High-uniform-elongation GPa-grade titanium and preparation method thereof

A technology of uniform elongation and titanium plate, applied in the field of mechanical properties of advanced structural materials, can solve the problem that pure titanium cannot obtain high strength and large tensile plasticity at the same time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

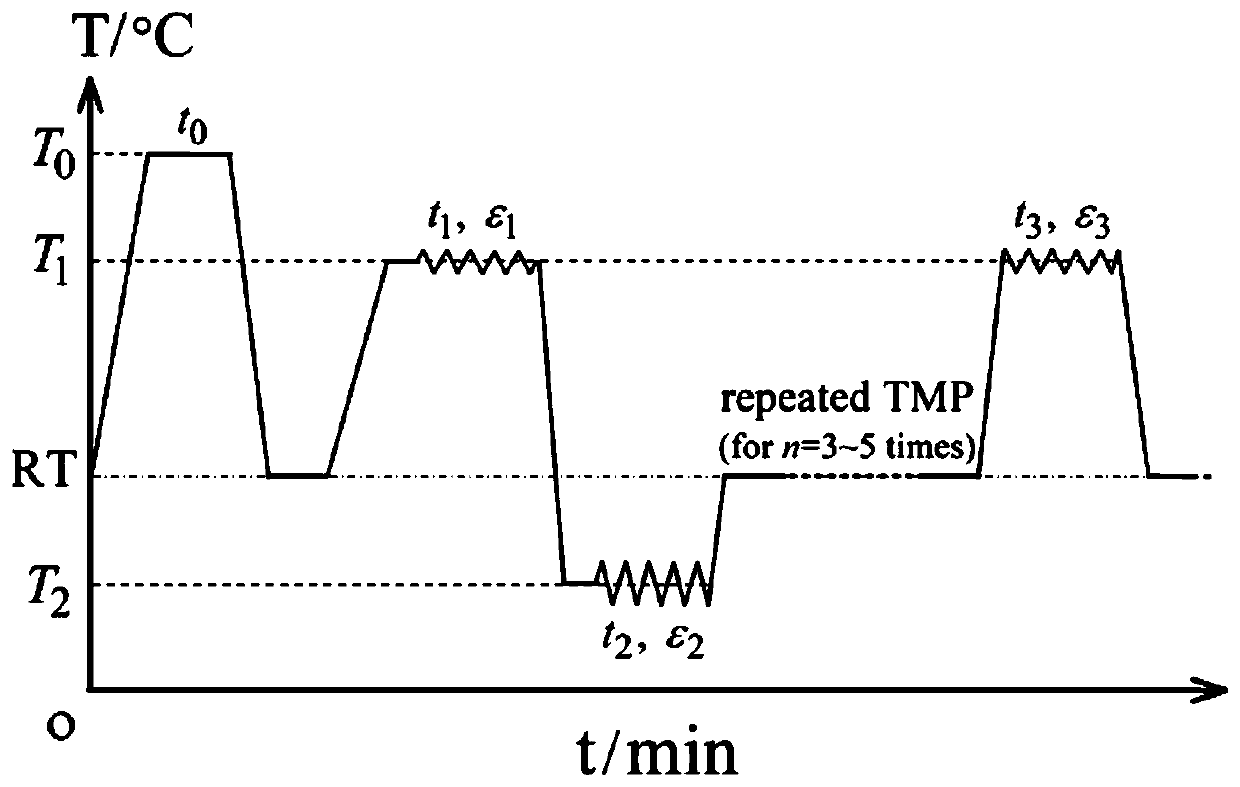

[0029] Such as figure 1 As shown, a schematic flow chart of a cyclic thermomechanical processing method according to an embodiment of the present invention is shown, which may specifically include the following steps:

[0030] Step 101, performing pretreatment on the titanium plate, the pretreatment step includes:

[0031] Step 102, pre-conditioning the titanium plate at a predetermined temperature range T 0 = 425 ~ 550 ℃ scheduled time is t 0 ≈40min solution treatment. The solution treatment is carried out in a salt bath furnace, the heating rate v 1 ≈400°C / min.

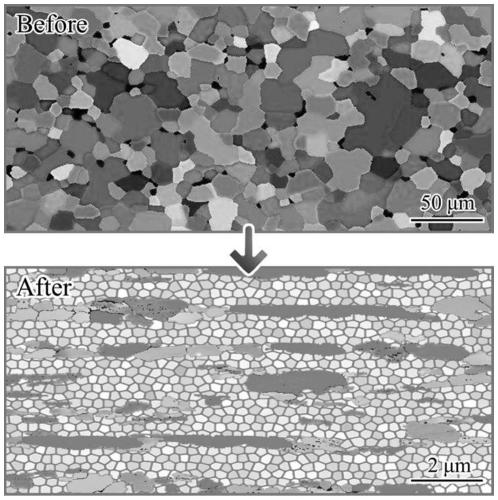

[0032] over the predetermined temperature range T 0 , annealing time t 0 and heating rate v 1 After solution treatment, the average grain size of the titanium plate in this example is about 20 μm, and the microstructure is uniform equiaxed coarse grain.

[0033] Step 103, performing mechanical grinding on the upper and lower surfaces of the solution-treated titanium plate, and processing the titanium plate t...

Embodiment 2

[0054] A GPa grade titanium with high uniform elongation is characterized in that: the volume fraction of the recrystallized lamellar structure in the titanium plate is 20-25%, and the volume fraction of the nanocrystalline matrix is 75-80%.

Embodiment 3

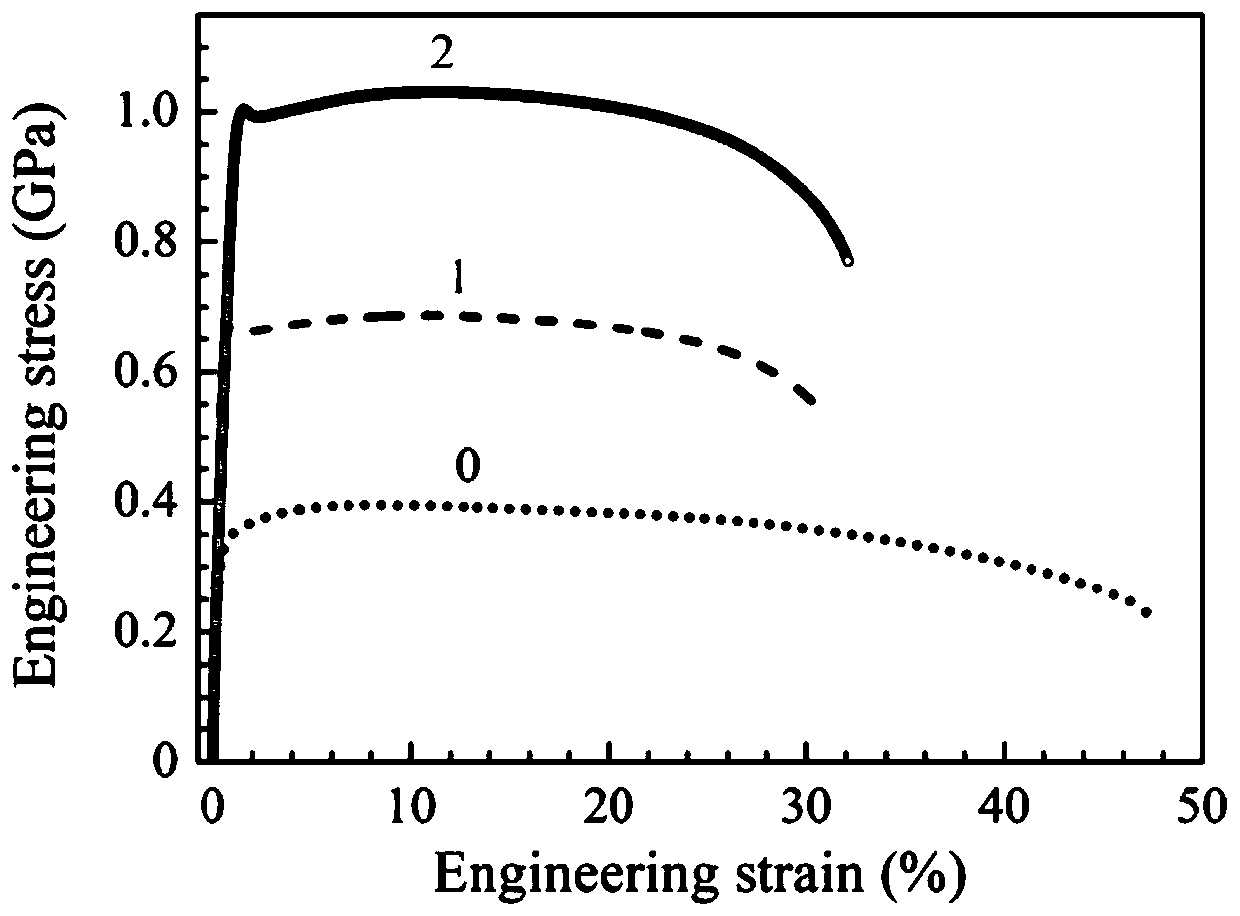

[0056] A high uniform elongation GPa grade titanium is characterized in that: the volume fraction of the recrystallized lamellar structure in the titanium plate is 20-25%, and the volume fraction of the nanocrystalline matrix is 75-80%; The distance between the recrystallized laminae is not more than 5 μm; the average grain size of the nanocrystalline matrix is less than 200 nm; the tensile yield strength of the titanium plate is 0.8-1.2 GPa, and the uniform elongation is ≥ 10%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| tensile yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com