Heat preserving and oxidation resisting method in aluminum electrolysis cell production and heat preserving covering device

A technology of aluminum electrolytic cell and covering device, which is applied in the fields of heat preservation and anti-oxidation, aluminum electrolytic cell heat preservation and anti-oxidation, and can solve the problem of increasing the capital backlog of electrolyte materials, increasing system investment and system operating costs, and difficulty in ensuring the uniformity of covering layer thickness and other issues, to achieve the effects of low requirements for experience and technical level, convenient batch and standardized production, stable heat preservation and anti-oxidation functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

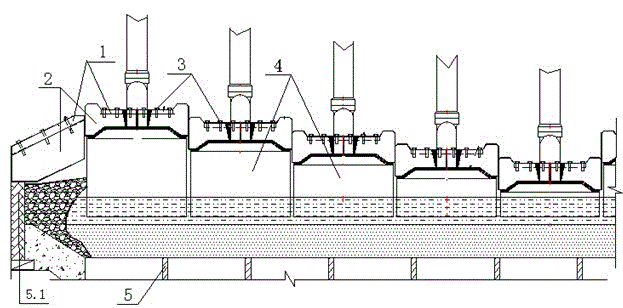

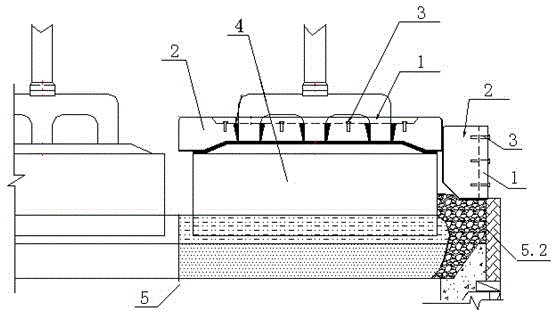

[0024] Embodiments of the present invention: when implementing the present invention, first according to making a kind of heat preservation of the present invention when the aluminum electrolytic cell is produced and the heat preservation covering device of anti-oxidation, this device structure schematic diagram is as follows figure 1 and figure 2 As shown, the device is composed of a steel component plate 1 and a thermal insulation refractory block 2. The steel component plate 1 can be made of ordinary steel plates, and the thermal insulation refractory block 2 can be made of existing materials with corrosion resistance and fire resistance. , the prepared thermal insulation refractory block 2 is connected as a whole with the steel component plate 1 through the bolt 3; the steel component plate 1 and the thermal insulation refractory material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com