Submerged automatic arc welding method of SA335P91 steel

A 1.SA335P91, submerged arc automatic welding technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of sensitive welding process and process parameters, inability to meet factory piping, large technical difficulties, etc., to achieve welding Stable and reliable seam quality, conducive to cost control, and the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

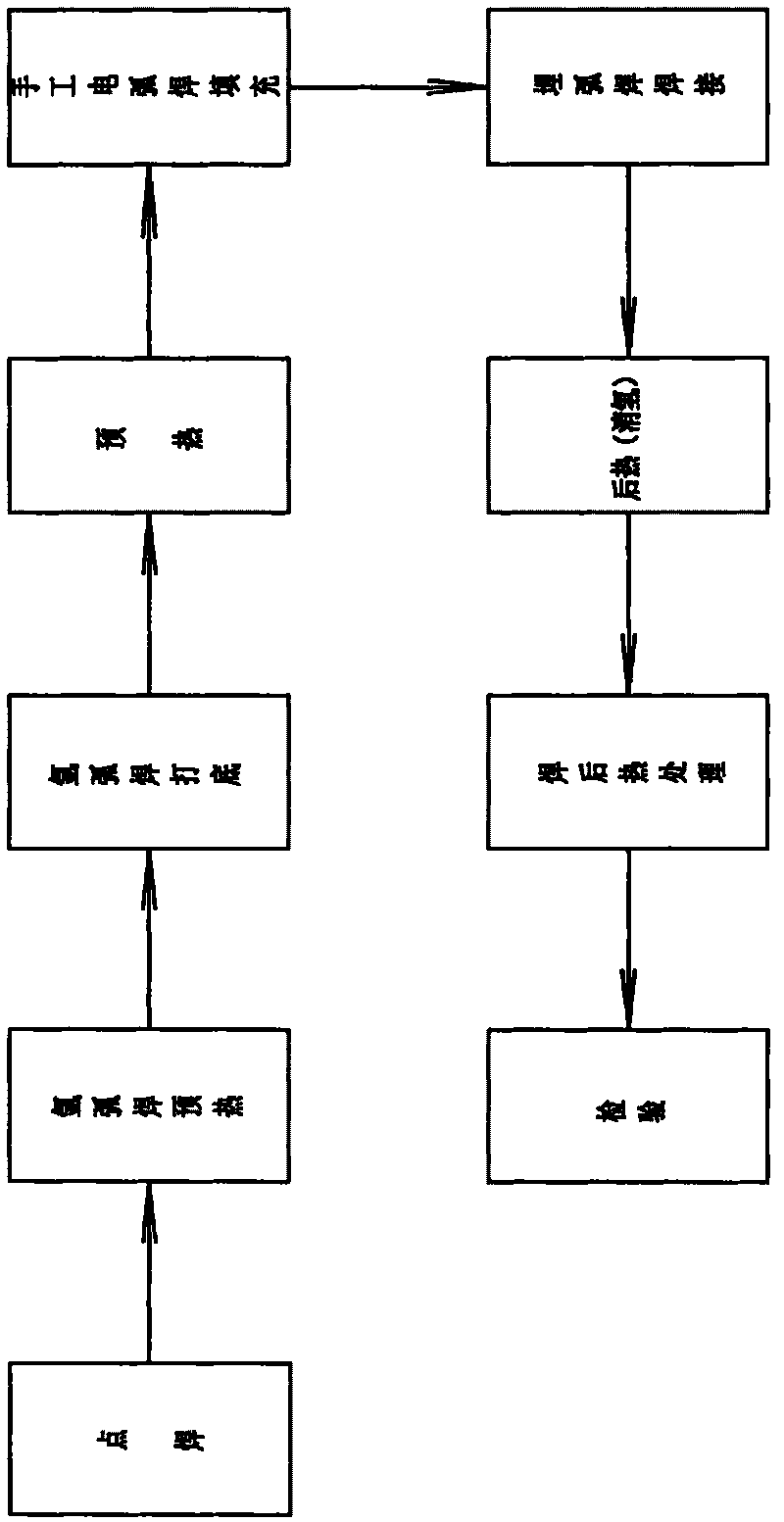

[0035] like figure 1 As shown, in the SA335P91 steel submerged arc automatic welding method of the present invention, the preparatory work before submerged arc automatic welding includes first using argon arc welding wire for backing welding, and then using manual arc welding for welding.

[0036] The specific welding steps of argon arc welding are:

[0037] ①. First cut a groove at the place to be welded;

[0038] ②.Pair spot welding: clean the groove until it reveals the metallic luster, control the gap between the joints at 2-4mm, and use the "positioning block" method to fix it;

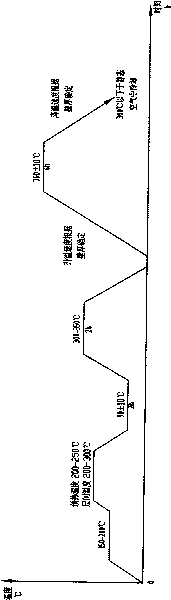

[0039] ③. Low-temperature preheating before argon arc welding: the preheating temperature is 150-200°C, and the constant temperature is kept for two hours;

[0040] ④. Argon arc welding primer: when argon arc welding, the inner wall of the pipe must be filled with argon or use argon-free protective agent for root protection to prevent root oxidation. Specification φ2.4mm, welding current 130-1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com