Method for reducing content of ethyl acetate in strong aromatic wine under mechanized production conditions

A technology for medium ethyl acetate and production conditions, which is applied in the production field of reducing the content of ethyl acetate in Luzhou-flavor liquor, can solve the problem that the proportion of the four major esters of newly produced Luzhou-flavor liquor is unbalanced, the style of the aroma is not prominent, and the operation is not suitable. requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

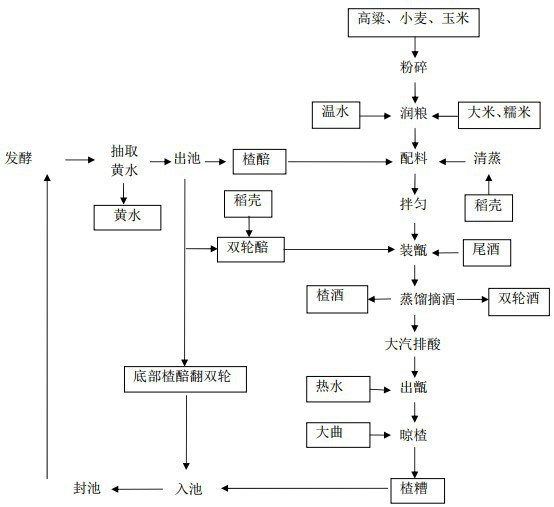

Method used

Image

Examples

Embodiment 1

[0035] a. Extraction of yellow water: 5 days before leaving the cellar, start to pump yellow water, extract 2 times a day from each cellar, and extract 100 parts each time.

[0036] b. Leaving the cellar: Uncover the cellar sealing mud after fermentation, take 9900 parts of big hawthorn wine grains in the cellar, make 2200 parts of hawthorn grains for the next round of double rounds, and store 2000 parts of double round wine grains after fermentation, and store them separately for later use .

[0037] c. Moisten grain: Add 2700 parts of crushed raw grain to 300 parts of warm water at 40-45°C, and stir evenly.

[0038] d. Ingredients: add 750 portions of steamed rice husks to the fermented grains of Dazhawine wine obtained in step b, and the moistened raw grains in step c, and mix evenly to obtain grain grains of Dazha; Add 30 parts of steamed rice husks to the unstrained spirits, stir evenly, and make Shuanglun grain grains.

Embodiment 2

[0046] a. Extraction of yellow water: 5 days before leaving the cellar, start to pump yellow water, extract 2 times a day from each cellar, and extract 150 parts each time.

[0047] b. Leaving the cellar: Uncover the cellar seal mud after fermentation, take 12,000 parts of big hawthorn wine grains in the cellar, make 2,000 parts of double-wheeled hawthorn grains for the next round, and 2100 parts of double-wheeled wine grains after fermentation, store them separately for later use .

[0048] c. Moisten grain: Add 3000 parts of crushed raw grain to 330 parts of warm water at 40-45°C, and stir evenly.

[0049] d. Ingredients: add 750 portions of steamed rice husks to the fermented grains of Dazhawine wine obtained in step b, and the moistened raw grains in step c, and mix evenly to obtain grain grains of Dazha; Add 50 parts of steamed rice husks to the unstrained spirits, stir evenly, and make Shuanglun grain grains.

[0050] e. Filling the retort: First add 100 parts o...

Embodiment 3

[0057] a. Extraction of yellow water: 5 days before leaving the cellar, start to pump yellow water, extract 2 times a day from each cellar, and extract 120 parts each time.

[0058] b. Leaving the cellar: Uncover the cellar seal mud after fermentation, take 11,000 parts of big hawthorn wine grains in the cellar, make 2100 parts of double-wheeled hawthorn grains for the next round, and 2200 parts of double-wheeled wine grains after fermentation, store them separately for later use .

[0059] c. Moisten grain: Add 3300 parts of crushed raw grain to 310 parts of warm water at 40-45°C, and stir evenly.

[0060] d. Ingredients: add 780 portions of steamed rice husks to the fermented grains of Dazha wine taken in step b and moistened raw grains in step c, and mix well to obtain grain grains of Dazha. Add 60 parts of steamed rice husks into the Shuanglun distiller's grains taken in step b, and mix evenly to obtain Shuanglun grain grains.

[0061] e. Filling the retort: First...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com