Template overhanging construction method for floor system with composite structure by utilizing profiled steel beams

A technology of combined structure and construction method, which is applied in the direction of building structure, construction, and building material processing, can solve the problems of reduced stability of the support system, low reuse rate of formwork, and high labor intensity of operators, so as to reduce construction costs. Cost, beneficial to integration and large-scale construction, low labor intensity of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

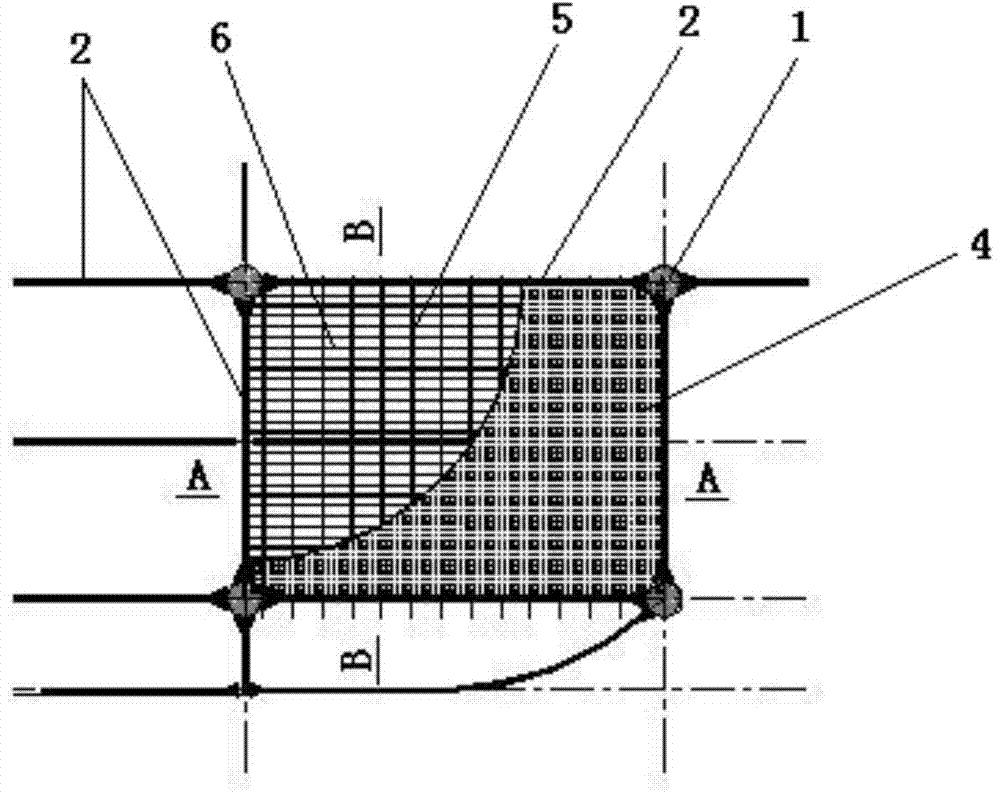

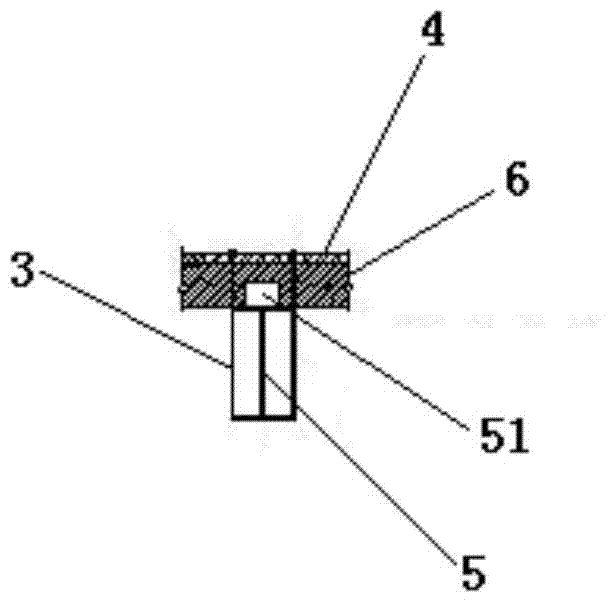

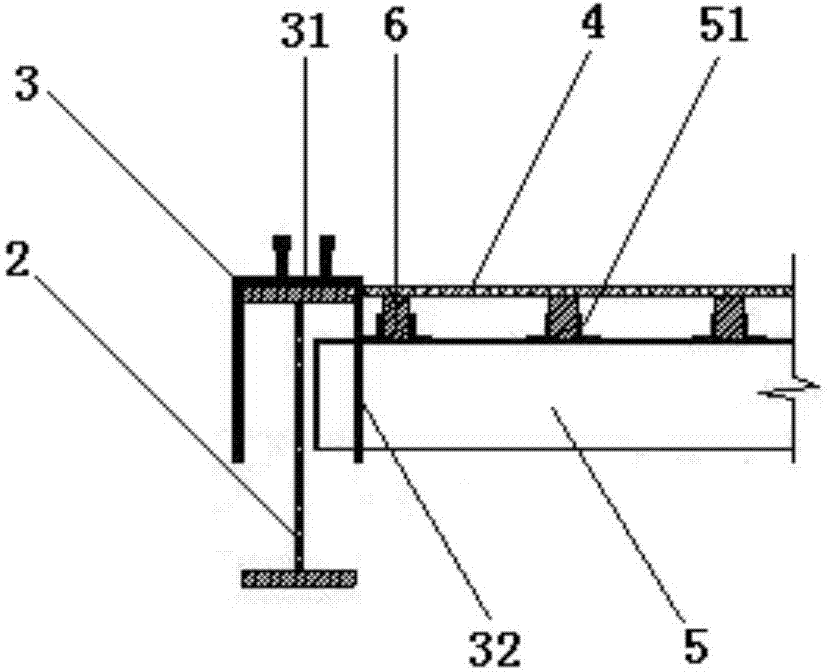

[0042] Below in conjunction with accompanying drawing of description, the present invention will be further described.

[0043] Such as figure 1 , figure 2 and image 3 As shown, a kind of composite structure floor that the present invention provides utilizes steel girder hanging formwork construction method, comprises following construction steps:

[0044] Step 1: Check frame column 1 and install steel beam 2;

[0045] The check of the frame column 1 is to correct the built frame column 1 for installing the steel beam 2, including the elevation, displacement, verticality and twist of the frame column 1;

[0046] The installation of the profiled steel beam 2 is to use the method of string hanging to carry out the installation of the H-shaped profiled steel beam 2 with one hook and multiple hangers, and the profiled steel beam 2 is installed between the adjacent frame columns that have been built. The order of orientation is first the upper layer, then the middle layer, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com