Integrated oil phase for emulsion explosive and preparation method thereof

A technology of emulsion explosives and oil phase, which is applied in the direction of explosives, non-explosive/non-thermal agent components, offensive equipment, etc., and can solve the problems of difficult control of emulsification and emulsification stability of emulsion explosives, transportation, warehousing manpower, material resources and energy waste, The preparation process of emulsion explosives is cumbersome and other problems, so as to reduce the cumbersome procurement of raw materials and the backlog of funds, ensure emulsification and emulsification stability, and overcome the effect of explosive product quality fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] One of the specific implementations of the integrated oil phase of an emulsion explosive of the present invention includes the following components in parts by mass: 10-18 parts of paraffin wax, 1-6 parts of microcrystalline wax, and 45-65 parts of wax paste , Composite additives 25 to 35 parts. Since the integrated oil phase of the emulsion explosive has optimized the ratio of each component and each component, as long as it is 10-18 parts of paraffin, 1-6 parts of microcrystalline wax, 45-65 parts of wax paste, and 25-35 parts of compound additives The addition of components in parts by mass to form an integrated oil phase can ensure the emulsification and emulsification stability of the emulsion explosive production process, and at the same time meet the explosive quality indicators of the emulsion explosive product such as detonation velocity, intensity, and detonation distance. .

[0029] Specifically, the wax ointment can be mineral oil minus four-line wax ointme...

Embodiment 2

[0037] One of the specific embodiments of the preparation method of an emulsion explosive integrated oil phase of the present invention:

[0038] Include the following steps:

[0039] Step 1, will prepare raw materials by the component in implementing 1;

[0040] Step 2, adding paraffin wax and microcrystalline wax into the blending kettle for heating and melting;

[0041] Step 3, add the wax paste and stir well until it is mixed and dissolved;

[0042] Step 4, after heating up and dehydrating, then cooling down;

[0043] Step 5, add the compound additives and stir at high speed until the mixture is uniform;

[0044] Step 6, filtering, discharging, cooling, molding and packaging.

[0045] In the step 4, the temperature rise is controlled at 100-125°C, and the temperature drop is controlled at 70-90°C.

[0046]Specifically, in step 4, the temperature rise can be controlled at 100-125°C, and the temperature rise process should be carried out slowly, and the temperature rise...

specific Embodiment approach

[0051] Weigh 1300kg of paraffin wax and 200kg of microcrystalline wax into the blending kettle to heat and melt, then weigh 2000kg of mineral oil minus four wax paste and 3500kg of mineral oil light dewaxing paste into the blending kettle, start the stirrer and stir until it is mixed and dissolved , the stirring speed is 100r / min. Then heat up to about 115°C and keep it for 0.5h, then cool it to about 80°C, then add 200kg of lecithin, 1,100kg of sorbitan stearate and 1,700kg of polyisobutylene butyrimide and stir at a high speed for 0.5 h to mix evenly, analyze and test its dropping point, viscosity and cone penetration index, then filter to remove impurities, then put the wax liquid into a fixed vessel to cool and shape, and finally pack it into a product.

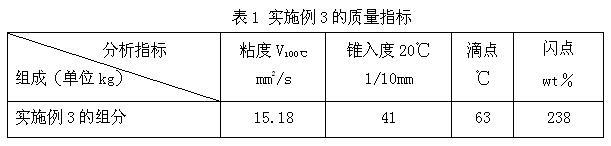

[0052] The quality index of the emulsion explosive integrated oil phase of embodiment 3 is as follows table 1:

[0053]

[0054] The industrial trial result of the emulsion explosive integrated oil phase of embodiment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com