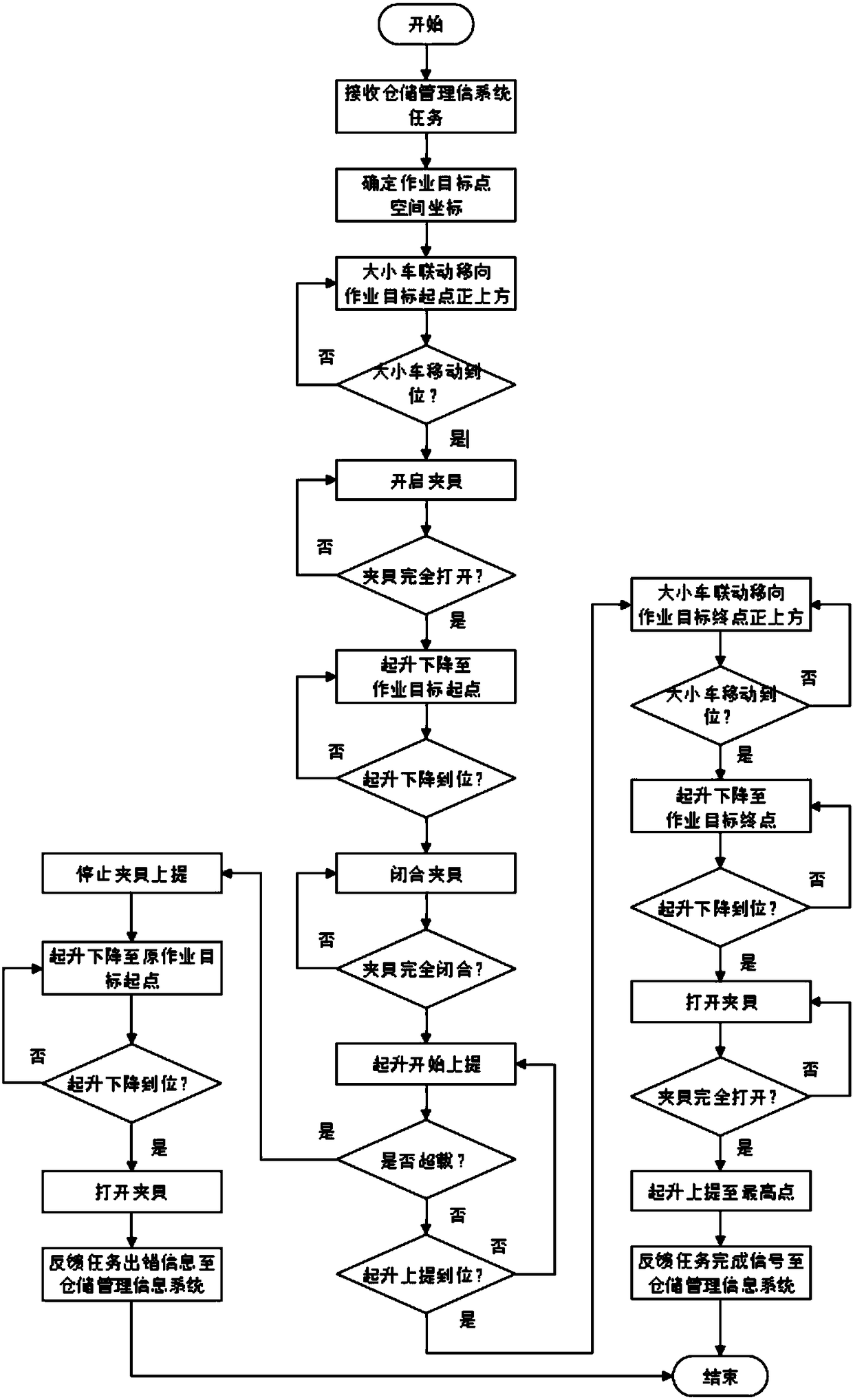

Automatic operation control method for full-automatic bridge-type storage crane

A crane, fully automatic technology, applied in the direction of safety devices, special data processing applications, instruments, etc., can solve problems such as damage, collision of warehouse goods, low efficiency, etc., to improve work efficiency and reliability, save energy consumption, and improve work conditional effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with the embodiments and accompanying drawings, but the present invention is not limited.

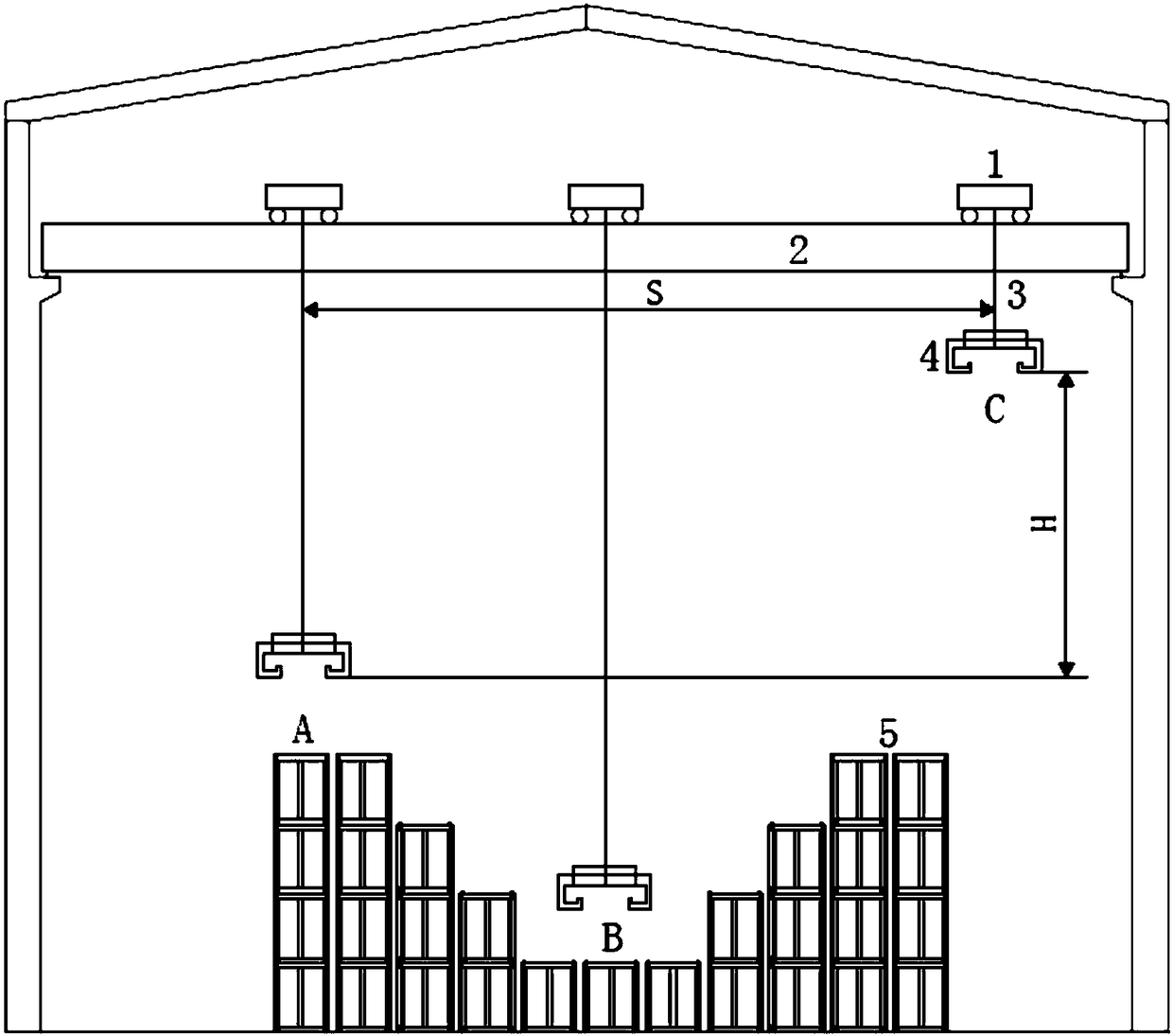

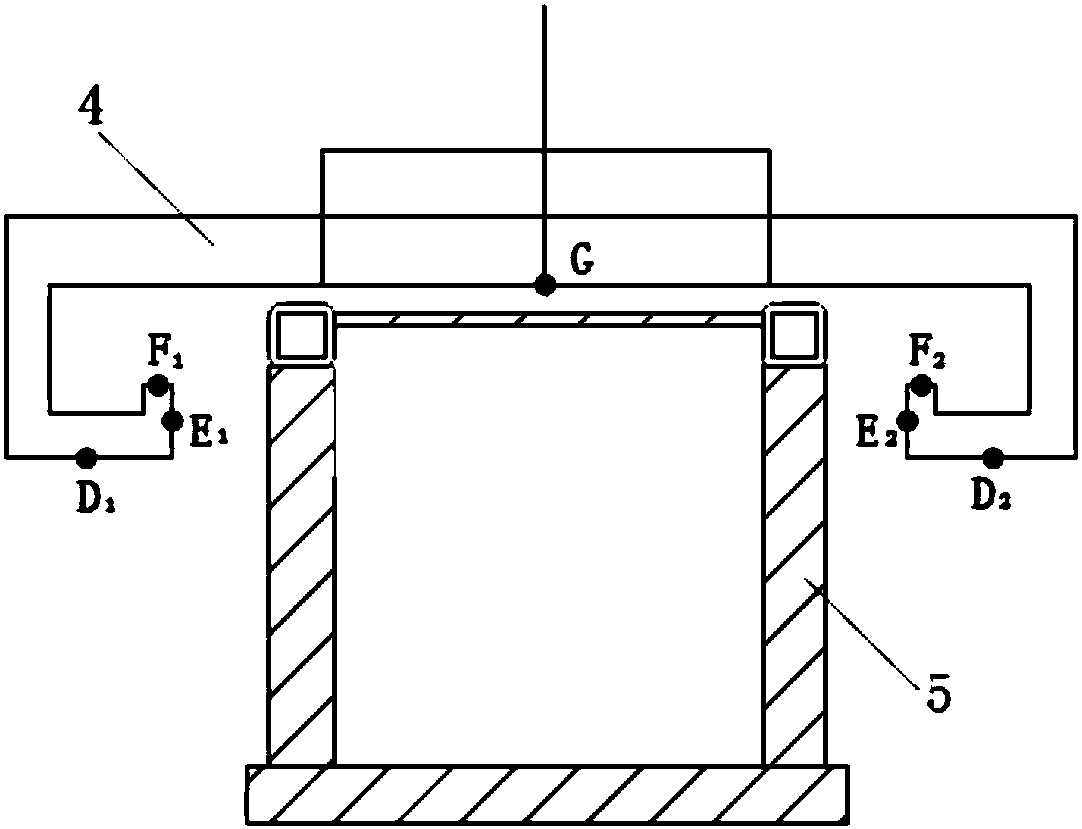

[0044] The automatic operation control method of the fully automatic bridge type storage crane provided by the present invention can pass Figure 2 to Figure 4 The full-automatic bridge-type storage crane shown is realized. The fully-automatic bridge-type storage crane is composed of trolley 1, cart 2, and hoisting mechanism 3. The hoisting mechanism 3 is equipped with clamp 4 to realize the clamping and freed.

[0045] The fully automatic bridge storage crane includes a bridge crane and a fully automatic control system, wherein: the bridge crane is a widely used lifting and handling equipment, but there is no fully automatic control, and the fully automatic control is an innovative part. "Repository" is to illustrate the usage scenario.

[0046] The fully automatic control system is composed of PLC controller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com