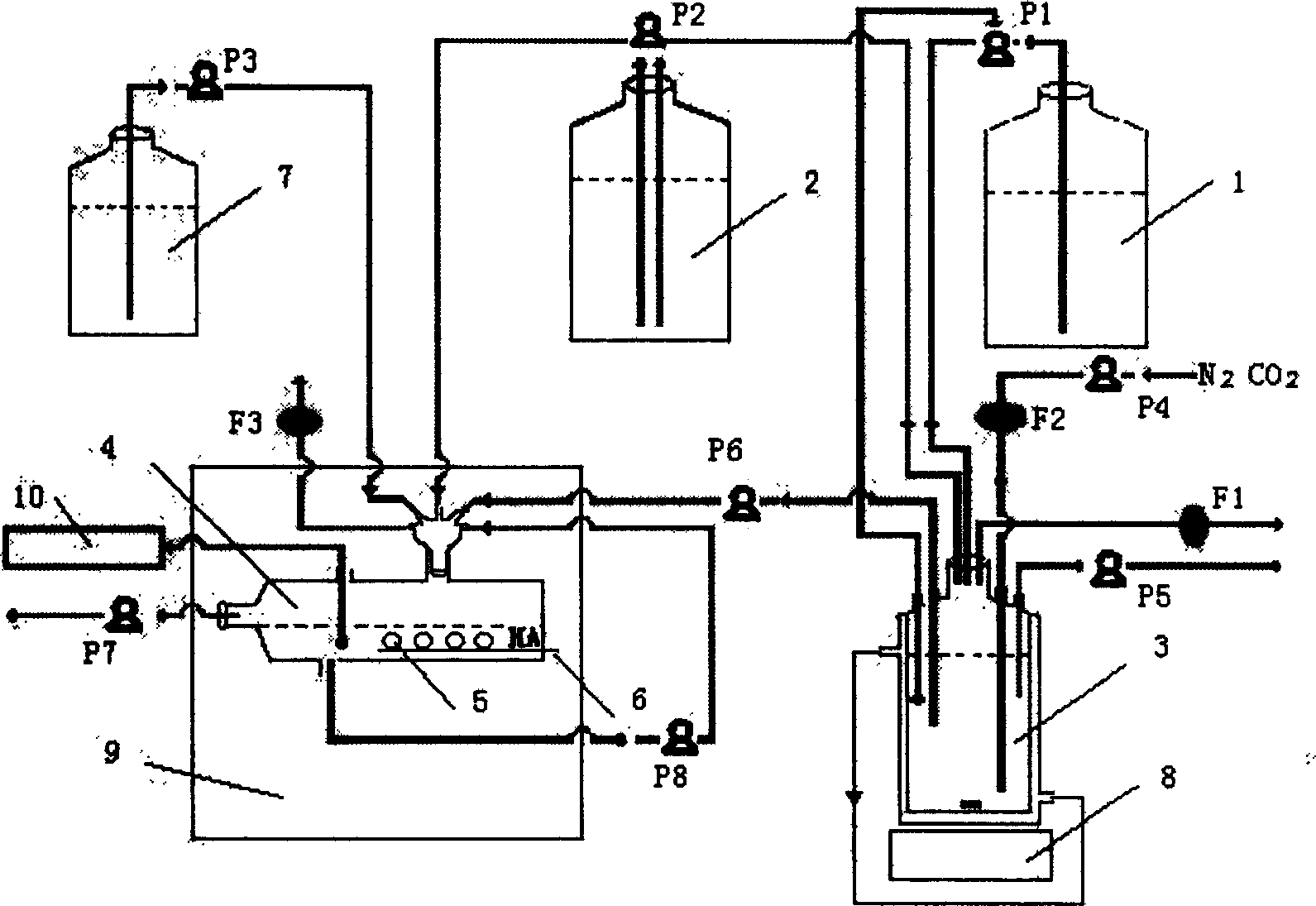

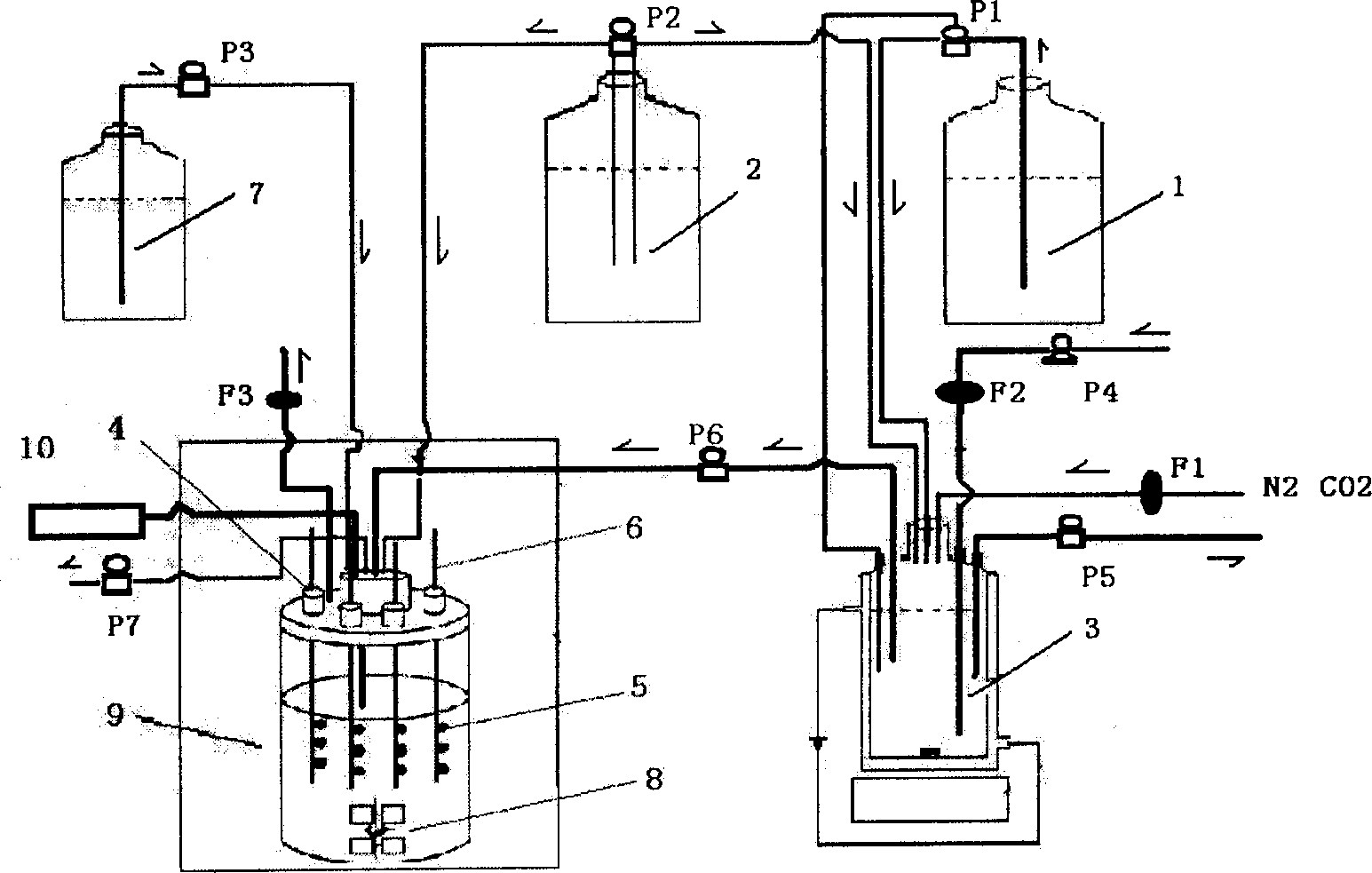

Oral biological film dynamic model device and its oral biological film forming method

InactiveCN1858200ARealize longitudinal continuous real-time monitoringEfficient formationBioreactor/fermenter combinationsBiological substance pretreatmentsPeristaltic pumpDynamic models

The dynamic oral cavity biomembrane model device includes an alkali liquor tank, a culture medium tank, a fermenting tank, a constant flow culture chamber and a sample applying bottle. It features the constant flow culture chamber comprising several serially connected vertical standard cylindrical constant flow culture chambers, the alkali liquor tank connected through peristaltic pump P1 to the fermenting tank, the culture medium tank connected peristaltic pump P2 to the fermenting tank, the fermenting tank with N2 and CO2 introduction through filter F2 and peristaltic pump P4 and waste liquid and waste gas exhaust through peristaltic pump P5 and filter F1, the constant flow culture chamber connected through peristaltic pump P6 to the fermenting tank and with waste liquid and waste gas exhaust through peristaltic pump P7 and filter F3, and the culture medium tank and the sample applying bottle connected through peristaltic pumps P2 and P3 to the constant flow culture chamber.

Owner:SICHUAN UNIV

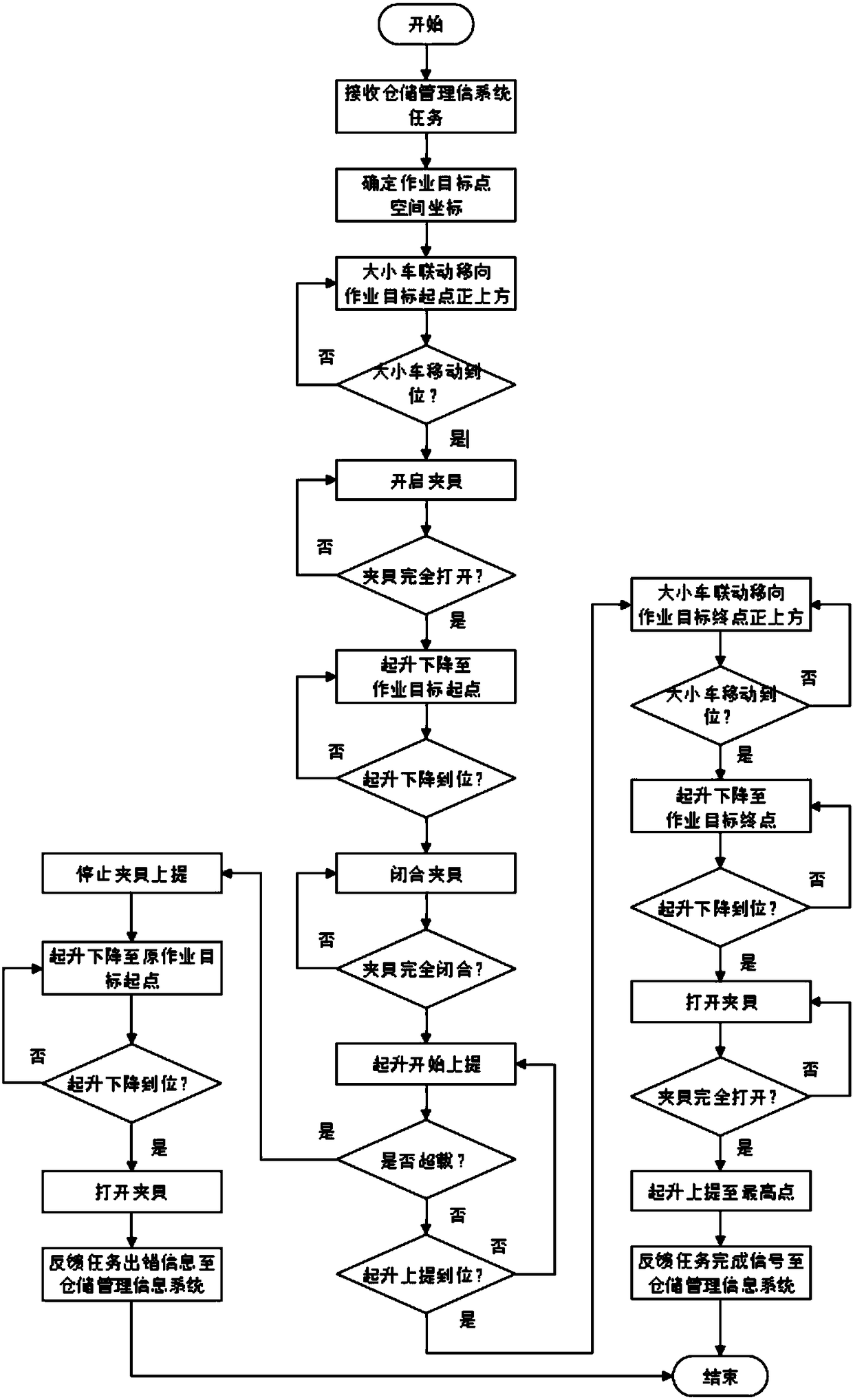

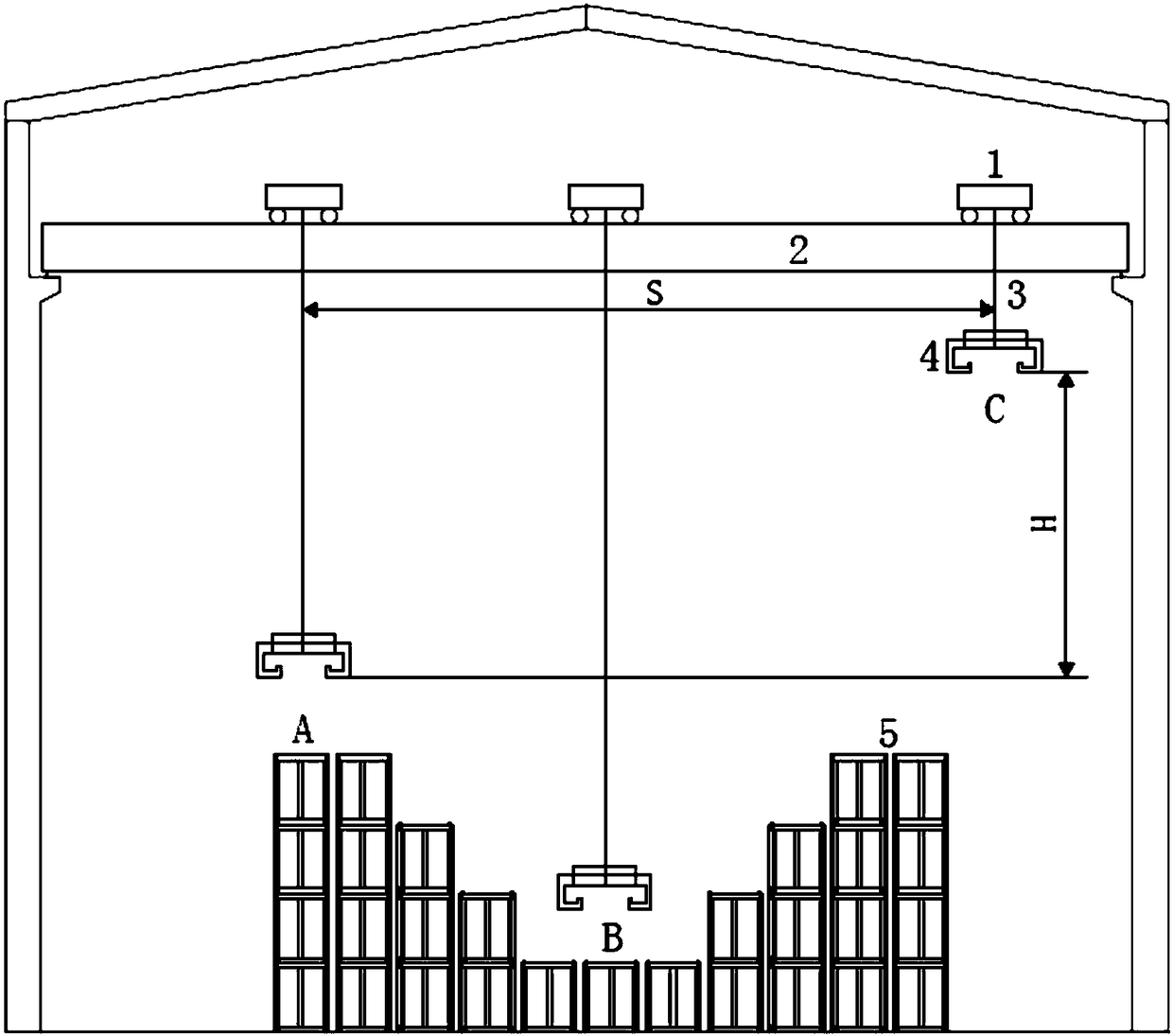

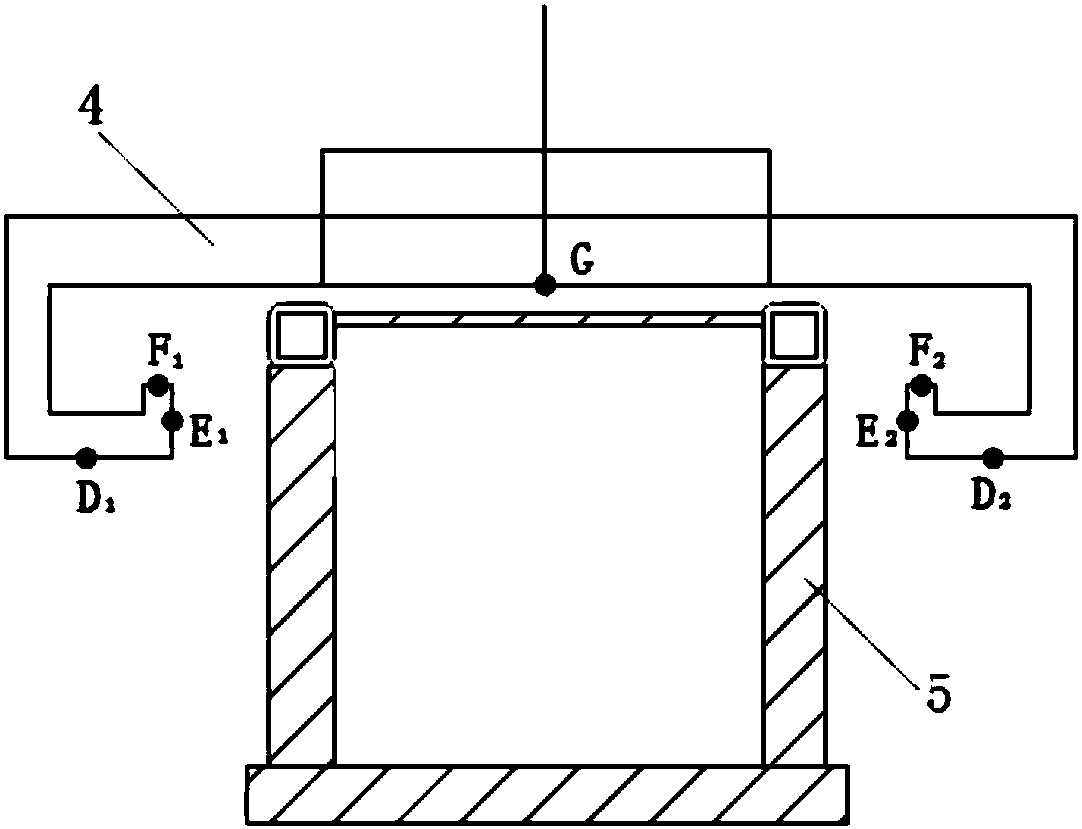

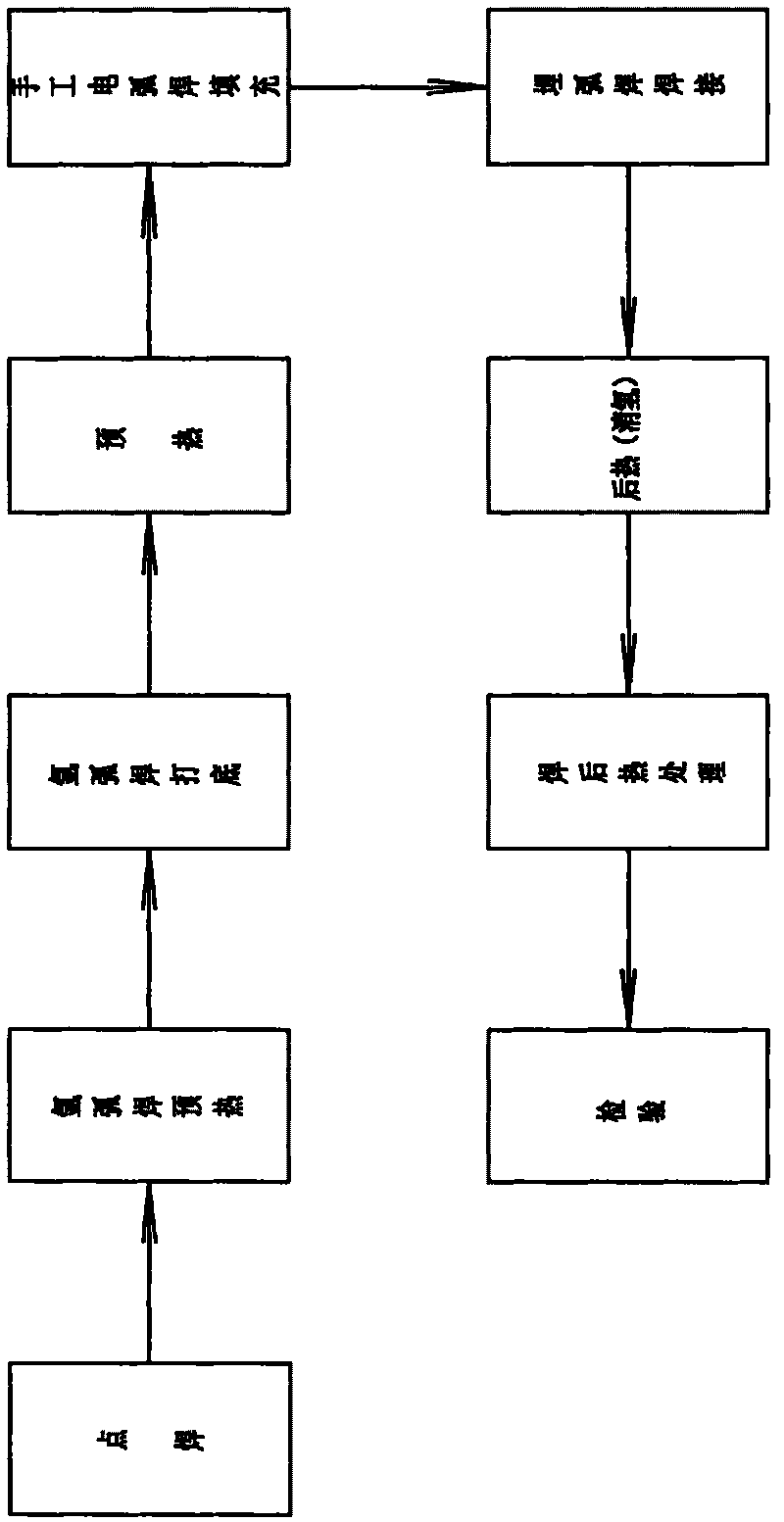

Automatic operation control method for full-automatic bridge-type storage crane

InactiveCN108545614AFully automatedAchieve mutual coordinationGeometric CADSpecial data processing applicationsAutomatic controlCost Controls

The invention discloses an automatic operation control method for a full-automatic bridge-type storage crane, the automatic operation control method comprises the following steps: space coordinates ofa working target point can be determined, a control system is used to realize automatic positioning of a big car, a trolley and a lifting mechanism, a clamp clamps goods, a proximity sensing sensor performs reliable clamping detection, the goods are lifted up and put down, the lifting mechanism automatically raises the clamp to a highest point, and a crane control system feeds back a completion signal of the operation to an upper storage management information system. The automatic operation control method can realize automatic speed planning of the full-automatic bridge-type storage crane, aflexible speed planning algorithm with jerk limitation can ensure the smooth running of each mechanism, thereby reliably realizing the automation of addressing operation points; at the same time, mutual coordination of the lifting mechanism and the clamp can be realized, and the automation of clamping or stacking of the goods can be realized; the working efficiency and reliability of the storagecrane can be improved, working conditions can be improved, energy consumption can be saved, and the automatic operation control method helps enterprises to control cost.

Owner:WUHAN UNIV OF TECH

Submerged automatic arc welding method of SA335P91 steel

ActiveCN101700599AIncrease productivityFast welding speedArc welding apparatusShielded metal arc weldingEngineering

The invention discloses a submerged automatic arc welding method of SA335P91 steel. After a welded junction is preheated, welding is carried out according to the following steps of backing welding by adopting an argon arc welding wire; manual arc welding; submerged automatic arc welding, integral heat treatment after welding and weld inspection. In the method, the working procedure of the backingargon arc welding is carried out before the submerged automatic arc welding so that root oxidation is prevented, the positioning problem of welding is ensured, and a good foundation for subsequent working procedures is provided. Along with the rapid development of supercritical units and the popularization and the application of SA335P91 materials in China, the welding technology can be widely applied to weld the welded junctions of the SA335P91 materials of four pipelines and boiler pipelines in factorial piping of supercritical units in heat power plants.

Owner:HENAN HUADIAN JINYUAN PIPING

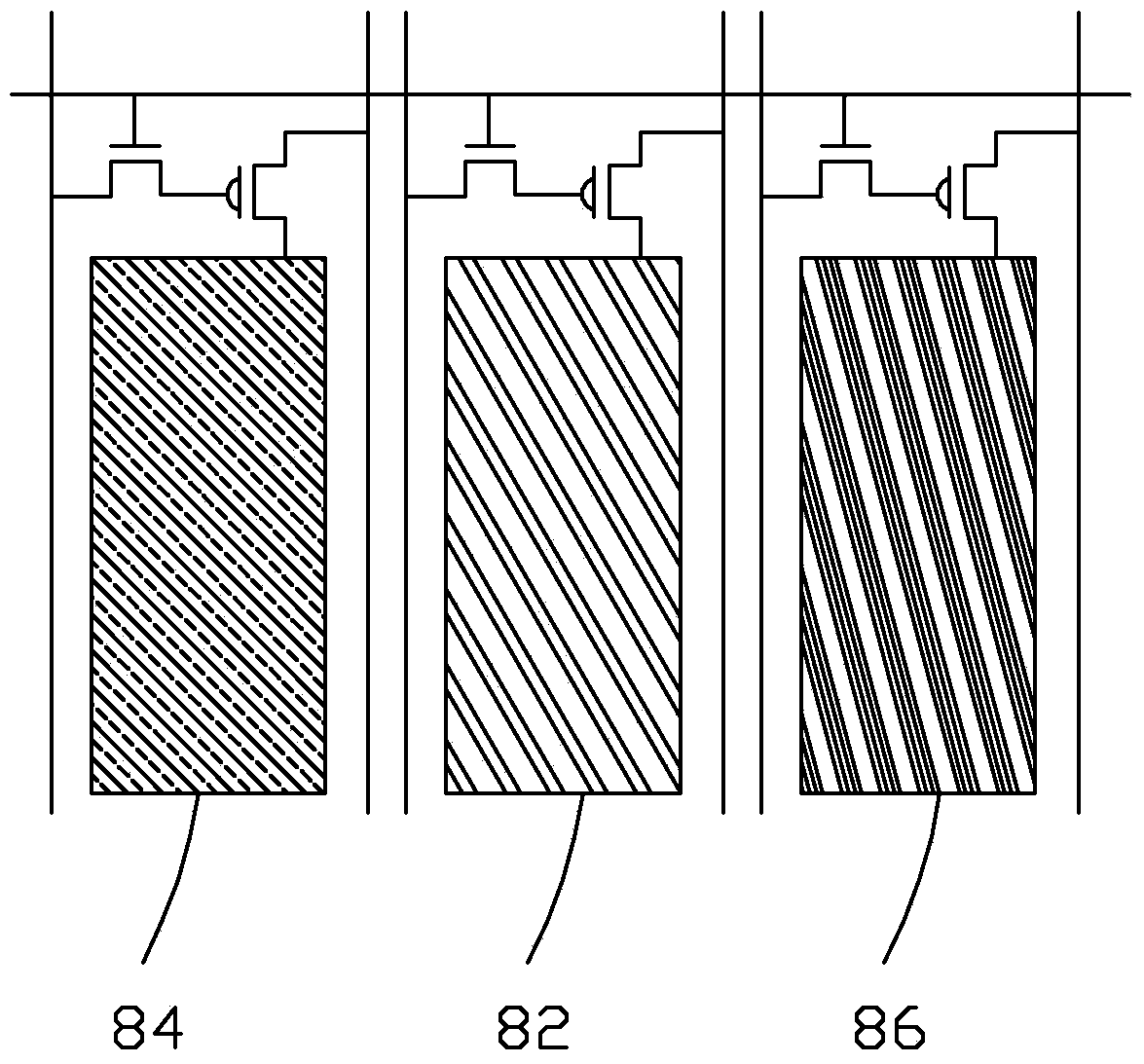

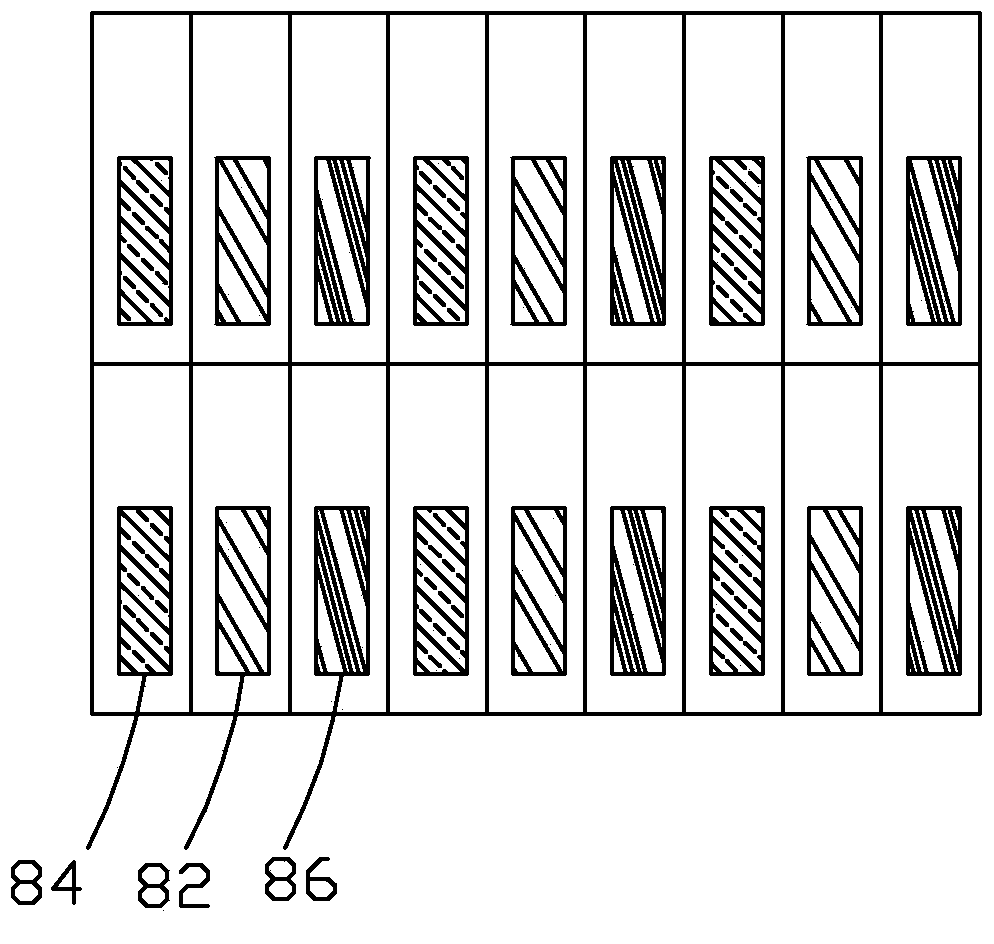

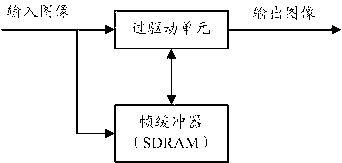

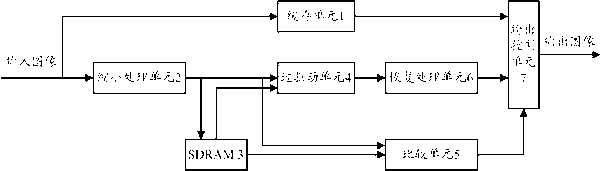

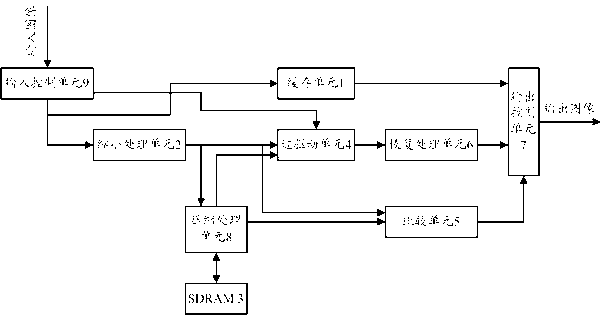

Image processing device and method and liquid crystal display

ActiveCN103065601AGuaranteed qualitySave spaceStatic indicating devicesError detection/correctionImaging processingLiquid-crystal display

The invention provides an image processing device which comprises a cache unit, a reduction processing unit, an SDRAM (synchronous dynamic random access memory), an overdrive processing unit, a comparison unit, a recovery processing unit and an output control unit. The invention also provides an image processing method and a liquid crystal display. The image processing device and method and the liquid crystal display provided by the invention do not directly perform overdrive processing on an input high-definition image but cache the input high-definition image in the cache unit while performing reduction processing on the input high-definition image, so that the image data quantity is reduced when in practical overdrive processing, the consumed SDRAM space is correspondingly reduced, the number of the SDRAM is not necessarily increased for inputting high-definition images, and the cost is easy to control. During output, a static image is directly output; and for a dynamic image, the image subjected to overdrive processing and recovered to the original definition is output so as to maintain the image quality.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

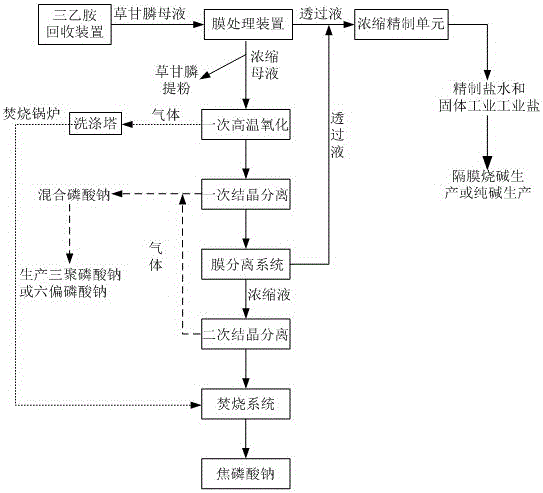

Incineration treatment process for glyphosate mother liquor

ActiveCN106082515ASolve the problem of low oxidation conversionSolve processing problemsGroup 5/15 element organic compoundsWater/sewage treatment bu osmosis/dialysisGlyphosateFlue gas

The invention discloses an incineration treatment process for glyphosate mother liquor. The incineration treatment process comprises the following steps: the glyphosate mother liquor is fed to a membrane treatment device, concentrated mother liquor and a permeate liquid are obtained; the concentrated mother liquor is subjected to glyphosate powder extraction and subjected to primary oxidation, primary crystalizing separation, treatment with a membrane separation system and secondary crystalizing separation, a product enters an incineration system, tetrasodium pyrophosphate is obtained, and flue gas produced through incineration is subjected to secondary burning after dust separation and then is emitted. The membrane treatment concentration technique for the glyphosate mother liquor is combined with the incineration process for the first time and used for completely solving the problem about treatment of the glyphosate mother liquor, salt obtained after incineration can be recycled, the flue gas produced through incineration is subjected to dust separation and secondary burning, so that dioxin in the flue gas can be reduced remarkably, and the environmental requirements are met.

Owner:SICHUAN LESHAN FUHUA TONGDA AGRO-CHEM TECH CO LTD

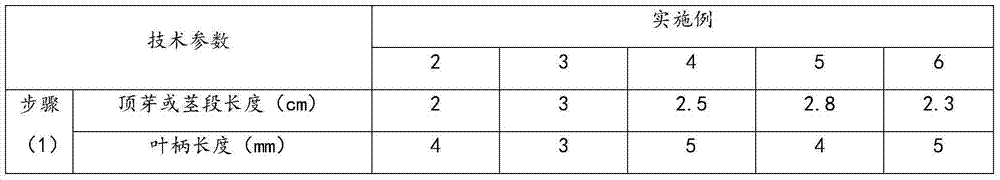

Rooting culture method of catalpa bungei tissue culture seedling

ActiveCN104719136AReduce manufacturing costEasy to industrializeHorticulture methodsPlant tissue cultureWoody plantCulture mediums

The invention discloses a rooting culture method of catalpa bungei tissue culture seedling. The method sequentially comprises the following steps: (1) obtaining aseptic seedlings of the catalpa bungei; (2) subculturing the aseptic seedlings; (3) performing rooting culture of the catalpa bungei tissue culture seedlings; (4) hardening seedlings and transplanting. By adopting the catalpa bungei tissue culture seedling rooting culture method, the propagation ratio is controlled to 1: (3-3.5), the height of the plant of the seedlings is controlled to be 2.5-4cm, and the rooting culture is carried out to guarantee that the rooting proportion is up to 90 percent or above; the production cost is reduced, and the same culture medium is used in the steps of obtaining the aseptic seedlings and subculturing during the rooting culture of the catalpa bungei tissue culture seedling, so that an operation step is eliminated and the production cost is reduced, thus being more suitable for industrial production. According to the rooting culture method of the catalpa bungei tissue culture seedling, the forest tissue culture industrialization for an experiment is realized, the industrialization process is simplified, the steps are reduced, the labor force is controlled, and the cost control is facilitated, thus promoting the industrialization of the woody plant tissue culture. The method is suitable for the rooting culture of the catalpa bungei tissue culture seedling.

Owner:上海菁艺生物科技有限公司

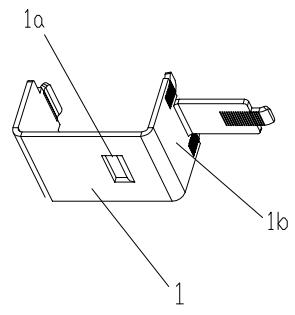

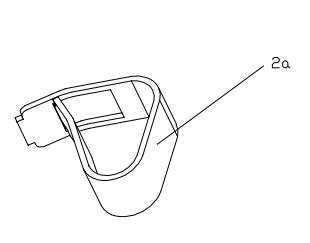

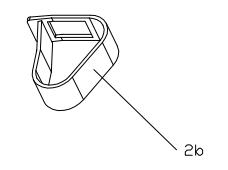

The installation structure of the connection terminal of the photovoltaic junction box

ActiveCN102291054AReduce temperatureConducive to cost controlPhotovoltaicsPhotovoltaic energy generationHeat resistanceEngineering

The invention discloses a mounting structure of a photovoltaic junction box connecting terminal. The mounting structure comprises a photovoltaic junction box base, a connecting terminal assembly and a diode; a mounting board is arranged in the photovoltaic junction box base; the connecting terminal assembly and the diode are installed on the mounting board; and the mounting board is connected in the photovoltaic junction box base in a clamping manner or is integrally injection molded in the photovoltaic junction box base. As the connecting terminal assembly is connected with the photovoltaic junction box base through the mounting board, the mounting board can adopt heat resistance and high intensity materials and can meet the requirement on the performance, moreover, as the mounting board is small in volume, the cost can be controlled, and the removable design of the mounting board is also convenient for automatic assembling and maintenance. In addition, the diode is arranged between two connecting terminals, a diode shell clings to one end of a radiating support element, so that the heat of the diode can be fast transferred to the radiating support element, the temperature of the diode can be reduced and the reliability of the diode can be improved.

Owner:浙江正泰鑫辉光伏有限公司

Automation of auditing claims

ActiveUS8073718B2Shorten the timeLow costDigital data information retrievalFinanceModel NumberData mining

Described are computer-based methods and apparatuses, including computer program products, for automation of auditing claims. Data indicative of a vehicle make and model is received, the data comprising one or more make fields and one or more model fields. The one or more model fields are prepared for translation. The one or more make fields are prepared for translation by applying one or more rules from the plurality of rules. Each field of the one or more make fields is associated with one or more make model entries from a plurality of predetermined make model entries. Each field of the one or more model fields is associated with one or more make model entries from the plurality of predetermined make model entries. The data is automatically translated into one or more vehicle identifiers based on the associated make model entries.

Owner:HYPERQUEST

Dust-suppression and haze-reduction bituminous mixture and preparation method thereof

ActiveCN104803629AEffective absorptionIncrease moisture contentBuilding insulationsAluminium chlorideRoad surface

The invention discloses a dust-suppression and haze-reduction bituminous mixture which is a composite material and comprises mineral aggregate and dust-suppression and haze-reduction asphalt, wherein the dust-suppression and haze-reduction asphalt comprises matrix asphalt and a dust-suppression and a haze-reduction asphalt modifier; the dust-suppression and haze-reduction asphalt modifier comprises a dust-suppression component and an anti-stripping component; the dust-suppression component comprises one or more of calcium chloride, ferric chloride, aluminium chloride, calcium oxalate and potassium oxalate; the anti-stripping component comprises one or more of calcium lignosulphonate, sodium lignosulphonate and petroleum resin. The invention further discloses a preparation method of the dust-suppression and haze-reduction bituminous mixture. The preparation method comprises the following steps: preparing the dust-suppression and haze-reduction asphalt and mixing and stirring the dust-suppression and haze-reduction asphalt and mineral aggregate at certain temperature. The dust-suppression and haze-reduction bituminous mixture can absorb moisture in air and forms a water film on a road surface to increase moisture content of dust, so that the dust cannot be raised by passing vehicles easily, and the dual effects of dust-suppression and haze-reduction and water conservation are realized.

Owner:BEIJING UNIV OF CIVIL ENG & ARCHITECTURE

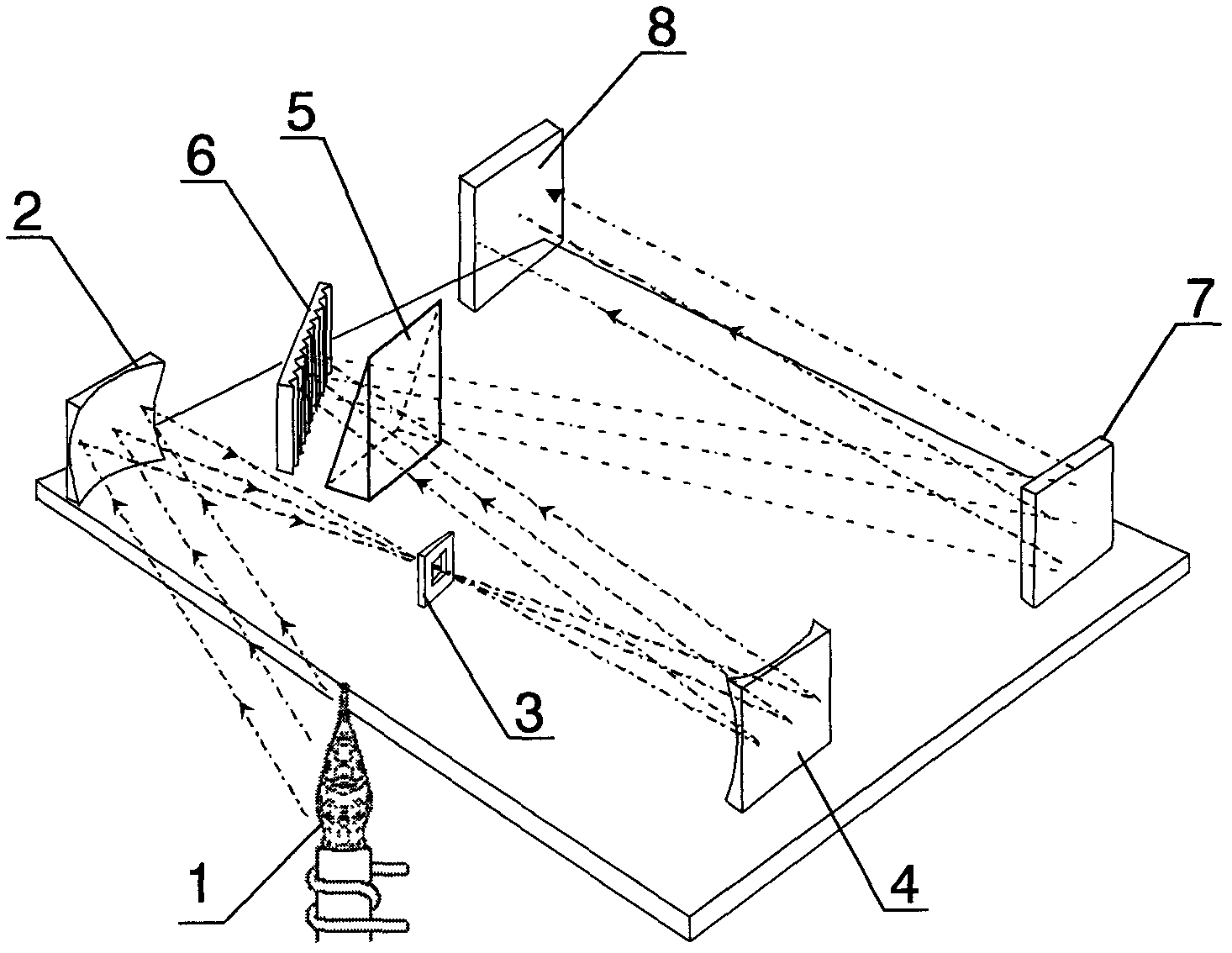

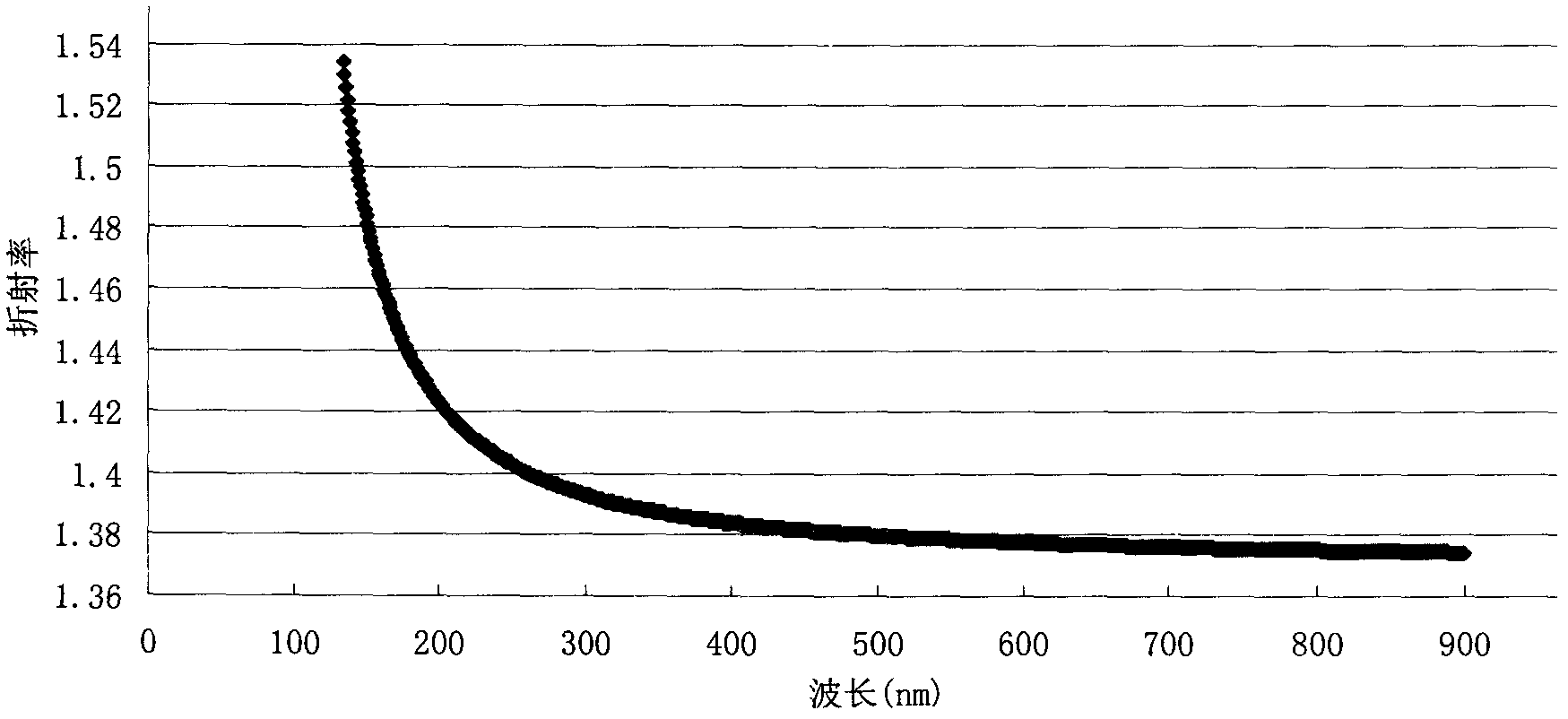

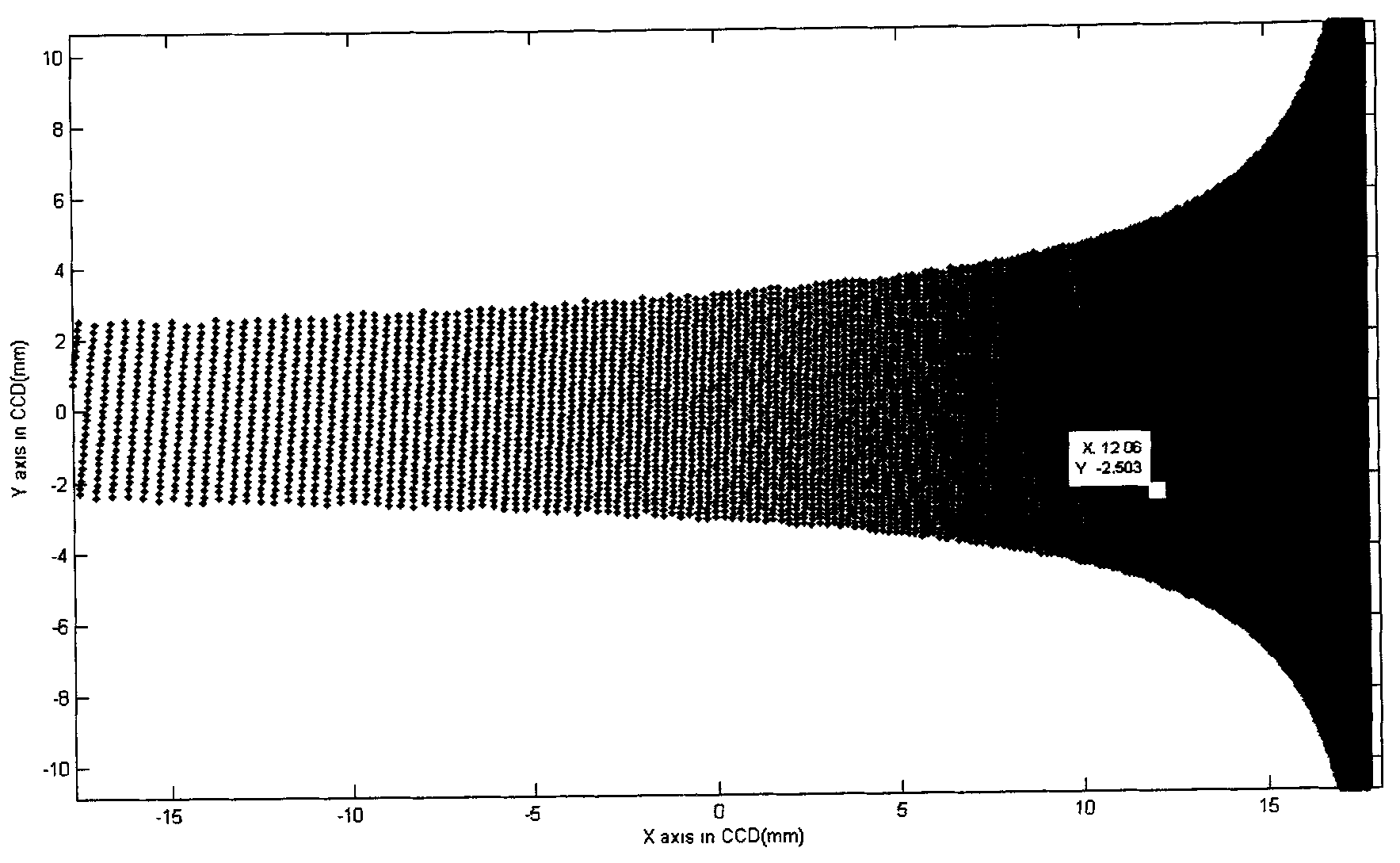

Light splitting device and method for improving spectrum probing range

ActiveCN102539360AConducive to cost controlEliminate overlapping interferenceRadiation pyrometryColor/spectral properties measurementsMaintainabilityWavelength

The invention provides a light splitting device for improving the spectrum probing range, which includes a first light splitting unit, a second light splitting unit, a detection unit and a processing unit, wherein the first light splitting unit is used for light splitting of measured light, and the wave length of the measured light covers the range of [lambda1, lambda 2]; the second light splitting unit includes chromatic dispersion component(s) Mi used for the light splitting of measured light before or / and after passing by the first light splitting unit and having different light splitting capabilities, wherein I equals to 1, 2 to N, and N equals to or is lager than 2, and the chromatic dispersion direction of the first and the second light splitting units are mutually vertical; the detection unit is used for converting optical signals of the received measured light passing by the first light splitting unit or the chromatic dispersion component(s) Mi into electrical signals Ii respectively, and transmitting the electrical signals to the processing unit, wherein I equals to 1, 2 to N, and N equals to or is lager than 2; and the processing unit is used for combining the received electrical signals Ii, so as to obtain the light intensity distribution of the measured light in the range of [lambda1, lambda 2], wherein I equals to 1, 2 to N, and N equals to or is lager than 2. The light splitting device provided by the invention has the advantages of excellent stability, simplicity in installation and debugging, excellent maintainability, low cost and the like.

Owner:FOCUSED PHOTONICS

Energy-absorbing method based on hybrid cross-linked network dynamic polymer

The invention discloses an energy-absorbing method based on a hybrid cross-linked network dynamic polymer. The method is characterized in that the hybrid cross-linked network dynamic polymer containing common covalent cross-linking, a dynamic covalent bond and an optional supramolecular hydrogen bond is used as an energy-absorbing material for energy-absorbing protection, wherein the dynamic covalent bond is an inorganic borate bond. The dynamic polymer provided by the invention integrates the respective advantages of the common covalent cross-linking and the dynamic covalent bond; the commoncovalent cross-linking endows the dynamic polymer with certain strength and stability; the dynamic covalent bond in the dynamic polymer has good dynamic reversibility, so the dynamic polymer has the characteristics of energy dissipation and energy absorption and can provide the functions of damping, shock absorption, sound insulation, impact resistance, noise abatement, impact resistance, high toughness and the like as an energy-absorbing material; and the dynamic polymer is especially applicable to the body protection of people during exercises, daily life and working, the body protection ofthe military police, explosion prevention, protection in airborne landing and aerial delivery, collision prevention of automobiles, anti-impact protection of electronic products and electric appliances, etc.

Owner:厦门逍扬运动科技有限公司

Aluminum trichloride (anhydrous) sublimation purification and preparation method

InactiveCN101311118AIncrease production capacityGood equipment cost controlAluminium chloridesAluminum trichlorideAluminium

A preparation method for sublimation and purification of anhydrous aluminium trichloride relates to a physical and chemical purifying preparation method of the anhydrous aluminium trichloride of inorganic salt by heating and subliming; an aluminium container is used for the heating and subliming of the anhydrous aluminium trichloride. The method of the invention takes fully consideration of the performance of corrosion resistance of a living container made from metallic aluminium material to aluminium trichloride and the volume of subliming process instrument made can be comparatively large so as to improve productivity and the cost control of the process instrument is relatively good; in addition, due to good heat conductivity of the metallic aluminium material, the purpose of saving energy can be realized and the production cost and price of LiAlCl4 / SOCl2 can be obviously reduced; the production cost of lithium-thionyl chloride batteries with the same specification can be reduced by 50 percent at most.

Owner:杨风春

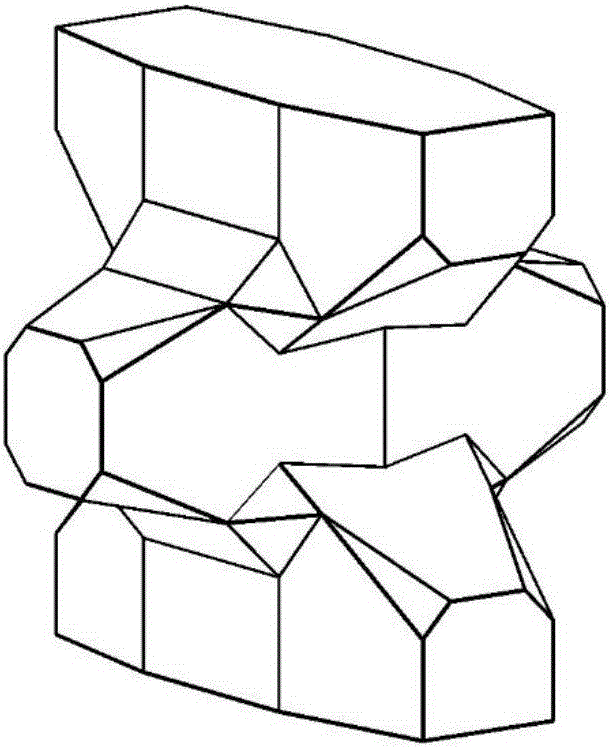

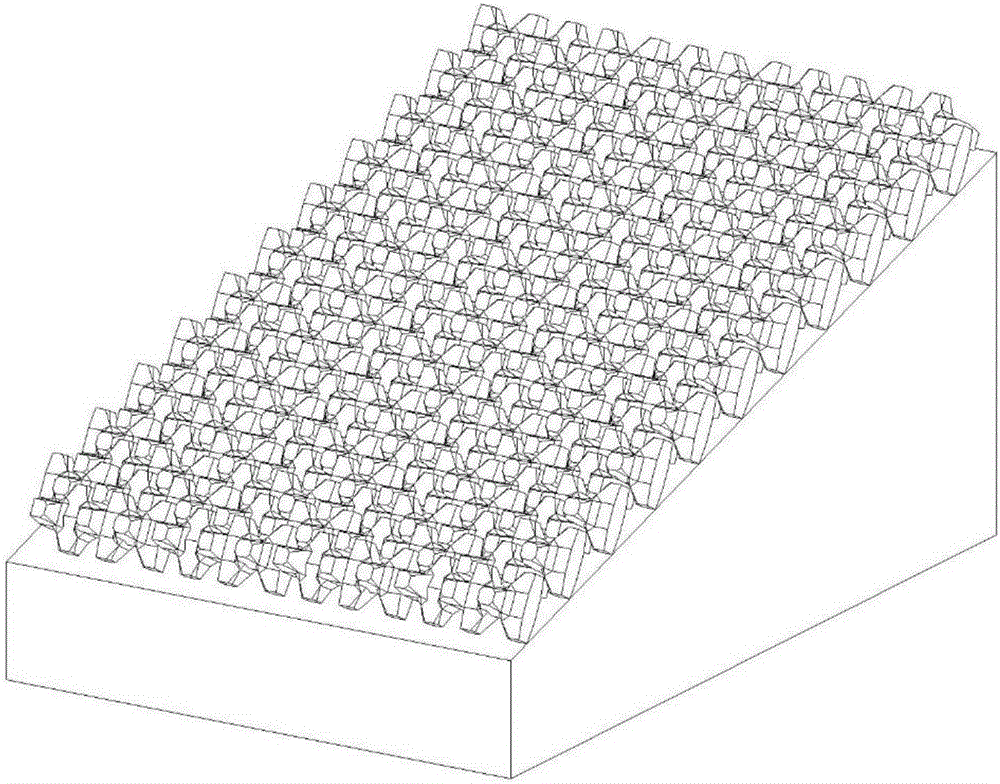

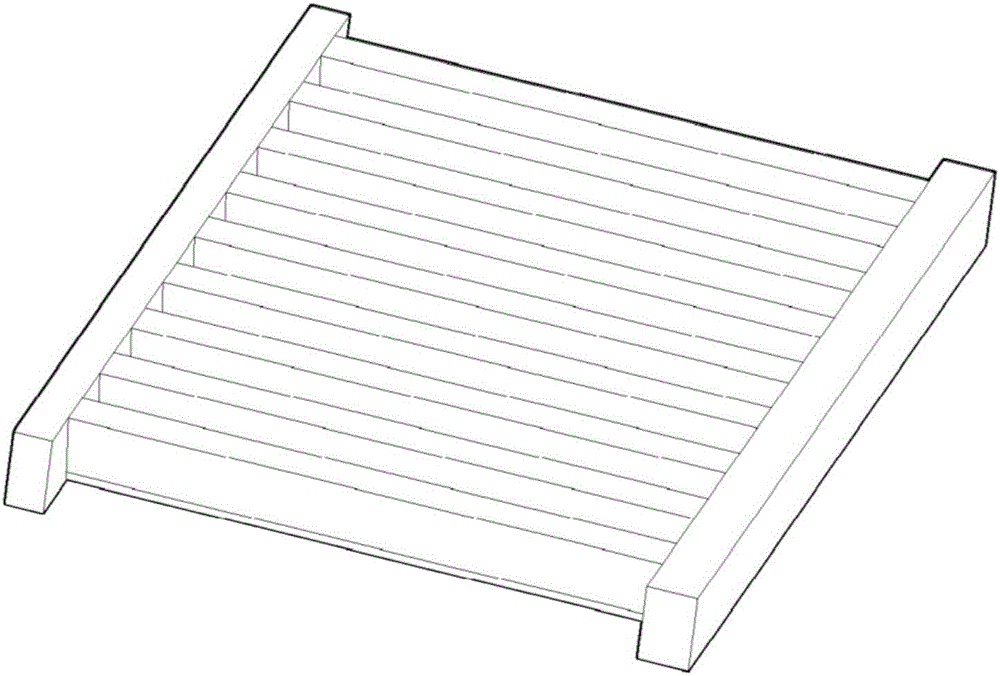

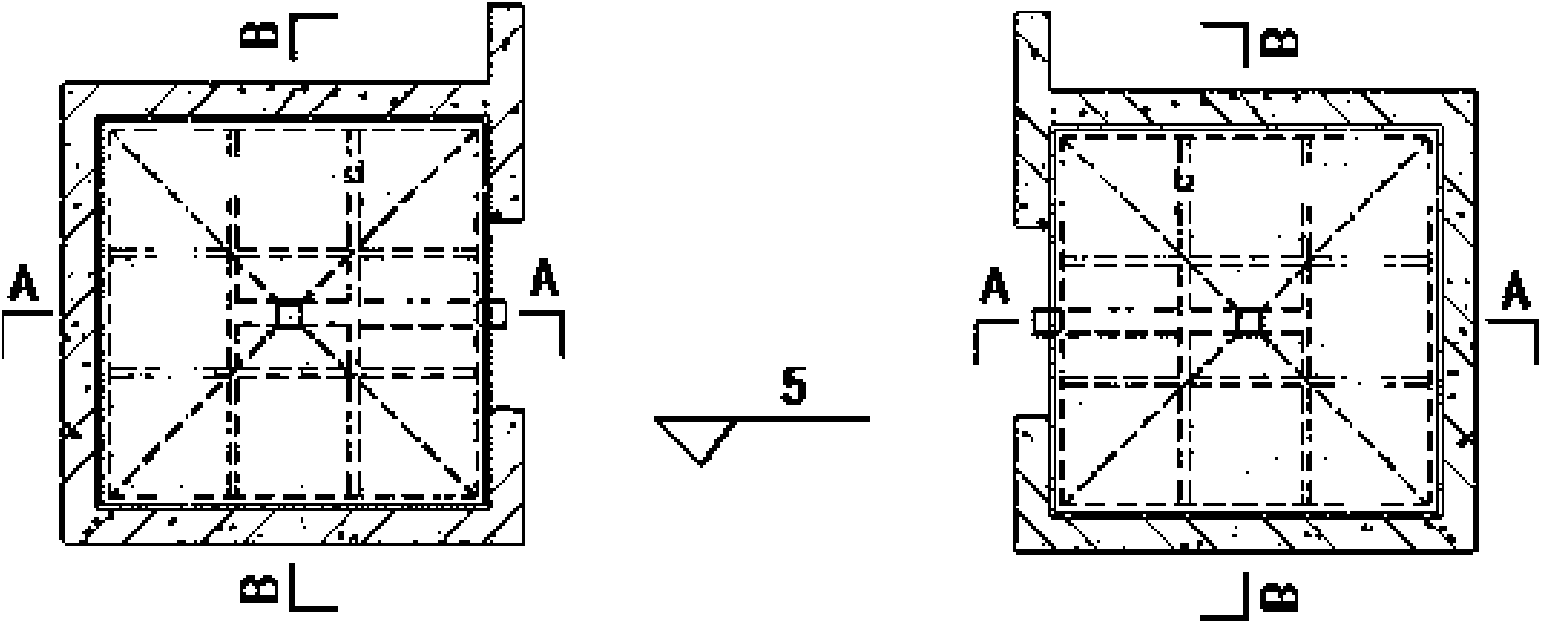

Artificial hill design method based on three-dimensional model scene grouping

InactiveCN108053472AImprove accuracyAchieve precisionImage enhancementAdditive manufacturing apparatusGroup methodData acquisition

The invention discloses an artificial hill design method based on three-dimensional scene grouping. The method comprises the steps of A, three-dimensional data collection, which comprises the steps ofA1, place environment three-dimensional data collection and A2, block artificial hill stone all-direction three-dimensional data collection; B, three-dimensional digital modeling, which comprises thesteps of B1, reverse three-dimensional modeling and B2, forward three-dimensional modeling; C, three-dimensional equal-scale physical model printing; D, artificial hill equal-scale physical model scene grouping, which comprises the steps of D1, artificial hill theme ideation and D2, artificial hill model scene grouping; and E, artificial hill scene grouping construction drawing production, whichcomprises the steps of E1, model construction precise design and E2, construction drawing design and production. Through the method, the artificial hill scene grouping method that shaping is performedaccording to stone in traditional garden building is optimized, the accuracy of artificial hill model production is improved, the precision of an artificial hill scene grouping design and construction drawing is realized, and it is convenient for an owner to perform scheme comparison, cost control, construction bidding and filing in a relevant administration department.

Owner:SUZHOU UNIV OF SCI & TECH

Method for detecting contents of lead, chromium, cadmium and copper in food

InactiveCN106290180ASimple stepsImprove work efficiencyColor/spectral properties measurementsMuffle furnaceAnalysis working

The invention provides a method for detecting contents of lead, chromium, cadmium and copper in food, wherein the method comprises the following steps: weighing a food sample, putting the food sample on an electric heating plate, and carrying out carbonization treatment, to obtain a sample after carbonization; introducing the sample after carbonization into a muffle furnace, and carrying out ashing treatment, to obtain a sample after ashing; adding a 0.5 mol / L nitric acid solution to the sample after ashing, and mixing evenly to obtain a to-be-detected sample liquid; introducing the to-be-detected sample liquid into an instrument, and carrying out instrument detection of the contents of lead, chromium, cadmium and copper, wherein the instrument is an atomic absorption spectrophotometer. According to the method for detecting the contents of lead, chromium, cadmium and copper in the food, the instrument detection of the four elements can be simultaneously carried out through one-time food sample pretreatment, the steps are simple, the working efficiency is high, and moreover, the test data precision and the recovery rate both can meet needs of analysis work.

Owner:INNER MONGOLIA MENGNIU DAIRY IND (GRP) CO LTD

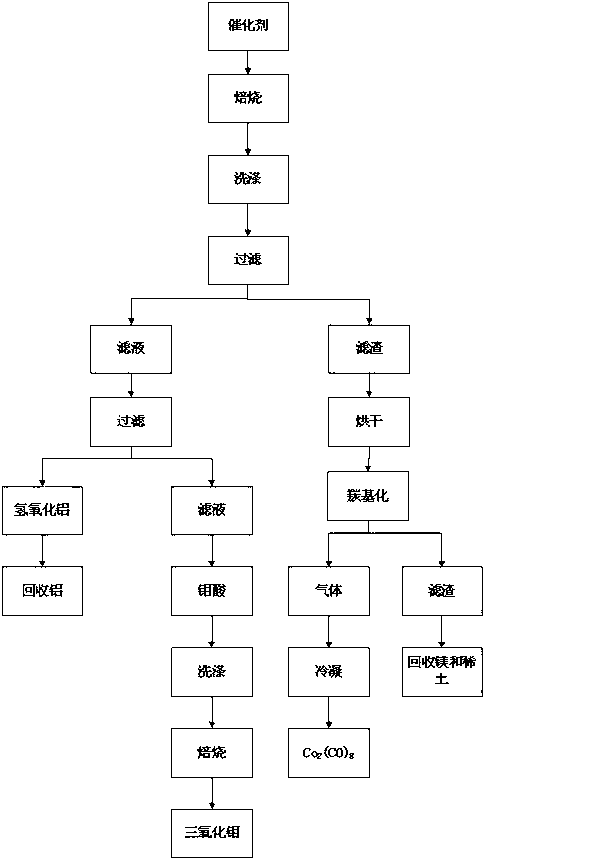

Method of recovering molybdenum and cobalt from waste cobalt-molybdenum catalyst

ActiveCN103074494AEasy to getShort recycling processProcess efficiency improvementPtru catalystAluminium hydroxide

The invention provides a method of recovering molybdenum and cobalt from a waste cobalt-molybdenum catalyst. The method comprises the following steps: adding alkali into the waste cobalt-molybdenum catalyst, then roasting the waste catalyst, carrying out washing and filtering, adding an acid into an obtained filtrate to adjust a pH value, filtering a reacted solution, with filter residue being aluminum hydroxide for recovery of aluminum and a filtrate being a molybdenum-containing solution, adjusting the pH value of the molybdenum-containing solution to obtain molybdic acid deposition, washing the molybdic acid deposition with distilled water to wash out impurities adhering on molybdic acid and carrying out roasting so as to obtain molybdenum trioxide; and adding alkali for roasting, drying washed filter residue, introducing carbon monoxide gas after moisture is totally removed and introducing tail gas into a collection container after condensation at the same time, wherein carbonyl cobalt is condensed to form a solid, which allows metal cobalt to be recovered, the tail gas is cyclically used, and reacted filter residue after introduction of carbon monoxide gas can be used for recovery of carriers like magnesium and rare earth. According to the method, used raw materials are cheap, which is beneficial for cost control; steps of the method are simple, so recovery flow of metal cobalt and molybdenum is shortened, and a recovery rate is increased.

Owner:JINGMEN GEM NEW MATERIAL

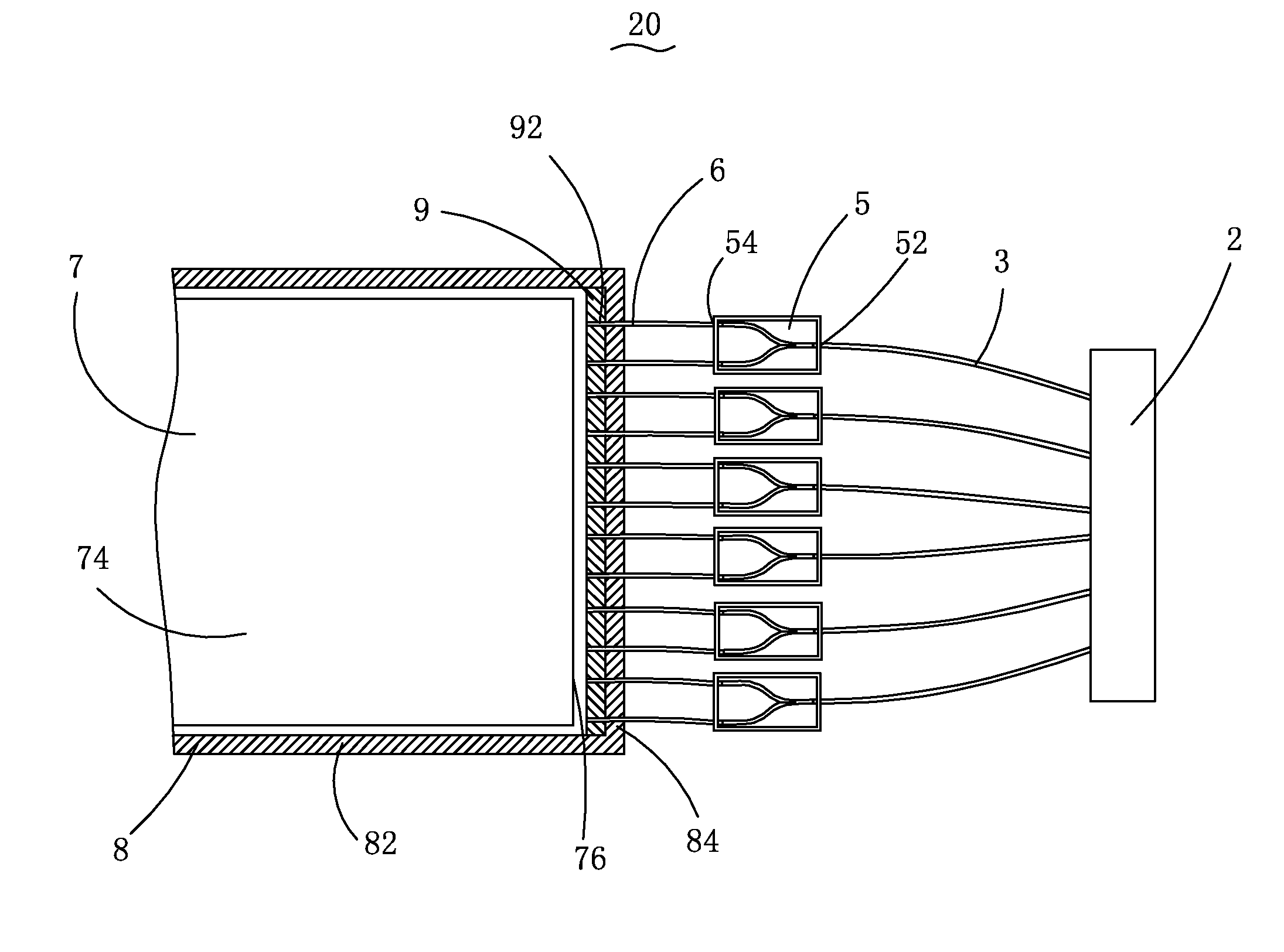

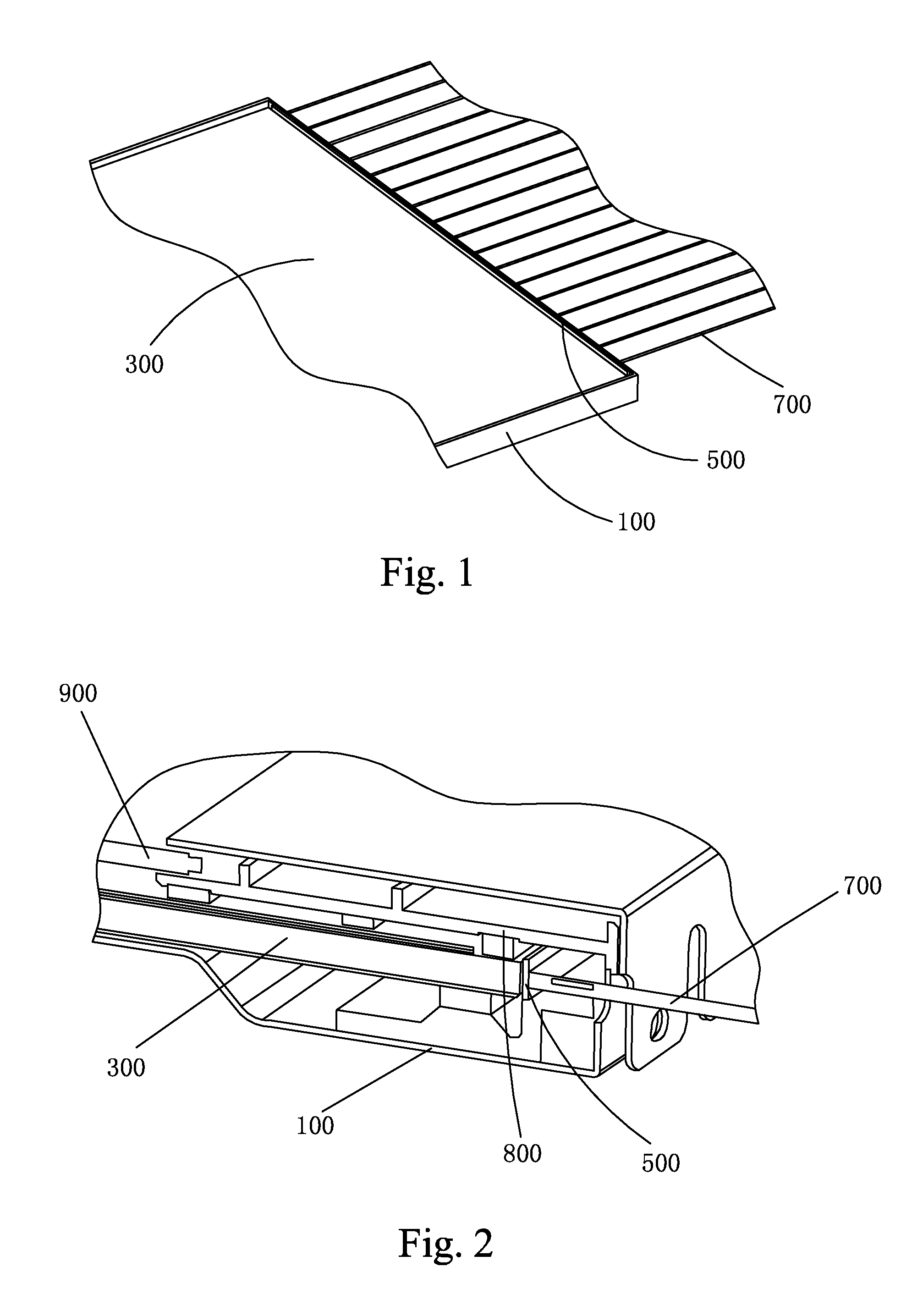

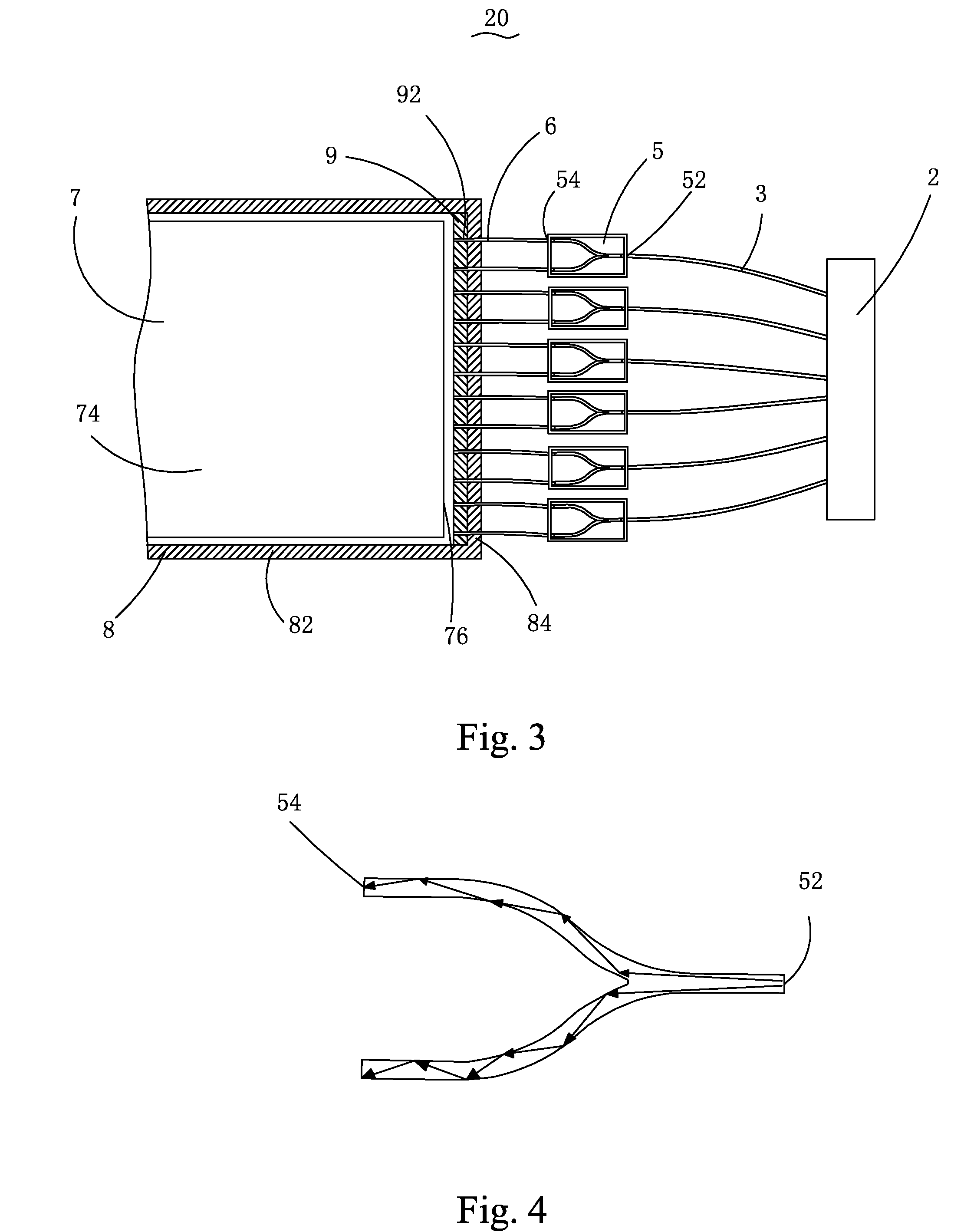

Backlight module and liquid crystal display device using same

ActiveUS20140146268A1Reduce manufacturing costOvercome effectBundled fibre light guideNon-linear opticsFiberLiquid-crystal display

The present invention provides a backlight module and a liquid crystal display device using the backlight module. The backlight module includes a light collector, a plurality of first optical fibers connected to the light collector, a plurality of first optical fiber splitters connected to the first optical fibers, a plurality of second optic fibers connected to the first optical fiber splitters, and a light guide plate arranged at one side of the second optic fibers. Each of the first optical fiber splitters includes a first light inlet and a plurality of first light outlets. The first light inlets are respectively connected to the first optical fibers and the first light outlets are respectively connected to the second optic fibers. The backlight module uses optic fiber splitters to split received sun light for making dense and uniform distribution of sun light at a light incidence site of a light guide plate.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

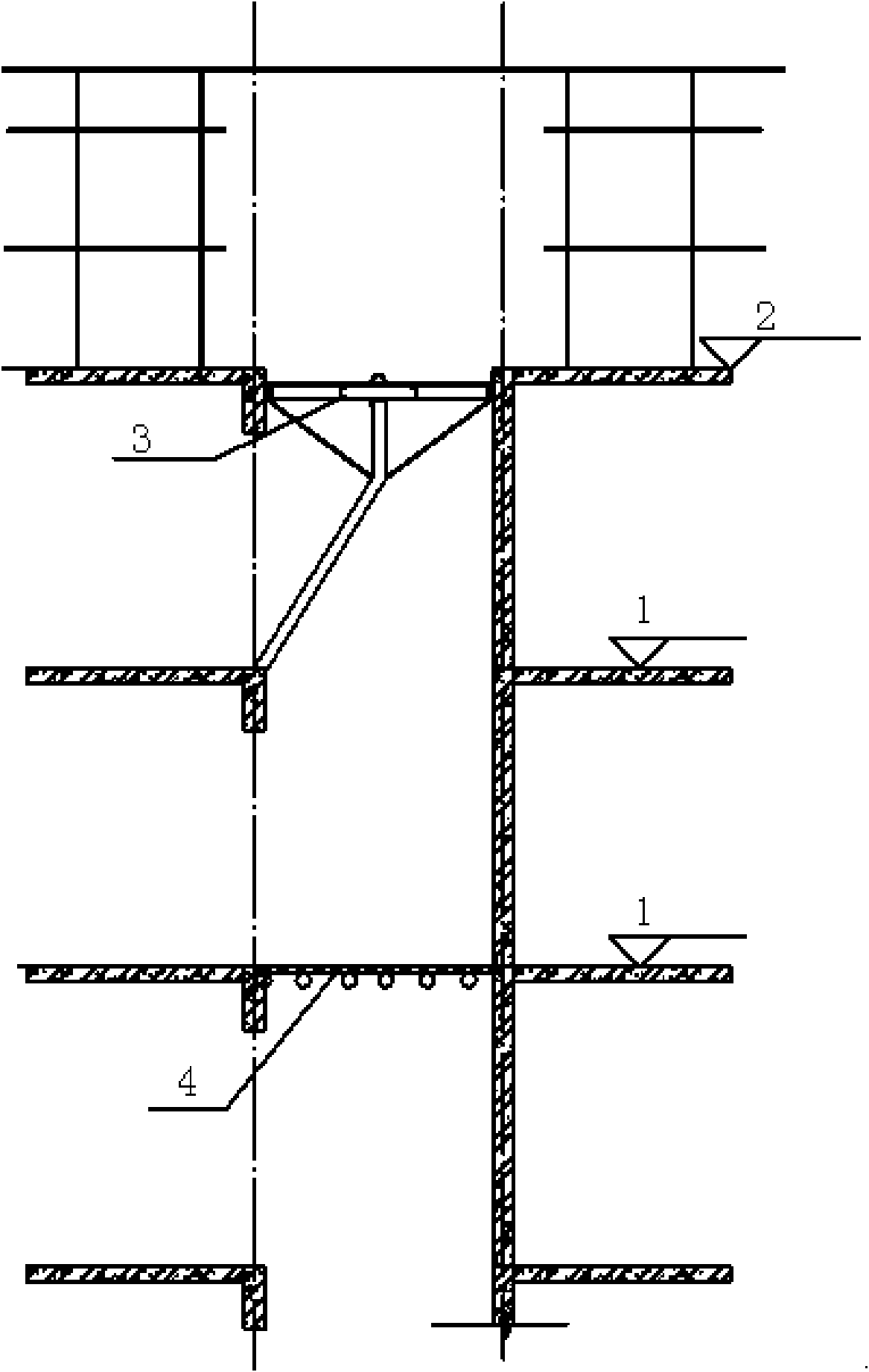

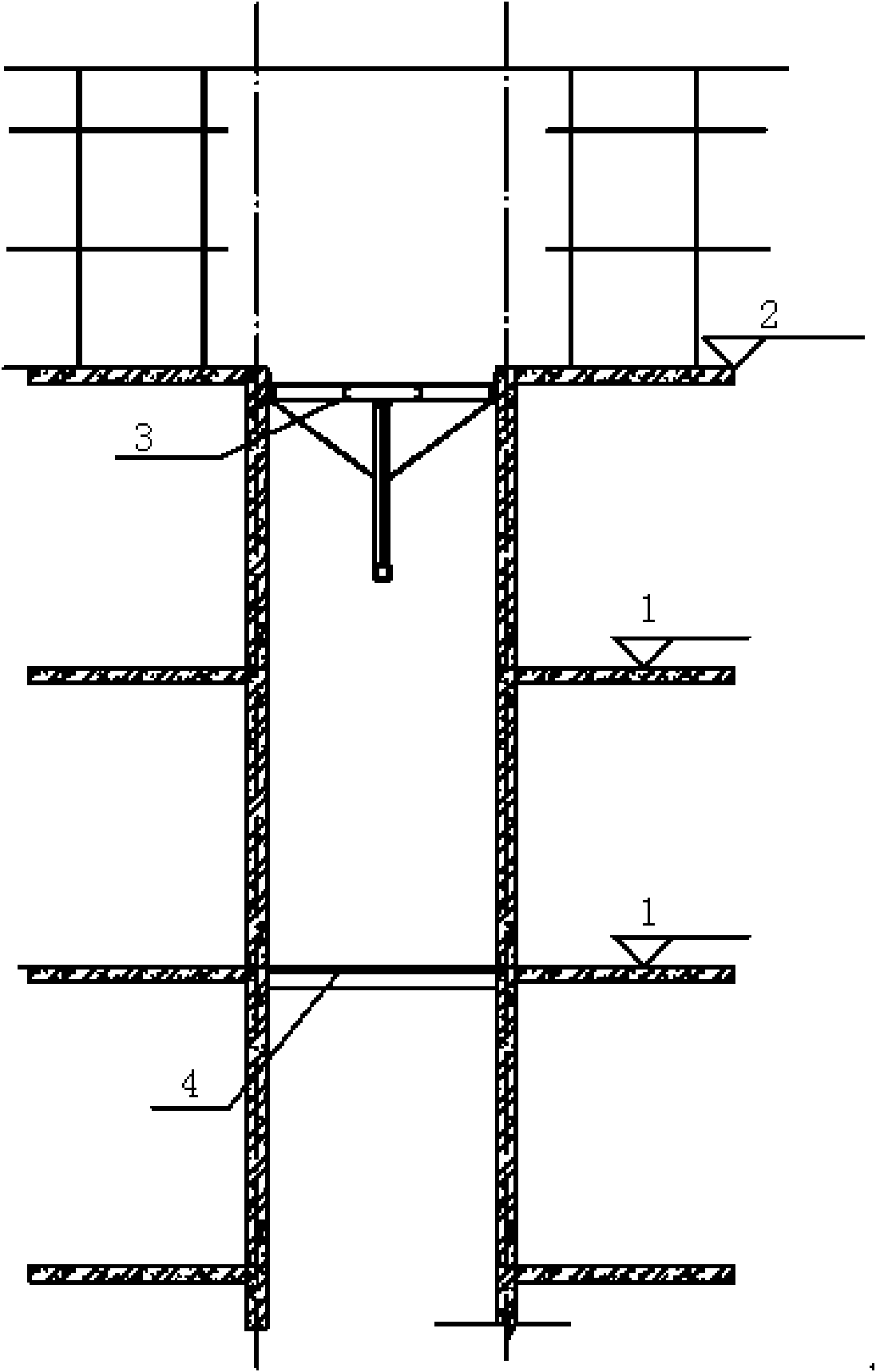

Constructing method for high-rise building elevator shaft through elevating type safety protection steel platform

InactiveCN102031862AEasy to processSave leaseBuilding material handlingBuilding support scaffoldsEconomic benefitsArchitectural engineering

The invention discloses a constructing method for a high-rise building elevator shaft through an elevating type safety protection steel platform, comprising the steps of: firstly, manufacturing a steel platform matched with the size of an elevator shaft, then installing the steel platform inside the bottom layer of the elevator shaft, carrying out elevator shaft construction operation by constructors standing on the steel platform, elevating the steel platform layer by layer after the construction on the current operation layer is completed until the steel platform is elevated to the elevator shaft of the upper floor to facilitate the elevator shaft construction operation, sealing the lower elevator shaft after the steel platform is elevated, and repeating the steps until the elevator shaft construction on all the floors of the whole building is completed. The construction method is featured by safety, simplicity and convenience for operation, easiness for construction, obvious economic benefits and the like, has the greatest advantages of saving lease expense of raw materials and facilitating cost control, and is particularly suitable for high-rise buildings and multistoried buildings with longer construction periods.

Owner:THE THIRD CONSTR & ENG OF CCFED

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com