Remote enterprise production management system

A production management system and central processing system technology, applied in the field of computer information, can solve the problems of not being able to grasp the progress of finished product production at any time, lag in the regulation of production activities, increase construction costs, etc., to achieve reasonable production and supply and marketing activities, and improve positive benefits. , the effect of improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

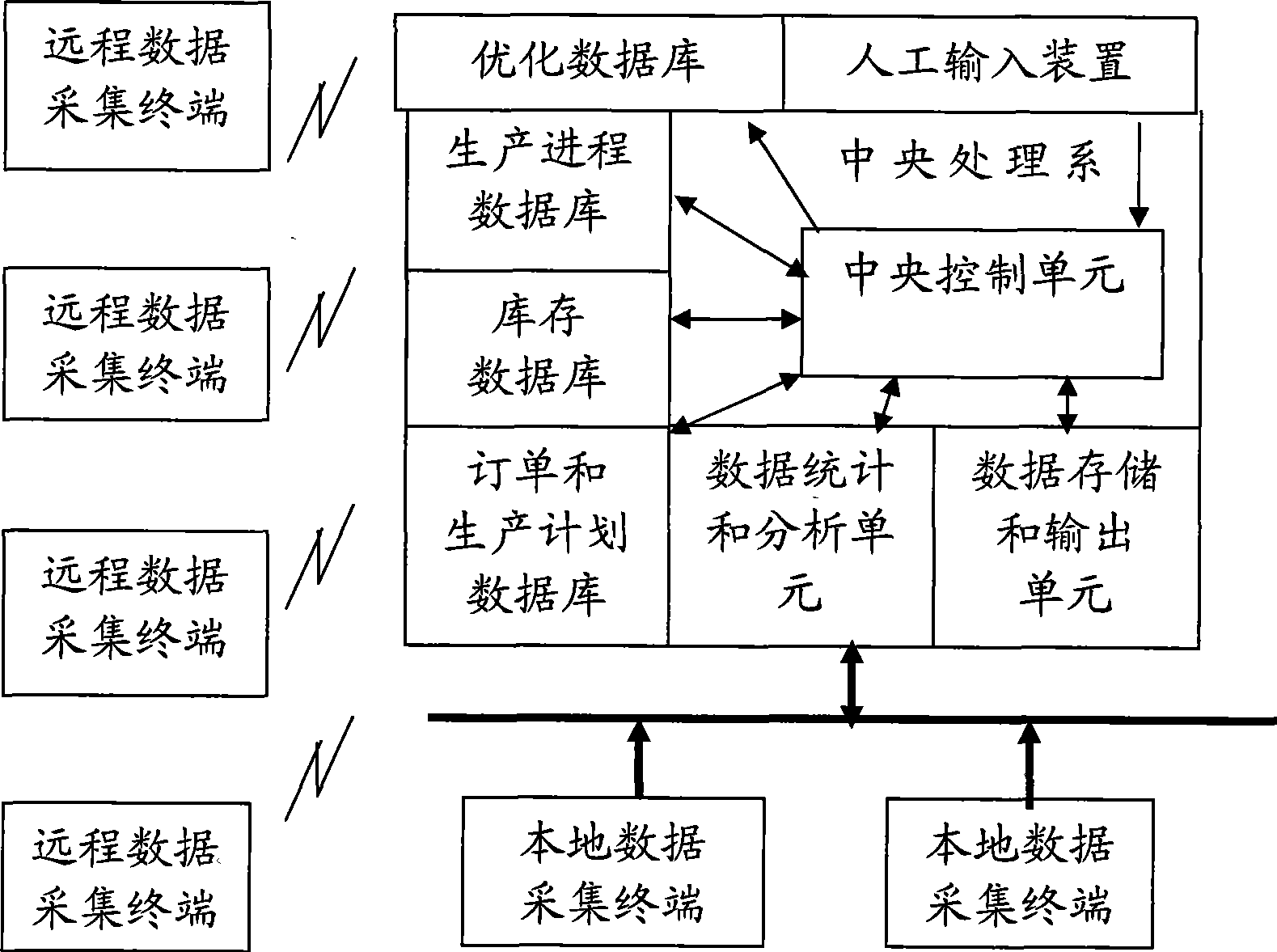

[0007] see figure 1 , the present invention provides a remote enterprise production management system, which mainly includes a central processing system, a remote data collection terminal for data exchange with the central processing system, and a local data collection terminal for data exchange with the central processing system through wired communication. The remote data acquisition terminal is provided with a wireless transmitting and receiving module, and communicates wirelessly with the central processing system through a wireless base station, and the central processing system is provided with a supporting wireless transmitting and receiving module, and receives remote data collection through a wireless base station The warehouse entry and exit data of various goods sent by the terminal, the data collection terminals collect the warehouse entry and exit data of various goods sent to the central processing system, as well as the production and storage data of various prod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com