High-strength porous casing and pipeline parts of nano polyvinyl chloride and their production process

A polyvinyl chloride, high-strength technology, applied in the direction of pipes/pipe joints/fittings, pipes, rigid pipes, etc., can solve the problems of fragility, affecting the quality of buried pipes, low strength and toughness, etc., and achieve good mechanical properties, The effect of light weight and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Production casing:

[0029] (1) Ingredients: nanoscale CaCo 3 Special resin for in-situ polymerization with vinyl chloride monomer: 100 parts by weight, heat stabilizer: 3 parts by weight, lubricant: 2 parts by weight, impact modifier: 8 parts by weight, processing modifier: 2 parts by weight, resistance Combustion agent: 4 parts by weight are mixed and prepared;

[0030] (2) Stirring: Stir the prepared raw materials in a high-speed mixer until the temperature reaches 105°C, then stir in a low-speed cold mixer to cool down to 60°C, and put them into the storage bin for standby;

[0031] (3) Extrusion: Use 65 or 55 twin-screw extruder to extrude the stirred material into the billet;

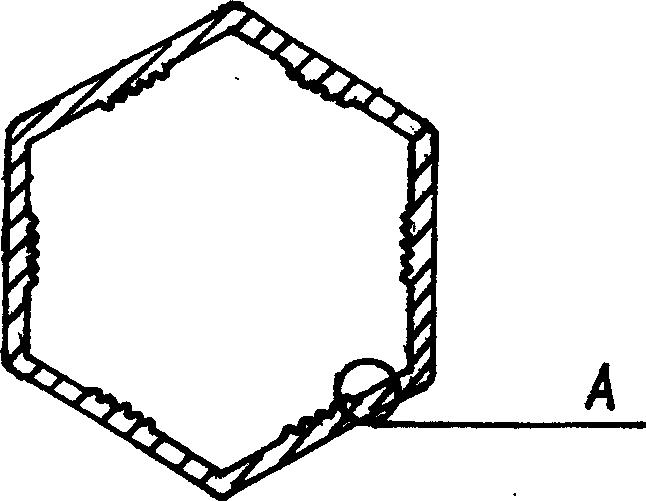

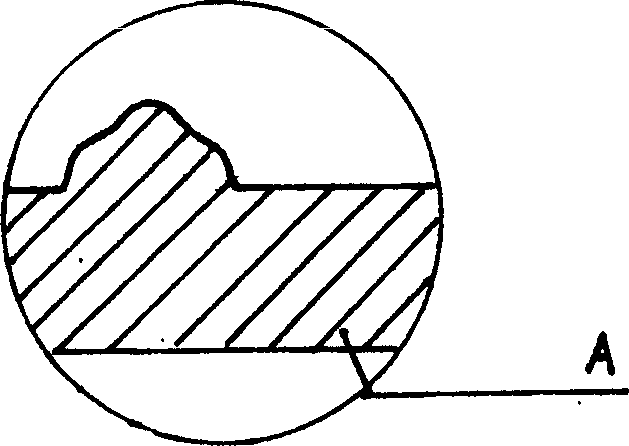

[0032] (4) Vacuum shaping: formed into a porous casing, such as figure 1 As shown, the casing structure is a bioengineering honeycomb arrangement with the closest packing of regular hexagonal lumens, such as figure 2 , image 3 As shown, the inner surface of the casing cavity is p...

Embodiment 2

[0044] (1) Process steps for producing casing:

[0045] (1) Ingredients: nanoscale CaCo 3 Special resin for in-situ polymerization with vinyl chloride monomer: 100 parts by weight, heat stabilizer: 3.5 parts by weight, lubricant: 3 parts by weight, impact modifier: 10 parts by weight, processing modifier: 2.5 parts by weight, resistance Combustion agent: 3 parts by weight are mixed and prepared;

[0046] (2) Stirring: Stir the prepared raw materials in a high-speed mixer until the temperature reaches 100°C, then stir in a cooling mixer to cool down to 60°C, and put them into the storage bin for standby;

[0047] (3) Extrusion: Use 65 or 55 twin-screw extruder to extrude the stirred material into the billet;

[0048] (4) Vacuum shaping: formed into a porous casing, such as figure 1 As shown, the casing structure is a bioengineering honeycomb arrangement with the closest packing of regular hexagonal lumens, such as figure 2 , image 3 As shown, the inner surface of the cas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com