Light steel grille concrete superposed beam

A technology of composite beams and concrete, which is applied in the direction of structural elements, building components, and long-strip structural components for load-bearing, can solve the problems of large impact of wet work on node connections, difficult removal, heavy hoisting weight, etc., to achieve Reduce the work of steel bar binding and connection, the effect of later use is good, and the effect of saving cost and time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

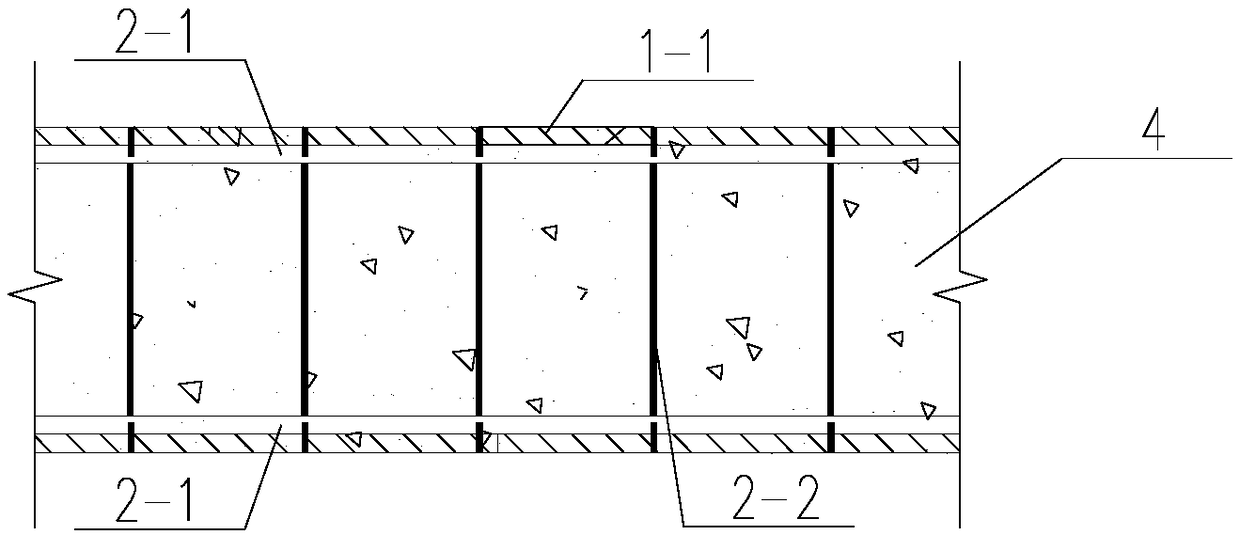

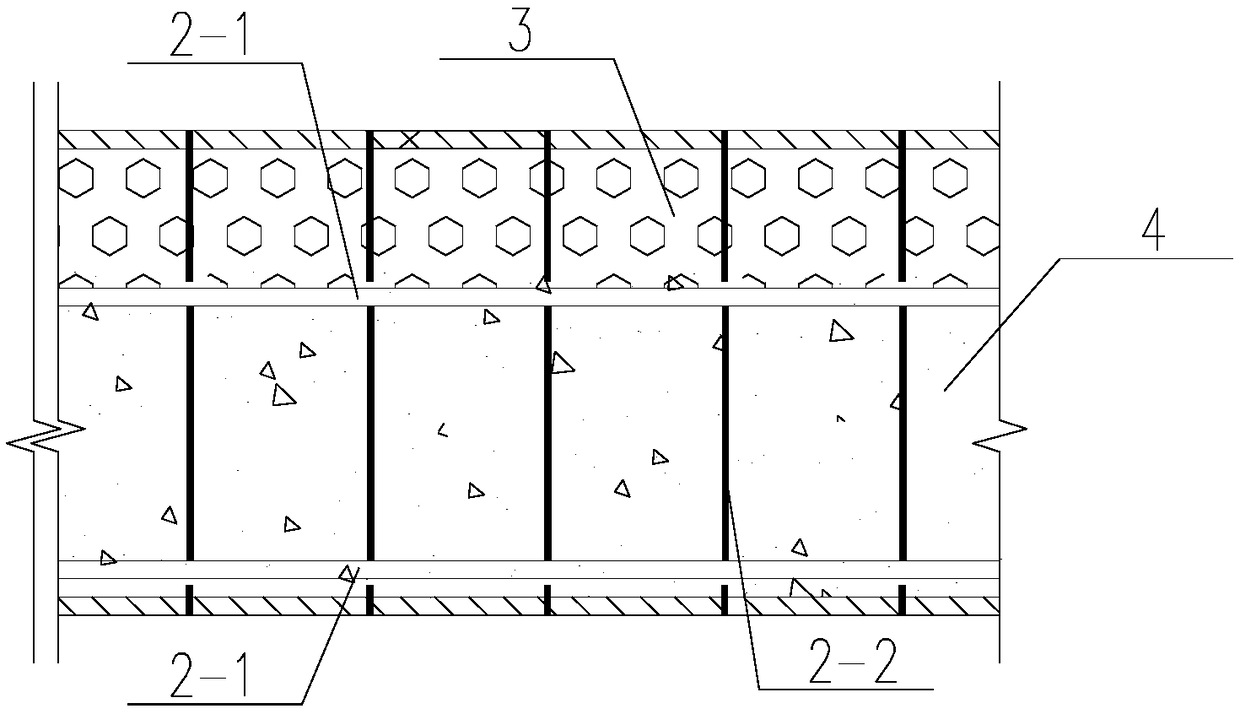

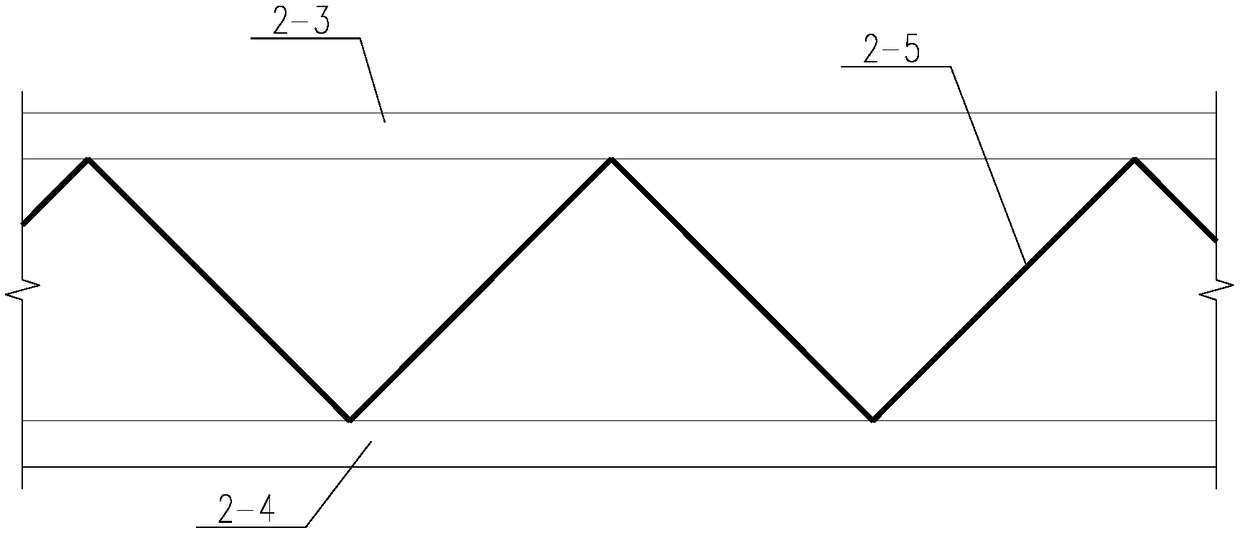

[0019] see Figure 1 to Figure 7 , a light steel grid concrete composite beam, comprising two side vertical plane light steel trusses 2-1 extending longitudinally along the beam, the bottoms of the two side vertical plane light steel trusses 2-1 are tied by multiple The steel bars I 2-2 are connected together, and the cement fiber plate beam side form 1-1 is connected to the outside of the light steel truss 2-1 on the side elevation plane of the two sides, and the light steel truss 2-1 on the side elevation plane of the two The bottom of the cement fiberboard beam bottom formwork 1-2 is provided with, two described cement fiberboard beam sideforms 1-1 and one described cement fiberboard beam bottom formwork 1-2 form the cement fiberboard beam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com