Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33results about How to "Save rental fee" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

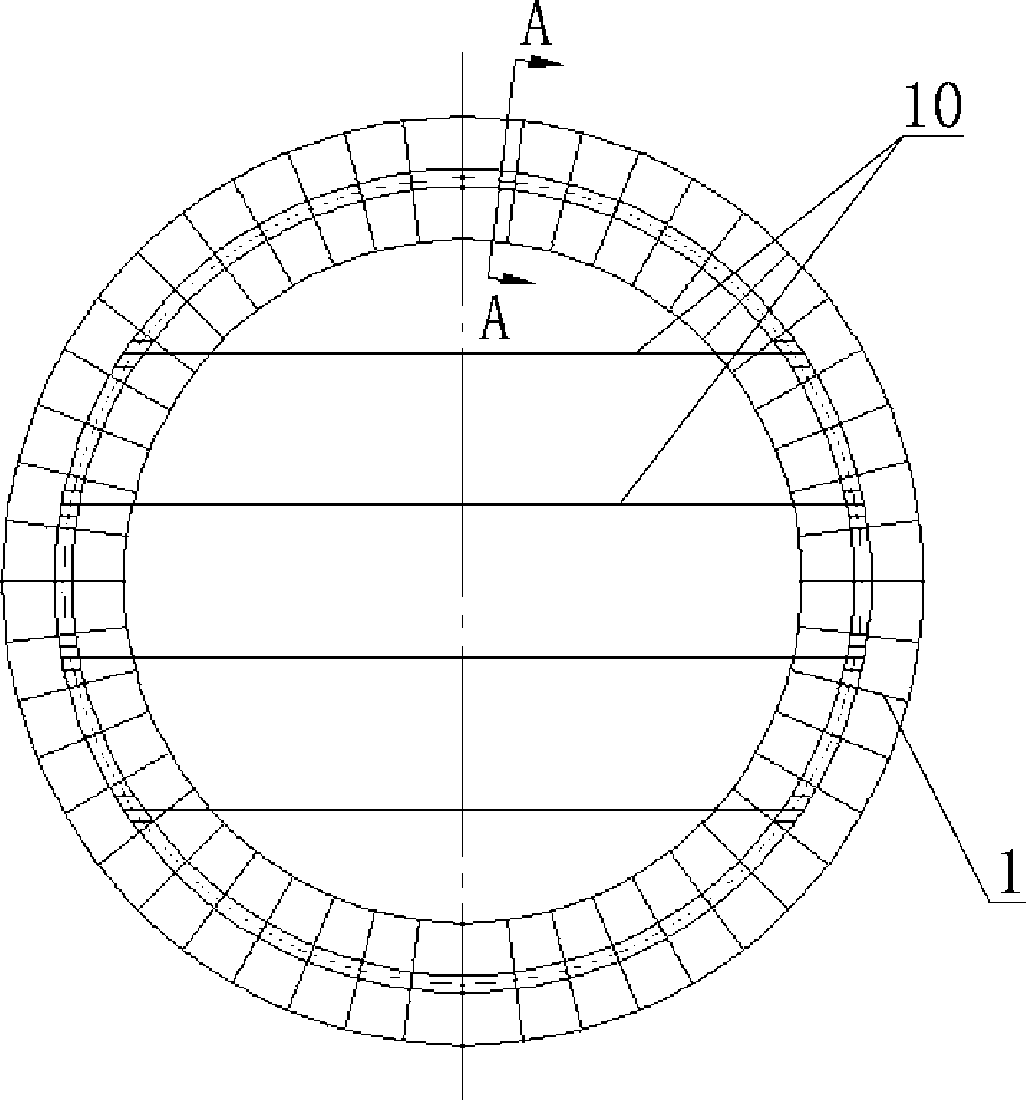

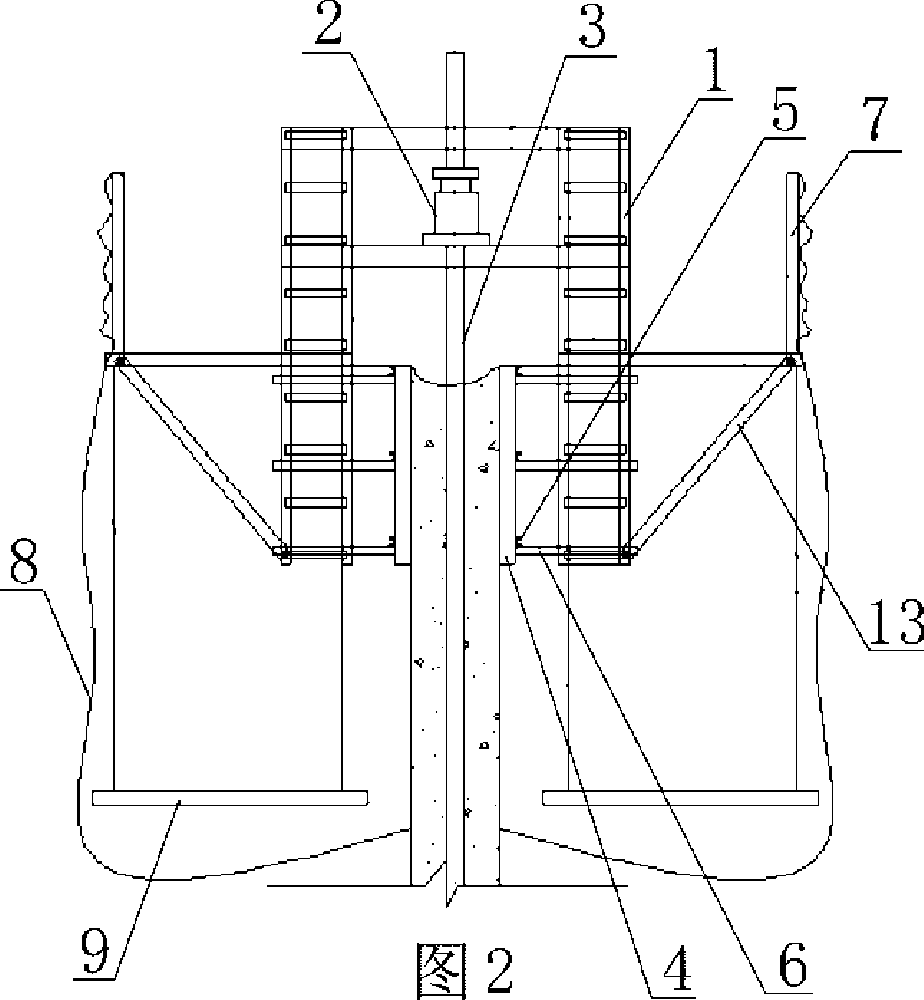

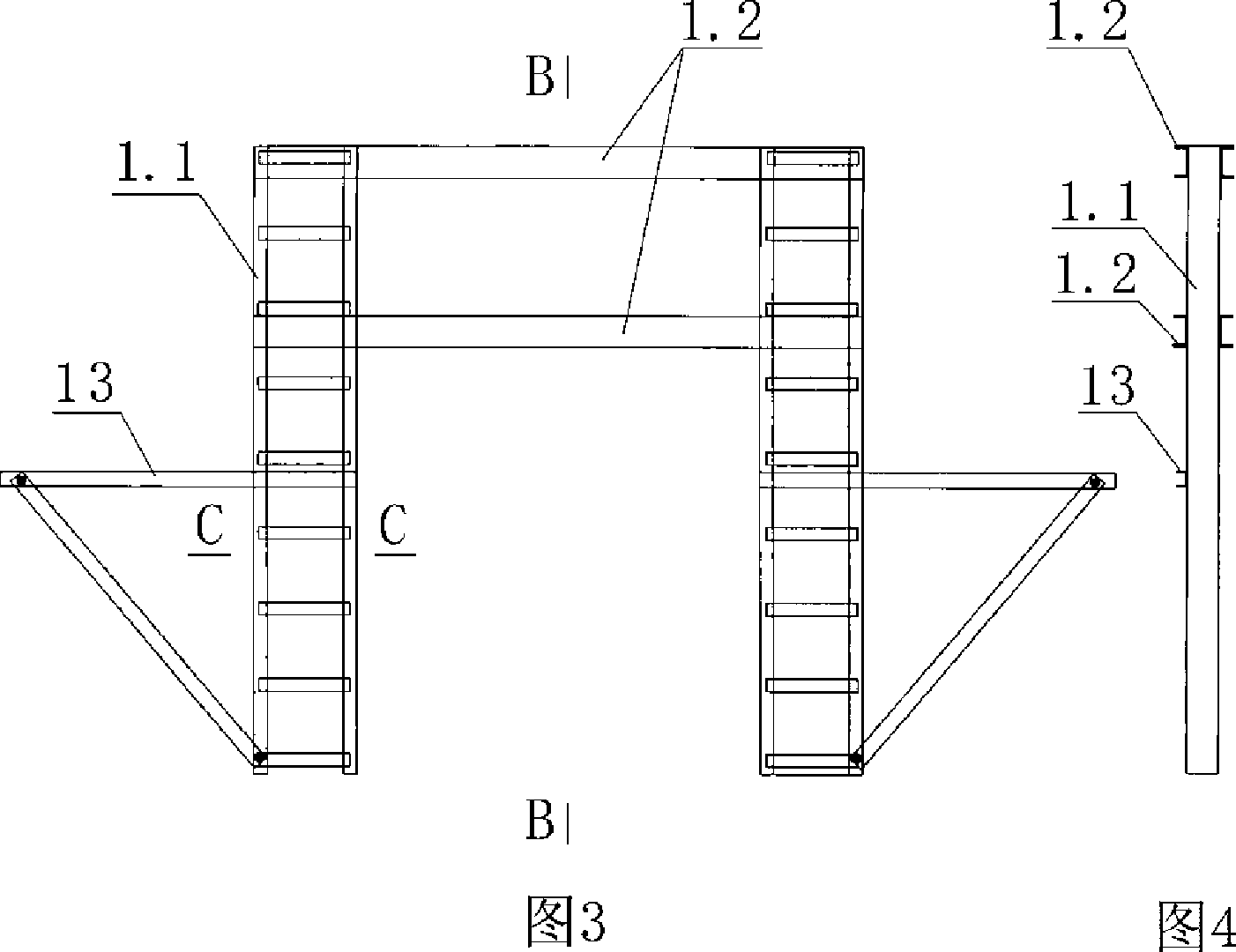

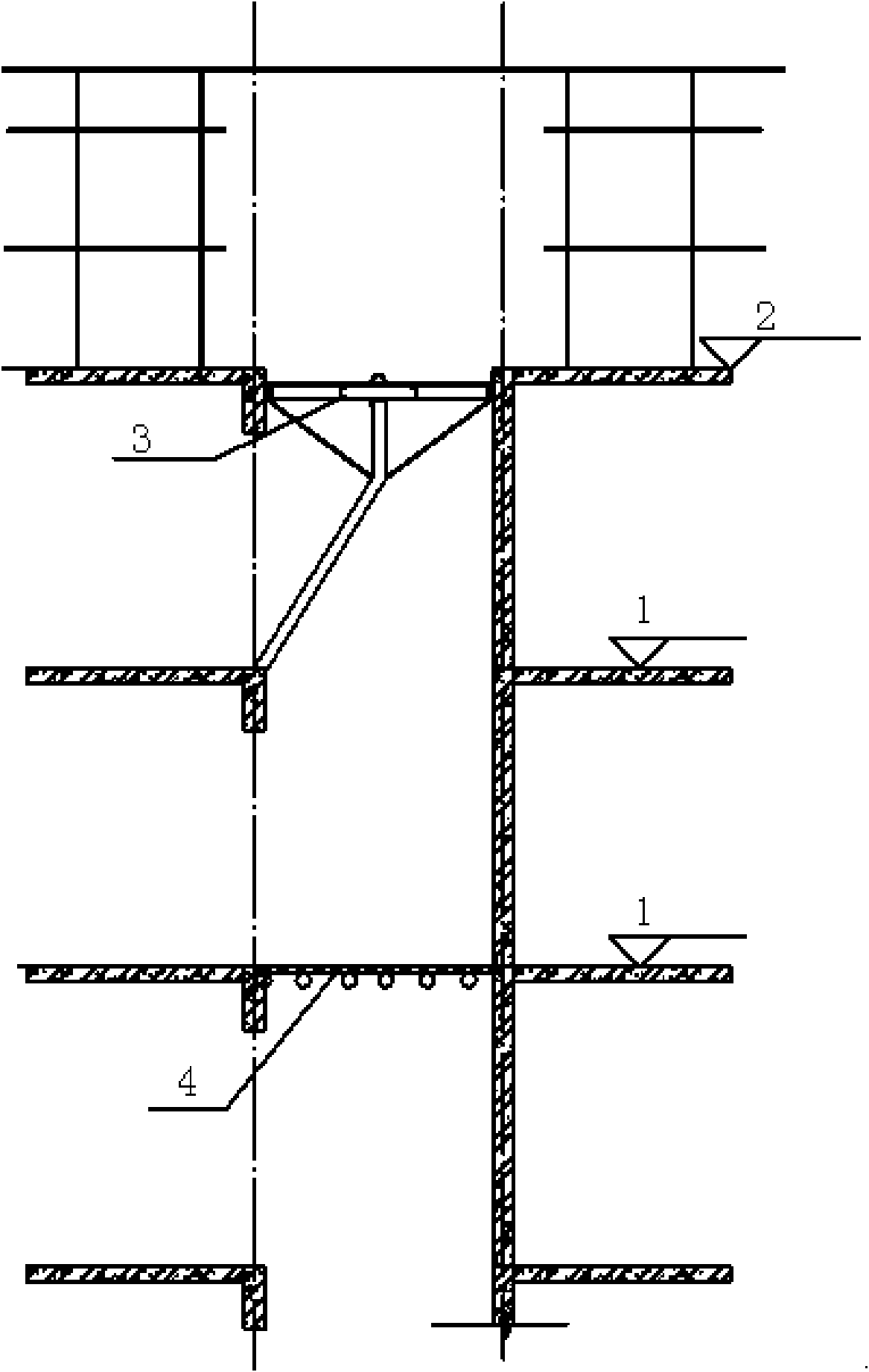

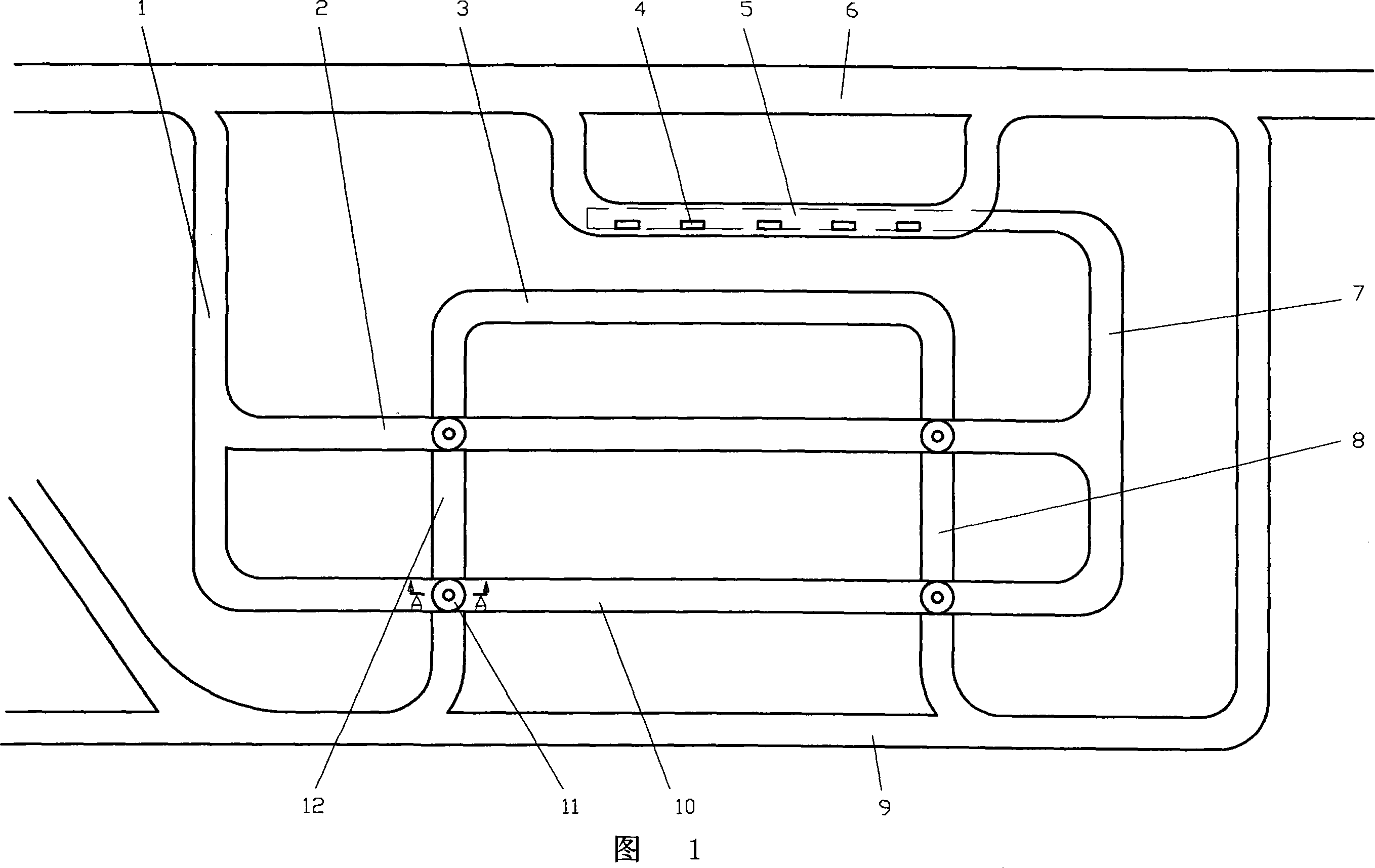

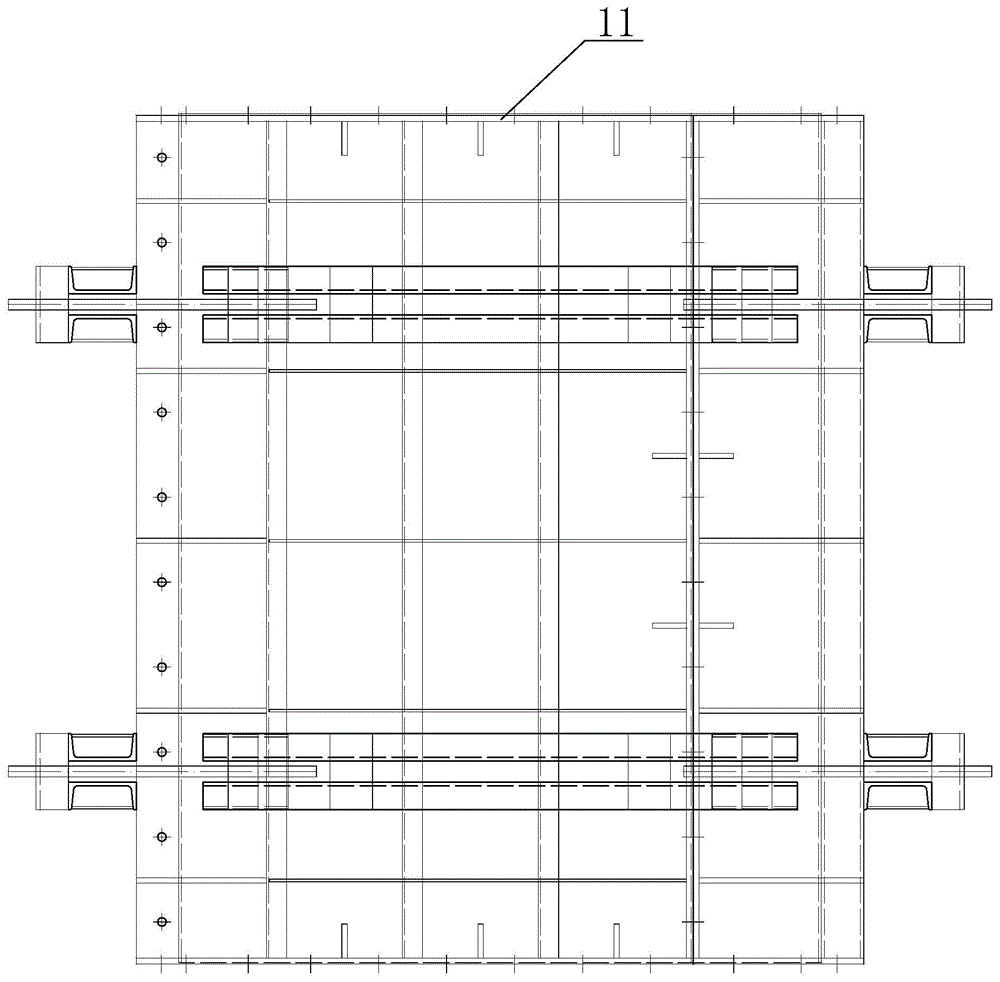

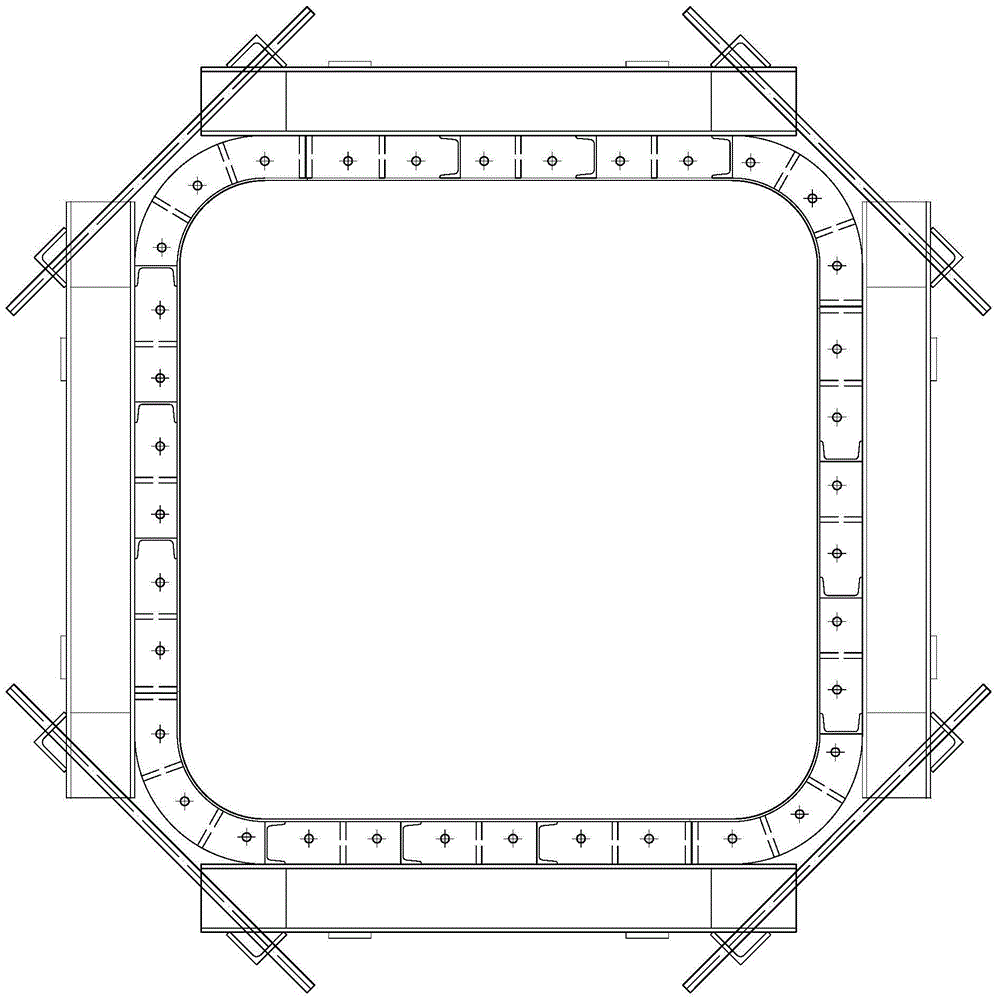

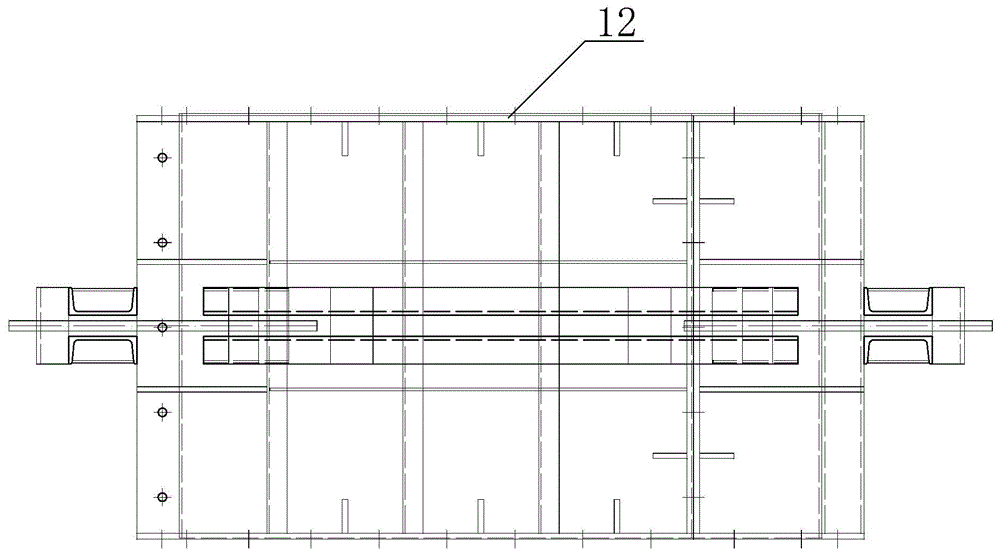

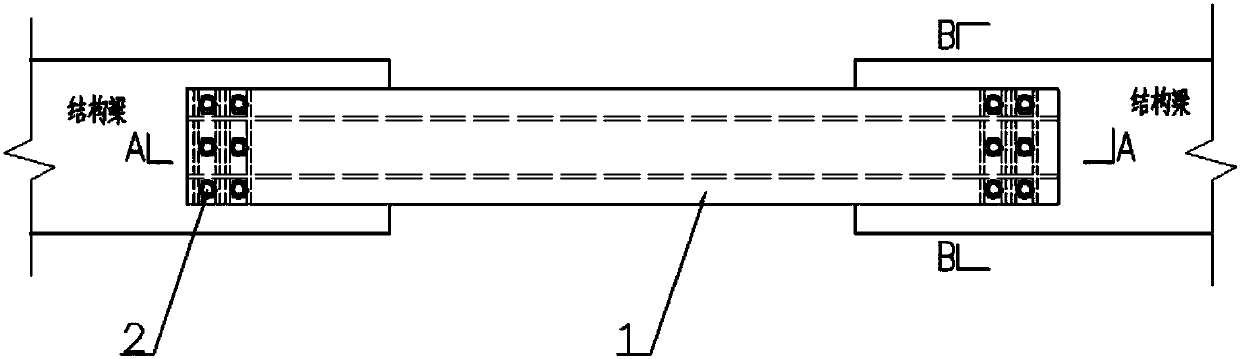

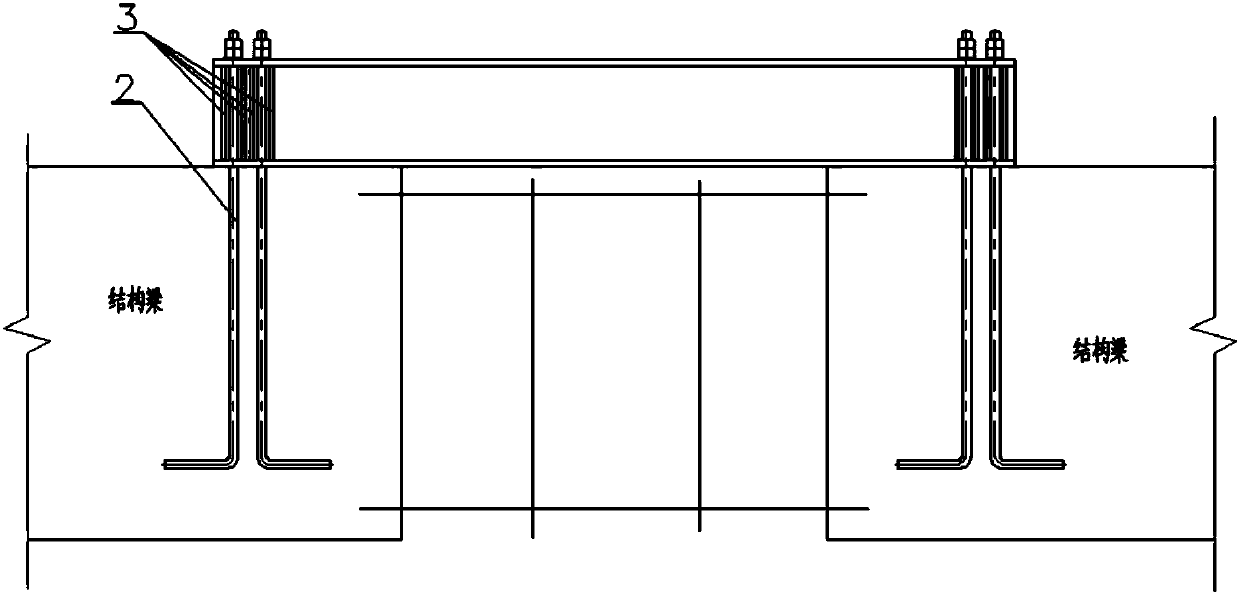

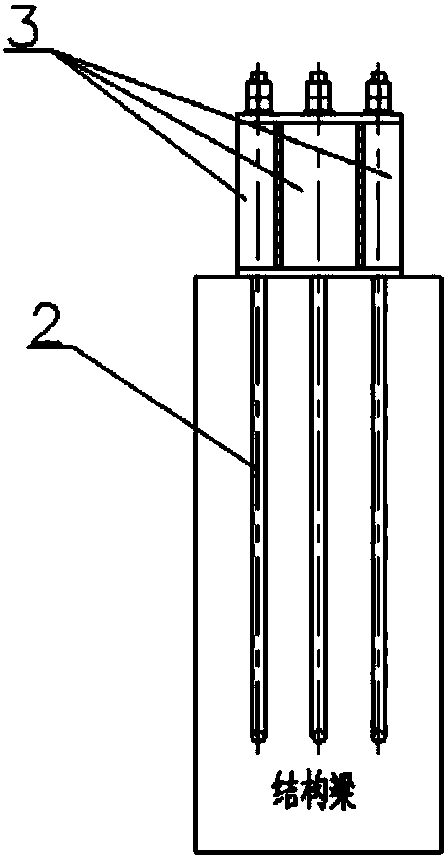

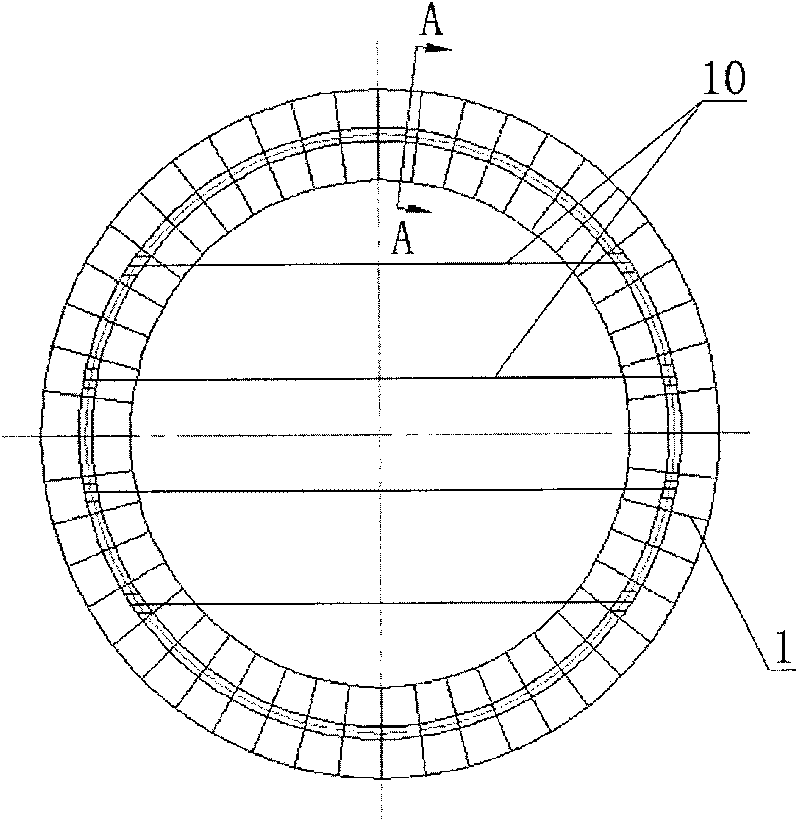

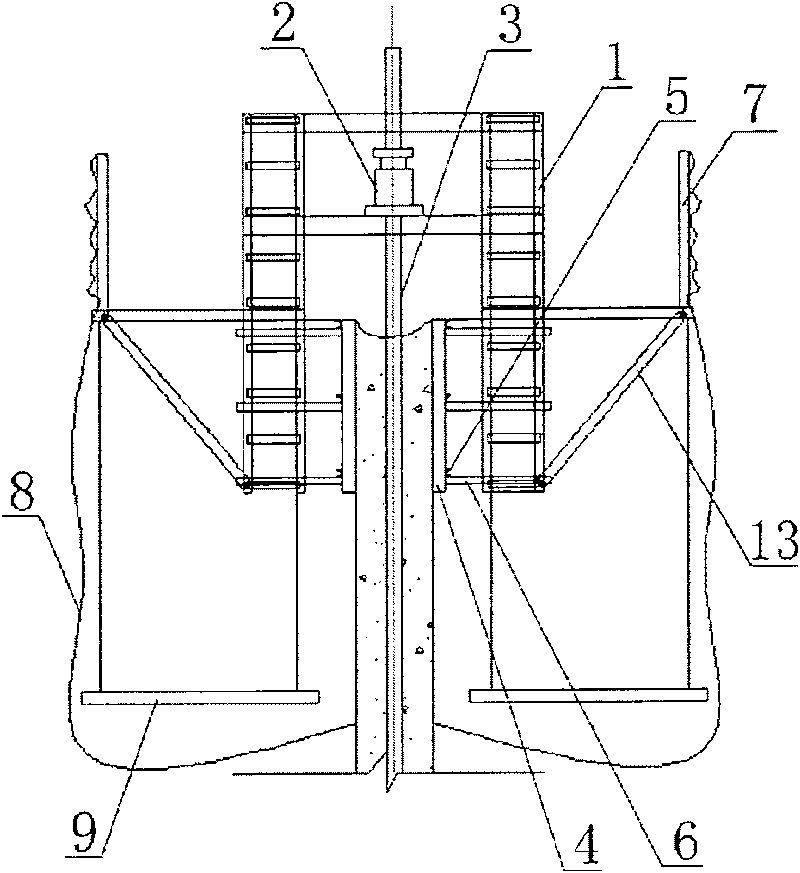

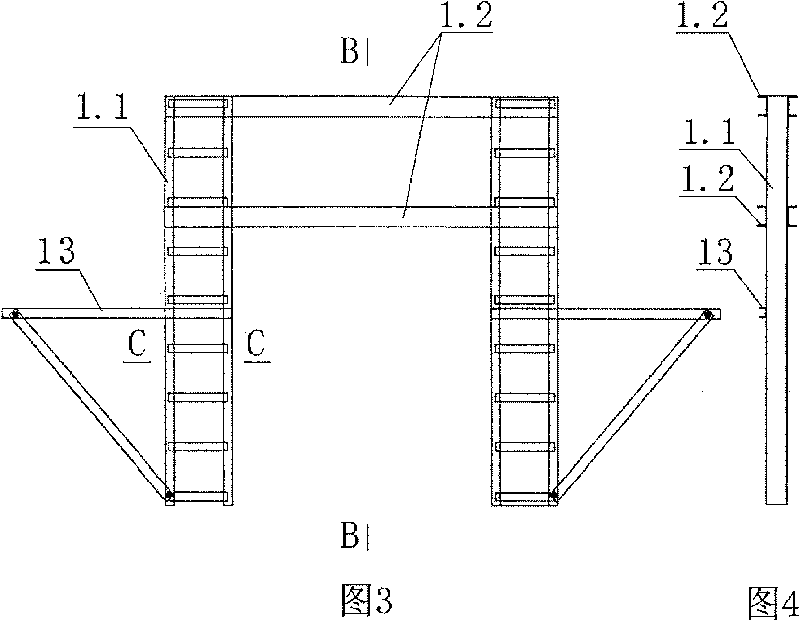

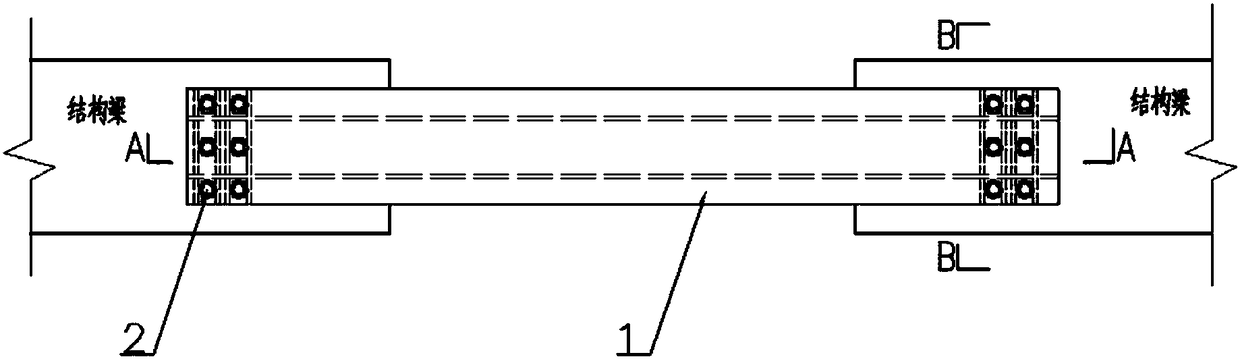

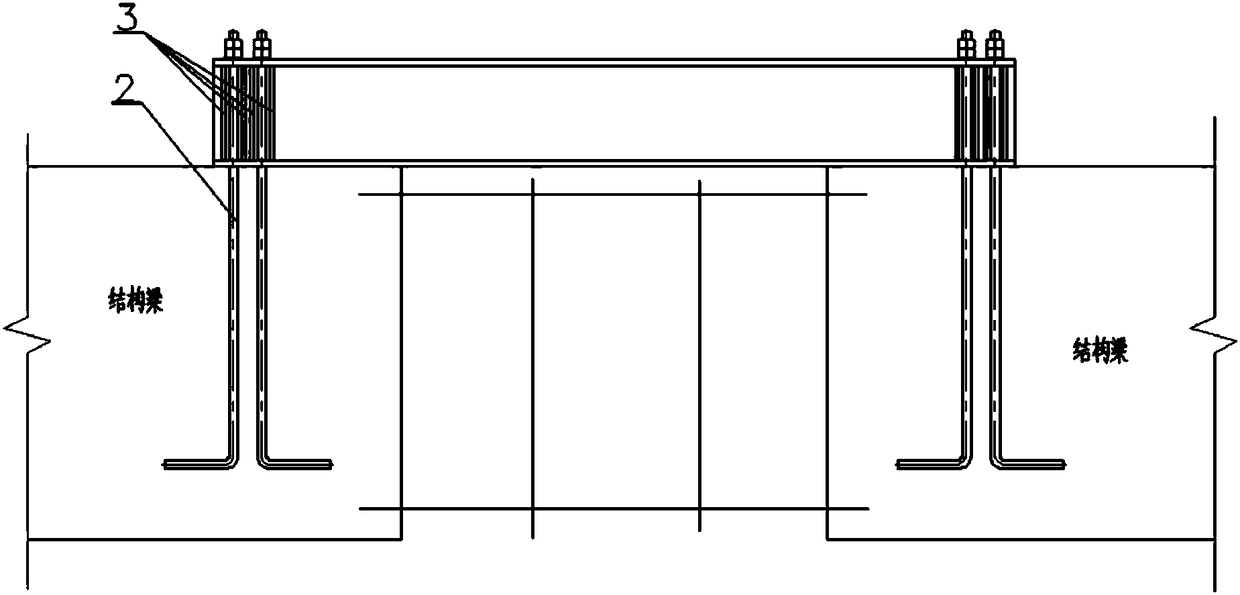

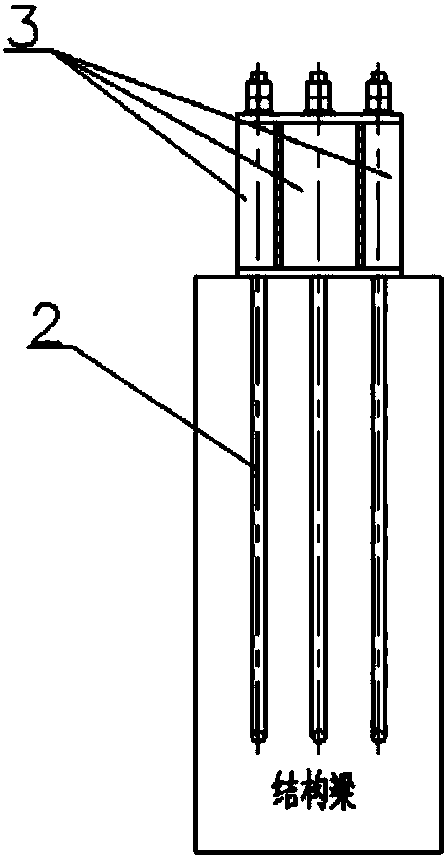

Cabin top steel beam hydraulic hoisting and positioning apparatus of cylinder cabin structure building and construction method thereof

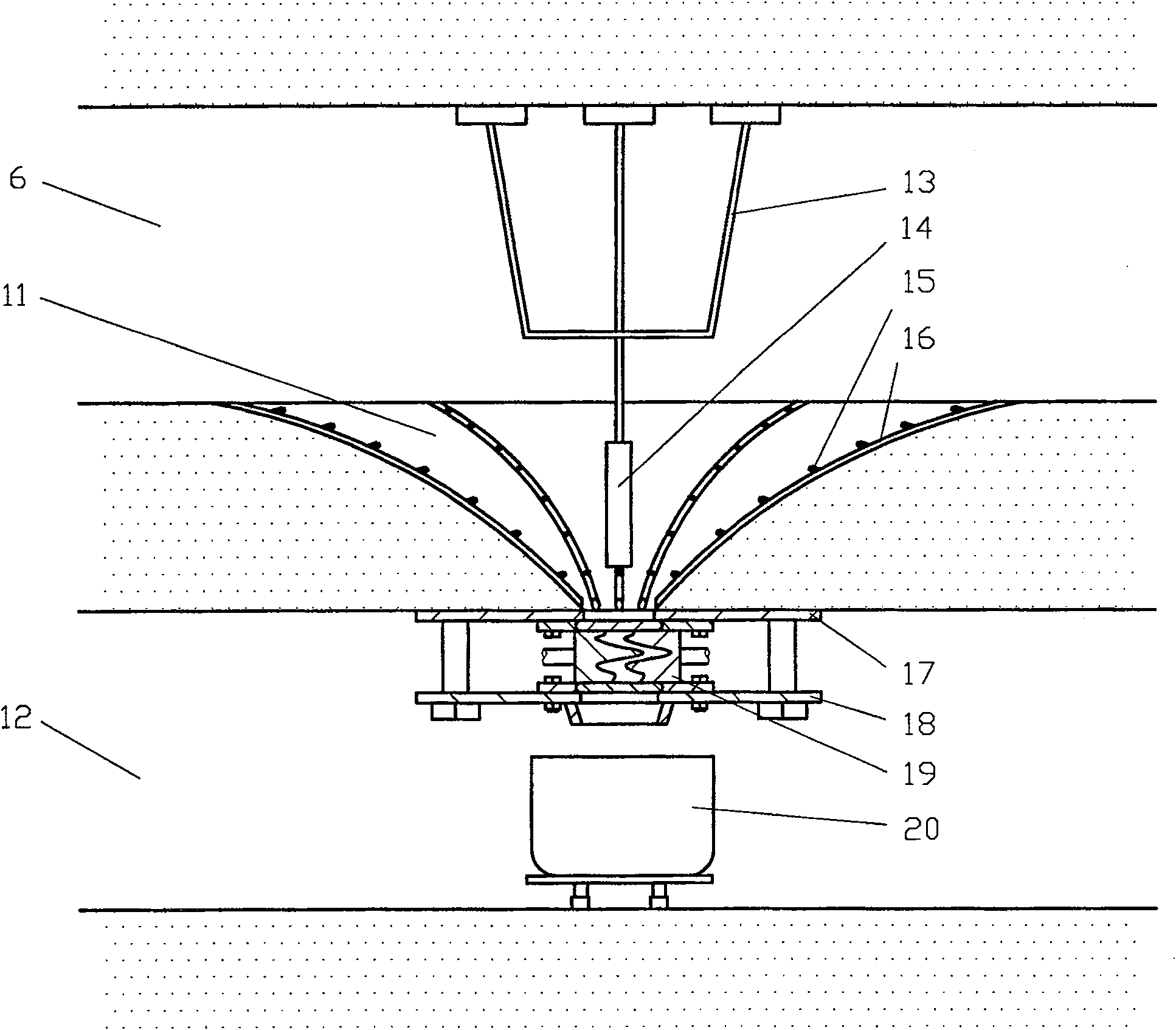

Disclosed is a steel beam hydraulic lifting emplacing device on the top of silo structure building, which comprises a sliding formwork device and a hydraulic lifting system, and is characterized in that the sliding formwork lifting frames of the sliding formwork device are connected with an inside formwork, an outside formwork, and an operating platform, a scissors support is connected between two lifting frame upright columns, the sliding formwork lifting frame is also connected with a steel beam supporting frame, the steel beam support frame is connected with the steel beam on the top of the silo to form a lifting integration, the hydraulic lifting system is utilized to be the lifting power system for the lifting integration, and the hydraulic lifting system is composed of a hydraulic jack, a support rod, a hydraulic console, and an oil circuit. The invention can rapidly, conveniently, reliably, and safely complete the construction task of mounting the steel beam on the top of the silo, without using large scale hoisting equipment, thereby avoiding the problems of difficult emplacement and lower efficiency of large scale hoisting equipment. The device of the invention can be widely applied to the hoisting and emplacement construction for the steel frame on the top of silo buildings.

Owner:THE THIRD CONSTR ENG CO LTD OF CHINA CONSTR SECOND ENG BUREAU +1

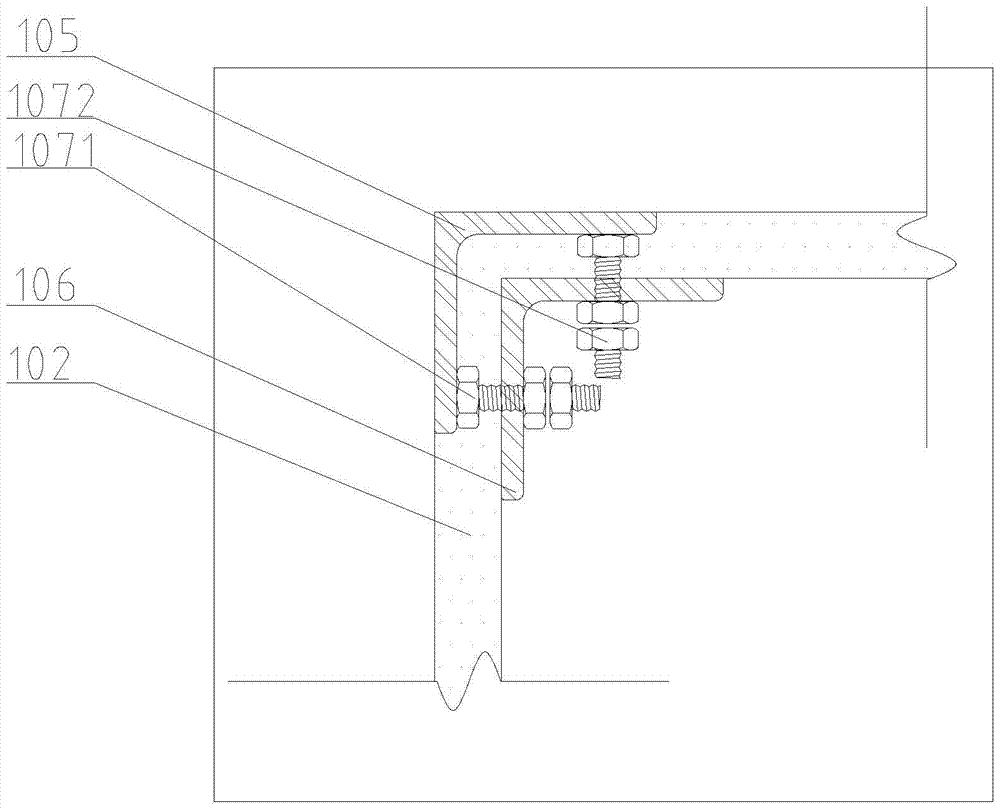

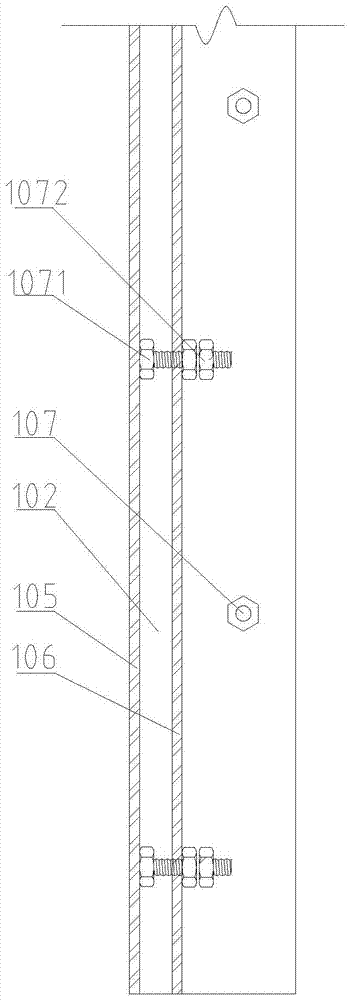

Installation and construction method for large suspension glass curtain walls

InactiveCN104818787ASave entry feeSave rental feeWallsBuilding material handlingFalseworkSocial benefits

The invention discloses an installation and construction method for large suspension glass curtain walls. The installation and construction method comprises the steps of construction preparation, embedded part prefabrication, scaffold building, glass bracket designing and manufacturing, glass transportation, measurement and paying-off location, embedded part checking, rear-arranged embedded part installation, upper bearing structure installation, suspension clamp installation, lower and side frame installation, full glass panel installation, glass panel checking, glass rib installation, joint glue injection, cleaning and acceptance check. According to the invention, the slotting fee and rental fee of large suspension machines can be saved, manual labor use can be reduced and the labor cost can be lowered; manufacturing and use are convenient, the construction efficiency is high, the construction speed is high, the construction period can be shortened by more than 20%, and the comprehensive economic benefits are remarkable; construction noise is lowered, high-noise construction equipment is not adopted, and therefore the noise influence to the surroundings is lowered to the maximum degree; the whole installation process is completed on the ground and in scaffolds, and therefore the personal safety of constructors is guaranteed, and the social benefits are high.

Owner:CHANGZHOU HUISEN ELECTRONICS

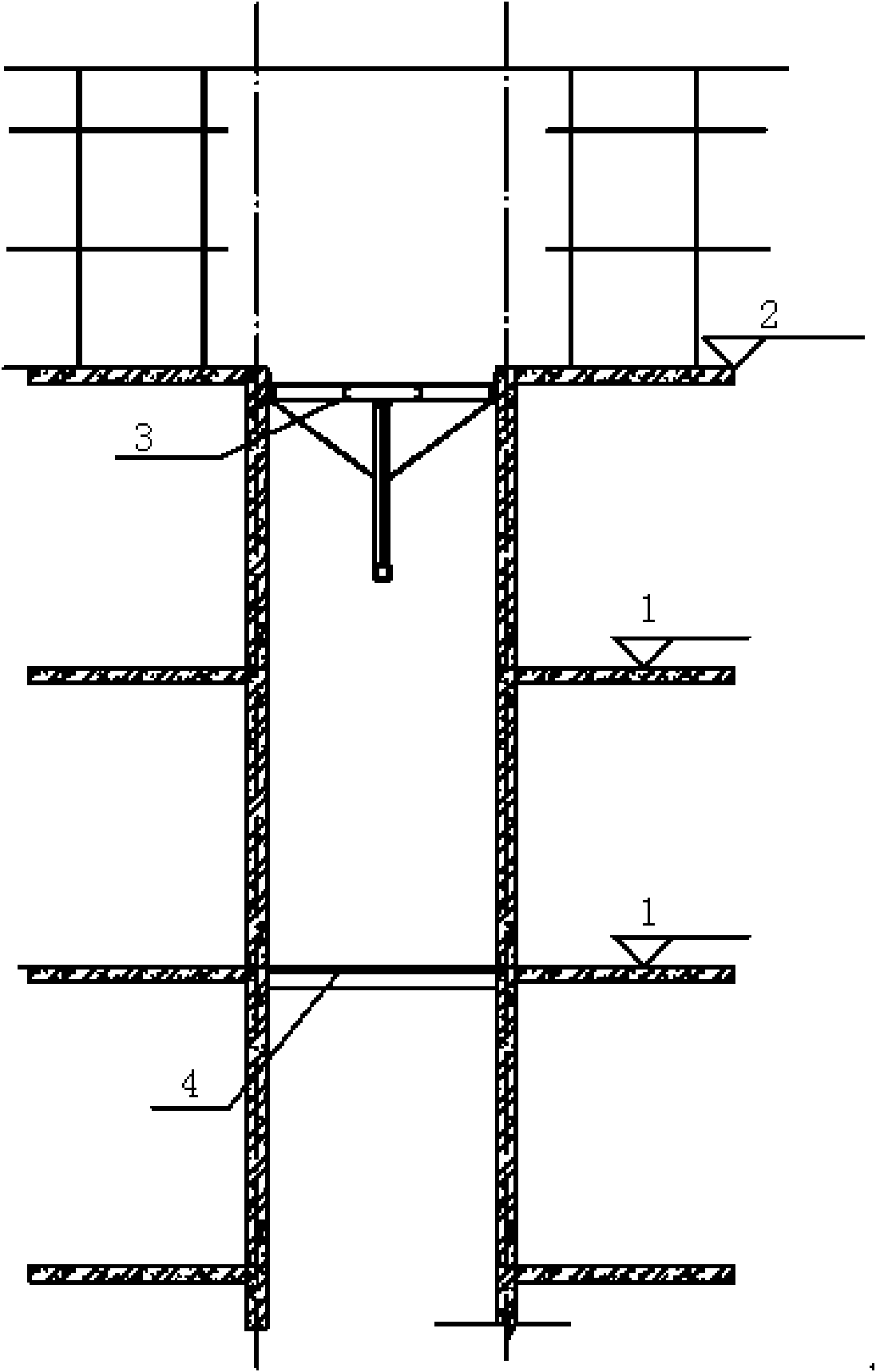

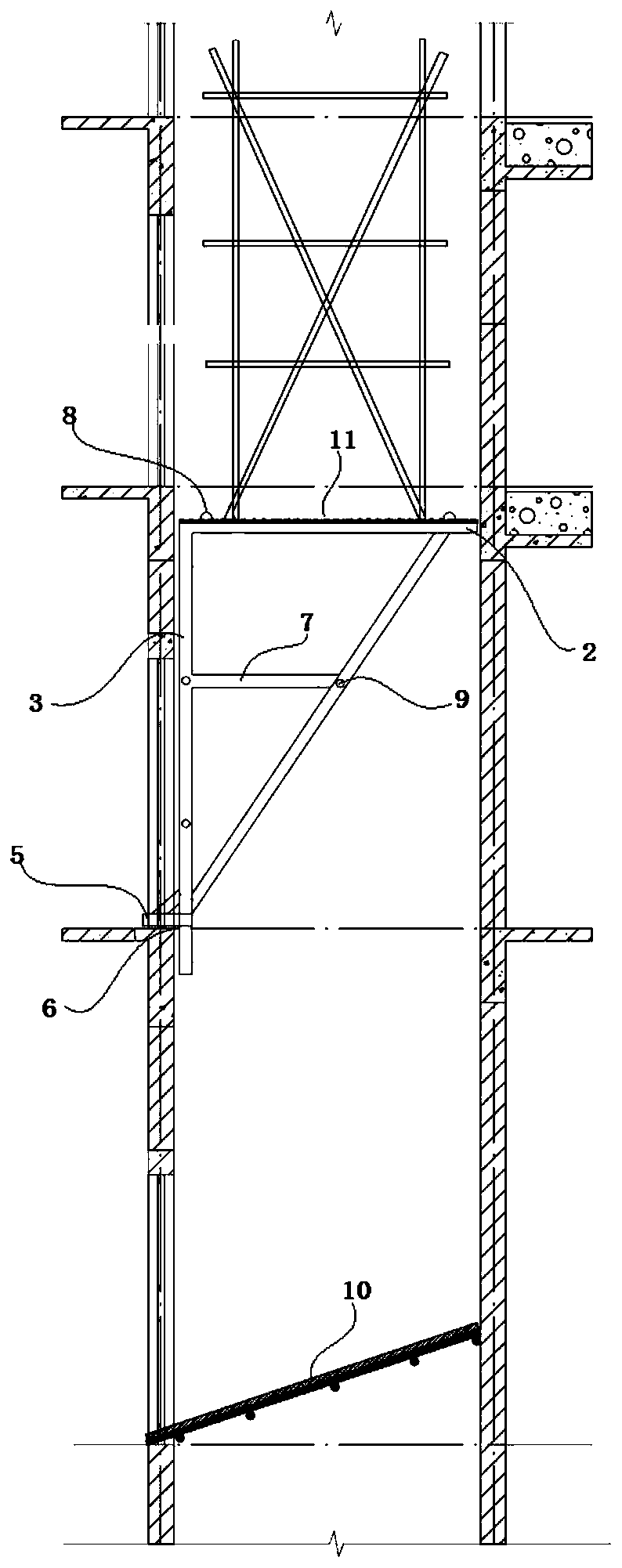

Constructing method for high-rise building elevator shaft through elevating type safety protection steel platform

InactiveCN102031862AEasy to processSave leaseBuilding material handlingBuilding support scaffoldsEconomic benefitsArchitectural engineering

The invention discloses a constructing method for a high-rise building elevator shaft through an elevating type safety protection steel platform, comprising the steps of: firstly, manufacturing a steel platform matched with the size of an elevator shaft, then installing the steel platform inside the bottom layer of the elevator shaft, carrying out elevator shaft construction operation by constructors standing on the steel platform, elevating the steel platform layer by layer after the construction on the current operation layer is completed until the steel platform is elevated to the elevator shaft of the upper floor to facilitate the elevator shaft construction operation, sealing the lower elevator shaft after the steel platform is elevated, and repeating the steps until the elevator shaft construction on all the floors of the whole building is completed. The construction method is featured by safety, simplicity and convenience for operation, easiness for construction, obvious economic benefits and the like, has the greatest advantages of saving lease expense of raw materials and facilitating cost control, and is particularly suitable for high-rise buildings and multistoried buildings with longer construction periods.

Owner:THE THIRD CONSTR & ENG OF CCFED

Installation method for suspending cable bridge under high-altitude platform

ActiveCN106848938ASave rental feeConstruction space is narrowApparatus for laying cablesCable trayShop drawing

The invention discloses an installation method for suspending a cable bridge under a high-altitude platform. The method comprises the steps of production and installation of a mobile platform, installation of the cable bridge, laying of a spring board and a safety rope, cable laying and subsequent disassembly and the like. The mobile platform comprises a steel tube erect rod, a cross beam, a skipping board, and a right-angle coupler, the steel tube erect rod comprises a left erect rod and a right erect rod, the bridge installation position is surveyed and mapped on site based on an operation map, the steel tube right-angle coupler is utilized to connect the left erect rod and the right erect rod, and the left erect rod, the right erect rod and a lifting lug at the upper end are connected through bolts, which facilitates assembly and disassembly. By means of the installation method for suspending the cable bridge under the high-altitude platform, the operation tasks of installation of the bridge and laying of cables in the bridge can be completed safely, efficiently, conveniently and with good quality, and the rental fee of all-around scaffolds is saved; the problem that in a conventional installation method, a passage is occupied for a long time is solved, and the installation method for suspending the cable bridge under the high-altitude platform has the advantages that the installation is convenient, the operation is safe, the operation cost is reduced, and the passage is not occupied and the like.

Owner:CHINA MCC17 GRP

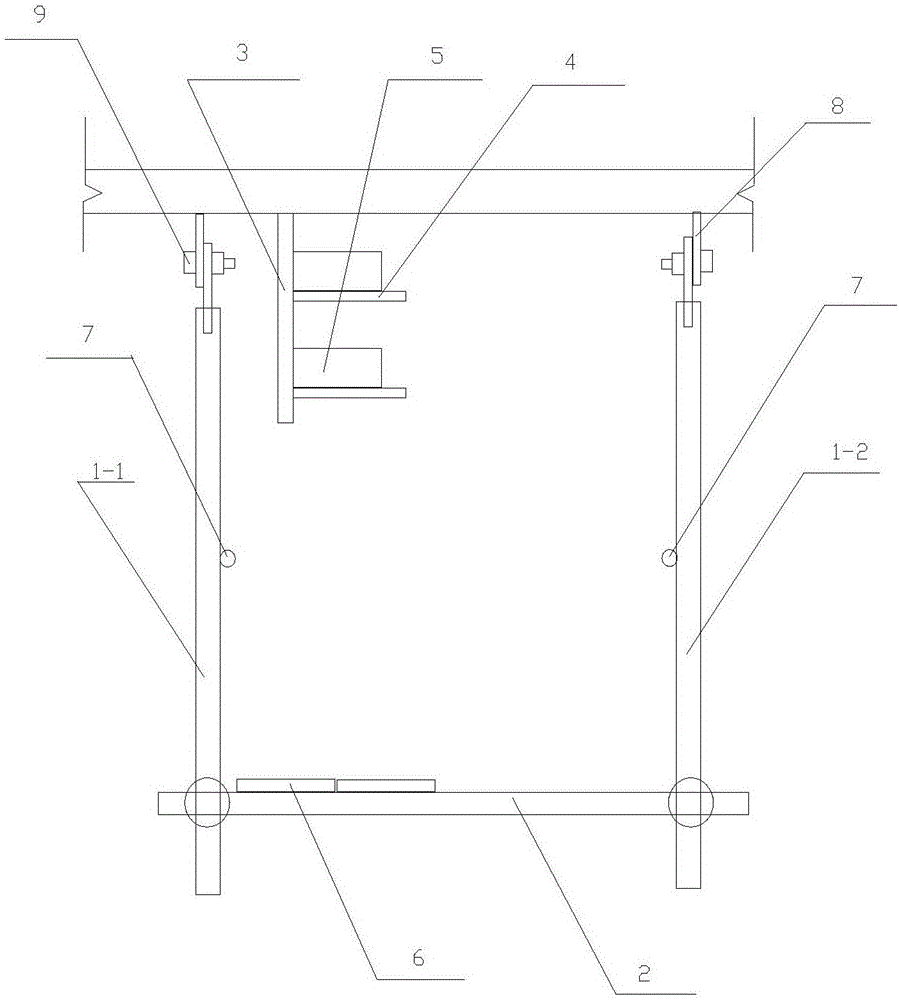

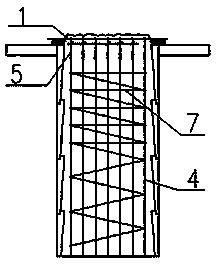

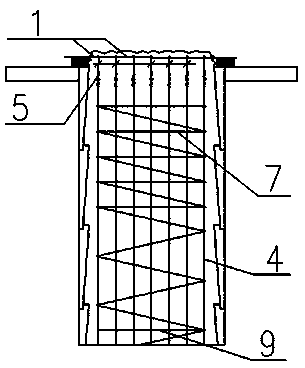

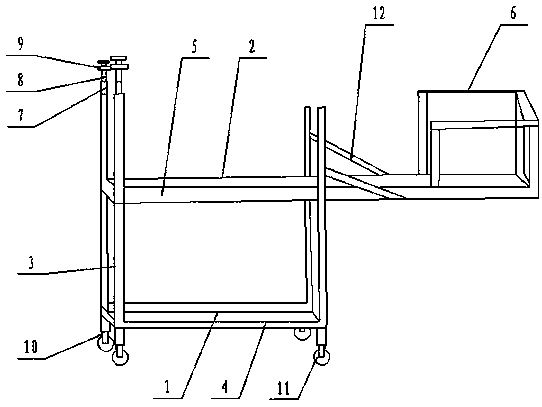

Manufacturing and mounting method and auxiliary mounting device for reinforcement cage in pile hole

The invention discloses a manufacturing and mounting method and an auxiliary mounting device for a reinforcement cage in a pile hole. The method comprises the steps as follows: a polygonal mounting rack with supporting legs arranged at all tips is placed at the opening of the dug pile hole, main ribs are gradually placed in the pile hole through guide grooves, and then the main ribs, outer hooping ribs and inner reinforcing ribs are fixedly mounted through soft ropes. The method is simple in construction technology and applicable to mounting of reinforcing steel bars in a large-diameter ultra-deep manually-dug pile, particularly to mounting of the reinforcing steel bars with poor pile hole position conditions or various pile hole size type conditions, and has the very good realistic value.

Owner:CHINA CONSTR FOURTH ENG DIV

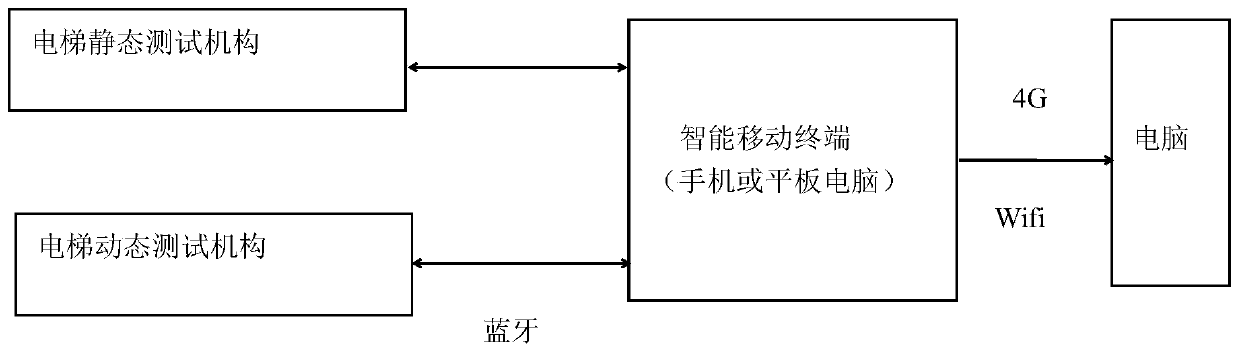

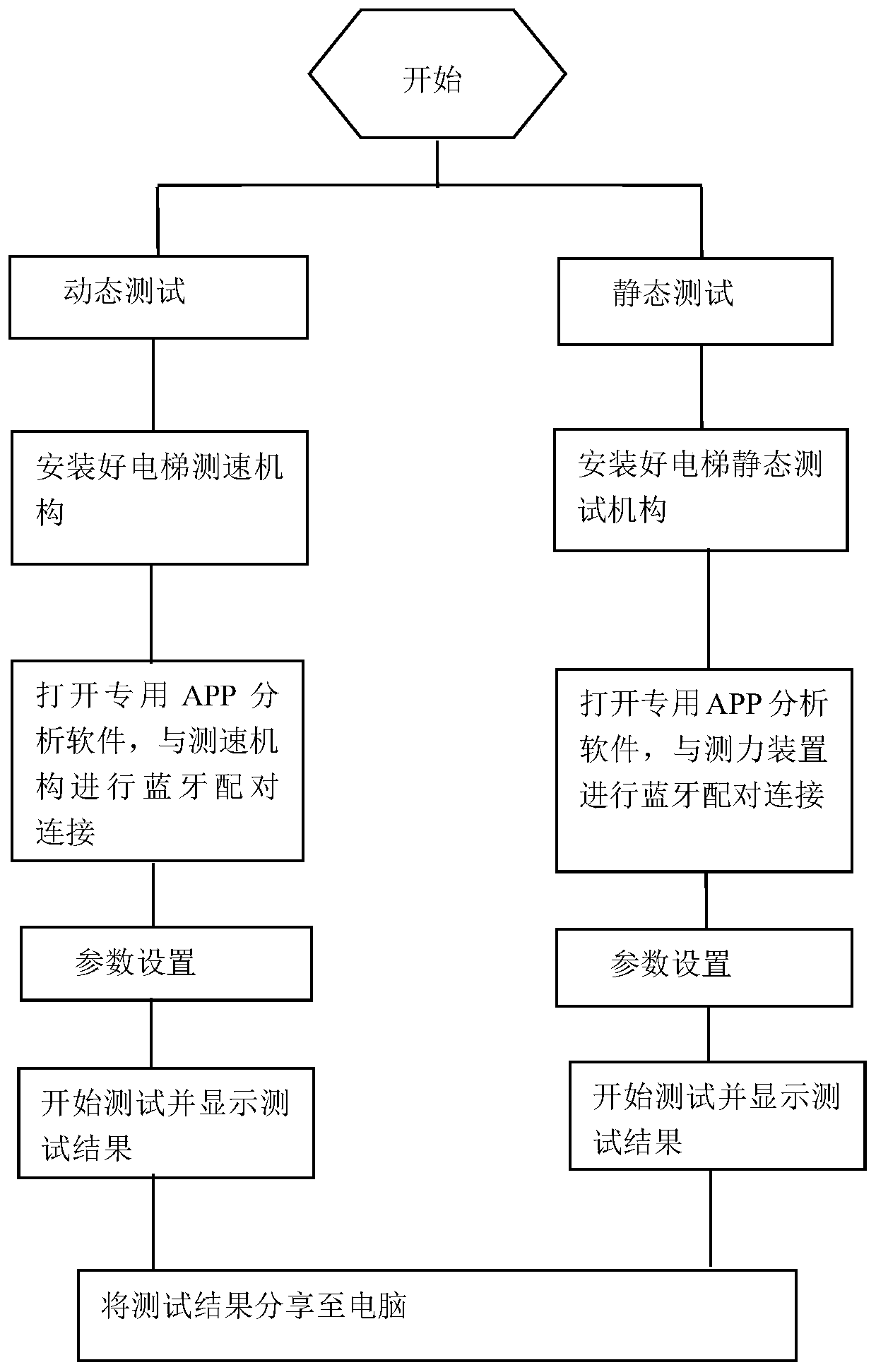

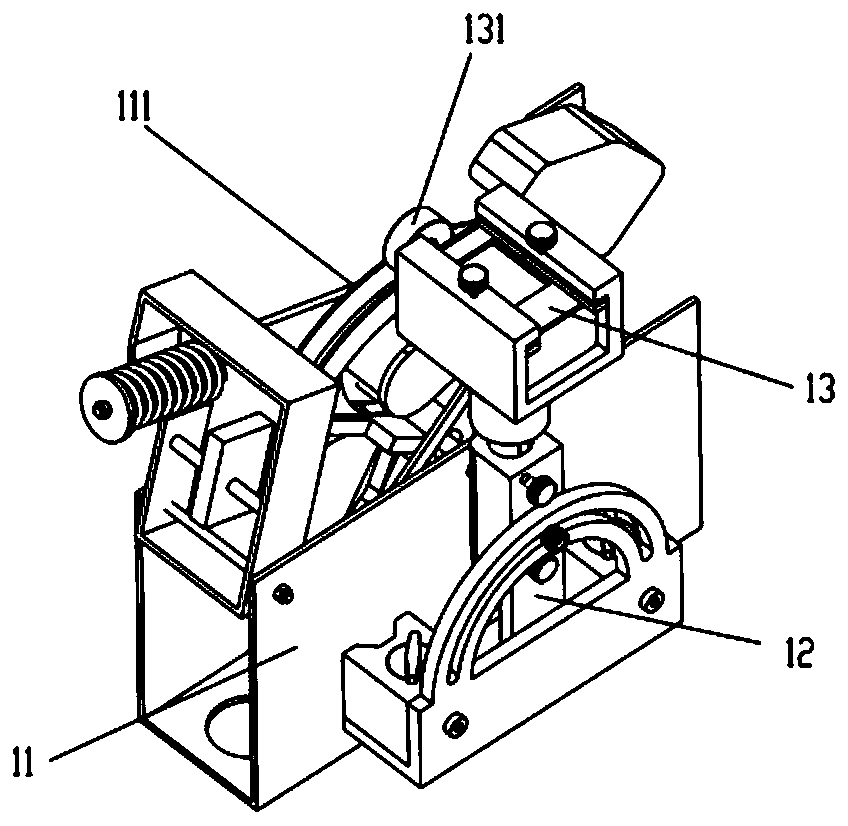

1.25-time brake experiment zero-load testing device and testing method of towing lift

ActiveCN109748168AEasy to operateReliable test resultsElectrical testingApparatus for force/torque/work measurementEngineeringTest fixture

The invention relates to a 1.25-time brake experiment zero-load testing device and a testing method of a towing lift, and can solve the technical problems that the damage of 1.25-time rated experimentto the lifts is large, and risk of experiment on old lifts is high. The 1.25-time brake experiment zero-load testing device comprises a lift static testing mechanism, a lift dynamic testing mechanism, an intelligent portable terminal and special APP analysis software, wherein the intelligent portable terminal is in communication with a speed testing mechanism and a force testing device in a wireless bluetooth manner; the combination testing of the lift speed testing mechanism and the intelligent portable terminal is dynamic testing; and the combination testing of the lift static testing mechanism and the intelligent portable terminal is static testing. The 1.25-time brake experiment zero-load testing device disclosed by the invention adopts a non-loaded detection method, and has the advantages that a link of repeatedly loading and unloading weights and regulating a weighting switch is omitted, labor cost and time cost are saved, and rental charge and cartage of the weights are saved;and under the premise that the inspection quality is guaranteed, the inspection efficiency is improved, and the damage of the 1.25-time rated load experiment to the old lifts is also avoided, and therisk of the experiment is reduced.

Owner:安徽中科智能高技术有限责任公司 +2

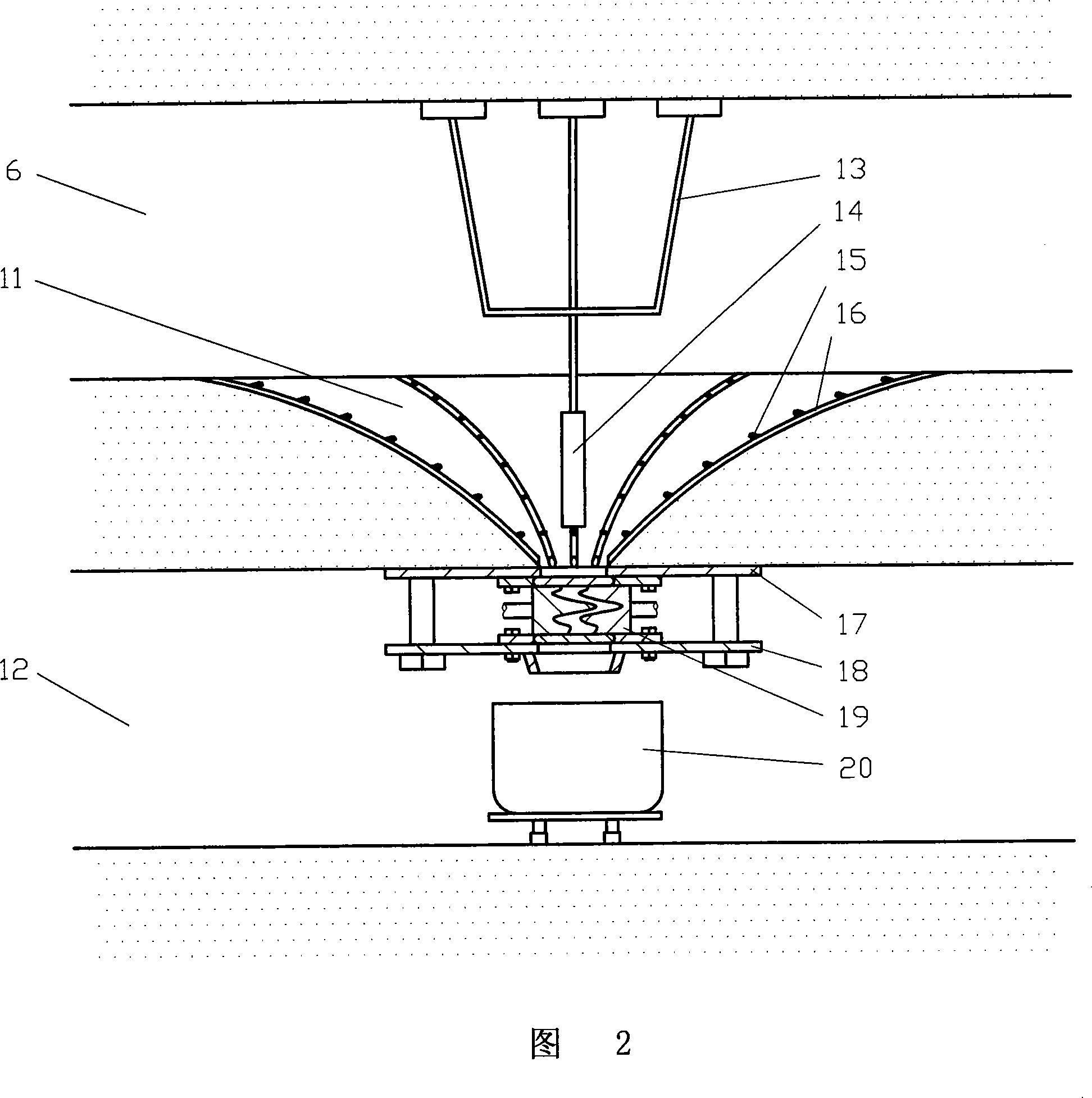

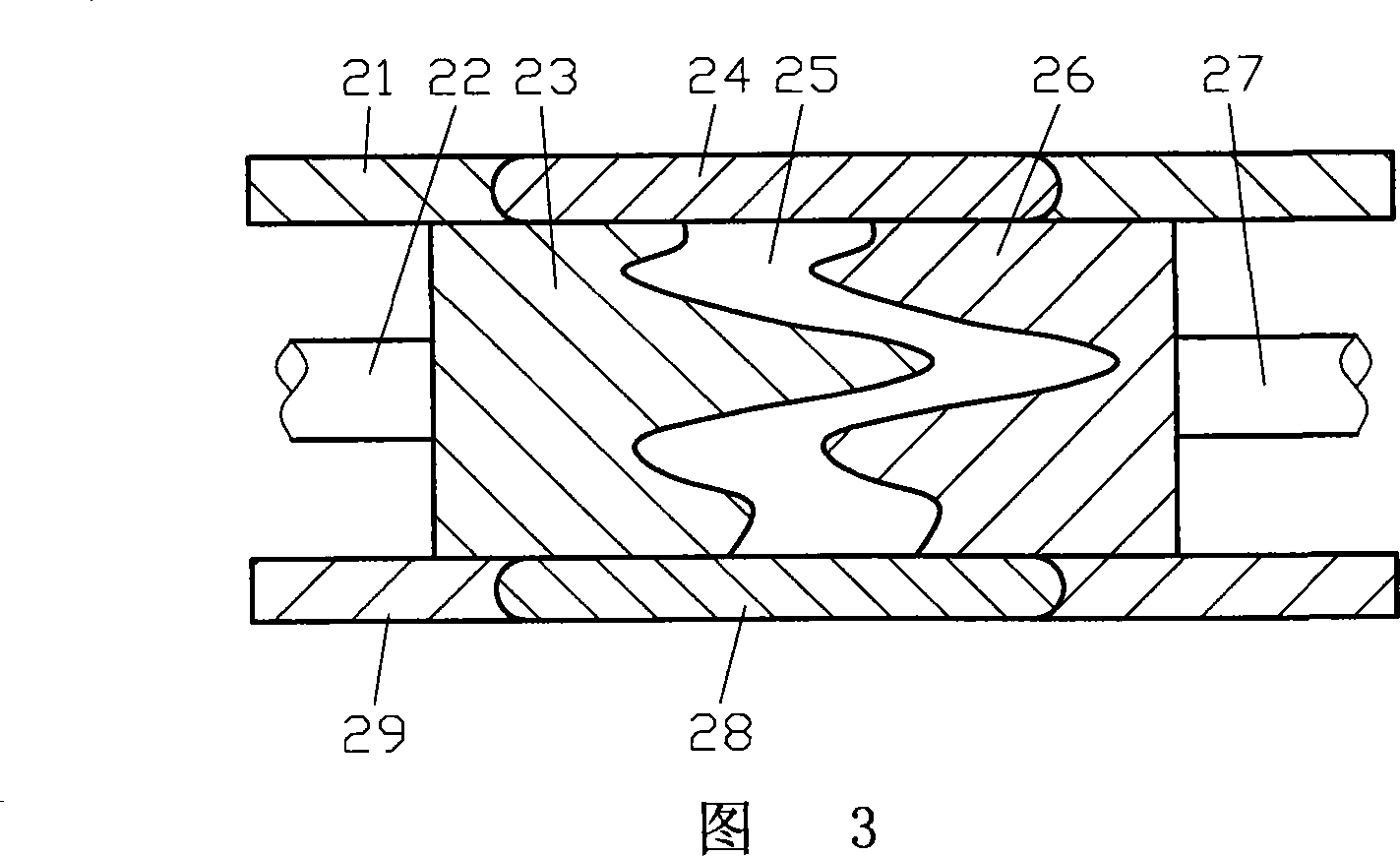

Apparatus for cleaning and transporting coal-mine water sump slurry

InactiveCN101074608AReduce troubleRelieve pressureEarth drilling and miningUnderground transportSlagSlurry

The invention relates to a water coal mud clear transforming device used in the mine well which is set with the center pump room, the inner / out center water store and bypass parallel with the mine lane. The lower of the inner / out center water store are opened with the left / right drainage lane and dog hole. The left and right drainage lanes are connected with the bypass, the drainage hole is opened at the bottom of the water cabin bottom; the output of the drainage hole is fixed with the upper / lower steel frame between which is fixed with the pressure releasing buffer valve. Under it has the coal mud dewater treating vehicle. The vehicle includes the condensing box, the slag pump, the hydraulic pressure station, the filter press, the spiral conveyer and the tank car. The output of the slag pump is connected with the inlet of the filter press. The filter press is controlled by the hydraulic pressure station which the output is fixed with the spiral conveyer, under which is the tank car. It can improve the safety ratio and water resistance ability.

Owner:暴万林 +2

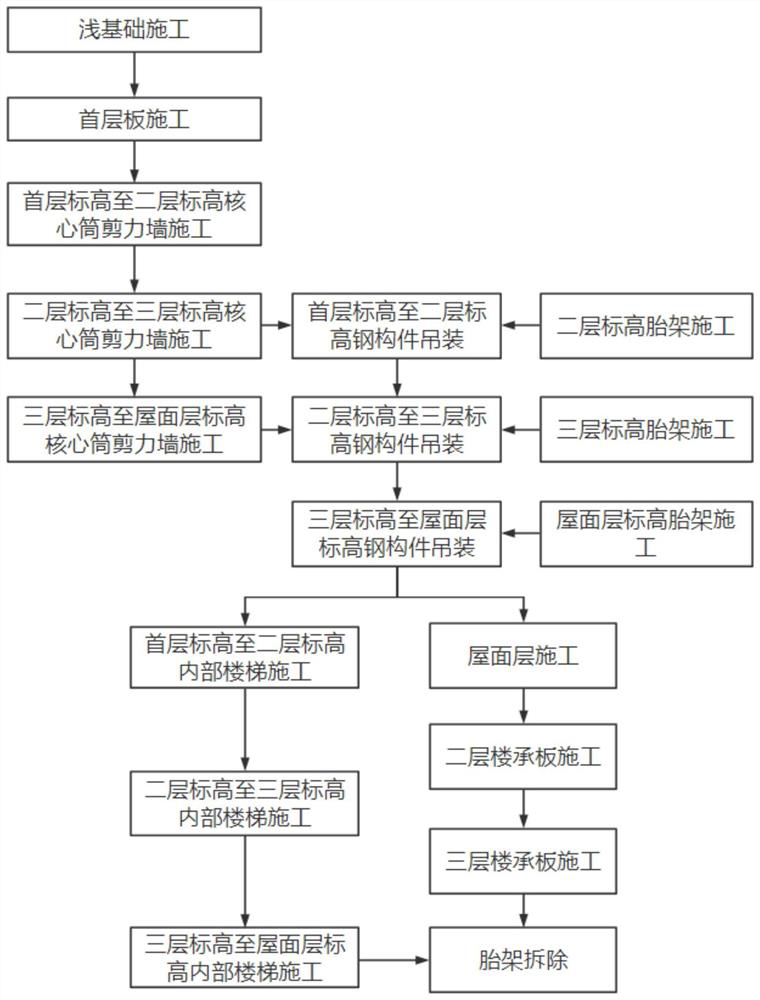

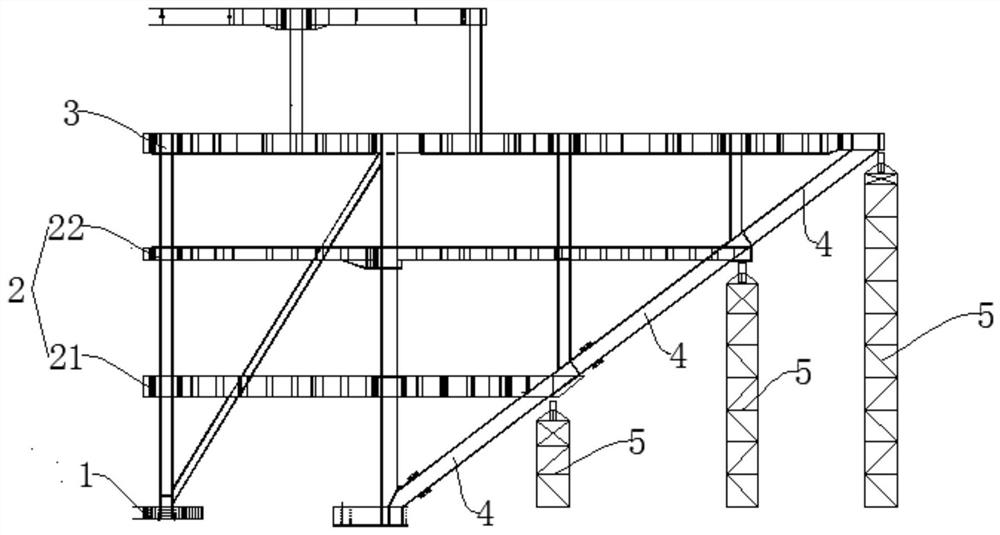

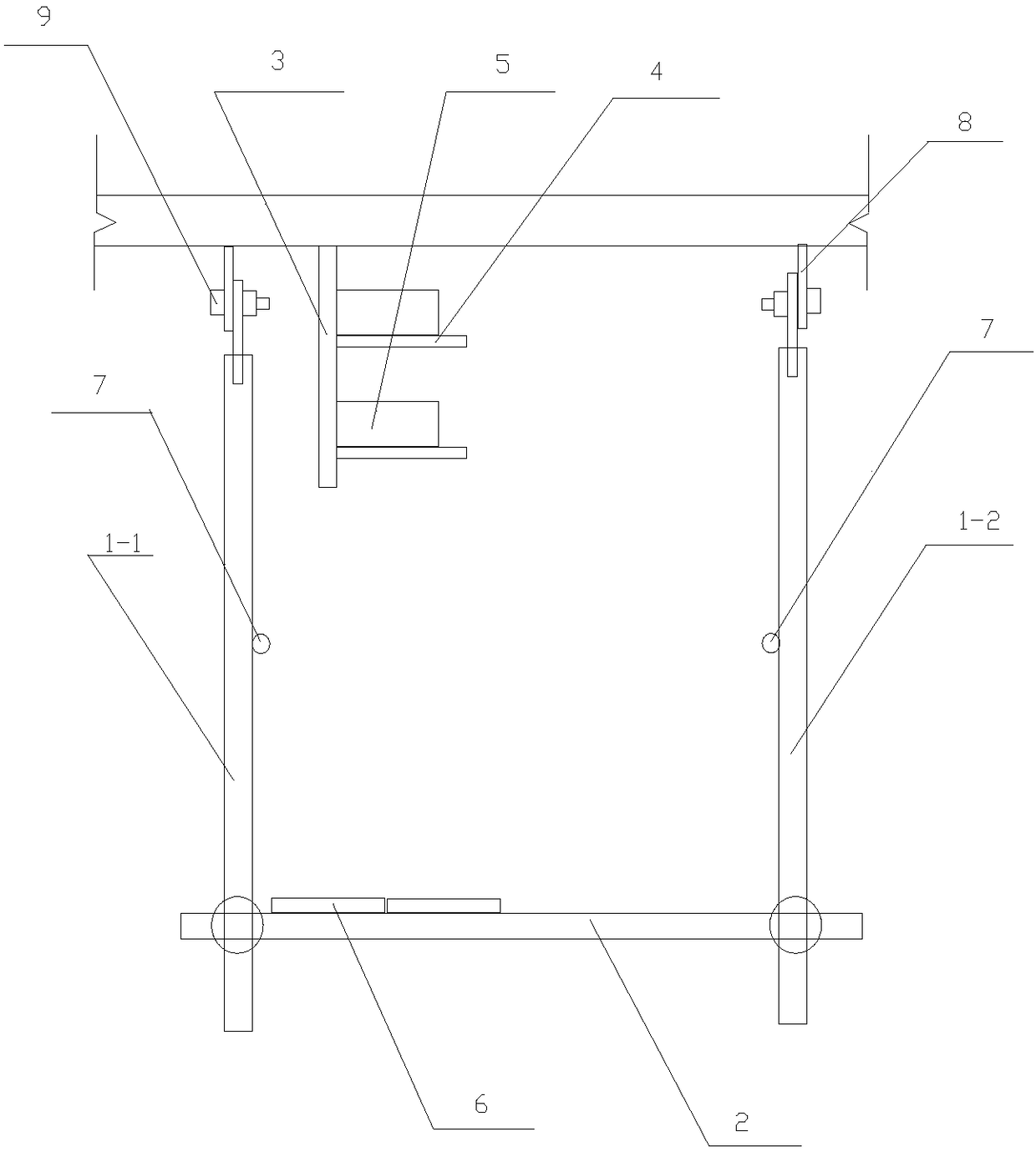

Construction method beneficial to horizontal force resistance of multi-layer special-shaped steel structure building

ActiveCN112160594AImprove stabilityShorten the construction periodWallsFloorsHorizontal forceArchitectural engineering

The invention relates to the technical field of steel structure system building construction, in particular to a construction method beneficial to horizontal force resistance of a multi-layer special-shaped steel structure building. The construction method comprises the steps that floor support plates are constructed, the floor support plates comprise a first floor plate, a middle floor support plate and a roof layer, and the roof layer is constructed in advance of the middle floor support plate. The roof layer is constructed, the concrete of the roof layer can reach the design strength in advance, the roof layer and the multi-layer special-shaped steel structure building are connected into a whole and stressed together, the stability of the structure is improved, a jig frame can be disassembled in advance, the construction period is shortened, and the leasing cost is reduced.

Owner:CHENGDU NO 4 CONSTR ENG

A method for hanging and installing cable bridges under high-altitude platforms

ActiveCN106848938BSave rental feeConstruction space is narrowApparatus for laying cablesCable trayEngineering

The invention discloses an installation method for suspending a cable bridge under a high-altitude platform. The method comprises the steps of production and installation of a mobile platform, installation of the cable bridge, laying of a spring board and a safety rope, cable laying and subsequent disassembly and the like. The mobile platform comprises a steel tube erect rod, a cross beam, a skipping board, and a right-angle coupler, the steel tube erect rod comprises a left erect rod and a right erect rod, the bridge installation position is surveyed and mapped on site based on an operation map, the steel tube right-angle coupler is utilized to connect the left erect rod and the right erect rod, and the left erect rod, the right erect rod and a lifting lug at the upper end are connected through bolts, which facilitates assembly and disassembly. By means of the installation method for suspending the cable bridge under the high-altitude platform, the operation tasks of installation of the bridge and laying of cables in the bridge can be completed safely, efficiently, conveniently and with good quality, and the rental fee of all-around scaffolds is saved; the problem that in a conventional installation method, a passage is occupied for a long time is solved, and the installation method for suspending the cable bridge under the high-altitude platform has the advantages that the installation is convenient, the operation is safe, the operation cost is reduced, and the passage is not occupied and the like.

Owner:CHINA MCC17 GRP

Construction method for automobile adit and slant chute

InactiveCN102352758ALabor savingShorten the construction periodUnderground chambersTunnel liningWellheadEngineering

The invention discloses a construction method for a slant chute, which comprises the following steps: firstly, performing a guniting operation on the inner walls of the slant chute and a tunnel; then, pouring a vertical wall for connecting bottom plates at the bottom part of the slant chute; supporting an arc-shaped template in the slant chute along the central points of the bottom plates; adjusting the included angle between the axis of the arc-shaped template and the bottom plates to be 70+ / -2 degrees; adjusting the deviation between the center of the arc-shaped template and the central points of the bottom plates to be less than or equal to 2mm; then, casting concrete; supporting the arc-shaped template again along the arc-shaped template; and pouring the concrete until the concrete is poured to the upper wellhead of the slant chute after the included angle between the axis of the arc-shaped template and the bottom plates and the deviation between the center of the arc-shaped template and the central points of the bottom plates are adjusted once again. In the construction method for the slant chute, process monitoring and control and the arc-shaped setting template can be fully utilized in the complicated and severe construction environments of mines to achieve the goal of controlling the roundness and the angle of the axis of the slant chute before the concrete is poured, thereby, secondary rework loss is avoided, the quality of the slant chute is ensured, manual work, materials and turnover tools are saved, the construction period is shortened, and the entity quality of the slant chute is good. The construction method for the slant chute has good economic benefits.

Owner:河北省第四建筑工程有限公司

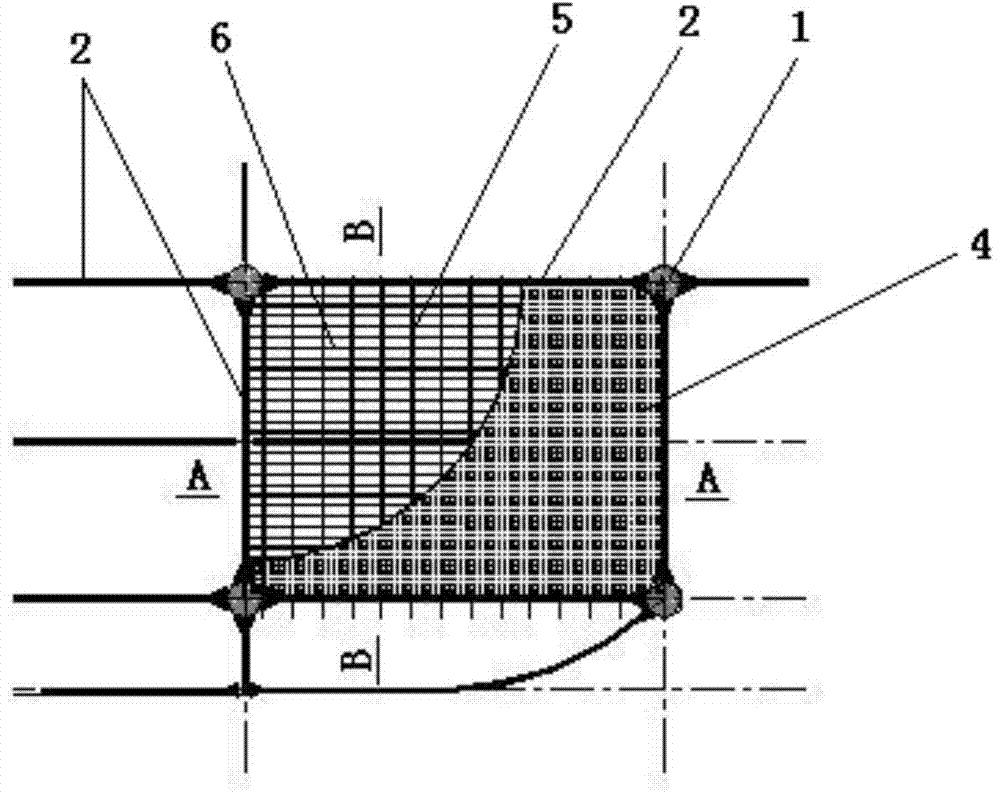

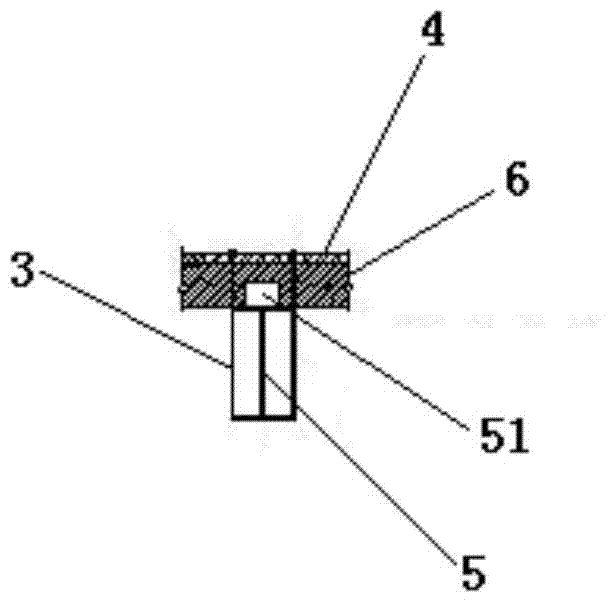

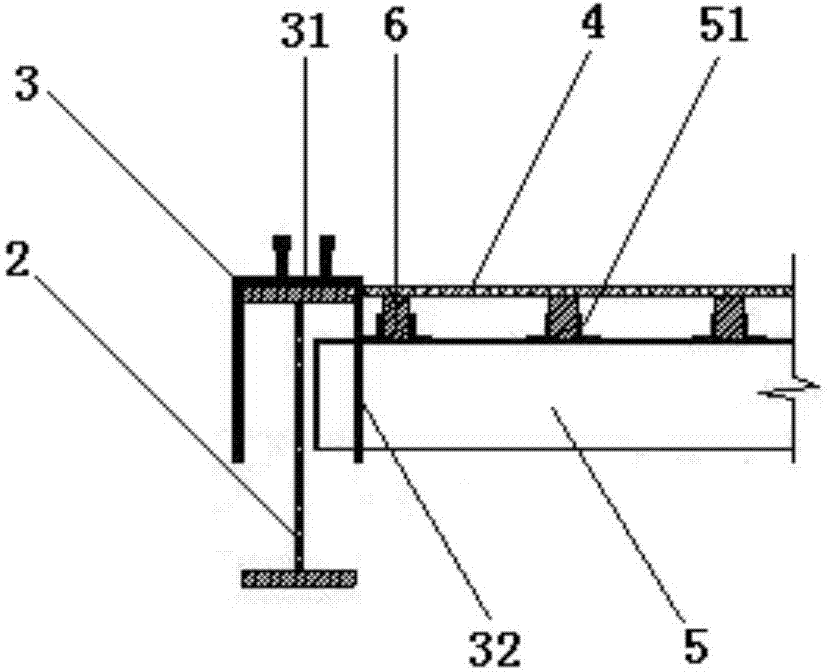

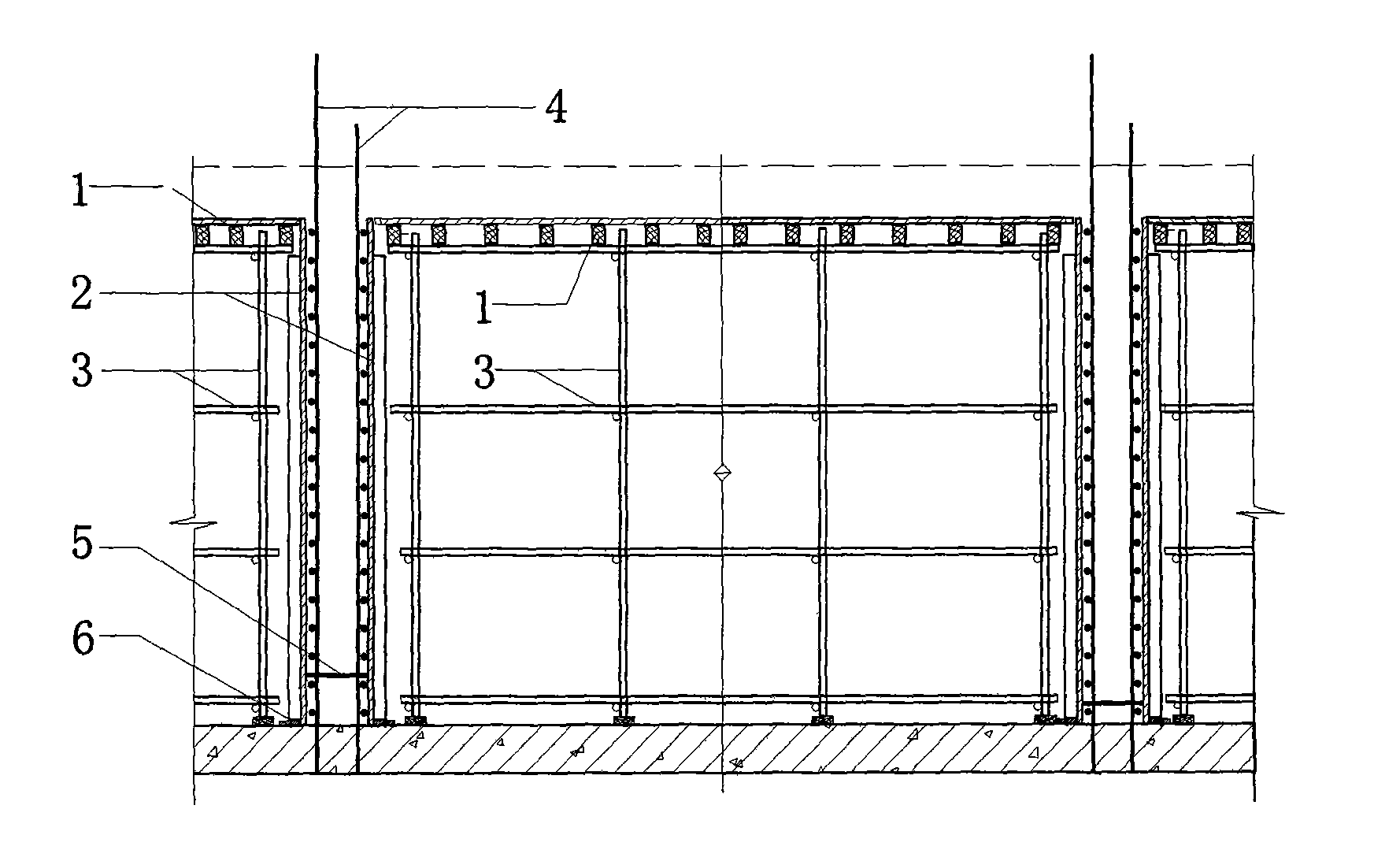

Template overhanging construction method for floor system with composite structure by utilizing profiled steel beams

InactiveCN104499715AReduce labor intensityIncrease usageBuilding material handlingSupporting systemJoist

The invention discloses a template overhanging construction method for a floor system with a composite structure by utilizing profiled steel beams. In the construction method, the profiled steel beams are utilized for overhanging templates to establish a supporting system; H-shaped steel joists are used as mail joists; the main joists are connected with the profiled steel beams through overhanging rings; a template system is suspended on the profiled steel beams, and the excellent mechanical properties of the H-shaped steel joists are sufficiently utilized to effectively transmit loads of the upper template to the profiled steel beams, so that the defects of the lower full hall scaffold supporting system of templates are overcome, the method is safe and reliable, the construction progress is greatly enhanced, and the labor intensity of workers is reduced; besides, the template system can be recycled, so that the use rate of materials is increased, and the construction cost is reduced; besides, the templates and sub-joists are made of macromolecular plastics, so that the loads of the template system are greatly reduced, and the whole stability of the supporting system is largely improved; materials are not easy to damage, so that the material turnover rate is greatly increased; the method is specially suitable for the construction of steel structural concrete floor and frame-structure concrete floor plates of high-rise buildings.

Owner:NANTONG CONSTR PROJECT GENERAL CONTRACTING

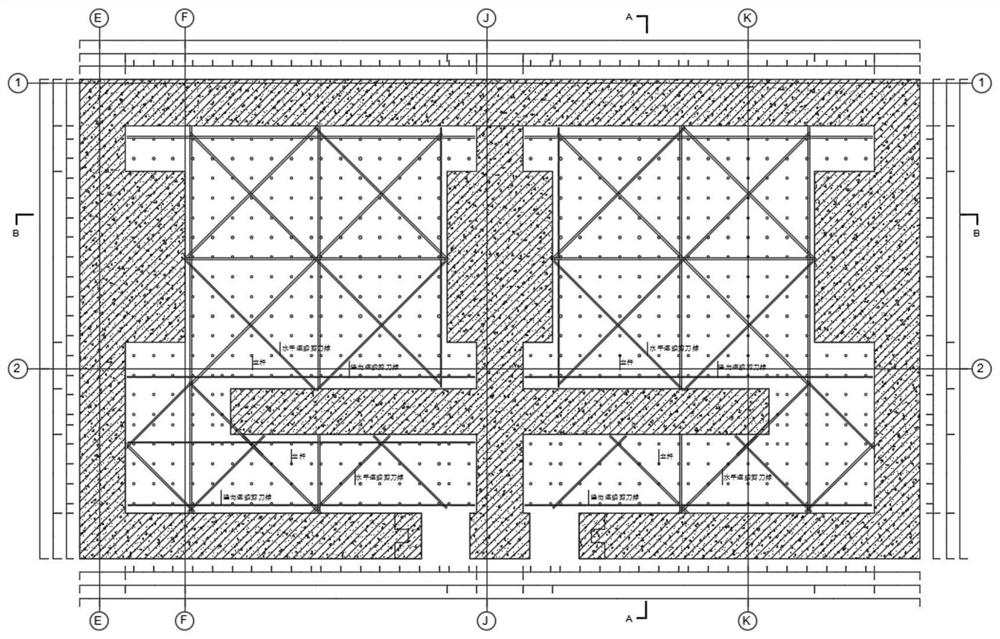

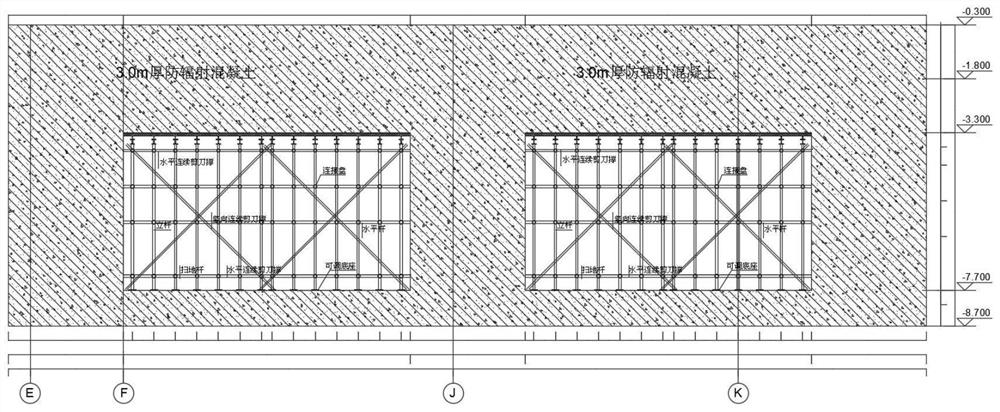

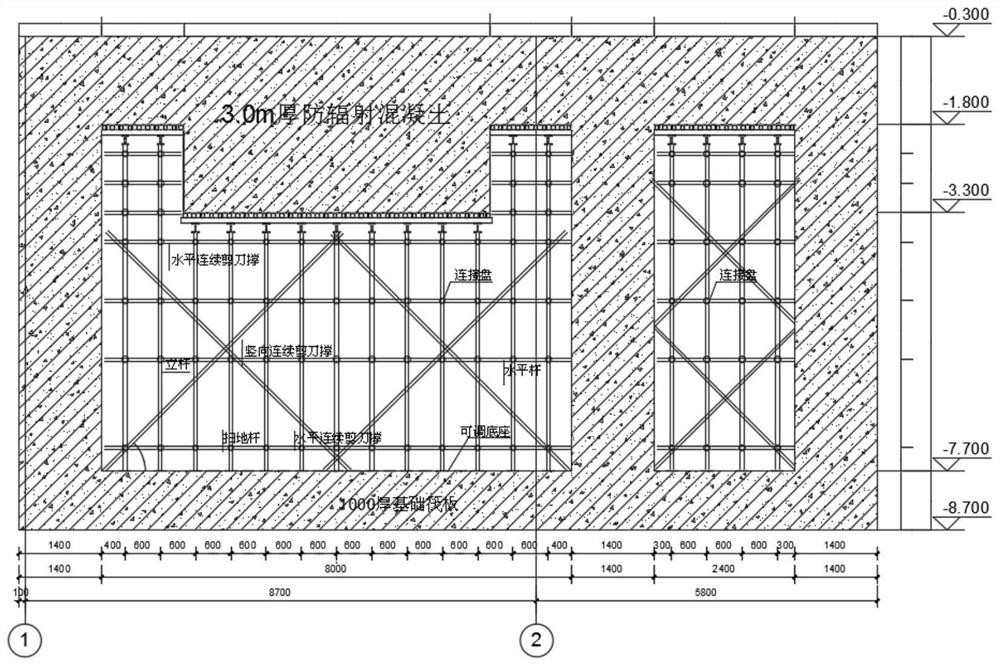

Construction method of super-thick overweight radiation protection concrete cast-in-place beam plate formwork supporting system

InactiveCN113090018AImprove bearing capacityReasonable mechanical designForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksSupporting systemArchitectural engineering

The invention discloses a construction method of a super-thick overweight radiation protection concrete cast-in-place beam plate formwork supporting system. The construction method comprises a beam plate bottom formwork, primary ridges, secondary ridges, vertical rods, horizontal rods, bottom horizontal rods, vertical inclined rods and horizontal inclined rods; the beam plate bottom formwork adopts 18 mm thick wood plywood; the secondary ridges are 70*70*5 mm square steel pipes; a distance between the adjacent square steel pipes is 150 mm; the primary ridges are 10# I-shaped steel; and a distance between every two adjacent I-shaped steel is 600 mm. The construction method of the super-thick overweight radiation protection concrete cast-in-place beam plate formwork supporting system has the advantages that the bearing capacity is high by creatively adopting the novel plate buckle type formwork supporting system, the construction of anti-radiation concrete with the thickness of 3.0 m can be well met, the risk of harmful cracks caused by insufficient rigidity of a traditional support system is avoided, the distance between the vertical rods and the step pitch of the horizontal rods can provide larger operation space compared with a traditional supporting system, and shuttling construction and material reshipment of workers are facilitated. In addition, assembly is fast, use is convenient, cost is saved, and popularization is worthy.

Owner:THE FOURTH OF CHINA EIGHTH ENG BUREAU

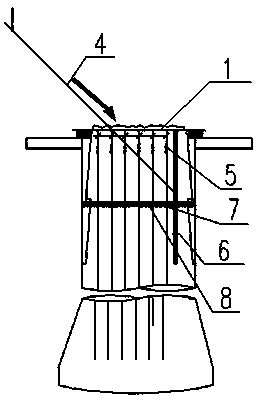

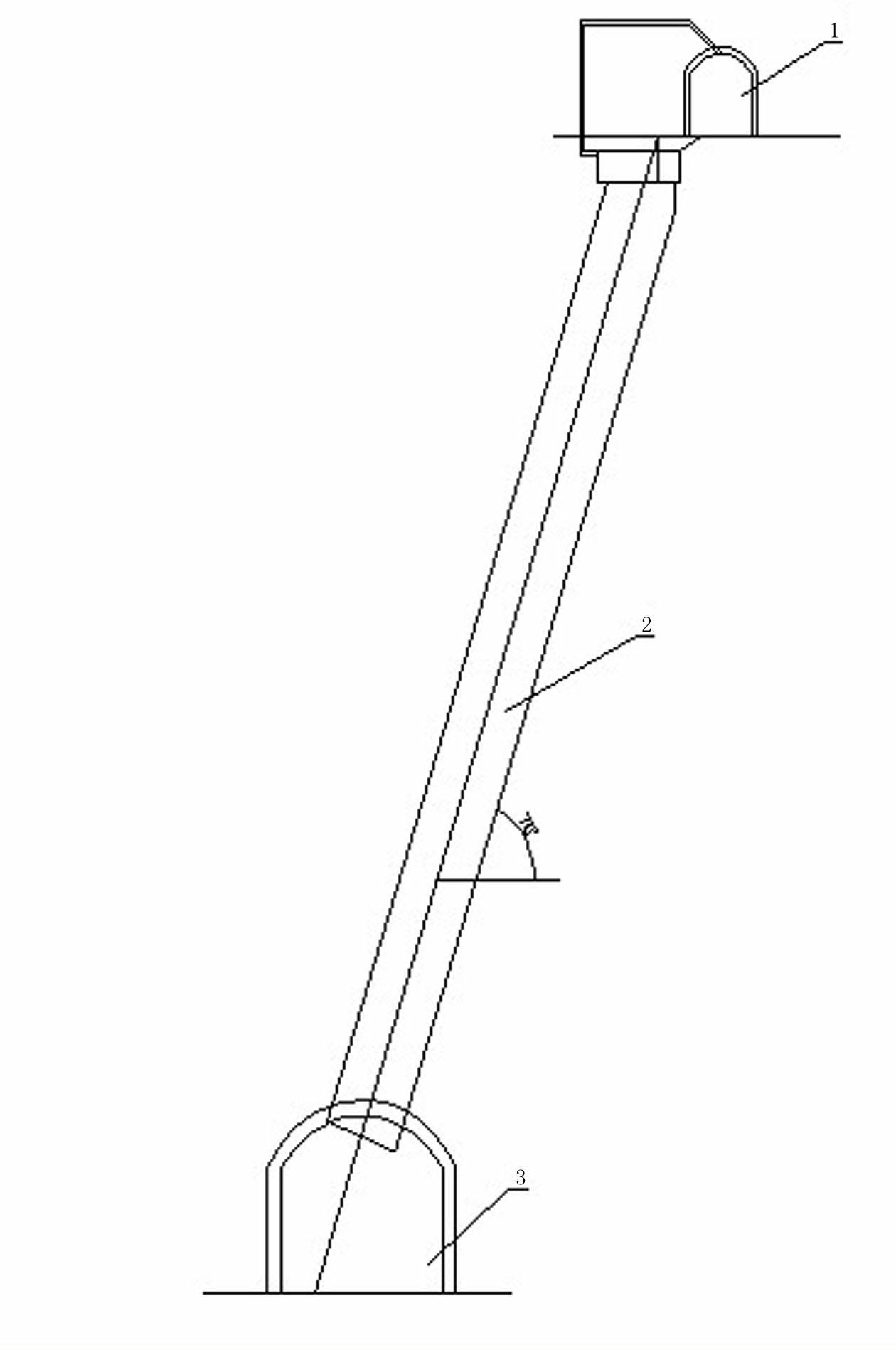

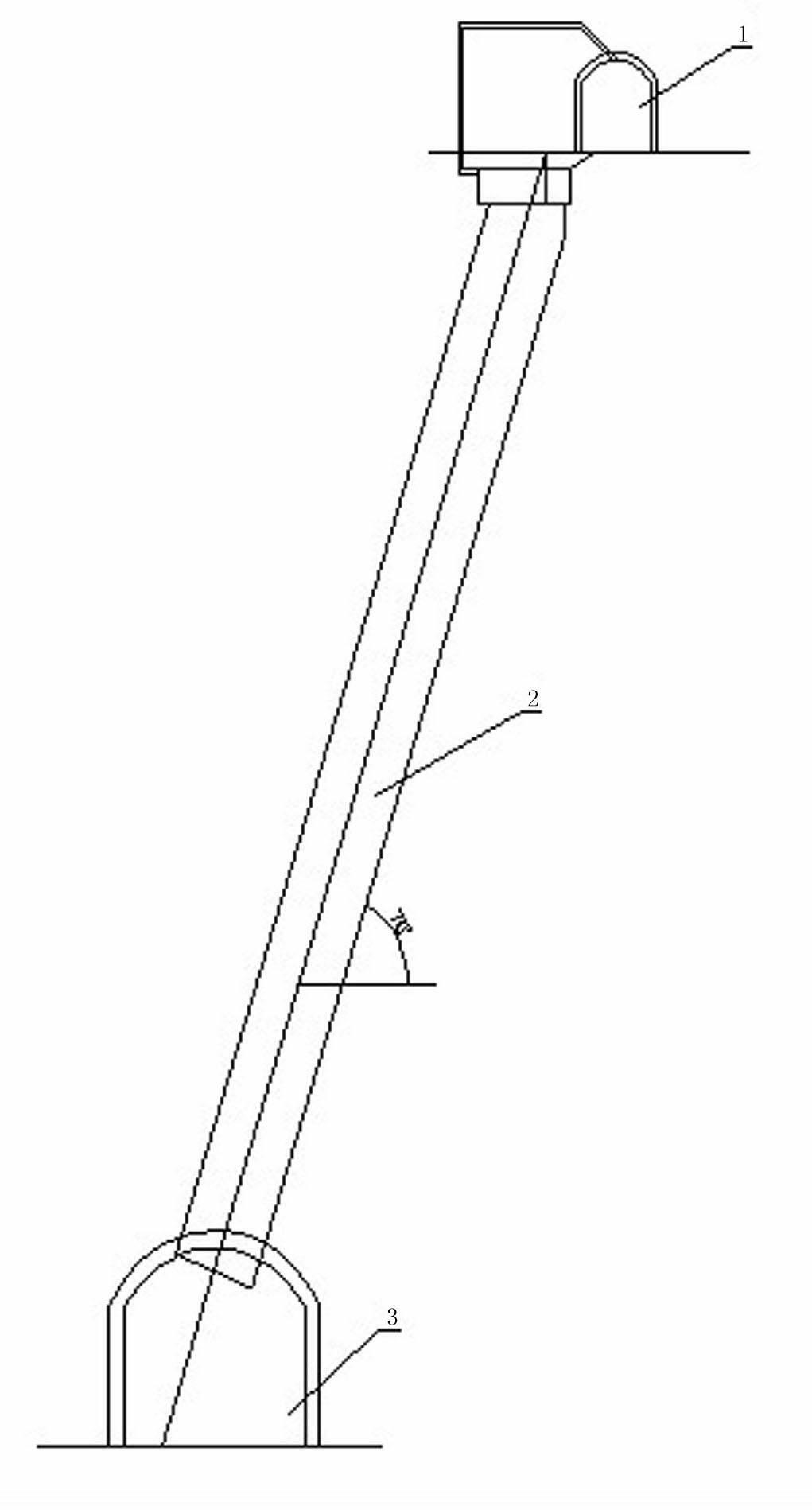

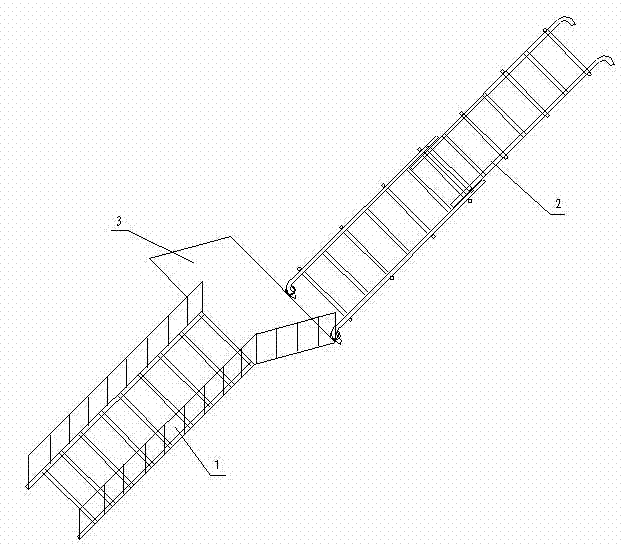

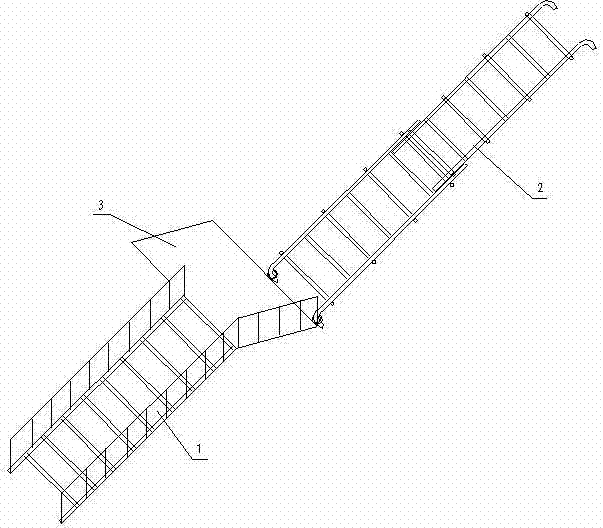

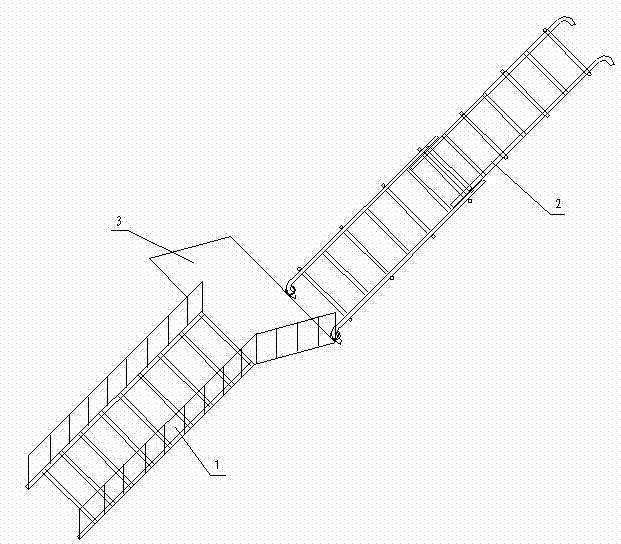

Once mounting, locating and constructing method for steel ladder outside concrete silo following sliding mould construction

The invention discloses a once mounting, locating and constructing method for a steel ladder outside a concrete silo following sliding mould construction. A construction process comprises the following steps of: leaving an upper inlet on a sliding mould operating platform of the concrete silo and fixing an upper end of a prepared tool type pulling steel ladder on a sliding mould enclosed ring; after sliding the sliding mould operating platform to a preset height during a concrete silo construction process, welding an engineering steel ladder on an outer wall of the concrete silo; and then hanging and welding the tool type pulling steel ladder on the engineering steel ladder; and repeating the steps till completely constructing. According to the method provided by the invention, rental feeof materials about ** Yuan can be saved, the cost of purchasing a safety net foot plank about ** Yuan can be saved, the cost of assembling and disassembling a riding track tower about ** Yuan can be saved, the cost of materials about ** Yuan can be saved, the cost of disassembling a needed machine matched with a tower crane or truck crane about ** Yuan per day can be saved, and the cost of a mounting machine of the steel ladder about ** Yuan can be saved. Totally, the cost about ** Yuan can be saved, a construction period can be reduced by two days, and the method is practical and economical as well as safe and has remarkable composite economic benefits.

Owner:河北省第四建筑工程有限公司

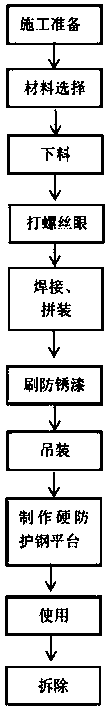

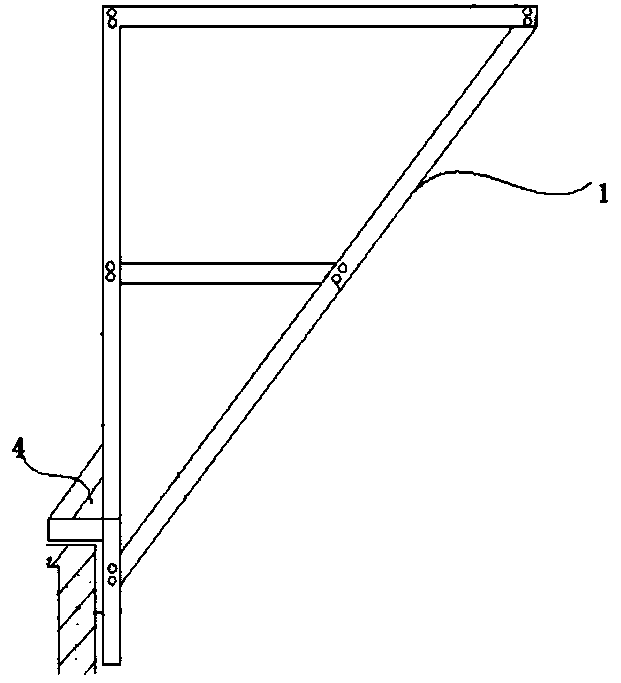

Construction method for tool-type all-steel construction platform of elevator shaft

InactiveCN110424710AEasy to processEasy to liftScaffold accessoriesBuilding support scaffoldsPunchingFall protection

The invention discloses a construction method for a tool-type all-steel construction platform of an elevator shaft. The construction method comprises (A) preparation for construction, (B) selection ofmaterials, (C) material unloading, (D) punching of screw eyes, (E) welding and splicing, (F) antirust paint brushing, (G) lifting, (H) fabrication of a hard protection steel platform, (I) use and (J)dismounting. The construction method disclosed by the invention is characterized in that the tool-type all-steel construction platform of the elevator shaft is used as near-edge anti-falling protection of the elevator shaft; processing is convenient; the platform can be dismounted and lifted layer by layer together with a main body structure; a tower crane is matched during lifting; lifting is convenient; construction is quick; the occupied area is small; safe operations are guaranteed; installation operations are convenient; practicability is high, etc. The method disclosed by the inventionhas the beneficial effects that a reinforcement process is simple; shaping quality is good; repeated use is feasible after one-time input; establishment of steel tube frames is not needed; only floorsealing is needed; rental for steel tubes can be reduced; economic benefits are significant; installation is convenient; dismounting is easy; and carrying and transportation are convenient.

Owner:YUNNAN CONSTR INVESTMENT HLDG GRP CO LTD

Mobile overhanging platform

The invention discloses a mobile overhanging platform. The mobile overhanging platform comprises a vertical frame and an overhanging working frame arranged on the vertical frame. The overhanging working frame is fixedly connected with the vertical frame and extends to the outside of the vertical frame and the vertical surfaces of a building. The vertical frame comprises four stand columns and a plurality of connecting rods. The overhanging working frame comprises two cross beams and a plurality of longitudinal beams uniformly distributed between the two cross beams. The two cross beams are located in the same plane and arranged in parallel. The front sections, horizontally extending forwards out of the vertical frame, of the cross beams serve as a working platform. The plurality of longitudinal beams are parallel, and the two ends of the longitudinal beams are welded to the two cross beams correspondingly. Vertical hollow screw rods are welded to the upper ends of the two stand columnson the rear side. Each screw rod is provided with an internal thread. Each screw rod is provided with a jacking rod in a sleeving mode. An external thread is machined on the outer wall of each jacking rod. The jacking rods are in screw-thread fit with internal threaded holes of the corresponding screw rods, so that the jacking rods conduct telescopic motion to enable the upper ends to abut against the bottom of a floor of an superstructure building to realize fixing on the overhanging platform. The installation and fixation difficulty of the overhanging platform can be reduced, and the mobileoverhanging platform is connected to assemble, disassemble and transfer.

Owner:CHINA METALLURGICAL CONSTR ENG GRP

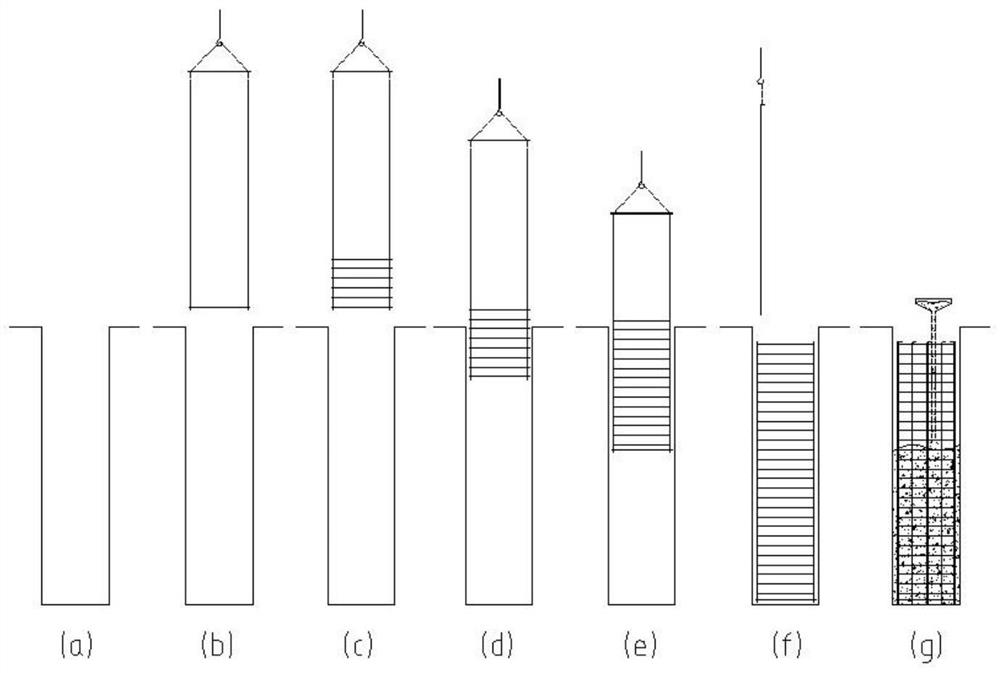

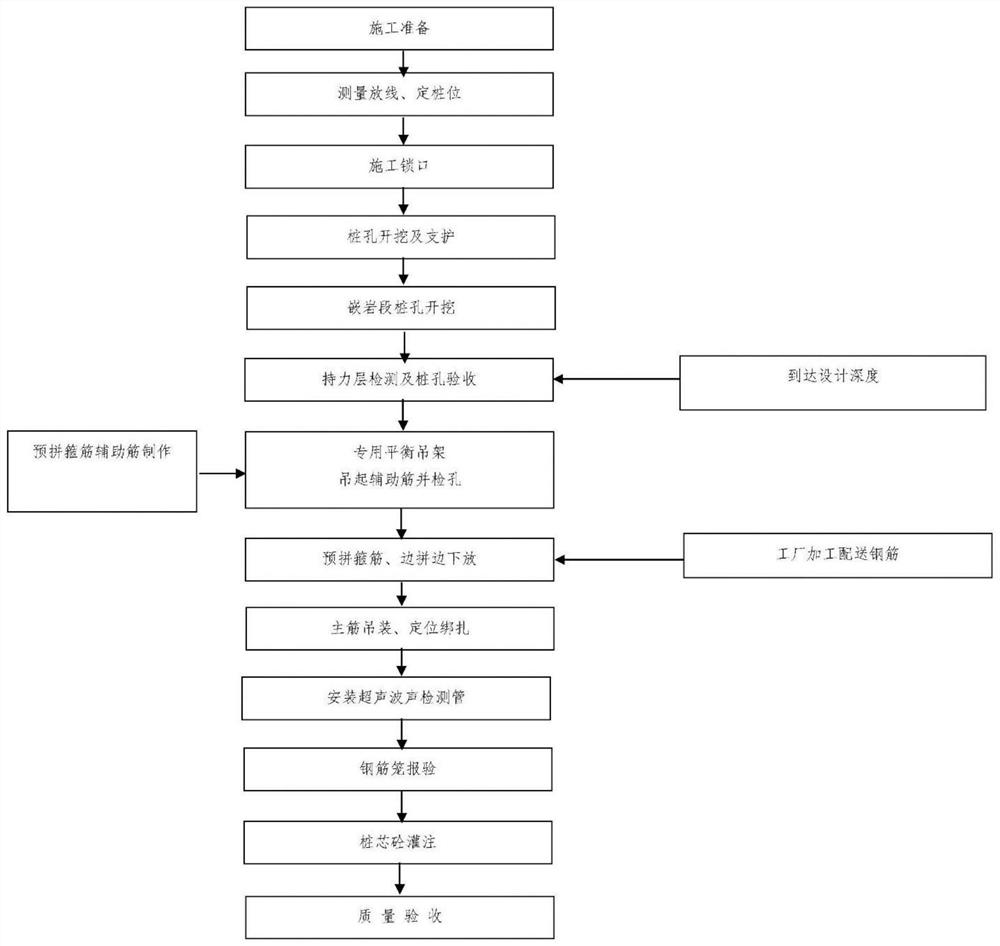

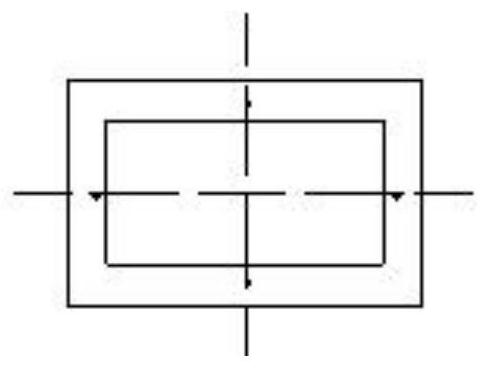

Complex site large rectangle pile stirrup pre-splicing construction method

The invention discloses a complex site large rectangle pile stirrup pre-splicing construction method, and relates to the field of stirrup construction. In order to achieve the aim, the method comprises the following steps of firstly, measuring setting out and pile position fixing; secondly, lock opening constructing; thirdly, pile hole excavating and supporting; fourthly, rock-socketed segment pile hole excavating; fifthly, supporting course detecting and pile hole acceptance check; sixthly, making auxiliary ribs for pre-splicing stirrups; seventhly, stirrup pre-splicing and lowering while splicing; eighthly, main rib lifting, positioning and binding; ninthly, ultrasonic acoustic detection tube mounting; and tenthly, pile core concrete pouring. Main ribs and stirrups of a steel reinforcement cage can achieve factory machining stirrup pre-splicing distribution, the stirrups can be in whole welding hooping splicing, on site, a stirrup cage is bound on a hole opening, influences of the main ribs are avoided, and the splicing speed is high.

Owner:重庆建工第四建设有限责任公司 +1

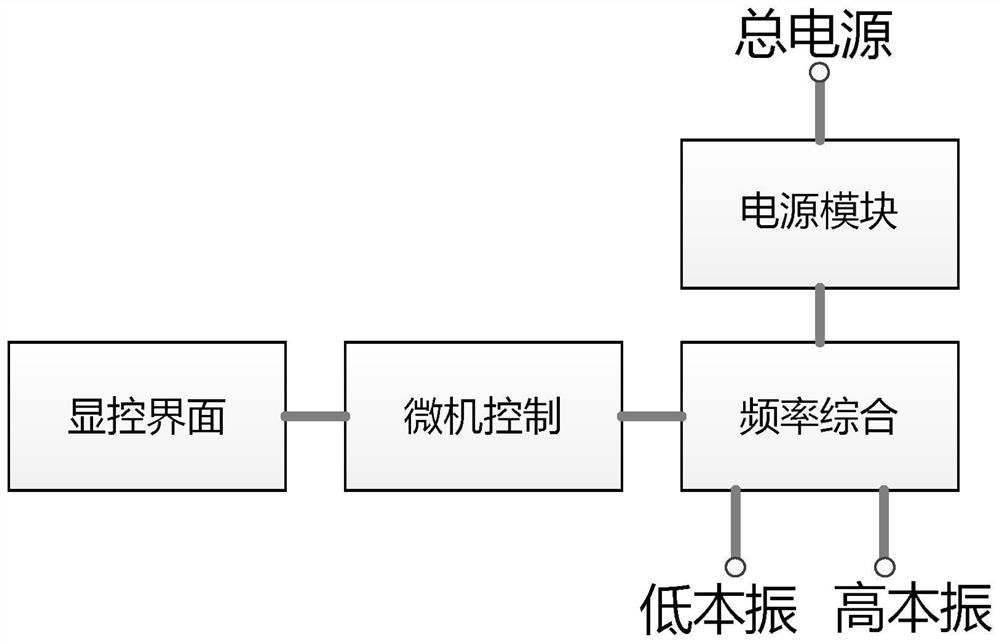

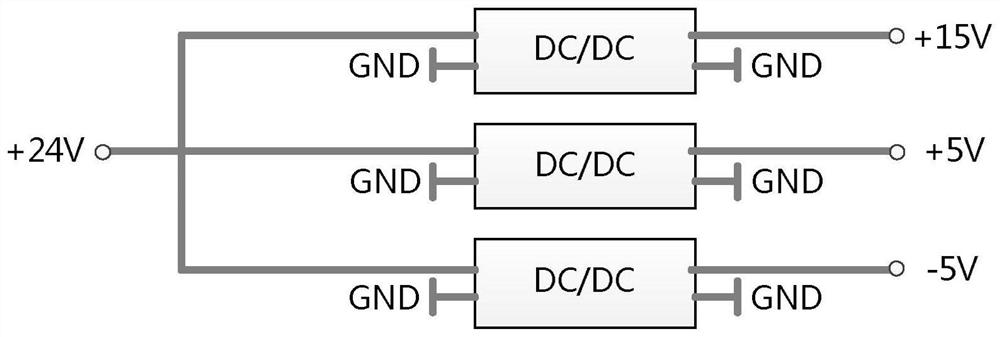

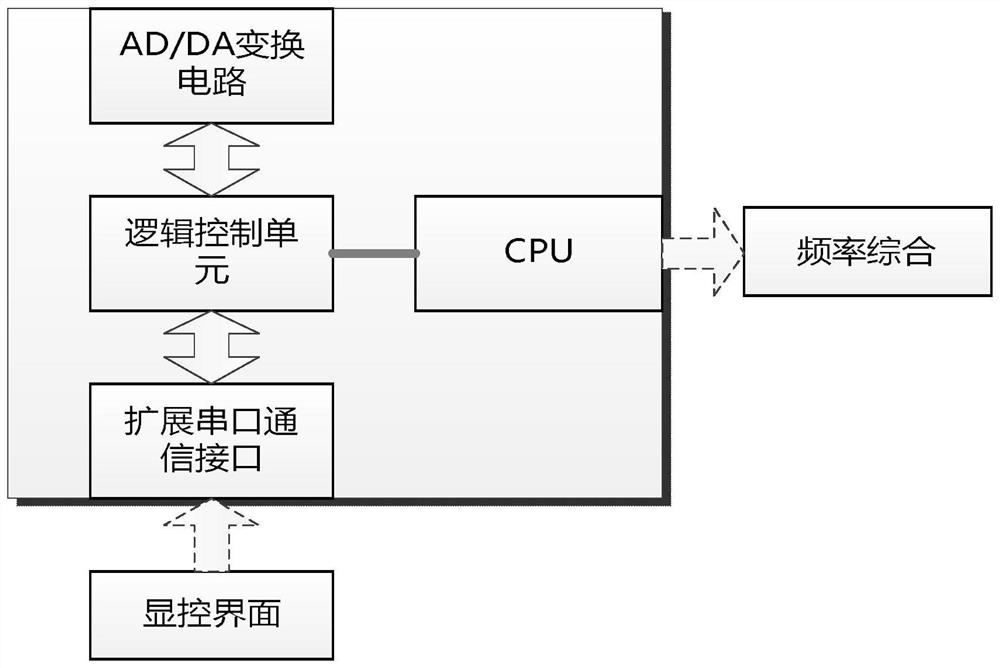

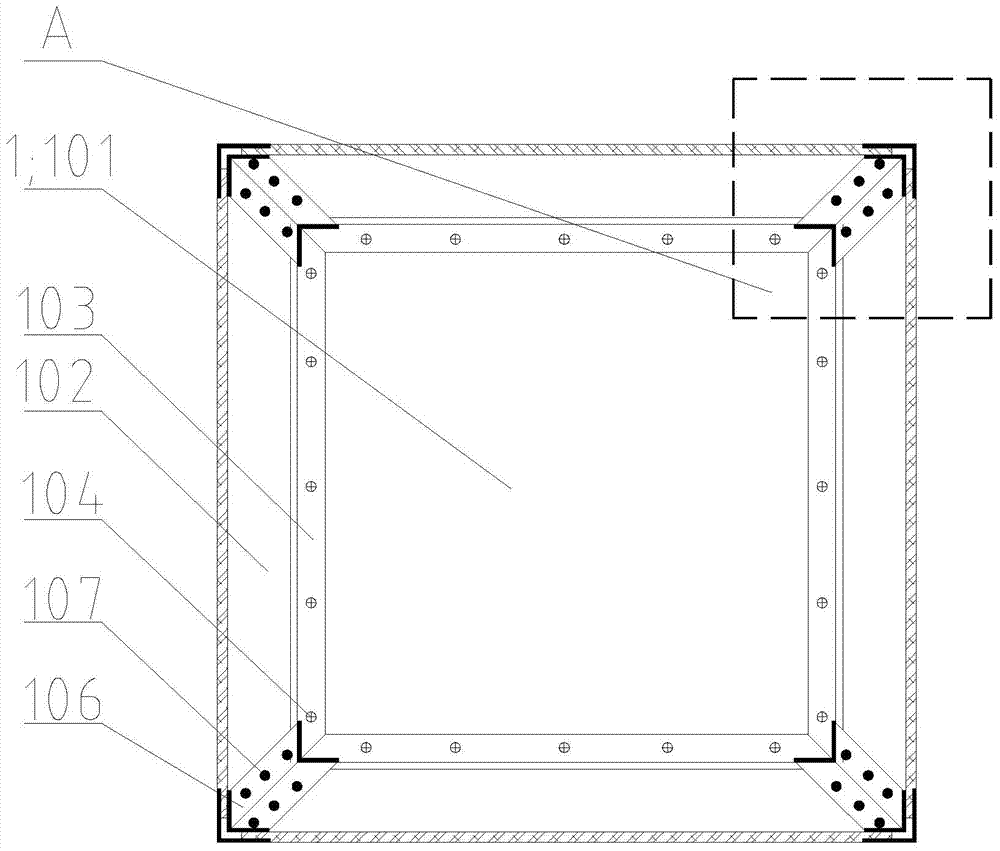

Aviation radio signal source

ActiveCN114567389ASave rental feeSolve the problem of no signal sourceTransmitters monitoringReceivers monitoringControl signalRadio signal

The aviation radio signal source disclosed by the invention is high in precision, short in conversion time, stable, reliable and high in practicability. According to the technical scheme, a microcomputer control module writes a program code according to a communication protocol and sends instructions of a working mode, a working state and a frequency point code and various generated control signals to a frequency synthesizer through a bus, the frequency synthesizer obtains output frequencies of a first local oscillator and a second local oscillator based on a direct digital synthesizer (DDS) and a phase-locked loop (PLL), and the output frequencies of the first local oscillator and the second local oscillator are transmitted to the frequency synthesizer. The frequency synthesizer generates a corresponding frequency control code to obtain a wave band control code and a corresponding control signal, the signal is processed by the radio frequency signal conditioning circuit and then is output to the to-be-tested equipment, an excitation signal required by the to-be-tested equipment is realized, each frequency value and amplitude required by an aviation radio station are provided, and by setting the hopping speed of frequency hopping, the frequency of the to-be-tested equipment is adjusted. And debugging and testing conventional indexes of the aeronautical radio station for data transmission of the frequency synthesizer, enabling control of frequency conversion and frequency hopping and code word conversion.

Owner:10TH RES INST OF CETC

Formwork strip paving construction method, combined split formwork and formwork quick-release joints

ActiveCN105544969BSave areaReduce dosageForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksSupporting systemRebar

Owner:中青建安建设集团有限公司 +1

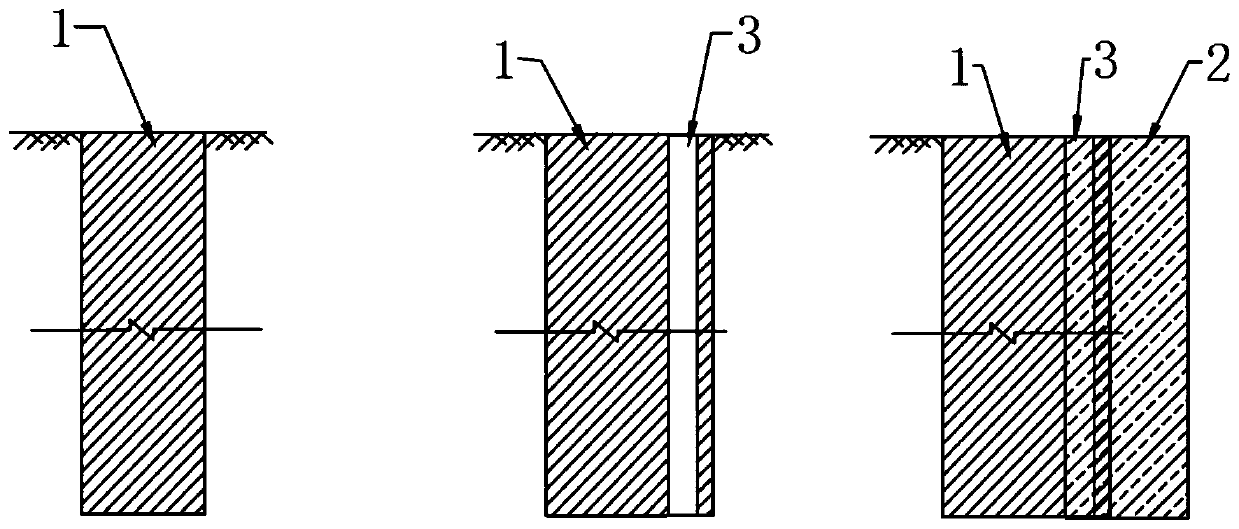

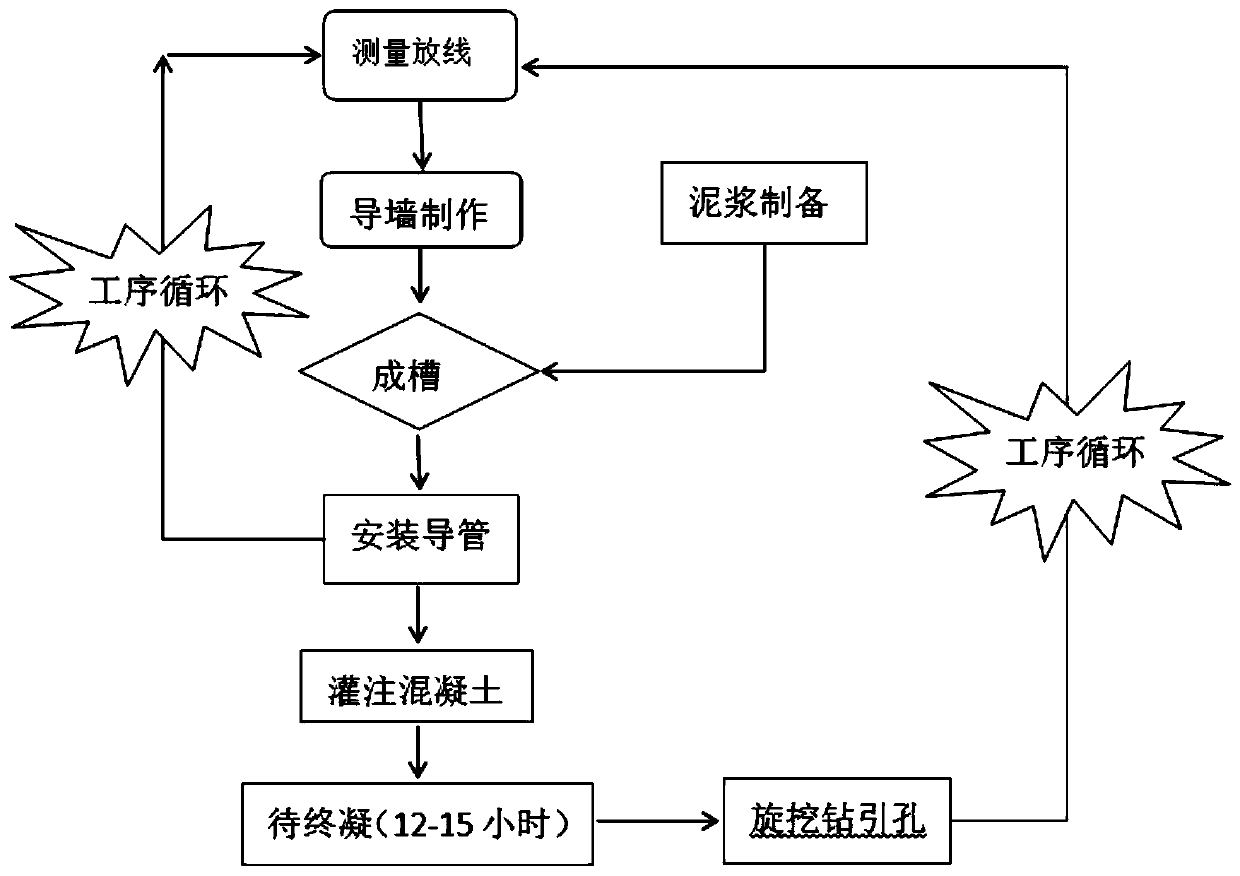

Construction method for treating ultra-deep plain concrete diaphragm wall guide hole joints

PendingCN111119218AReduce riskAvoid failureFoundation testingBulkheads/pilesArchitectural engineeringStructural engineering

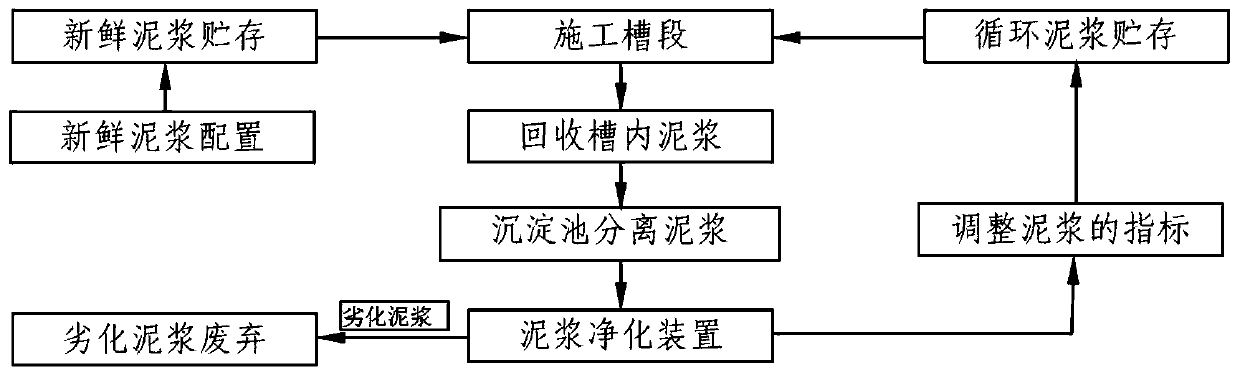

An embodiment of the invention discloses a construction method for treating ultra-deep plain concrete diaphragm wall guide hole joints. The method comprises the following steps: surveying and settingout: plane surveying and elevation surveying are performed to determine a datum traverse and an elevation control point; guide wall fabrication: the bottom wall axis and the position of a guide wall are set out by a total station, the bottom is cleared manually after the guide wall is excavated, concrete is poured after a formwork of the guide wall is built, and the formwork is removed after strength reaches 70%; trenching construction: concrete is poured into trenches, and trench section detection, bottom clearing and wall brushing are performed; installation of conduits: the conduits are inserted into the position at elevation of 300-800 mm from the bottom of the trenches, and the concrete storage in conduit collecting hoppers ensures the initial pouring quantity; concrete pouring: pouring is performed at constant speed to ensure that the pouring rising speed is not lower than 2 m / h; rotary drilling of guide holes: when strength reaches 1.5 MPa after pouring construction of an antecedent diaphragm wall is constructed, a rotary drilling rig is used to drill holes in the antecedent wall, instead of a fore shaft pipe or a joint box, to treat the joints, and trenching construction isperformed on adjacent following walls after drilling. The problems of long construction period and high cost of the existing plain concrete diaphragm wall are solved.

Owner:王君舫 +1

Logistical method for conveying ballastless tracks in twin-track tunnel in construction

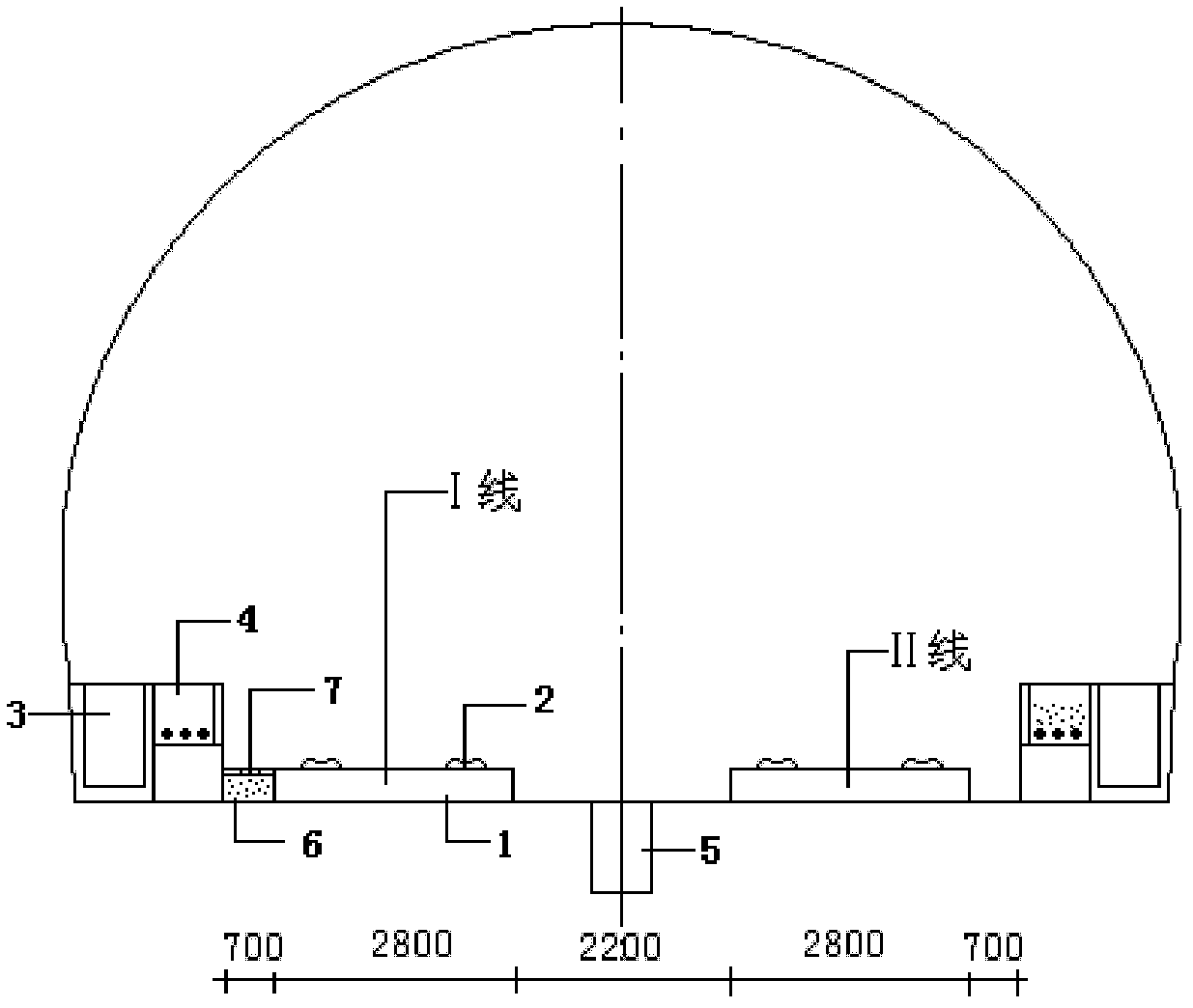

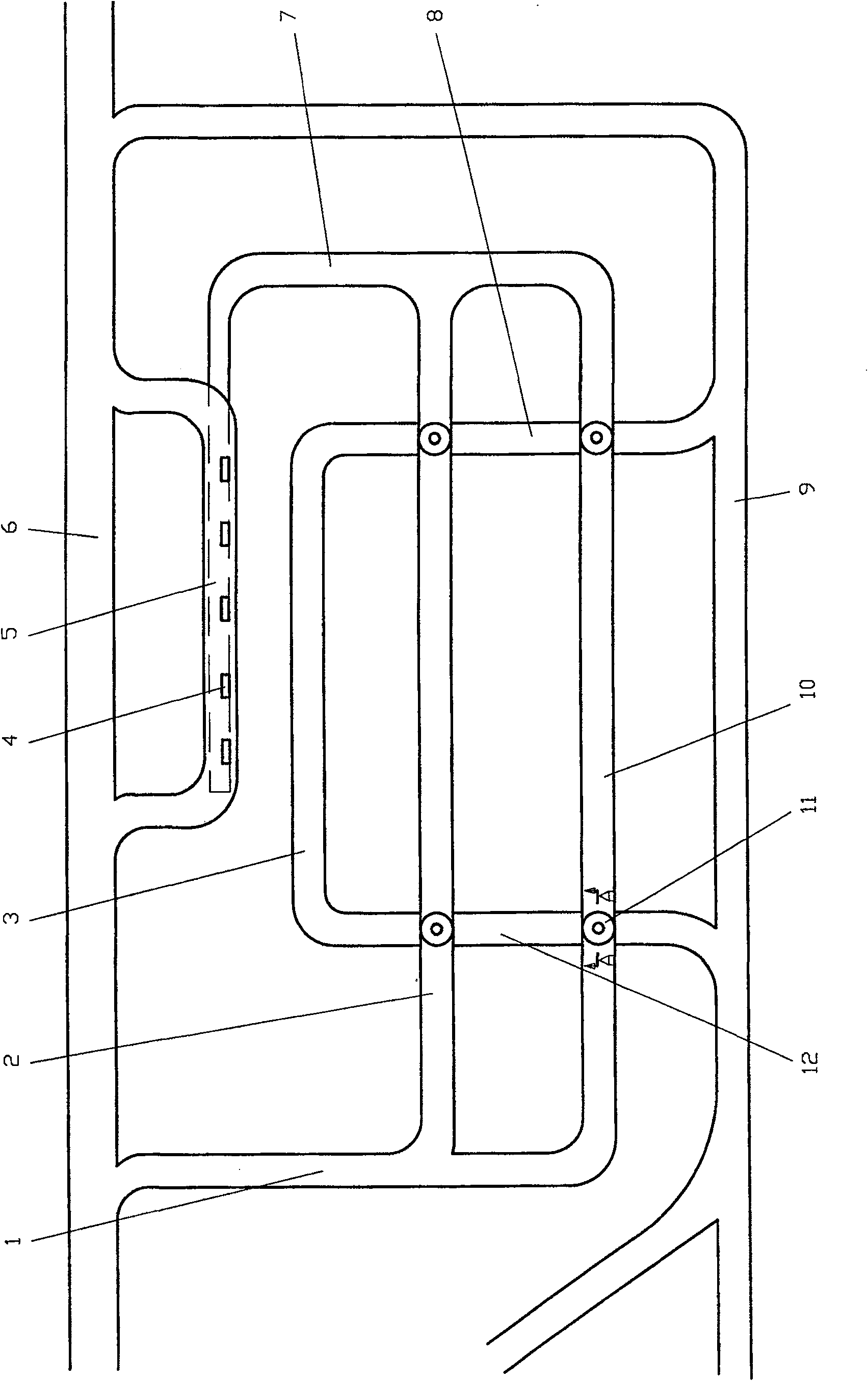

ActiveCN102561117BSave rental feeSave layingRailway track constructionBuilding constructionTrack bed

The invention discloses a logistical method for conveying ballastless tracks in a twin-track tunnel in construction, which includes: in construction of a line I, the position for a line II not being constructed is used as a trackless logistical passage for construction of the line I; in construction of the line II, sand planned to be laid in a line I cable trench is laid in a 700mm wide track inspection trench outside track bed plates of the finished line I, wood boards are laid on the sand, wheels on one side of a transport vehicle are allowed to run in the center of each track bed plate of the line I, wheels on the other side of the transport vehicle are allowed to run on the wood boards, a temporary trackless logistical passage is formed, and when the construction of the line II is complete, the wood boards need to be removed and the sand needs to be backfilled into the cable trench; vehicle U-turn positions are reserved in the tunnel at intervals of 1km-2km, namely ranges of 50-100m is reserved for temporary no construction and for U-turn of the vehicles, and the ranges are made up when engineering in the tunnel draws close to completion. Logistics includes construction expendables and turnover tools, wherein the construction expendables are supplied as required at any time through transport vehicles from outside of the tunnel, and the turnover tools are transferred to the front operation area from the back operation area of a construction site.

Owner:THE 2ND ENG CO LTD OF CHINA RAILWAY 17 BUREAU GRP

Apparatus for cleaning and transporting coal-mine water sump slurry

InactiveCN100572753CReduce troubleRelieve pressureDrainageUnderground transportFixed frameFilter press

The invention relates to a coal mine underground water tank coal slime cleaning and transportation device. A central pump room, inner and outer central water tanks, and a bypass are arranged parallel to the coal mine main road. The lower ends of the inner and outer central water tanks are provided with left and right The drainage lane and the connecting lane, the left and right drainage lanes are connected with the bypass. There are drainage holes at the bottom of the inner and outer central water tanks. There is a coal slime dehydration treatment vehicle under the pressure relief buffer valve, and the coal slime dehydration treatment vehicle includes a thickening tank, a slurry pump and a hydraulic station, a filter press, a screw conveyor and a tank car, and the outlet of the slurry pump It communicates with the inlet of the filter press, the filter press is controlled by a hydraulic station, the screw conveyor is fixed at the outlet of the filter press, and there is a tanker under the outlet of the screw conveyor. It saves labor, time, equipment, energy consumption, does not pollute the environment, and improves the safety factor and flood resistance of the mine.

Owner:暴万林 +2

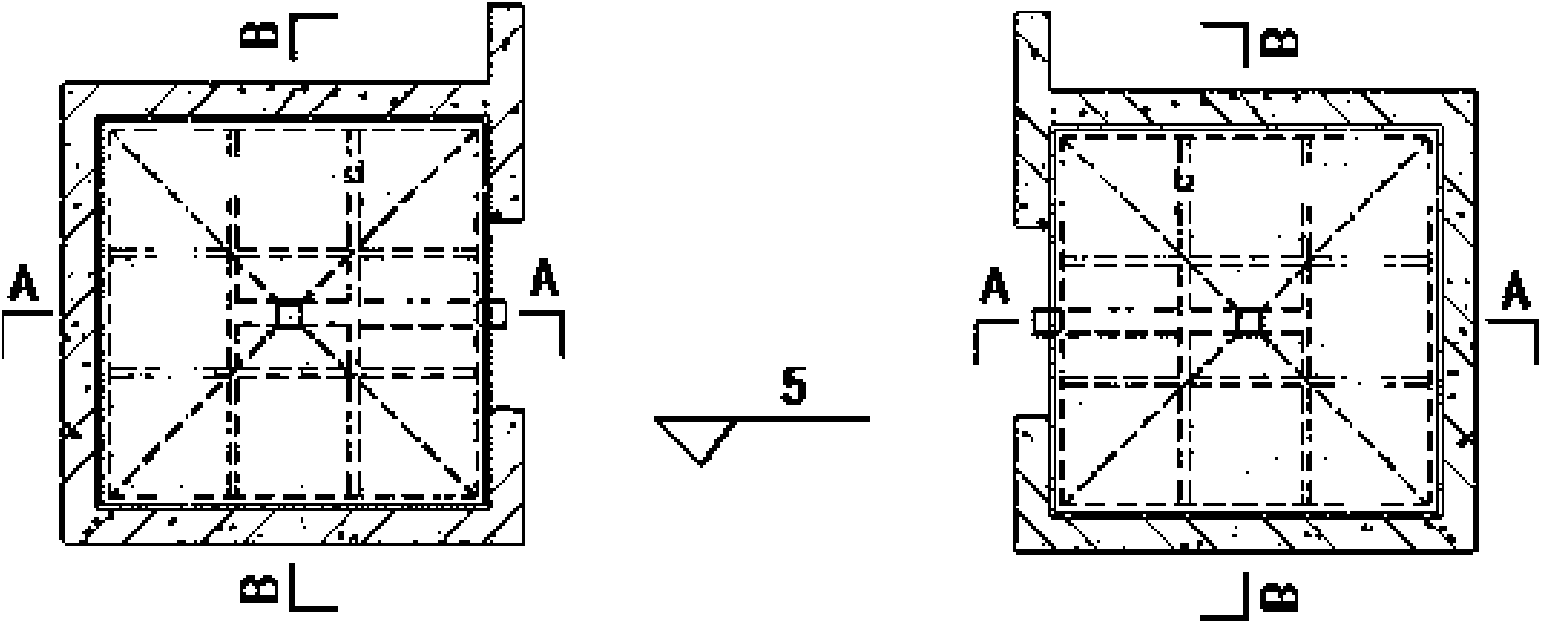

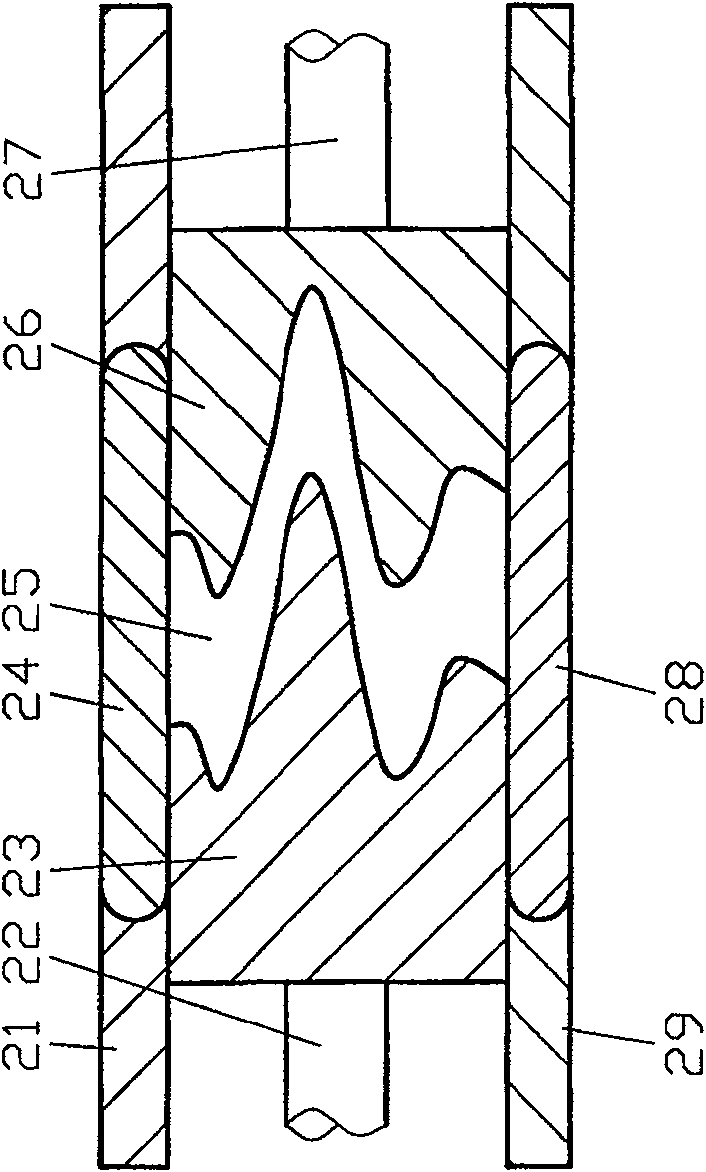

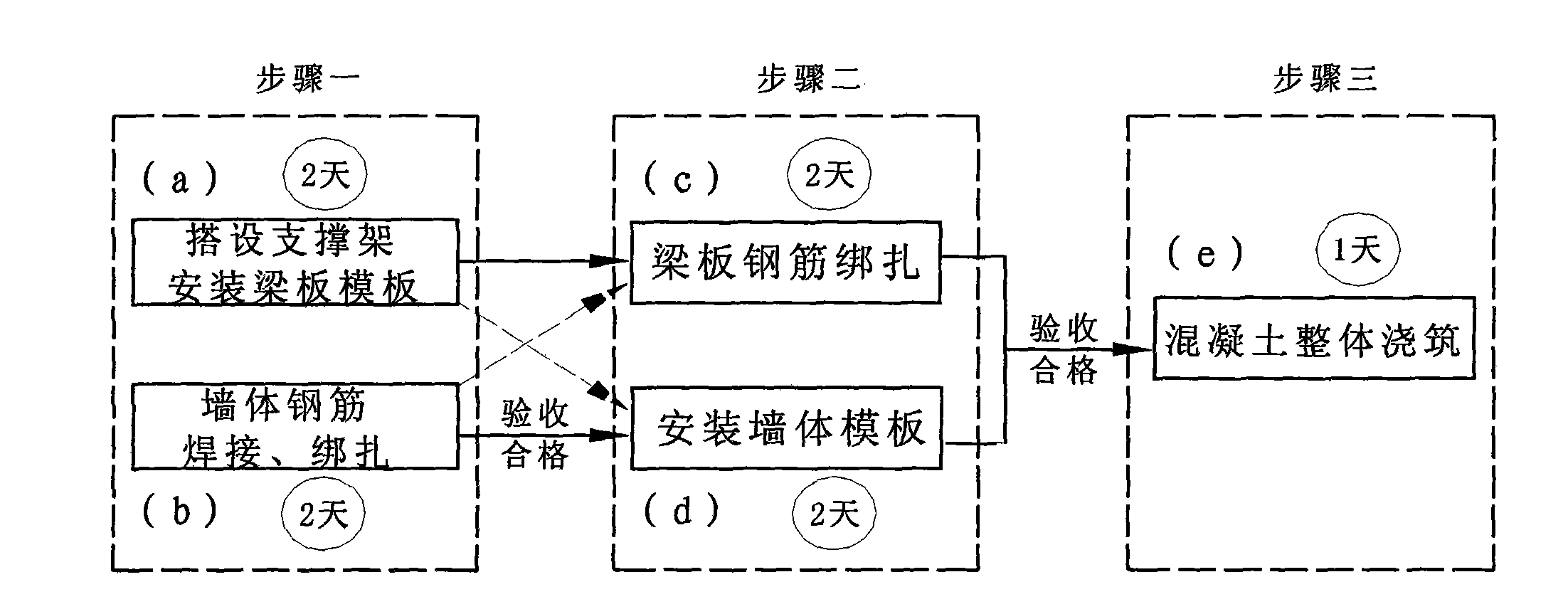

Inverted construction method for template engineering of cast-in-place shear wall structure system

The invention relates to an inverted construction method for template engineering of a cast-in-place shear wall structure system, which specifically comprises the following operation steps: step one, synchronously carrying out (a) a process of setting up a support frame and mounting a beam plate template and (b) a process of welding and binding wall steel bars; step two, (c) a process of binding beam plate steel bars and (d) a process of mounting a wall template; and step three, (e) a process of integrally casting wall panel concrete. The method is suitable for the industrial and civil engineering adopting a shear wall, in particular a short-pier shear wall structure system, is also suitable for scattered-split support templates or steel frame combined templates, and is further suitable for all steel supports adopted by the beam plate template; the work efficiency is remarkably improved, and the construction period of a main body structure is shortened by about 40 percent compared with the prior construction method; the engineering quality is ensured, namely the root of the wall is ensured to be clean, the dislocation and slag inclusion are prevented, the quality of a joint of thebeam plate and the wall is ensured, and the verticality of the wall is ensured; the construction safety is ensured; and the construction period is saved by about 40 percent.

Owner:THE 4TH CONSTR ENG CO LTD OF CHINA RAILWAY NO 4 ENG GRP

Integrated construction technology of adjustable tie beam and pier column and special formwork for construction

ActiveCN105178192BAvoid multiple bendsAvoid secondary supportBridge structural detailsForms/shuttering/falseworksRear quarterEngineering

The invention relates to an adjustable tie beam and pier stud integrated construction process and a special construction template. The special construction template comprises a pier stud template, a connecting template and a tie beam template, wherein a connecting template lower connecting plate is arranged on the bottom surface of the connecting template; a pier stud template upper connecting plate is arranged at the top of the pier stud template; the connecting template lower connecting plate is connected with the pier stud template upper connecting plate; the connecting template takes the shape of downward C formed by sequentially connecting a module III, modules I and a module II; the head parts of the modules I are connected with the tail part of the module II; a tie beam side connecting plate is arranged at the head part of the module II; a tie beam side connecting plate is arranged on the module III; one or more tie beam heightening modules are further arranged at the lower part of the connecting template; the tops of the tie beam pad heightening modules is connected with a tie beam bottom connecting module; a tie beam bottom connecting side plate is arranged on the tie beam bottom connecting module; the tie beam template comprises a tie beam side plate and a tie beam bottom template; and the end faces of the tie beam side and bottom templates are connected with the tie beam side and bottom connecting plates. The special construction template has the advantages that simultaneous casting construction of the tie beam and the pier stud of different heights is realized.

Owner:天津五市政公路工程有限公司

Once mounting, locating and constructing method for steel ladder outside concrete silo following sliding mould construction

ActiveCN102409862BSave rental feeLow management feeBuilding material handlingSafety netEconomic benefits

The invention discloses a once mounting, locating and constructing method for a steel ladder outside a concrete silo following sliding mould construction. A construction process comprises the following steps of: leaving an upper inlet on a sliding mould operating platform of the concrete silo and fixing an upper end of a prepared tool type pulling steel ladder on a sliding mould enclosed ring; after sliding the sliding mould operating platform to a preset height during a concrete silo construction process, welding an engineering steel ladder on an outer wall of the concrete silo; and then hanging and welding the tool type pulling steel ladder on the engineering steel ladder; and repeating the steps till completely constructing. According to the method provided by the invention, rental feeof materials about ** Yuan can be saved, the cost of purchasing a safety net foot plank about ** Yuan can be saved, the cost of assembling and disassembling a riding track tower about ** Yuan can be saved, the cost of materials about ** Yuan can be saved, the cost of disassembling a needed machine matched with a tower crane or truck crane about ** Yuan per day can be saved, and the cost of a mounting machine of the steel ladder about ** Yuan can be saved. Totally, the cost about ** Yuan can be saved, a construction period can be reduced by two days, and the method is practical and economical as well as safe and has remarkable composite economic benefits.

Owner:河北省第四建筑工程有限公司

A method of using an auxiliary device for installing a transformer

ActiveCN104795225BSave rental feeStop breakingTransformers/reacts mounting/support/suspensionSubstation mounted on poleTerrainTransformer

A method for using an auxiliary device for installing a transformer, which relates to the field of power transmission lines. The other end is provided with anti-screws, and the positive and negative screws at both ends of the fastening sleeve are socketed on the screw rod at the end of the connecting support rod. The ring is semicircular, and there are bolt holes at both ends of the cladding ring, and the bolts pass through the bolt holes to fix the cladding ring into a closed circle, and a pulley is set on the connecting support rod. The beneficial effects of the present invention are: the present invention is simple in structure, easy to install, not restricted by the terrain, reduces the rental fee of cranes, eliminates the cost of breakage and deformation caused by wooden poles, and has good economy. Using the present invention to install transformers, switches, Measuring boxes and other devices are safe, convenient, practical and fast.

Owner:HUANGHUA POWER SUPPLY COMPANY OF STATE GRID QINGHAI ELECTRIC POWER +1

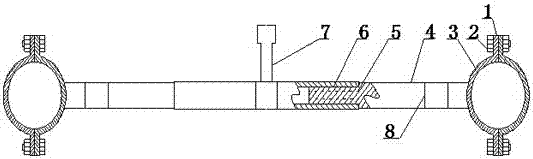

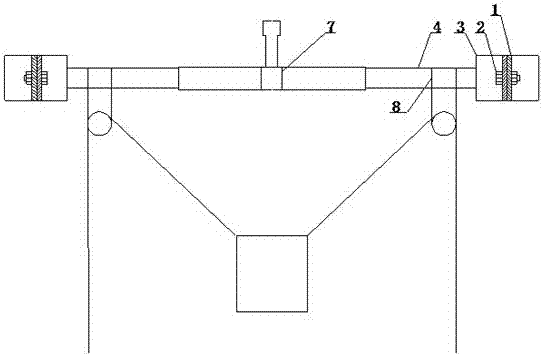

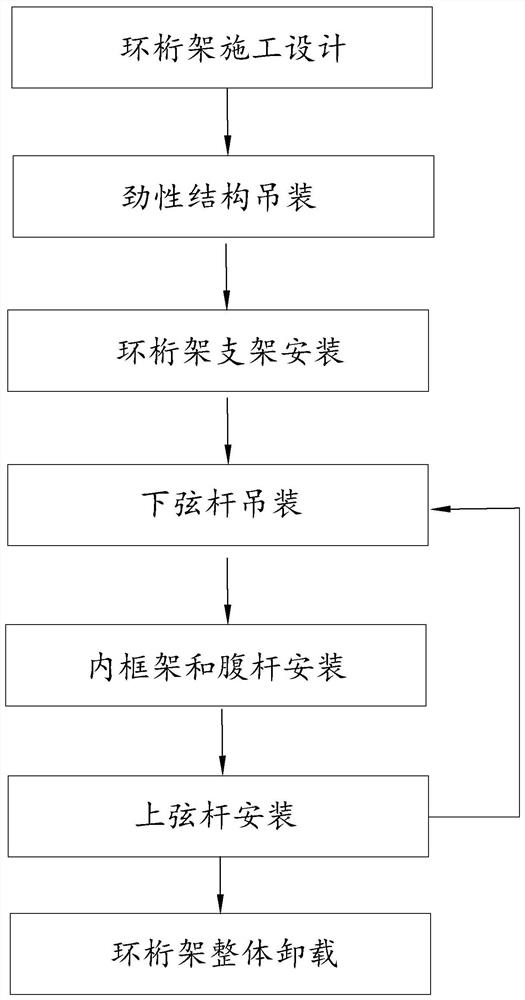

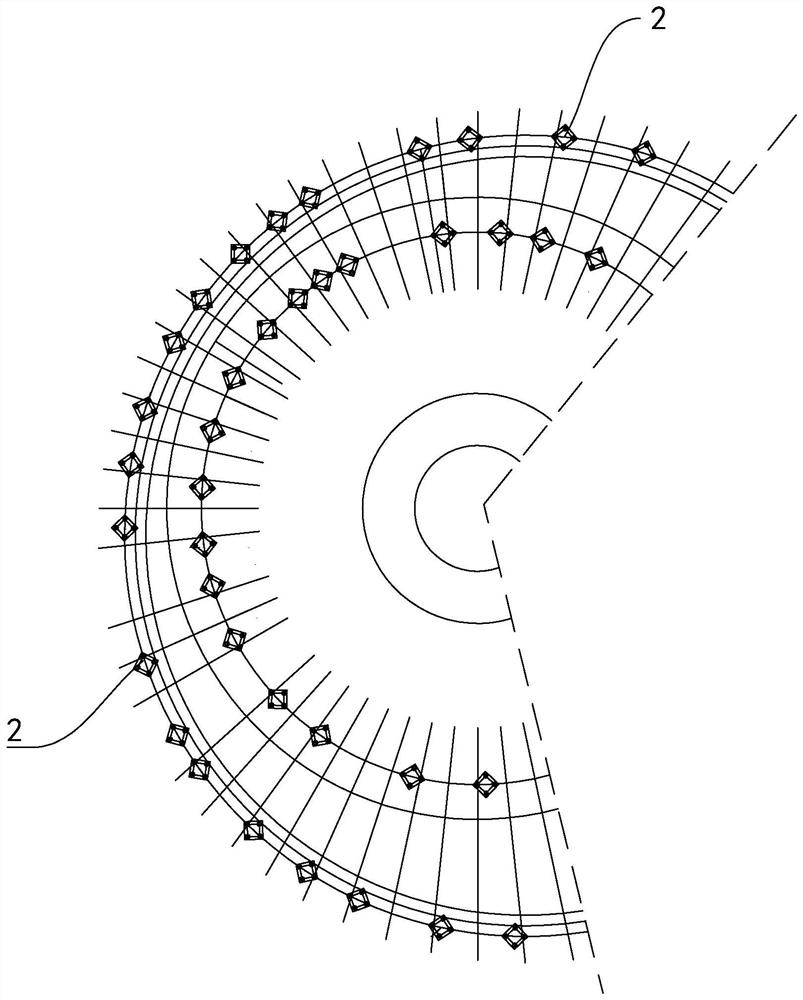

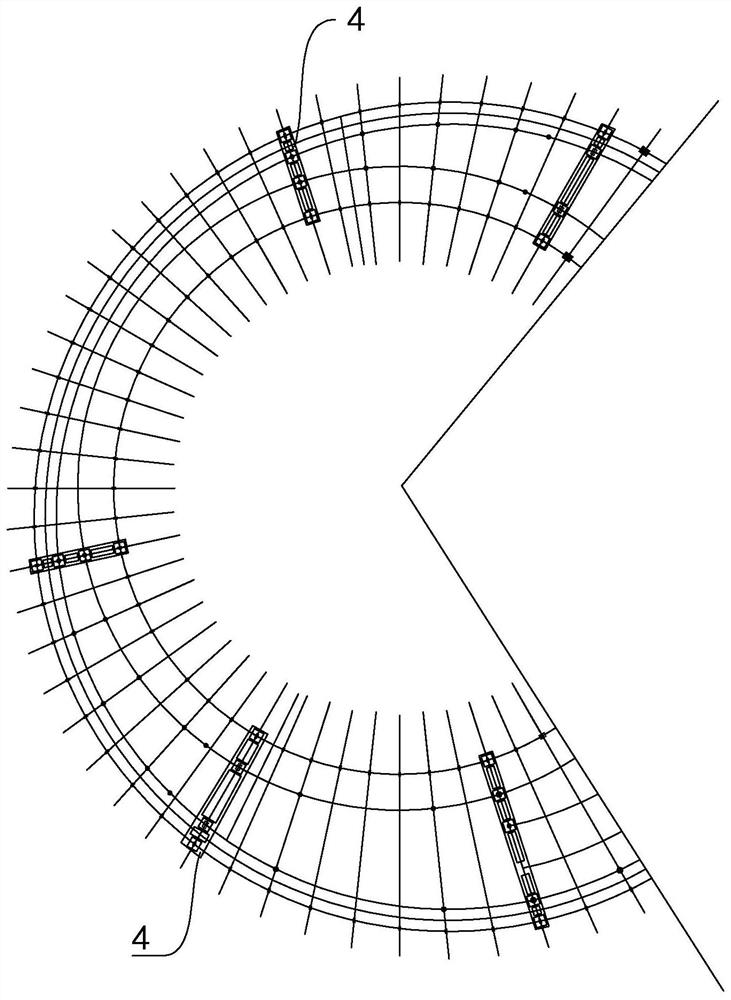

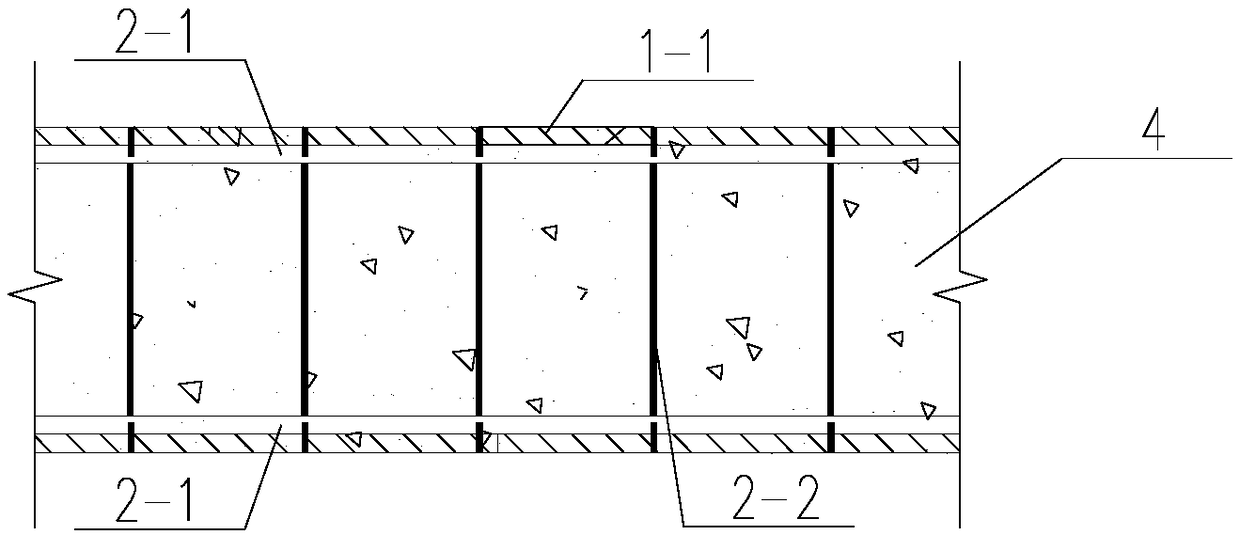

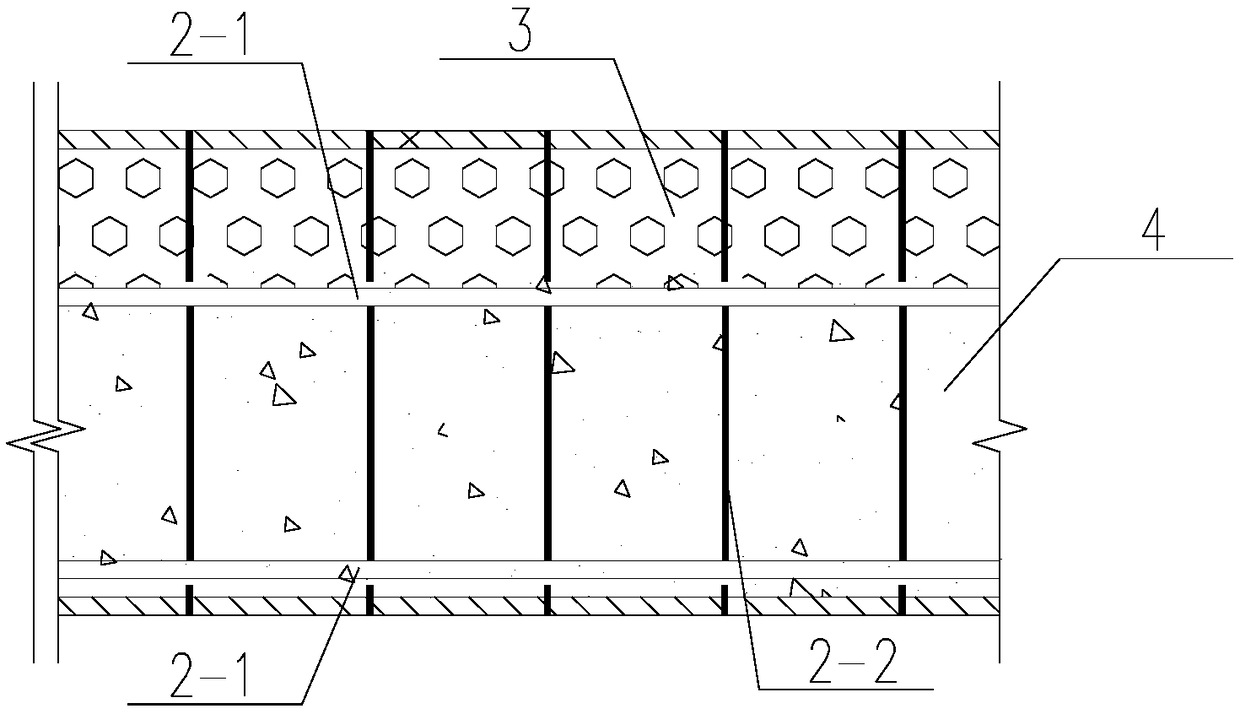

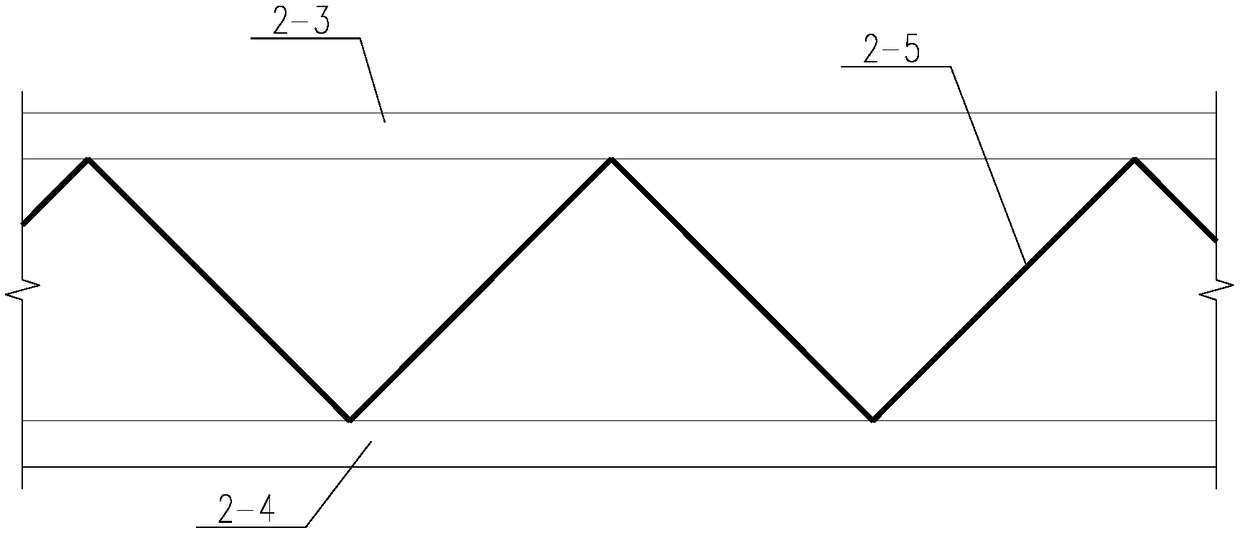

A high-altitude in-situ bulk construction method for ring trusses

ActiveCN111945891BSolve the problem of poor lateral stabilityGuaranteed rental feeArched structuresVaulted structuresArchitectural engineeringEconomic benefits

This application relates to a high-altitude in-situ scattered construction method for a ring truss, which belongs to the technical field of building truss installation, and includes the following steps: overall design of the ring truss→stiff structure hoisting→concrete shear wall construction→ring truss support installation→ring Hoisting of the lower chord of the truss → hoisting of the inner frame of the ring truss → hoisting of the web of the ring truss → hoisting of the upper chord of the ring truss → hoisting of the roof rigid frame → the overall unloading of the ring truss and the removal of the bracket. In this application, the ring truss is divided into multiple sections according to the characteristics of the lower chord, web and upper chord, and the bracket is used as a temporary support to hoist the ring truss members to the position to be installed and assemble them in situ, which solves the problem of ring truss installation in areas with complex terrain Difficult problems have achieved good economic and environmental benefits.

Owner:北京城建二建设工程有限公司

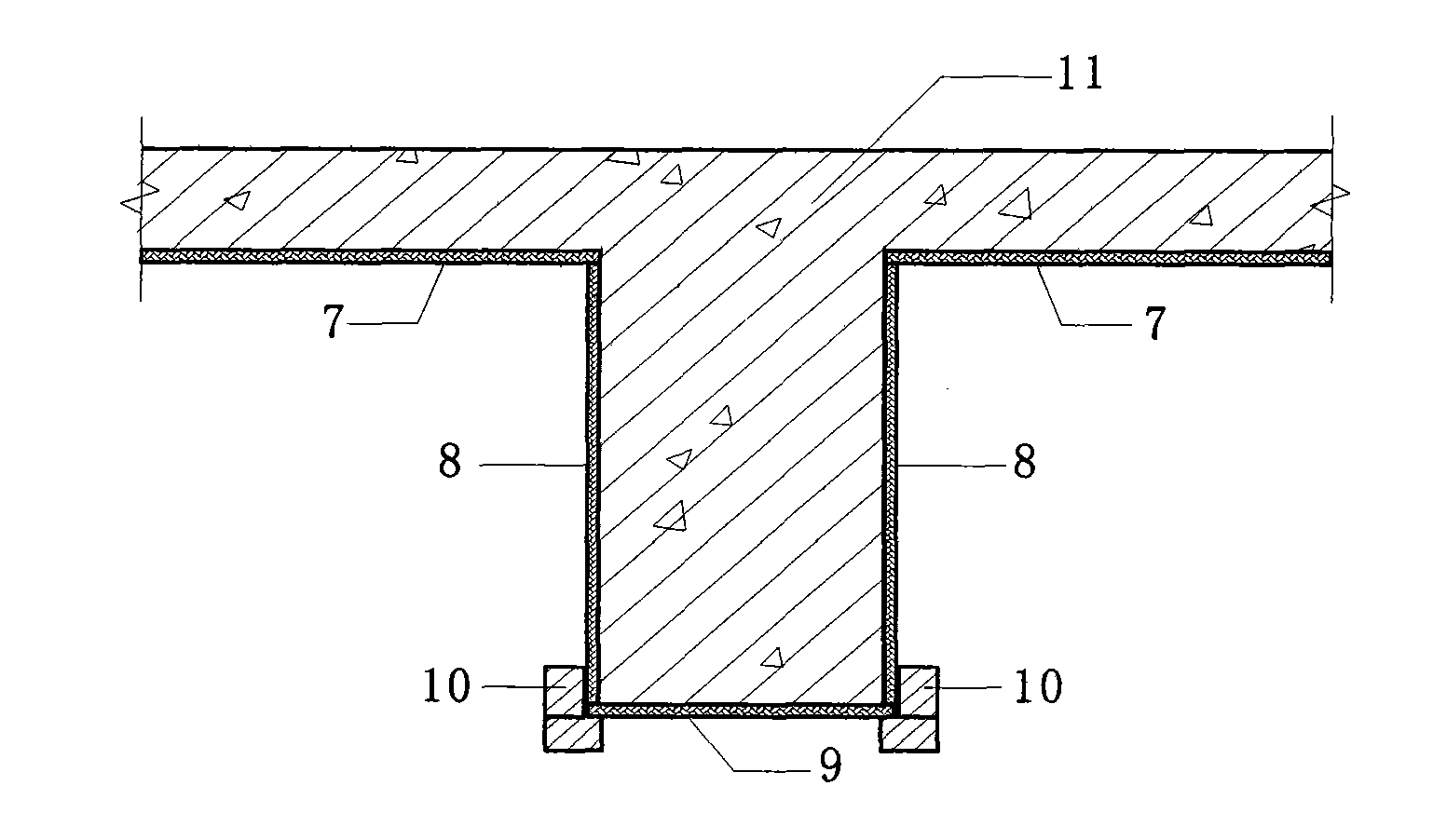

Light steel grille concrete superposed beam

The invention relates to a building structure, and discloses a light steel grille concrete superposed beam comprising two lateral erecting plane light steel trusses extending along the longitudinal direction of the beam, the bottom parts of two lateral erecting plane light steel trusses are connected together by multiple tied steel bars I; the outer side of each lateral erecting plane light steeltruss is connected with a side mold of a cement fiber board beam; the bottom parts of the two lateral erecting plane light steel trusses are provided with a bottom mold of the cement fiberboard beam;the two side molds of the cement fiber board beam and one bottom mold of the cement fiber board beam form a cement fiber board beam mold having a cross section of a trough shape; the cement fiber board beam mold is internally poured with a concrete solid; the concrete solid, the two lateral erecting plane light steel trusses and the cement fiberboard beam mold are superposed into a whole to form the superposed beam under integral stress. The lifting weight of a prefabricated beam on construction site is greatly reduced, and the construction process is economical and safe; the use of zero template is achieved, reinforcing steel bars are not matched or a fewer of the reinforcing steel bars are matched, the construction period is greatly shortened and the project cost is reduced.

Owner:TIANJIN UNIV RES INST OF ARCHITECTRUAL DESIGN & URBAN PLANNING

Construction method for synchronous dismantling of lower formwork frame system and peripheral formwork support of retractable post-pouring belt

The invention discloses a construction method for synchronous dismantling of a lower formwork frame system and a peripheral formwork support of a retractable post-pouring belt. The construction methodcomprises the following steps that cambering is conducted according to the standard when beam end formworks on the two sides of the post-pouring belt are mounted; in-beam steel bars and in-plate steel bars are bound to form a steel bar frame; high-strength bolts are pre-embedded at the ends, at the in-beam steel bars, of the post-pouring belt, and the upper ends of the high-strength bolts stretchout of the upper side of the steel bar frame; concrete is poured, the beam tops are leveled before initial set of the concrete; after the concrete is cured to be qualified, steel structure bearing members are connected to the positions, on the two sides of the post-pouring belt, of the beam end top faces through the pre-embedded high-strength bolts; and the lower formwork frame system and the peripheral formwork support of the post-pouring belt are dismantled. In the construction process of beams and floors on the two sides of the retractable post-pouring belt, the structure bearing members are mounted in the positions, on the two sides of the post-pouring belt, between the beam end top faces through the pre-embedded high-strength bolts, the structure bearing members replace original structural beams to bear the shearing force and torque at the post-pouring belt, and therefore, when the peripheral formwork support of the post-pouring belt is dismantled, the lower formwork frame systemof the post-pouring belt can be dismantled synchronously.

Owner:CHINA CONSTR FIFTH ENG DIV CORP LTD

Cabin top steel beam hydraulic hoisting and positioning apparatus of cylinder cabin structure building and construction method thereof

InactiveCN101435276BGuaranteed durationEnsure construction safetyBulk storage containerSteel frameEngineering

Disclosed is a steel beam hydraulic lifting emplacing device on the top of silo structure building, which comprises a sliding formwork device and a hydraulic lifting system, and is characterized in that the sliding formwork lifting frames of the sliding formwork device are connected with an inside formwork, an outside formwork, and an operating platform, a scissors support is connected between twolifting frame upright columns, the sliding formwork lifting frame is also connected with a steel beam supporting frame, the steel beam support frame is connected with the steel beam on the top of thesilo to form a lifting integration, the hydraulic lifting system is utilized to be the lifting power system for the lifting integration, and the hydraulic lifting system is composed of a hydraulic jack, a support rod, a hydraulic console, and an oil circuit. The invention can rapidly, conveniently, reliably, and safely complete the construction task of mounting the steel beam on the top of the silo, without using large scale hoisting equipment, thereby avoiding the problems of difficult emplacement and lower efficiency of large scale hoisting equipment. The device of the invention can be widely applied to the hoisting and emplacement construction for the steel frame on the top of silo buildings.

Owner:THE THIRD CONSTR ENG CO LTD OF CHINA CONSTR SECOND ENG BUREAU +1

The construction method of synchronously dismantling the lower formwork system and the surrounding support formwork after telescopic post-casting

The invention discloses a construction method for synchronously dismantling the lower formwork system of the telescopic post-casting belt and the surrounding formwork supports, comprising the following steps: arching according to the specifications when installing the beam end formwork on both sides of the post-casting belt; binding the steel bars in the beam and the plate Form a steel bar frame; pre-embed high-strength bolts at the end of the post-casting belt of the steel bar in the beam, and the upper end of the high-strength bolt protrudes from the upper side of the steel bar frame; pour concrete, and level the top of the beam before the initial setting of the concrete; After the maintenance is qualified, the steel structure load-bearing members are connected to the beam end top surface on both sides of the post-casting belt through pre-embedded high-strength bolts; the lower formwork system and surrounding formwork of the post-casting belt are removed. That is, during the construction of the beams and floors on both sides of the telescopic post-casting belt, steel structural load-bearing members are installed between the beam ends and top surfaces on both sides of the post-casting belt through pre-embedded bolts, and the original structural beams are replaced by steel structural bearing members The shear force and bending moment at the post-casting belt, so when the supporting formwork around the post-casting belt is removed, the lower formwork system of the post-casting belt can be removed at the same time.

Owner:CHINA CONSTR FIFTH ENG DIV CORP LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com