Constructing method for high-rise building elevator shaft through elevating type safety protection steel platform

A technology for safety protection and high-rise buildings, which is applied in construction, building structure, and building material processing. The environmental benefits are obvious, which is conducive to cost control and the effect of saving steel pipe rent.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

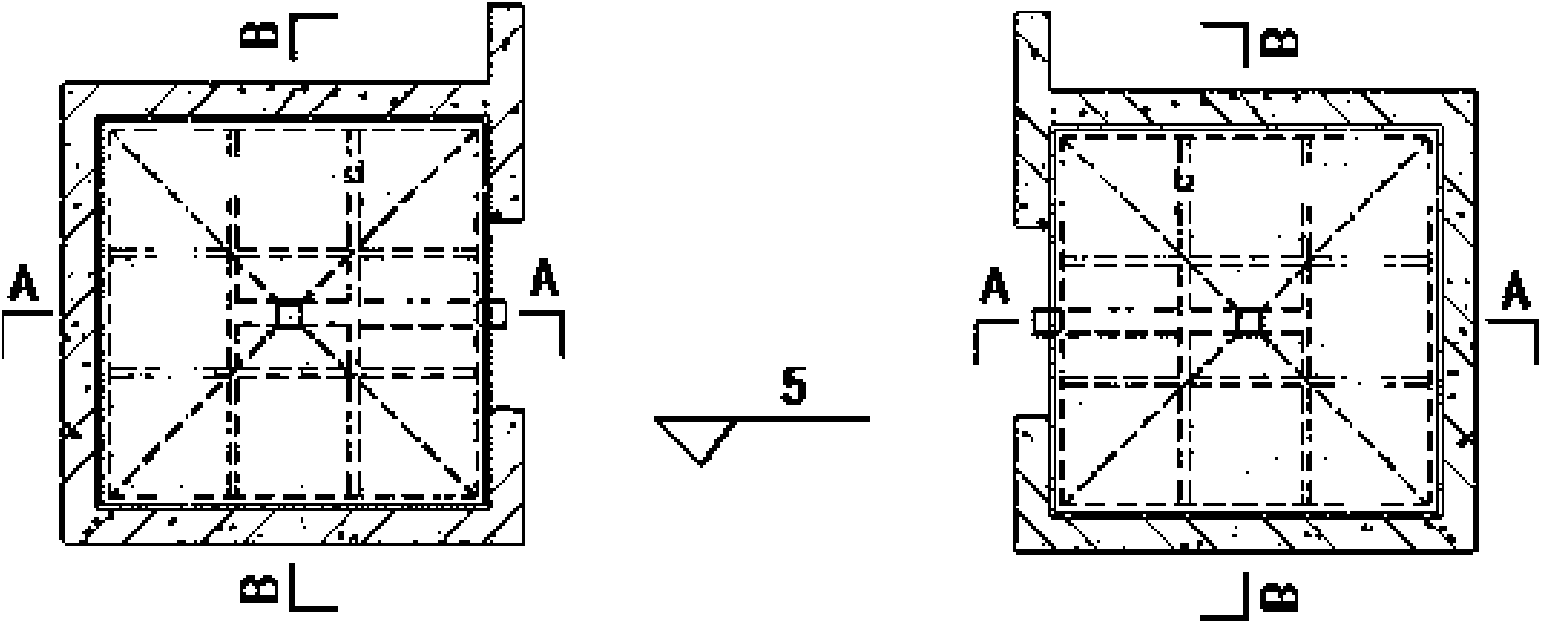

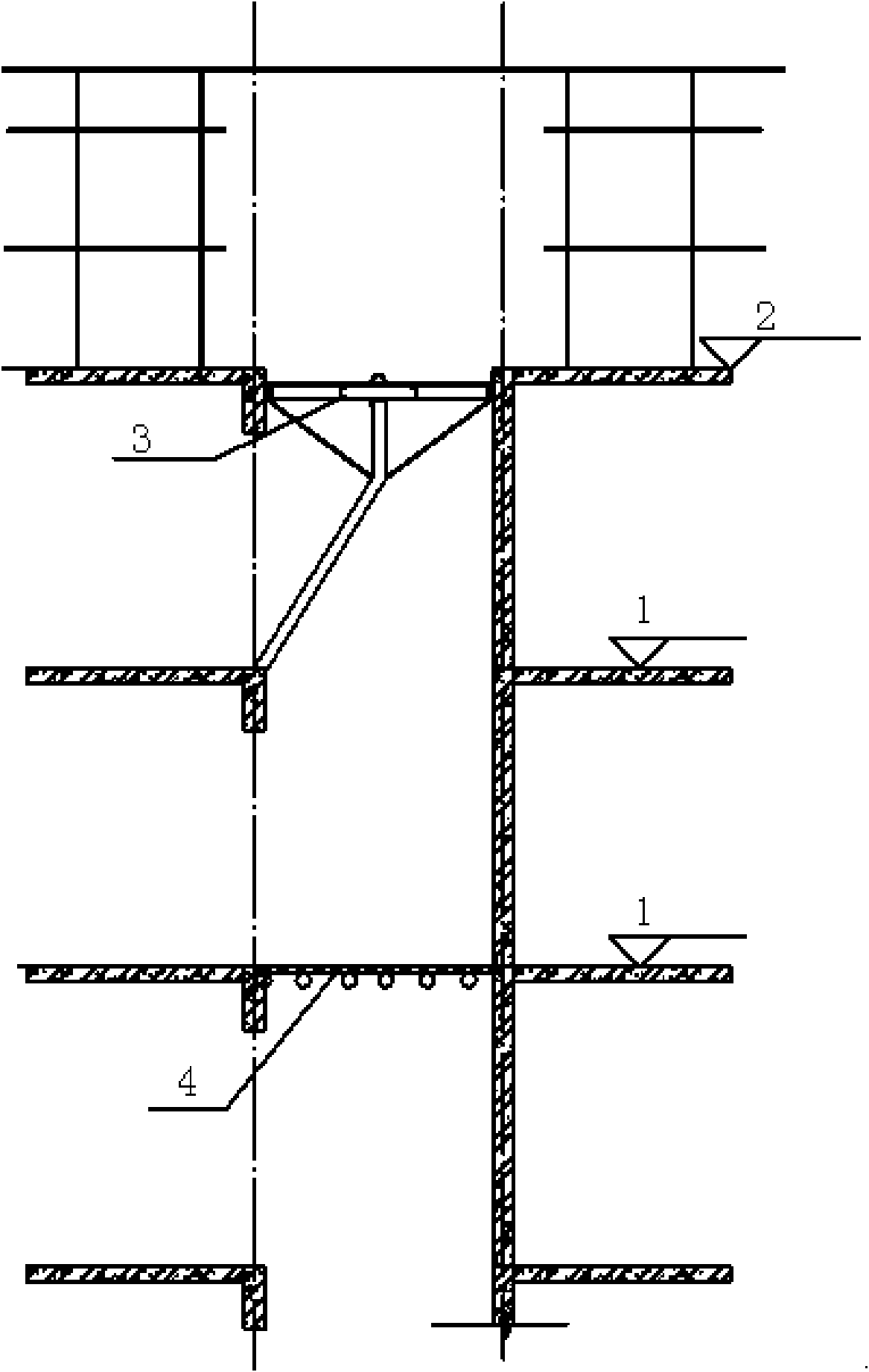

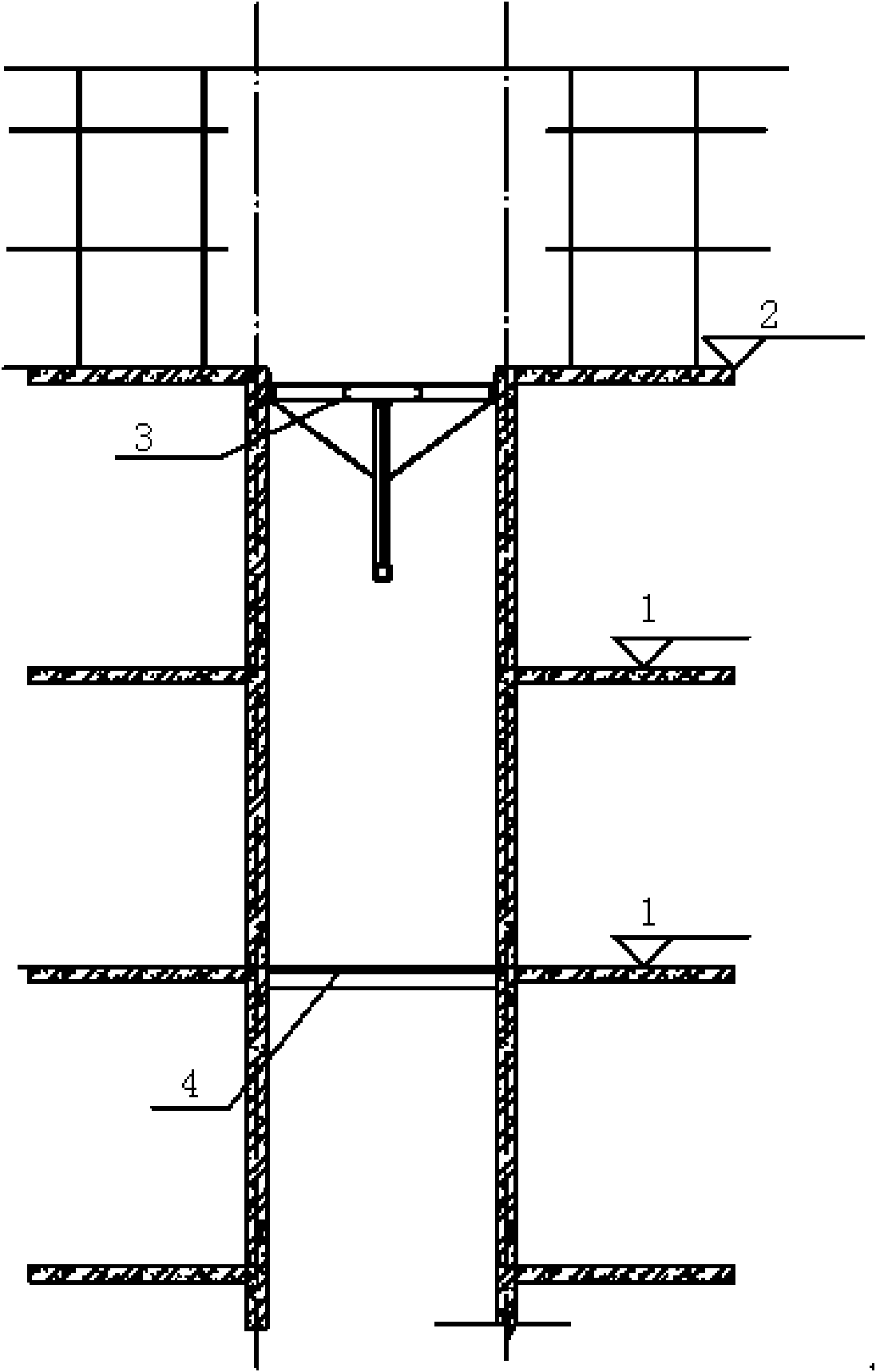

[0014] Example 1. Such as figure 1 , 2 Or as shown in 3, earlier according to the size of the construction elevator shaft, connect and process a steel platform matching the size of the elevator shaft with bolts. The steel platform in this example is made of section steel and steel plate connected by bolts. Then use the tower crane to transport the steel platform to the construction site, and install it in the elevator shaft at the bottom. In order to ensure that the steel platform can rise freely, there is a distance between the edge of the steel platform and the inner wall of the elevator shaft that allows the steel platform to rise freely. . The construction workers stand on the steel platform to carry out construction work. After the construction of the working layer is completed, the steel platform is lifted layer by layer to the elevator shaft on the previous floor with a tower crane or electric hoist to carry out the elevator shaft construction work until all floors o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com