Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

72results about How to "Increased tensile yield strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

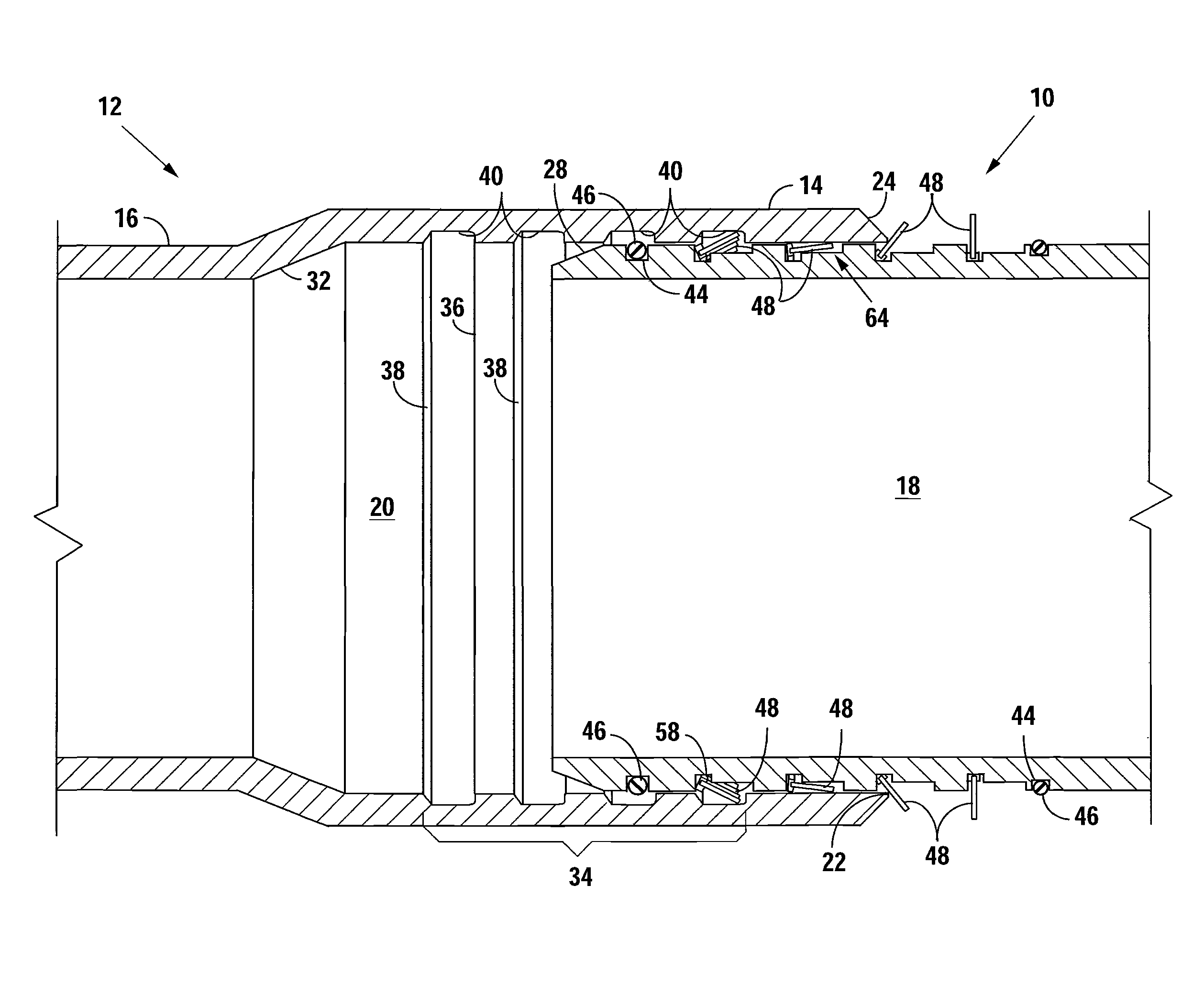

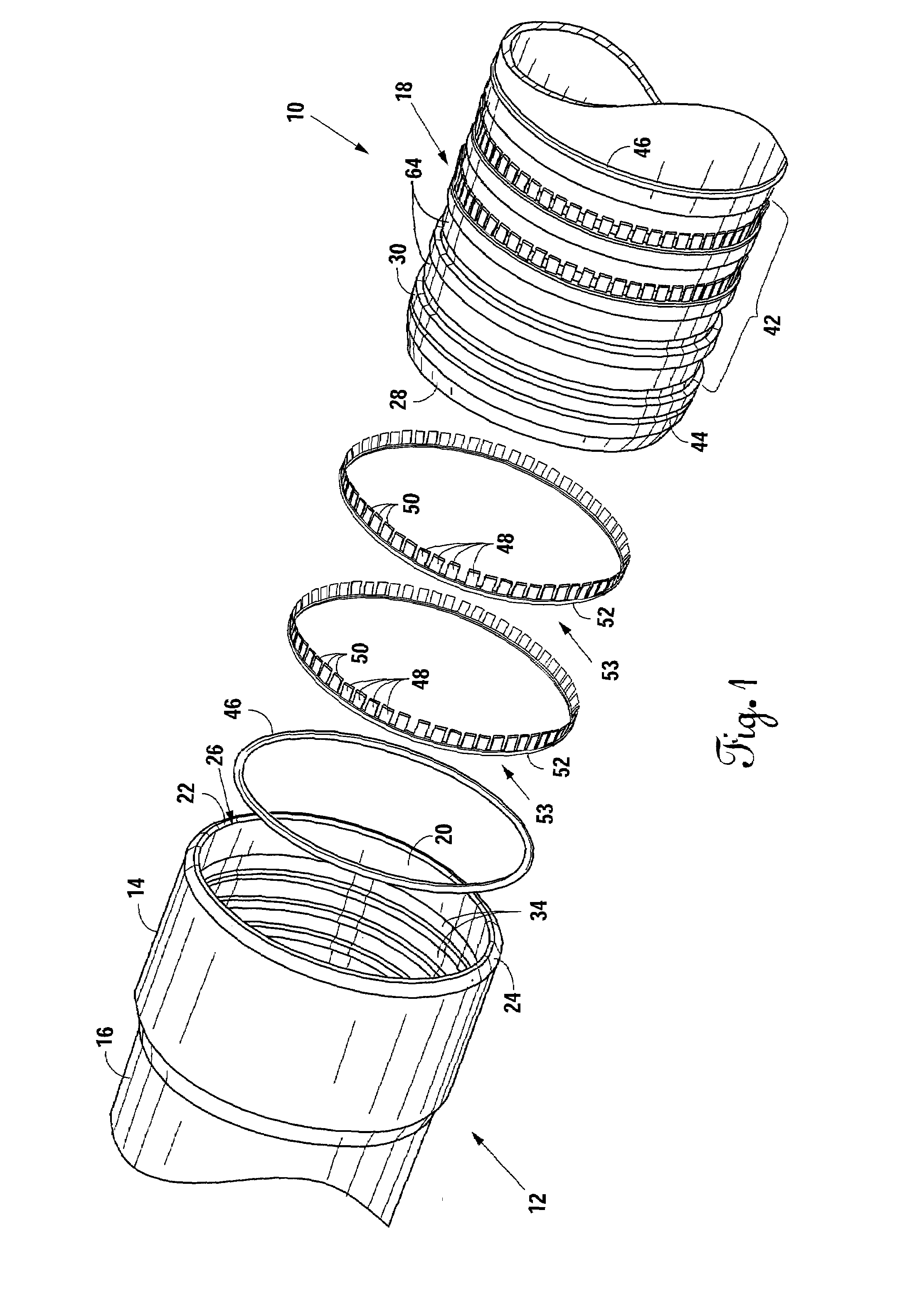

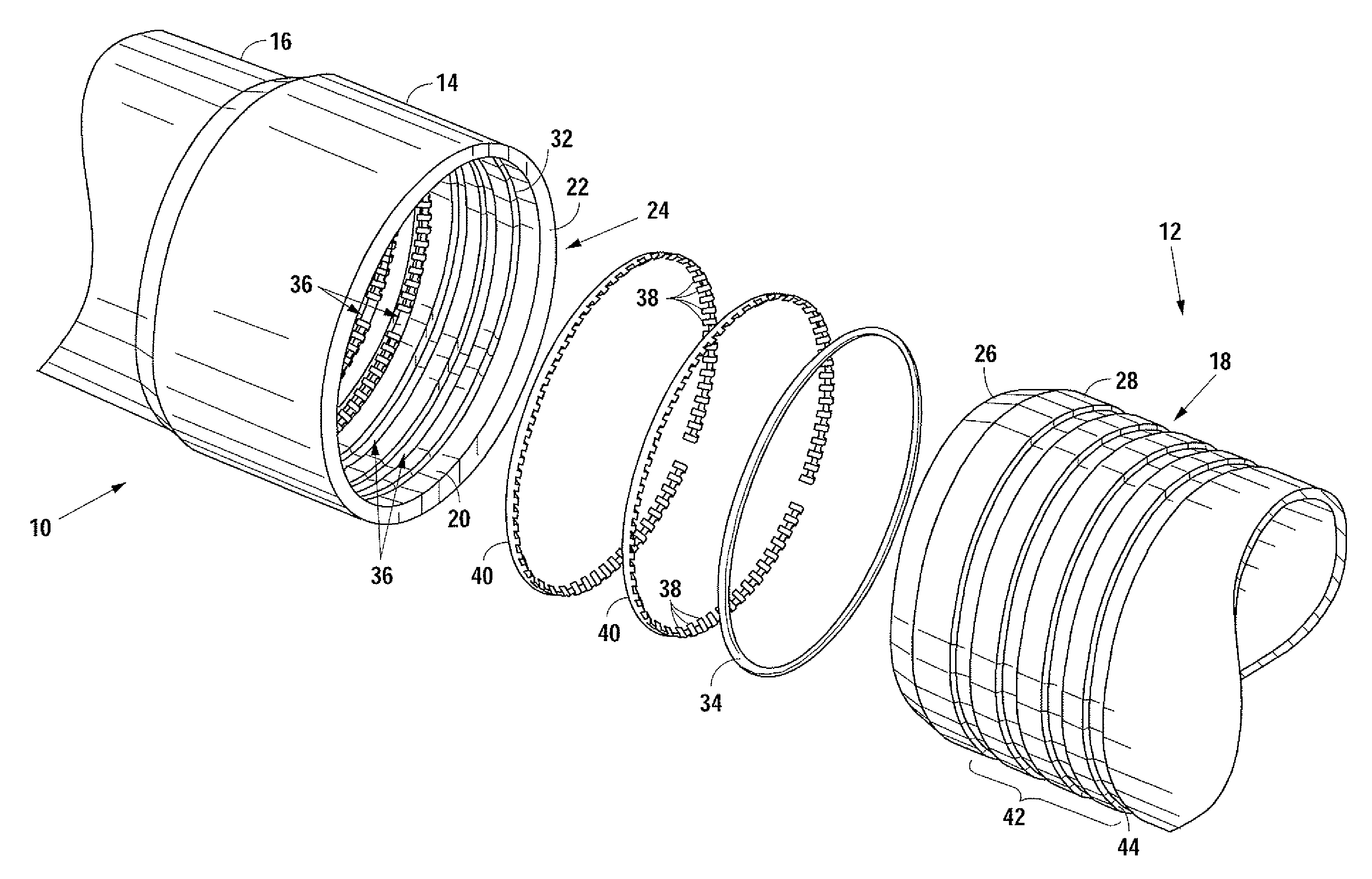

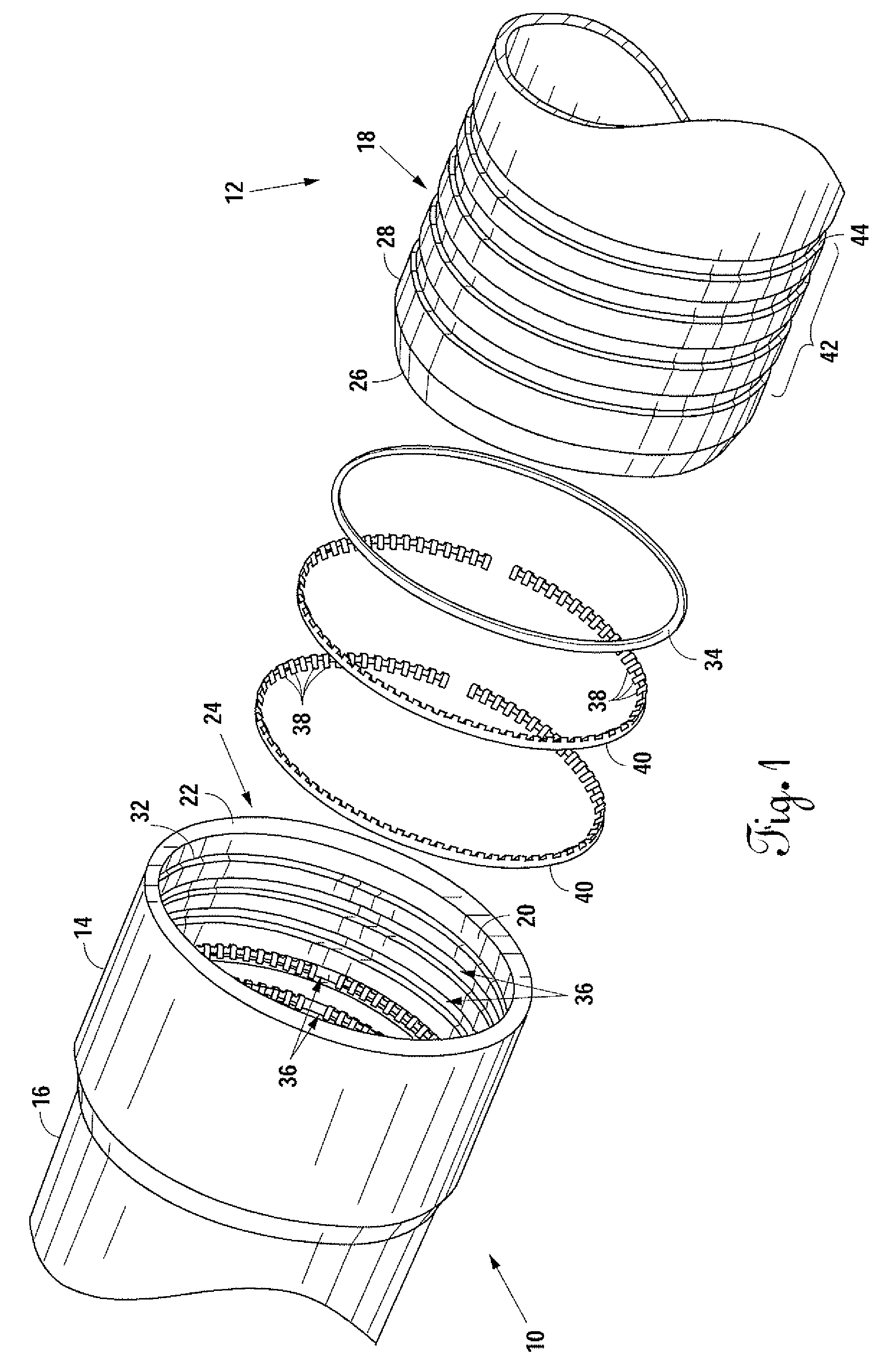

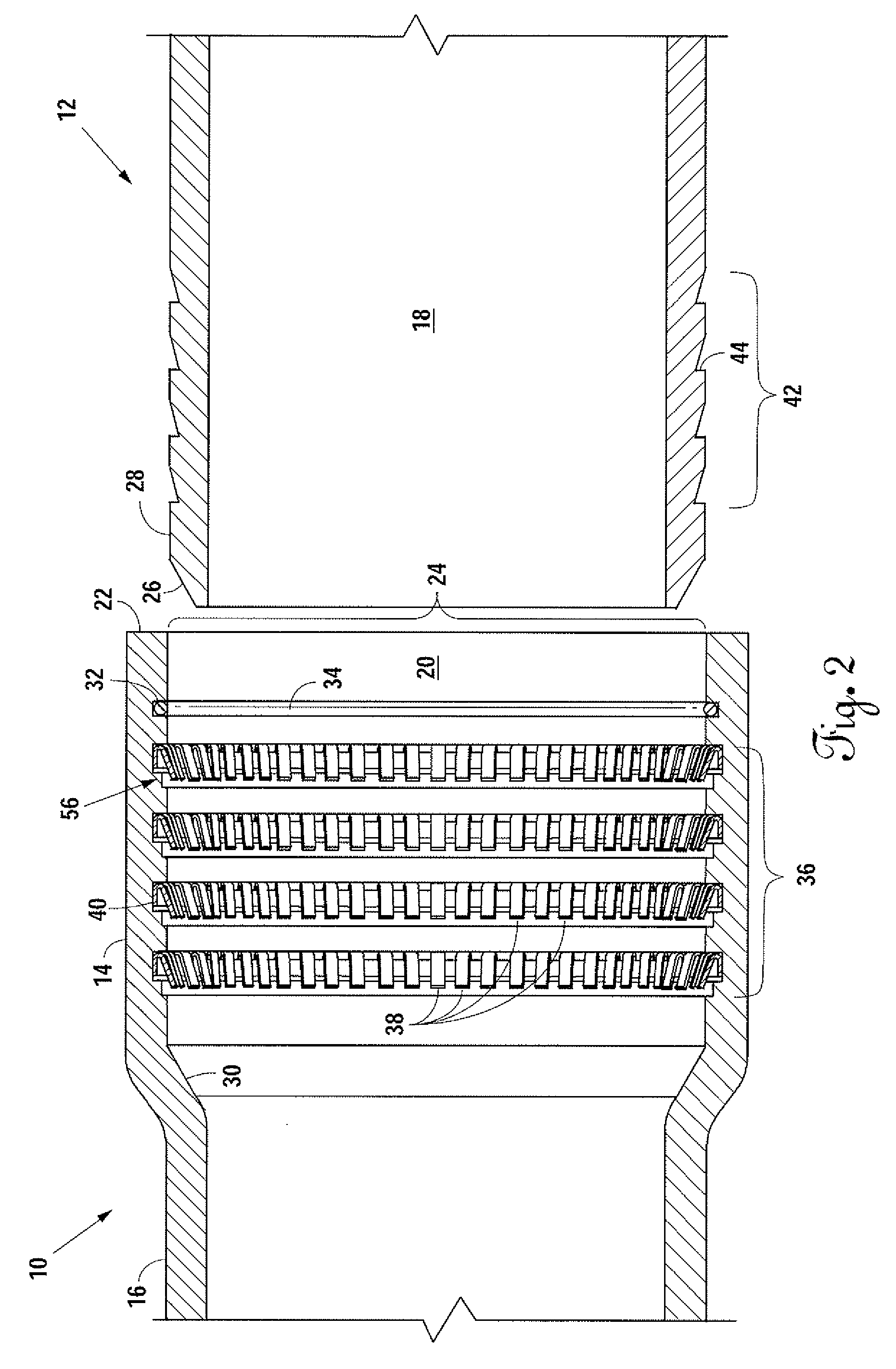

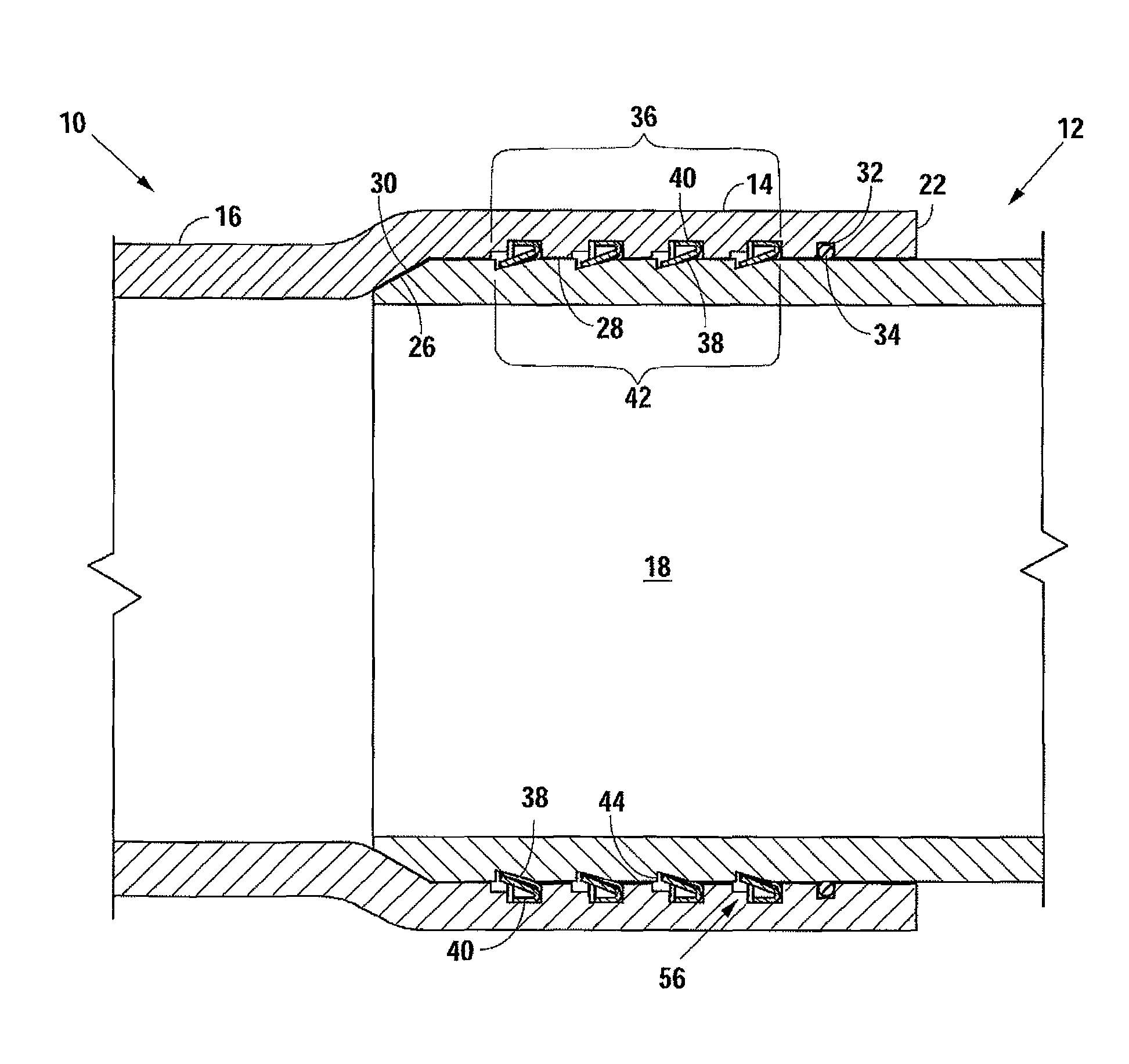

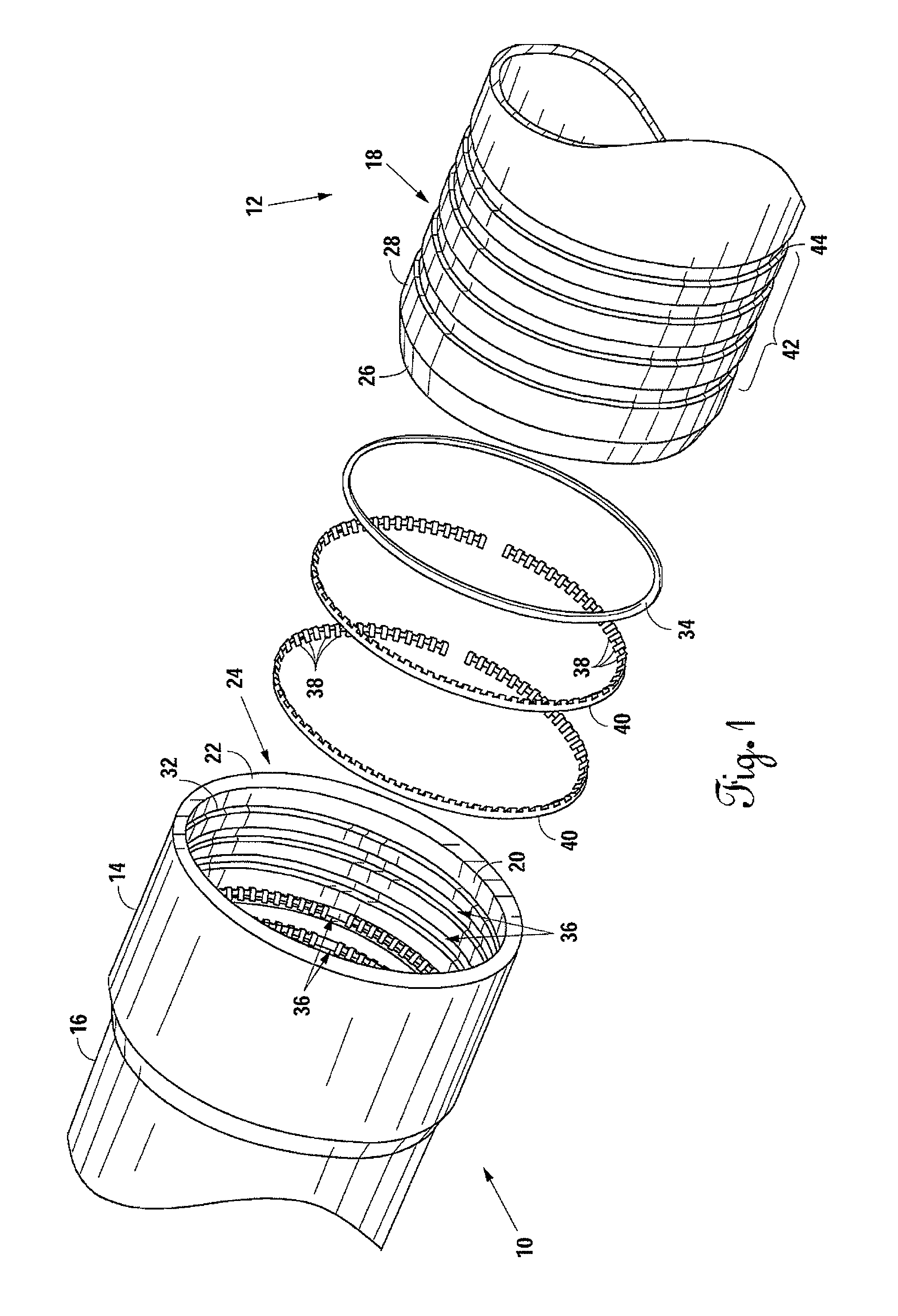

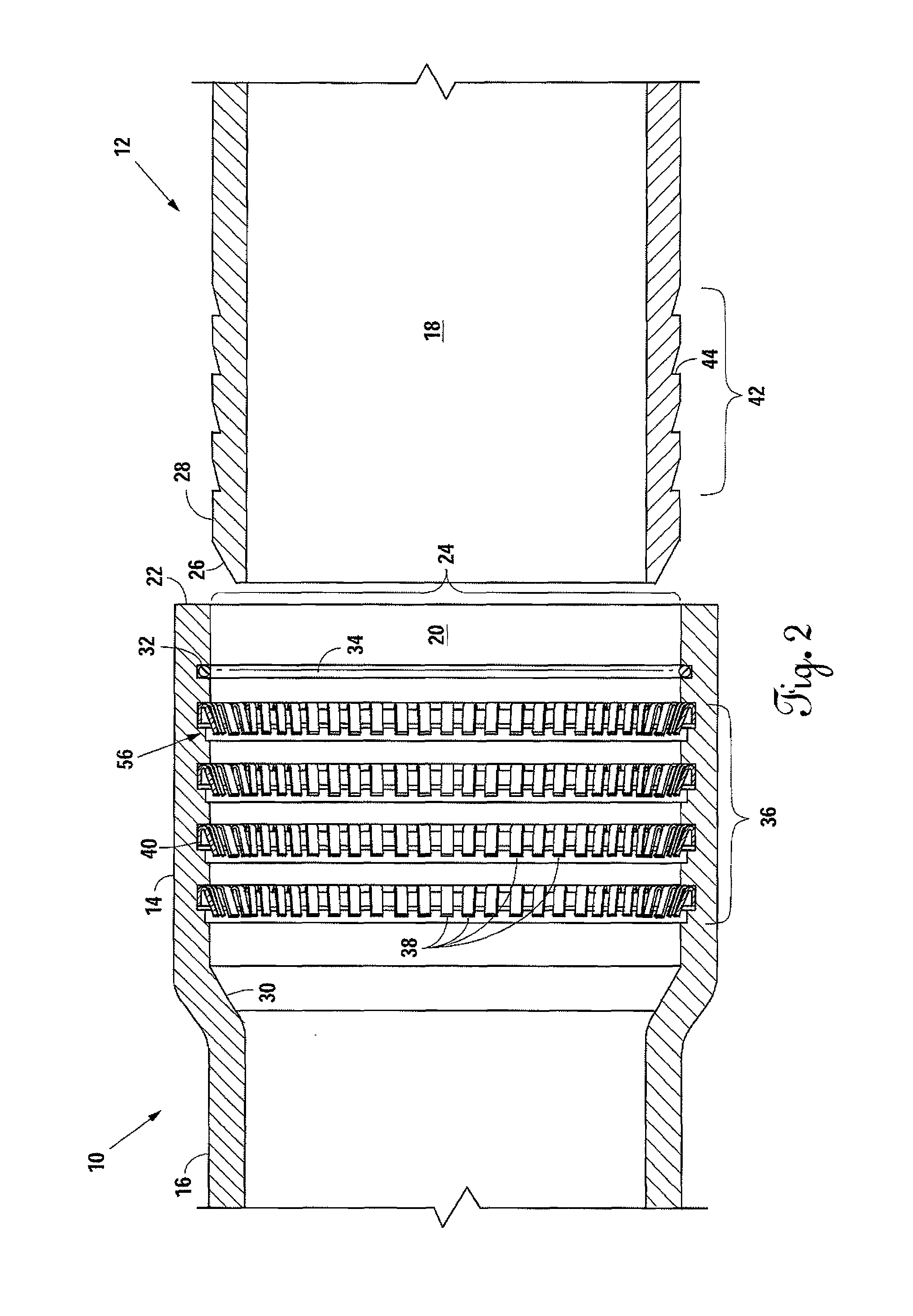

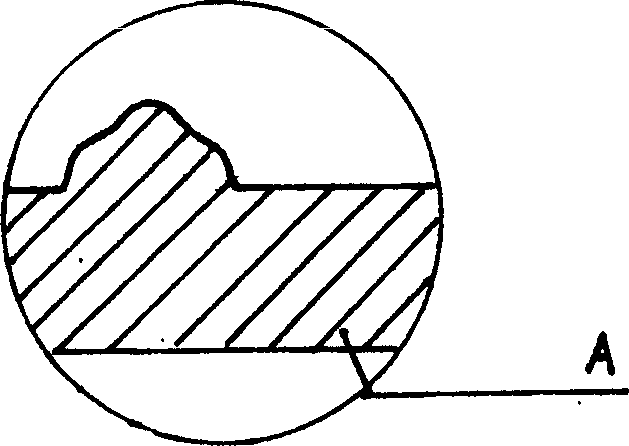

Male push lock pipe connection system

A pipe for connecting to a similar adjacent pipe. The pipe has a male end with a plurality of rigid fingers extending from within and out of at least one exterior circumferential groove disposed on its exterior surface. On the female end is at least one interior circumferential groove sized and positioned to receive the plurality of rigid fingers from a corresponding exterior circumferential groove on the male end of an adjacent pipe. The number of exterior circumferential grooves on the male end typically corresponds to the number of interior circumferential grooves on the female end. When the male end of the pipe inserts into the female end of a similar adjacent pipe, the plurality of rigid fingers is received within a corresponding interior circumferential groove on the female end, thereby preventing the male end of the pipe from being withdrawn from the female end of the similar adjacent pipe.

Owner:AQSEPTENCE GROUP INC

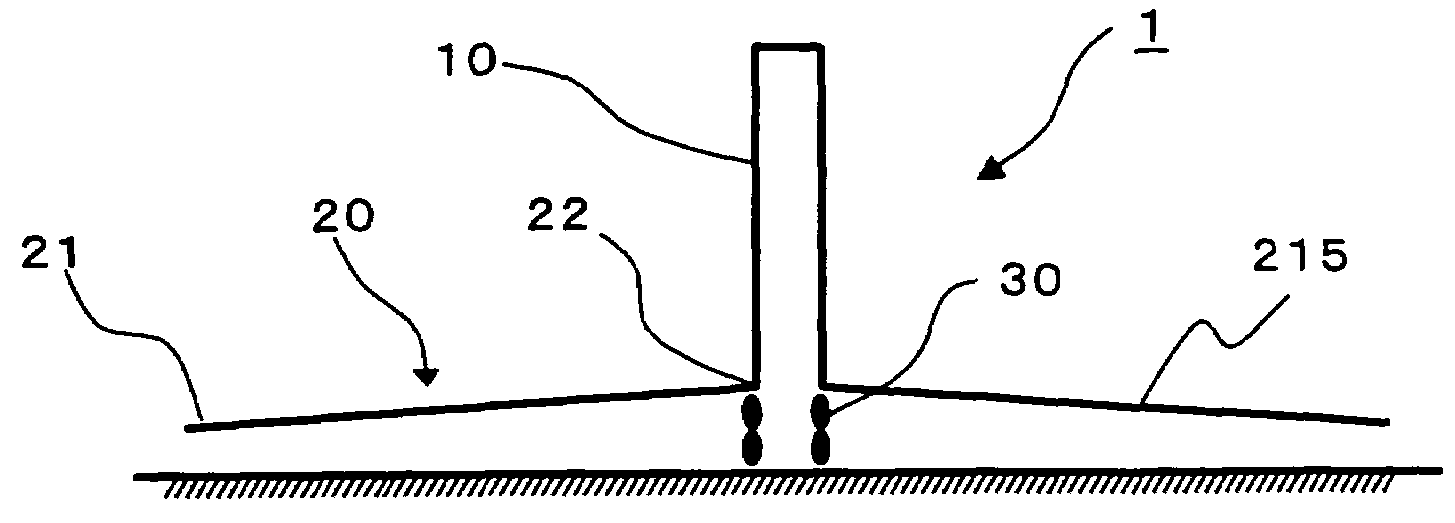

Covering material for solar thermal power generating system and solar thermal power generating system formed by spreading the covering material

ActiveUS7325543B2Increased tensile yield strengthHigh transparencyAuxillary drivesSolar heat devicesTransmittanceEngineering

Owner:ASAHI GLASS CO LTD

High-strength and high-toughness biodegradable film and preparation method thereof

InactiveCN106433047AIncreased tensile yield strengthHigh tear strengthFlat articlesTear resistanceFiber

The invention provides a high-strength and high-toughness biodegradable film and a preparation method thereof. The high-strength and high-toughness biodegradable film comprises components of raw materials in percentage by mass as follows: 10wt%-90wt% of biodegradable resin, 2wt%-60wt% of filler, 0.1wt%-50wt% of reinforced fibers, 0.1wt%-20wt% of a compatilizer and 0.5wt%-25wt% of a processing aid. The high-strength and high-toughness biodegradable film has higher tensile yield strength and tearing strength, the tensile yield strength of the film reaches 20 Mpa or higher, Elmendorf tearability is higher than 400 gf, and the biodegradable film can pass biodegradability tests such as ASTM D6400 and the like, integrates excellent tensile property, tearing resistance and rigidity and is suitable for occasions such as postal and express packing and the like with higher requirements for tensile yield strength and tearing strength. The preparation method of the high-strength and high-toughness biodegradable film is easy to implement, low in production cost and high in production efficiency.

Owner:SHENZHEN HONGCAI NEW MATERIAL TECH

Push Lock Pipe Connection System

ActiveUS20100194098A1Increased tensile yield strengthFast formingSleeve/socket jointsFluid pressure sealed jointsEngineering

A pipe for connecting to a similar adjacent pipe. The pipe has a female end with a plurality of rigid fingers extending into the space within the female end. The plurality of rigid fingers extends from at least one interior circumferential groove on the interior surface of the female end. On the male end of the pipe there is at least one exterior circumferential groove that is sized and positioned to receive the plurality of rigid fingers from a corresponding interior circumferential groove on the female end of an adjacent pipe. The number of interior circumferential grooves on the female end with the plurality of rigid fingers extending from them typically corresponds to the number of exterior circumferential grooves on the male end. When the male end of a similar adjacent pipe is inserted into the female end of the pipe, the plurality of rigid fingers is received within the corresponding exterior circumferential groove on the male end, thereby preventing the male end of the similar adjacent pipe from being withdrawn from the female end of the pipe.

Owner:JOHNSON SCREENS

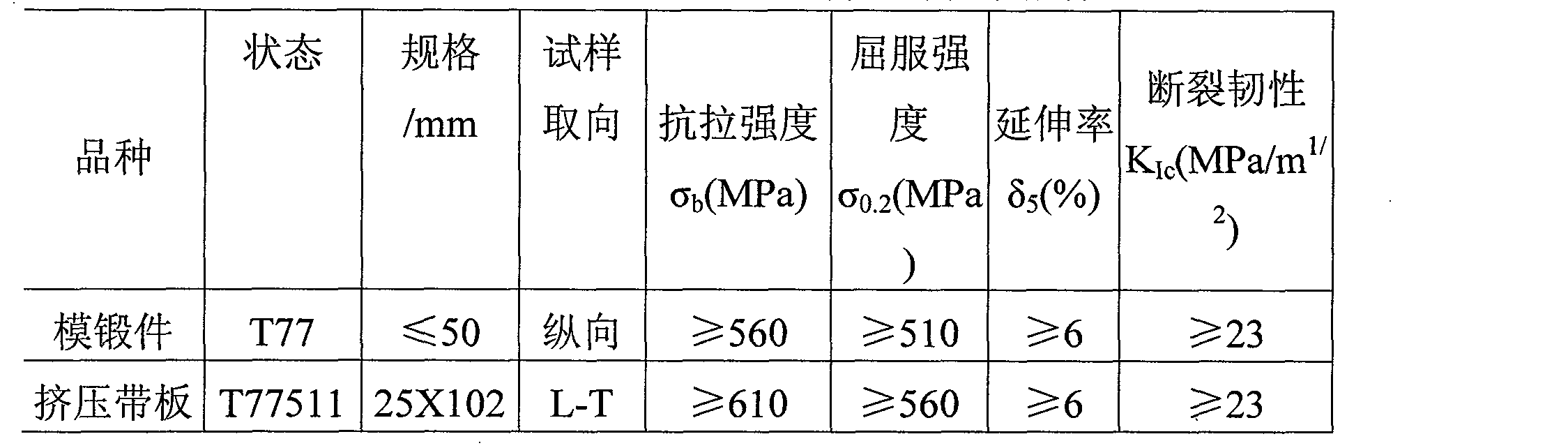

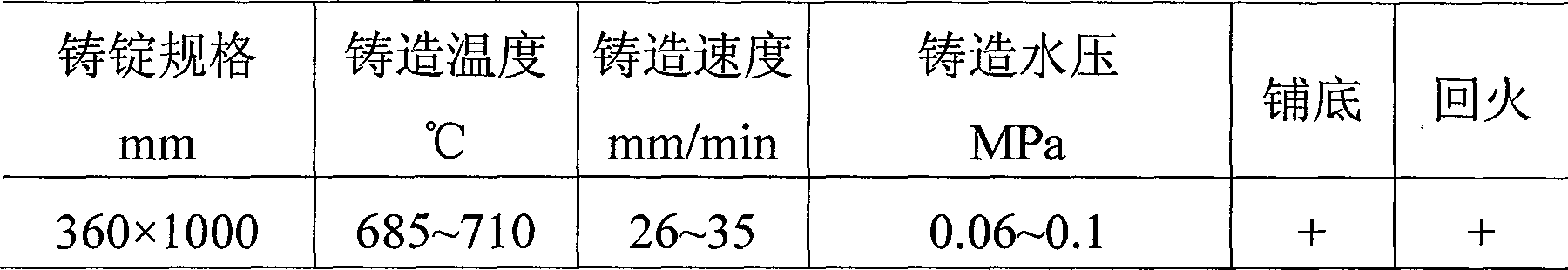

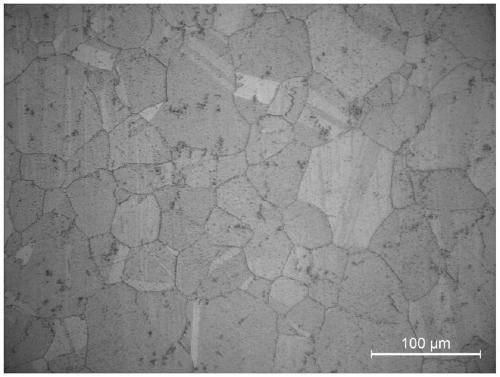

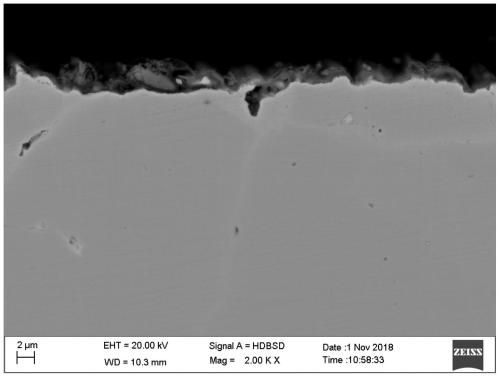

7055 aluminum alloy in high intensity, and high toughness, and preparation method

This invention relates to a method for preparing high-strength and high-toughness 7055 Al alloy. Present 7055 Al alloy has strength of only 500 MPa, and elongation at breakage of only 5%. The high-strength and high-toughness 7055 Al alloy is prepared from: Si 0.1 wt.%, Fe 0.15 wt.%, Cu 2-2.6 wt.%, Mn 0.05 wt.%, Mg 1.8-2.3 wt.%, Cr 0.04 wt.%, Ti 0.06 wt.%, Zr 0.08-0.2 wt.%, Zn 7.6-8.4 wt.%, impurities 0.1 wt.%, and Al as balance. The strength of the high-strength and high-toughness 7055 Al alloy is greater than or equal to 610 MPa (100 MPa more than other 7055 Al alloys), and the elongation at breakage is greater than or equal to 6% (1% more than other 7055 Al alloys). The method can cast Phi 405X1000 mm and Phi 360X1000 mm ingots of the high-strength and high-toughness 7055 Al alloy.

Owner:NORTHEAST LIGHT ALLOY CO LTD

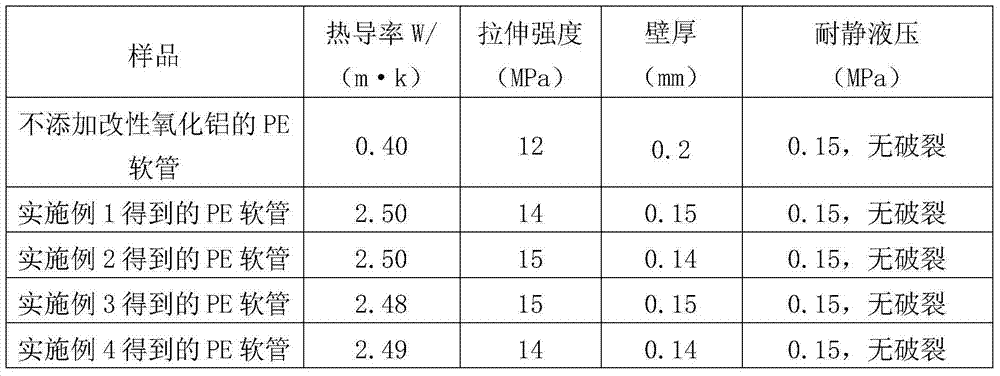

Thin-wall and high-pressure-resisting PE (Polyethylene) hose and preparation method thereof

ActiveCN103756092AImprove thermal conductivityGood weather resistanceTubular articlesLow-density polyethyleneLinear low-density polyethylene

The invention provides a thin-wall and high-pressure-resisting PE (Polyethylene) hose and a preparation method thereof. The thin-wall and high-pressure-resisting PE hose is prepared from the following components in percentage by weight: 35%-45% of high density polyethylene, 10%-22% of low density polyethylene, 20%-30% of linear low density polyethylene, 6%-20% of modified aluminum oxide and 0.5%-4% of a fluorine-containing polymer auxiliary agent PPA (phenyl-propanolamine) functional master batch. According to the thin-wall and high-pressure-resisting PE hose, modified aluminum oxide is added into a formula to improve the heat conductivity of the PE hose so that the weather resistance of the PE hose is improved; the modified aluminum oxide is added so that the tensile strength of the material is improved and the aim of reducing the wall thickness of the PE hose is realized under the precondition of guaranteeing that various performance indexes of the PE hose reach the standard.

Owner:大禹节水(天津)有限公司

High-strength porous casing and pipeline parts of nano polyvinyl chloride and their production process

The invention discloses a nano PVC high-strength multiaperture casing pipe and pipe fitting as well as the production method. The main components are nano PVC ester, heat-stabilizing agent, lubricant, shock-resistant denaturing agent, process denaturing agent, combustion-preventing agent; the method of producing the casing pipe includes the following steps: preparing the materials, stirring, extruding, vacuum shaping, fixed-length cutting-off, testing, packing and being put in storage; the method of producing pipe fitting includes the following in-order technical steps: preparing the materials, stirring, making the particles, injection moulding, cool shaping, trimming, testing, packing and being put in storage. The invention has the characters of light weight, corrosion resistance, good mechanical capability, higher compression strength, convenient construction and so on.

Owner:周辉 +2

Reinforced and toughened polypropylene plastic and preparation method thereof

The invention discloses a reinforced and toughened polypropylene plastic and a preparation method thereof. The reinforced and toughened polypropylene plastic comprise the following components in parts by weight: 70-90 parts of PP (Propene) resin, 5-15 parts of POE (Polyolefin Elastomer) resin and 5-15 parts of barium sulfate. Compared with the pure PP plastics, the reinforced and toughened polypropylene plastic is improved in tensile yield strength and has higher rigid strength; besides, the reinforced and toughened polypropylene plastic is greatly improved and has better toughness. The reinforced and toughened polypropylene plastic can be widely applied to the production of products such as household appliances, plastic pipes and automotive interior parts.

Owner:浙江湘溪塑业股份有限公司

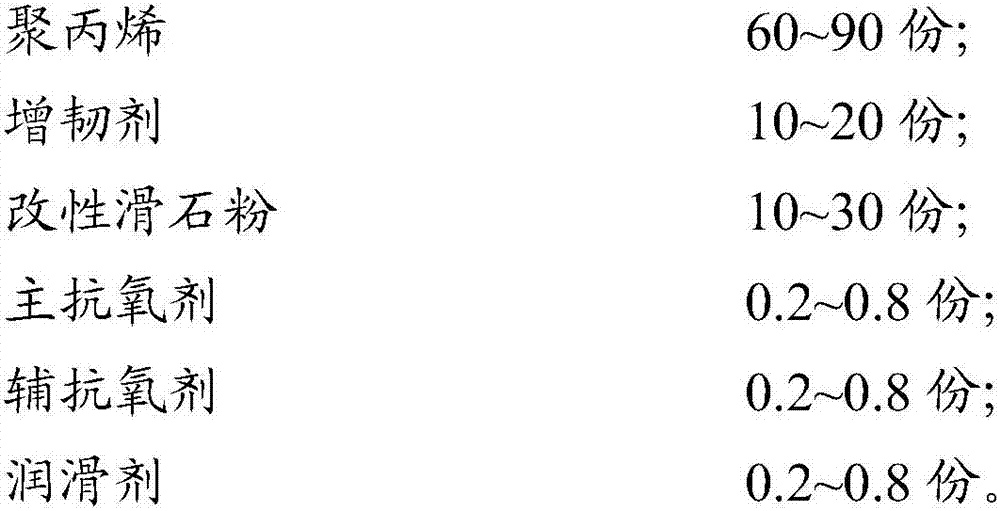

Modified talcum powder and preparation method thereof as well as polypropylene composite and preparation method thereof

The invention provides modified talcum powder and a preparation method thereof. According to the technical scheme provided by the invention, a brucite component in the talcum powder can react with a pretreatment agent, so that Vander Wale force of the talcum powder is damaged; interlayer stripping is generated; meanwhile, the size of the talcum powder is decreased; through treatment of a coupling agent, the agglomeration of the talcum powder can be effectively avoided. Through the modified talcum powder obtained by the modification method, the phenomenon of agglomeration of the talcum powder can be avoided.

Owner:JILIN HENGHUI NEW MATERIAL LTD

Method for producing high-purity micro-silica plastics anti-block agent

InactiveCN101423216AImprove the premium rateIncreased tensile yield strengthSilicon compoundsSilicic acidSilica gel

The invention provides a production method of a high-purity micro-powder silica plastic anti-block agent; high-purity water glass reacts with sulfuric acid to gain sodium sulfate and silicic acid; the sodium sulfate is washed by water to gain silicious colloid which is centrifugally dehydrated, and dried by micro-wave to gain pure SiO2 powder which is crushed by an airflow crusher to gain the high-purity micro-powder silica plastic anti-block agent. The production method of the high-purity micro-powder silica plastic anti-block agent has simple process, high purity and small particle size of the gained products, is suitable for the production and use of top-class plastic films, can obviously improve the top-grade product rate, reduces the cost of the product, improves the tensile yielding strength of the film to 13.5-14.5MPa generally, improves the tensile breaking elongation rate of the film to about 1400 percent, and obviously reduces the fish eye number of the film.

Owner:山西天一纳米科技股份有限公司

Water-soluble biodegradable material, and its preparing method and injection moulded product

The invention relates to water solubility biodegradable material. The material contains the outcome formed by mixture fusing which contains starch, polyhydric alcohol, and aqueous polyvinyl alcohol which has hydrophilicity. Using the mixture total weight as the criterion, the content of the polyhydric alcohol is between 0.1wt% and 10wt%. Its fusing temperature is 140-190 degree centigrade; decomposition temperature is 250-400 degree centigrade. Thus it can realize squeezing granulation and injection molding. The formed water solubility biodegradable material has better simply supported beam impact strength, yield strength in tension, water solubility and biodegradability.

Owner:BEIJING HONGHUA BIOMATERIAL

Polyethylene water supply pipe for trenchless construction

The invention relates to a polyethylene water supply pipe for trenchless construction. The pipe which is formed by blending and extrusion molding of a special high-density polyethylene pipe material and co-polypropylene mixture which are used as base materials, a glass fiber and a proper number of auxiliary agent comprises more than 70 percent of polyethylene, 10-20 percent of co-polypropylene, 5-15 percent of boron and alkali-free (E-CR) glass fiber, an antioxidant, an activating agent and a compatilizer. Compared with the traditional PE100 water supply polyethylene pipe, the polyethylene water supply pipe prepared by the raw materials through methods of high-speed kneading, mixed granulation and extrusion molding has higher ring stiffness and tensile strength, improves the ring stiffness by more than 25 percent and improves the tensile yield strength by more than 30 percent. The pipe disclosed by the invention can be prevented from being flattened or broken during trenchless construction, the dragging and ejecting length of the pipe is greatly reduced, the pipe cost is reduced and the construction cost is also reduced.

Owner:浙江经纬集团环保工程有限公司

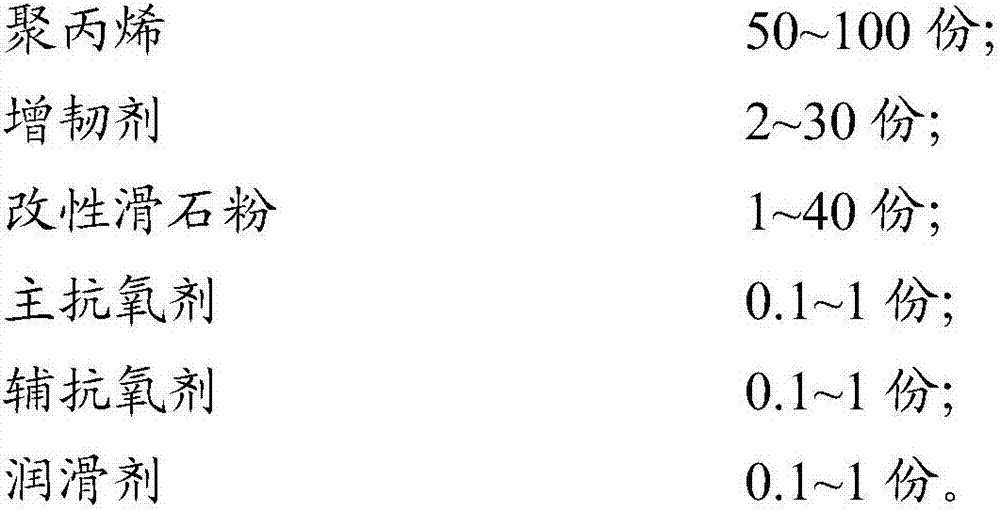

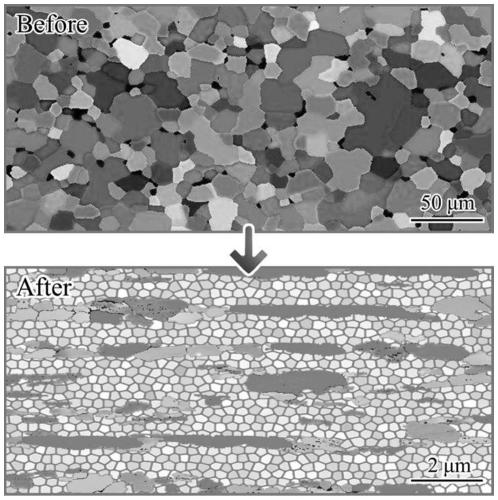

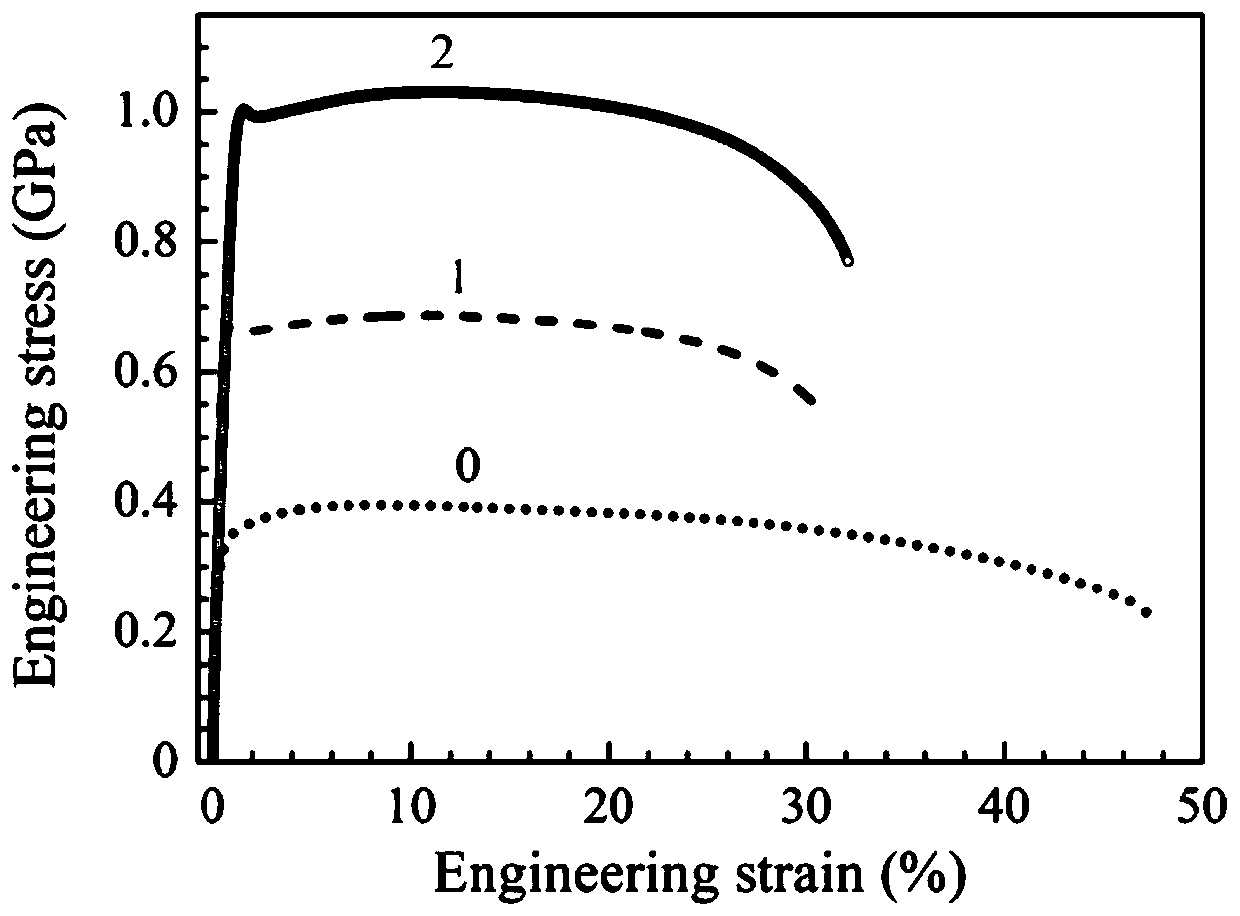

High-uniform-elongation GPa-grade titanium and preparation method thereof

The invention discloses a high-uniform-elongation GPa-grade titanium. The volume fraction of a re-crystallized lamellar structure in a titanium plate is 20%-25%, and the volume fraction of a nanocrystalline matrix is 75%-80%. The invention also discloses a circulating thermal mechanical processing method of the high-uniform-elongation GPa-grade titanium. Finally, a titanium sheet / strip material which is obtained with the non-uniform lamellar structure not only has a GPa-grade tensile yield strength, but also has a high-uniform tensile elongation of more than or equal to 10%. The product prepared by the method can be obtained through a conventional rolling forming technology in the industry so that large-scale production can be easily formed in the industry.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

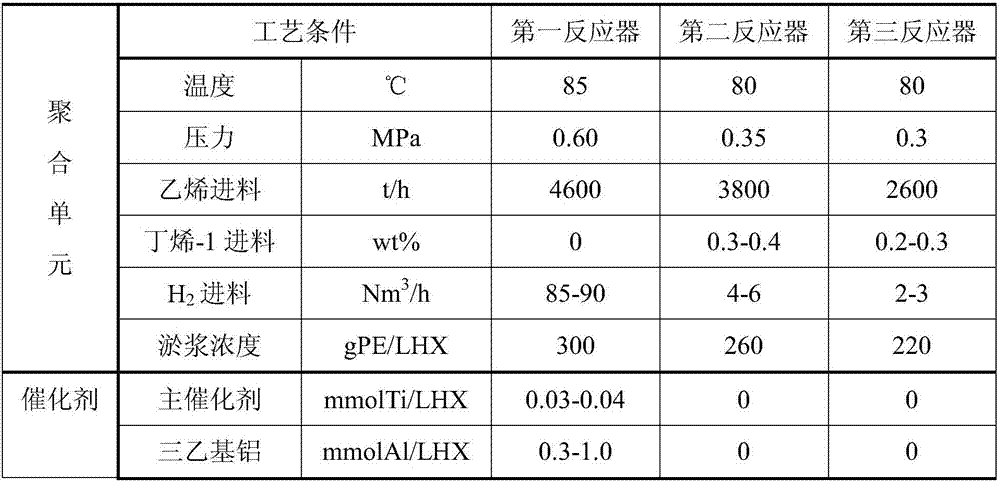

High-density polyethylene resin for preparing small hollow product with extrusion blow molding

InactiveCN107286420AImprove mechanical propertiesIncreased tensile yield strengthBulk chemical productionLow-density polyethylenePolymer science

The invention relates to high-density polyethylene resin for preparing a small hollow product with extrusion blow molding. A process of connecting two kettles of a Mitsui slurry polymerization device in series is adopted; then a reaction kettle is connected in series; only ethylene is added into the first reaction kettle; ethylene and butene-1 are added into a second reaction kettle and a third reaction kettle; the molecular weight distribution of HDPE (High-Density Polyethylene) is widened further through the polymerization of the third reaction kettle; meanwhile, the content of the butene-1 as a copolymer monomer of a high-molecular weight part is increased in order to meet the requirement on the HDPE for preparing the small hollow product with the extrusion blow molding. The HDPE has superior mechanical performance, can be up to 28MPa in tensile yield strength to the maximum extent, is over 200h in environmental stress cracking resistance, is improved remarkably in toughness, and can be widely applied to molding and processing of the small hollow product.

Owner:SINOPEC YANGZI PETROCHEM +1

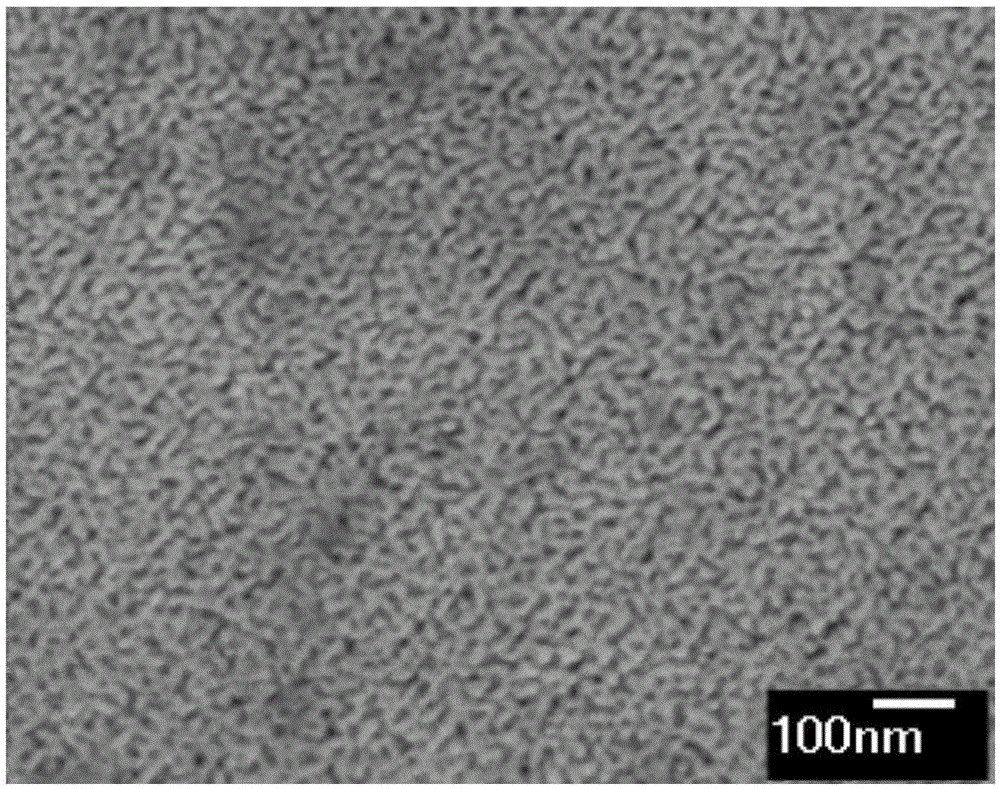

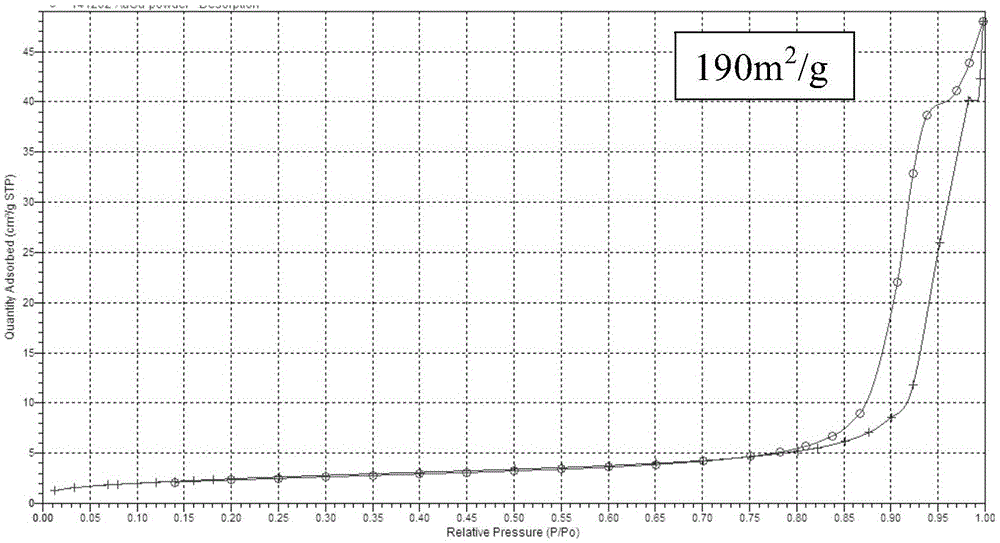

Preparation method of doped nanoporous gold (NPG) with small pore diameter and large specific surface area

InactiveCN105107499ALarge specific surface areaImproves Strength and ToughnessMetal/metal-oxides/metal-hydroxide catalystsSolventSurface-active agents

The invention provides a preparation method of doped nanoporous gold (NPG) with a small pore diameter and a large specific surface area. The preparation method comprises the following steps: 1, cleaning gold alloy foils thoroughly, and drying for standby application; 2, mixing lauryl sodium sulfate or sodium dodecyl benzene sulfonate (SDBS) with corrosive mineral acid uniformly to obtain a corrosive medium solution; 3, placing the gold alloy foils in the corrosive medium solution for dealloying treatment; 4, boiling, washing and soaking the gold alloy foils subjected to dealloying treatment by adopting absolute ethyl alcohol as a solvent, drying to obtain the doped nanoporous gold (NPG) with a small pore diameter and a large specific surface area. According to the preparation method of the doped nanoporous gold (NPG) with a small pore diameter and a large specific surface area, provided by the invention, nanoporous gold (NPG) with high toughness, a small pore diameter and a large specific surface area is prepared by adopting the surface active agent-induced electrochemical corrosion dealloying technology, therefore the advantages that the process is simple, the cost is quite low, the structure is easy to control and the toughness is higher are achieved.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Preparation method for natural plant fiber plastic

The invention relates to a preparation method for a plastic raw material, especially a preparation method for a natural plant fiber plastic. The preparation method for a natural plant fiber plastic includes the first step by melting (by weight percentage) 59.5-69.5 base resin, 0.1-0.4 compatilizer, and 0.1-0.4 ageing resistance auxiliary agent, to obtain molten resin; the second step by adding 30-40% free-water-free hydrophobic modified bastose into the molten resin for performing blending; the third step by extruding via a short screw stem for granulation after the bastose is uniformly dispersed in the base resin. The plastic material obtained via the method has the advantages of high tensile yield strength, high bending strength, and high notch-free impact strength, and can be used in a plane, a steamship, an automobile, and other instruments. Relative to conventional loading strength material, plastic has lighter weight and can reduce whole weight of a transportation tool, with obvious effect.

Owner:WENZHOU NAIDANGLAO SHOES MATERIALS

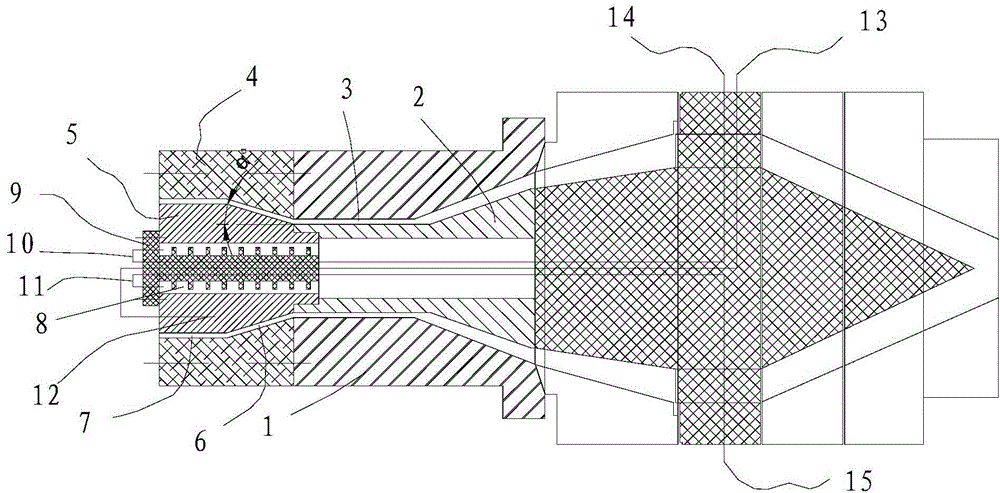

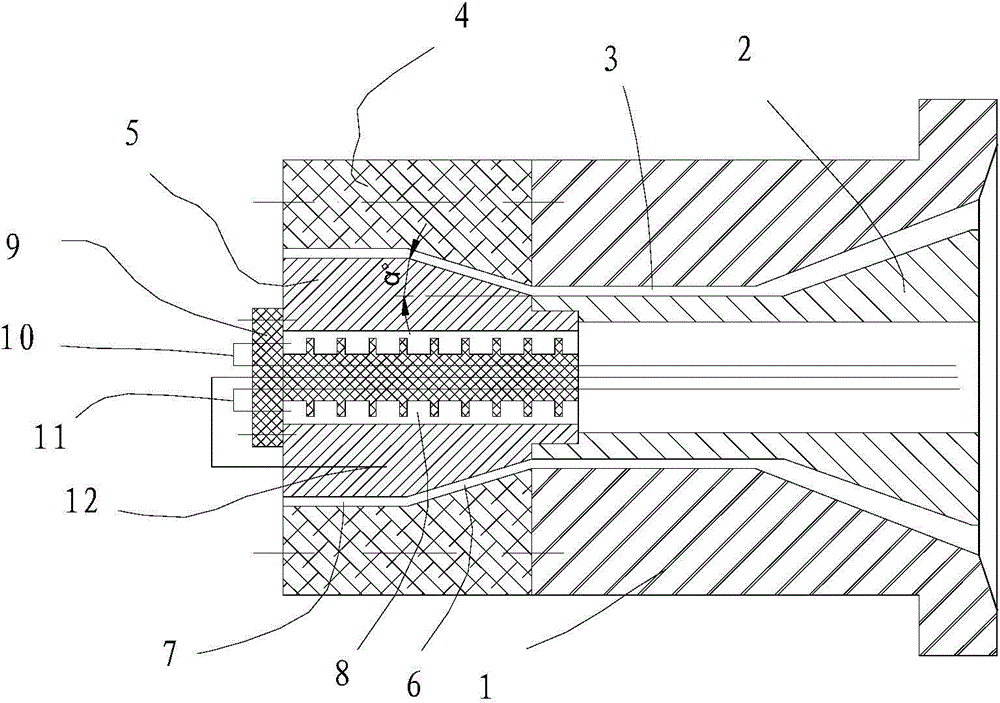

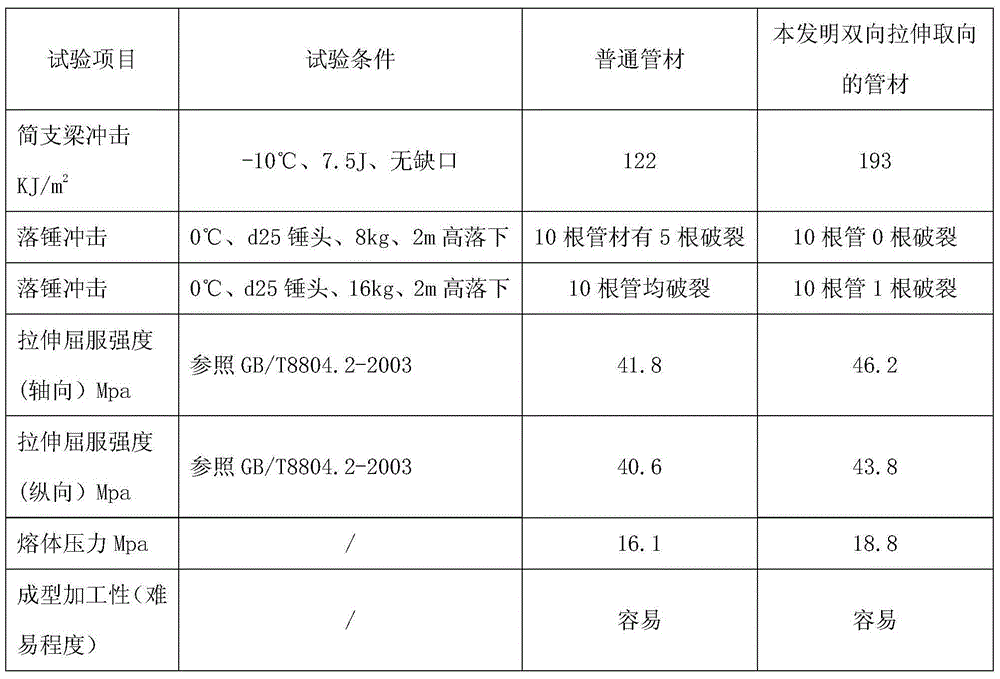

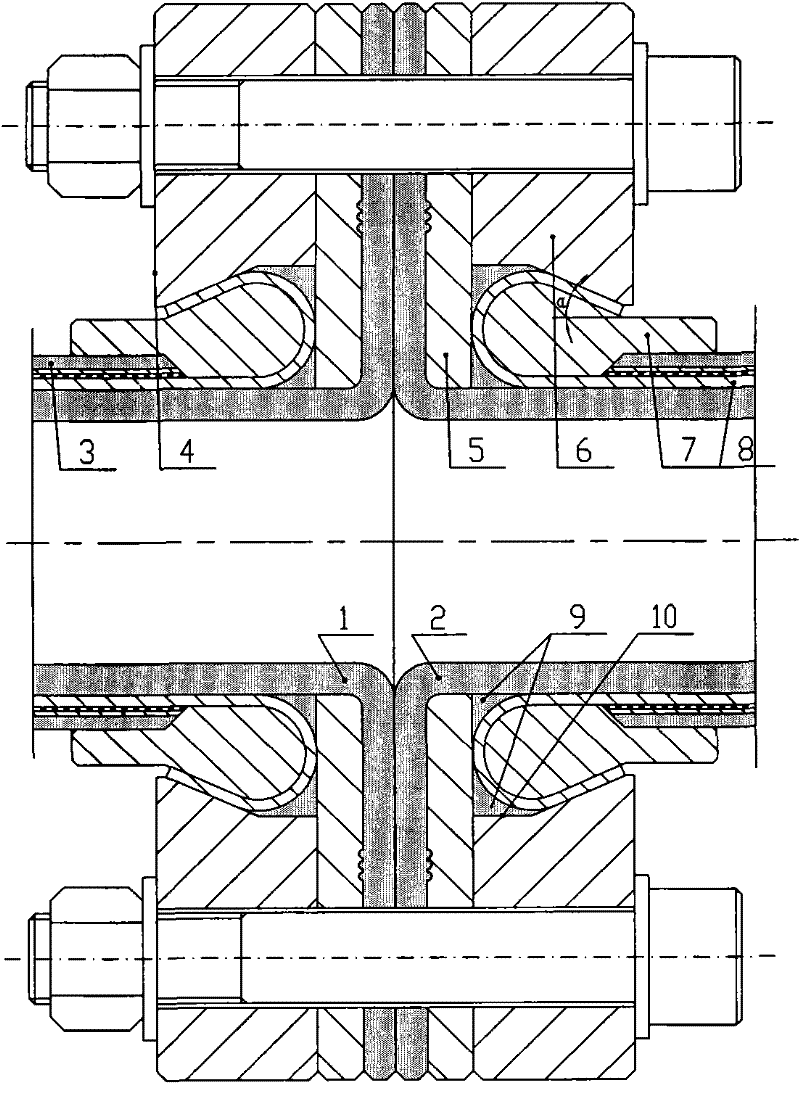

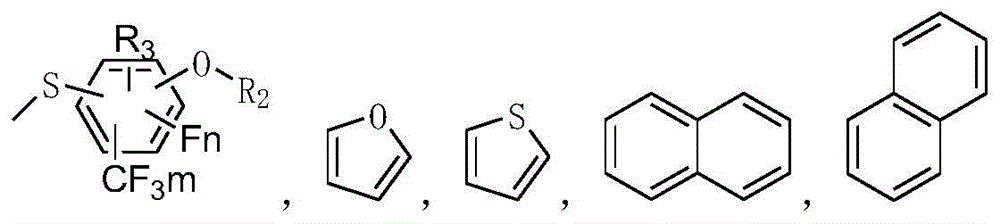

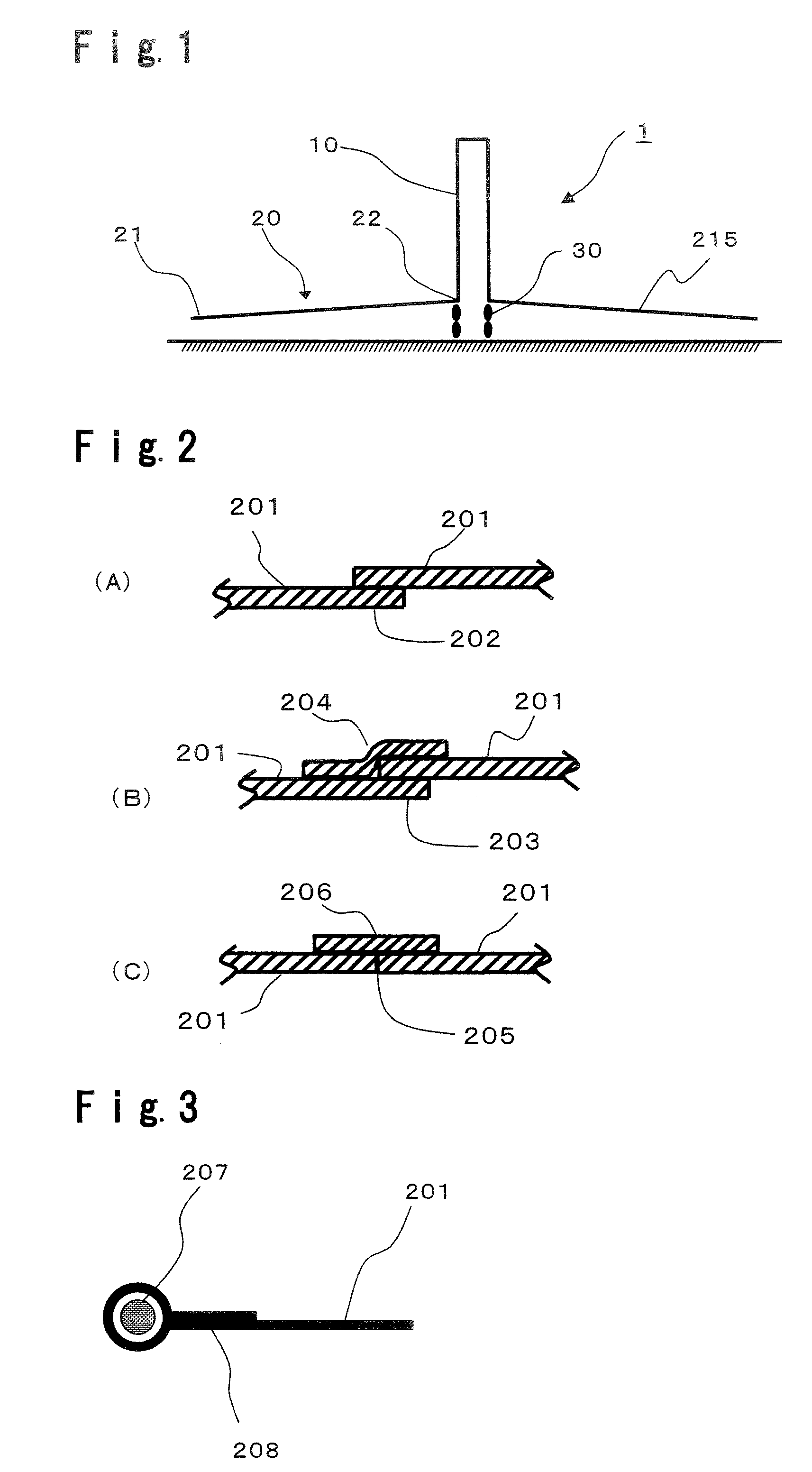

Online two-way stretching device of plastic pipes

The invention discloses an online two-way stretching device of plastic pipes. The online two-way stretching device comprises a die, a mandrel and a circular runner, wherein the die is arranged on an extrusion die, and the circular runner is arranged between the die and the mandrel. The online two-way stretching device is provided with a mold cavity connected with the die and a mold core connected with the mandrel. An expansion circular runner communicated with the circular runner and a horizontal circular runner communicated with the expansion circular runner are sequentially arranged between the mold cavity and the mold core, the mold core is provided with a cavity, a cyclone is arranged in the cavity, and an inlet pipe and an outlet pipe of the cyclone are connected with an external mold temperature controller respectively. The online two-way stretching device has the advantages that two-way stretching of pipes can be continuously realized online, impact resistance and stretching performance of the pipes are improved, and without high-pressure media, the online two-way stretching device is convenient to seal, simple in structure and safe and reliable to use.

Owner:RIFENG ENTERPRISE FOSHAN CO LTD +2

Push Lock Pipe Connection System

A pipe for connecting to a similar adjacent pipe. The pipe has a female end with a plurality of rigid fingers extending into the space within the female end. The plurality of rigid fingers extends from at least one interior circumferential groove on the interior surface of the female end. On the male end of the pipe there is at least one exterior circumferential groove that is sized and positioned to receive the plurality of rigid fingers from a corresponding interior circumferential groove on the female end of an adjacent pipe. The number of interior circumferential grooves on the female end with the plurality of rigid fingers extending from them typically corresponds to the number of exterior circumferential grooves on the male end. When the male end of a similar adjacent pipe is inserted into the female end of the pipe, the plurality of rigid fingers is received within the corresponding exterior circumferential groove on the male end, thereby preventing the male end of the similar adjacent pipe from being withdrawn from the female end of the pipe.

Owner:BILFINGER WATER TECHNOLOGIES INC

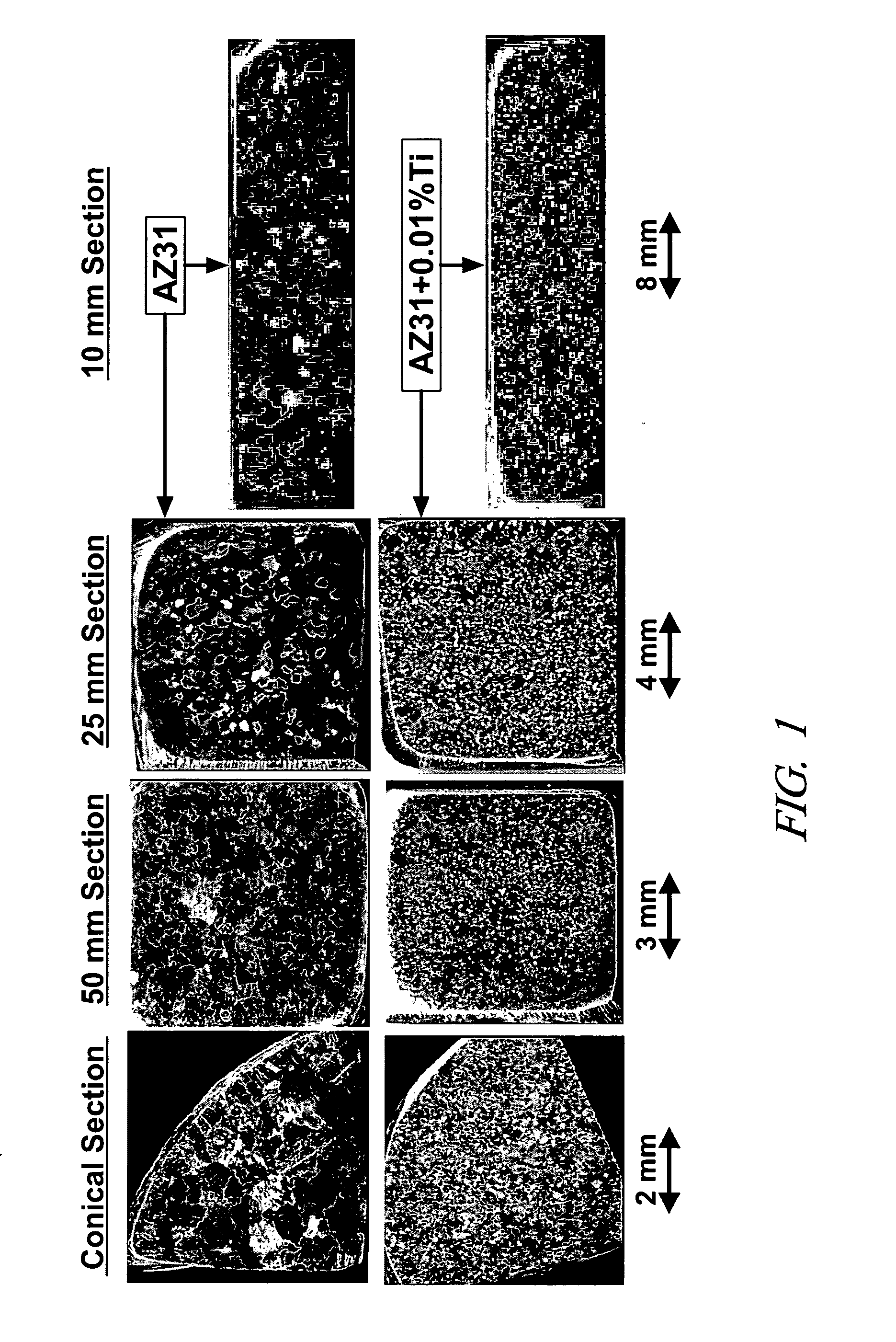

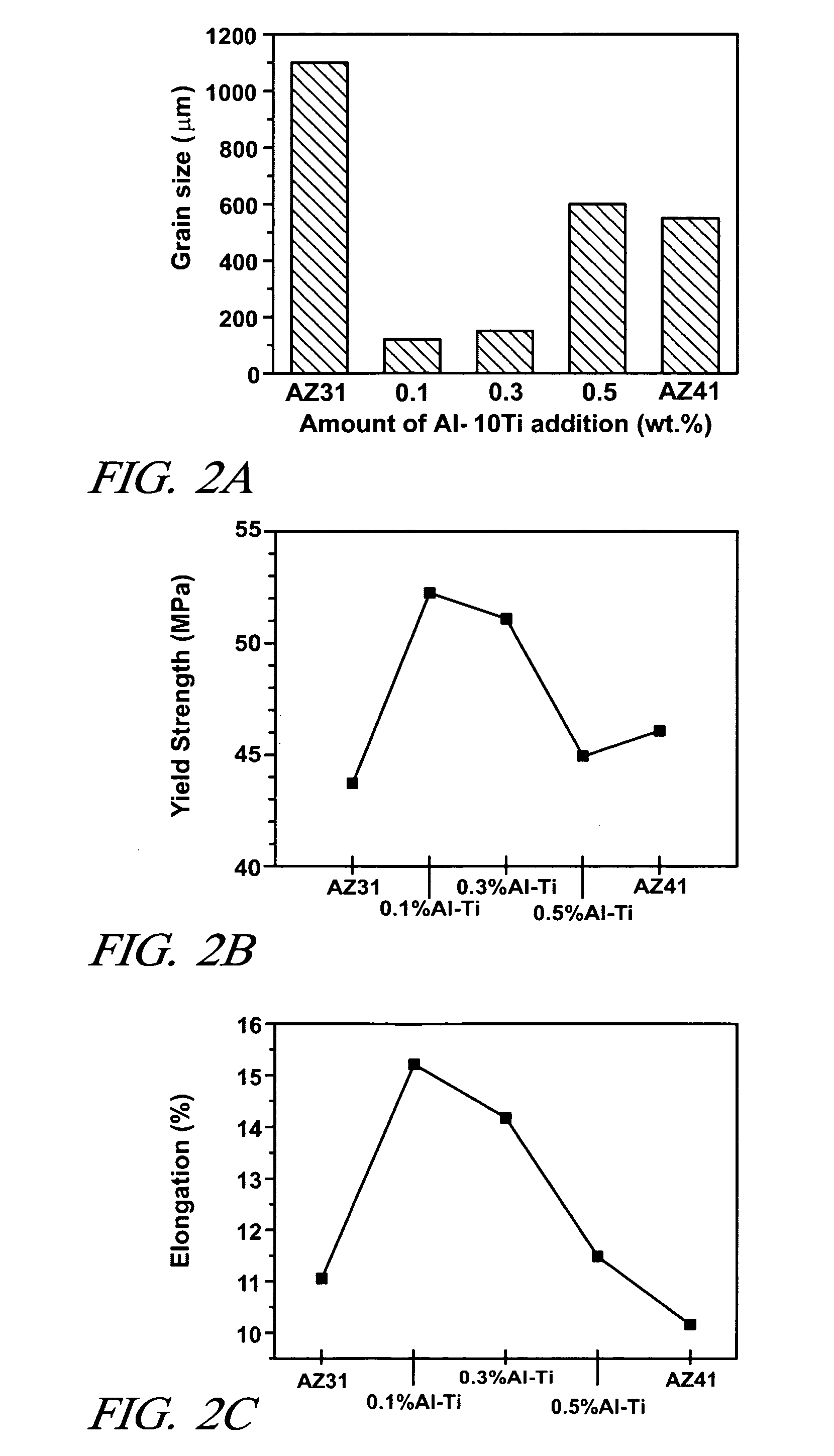

Magnesium grain-refining using titanium

InactiveUS20070181226A1Reduce and refine average grain sizeIncreased tensile yield strengthTitaniumUltimate tensile strength

The grain size of magnesium alloys is effectively refined and made smaller by the addition of a small amount of titanium. The effect of the reduction of grain size is often an improvement in the strength and processability of a cast magnesium alloy. Often less than about 0.1% by weight of titanium need be used. It may be preferred to incorporate the titanium with another alloying constituent (such as aluminum) for addition to a melt of a magnesium base alloy.

Owner:GM GLOBAL TECH OPERATIONS LLC

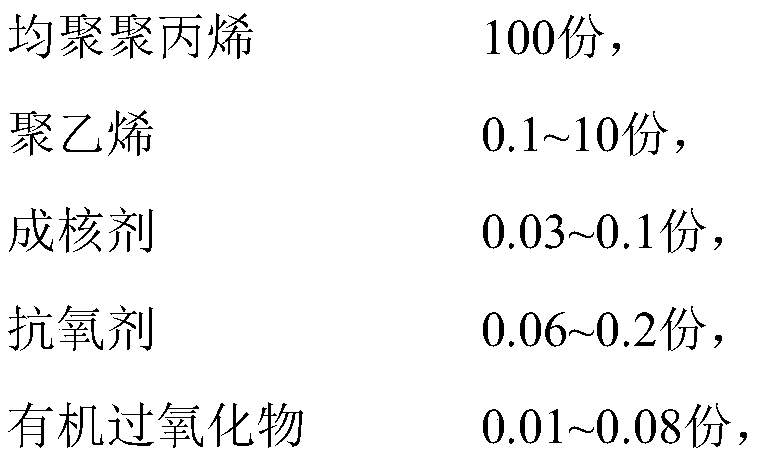

Toughening polypropylene material and preparation method thereof

ActiveCN109851913ALower crystallization temperature and longer crystallization timeIncrease production costPolypropyleneCrystallite

The invention discloses a toughening polypropylene material, comprising the following components in parts by weight: 100 parts of homo-polypropylene, 0.1-10 parts of polyethylene, 0.05-0.2 part of nucleating agent, 0.04-0.3 part of antioxygen, and 0.01-0.04 part of organic peroxide. The invention also discloses a preparation method of the toughening polypropylene material, and the preparation method includes the following steps: adding homo-polypropylene, polyethylene, a nucleating agent, an antioxygen and an organic peroxide into a high speed mixer for mixing, and conducting melting blendingextruding pelletizing on the uniformly mixed premix by a twin screw extruder, so as to obtain the final product. According to the invention, a low proportion of polyethylene is added into the formulacomponents and is used as a toughening agent of polypropylene, thereby realizing impact modification of polypropylene, refining grain size of polypropylene crystal, increasing impact resistance of thepolypropylene material, enhancing low-temperature resistance, and decreasing the melting point of the polypropylene material, decreasing the processing temperature and correspondingly reducing energyconsumption.

Owner:东华能源(宁波)新材料有限公司 +2

Steel belt self-locking type flange pipe connector used for connecting compound pipes

InactiveCN102242846AReasonable structural designSimple preparation processPipe connection arrangementsSelf lockingEngineering

The invention discloses a steel belt self-locking type flange pipe connector used for connecting compound pipes and belongs to the technical field of the pipe connector. The steel belt self-locking type flange pipe connector comprises a shrinking sleeve, a flange 4, a sleeve liner, a steel belt and a filling layer, wherein the flange 4 is composed of an upper flange 5 and a lower flange 6; the shrinking sleeve is arranged between the steel belt and the sleeve liner; a ladder-shaped inner hole is formed on one side, which is close to a pipe body, of the lower flange 6; the sleeve liner is positioned in a hollow cavity; the steel belt is tangent with the outer side of the upper flange 5 and an end of the steel belt is matched with the inner wall of the inner hole, thereby forming the hollow cavity; the filling layer is positioned in the hollow cavity which is encircled by the steel belt, the upper flange 5 and the inner wall of the inner hole; the steel belt is positioned between the sleeve liner and the inner hole; an inclined angle of 30 degrees is formed between the slope of the ladder-shaped inner hole and the axial line of the pipe body. The steel belt self-locking type flange pipe connector can be used for reducing 10% of cost. The loading capacity is above dozens of MPa and the tensile yield strength is above 10MPa. The steel belt self-locking type flange pipe connector used for connecting compound pipes is capable of being used for efficiently promoting the tensile yield strength of the pipes and is reliable in connection and long in service life.

Owner:JIANGSU SHENSHI NEW MATERIAL TECH

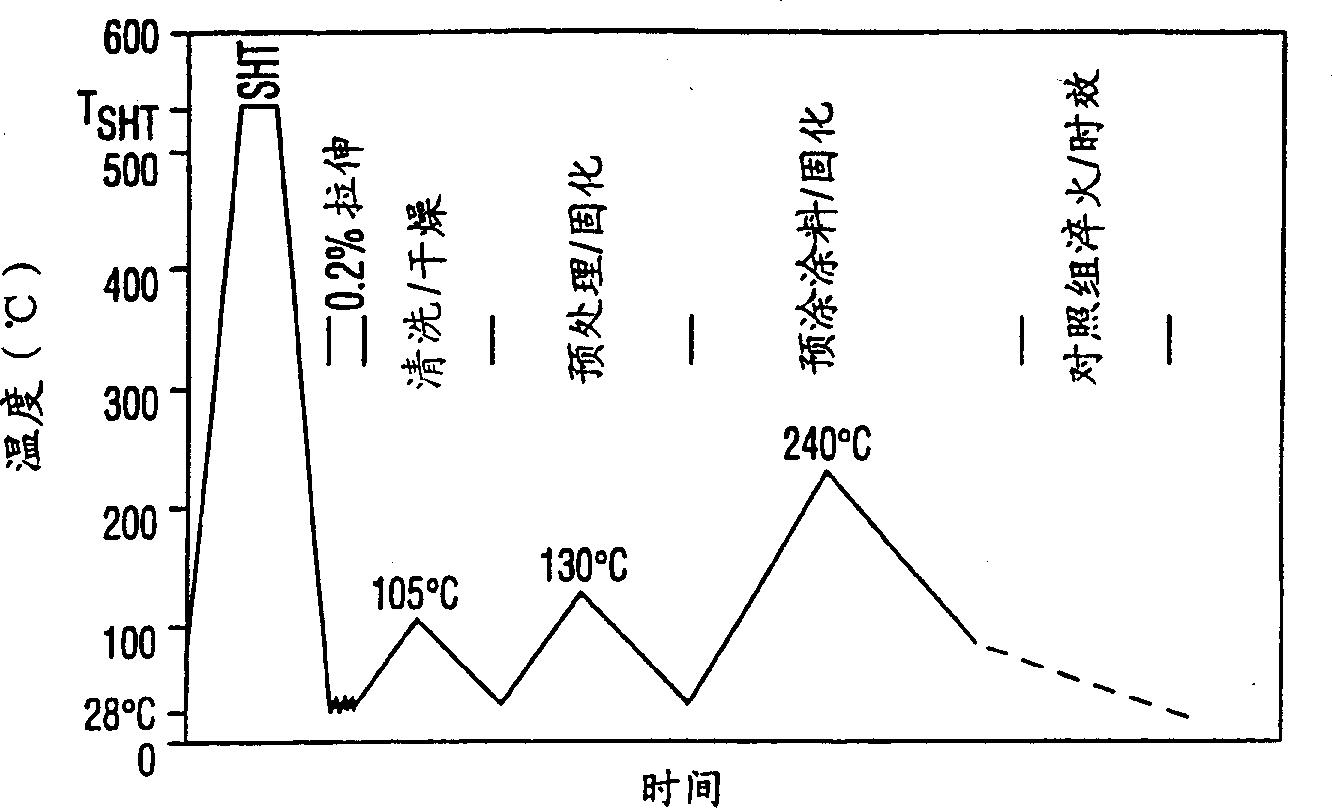

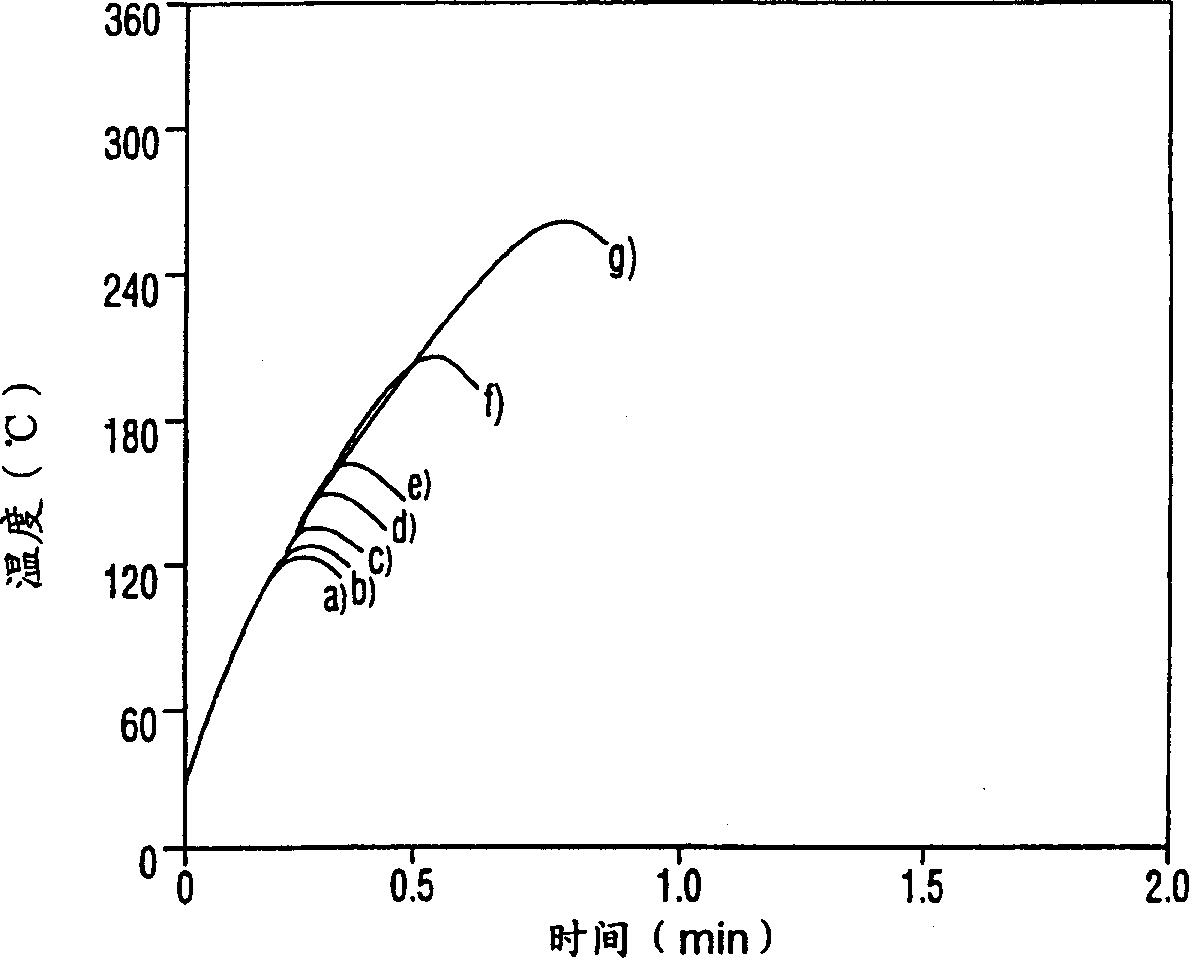

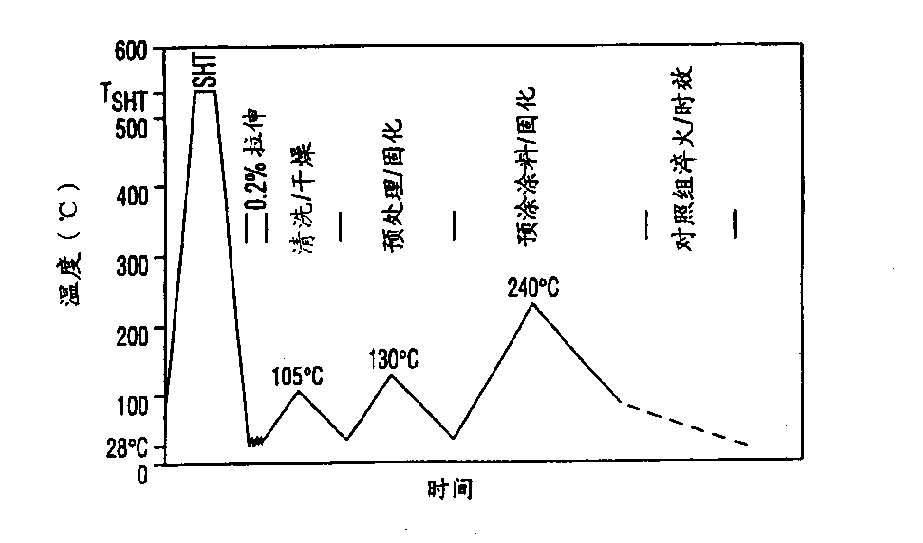

Heat treatment process for aluminum alloy sheet

A process of producing solution heat treated aluminum alloy sheet material comprises subjecting hot- or cold-rolled aluminum alloy sheet to solution heat treatment followed by quenching and, before substantial age hardening has taken place, subjecting the alloy sheet material to one or more subsequent heat treatments involving heating the material to a peak temperature in the range of 100-300 DEG C(preferably 130-270 DEG C), holding the material at the peak temperature for a period of time less than about 1 minute, and cooling the alloy from the peak temperature to a temperature of 85 DEG C or less. The sheet material treated in this way can be used for automotive panels and has well a good 'paint bake response', i.e. an increase in yield strength from the T4 temper to the T8X temper upon painting and baking of the panels.

Owner:NOVELIS INC

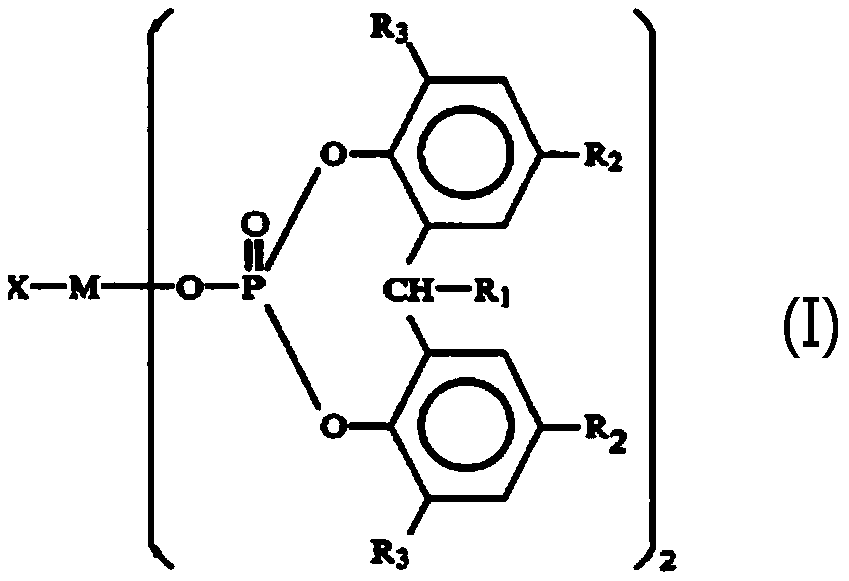

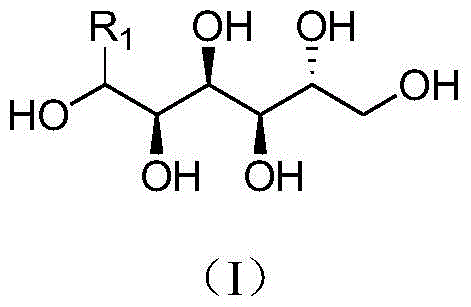

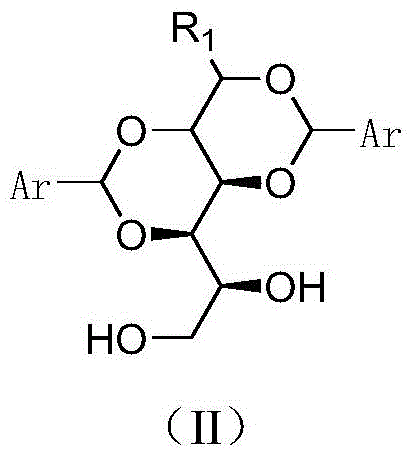

Sorbitol derivatives and preparing method and application of DBS polyolefin nucleating agent synthesized with sorbitol derivatives

InactiveCN105732315AImprove smellFast crystallizationOrganic compound preparationHydroxy compound preparationHeat deflection temperaturePolyolefin

The invention relates to sorbitol derivatives and a preparing method and application of a DBS polyolefin nucleating agent synthesized with the sorbitol derivatives.The sorbitol derivatives include 1-(2-butenyl) sorbitol, 1-butyl sorbitol, 1-(2-methyl allyl)sorbitol, 1-isobutyl sorbitol, 1-vinyl sorbitol, 1-ethyl sorbitol and the like.The nucleating agent prepared from the series of novel sorbitol derivatives is odorless, and thus the odor issue of an existing nucleating agent is effectively relieved.The nucleating agent effectively increases the crystallization speed of polyolefin resin and improves the degree of crystallinity of polyolefin resin, the transparence and the surface gloss of polyolefin are improved, and the physical and chemical properties such as the bending modulus, the tensile yield strength, the heat deflection temperature and the impact strength of polyolefin are improved; in addition, the preparing method is simple in step, and industrialized production is easy to achieve.

Owner:APLENE TECHNOLOGY CO LTD (HANGZHOU)

Heat dissipating material for LCD touch liquid crystal display and preparation method and application thereof

ActiveCN106832496AIncreased tensile yield strengthHigh heat distortion temperatureHeat-exchange elementsNon-linear opticsNitrateLiquid-crystal display

The invention discloses a heat dissipating material for LCD touch liquid crystal display and a preparation method and application thereof. The heat dissipating material is prepared from the following raw materials in parts by weight: 15 to 23 parts of graphite, 9 to 17 parts of nickel nitrate, 5 to 12 parts of vinyltriethoxysilane, 3 to 7 parts of dibenzoylquinone dioxime, 11 to 19 parts of diacetone-acryloamide and 20 to 30 parts of waste rubber powder. The preparation method comprises the following steps: putting the waste rubber powder and a vinyltriethoxysilane solution in a polytetrafluoroethylene reaction still for sealing, pressurization, heating stirring processing to prepare a modified waste rubber mixture; mixing and grinding the graphite, nickel nitrate and dibenzoylquinone dioxime, then heating a diacetone-acryloamide solution to prepare a modified graphite mixture; mixing the two mixtures, and carrying out ultrasonic processing, heating stirring, melt extrusion and injection molding to form the heat dissipating material. According to the heat dissipating material, relatively high heat-conducting property and insulating property are effectively maintained, and the tensile yield strength and elongation at break are improved. The heat dissipating material disclosed by the invention is resistant to high temperature, resistant to aging and resistant to corrosion, and is low in production cost.

Owner:CHENZHOU HAILI MICROELECTRONICS TECH

Covering material for solar thermal power generating system and solar thermal power generating system formed by spreading the covering material

InactiveUS20080115819A1Increased tensile yield strengthHigh transparencyWind motor with solar radiationFrom solar energyTransmittanceEngineering

A covering material for solar thermal power generation system, characterized in that it is made of a film which has a tensile yield strength of at least 10 N / mm2 according to JIS K7127, a solar radiation transmittance of at least 85% according to JIS R3106, and a retention of at least 80% against the initial value of the tensile breakage strength after 5000 hours of the sunshine carbon arc lamp weather test according to JIS B7753.

Owner:AGC INC

Method for preparing 7055 aluminum alloy with high intensity and high toughness

This invention relates to a method for preparing high-strength and high-toughness 7055 Al alloy. Present 7055 Al alloy has strength of only 500 MPa, and elongation at breakage of only 5%. The high-strength and high-toughness 7055 Al alloy is prepared from: Si 0.1 wt.%, Fe 0.15 wt.%, Cu 2-2.6 wt.%, Mn 0.05 wt.%, Mg 1.8-2.3 wt.%, Cr 0.04 wt.%, Ti 0.06 wt.%, Zr 0.08-0.2 wt.%, Zn 7.6-8.4 wt.%, impurities 0.1 wt.%, and Al as balance. The strength of the high-strength and high-toughness 7055 Al alloy is greater than or equal to 610 MPa (100 MPa more than other 7055 Al alloys), and the elongation at breakage is greater than or equal to 6% (1% more than other 7055 Al alloys). The method can cast Phi 405X1000 mm and Phi 360X1000 mm ingots of the high-strength and high-toughness 7055 Al alloy.

Owner:NORTHEAST LIGHT ALLOY CO LTD

High-strength corrosion-resistant nickel-based polycrystalline high-temperature alloy and preparation method thereof

InactiveCN111394619AImprove stabilityImproved corrosion/oxidation resistanceSuperalloyUltimate tensile strength

The invention relates to a high-strength corrosion-resistant nickel-based polycrystalline high-temperature alloy and a preparation method thereof. The alloy comprises the following components of, in percentage by mass, 13%-17% of Cr, 15%-20% of Co, 0.1%-0.5% of Ti, 5.0%-5.5% of Al, 3.0%-7.0% of W, less than or equal to 0.5% of Si, less than or equal to 0.5% of Mn, 1.5%-2.0% of Nb, 0.04%-0.07% of Cand the balance Ni. Homogenizing treatment is conducted after smelting is conducted, hot rolling is conducted and finally heat treatment is conducted. The alloy has excellent strength and corrosion resistance, and the tensile yield strength of the alloy at a room temperature and 850 DEG C is higher than 900 MPa and 680 MPa respectively, and the alloy has excellent processing performance and structure stability at the same time.

Owner:HUANENG POWER INTERNATIONAL +1

Production method of 1-hexene copolymerized linear polyethylene resin

ActiveCN109535532AImprove quality stabilityImprove performanceBulk chemical productionBreaking strengthPolymer science

The invention discloses a production method of 1-hexene copolymerized linear polyethylene resin. The method includes the steps of: (1) on a Unipol polyethylene process unit, taking ethylene, hydrogenand 1-hexene as the raw materials, using a Ziegler-Natta Ti based catalyst, carrying out reaction in a gas-phase fluidized bed reactor to obtain copolymer powder; and (2) adding an antioxidant and heat stabilizer into the copolymer powder obtained by step (1), conducting material granulation and drying, thus obtaining the 1-hexene copolymerized linear polyethylene resin. The 1-hexene copolymerizedlinear polyethylene resin prepared by the method provided by the invention has high quality stability, and greatly improved performance compared with the copolymers produced by the existing technology, especially higher melt flow index, tensile breaking strength, tensile elongation at break, tensile yield strength, tensile yield elongation and other data, and lower bending modulus, is very suitable for application to automobile fenders, and can effectively meet the ever-increasing performance requirements for polyethylene.

Owner:CHINA PETROLEUM & CHEM CORP

High-strength porous casing and pipeline parts of nano polyvinyl chloride and their production process

InactiveCN1186382CReduce weightCorrosion resistanceRigid pipesCompressive resistanceIn situ polymerization

The invention discloses a nano PVC high-strength multiaperture casing pipe and pipe fitting as well as the production method. The main components are nano PVC ester, heat-stabilizing agent, lubricant, shock-resistant denaturing agent, process denaturing agent, combustion-preventing agent; the method of producing the casing pipe includes the following steps: preparing the materials, stirring, extruding, vacuum shaping, fixed-length cutting-off, testing, packing and being put in storage; the method of producing pipe fitting includes the following in-order technical steps: preparing the materials, stirring, making the particles, injection moulding, cool shaping, trimming, testing, packing and being put in storage. The invention has the characters of light weight, corrosion resistance, good mechanical capability, higher compression strength, convenient construction and so on.

Owner:周辉 +2

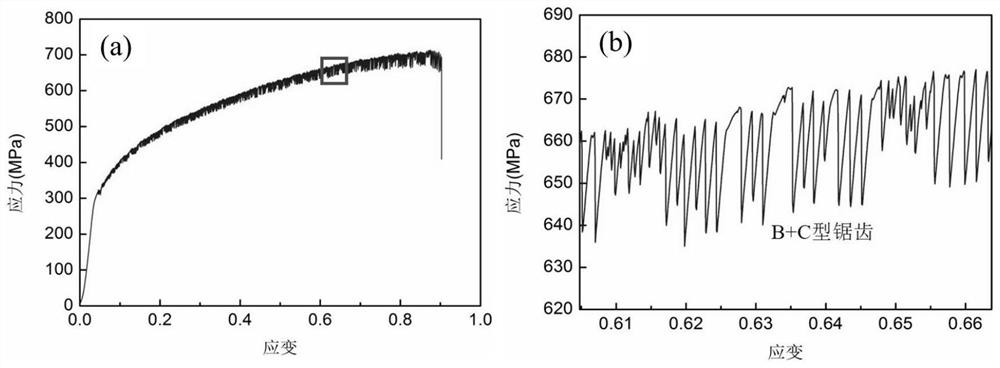

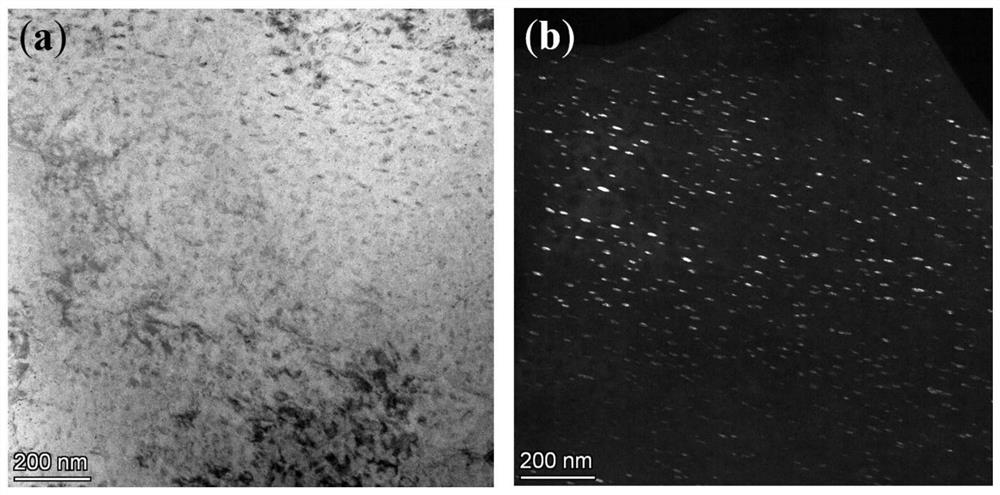

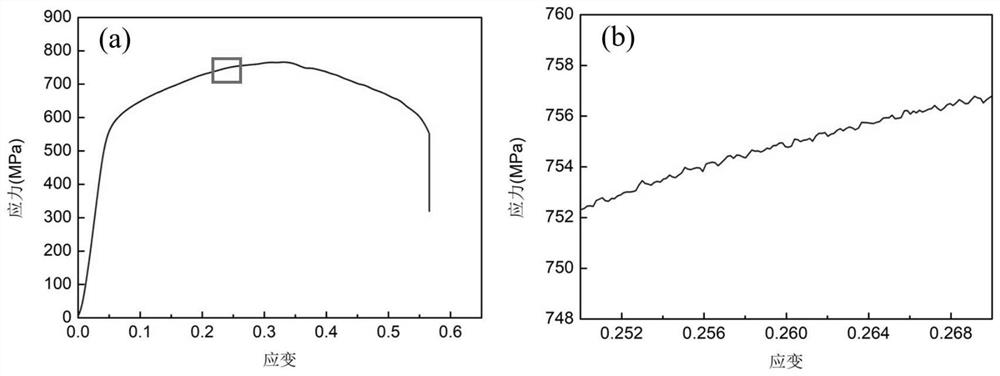

Method for inhibiting sawtooth rheological phenomenon of nickel-based superalloy

The invention discloses a method for inhibiting a sawtooth rheological phenomenon of nickel-based superalloy. The method includes the following steps: a heat treatment furnace is heated to a target solution treatment temperature, an Inconel 625 alloy sample is put into a hearth of the heat treatment furnace, the Inconel 625 alloy sample is immediately taken out of the heat treatment furnace after the solution treatment heat preservation time is reached, and the Inconel 625 alloy sample is quenched and cooled to the room temperature; the target solution treatment temperature is higher than the temperature of the MC type carbide precipitate of the Inconel 625 alloy, and the solution treatment heat preservation time is t1 = (d * 0.6 + 40) min-(d * 0.6 + 80) min; the Inconel 625 alloy sample obtained after solution treatment is put into the hearth, and then the temperature of the heat treatment furnace is increased to the target aging treatment temperature; after the aging treatment heat preservation time is reached, the Inconel 625 alloy sample is taken out, and quenched and cooled to the room temperature; and the target aging temperature is within the temperature interval of precipitating gamma ''-delta phases in the Inconel 625 alloy, and the aging treatment heat preservation time is 200-800 h. The method can effectively inhibit the sawtooth rheological phenomenon.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com