Steel belt self-locking type flange pipe connector used for connecting compound pipes

A composite pipe, self-locking technology, applied in the direction of pipes/pipe joints/fittings, pipe connection layout, mechanical equipment, etc., can solve the problems of poor tensile yield strength, low pressure bearing capacity, seal failure, etc., to achieve pressure bearing High capacity, improved tensile yield strength, and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

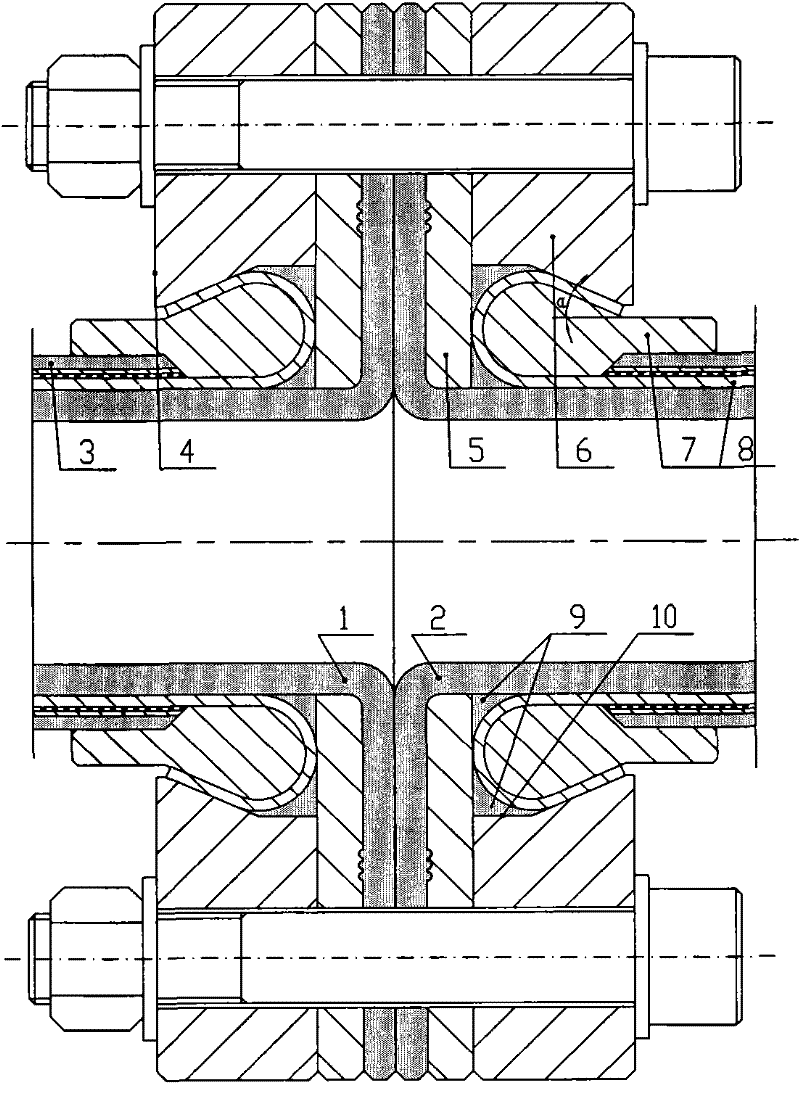

[0019] As shown in Figure 1 of the present invention, the steel strip self-locking flange pipe joint for composite pipe connection includes a shrink sleeve, a flange 4, a bushing, a steel strip, and a filling layer. The flange 4 is composed of an upper flange 5 and a lower flange 6, and the shrink sleeve is arranged between the steel band and the bushing. The outer surface of the upper flange 5 coincides with the inner surface of the flanging part of the pipe body, and a trapezoidal inner hole is arranged on the side of the lower flange 6 close to the pipe body, and the trapezoidal slope forms a 30° angle slope with the axis of the pipe body. , The lower flange 6 and the inner hole are integrally formed by machining. The bushing is placed in the cavity formed by the steel strip tangent to the outer surface of the upper flange 5, and its end coincides with the inner wall of the inner hole. The material used is No. 20 steel, which is formed by machining. The filling layer is pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com