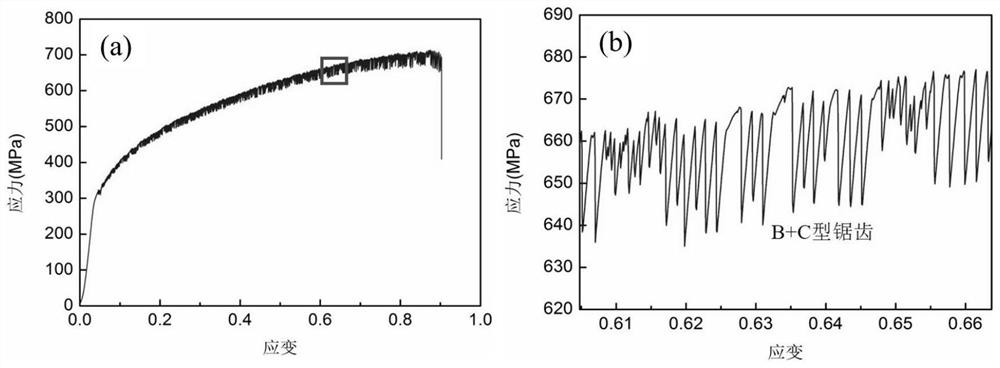

Method for inhibiting sawtooth rheological phenomenon of nickel-based superalloy

A nickel-based high-temperature alloy and sawtooth technology, applied in the field of alloys, to achieve high feasibility, increase tensile yield strength, and suppress the rheological phenomenon of sawtooth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

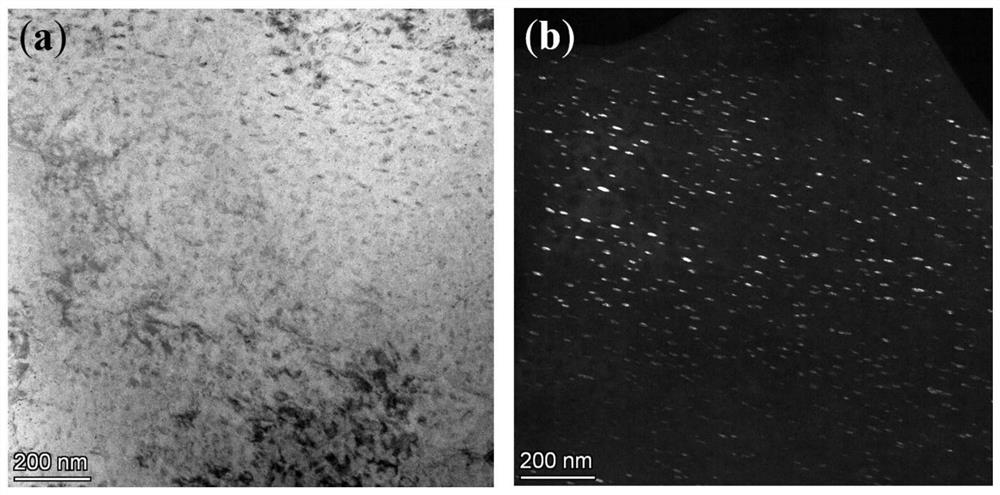

Image

Examples

Embodiment 1

[0031] A method for suppressing Inconel625 alloy sawtooth rheology, comprising the following steps:

[0032] Step 1: Perform solution treatment on Inconel625 alloy: first machine the sample into a specified size to meet the furnace requirements and ensure that the sample is heated evenly; then raise the temperature of the box-type resistance furnace to 1130°C;

[0033] The heating method is as follows: raise the temperature to 550°C at a rate of 10° per minute, and then raise the temperature to 850°C at a rate of 5° per minute. Then the temperature was raised to 1130° C. at a rate of 3° per minute.

[0034]After the furnace temperature reaches 1130°C, put the sample into the furnace, and pad the bottom of the sample with refractory bricks; the thickness of the refractory bricks shall be determined to ensure that the sample is located in the middle of the furnace.

[0035] After the furnace temperature is stable, start timing and heat preservation for 60 minutes; after the hea...

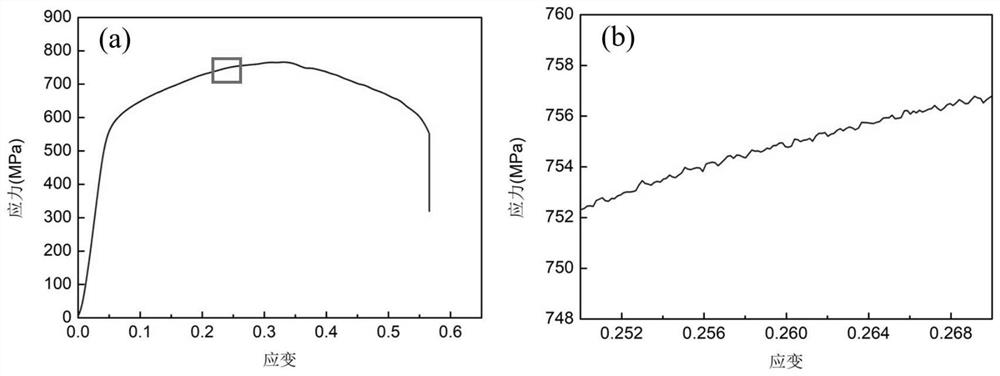

Embodiment 2

[0043] A method for suppressing Inconel625 alloy sawtooth rheology, comprising the following steps:

[0044] Step 1: Perform solution treatment on Inconel625 alloy: first machine the sample into a specified size to meet the requirements of the furnace and ensure that the sample is heated evenly; then raise the temperature of the box-type resistance furnace to 1150°C;

[0045] The heating method is as follows: raise the temperature to 550°C at a rate of 10° per minute, and then raise the temperature to 850°C at a rate of 5° per minute. Then the temperature was raised to 1150° C. at a rate of 3° per minute.

[0046] After the furnace temperature reaches 1150°C, put the sample into the furnace, and pad the bottom of the sample with refractory bricks; the thickness of the refractory bricks shall be determined to ensure that the sample is located in the middle of the furnace.

[0047] After the furnace temperature is stable, start timing and heat preservation for 55 minutes; after...

Embodiment 3

[0054] A method for suppressing Inconel625 alloy sawtooth rheology, comprising the following steps:

[0055] Step 1: Perform solid solution treatment on Inconel625 alloy: first machine the sample into a specified size to meet the requirements of the furnace and ensure that the sample is heated evenly; then raise the temperature of the box-type resistance furnace to 1100°C;

[0056] The heating method is as follows: raise the temperature to 550°C at a rate of 10° per minute, and then raise the temperature to 850°C at a rate of 5° per minute. Then the temperature was raised to 1100°C at a rate of 3° per minute.

[0057] After the furnace temperature reaches 1100°C, put the sample into the furnace, and pad the bottom of the sample with refractory bricks; the thickness of the refractory bricks shall be determined to ensure that the sample is located in the middle of the furnace.

[0058] After the furnace temperature is stable, start timing and heat preservation for 60 minutes; a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com