Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

439results about How to "Reduce backlog" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

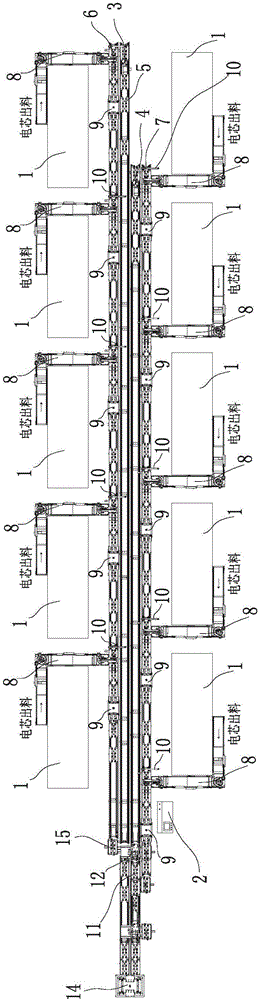

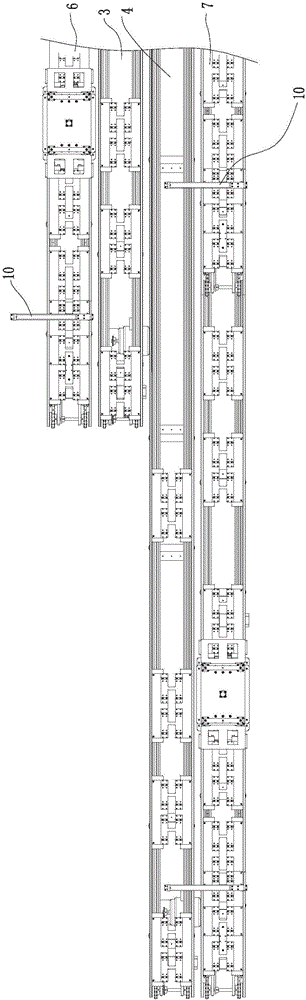

Automatic cell conveying line

ActiveCN106081597AReduce backlogImprove work efficiencyConveyorsConveyor partsWinding machineEngineering

The invention relates to an automatic cell conveying line. The automatic cell conveying line comprises a plurality of cell winding machines and a main control box and further comprises a first main conveying belt and a second main conveying belt which are located in the center. Carrying boxes carrying naked cells are arranged on the first main conveying belt and the second main conveying belt. A first empty carrying box conveying belt is further arranged on the lower layer of the outer side of the first main conveying belt, and a second empty carrying box conveying belt is further arranged on the lower layer of the outer side of the second main conveying belt. A cell feeding and conveying device is further arranged beside each cell winding machine. Each empty carrying box conveying belt is further provided with an empty carrying box lifting device lifting and transferring empty carrying boxes to the corresponding main conveying belt. A shared conveying belt for transferring the carrying boxes to one conveying belt for facilitating discharging is further arranged at the tail ends of the first main conveying belt and the second main conveying belt. In the full-automatic production process, the naked cells can be effectively diverted, accumulation of the naked cells is relieved, the work efficiency of the cell winding machines is higher, the overall production speed is increased, the quality of the naked cells is guaranteed, and the automatic cell conveying line is more environment-friendly and more reliable.

Owner:ZHUHAI HIGRAND ELECTRONICS TECH

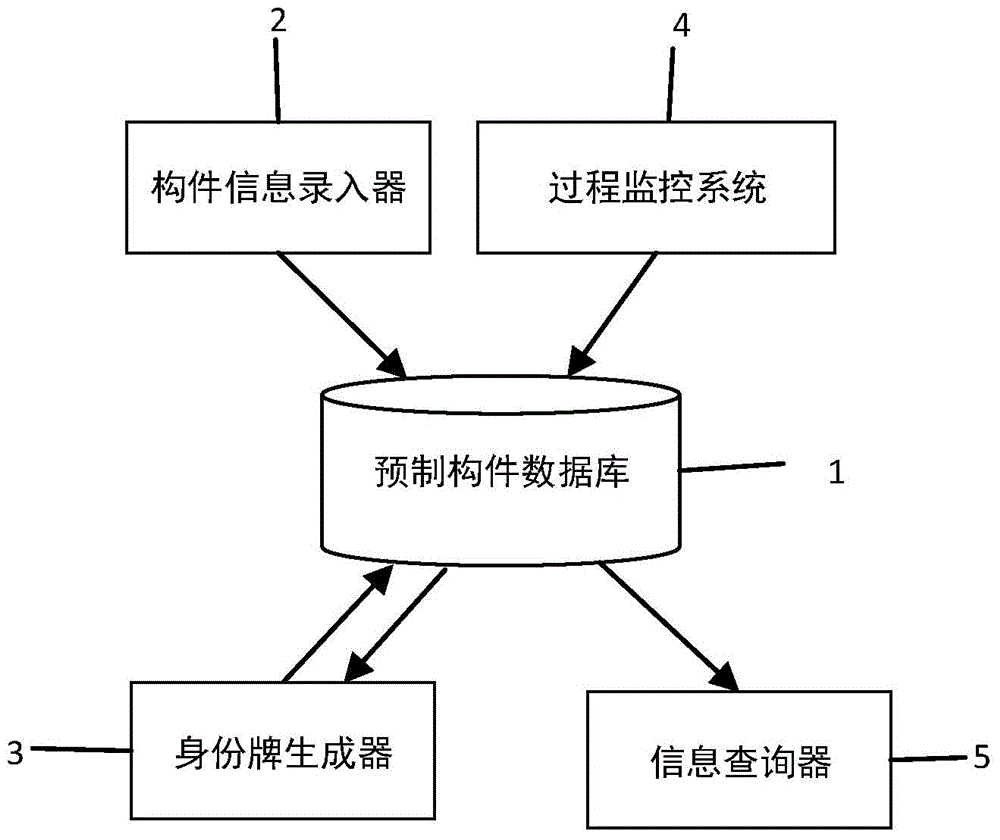

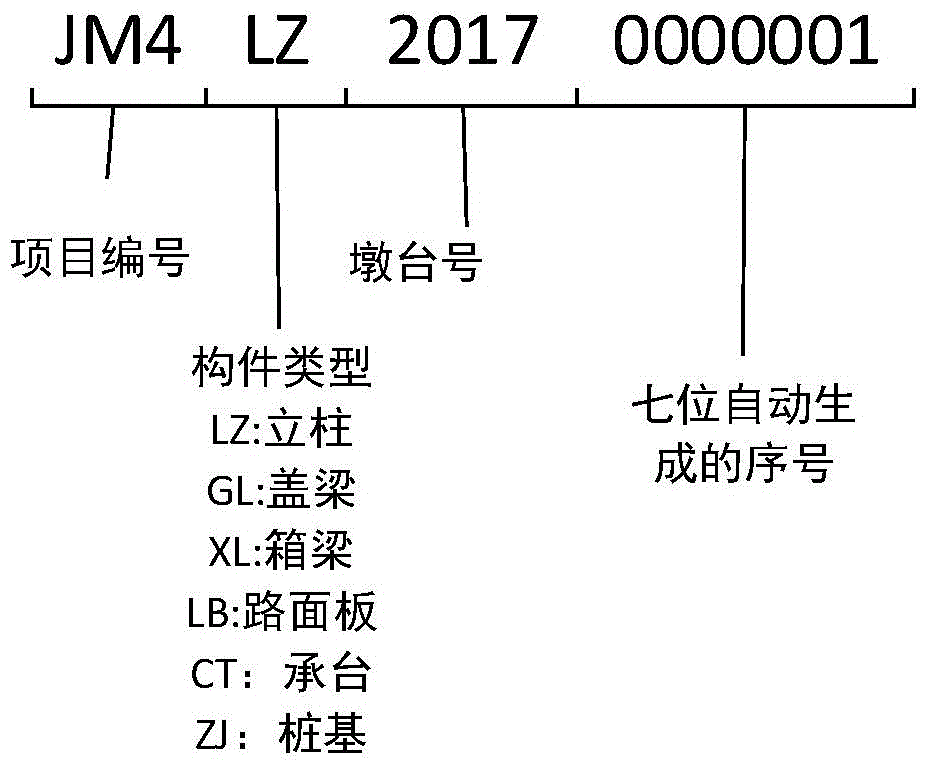

Bridge precast concrete member monitoring system based on two-dimensional code and control method thereof

InactiveCN104636873AReduce backlogSafe and Stable Data SupportResourcesMonitoring systemDimensional modeling

The invention discloses a bridge precast concrete member monitoring system based on a two-dimensional code and a control method thereof, belongs to the technical field of network communication and management, and aims to solve the problem of influence on the construction period due to member overstock caused by extensive management in the production, transportation, storage and installation processes of the conventional bridge precast concrete member. The process monitoring system comprises a database, an information input device, an identity card generator, a process monitoring system and an information inquiry device. The control method comprises the following steps: inputting the two-dimensional code information of a precast member; making a machining order and identity card of the precast member; inputting and storing information of a reinforcement cage machining process; inputting and storing pouring process information; inputting and storing delivery information; inputting and storing construction field material information; inputting and storing installation information. The process monitoring system and the control method are easy to operate and manage, the overstock of precast members is reduced, and the construction period and construction cost are saved.

Owner:SHANGHAI HIGHWAY INVESTMENT CONSTR DEV CO LTD +1

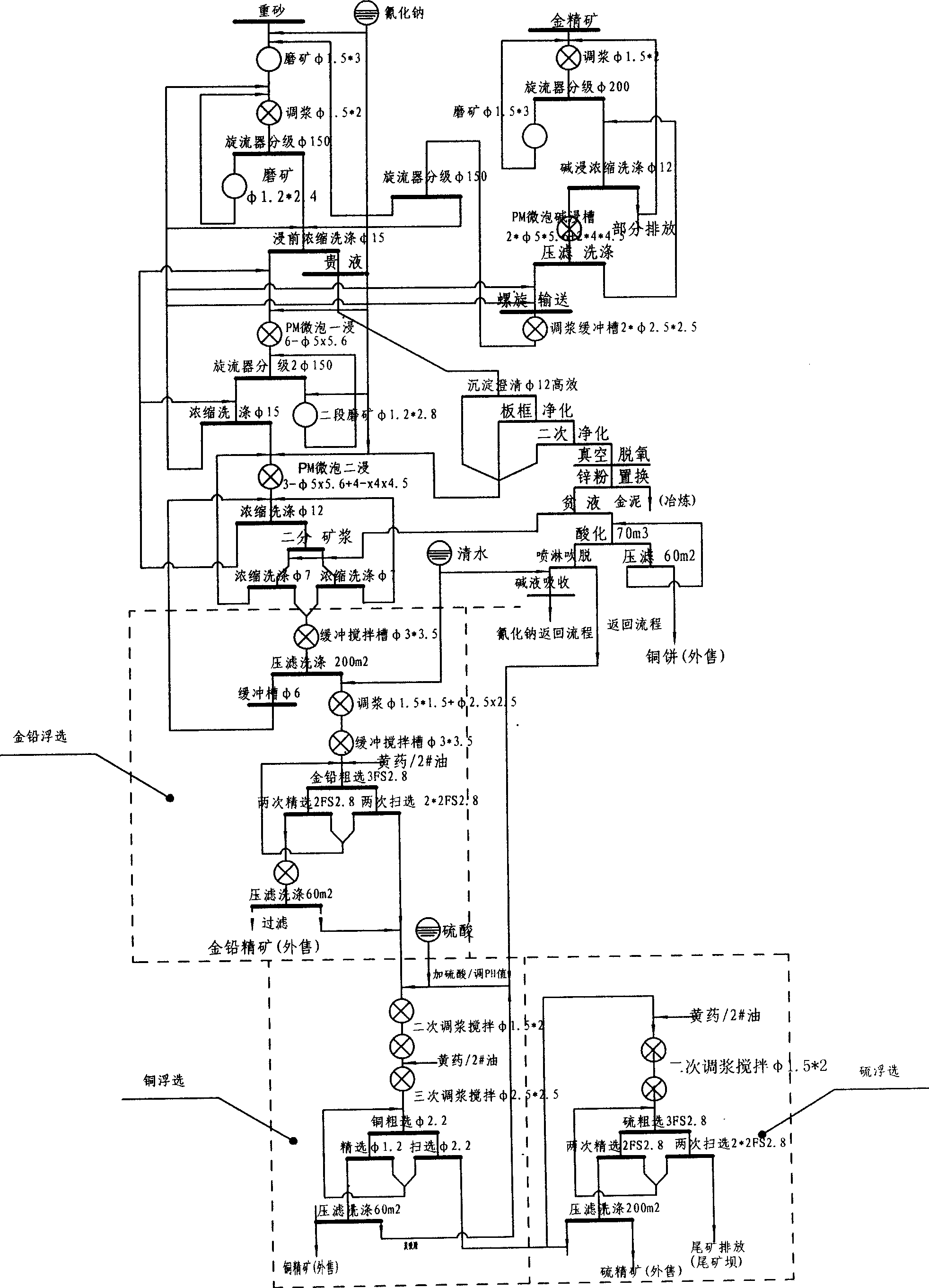

Comprehensive recovery method for directly cyanating and intensified leaching multi-metal gold ore concentrate

ActiveCN101451192AHigh recovery rateReduce backlogProcess efficiency improvementRecovery methodFiltration

The invention discloses a comprehensive recovery method for directly cyaniding, consolidating and leaching polymetallic gold concentrate, which comprises the following steps: after the gold concentrate is pulped, fractionated and grinded, qualified grinded and fractionated products are subjected to dehydration and reagent removal operation, and underflow is subjected to pre-alkaline leaching operation; pulp after alkaline leaching is subjected to alkaline leaching and pressure filtration; pulp after primary cyaniding leaching is subjected to primary washing, and 99.9 percent of finished products, namely gold ingots / silver ingots are produced; the underflow after primary washing is subjected to secondary leaching operation, and leached pulp is subjected to countercurrent washing; washed underflow pulp is subjected to pressure filtration; pulp after pulping is subjected to cyanide residue floatation operation, and gold lead concentrate, copper concentrate and sulfur concentrate are respectively recovered by floatation and taken as concentrate goods for sale; and tailings after floatation are subjected to pressure filtration and discharged as waste tailings. The method improves the recovery rate of difficulty leached gold concentrate to more than 96 percent, simultaneously reduces equipment investment, shortens the leaching technological flow, and reduces the metal overstock flow. The direct cyanidation recovery rate of gold reaches more than 96 percent, and the comprehensive recovery rate of the gold reaches more than 98 percent, so as to reach the advanced level in the same industry in China.

Owner:LINGBAO CITY JINYUAN MINING

Instant bath chap product and production method thereof

The invention relates to an instant bath chap product and a production method thereof. The instant bath chap product takes hogface as raw material, and is prepared by pre-processing the raw material,preparing soup bases, one-time cooking, boning, dividing, two-time cooking, dipping taste, toning, being packaged with liposuction and greasy cleaning substances in a matching way and sterilizing. Theproduct consists of bath chap, grease absorbing substance and seaweed block pieces, the weight percentage thereof are respectively as follows: 80-95% of bath chap, 1-10% of grease absorbing substanceand 1-10% of seaweed block piece. The preparation method of the invention has reasonable process and strong operability, thereby being applicable to large scale production. The bath chap product prepared by the method has balanced nutrition, has the functions of tonifying and health care, and has good color, sweet and flavour, tidy and beautiful appearance, good taste, long retention time, security and sanitation and convenient of eating, thereby being applicable to demands of different consumers.

Owner:TAIXIANG GRP TECH DEV

Productive technology for magma fruit 1iquor

The production process of raw nectar fruit white liquor mainly includes the procedures of raw material preparation, fermentation and distillation, etc. and it is characterized by that it includes thefollowing steps: cleaning fruit, cutting the fruit into small blocks; saccharifying glutinous rice or rice and converting it into mixed pulp containing dextrine and glucose; adding double-functional distiller's yeast, adding clean water and making fermentation, then making distillation, filtering and removing impurities so as to obtain the invented product with palatable taste.

Owner:李松林

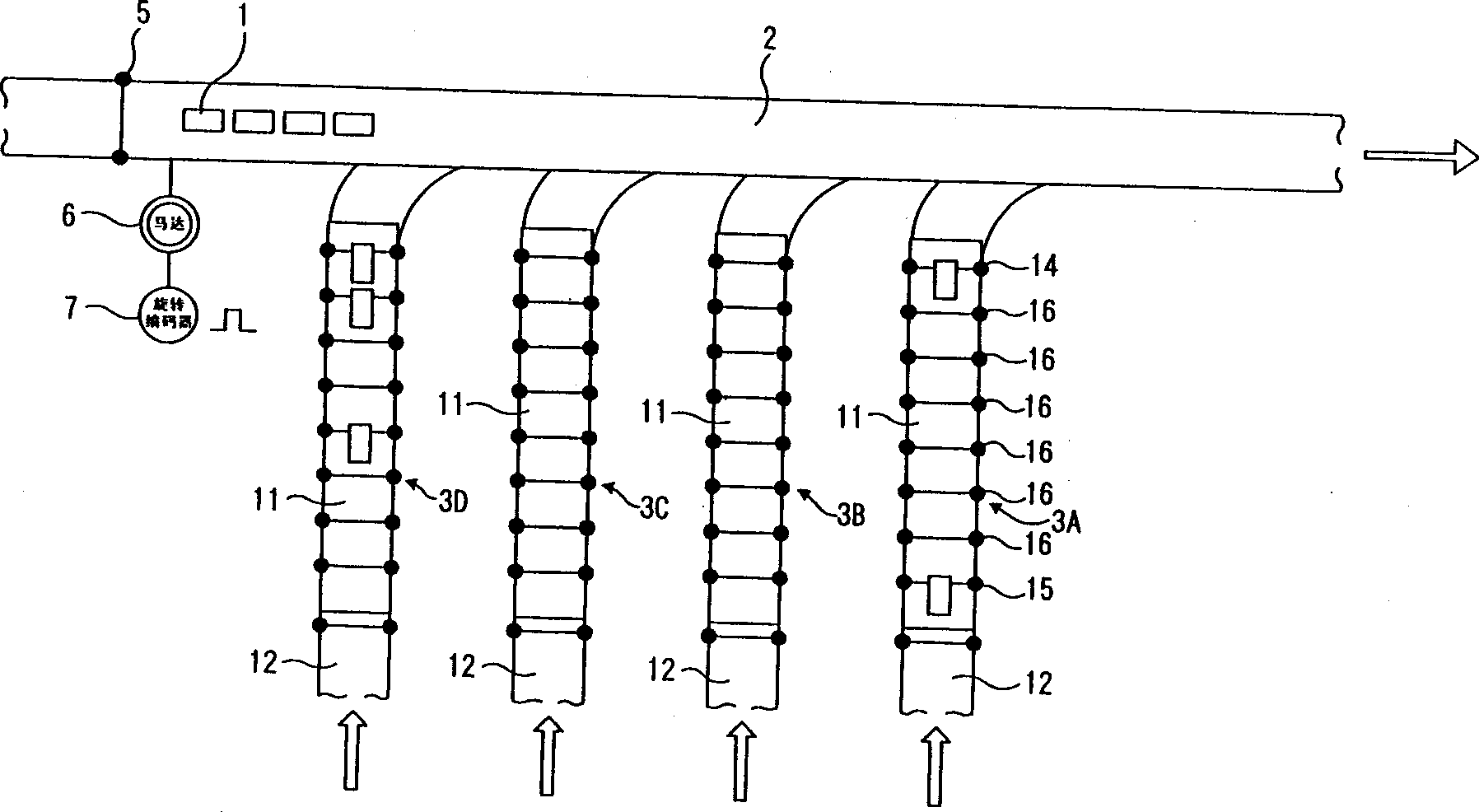

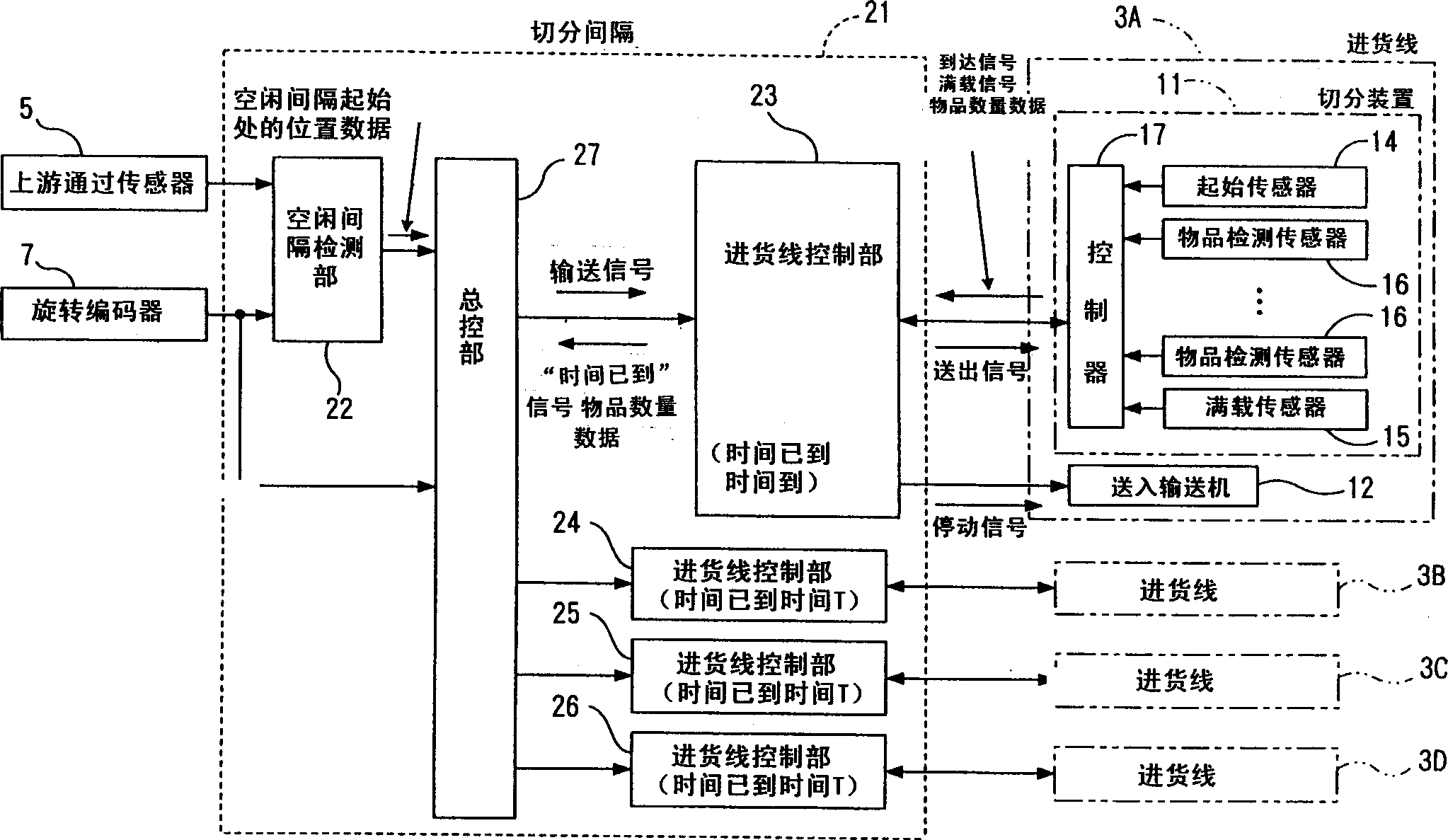

Cocurrent control method for goods

InactiveCN1369419AReduce idle intervalReduce backlogControl devices for conveyorsStorage devicesIndustrial engineeringWaiting time

The article merging control method is to reserve an empty interval (segmentation interval S) of a predetermined length or more between the loads of the conveyed article 1 or between the articles 1 on the main line 2 on the incoming line 3 where the article 1 is stored. Idle interval, when this idle interval is close to the confluence location of the reserved incoming goods line 3, the incoming goods line 3 will cut the article 1 corresponding to the length of the reserved empty interval to the main line 2. According to this method, the idle interval on the main line 2 that does not transport the item 1 can be reduced to improve the merging efficiency. In addition, by reducing the storage capacity of the item 1 on the incoming line 3, the waiting time for the item 1 to be put into the incoming line 3 can be reduced, thereby improving the efficiency. Efficiency of input work.

Owner:DAIFUKU CO LTD

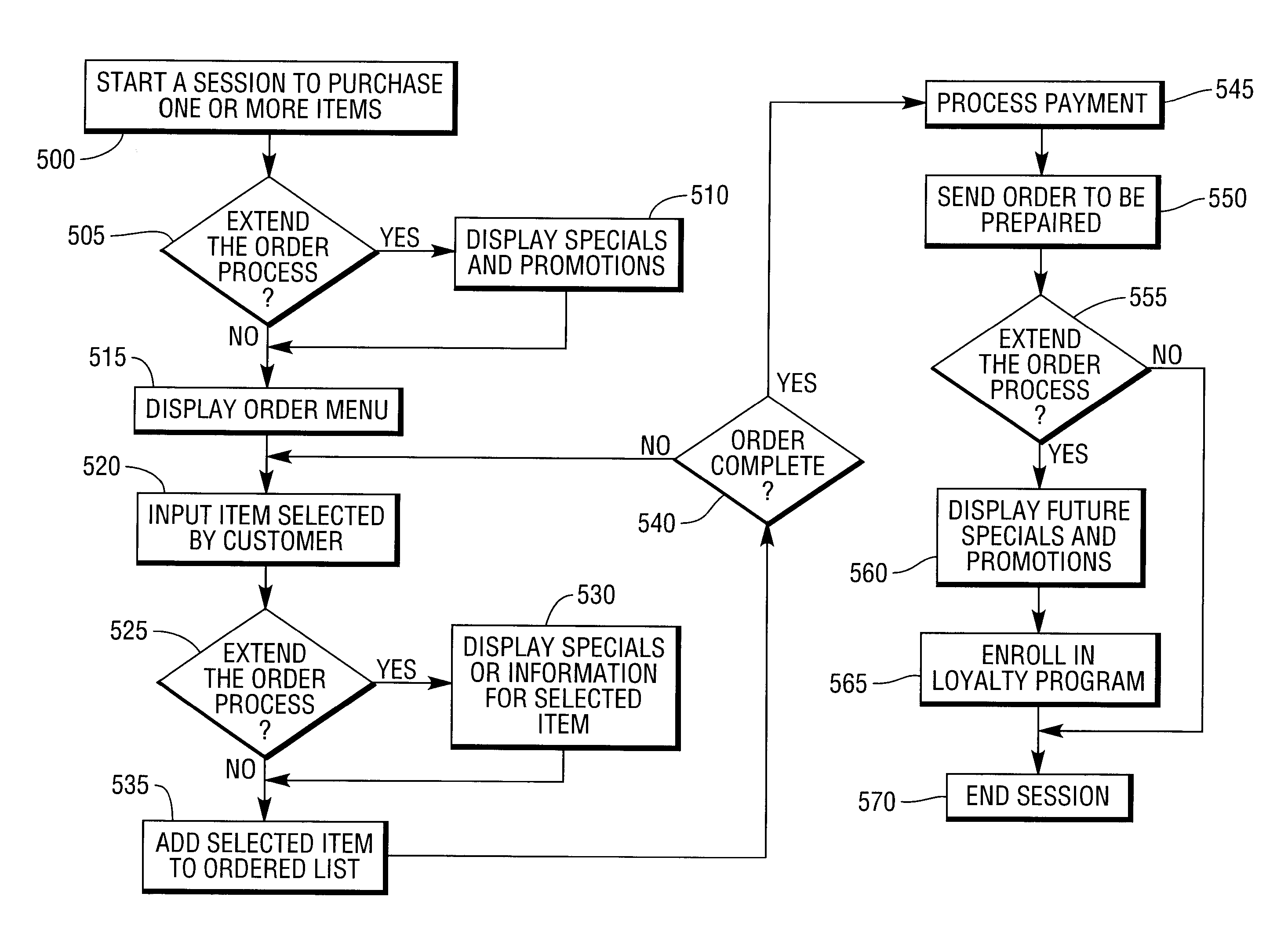

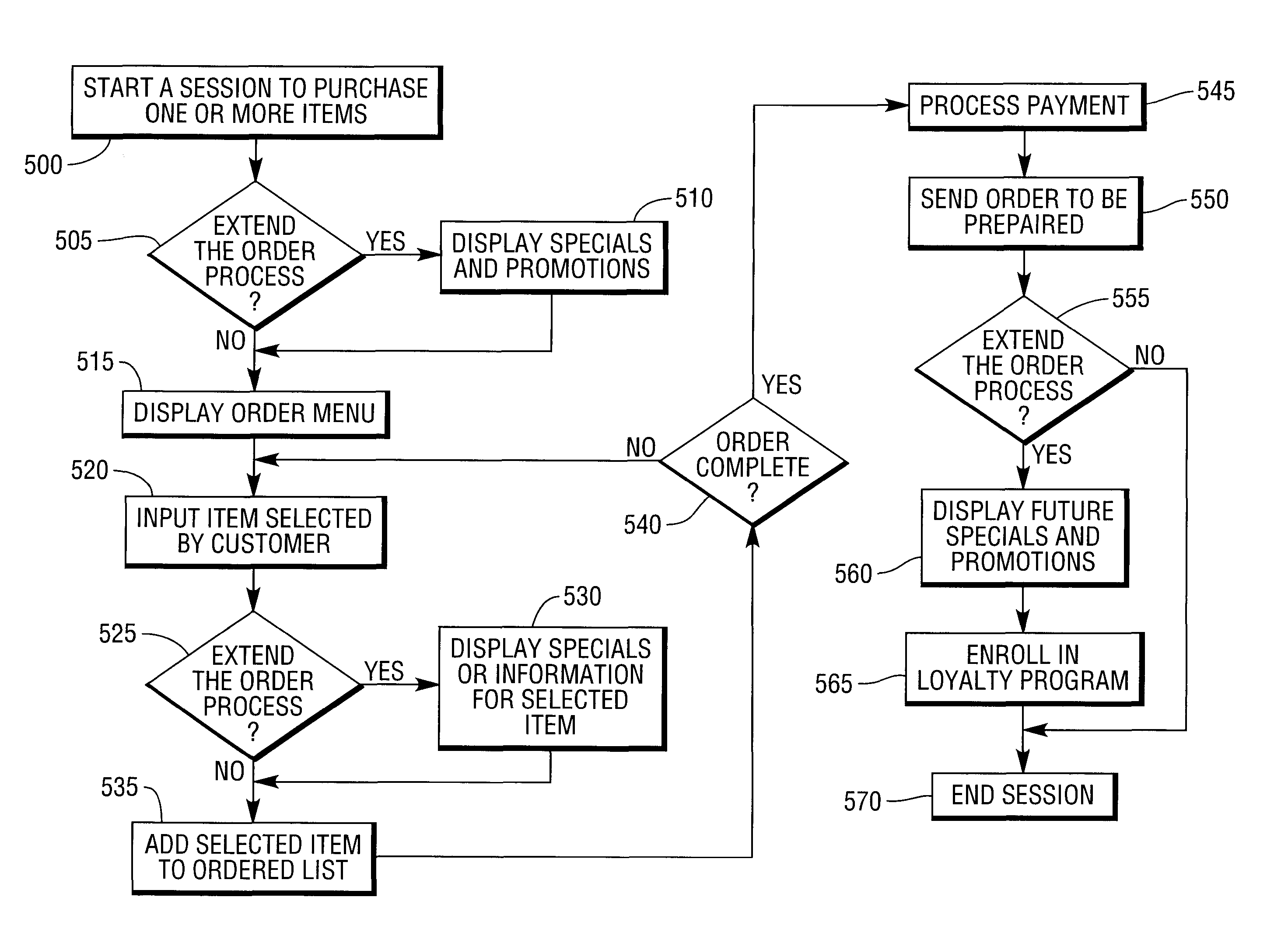

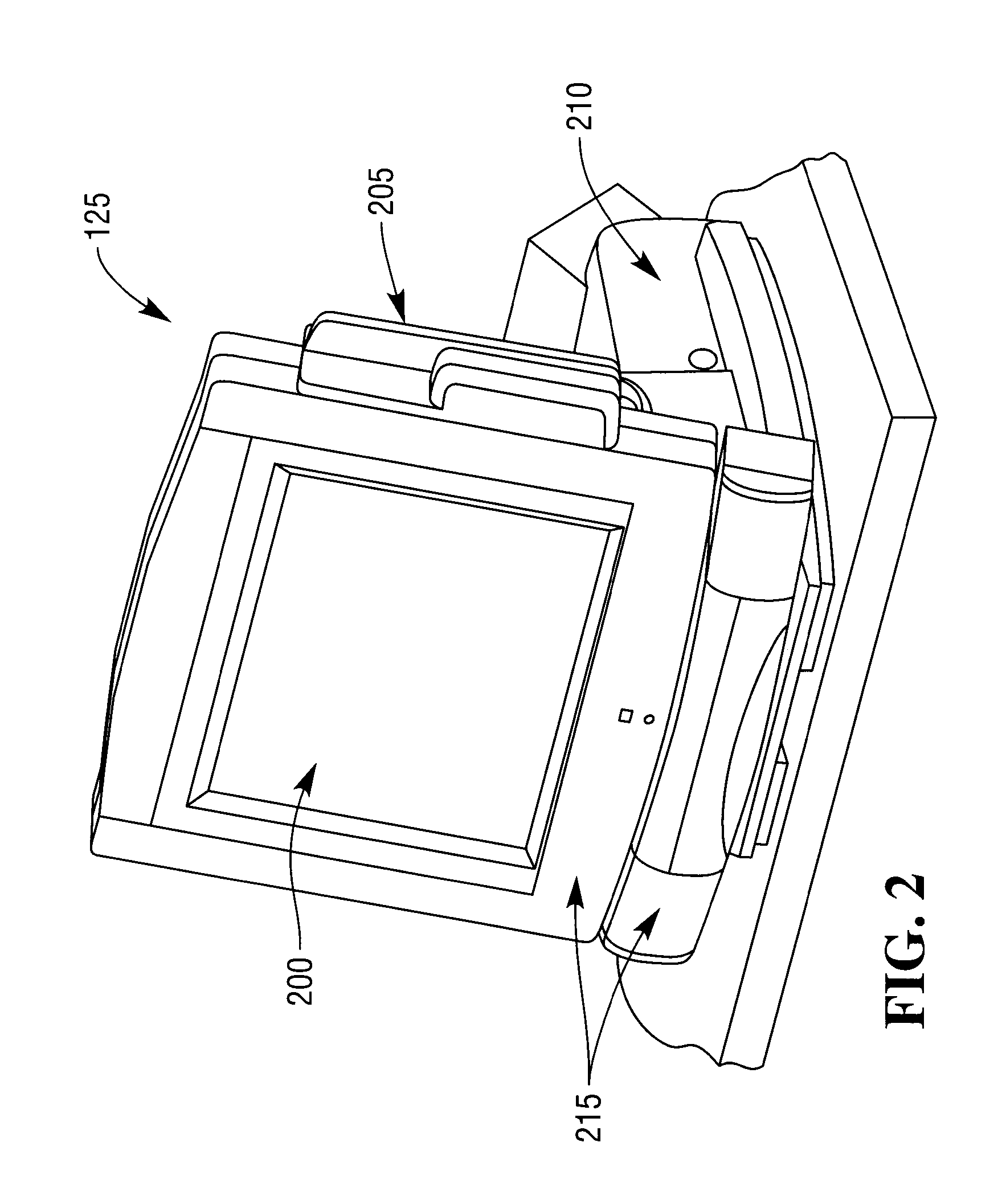

Apparatus, system and method for controlling the flow of customers

ActiveUS20110225032A1Optimized for speedShorten the timeAcutation objectsChecking apparatusEngineeringOrder entry

An apparatus, system and method are presented for controlling the flow of customers using self-service terminals. It is possible for self-service terminals to receive and process customer orders faster than the orders can be prepared for delivery to the customer thus causes long wait times for the customer if the condition is allowed to exist for an extended period of time. Controlling the flow of customers through the order entry process prevents the situation.

Owner:NCR CORP

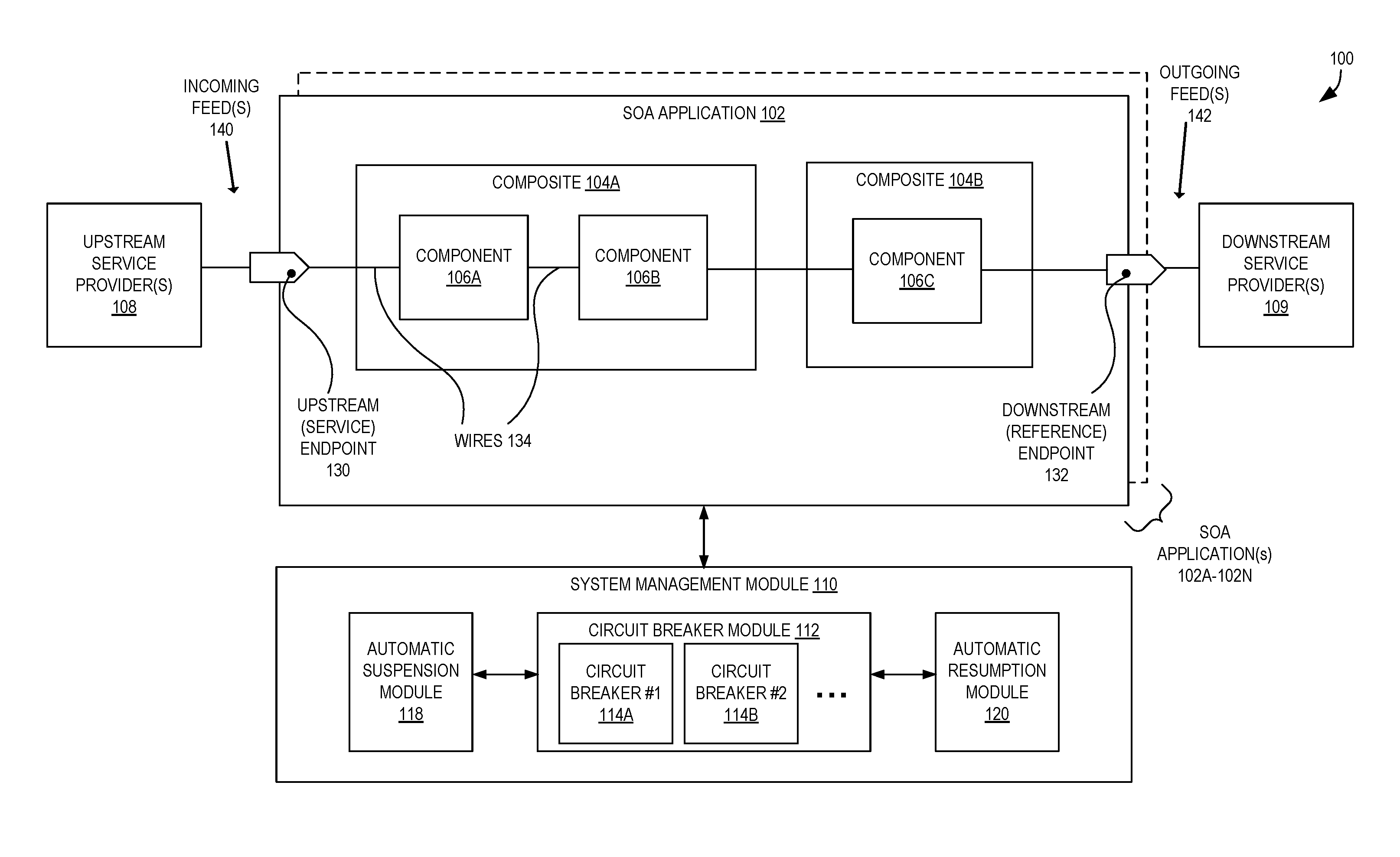

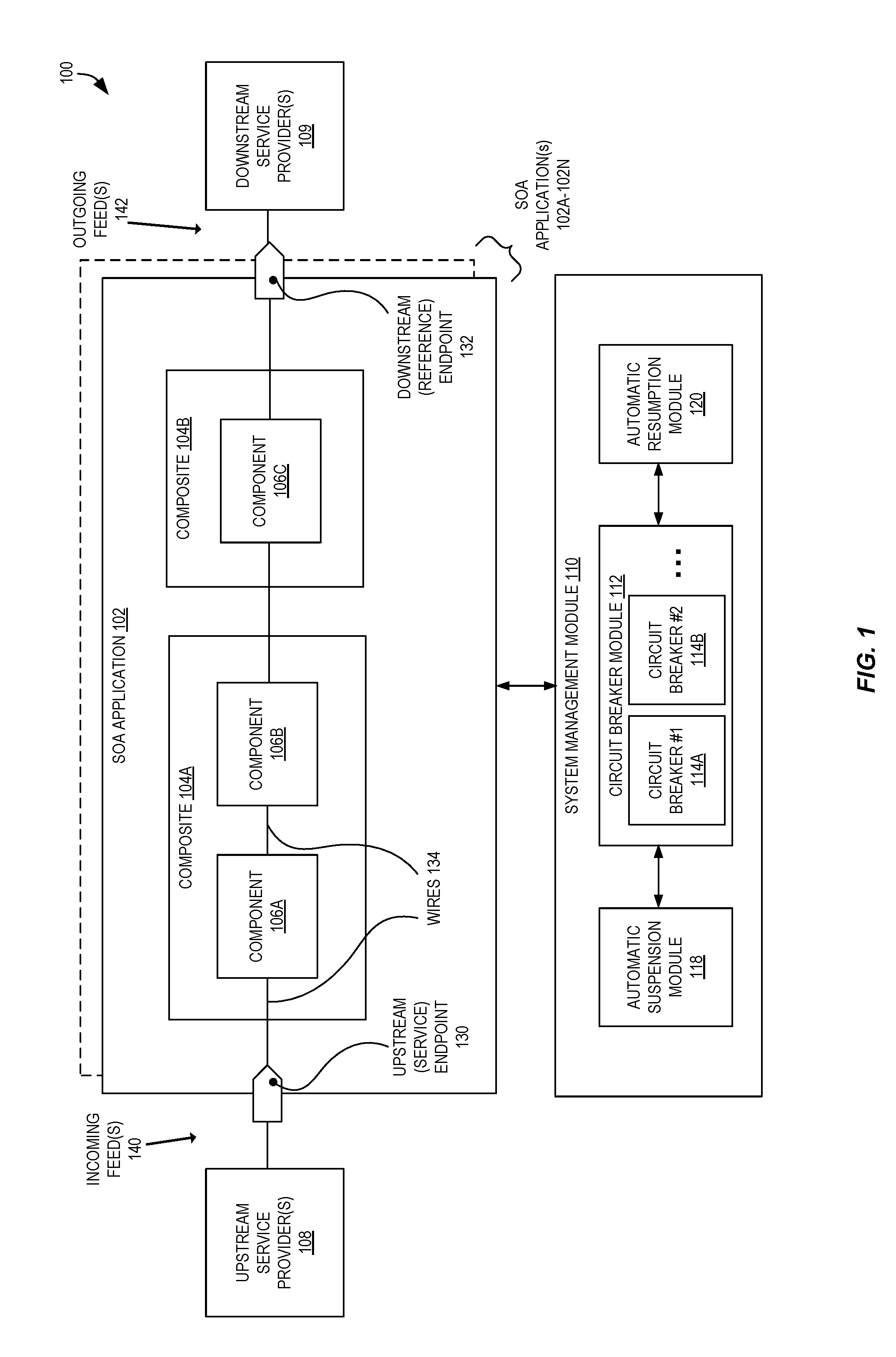

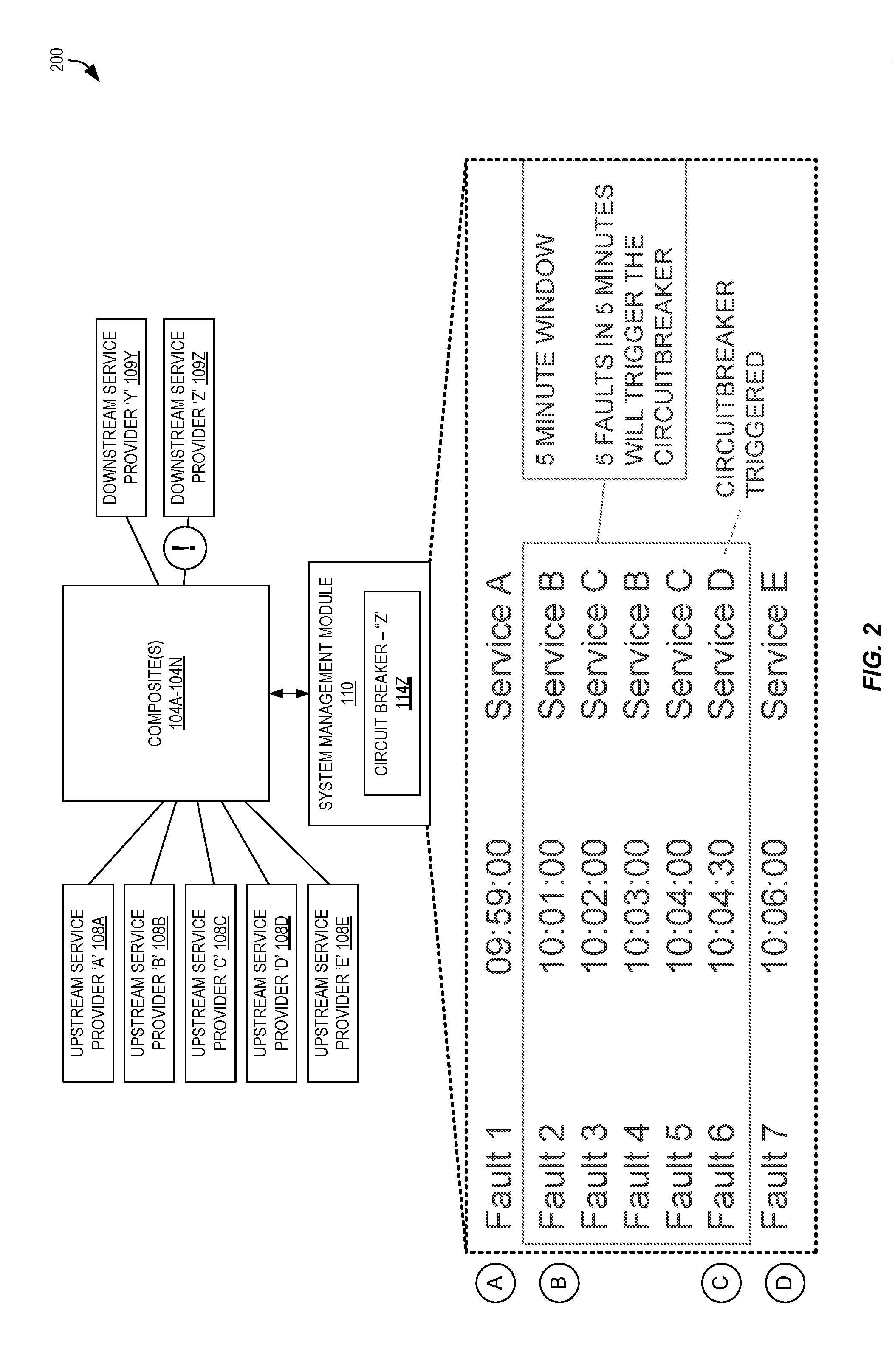

Automatic upstream service resumption after downstream system failure

ActiveUS20160316028A1Tremendous operational overheadAvoid the needData switching networksService provisionSystem failure

Techniques described herein relate to automatic upstream service resumption after downstream system failure. An automatic resumption module may be configured to monitor a downstream endpoint (of a problematic downstream service provider) and determine when it again successfully can process requests by periodically processing inbound requests (e.g., from suspended upstream service providers) and automatically re-enabling upstream endpoints for the suspended upstream service providers in the case of success. The automatic resumption module may start a trickle feed timer for each upstream endpoint to allow messages to be processed at a configured retry rate while the upstream endpoint remains suspended. The trickle feed timer may be configured to start upon the triggering of a circuit breaker for the involved downstream service. When downstream endpoint invocation succeeds, the automatic resumption module can resume all upstream endpoints associated with the downstream endpoint.

Owner:ORACLE INT CORP

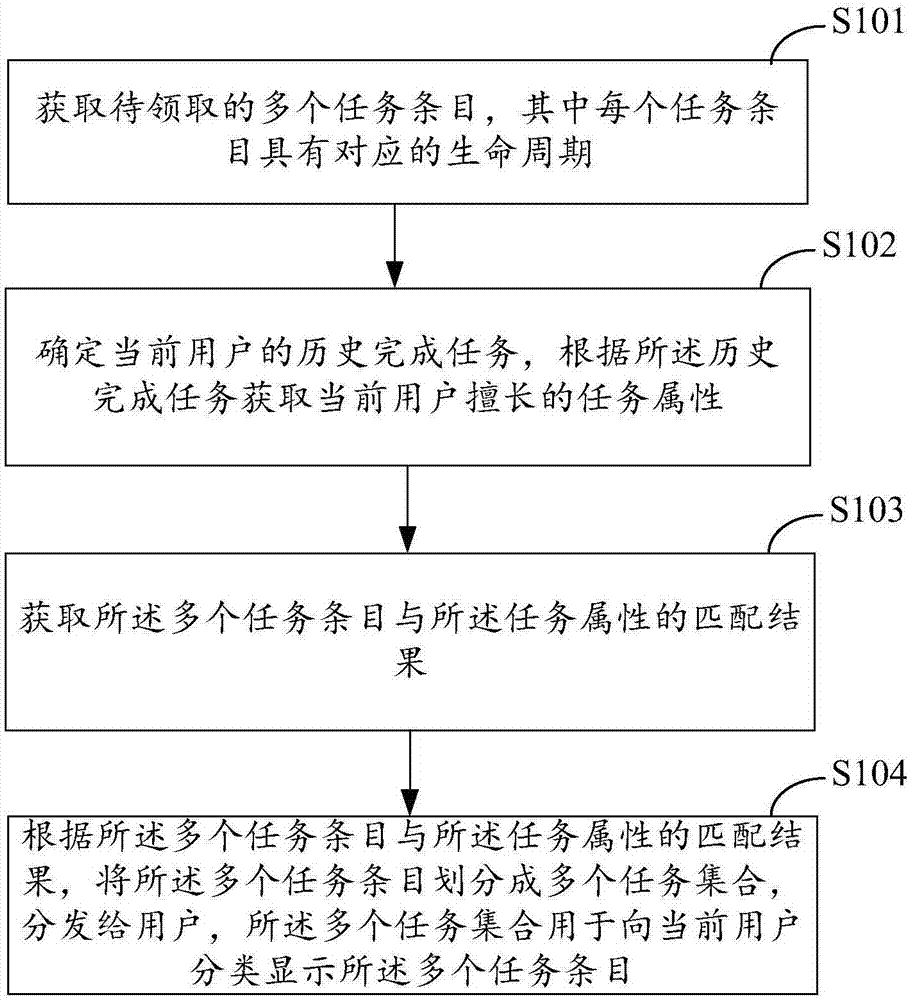

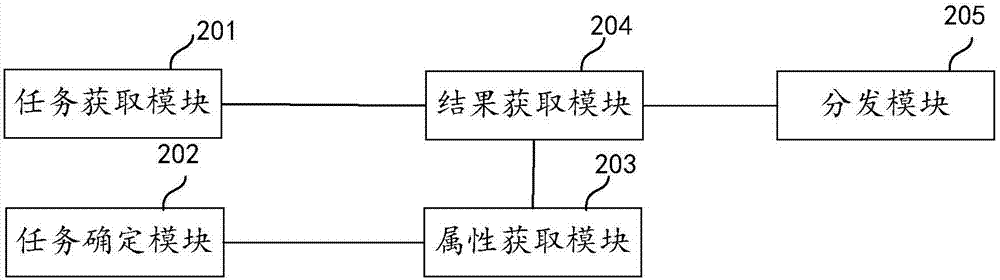

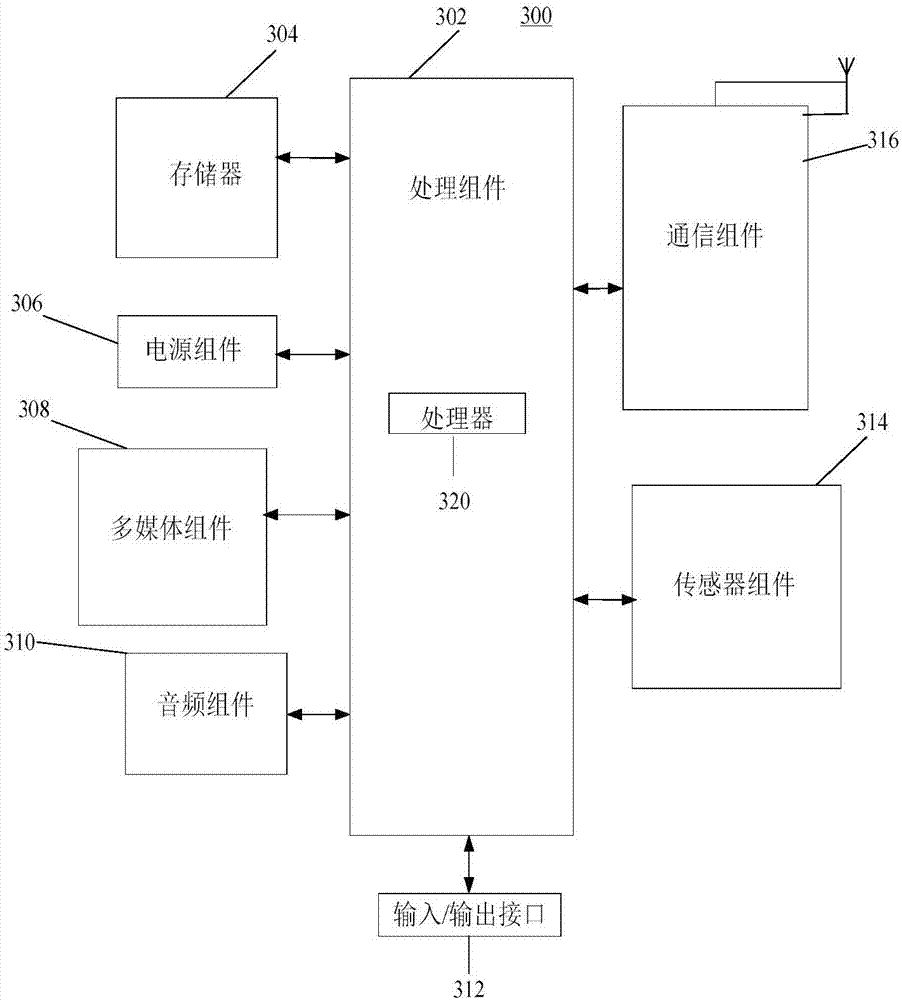

Task entry distribution method and relevant device

ActiveCN107992604AEasy to classify and displayReduce backlogWebsite content managementSpecial data processing applicationsDistribution methodData mining

The invention provides a task entry distribution method and a relevant device. The method includes the steps: acquiring a plurality of task entries to be taken with corresponding life cycles; determining historical finishing tasks of current users, and acquiring skilled task attributes of the current users according to the historical finishing tasks; acquiring matching results of the task entriesand the task attributes; dividing the task entries into a plurality of task sets according to the matching results of the task entries and the task attributes, and distributing the task sets to the users. The task sets are used for displaying the task entries to the current users in a classified manner. According to the method, users no longer view and take from a lots of task entries, a pluralityof task entries are displayed to the users in a classified manner, the user can rapidly search the task entries from interested task sets, accumulation of the task entries is reduced, so that computing resources are saved, and user experience is improved.

Owner:BEIJING SOGOU TECHNOLOGY DEVELOPMENT CO LTD

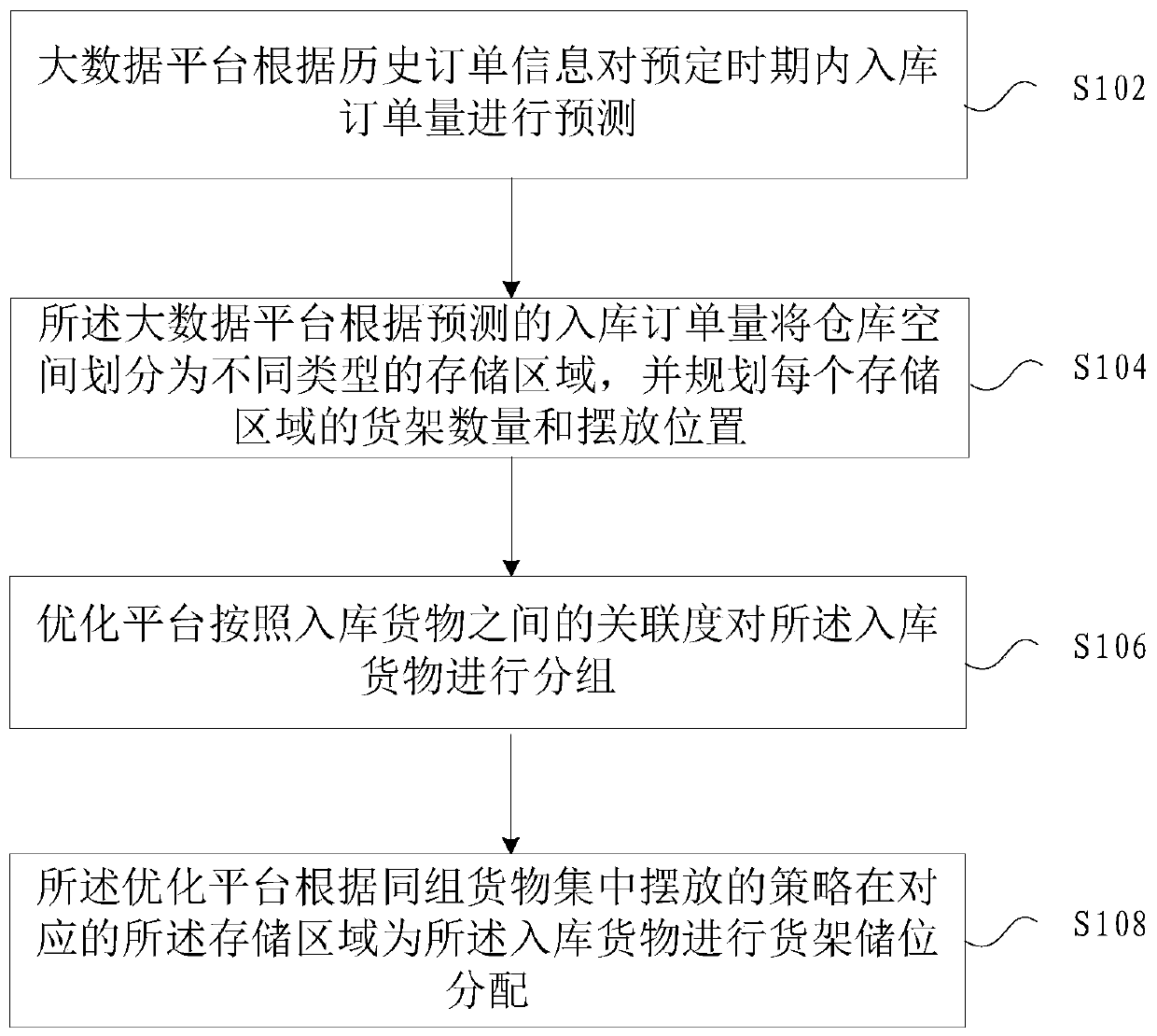

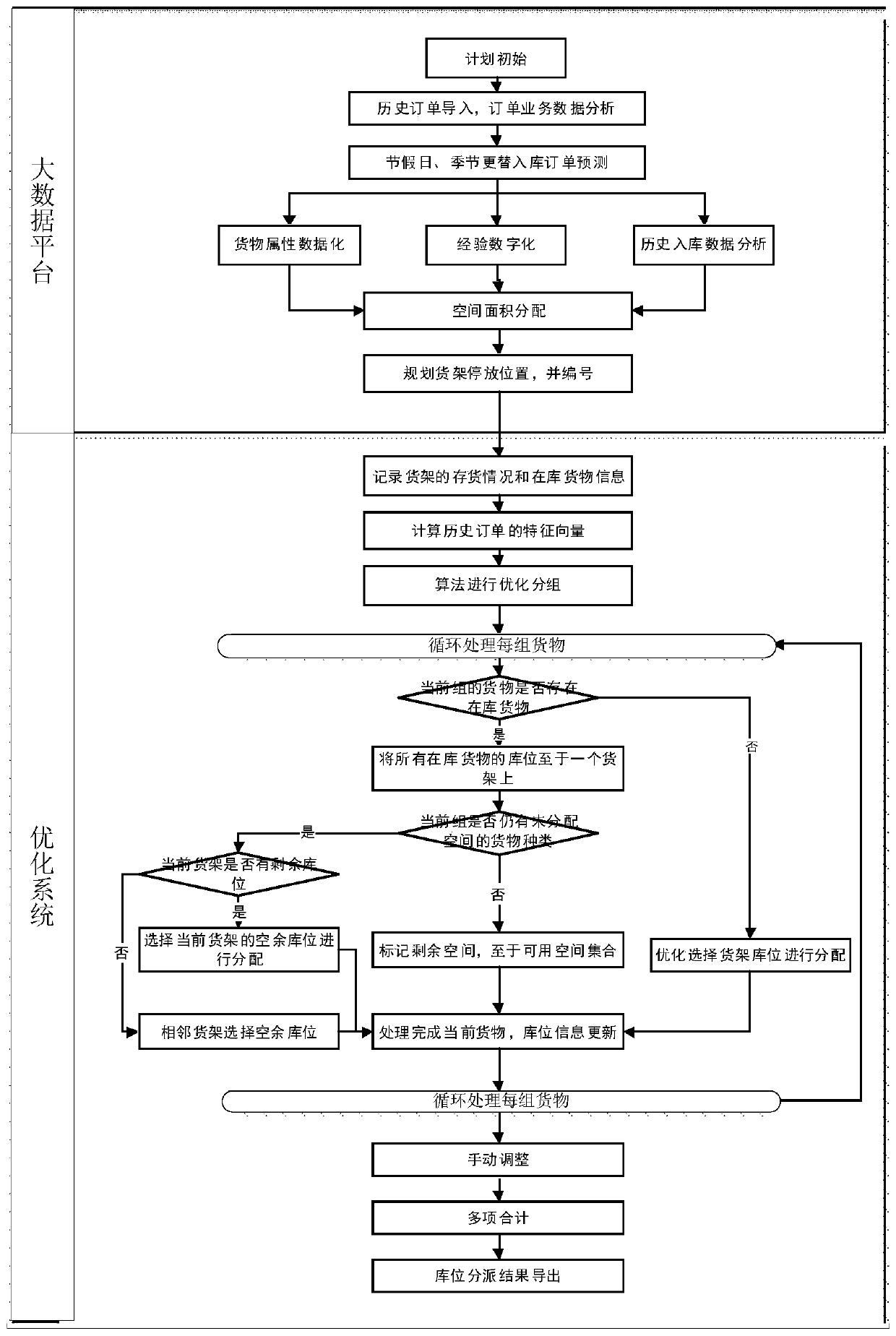

Warehouse storage location allocation method and system based on big data

The invention provides a warehouse storage location allocation method based on big data. The method comprises the steps that a big data platform predicts the warehousing order quantity in a predetermined period according to historical order information; the big data platform divides the warehouse space into different types of storage areas according to the predicted warehousing order quantity, andplans the shelf number and the placement position of each storage area; an optimization platform groups the warehoused goods according to the association degree between the warehoused goods; and theoptimization platform performs shelf storage location allocation on the warehoused goods in the corresponding storage areas according to the strategy of centralized placement of the goods in the samegroup. According to the invention, the big data platform is adopted to predict the warehousing order quantity in the predetermined period so as to carry out warehouse storage location allocation, at least the problem of unreasonable warehouse storage location allocation in the related technology is solved, and thus the order picking efficiency and the warehouse utilization rate are improved.

Owner:SHANGHAI MININGLAMP ARTIFICIAL INTELLIGENCE GRP CO LTD

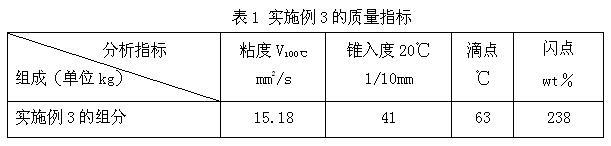

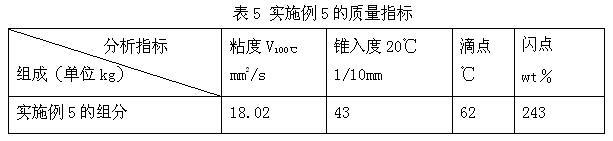

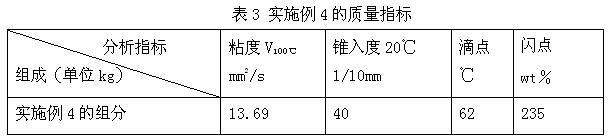

Integrated oil phase for emulsion explosive and preparation method thereof

InactiveCN102079681AGuaranteed emulsifying effectGuaranteed emulsification stabilityNon-explosive/non-thermic compositionsParaffin waxMicrocrystalline wax

The invention discloses an integrated oil phase for emulsion explosive and a preparation method thereof. The integrated oil phase for the emulsion explosive comprises the following components in part by mass: 10 to 18 parts of paraffin, 1 to 6 parts of microcrystalline wax, 45 to 65 parts of cerate and 25 to 35 parts of complex additive. The preparation method for the integrated oil phase for the emulsion explosive comprises the following steps of: preparing the components; adding the paraffin and the microcrystalline wax into an adjustable dehydrator, and heating for melting; adding the cerate, and fully stirring until the components are mixed and dissolved; raising the temperature for dehydration, and reducing the temperature; adding the complex additive, and stirring at a high speed until the components are mixed and dissolved; and filtering, discharging, cooling, forming and packaging. The integrated oil phase for the emulsion explosive integrates various components, has generality, and easily operates and controls the quality of the emulsion explosive, and can ensure the emulsifying property and emulsion stability in the production process of the emulsion explosive; the raw materials are easily obtained, low in cost and convenient to use; and the preparation method provides favorable guarantee for popularization and promotion in the industry.

Owner:GUANGDONG SUNION CHEM & PLASTIC

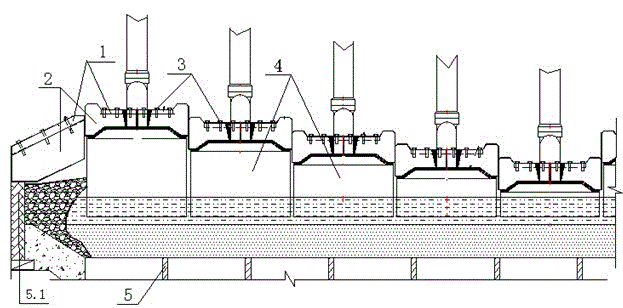

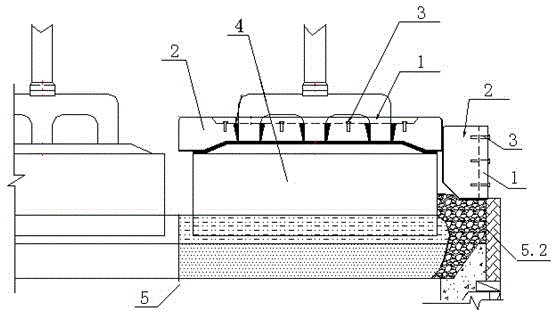

Heat preserving and oxidation resisting method in aluminum electrolysis cell production and heat preserving covering device

ActiveCN102747382AReduce fluctuating energy consumptionMaintain thermal insulation and anti-oxidation functionsSurface oxidationAluminum electrolysis

The invention discloses a heat preserving and oxidation resisting method in aluminum electrolysis cell production and a heat preserving covering device. The invention adopts a movable and monoblock heat preserving covering device formed by connection of steel member plates and heat preserving refractory material blocks to cover each positive electrode of an aluminum electrolysis cell and the ends as well as the lateral parts of the aluminum electrolysis cell, so that the effective heat preservation of the aluminum electrolysis cell can be realized and positive electrode surface oxidation of the aluminum electrolysis cell can be prevented. In the invention, the mode of employment of a mixed covering material layer composed of alumina and an electrolyte in the prior art is completely discarded. Compared with the prior art, the heat preserving covering device of the invention not only has the advantages of convenient operation, low running cost, labor saving, time saving, and high working efficiency, but also has the advantages of simple structure, good and stable heat preserving and oxidation resisting effects, resource saving, low requirements for the experience and technical level of operators, as well as convenience for mass production and standardized production, etc.

Owner:GUIYANG AL-MG DESIGN & RES INST

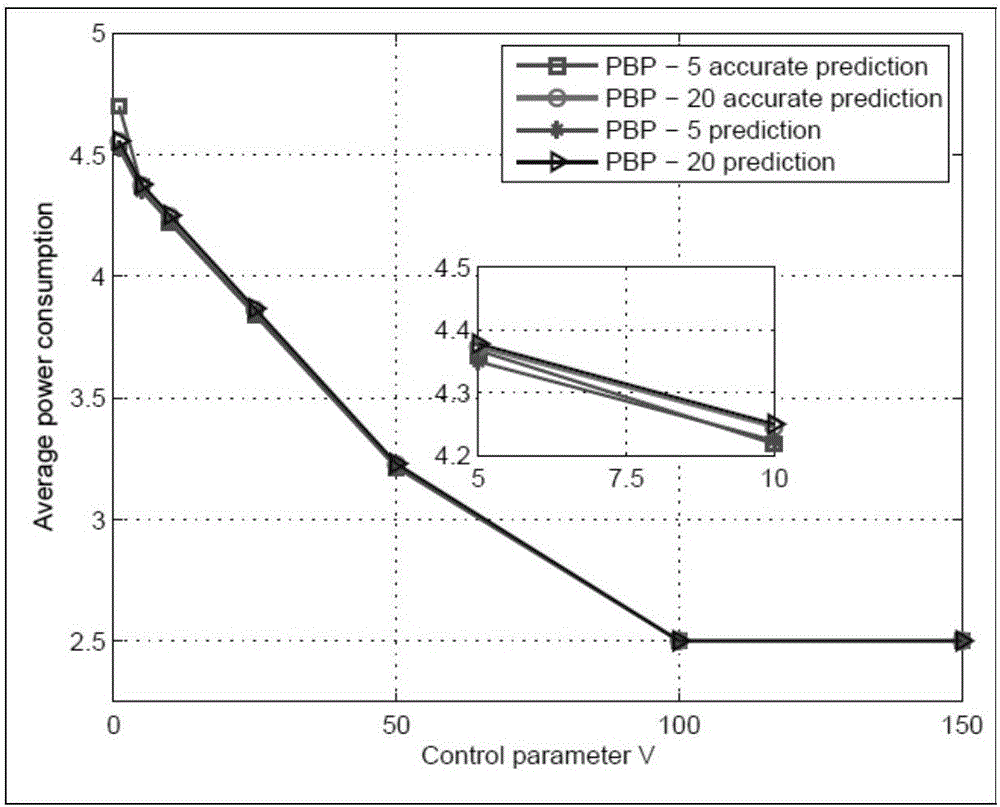

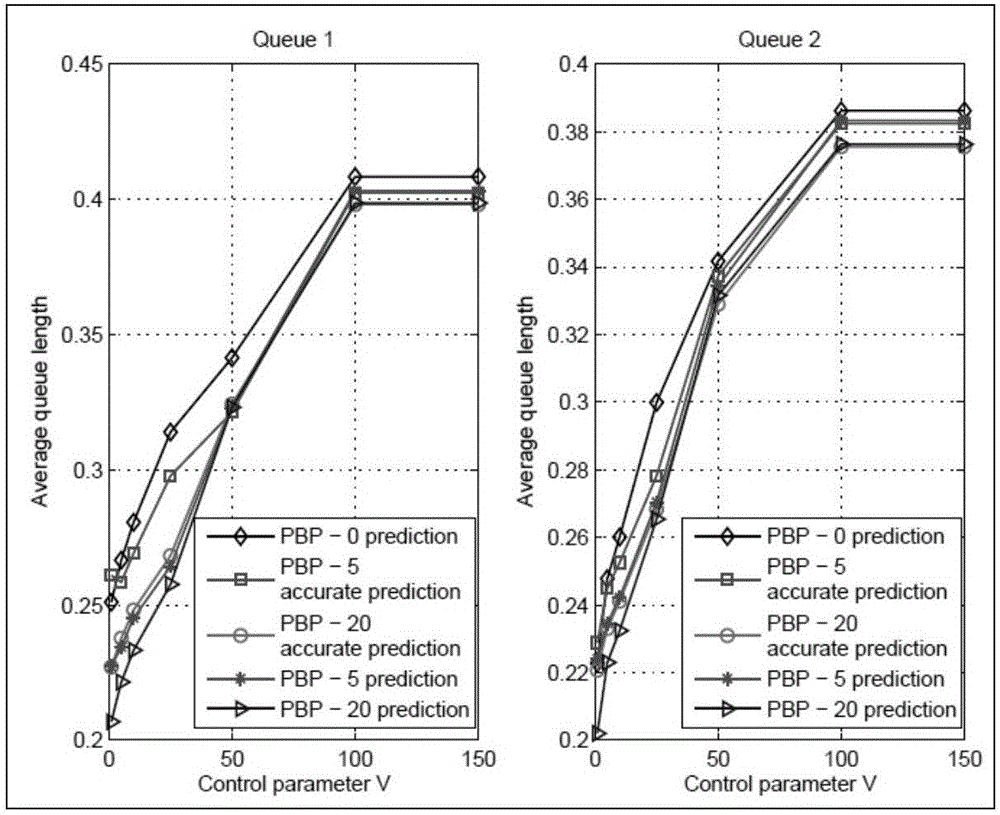

Allocation method and device for satellite resources in space information network

ActiveCN106685515AReduce backlogAlleviate technical problems that cannot reasonably allocate service resourcesRadio transmissionData switching networksTraffic capacityDistribution method

The invention provides an allocation method and device for satellite resources in a space information network, and relates to the technical field of satellite detection. The method comprises the steps that traffic data of multiple information source satellites in a current time slot is counted; historical traffic data of each information source satellite is acquired; traffic data in a target time slot is predicted according to the counted traffic data in the current time slot and the acquired historical traffic data to obtain prediction information, wherein the prediction information is used for predicting the queue length of a to-be-transmitted data queue of each information source satellite in the target time slot; service resources are pre-allocated according to service arrival of the prediction information to the target time slot, so that each information source satellite transmits the data according to the pre-allocated service resources, wherein the service resources comprise transmission power. Accordingly, the technical problem that in the prior art, the service resources cannot be reasonably allocated when the service resources are allocated is solved.

Owner:TSINGHUA UNIV

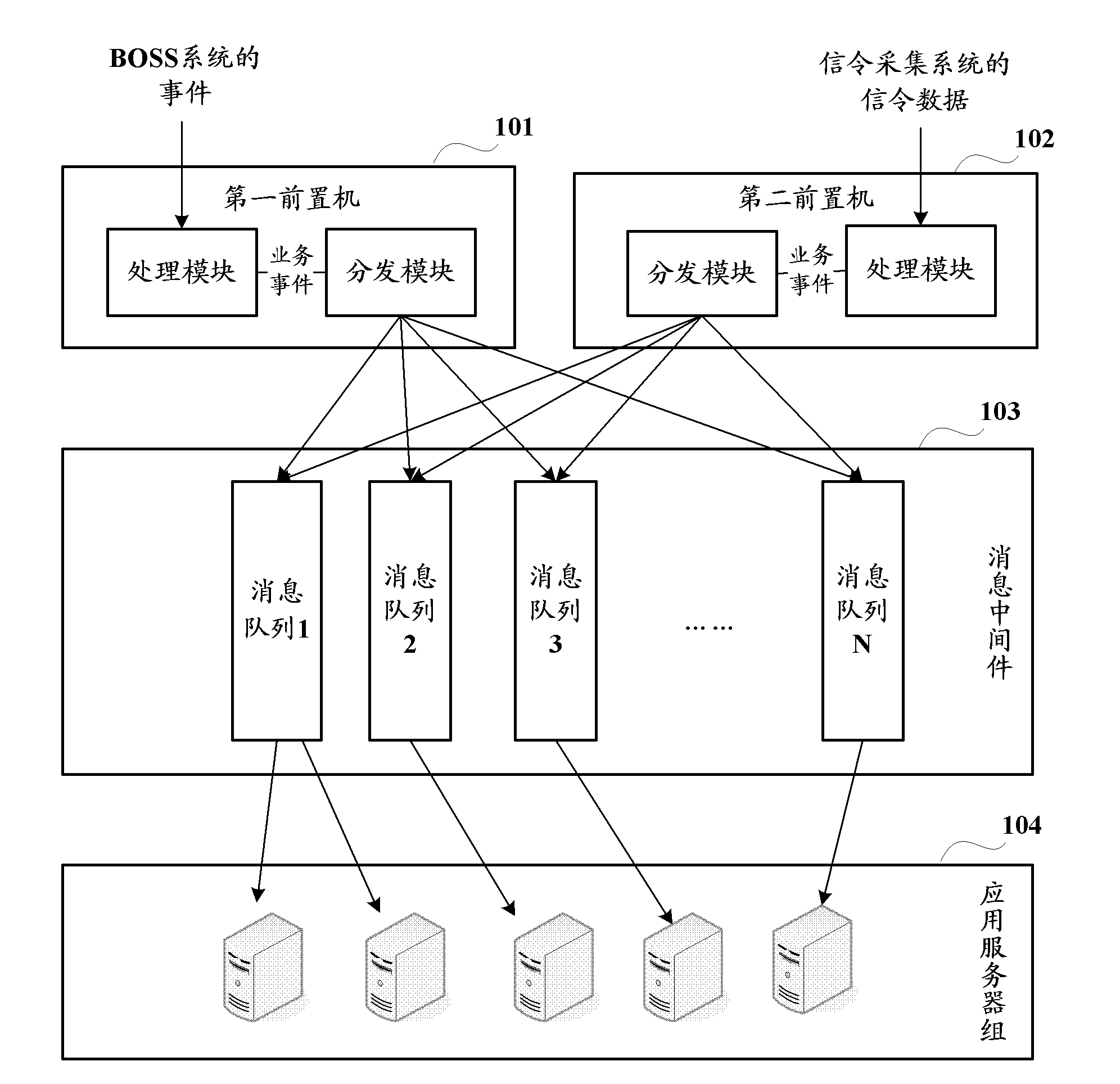

Message distribution method and device

ActiveCN102761832AReduce backlogImprove timelinessNetwork traffic/resource managementBroadcast service distributionMessage queueDistribution method

The invention discloses a message distribution method and a device, wherein the message distribution method comprises the steps as follows: determining the quantity of messages respectively stored in each message queue; determining a weight value respectively corresponding to each message queue according to the quantity of messages respectively stored in each message queue; using the weight values to express the quantity of messages which can be continuously received by the message queues; and distributing messages to each message queue according to the weight value respectively corresponding to each message queue. According to the technical scheme, the method can determine the quantity of the messages which can be continuously distributed to each message queue according to the quantity of the messages stored in each message queue, namely that the method can determine the quantity of the messages which can be distributed to each message queue according to the quantity of the messages actually stored in each message queue, thereby reducing the backlog of large numbers of messages in the message queues and enhancing the timeliness for processing messages.

Owner:XINYANG BRANCH HENAN CO LTD OF CHINA MOBILE COMM CORP

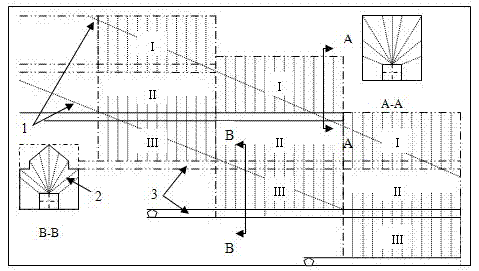

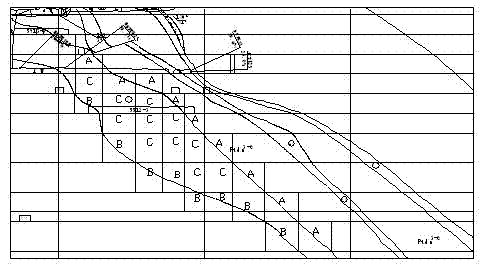

Pillarless sublevel caving method based vertical partitioning and combined ore drawing extraction technology of gently inclined ore bodies

InactiveCN102444403ATop in timeReduce depletionUnderground miningSurface miningMining engineeringMechanical engineering

The invention discloses a pillarless sublevel caving method based extraction technology used under the condition of gently inclined ore bodies. A series of problems of the pillarless sublevel caving method under the condition of gently inclined ore bodies such as efficient extraction of sublevel hanging wall and footwall triangle ore bodies, sublevel transition ore quantity, efficient recovery of footwall residual ores, timely supplementing and caving realization and the like are solved by the technical measures such as vertical partitioning, combined ore drawing, timely supplementing and caving, footwall residue full covering and the like. By designing the new pillarless sublevel caving method based vertical partitioning and combined ore drawing extraction scheme suitable for the condition of gently inclined ore bodies, the loss and dilution indexes when the pillarless sublevel caving method is applied under the condition of gently inclined ore bodies can be substantially reduced and the technical and economic benefits of mining can be increased.

Owner:SOUTHWEAT UNIV OF SCI & TECH +1

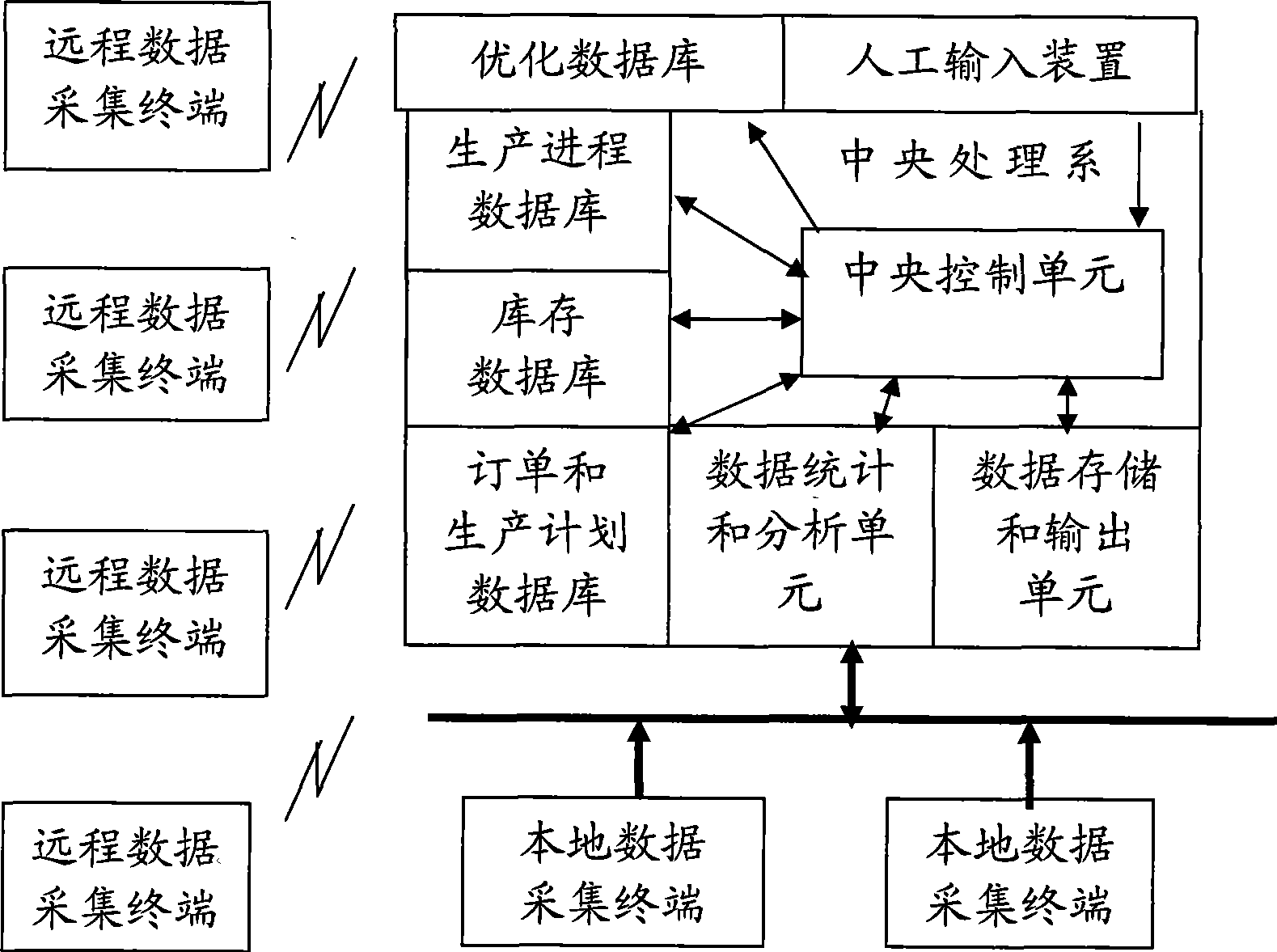

Remote enterprise production management system

InactiveCN101441741AImprove positive benefitsBalanced arrangementSensing record carriersLogisticsData acquisitionComputer terminal

The invention relates to a remote enterprise production management system, which mainly comprises a central processing system, a remote data acquisition terminal for exchanging data with the central processing system, as well as a local data acquisition terminal for exchanging data with the central processing system through a wire communication mode, wherein the remote data acquisition terminal and the central processing system are provided with respective wireless transmitting and receiving modules which communicate with each other through a wireless base station; the data acquisition terminals acquire warehouse in / out data of various goods, which is sent into the central processing system, as well as the production and storage data of each product in each process; and the central processing system counts, analyzes and stores the warehouse in / out data, as well as the production and storage data of each product in each process. As the system can master and analyze various types of inventory data, and can count and analyze the progress situations of the actual production of various products at any time, the production progress can be convenient to regulate in time, and unreasonable situations appearing in each production-supply-marketing link can be solved in time.

Owner:BEIJING AOTENGXUNDA SCI & TECH

Apparatus, system and method for controlling the flow of customers

ActiveUS8762207B2Optimized for speedEasy to useAcutation objectsChecking apparatusComputer terminalEngineering

An apparatus, system and method are presented for controlling the flow of customers using self-service terminals. It is possible for self-service terminals to receive and process customer orders faster than the orders can be prepared for delivery to the customer thus causes long wait times for the customer if the condition is allowed to exist for an extended period of time. Controlling the flow of customers through the order entry process prevents the situation.

Owner:NCR CORP

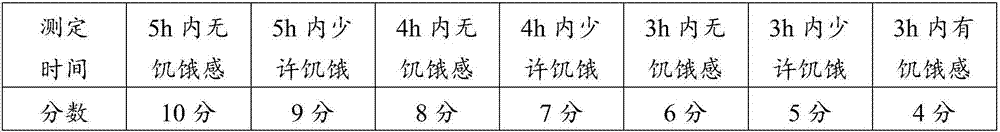

Scientific weight losing fully nutritional powder composition having satiety

InactiveCN107440095AClearing away heat and nourishing the lungsHas a preventive effectVitamin food ingredientsNatural extract food ingredientsIntestinal structureAdditive ingredient

The present invention discloses a scientific weight losing fully nutritional powder composition having satiety and belongs to the field of special dietary food processing. The composition is characterized by comprising the following components in percentages by mass: oat dietary fibers, plantago ovate seed shell powder, a garcinia cambogia fruit extract, a green coffee bean extract, sodium caseinate and mogrosides, and is also prepared by mixing the following raw materials: soybean protein isolate, plant fat powder, compound vitamins and compound minerals. By adding the oat dietary fibers, plantago ovate seed shells, sodium caseinate and mogrosides, the composition reaches effects of promoting satiety, moistening intestines and relaxing bowels. By adding the garcinia cambogia fruit extract and coffee bean extract, the composition has effects of inhibiting appetite and promoting fat metabolism. By adding the soybean protein isolate, plant fat powder, compound vitamins and compound minerals, the composition can supplement body with proteins, fats, vitamins and minerals, enables the body to reach purposes of being health and losing weight, and is especially suitable for populations with obesity and overweight.

Owner:MEILU BIOTECH CO LTD

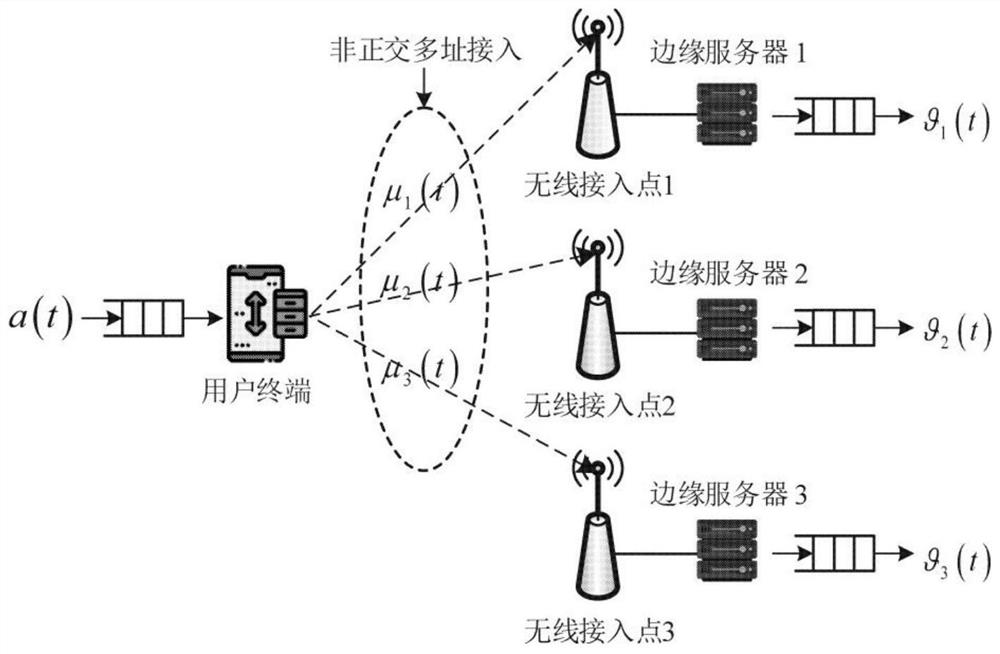

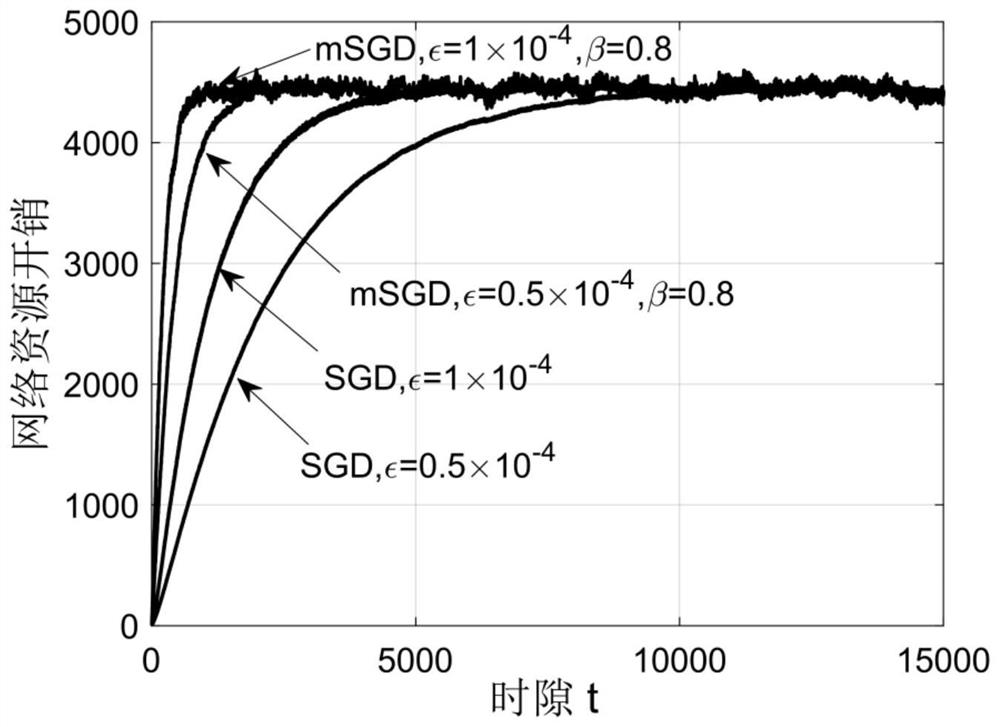

Resource optimization method in mobile edge computing task unloading and electronic equipment

ActiveCN112148380AReduce backlogProgram initiation/switchingResource allocationDescent algorithmAlgorithm convergence

The invention discloses a resource optimization method in mobile edge computing task unloading and electronic equipment. The method comprises the following steps: constructing a queue stability indextaking minimization of the task queue length of a user terminal and the task queue length of an edge server as a target; constructing a network resource overhead index; constructing a random network resource optimization model by taking the queue stability index as a constraint condition; introducing a Lagrange multiplier to carry out variable relaxation on constraint conditions of the random network resource optimization model, and constructing a coupling model; and solving the coupling model based on a momentum stochastic gradient descent algorithm to obtain an optimal resource allocation decision of each time slot. According to the method, the coupling model of the random network resource optimization model is constructed based on the original coupling theory, the coupling problem is solved online based on the momentum stochastic gradient descent algorithm, and task queue overstock is reduced while algorithm convergence is accelerated. The task queue backlog can be further reduced under the condition that the network resource overhead is not increased.

Owner:PENG CHENG LAB

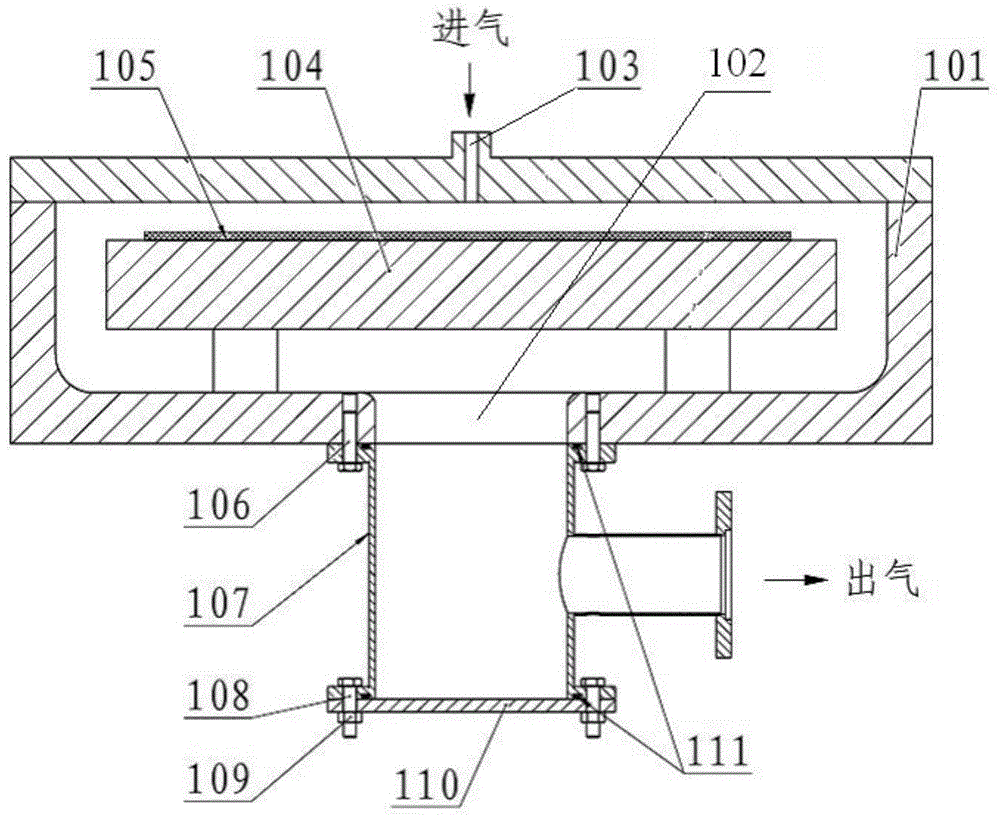

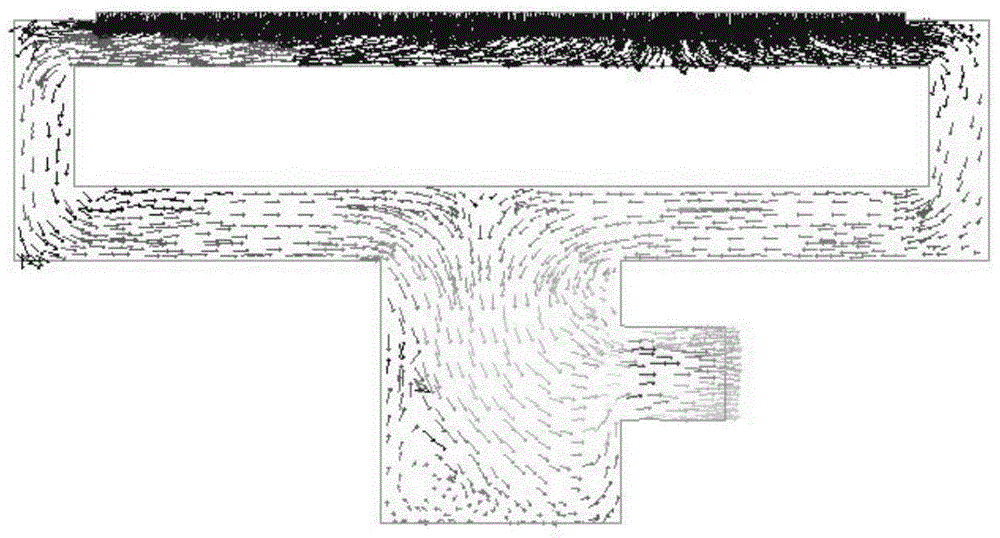

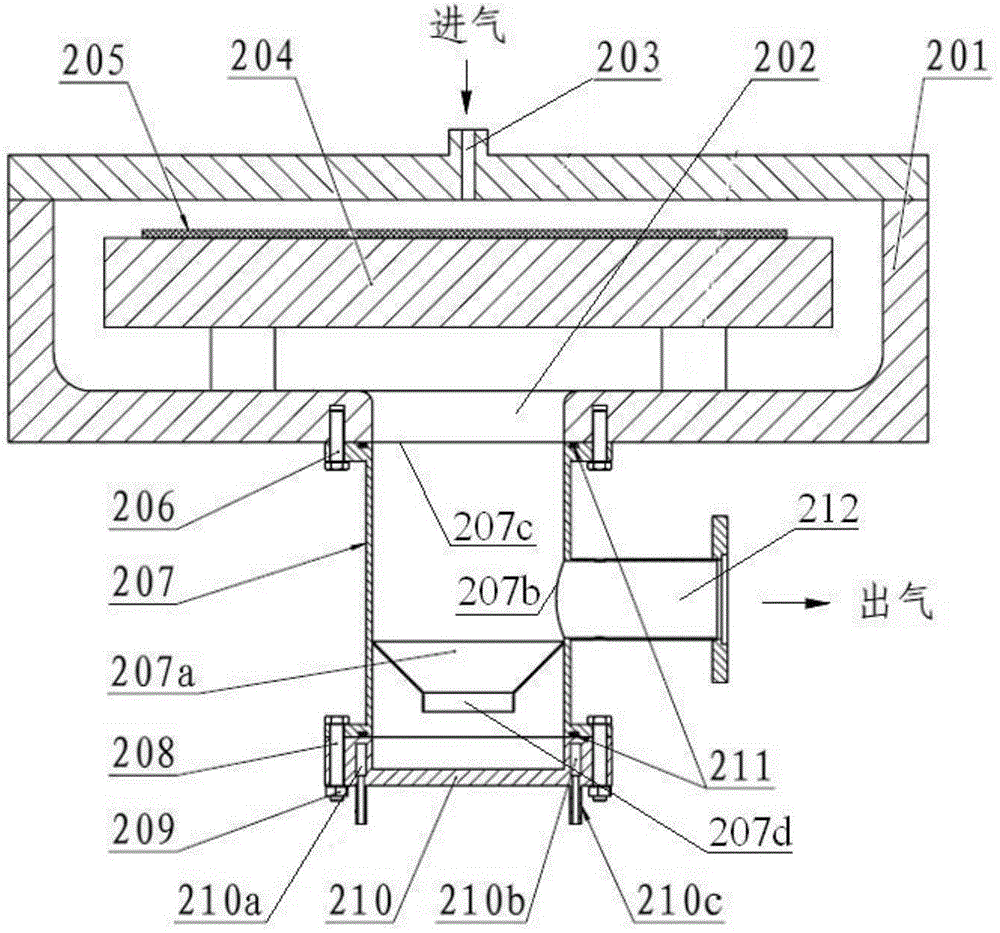

Semiconductor processing device

ActiveCN104979237ASpeed up the flowEfficient dischargeSemiconductor/solid-state device manufacturingEngineeringSemiconductor

A semiconductor processing device, comprising a reaction chamber (201) and an air extraction chamber (207) which is arranged at the bottom of the reaction chamber, wherein an air exhaust port (202) is provided at the bottom of the reaction chamber, an air inlet port (207c) is provided at the top of the air extraction chamber correspondingly, and the air inlet port is connected to the air exhaust port; an air outlet port (207b) is provided on a side wall of the air extraction chamber for exhausting air in the air extraction chamber; a funnel-shaped conical ring (207a) is provided in the air extraction chamber and is located below the air outlet port, wherein a lower port of the conical ring is smaller than an upper port thereof; and the conical ring is used for dividing the air extraction chamber into an upper chamber and a lower chamber, wherein the upper chamber is in communication with the lower chamber through a ring hole of the conical ring. The semiconductor processing device can reduce the accumulation of some by-product granules carried in an airflow, and can restrain the accumulated by-product granules from being raised by the airflow, thereby preventing the by-product granules from returning to the reaction chamber.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

Treatment process for raw material of cigar

ActiveCN1757332AShorten the fermentation cycleImprove turnover rateTobacco preparationHigh humidityEngineering

A technology for processing the raw material of cigar includes moistening tobacco leaves and high-temp and high-humidity fermenting at 35-50 deg.C and under 65-80% in relative humidity for 7-15 days. Its advantages are short period and high quality of product.

Owner:CHINA TOBACCO SHANDONG IND

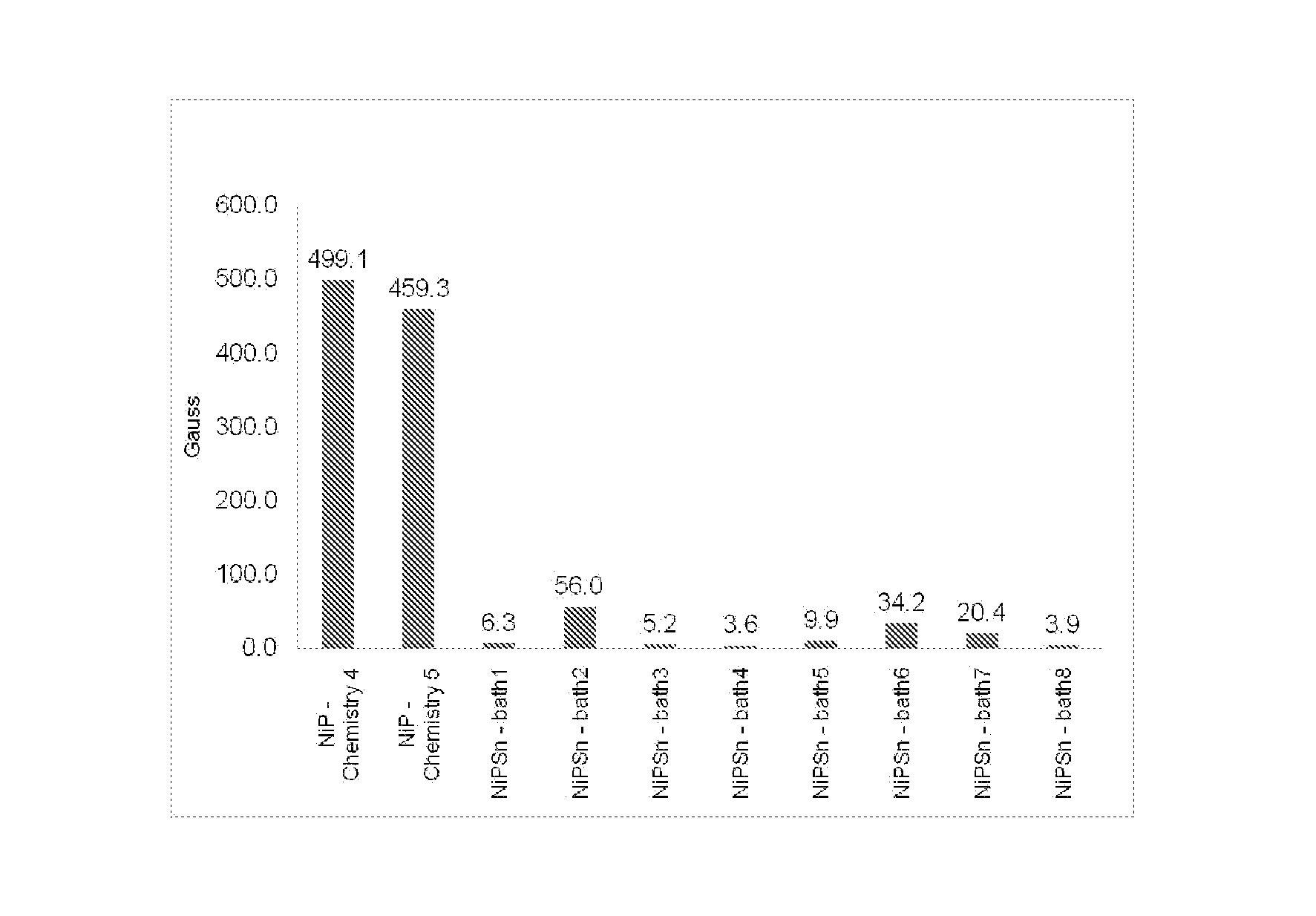

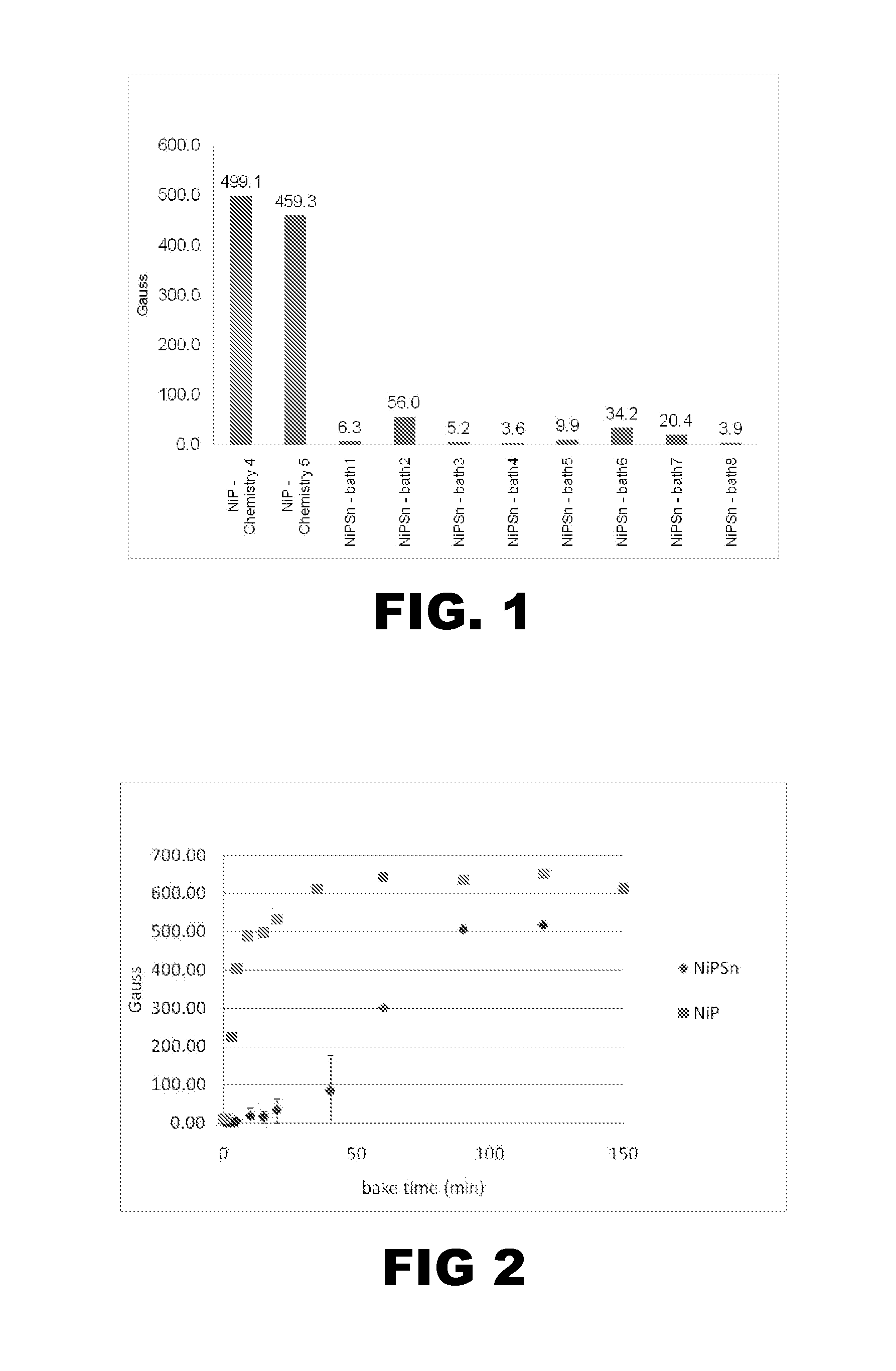

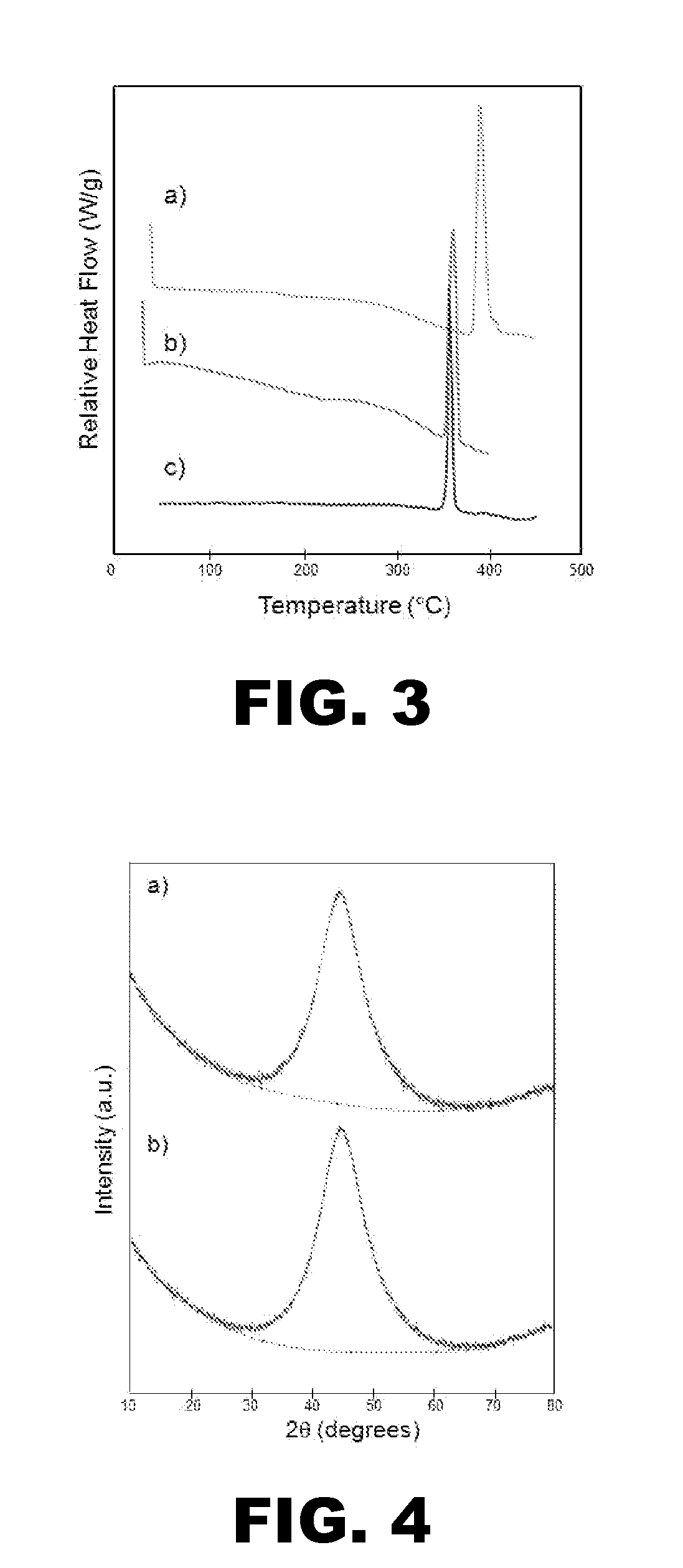

Electroless nickel alloy plating bath and process for depositing thereof

ActiveUS20120058259A1Increase thermal stabilityImprove thermal stabilityAnti-corrosive paintsLiquid/solution decomposition chemical coatingElectroless platingAlloy deposition

An aqueous nickel phosphorus tin alloy electroless plating bath and process for depositing a nickel phosphorus tin alloy onto a substrate, particularly an aluminum substrate for memory disk applications, wherein the nickel phosphorus tin alloy deposit provides enhanced thermal stability, as defined by the inhibition of crystallization and suppression of magnetization upon high temperature annealing when compared to typical NiP deposits.

Owner:MACDERMID INC

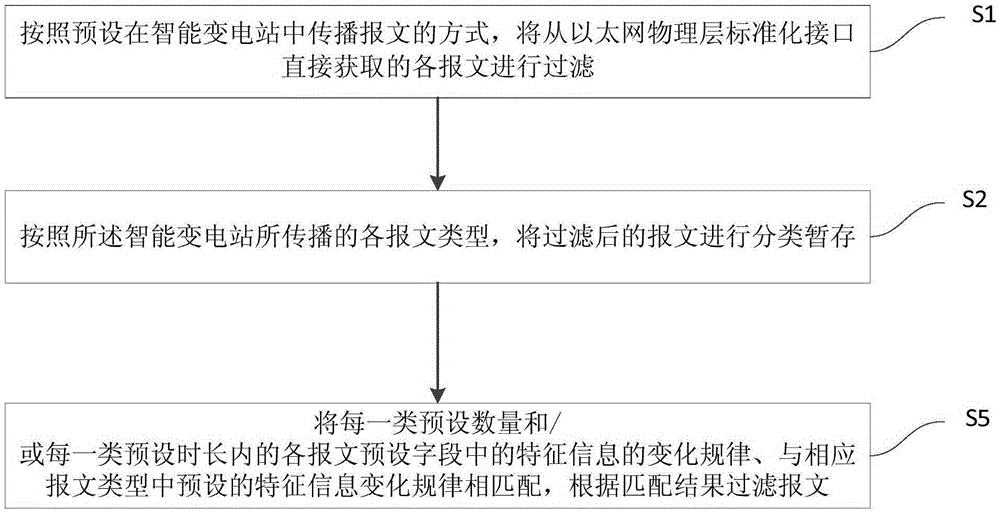

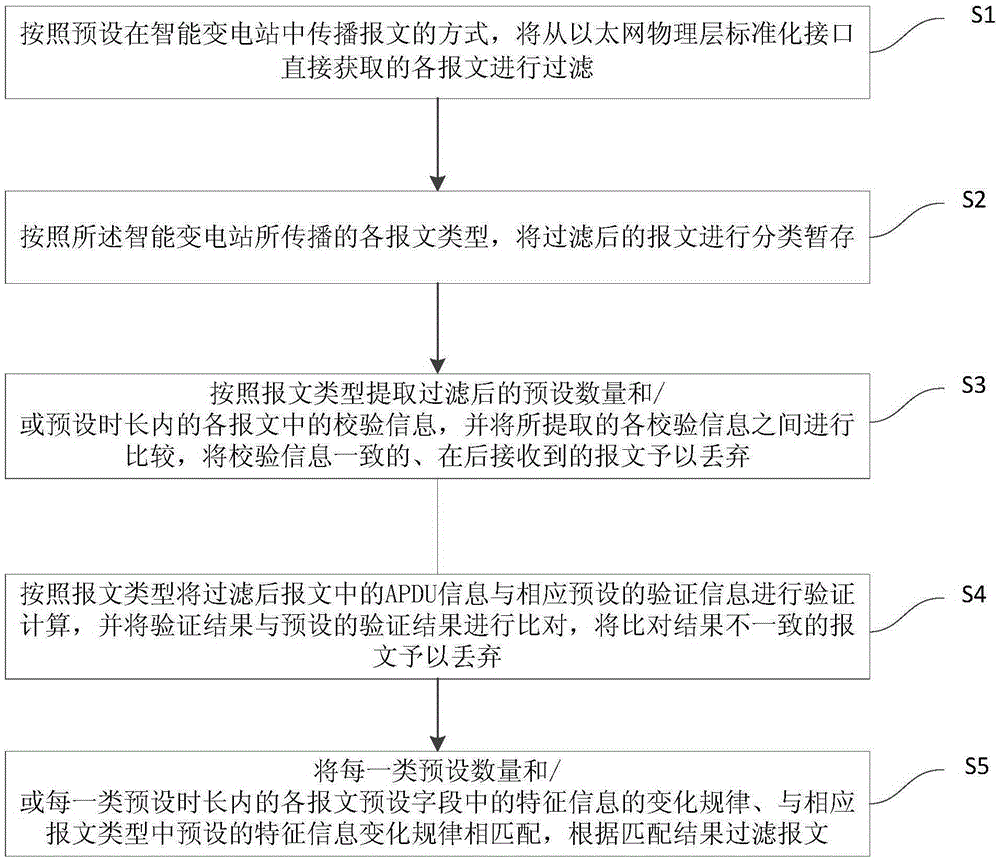

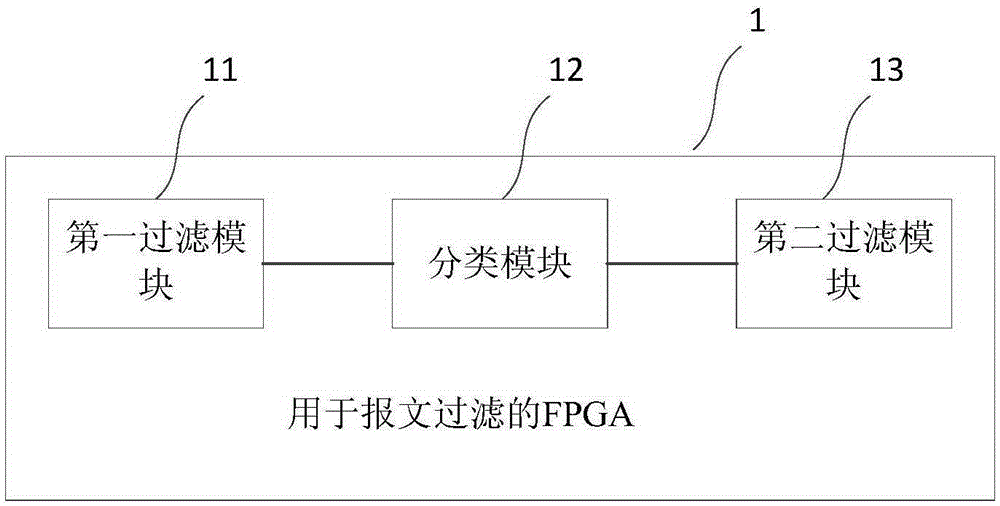

Message filtering method and applicable FPGA and intelligent substation

ActiveCN105357137AFast filter processingReduce backlogCircuit arrangementsData switching networksSmart substationMessage type

The invention provides a message filtering method and an applicable FPGA and an intelligent substation. The method comprises the following steps: filtering messages directly obtained from an Ethernet physical layer standard interface according to a preset message transmission manner in the intelligent substation by the FPGA; temporarily storing the filtered messages in a classified manner according to the types of the messages transmitted by the intelligent substation; and matching a change rule of feature information in preset fields of the messages within each preset number of each type and / or a preset duration of each type with the change rule of preset feature information in a corresponding message type, and filtering the messages according to the filtering result. The message filtering method provided by the invention is used for effectively improving the message filtering speed of the intelligent substation.

Owner:上海思源弘瑞自动化有限公司

Reusable express item packaging container lease circulation system

InactiveCN107585429AReduce backlogReduce use costPackage recyclingLocking devicesEngineeringMobile phone

The invention relates to a reusable express item packaging container lease circulation system. The reusable express item packaging container lease circulation system comprises lease circulation relation among an operation platform, a sender, an express company, express tail ends, a receiver and a packaging container; the packaging container circulating process includes the steps that a packaging material supplier provides reusable express packaging containers for the operation platform, and the operation platform deliveries the packaging containers to all the express tail ends according to theagreement; the sender logs in on the operation platform with the real name, provides guarantee deposit according to the needing number to obtain the right to use the corresponding packaging containers; the sender packages the goods purchased or ordered by the receiver with the packaging containers and submits the packaging containers with the goods to a carrier for goods carrying; the carrier receives the orders and transports the goods to all the express tail ends; the receiver scans to pick up the items through mobile phone application after receiving the express items and returns the packaging containers to the express tail ends after taking the goods out of the containers, return information is recorded by conducting scanning once more, the operation platform charges certain rent andreleases the guarantee deposit, and the packaging containers enter the circulation state again. One lease circulation is completed.

Owner:JIANGNAN UNIV

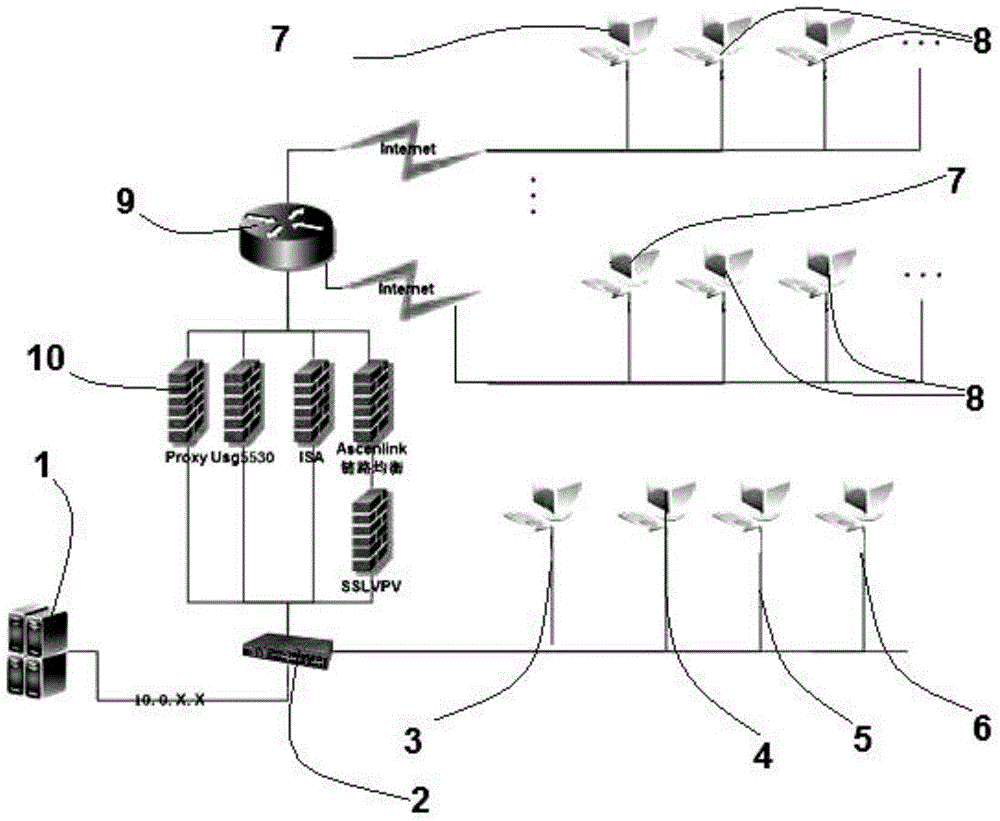

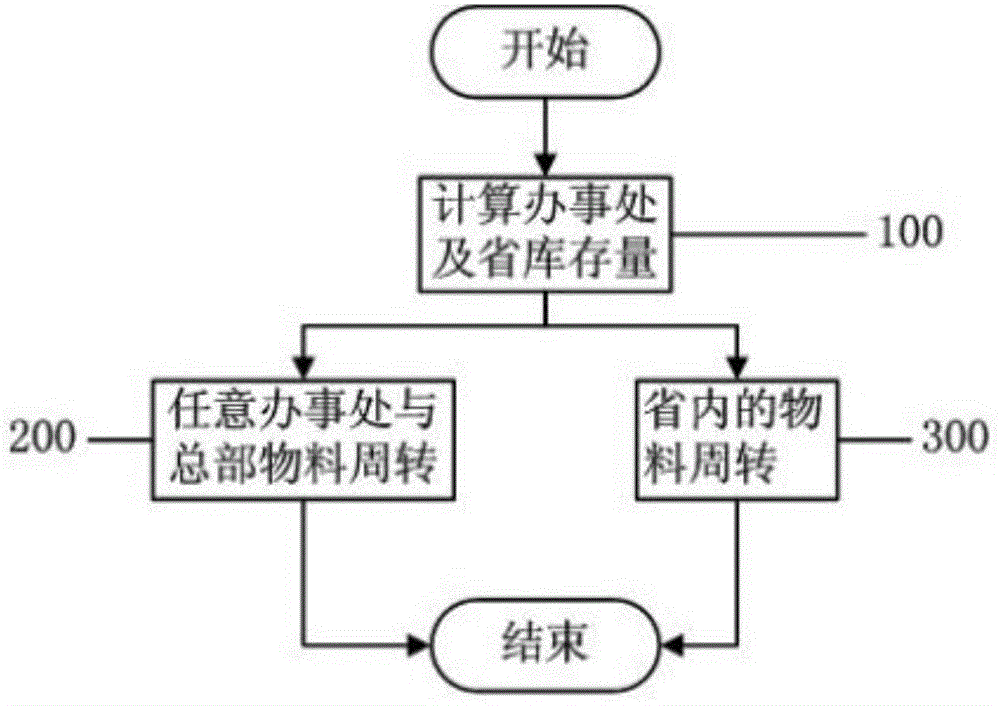

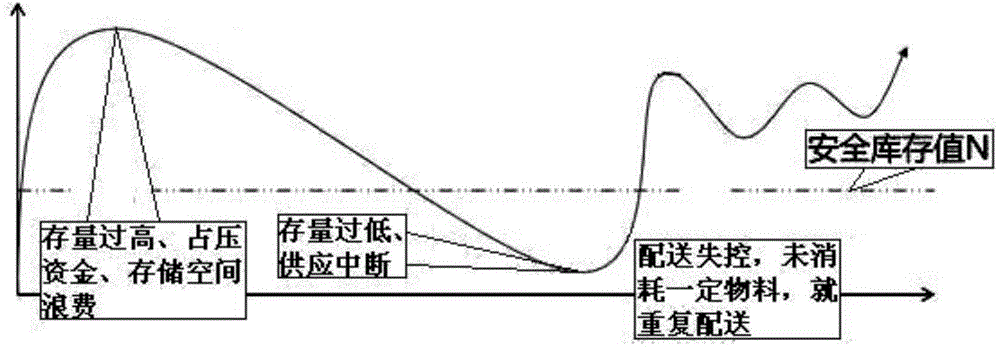

Control method of safe stock control system

The invention discloses a control method of a safe stock control system. The control system comprises a server, a switch, a dispatching computer, a spare part planning computer, a warehouse computer, a director computer, province material management computers and office computers, wherein the server, the switch, the dispatching computer, the spare part planning computer, the warehouse computer and the director computer are arranged in headquarters; the province material management computers are arranged in each province; the office computers are arranged in each office in the provinces; the switch is electrically connected with the server, the dispatching computer, the spare part planning computer, the warehouse computer and the director computer; and the switch is respectively connected with each province material management computer and each office computer through Internet. The control method provided by the invention has the characteristics that the stock is always in a reasonable range; overstocked products are effectively reduced; the stock turnover is accelerated; and the stock occupation cost is further reduced.

Owner:EASTERN COMM

A method of preparing a color-mixed colorized pattern-carrying fabric based on color matching of primary color fibers

A method of preparing a color-mixed colorized pattern-carrying fabric based on color matching of primary color fibers is disclosed. The method includes: forming four fiber primary colors by adopting yellow, pinkish red, green, black and white fibers as raw materials, and blending and weaving fibers having at least three colors from the yellow, pinkish red, green, black and white fibers of the same kind, or fibers having at least three colors from yellow, pinkish red, green, black and white fibers of the different kinds. The color-mixed colorized pattern-carrying fabric shows randomness and irregularity in appearance and styles to a larger degree, and is enhanced in color layering sense and novel in style. The method can reduce reserves of dye varieties and color fiber varieties, thus reducing overstocked funds, and facilitating management.

Owner:泰州吉泰毛纺织染厂 +2

Pine pollen fiber biscuit

InactiveCN102919330AReduce absorptionReduce backlogDough treatmentBakery productsBiotechnologyPhospholipin

The invention provides a pine pollen fiber biscuit. The main raw materials of the biscuit comprise the following components by weight part: 5-15 parts of pine pollen, 1-2 parts of konjaku flour, 3-5 parts of l-carnitine, 0-2 parts of phospholipid, 40-50 parts of wheat flour, 0-25 parts of starch, 5-8 parts of vegetable oil, 0-5 parts of dry skim milk, 0-2 parts of ghee, 0-2 parts of egg, 6-12 parts of sweetener, 10-20 parts of lotus leaf and 1-10 parts of kelp. The pine pollen fiber biscuit not only can allow a user to be satisfactorily full and to absorb less heat production nutrient, but also can facilitate decomposition and oxidation of internal fat so as to reduce fat storage and further realize easy and effective weight losing, and also has the function of preventing and curing prostatic disorders.

Owner:承德畅达生物科技有限公司

Cathode gold electrolytic refining process

InactiveCN102978658ASolving Corrosion ProblemsSolve layeringPhotography auxillary processesElectrodesSolubilityConcentration polarization

The invention provides a cathode gold electrolytic refining process. According to the invention, an electrolyte formula is changed, and electrolytic refining is carried out in a hydrochloric acid system with low gold ion solubility (Au<3+> 80-120g / L) and low acid (60-90g / L) with a titanium motherboard used for replacing a traditional gold starting sheet as a cathode. During the electrolysis process, with a quantitative dosing device, an inhibiting agent is automatically added online according to the variation of the components of the electrolyte, such that interferences of impurities such as lead and silver upon electric gold quality and an anode passivation problem are solved. Also, an automatic thermal insulation measure is provided for the electrolyte, such that a phenomenon of easy stratification and concentration polarization is eliminated. Higher than 99.995% electric gold products with qualified physical specifications and chemical qualities can be produced through one-step direct electrolysis. Aiming at a workplace environment ventilation problem, inner-ring and outer-ring skilful isolation is adopted, such that process exhaust problems of product pollution, environment pollution and equipment corrosion are solved. With the process provided by the invention, purposes of high efficiency, environment protection, and energy saving are realized. The process has a high popularization value in the field of precious metal refining.

Owner:JIANGXI COPPER

Inventory replenishment scheduling method and system

PendingCN111178797AReduce Replenishment Scheduling ManagementConvenient replenishment scheduling managementLogisticsOperations researchIndustrial engineering

The invention provides an inventory replenishment scheduling method and system, and the method comprises the steps: analyzing the stock amount of a store in the next month according to the recorded actual sales volume of the store and the current stock of the store and a distribution warehouse; after a purchasing center confirms the influence of a fluctuation factor on the next month stock amount,summarizing a month reservation order and generating a headquarters purchasing month reservation order; and enabling the purchasing center to export the month reservation order to a supplier, so thata central warehouse dispatches and distributes the month reservation order according to the month purchasing order of the supplier. By means of the scheme, the problem that deviation is likely to exist in manual intervention in the existing replenishment scheduling process is solved, manual intervention can be reduced, and it is guaranteed that the replenishment scheduling process is reasonable,efficient and accurate.

Owner:武汉微批科技有限公司

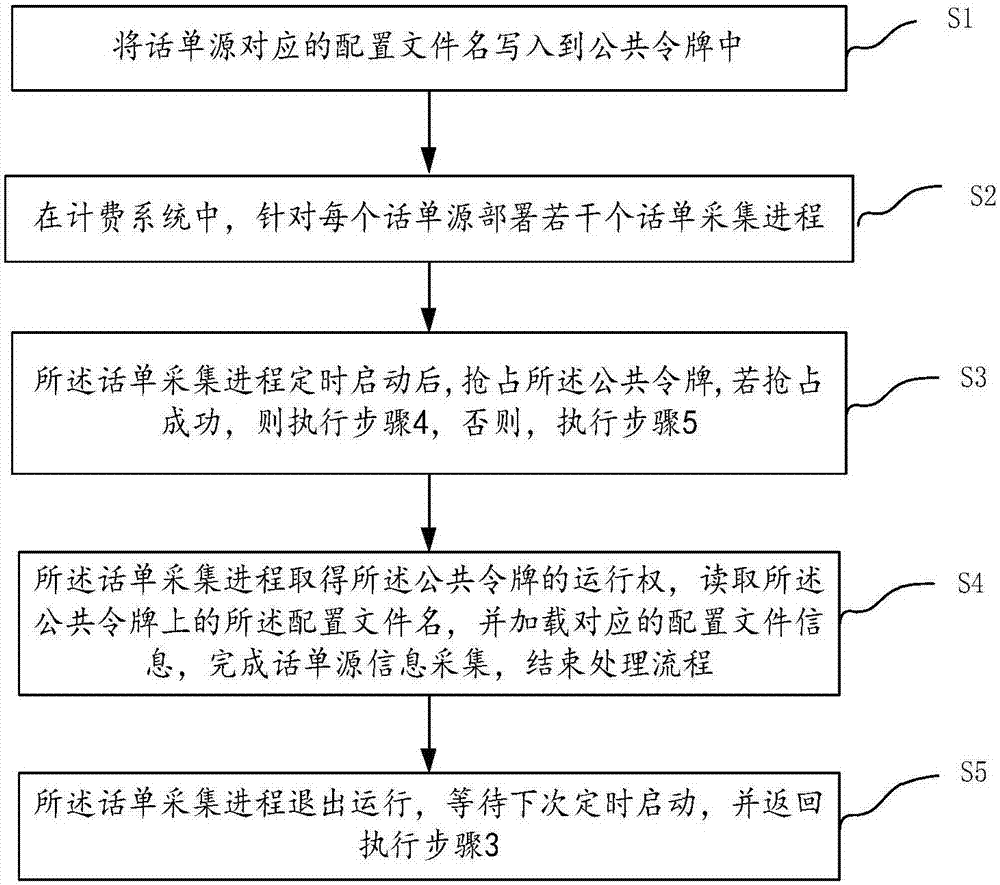

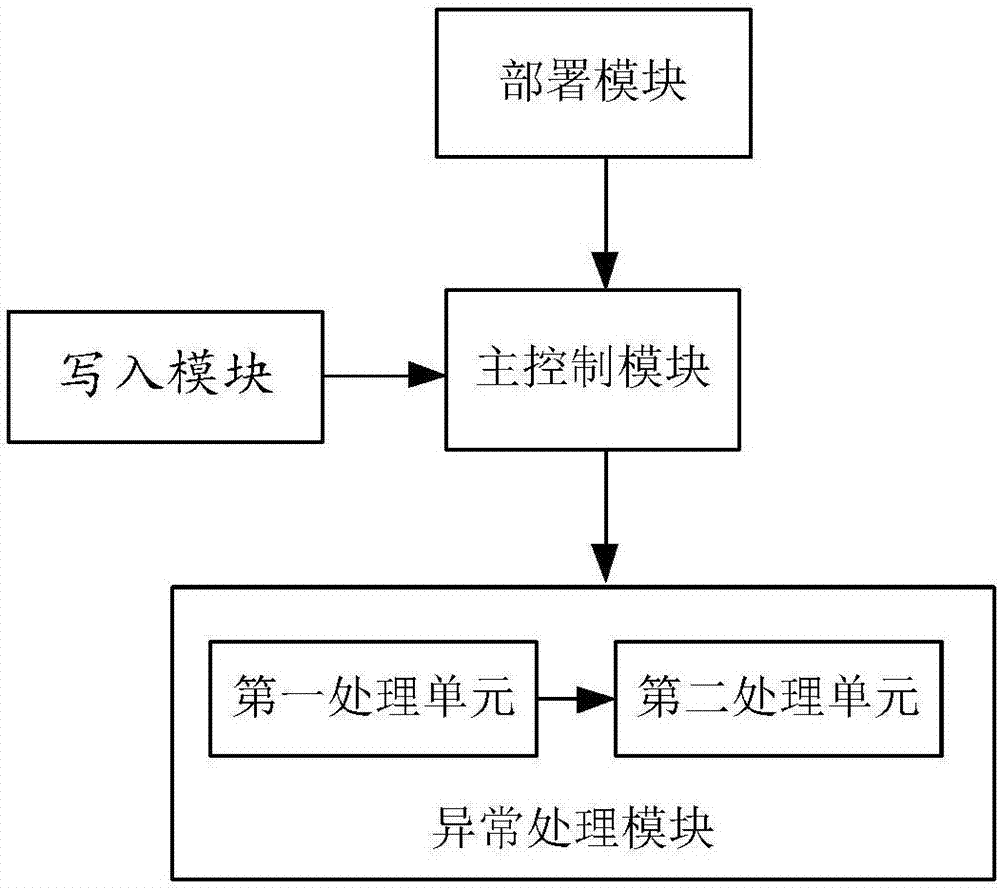

Distributed telephone bill collection method and system

ActiveCN107124522AImprove stabilityGuaranteed real-timeTelephonic communicationTelecommunicationsCollection methods

The invention relates to a distributed telephone bill collection method and system. The method comprises the following steps of S1, writing configuration file names corresponding to telephone bill sources into a public token; S2, in a billing system, deploying a plurality of telephone bill collection threads for each telephone source; S3, after the telephone bill collection threads are started periodically, seizing the public token, if the public token is seized successfully, performing a step S4, otherwise, performing a step S5; S4, obtaining the operation right of the public token, reading the configuration file names on the public token and loading the corresponding configuration file information by the telephone bill collection threads, thereby finishing collecting the telephone bill source information and terminating a processing process; and S5, quitting operation and waiting for next periodic starting by the telephone bill collection threads, and returning to perform the step 3. According to the distributed telephone bill collection method and system provided by the method and the system, the distributed deployment can be realized, the method is flexible, the application is simple, and the telephone bill collection stability and timeliness can be improved.

Owner:北京思特奇信息技术股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com