Heat treatment process for aluminum alloy sheet

A technology of aluminum alloy plate and alloy plate, which is applied in the field of heat treatment of aluminum alloy plate, and can solve the problems that the degree of improvement cannot be achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0045] Various alloys shown in Table 1 below were used in this example. These alloys are in the form of plates with a thickness of 0.1 cm (0.039 inches).

[0046] Table 1

[0047] Alloy

CU

FE

MG

MN

Si

Ti

X 611 *

<0.01

0.15

0.77

<0.01

0.93

0.06

AA 6111

0.78

0.11

0.81

0.16

0.60

0.08

AA 6009

0.33

0.23

0.49

0.31

0.80

AA 6016

0.10

0.29

0.40

0.08

1.22

0.01

AA 2036

2.2

0.15

0.18

0.10

0.18

KSE*

1.10

0.15

1.22

0.08

0.26

LSG*

1.52

0.15

1.22

0.08

0.33

[0048] * experimental alloy

[0049] These alloys were initially solution heat treated and naturally aged tempered, and tensile...

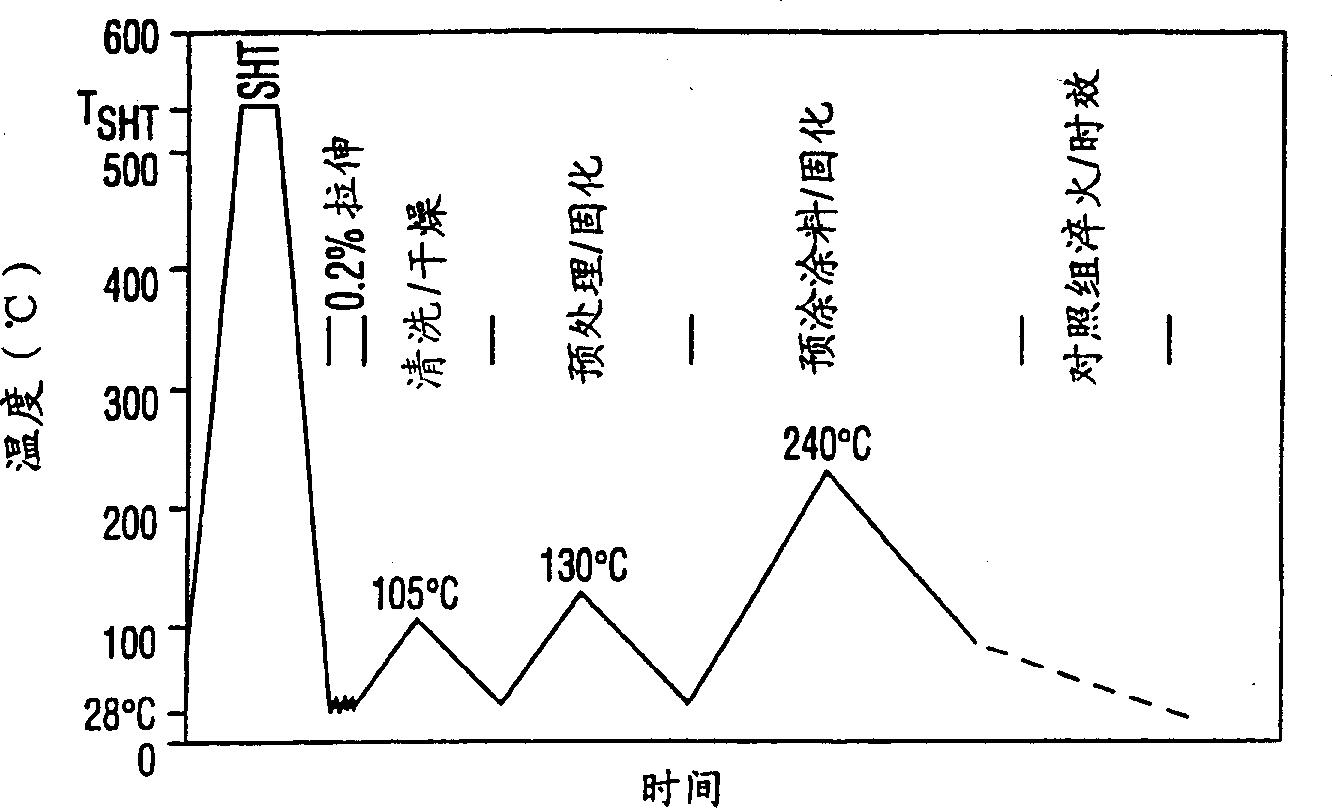

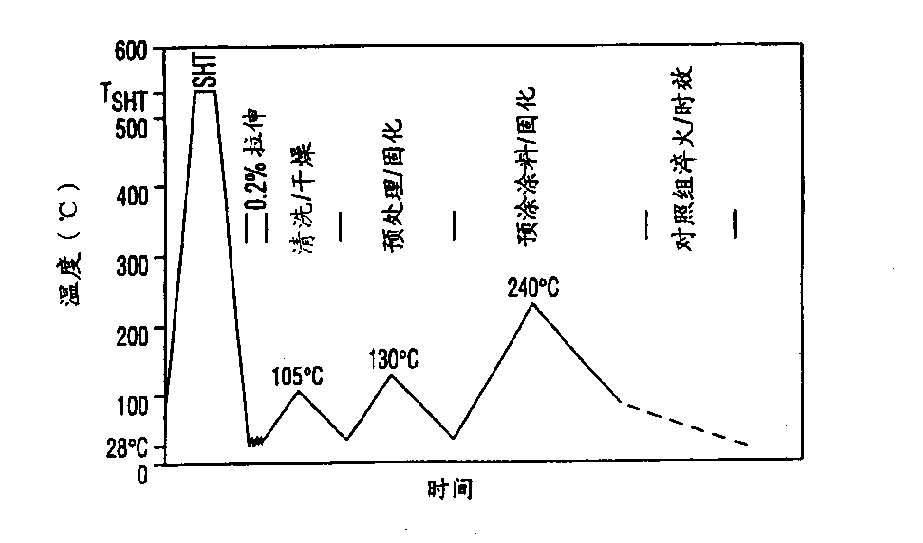

example 2

[0079] Table 6 below shows the average tensile properties of AA6111 and AA6016 sheets after different thermal peak effects and different pre-aging treatments.

[0080] heat change history

AA 6111

AA 6016

T4

T8X

T4

T8X

YS

kg / cm 2

(KSI)

%

EL

YS

kg / cm 2

(KSI)

%EL

YS

kg / cm 2

(KSI)

%

EL

YS

kg / cm 2

(KSI)

%

EL

Solution heat treatment + quenching

Fire + at room temperature (RT)

next week (control)

1427.1

(20.3)

27

2102

(29.9)

23

1195.1

(17.0)

32

1834.8

(26.1)

24

Solution heat treatment + quenching

fire * + stabilizer

Reason (105°C) + No.

secondary stabilization

(130℃)+3rd

secondary stabilization

(240°C)+:

a) Next star on RT

Expect

b) at 85°C for 5

hours without warra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com