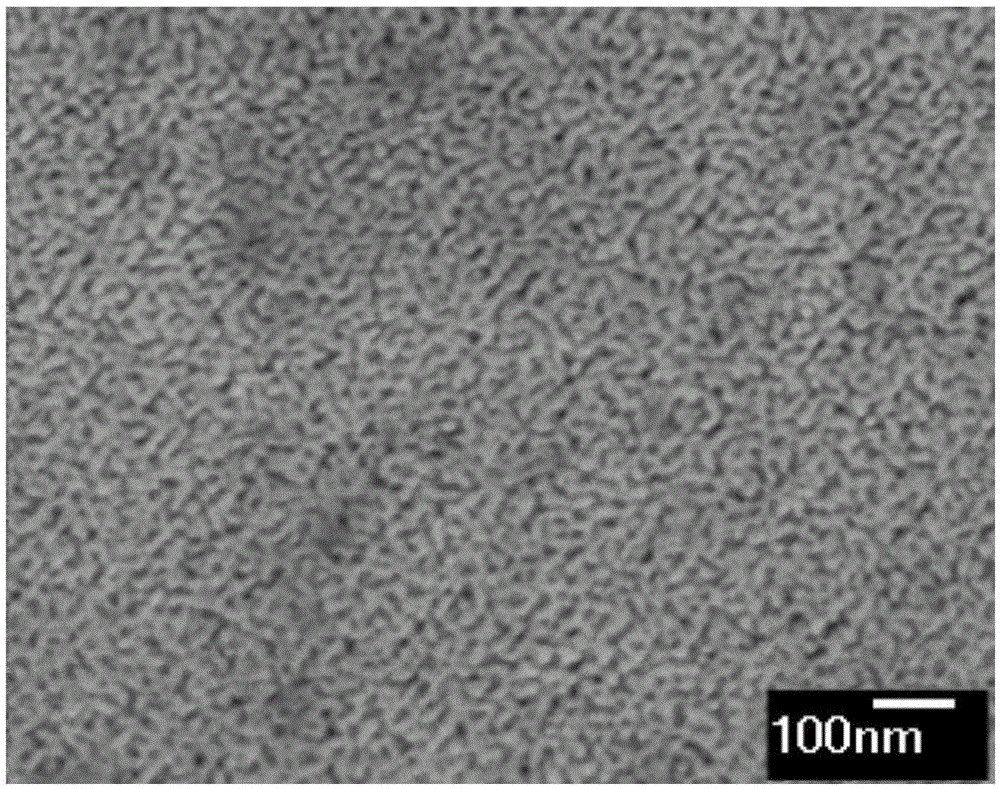

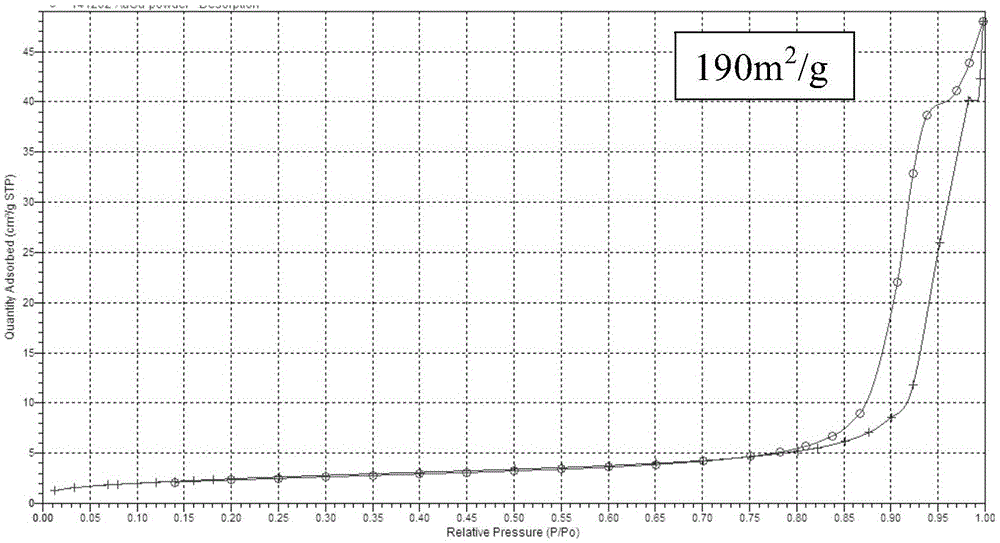

Preparation method of doped nanoporous gold (NPG) with small pore diameter and large specific surface area

A technology of large specific surface area and nanoporous gold, which is applied in the field of preparation of doped nanoporous gold, can solve the problems of prone to intergranular fracture, poor toughness of porous film, and hinder the practical application of nanoporous gold, so as to achieve easy structure control , low cost, high toughness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] In this embodiment, the preparation method of doped nanoporous gold with small pore diameter and large specific surface area includes the following steps:

[0036] Step 1. Clean the gold alloy foil with a thickness of 50 μm, a width of 10 mm, and a length of 30 mm and dry it for use; the gold alloy foil is Au-x binary alloy foil or Au-x-y ternary alloy Foil, the x is Ag, Cu, Al, Ni or Zn, and the y is Pt or Pd; this embodiment is preferably an Au-Ag binary alloy foil (nominal composition is Au-75Ag);

[0037] Step 2, mixing sodium lauryl sulfate and corrosive inorganic acid in a mass ratio of 0.05:100 to obtain a corrosive medium solution; the corrosive inorganic acid is perchloric acid with a concentration of 0.1mol / L;

[0038] Step 3: Put the gold alloy foil dried in step 1 into the corrosive medium solution described in step 2, use the gold alloy foil as the anode and the platinum sheet as the cathode, at a temperature of 40°C and a voltage of Electrochemical corros...

Embodiment 2

[0046] In this embodiment, the preparation method of doped nanoporous gold with small pore diameter and large specific surface area includes the following steps:

[0047] Step 1. Clean the gold alloy foil with a thickness of 90 μm, a width of 10 mm, and a length of 20 mm and dry it for use; the gold alloy foil is Au-x binary alloy foil or Au-x-y ternary alloy Foil material, said x is Ag, Cu, Al, Ni or Zn, said y is Pt or Pd; The gold alloy foil material preferred in this embodiment is Au-Cu binary alloy foil material (nominal composition is Au-75Cu );

[0048] Step 2, mixing sodium dodecylbenzenesulfonate and corrosive inorganic acid in a mass ratio of 0.5:100 to obtain a corrosive medium solution; the corrosive inorganic acid is nitric acid with a concentration of 3mol / L;

[0049] Step 3: Put the gold alloy foil dried in step 1 into the corrosive medium solution described in step 2, use the gold alloy foil as the anode and the platinum sheet as the cathode, at a temperature ...

Embodiment 3

[0057] In this embodiment, the preparation method of doped nanoporous gold with small pore diameter and large specific surface area includes the following steps:

[0058] Step 1. Clean the gold alloy foil with a thickness of 40 μm, a width of 8 mm, and a length of 20 mm and dry it for use; the gold alloy foil is an Au-x binary alloy foil or an Au-x-y ternary alloy Foil, the x is Ag, Cu, Al, Ni or Zn, and the y is Pt or Pd; the preferred gold alloy foil in this embodiment is Au-Al-Pt ternary alloy foil (nominal composition is Au -65Cu-5Pt);

[0059] Step 2, mixing sodium dodecylbenzenesulfonate and corrosive inorganic acid uniformly in a mass ratio of 0.05:100 to obtain a corrosive medium solution; the corrosive inorganic acid is sulfuric acid with a concentration of 10mol / L;

[0060] Step 3. Put the gold alloy foil dried in step 1 into the corrosive medium solution described in step 2, use the gold alloy foil as the anode and the platinum sheet as the cathode, at a temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com