Incineration treatment process for glyphosate mother liquor

A technology of glyphosate mother liquor and treatment process, which is applied in the incineration treatment process of glyphosate mother liquor with recovered mixed sodium phosphate, and in the field of incineration treatment technology of glyphosate mother liquor, which can solve the problem of low oxidation conversion rate and achieve operation cost Low, reduce energy consumption, reduce the effect of environmental protection pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

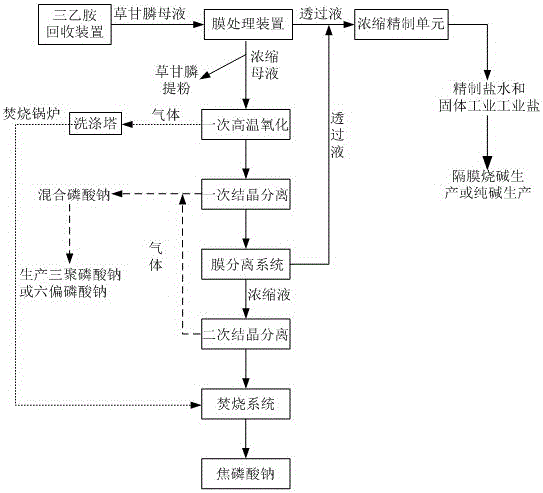

Image

Examples

Embodiment 1

[0037] The present embodiment proposes a kind of incineration treatment process of glyphosate mother liquor, comprises the following steps:

[0038] A. Send the glyphosate mother liquor into the membrane treatment device to obtain concentrated mother liquor and permeate. In the concentrated mother liquor, 10% is used for glyphosate powder extraction, and 90% is used to complete the operation of step B;

[0039] B. After the concentrated mother liquor is oxidized once and separated by crystallization, a centrifuge filtrate is obtained, and the centrifuge filtrate is sent to a membrane separation system to obtain a concentrate and a permeate;

[0040]C. The concentrated solution obtained by the membrane separation system is subjected to secondary crystallization and separation, and the centrifugal filtrate is sent to the incineration system to obtain sodium pyrophosphate, and the flue gas generated by incineration is separated from dust and then subjected to secondary combustion....

Embodiment 2

[0042] The present embodiment proposes a kind of incineration treatment process of glyphosate mother liquor, comprises the following steps:

[0043] A, sending the glyphosate mother liquor into the membrane treatment device to obtain concentrated mother liquor and permeate, in the concentrated mother liquor, 20% is used for glyphosate powder extraction, and 80% is used to complete the operation of step B;

[0044] B. After the concentrated mother liquor is oxidized once and separated by crystallization, a centrifuge filtrate is obtained, and the centrifuge filtrate is sent to a membrane separation system to obtain a concentrate and a permeate;

[0045] C. The concentrated solution obtained by the membrane separation system is subjected to secondary crystallization and separation, and the centrifugal filtrate is sent to the incineration system to obtain sodium pyrophosphate, and the flue gas generated by incineration is separated from dust and then subjected to secondary combust...

Embodiment 3

[0048] The present embodiment proposes a kind of incineration treatment process of glyphosate mother liquor, comprises the following steps:

[0049] A. Send the glyphosate mother liquor into the membrane treatment device to obtain concentrated mother liquor and permeate. In the concentrated mother liquor, 15% is used for glyphosate powder extraction, and 85% is used to complete the operation of step B;

[0050] B. After the concentrated mother liquor is oxidized once and separated by crystallization, a centrifuge filtrate is obtained, and the centrifuge filtrate is sent to a membrane separation system to obtain a concentrate and a permeate;

[0051] C. The concentrated solution obtained by the membrane separation system is subjected to secondary crystallization and separation, and the centrifugal filtrate is sent to the incineration system to obtain sodium pyrophosphate, and the flue gas generated by incineration is separated from dust and then subjected to secondary combustion...

PUM

| Property | Measurement | Unit |

|---|---|---|

| combustion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com