Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

44results about How to "Improve lipophilic and hydrophobic properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lipophilic polyurethane sponge and preparation method thereof

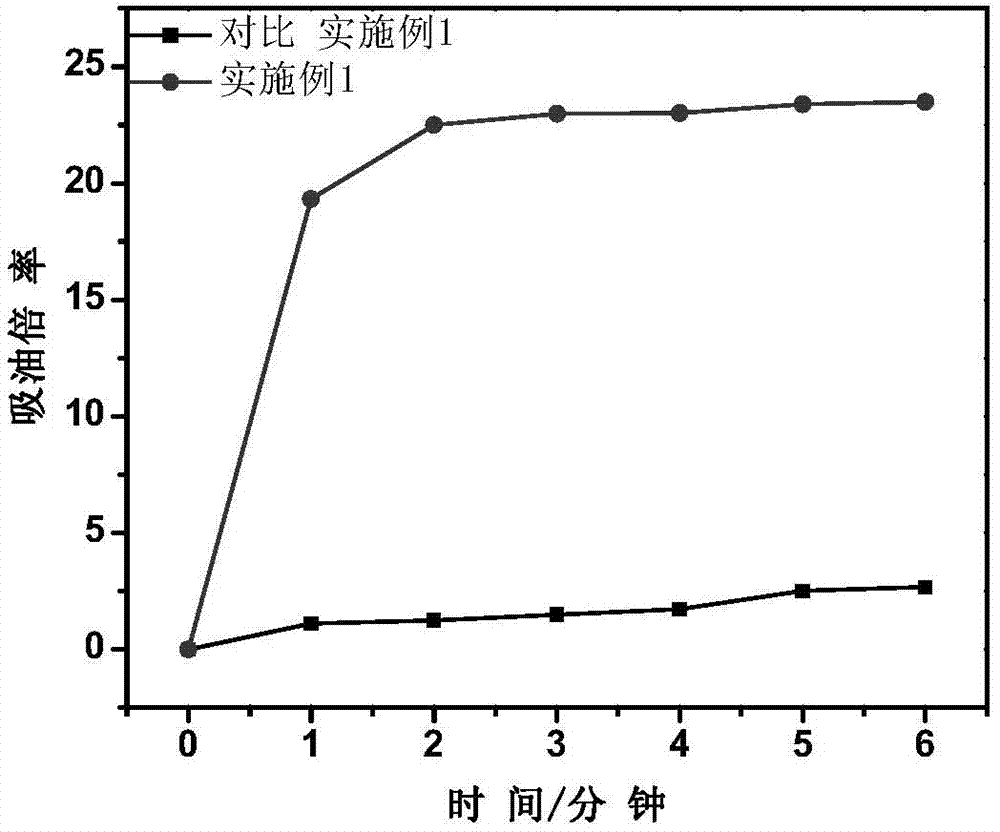

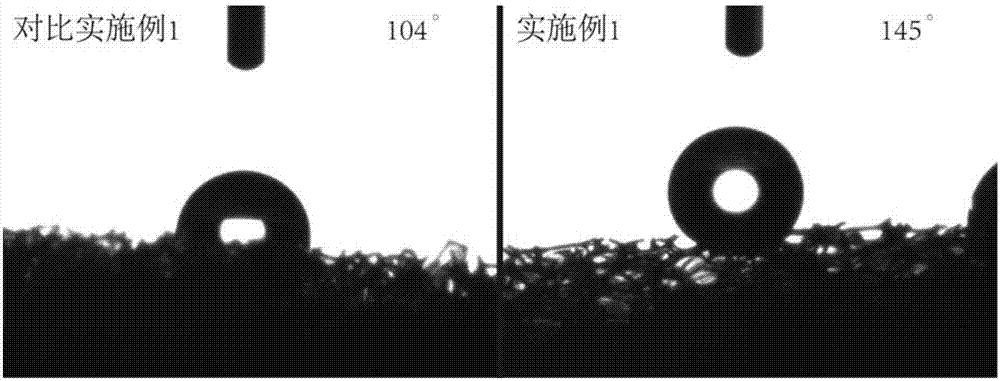

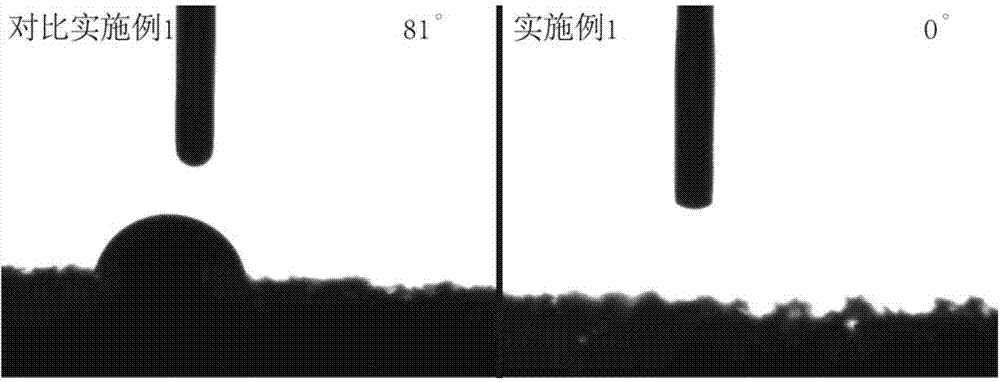

ActiveCN104725662AFast oil absorptionShorten the timeWater cleaningGeneral water supply conservationPollutionPolymer chemistry

The invention provides lipophilic polyurethane sponge and a preparation method thereof. The lipophilic polyurethane sponge is based on porous polyurethane sponge as a matrix, and the matrix is grafted with a hydrophilic oleophobic C-C long chain group. As a way for implementation, by reaction of the polyurethane sponge and a C-C long chain-containing acyl chloride compound, so that the polyurethane sponge can be grafted with a C-C long chain by bonding of chemical bonds of amino, hydroxyl and-C (O) Cl functional groups in polyurethane. Experiments confirm that the structure can greatly reduce the surface energy of the polyurethane sponge, greatly improves the oil absorption capacity, and is low in price, non-toxic and non-pollution, so that the lipophilic polyurethane sponge is a good oil adsorption material, and can be used to quickly and efficiently adsorb and recover crude oil and other substances in crude oil leakage and other situations.

Owner:SHANDONG OCEAN PIONEER NEW MATERIALS TECH CO LTD

Nadic anhydride surface modified calcium carbonate filler

ActiveCN103788411AImprove lipophilicity and hydrophobicityGood padding and reinforcementPigment treatment with macromolecular organic compoundsPigment treatment with organosilicon compoundsChemistryCalcium EDTA

The invention relates to calcium carbonate fillers and particularly relates to a nadic anhydride surface modified calcium carbonate filler. Modified calcium carbonate is prepared from the following raw materials in parts by weight: 200 parts of calcium carbonate, 1-2 parts of sorbitan aliphatic ester, 1-2 parts of silver nitrate, 5-6 parts of alums, 1-2 parts of silicon dioxide, 1-2 parts of calcium alginate, 3-4 parts of nano clay, 1-2 parts of nadic anhydride and 4-5 parts of an auxiliary agent. The modified calcium carbonate powder is obtained by carrying out modification treatment on the calcium carbonate raw materials including the nadic anhydride, the sorbitan aliphatic ester and the like; the performance indexes including oil absorption values, viscosity, the activating rate and the like of the obtained modified calcium carbonate powder are improved; the nadic anhydride surface modified calcium carbonate filler can be easily dispersed and dissolved in high-molecular polymers and the mechanical property of a PVC (Polyvinyl Chloride) material can be effectively improved; the toughening and reinforcing effects are realized.

Owner:安徽雪城超细碳酸钙有限公司

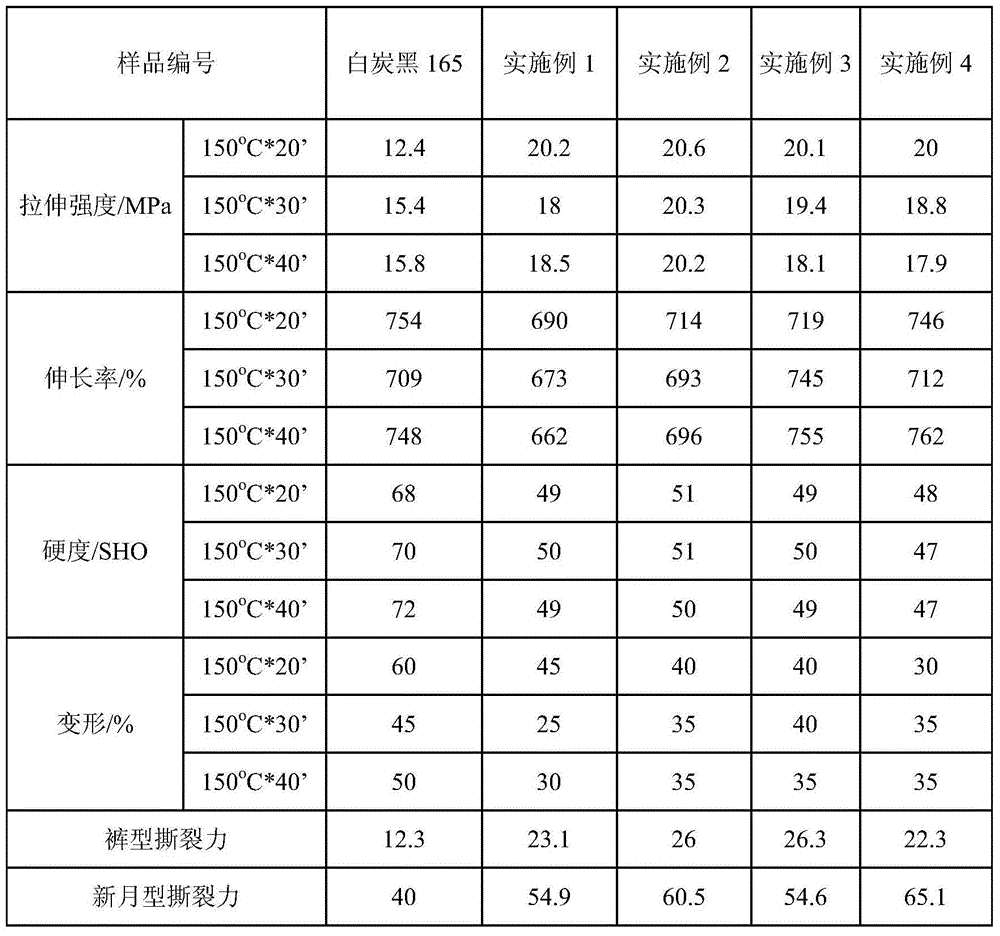

Preparation method for high-dispersion deposition white carbon black

ActiveCN105273442AImprove hydrophobicityImprove wear resistancePigment treatment with organosilicon compoundsRolling resistanceCoupling

The invention relates to a preparation method for white carbon black, and concretely relates to a preparation method for high-dispersion deposition white carbon black. A white carbon black suspension, an umbrella-shaped siloxane dispersant and a siloxane coupling agent containing sulfydryls or carbon-carbon double bonds are mixed, the pH value is adjusted to 2-7 after mixing, the mixture is heated to 30-79 DEG C and reacted for 1-6h, and high-dispersion deposition white carbon black is obtained. The umbrella-shaped siloxane dispersant and the white carbon black suspension are mixed at a mass ratio of 1:1-1:20. The siloxane coupling agent and the white carbon black suspension are mixed at a mass ratio of 1:1-1:20. The prepared white carbon black has superstrong hydrophobicity, the processing performance in subsequent preparation of rubber compounds can be raised effectively, dynamic mechanical properties of vulcanized rubber as tyre tread rubber can be improved effectively, the rolling resistance of tread rubber is lowered effectively, and the wear resistant performance of tread rubber is raised.

Owner:SHENYANG RES INST OF CHEM IND

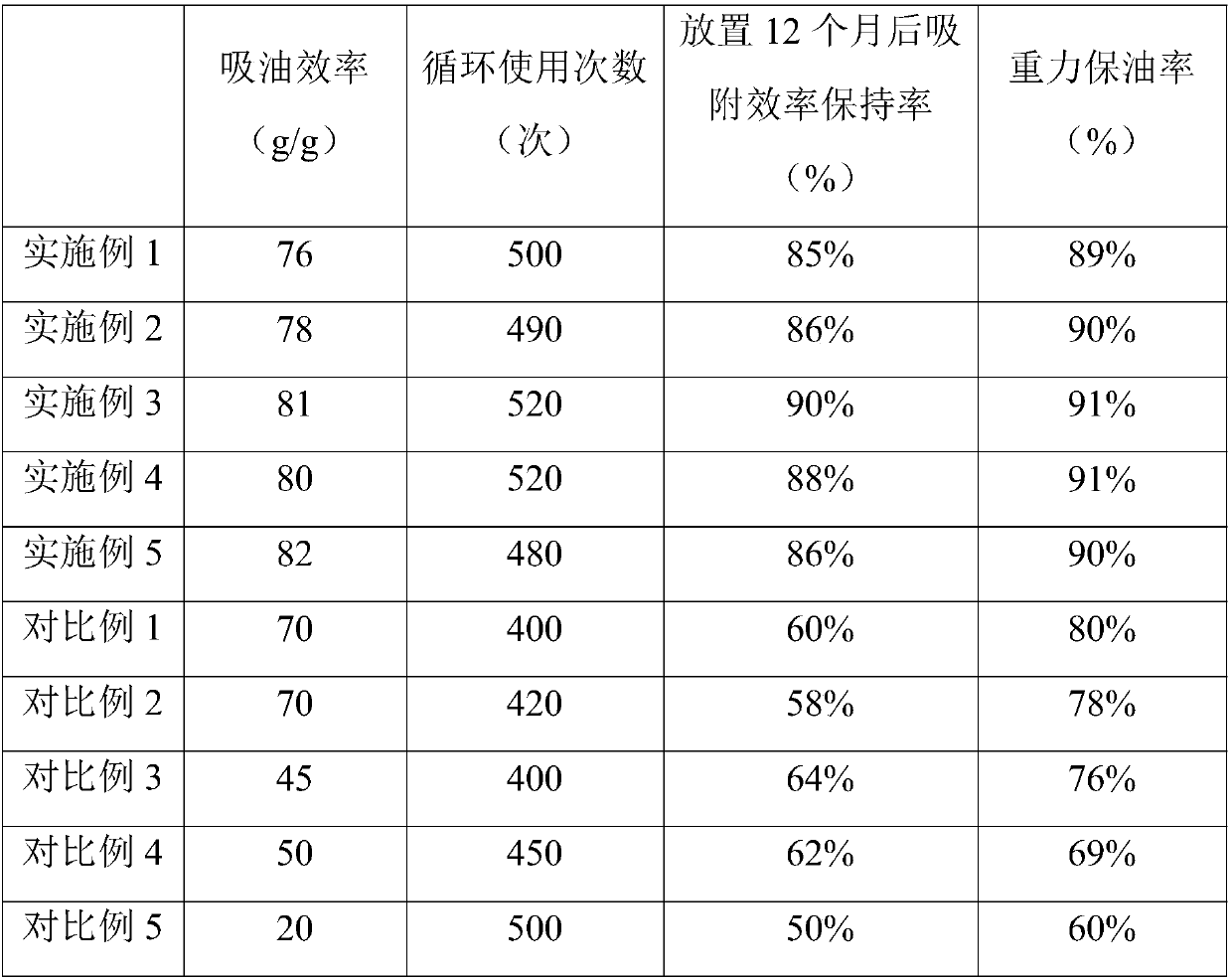

Oil absorption felt material with skin/core composite structure

InactiveCN104441854AImprove oil absorption capacityGood oil retentionSynthetic resin layered productsCleaning equipmentPolyesterNonwoven fabric

The invention relates to an oil absorption felt material with a skin / core composite structure. A compact non-woven material forms a skin layer, and a core layer material is composed of multilayers of loose non-woven materials. The skin layer material is a polypropylene melt-blown non-woven material with a gram weight of 15-50g / m<2>, the core layer material is a polypropylene / polyester mixed melt-blown non-woven material with a thickness of 3-5cm, the core layer material is coated by the skin layer material hermetically, and the periphery is sealed by means of hot pressing. For the oil absorption felt material, the skin layer material has high oleophylic and hydrophobic effects, when the oil absorption felt contacts oil, oil molecules can be led into the oil absorption felt inner core to be adsorbed by the inner core layer material, and water molecules cannot enter the core layer through the skin layer material, the core layer material can adsorb oil products with a self weight of 10-15 times, the oil products are sealed and stored in the oil absorption felt core layer and do not leak. The oil absorption felt provided by the invention has high oil absorption and oil holding performance.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

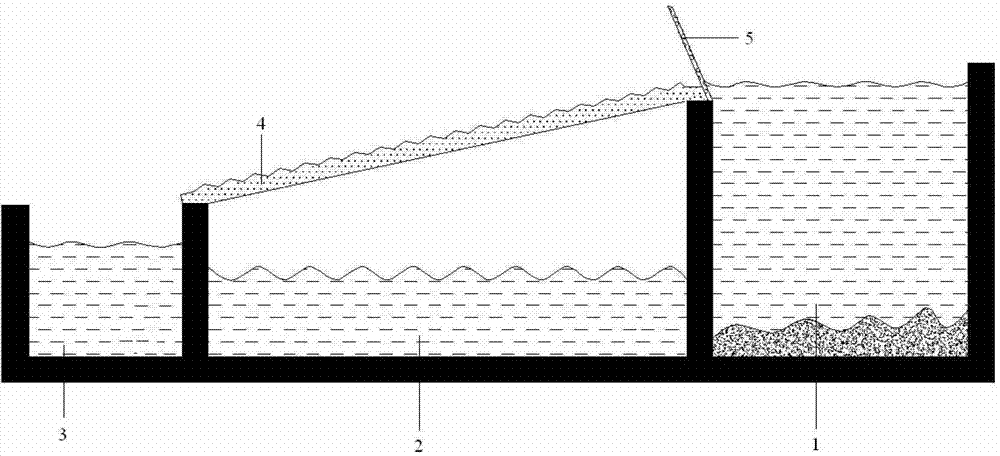

Oil-water separation system

ActiveCN103172137AAchieve separationLower surface energyFatty/oily/floating substances removal devicesLiquid separationWater storage tankFilm coating

The invention discloses an oil-water separation system. The oil-water separation system comprises an oil-water separation board, an oil storage tank and a water storage tank, wherein the oil-water separation board is arranged on the top of the oil storage tank and comprises an oleophylic and hydrophobic material; the oleophylic and hydrophobic material comprises aggregates and an oleophylic and hydrophobic resin film coating the aggregates, and the oleophylic and hydrophobic resin film is formed by modified resin from one or more of fluorine, silicon and sulfur; and the side wall, away from the water storage tank, of the oil storage tank is higher than the side wall, close to the water storage tank, of the oil storage tank; and the oil-water separation board covers the top of the oil storage tank and forms an included angle with a horizontal plane. According to the oil-water separation system, as comprising the oleophylic and hydrophobic material, the oil-water separation board has oleophylic and hydrophobic performance; and when oily sewage flows through the oil-water separation board, oil seeps into the oil storage tank through the oil-water separation board, and water flows away from the oil-water separation board, thus realizing oil-water separation.

Owner:BEIJING RECHSAND SCI & TECH GRP

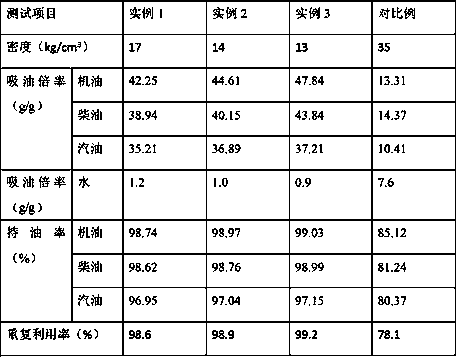

Preparation method of degradable oil absorbing material

InactiveCN108273480AImprove lipophilic and hydrophobic propertiesHigh porosityOther chemical processesLiquid separationCelluloseWax

The invention relates to the technical field of preparation of oil absorbing materials, and specifically relates to a preparation method of a degradable oil absorbing material. According to the preparation method, meerschaum and enteromorpha prolifera are used as raw materials to prepare activated stone slurry and purified algae cellulose, nanofiber is scattered in the activated stone slurry so asto obtain nanofiber sponge sizing agent, the purified algae cellulose and the nanofiber sponge sizing agent are mixed so as to obtain a dispersed sizing agent, and compound sponge fiber, poly dimethylsiloxane, liquid paraffin wax and other matters are mixed and put into a fermentation tank to be fermented and modified, so as to obtain the degradable oil absorbing material. The meerschaum fiber isadsorbed on the surface and in pores of the organic nanofiber, so that the oil absorbing quantity of the oil absorbing material is increased; the poly dimethylsiloxane and other oily matters generateoleophilic nonpolar radicals on the surface of the fiber sponge, so that the oleophilic and hydrophobic performance of the fiber sponge is enhanced; and the fiber materials and the stone slurry are easy to recycle and do not pollute the environment. The preparation method has a bright application prospect.

Owner:许水仙

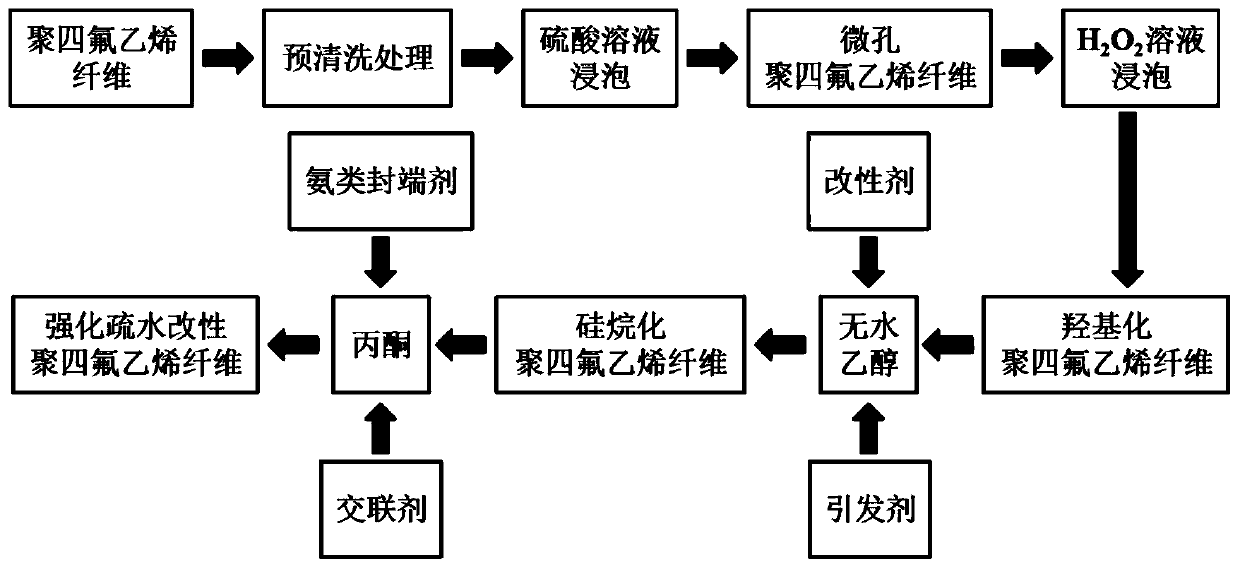

Modified polytetrafluoroethylene composite coalescent pack for oil-water mixed liquid separation

ActiveCN110935415AReduce interfacial energyImprove lipophilic and hydrophobic propertiesFatty/oily/floating substances removal devicesChemical/physical/physico-chemical processesPolymer chemistrySulfuric acid

The invention relates to a modified polytetrafluoroethylene composite coalescent pack for oil-water mixed liquid separation. Firstly, sulfuric acid solution soaking, hydroxylation modification, silanization modification and amination end-capping reaction are combined, and an initiator, a coupling agent and an end-capping agent are matched to carry out reinforced hydrophobic modification treatmenton polytetrafluoroethylene fibers; then, the modified polytetrafluoroethylene fibers and an odd number (n is equal to 3, 5, 7,...) of metal fibers are mixed and woven into a composite coalescent material fiber bundle in a tooth-shaped structure, and then the composite coalescent material fiber bundle is woven into meshed fibers in a cross-shaped staggered mode; and finally, the plurality of meshedfibers are combined in parallel to form the composite coalescent pack. According to the composite coalescent pack, through the interception effect of the cross-shaped interwoven net structure on micro-oil drops and the capture characteristic of the tooth-shaped woven reinforced hydrophobic modified polytetrafluoroethylene fibers on the micro-oil drops, the micro-oil drops in the oil-water mixed liquid can be efficiently removed.

Owner:EAST CHINA UNIV OF SCI & TECH

TPE/PVAC composite fresh-keeping box cover and preparation method thereof

InactiveCN107189321AImprove high temperature resistanceEnhanced couplingMagnesium saltTemperature resistance

The invention discloses a TPE / PVAC composite fresh-keeping box cover and a preparation method thereof. The preparation method comprises: 1) mixing a soluble aluminum salt, a soluble magnesium salt, a soluble zirconium salt, urea and water into a salt solution, and then carrying out hydrothermal reaction to obtain a hydrothermal product; 2) subjecting the hydrothermal product to ball milling in a silane coupling agent to obtain a modified hydrothermal product; and 3) subjecting TPE (thermoplastic elastomer), PVAC (polyvinyl acetate), talcum powder, stearic acid, paraffin oil, diisononyl phthalate, silica powder, the modified hydrothermal product and oleic acid to mixing, and performing molding so as to obtain the TPE / PVAC composite fresh-keeping box cover. The TPE / PVAC composite fresh-keeping box cover has excellent high-temperature resistance, and the preparation method also has the advantages of simple process and easily available raw materials.

Owner:ANHUI YUEERWEI PLASTIC MACHINE CO LTD

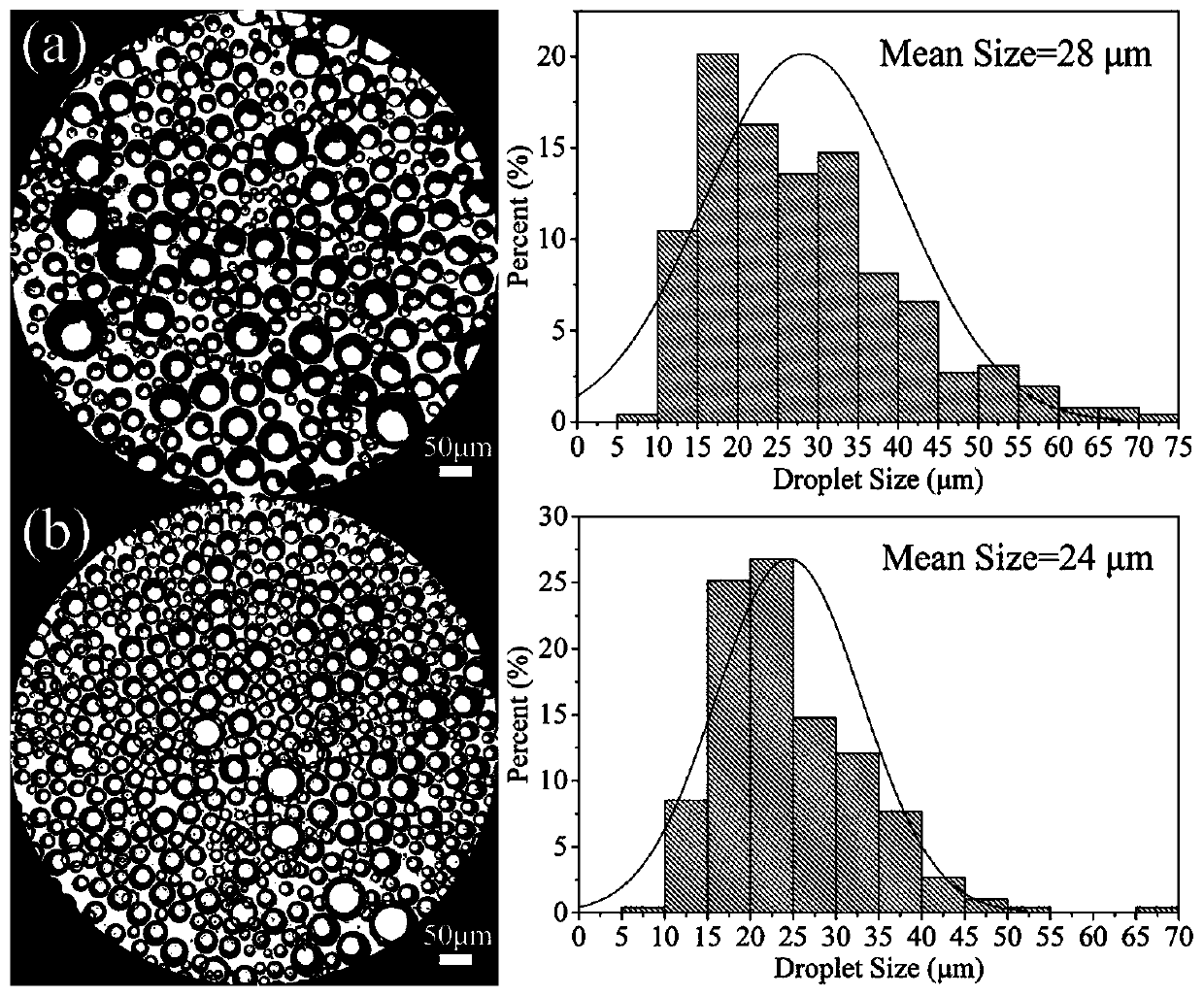

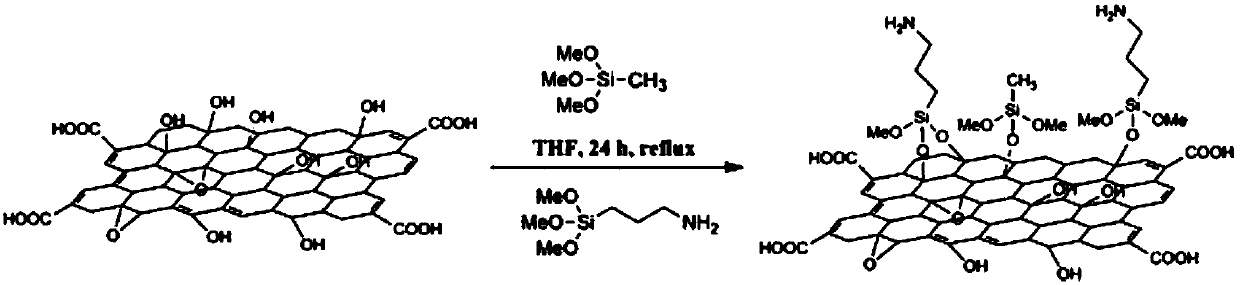

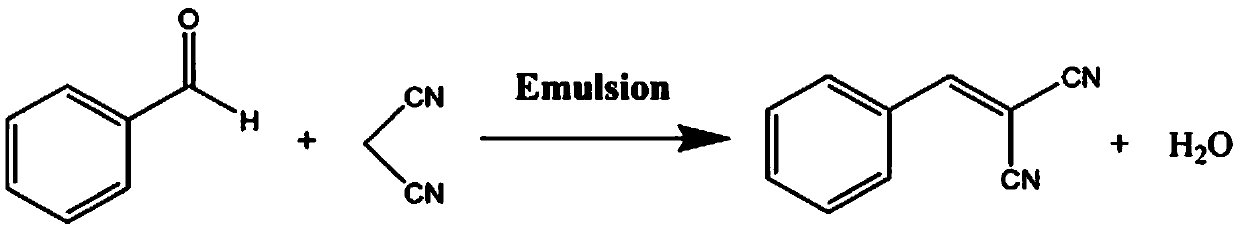

Preparation method of bifunctional Pickering emulsion catalyst

PendingCN111195528AHigh catalytic activityRegulating lipophilicity and hydrophobicityCarboxylic acid nitrile preparationOrganic compound preparationPolymer sciencePtru catalyst

The invention belongs to the field of chemical engineering, and relates to a preparation method of a bifunctional Pickering emulsion catalyst, which comprises the following steps of: carrying out ultrasonic treatment and mechanical stirring on a bifunctional graphene oxide material, benzaldehyde and water to prepare the bifunctional Pickering emulsion catalyst. The bifunctional graphene oxide (GO-NH2-Si) is prepared by simultaneously modifying graphene oxide (GO) by utilizing 3-aminopropyltrimethoxysilane (APTMS) and 3-methyltrimethoxysilane (MTMS). The preparation method of the Pickering emulsion catalyst is simple, the preparation cost is low, the catalytic activity is high, and compared with an emulsion catalyst prepared by only utilizing APTMS modified GO (GO-NH2) in the prior art, theconversion rate of benzaldehyde is increased by about 24% in a Knoevenagel reaction.

Owner:CHANGZHOU UNIV

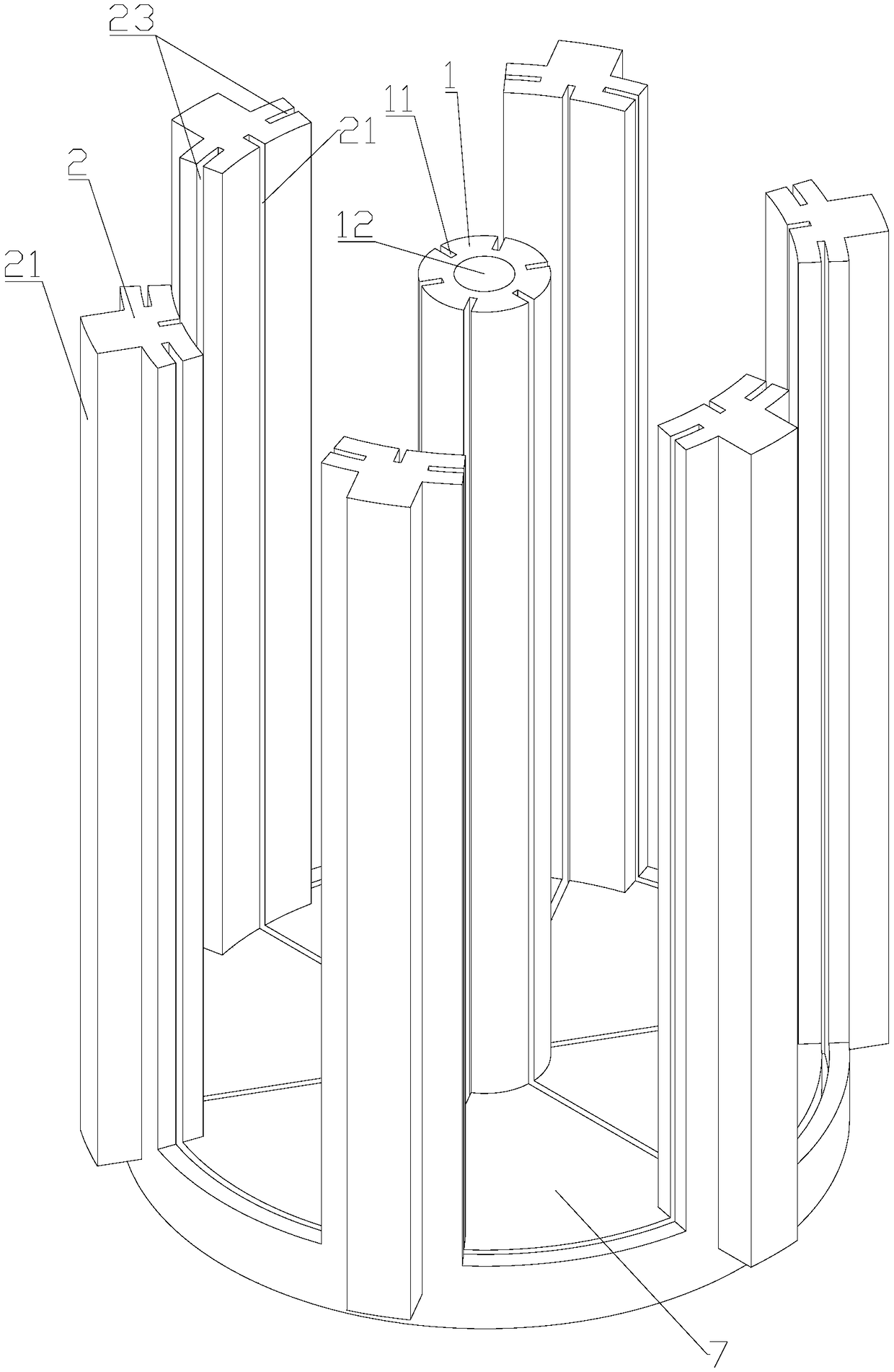

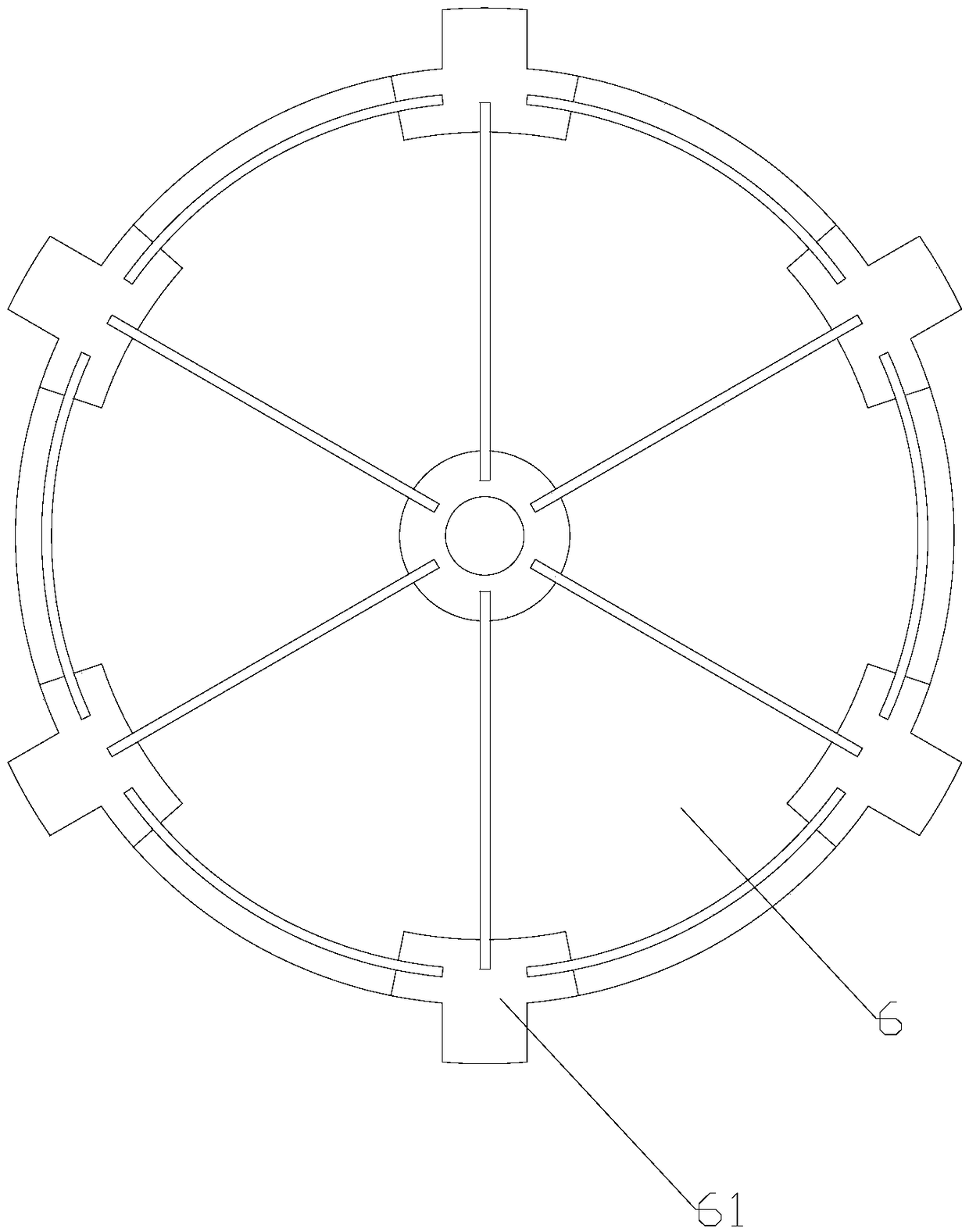

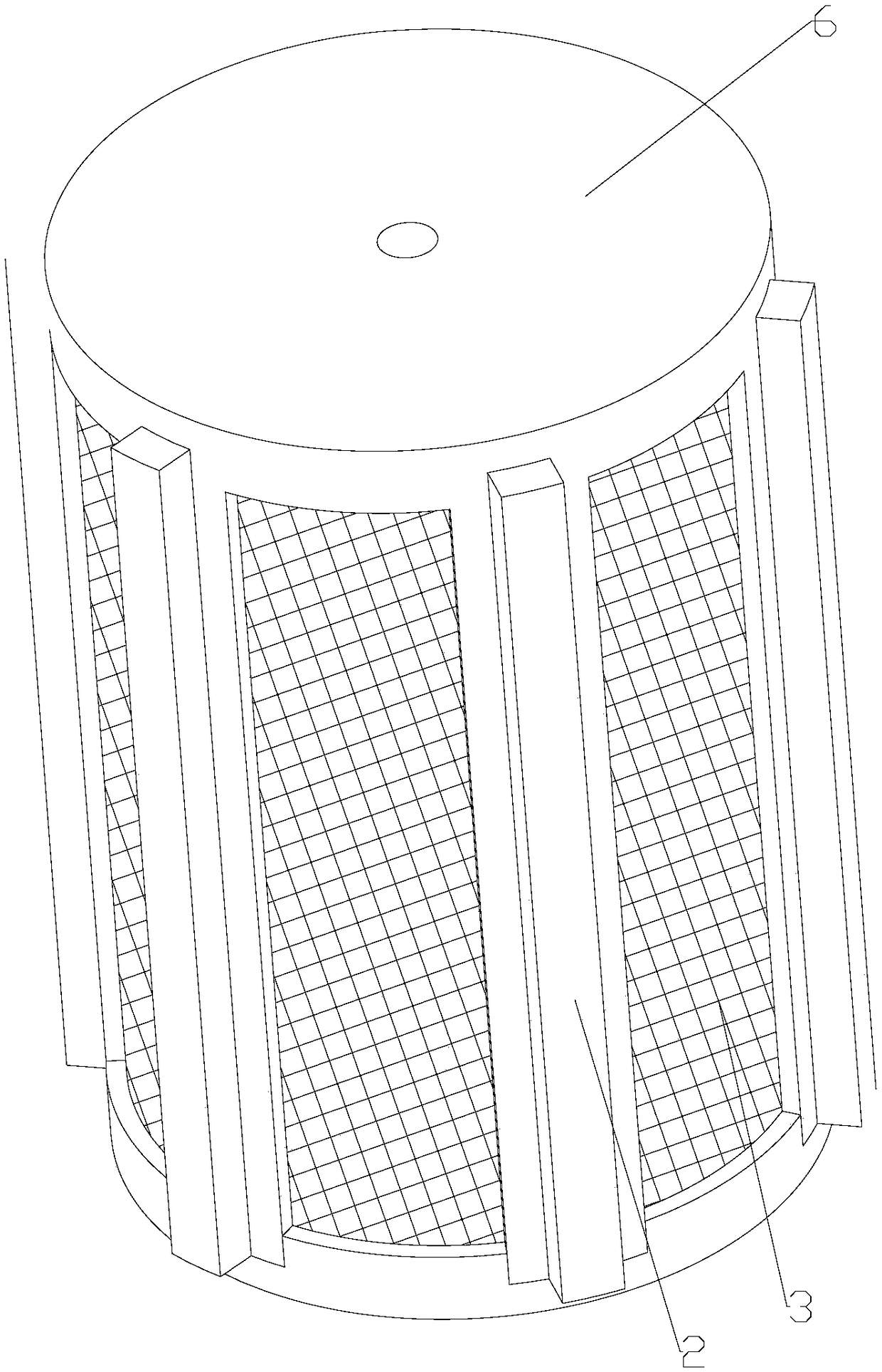

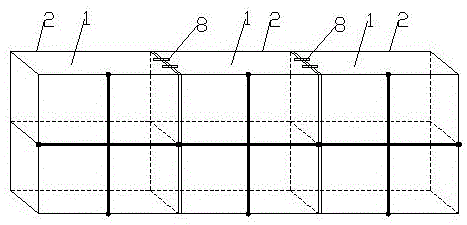

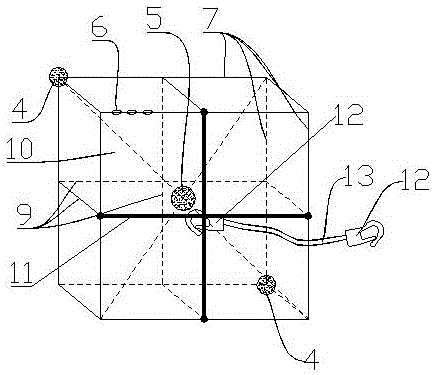

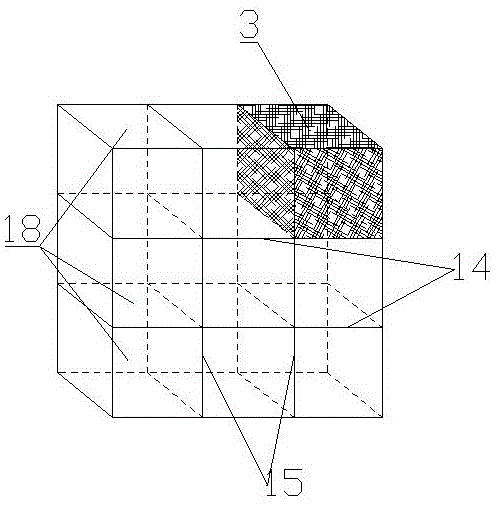

Overwater overflow-oil recovery device in rotatable roller boom form

PendingCN109183760AWith impact resistanceGood floatationWater cleaningGeneral water supply conservationEngineeringMechanical engineering

The invention relates to an overwater overflow-oil recovery device in a rotatable roller boom form. The device is made of lightweight materials and comprises a roller and oil absorption elements, wherein the roller comprises a stand column (1) fixedly or detachably arranged on the middle of a roller bottom (7), a plurality of wall bodies (2) fixedly or detachably arranged on the circumference of the roller bottom (7), and covers (6) detachably covering the stand column (1) and the wall bodies (2); a shaft hole (12) is formed in the stand column (1); a flexible shaft or a cable penetrates through the shaft hole; the roller bottom (7) and the covers (6) are provided with through holes corresponding to the shaft hole (12); the adjacent wall bodies (2) are connected through a grid-shaped arc pore plate (3); each wall body (2) and the stand column (1) are connected through a grid-shaped plane partition plate (4); the roller is internally divided into a plurality of divided spaces; the oil absorption elements are disposed in each divided space; and the oil absorption elements can freely rotate in the corresponding divided space.

Owner:孙娟

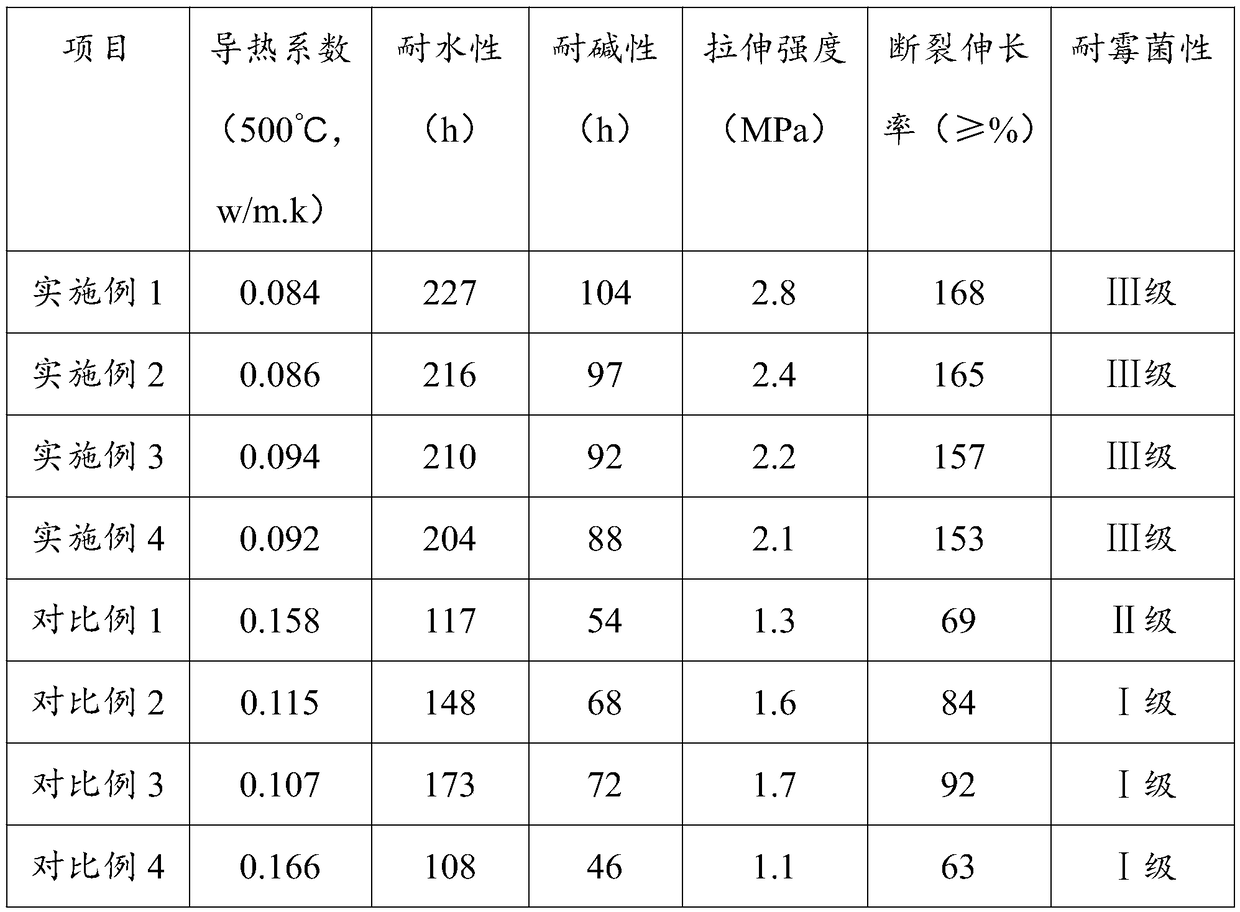

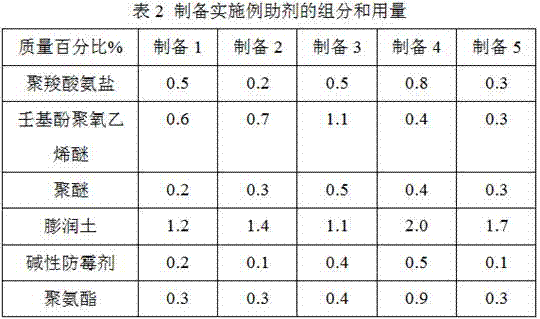

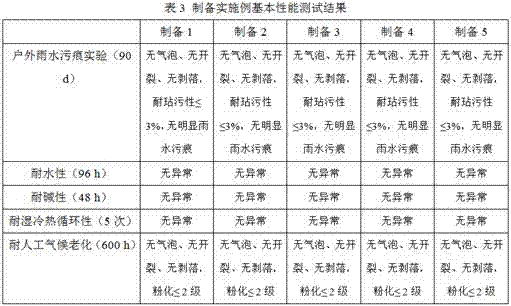

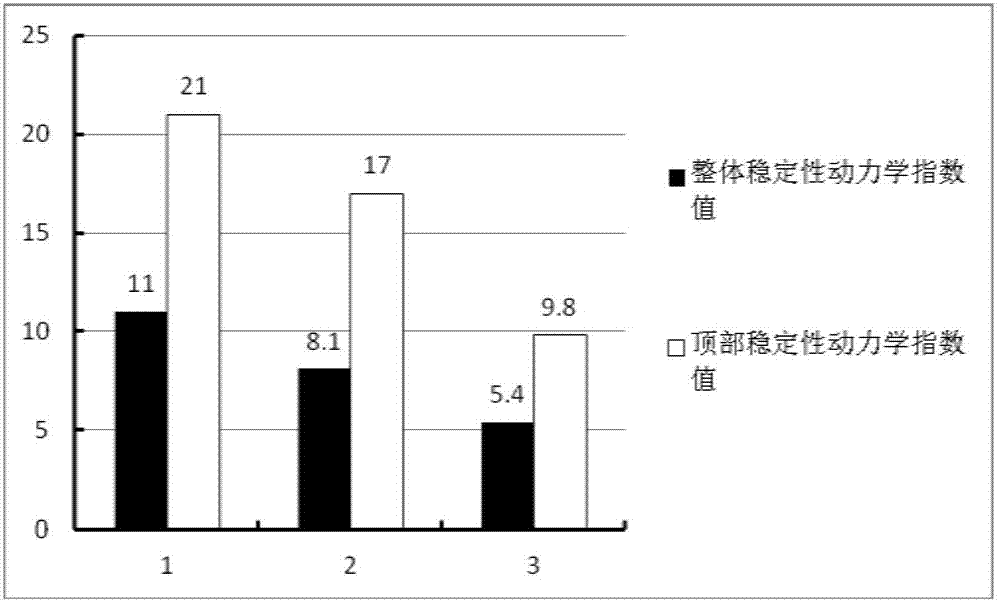

External wall panel insulating coating and preparation method thereof

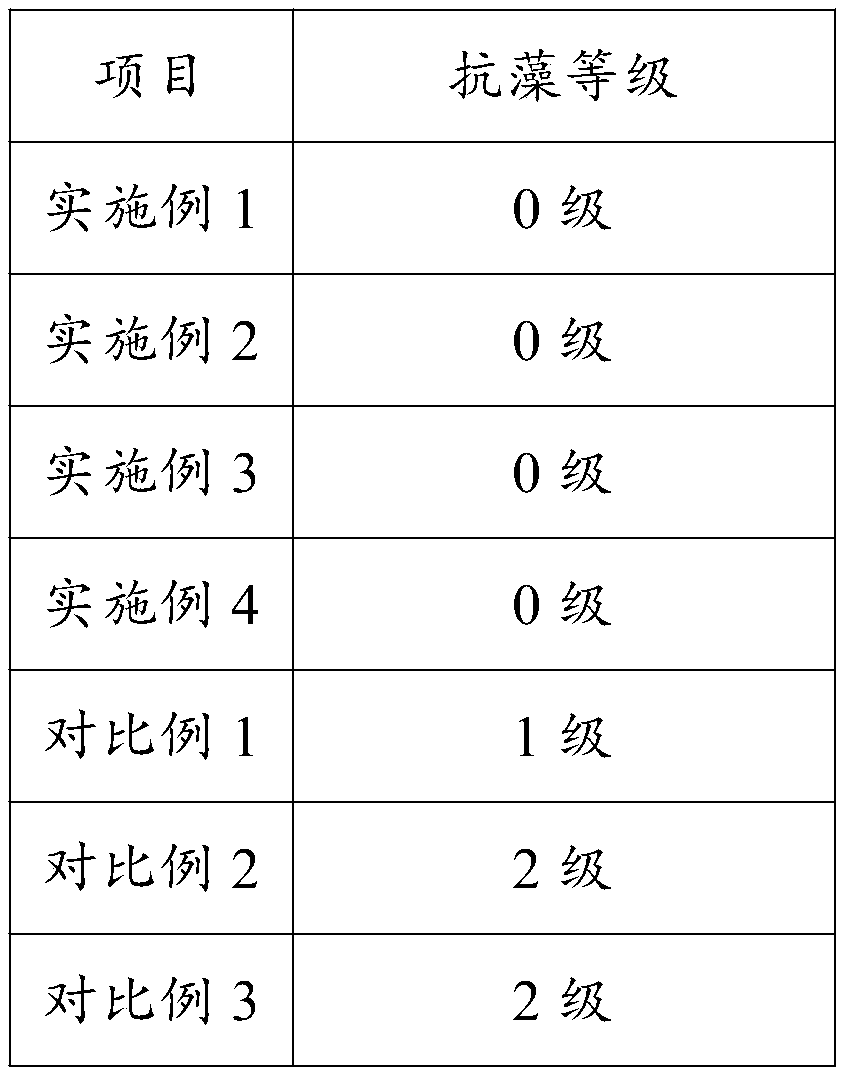

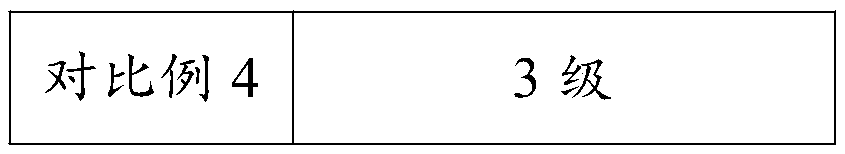

ActiveCN109233476AImprove hydrophobicityHigh tinting strengthAntifouling/underwater paintsPaints with biocidesSodium BentoniteMicrosphere

The invention discloses an external wall panel insulating coating and a preparation method of the insulating coating. The insulating coating comprises the following ingredients in parts by mass: 100-130 parts of vinyl chloride / vinyl acetate / acrylate copolymerization emulsion, 20-40 parts of silane coupling agent, 6-18 parts of rutile titanium dioxide, 5-10 parts of texanol, 3-7 parts of modified bentonite, 2-5 parts of nano antibacterial high polymer microsphere, 0.1-0.8 parts of curing agent, 0.6-1.3 parts of anti-alga agent and 40-70 parts of tetrahydrofuran. The preparation method comprisesthe steps of emulsion particle preparation, antibacterial and anti-alga mixed solution preparation, mixed emulsion preparation and insulating coating preparation. The external wall panel insulating coating has better hydrophobicity and chemical resistance, and good mold and alga growth inhibition performance after absorbing moisture, and a low heat conductivity coefficient and a heat insulating effect of the coating are kept.

Owner:浙江立盛新型墙体材料有限公司

Energy saving super hydrophobic colorful luminous latex paint for exterior walls and preparation method thereof

InactiveCN106905782ASimple componentsSuperhydrophobic stabilityAntifouling/underwater paintsLuminescent paintsEmulsionStearate

The invention relates to the technical field of hydrophobic paint for exterior walls, and discloses energy saving super hydrophobic colorful luminous latex paint for the exterior walls and a preparation method thereof. The energy saving super hydrophobic colorful luminous latex paint comprises the following components by mass: 30-50% of styrene acrylic emulsion, 1-15% of stearate, 1-5% of nano silica, 10-30% of a luminescent pigment, 1-5% of a coloring pigment, 3-5% of an assistant and 20-40% of water. The energy saving super hydrophobic colorful luminous latex paint has the advantages of low cost, simple preparation, stable ultra hydrophobic property, saving energy and environmental-friendliness.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION +1

Preparation method of hydrophobic heat-insulating aerogel mortar

InactiveCN110668753AIncreased pore surface areaImprove lipophilic and hydrophobic propertiesCeramicwareCelluloseFiber

The invention belongs to the technical field of preparation of building materials, and particularly relates to a preparation method of a hydrophobic heat-insulating aerogel mortar. Green algae and sepiolite are respectively used as raw materials to prepare dehydroxylated cellulose and an activated stone slurry, nanofibers are placed into the activated stone slurry and are processed to obtain a dispersed slurry, and composite sponge fibers, polydimethylsiloxane and liquid paraffin are mixed and fermented, and then are dried to obtain a hydrophobic aerogel powder. The sepiolite fibers are adsorbed on surfaces and in pores of the organic nanofibers to increase the pore surface area, and phosphoric acid molecules permeate into a petrochemical sponge slurry to dissolve out carbonate salts and break through interlayer and pore channel impurities in order to form high-density nano-pores, so the thermal insulation performance of the mortar is greatly improved; and blind holes and internal channels of the fiber sponge are opened by oily substances such as polydimethylsiloxane under the action of microorganisms in the fermentation modification process, so that the surface of the fiber spongeis roughened, the oleophylic and hydrophobic properties of the fiber sponge are improved, materials are saved, and the fiber sponge has a wide application prospect.

Owner:李滔

Oil absorption device for ocean oil contamination treatment

ActiveCN105113474AMeet timeliness requirementsImprove oil absorption efficiencyWater cleaningGeneral water supply conservationGraphite particleContamination

Disclosed is an oil absorption device for ocean oil contamination treatment. The oil absorption device comprises a plurality of oil absorption single bodies which are connected with one another through retaining rings. Each oil absorption single body comprises a single body outer framework and an oil absorption core bag placed in the single body outer framework. Expanded graphite particles are contained in each oil absorption core bag. Two balance weight devices are arranged at the symmetrical positions of the lowermost portion of each single body outer framework, and the specific value of the total weight of the two balance weight devices to the displacement of the corresponding oil absorption single body is 1:5 to 1:10. The oil absorption device works at the interface of water and oil all the time by adding the variable balance weight devices through buoyancy calculation; dynamic adsorption is formed by dragging a dragging rope, and the absorption speed is increased; through experimental determination, the oil absorption efficiency is improved by more than four times. The oil absorption device has the actual effects of being high in treatment speed and high in absorption cleanliness on ultrathin water surface spillage oil commonly happening to oil spillage treatment; meanwhile, the device has the advantages that stretching resistance and impact resistance are achieved and the device can be suspended.

Owner:孙勇

Super-hydrophobic transparent luminous latex coating for outer wall and preparation method thereof

InactiveCN106957567ASimple componentsTransparent appearanceAntifouling/underwater paintsLuminescent paintsEmulsionMetallurgy

The invention relates to the technical field of hydrophobic coating for an outer wall, and discloses a super-hydrophobic transparent luminous latex coating for an outer wall and a preparation method thereof. The coating is prepared from the following components in percentage by mass: 35-55 percent of styrene-acrylic emulsion, 10-30 percent of luminous pigment, 3-20 percent of stearate, 1-5 percent of nano-silicon dioxide, 3-5 percent of auxiliary and 20-30 percent of water. The super-hydrophobic transparent luminous latex coating for an outer wall has the advantages of low cost, simplicity in preparation and environmental protection, and can be applied in a large scale.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION +1

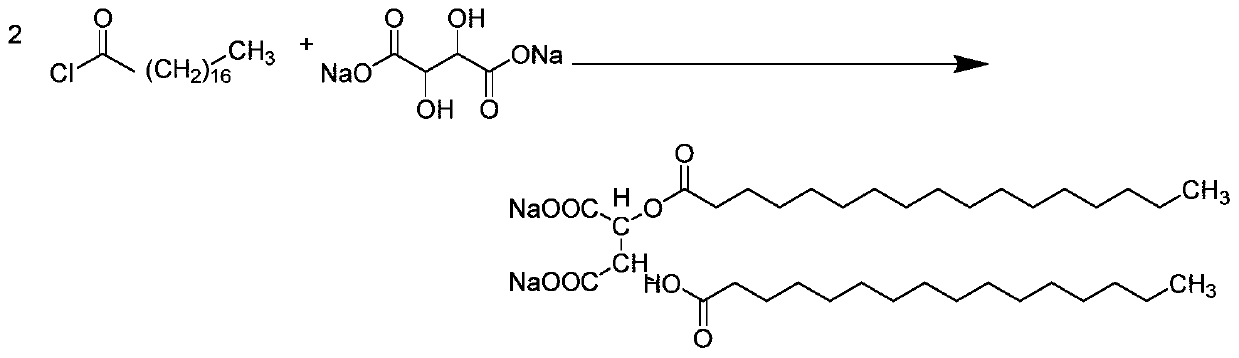

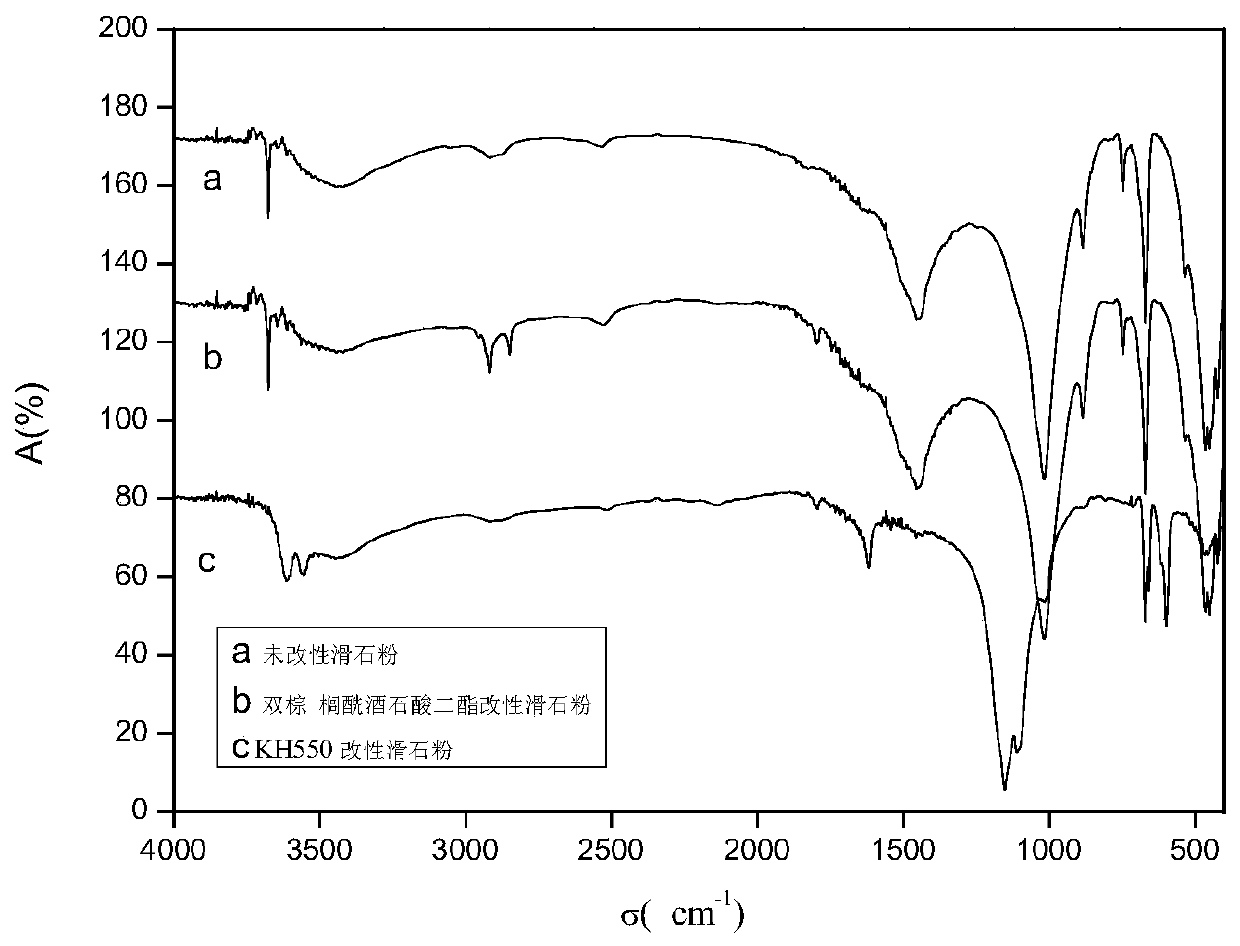

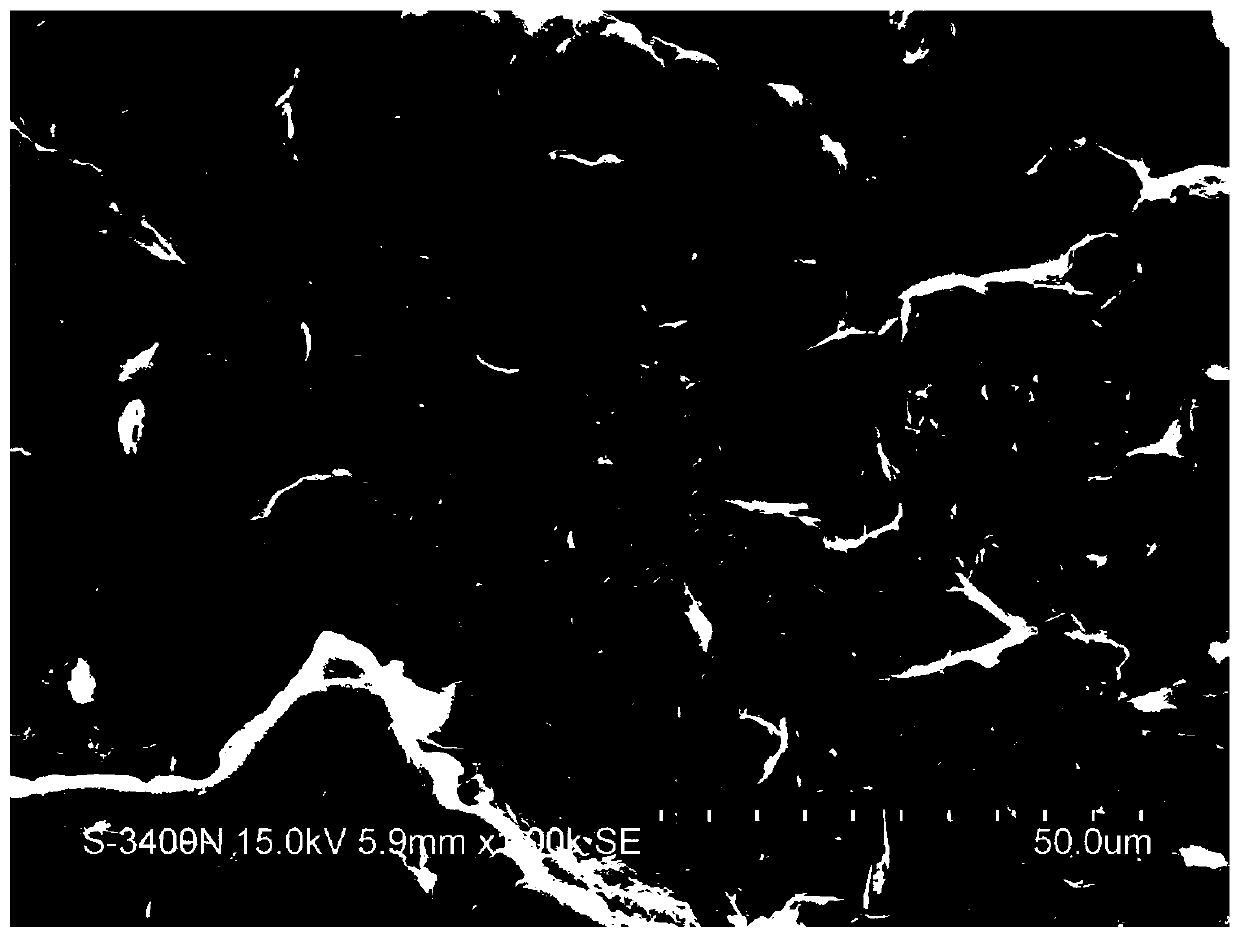

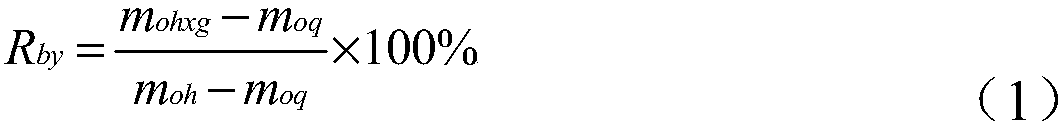

Preparation method of distearoyl sodium tartrate diester modified talcum powder and nylon composite material

ActiveCN110951245AImprove lipophilic and hydrophobic propertiesImprove surface propertiesPolymer scienceActive agent

The invention relates to a preparation method of a distearoyl sodium tartrate diester modified talcum powder and nylon composite material, and belongs to the field of composite materials. The preparation method comprises the following steps: firstly, skillfully selecting a dimeric surfactant consisting of a plurality of hydrophobic chains and a distearoyl sodium tartrate diester to modify talcum powder; then proportionally mixing the modified talcum powder with lactam or a diamine and a dibasic acid monomer, feeding an obtained mixture into a mold for casting molding by adopting an in-situ anionic free radical polymerization method, cooling and taking out the mold. The distearoyl sodium tartrate diester modified talcum powder and nylon composite material prepared by the method has the advantages of simple synthesis technique, higher component uniform dispersity and favorable compatibility, and has obvious performance in the aspects of mechanical properties and surface properties.

Owner:MITSUBISHI ELECTRIC CHINA CO LTD

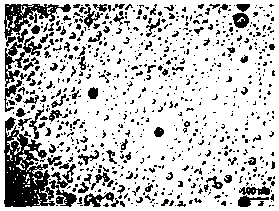

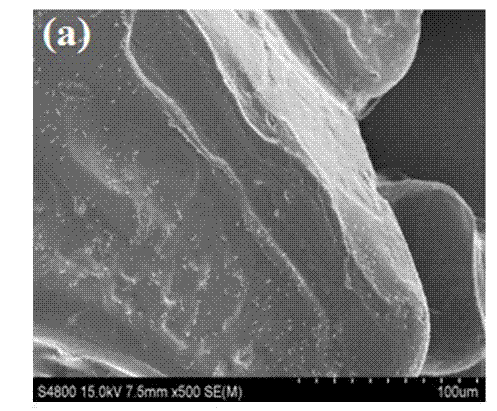

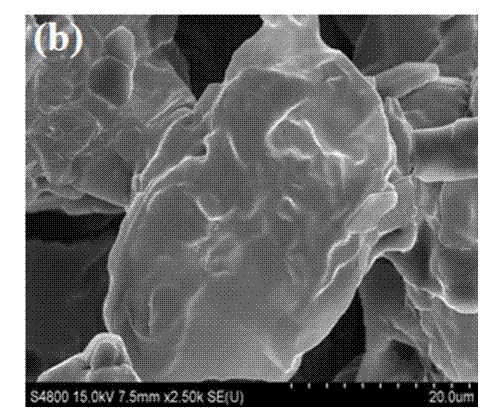

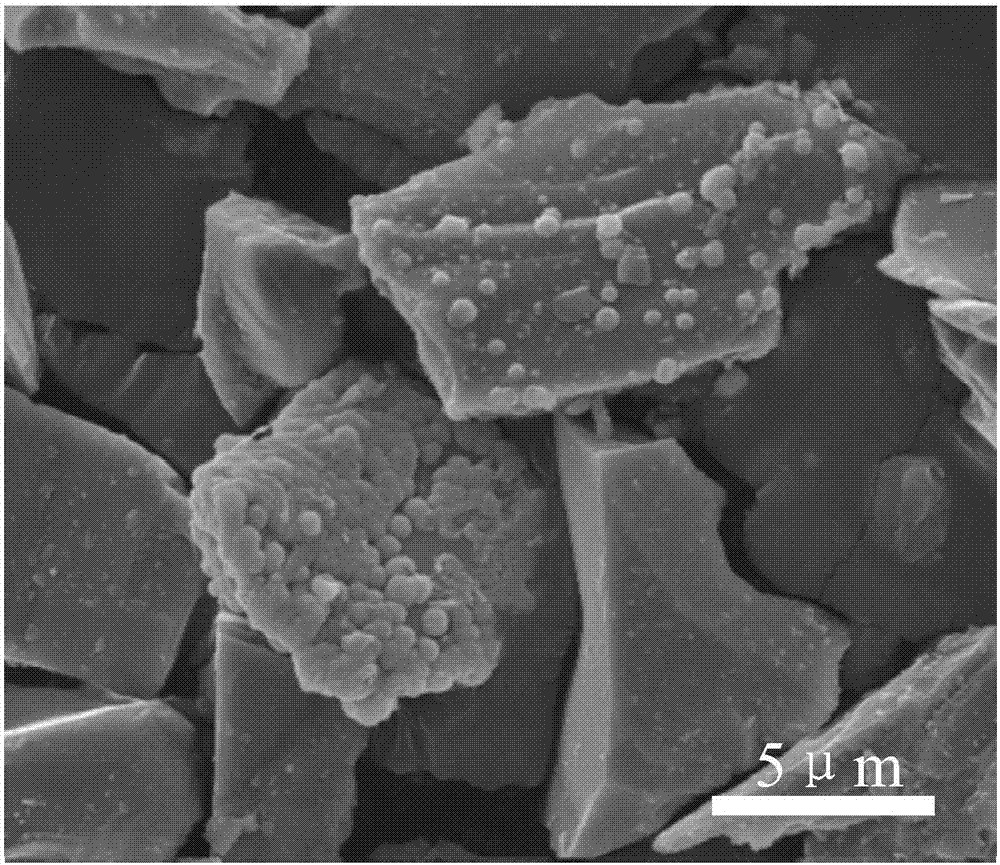

Porous nano composite oil absorption material, preparation method and application thereof, and oily water treatment device

InactiveCN110404294AImprove oil absorption efficiencyImprove oil absorption capacityLiquid separationNano structuringSewage treatment

The invention discloses a porous nano composite oil absorption material, a preparation method and application thereof, and an oily water treatment device, and relates to the technical field of oil absorption materials. The porous nano composite oil absorption material comprises a three-dimensional porous material substrate and nanomaterials distributed on the three-dimensional porous material substrate and provided with a one-dimensional nano structure array; and the porous nano composite oil absorption material is modified with hydrophobic substances. The preparation method of the porous nanocomposite oil absorption material includes the following steps that the nanomaterials with the one-dimensional nano structure array grow on the three-dimensional porous material substrate through a hydrothermal method so as to obtain a three-dimensional porous material-nanomaterial complex, and then the complex is subjected to hydrophobic modification to obtain the porous nano composite oil absorption material. The problems that existing oil absorption materials are low in oil absorption capacity and poor in oil reservation effect and cannot be recycled are relieved. The porous nano compositeoil absorption material can effectively absorb oil, is high in oil absorption capacity, can also adsorb heavy metal and organisms, and has the advantages of good oil reservation effect and cyclic utilization.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI +1

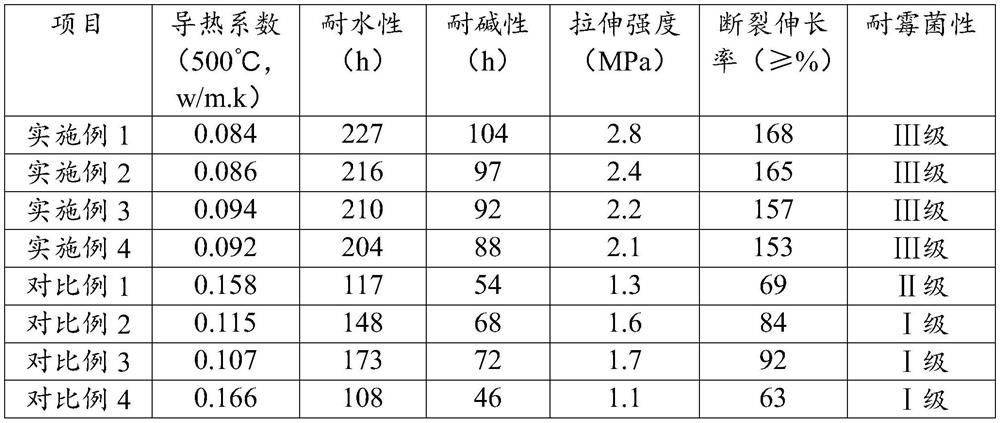

High-thermal-conductivity wear-resistant UPR/polyamide composite film and preparation method thereof

The invention discloses a high thermal conductivity wear resistant UPR / polyamide composite film and a preparation method thereof, the composite film comprises the following components by weight: 1%-8% of modified alumina (Al2O3), 10%-20% of unsaturated polyester (UPR), 0%-5% of a thermoplastic polymer, 20%-60% of polyamide, 2%-5% of a coupling agent, and other auxiliary agents. The preparation method specifically comprises the following steps: firstly, preparing and modifying Nano-ZrO2 / Al2O3, then preparing the URR composite material, and finally preparing the UPR / polyamide composite film. The method has the beneficial effects that the preparation process is simple, the yield is high, the maximum heat conductivity coefficient can reach 1.21 W / mK, the product validity period is long, the method can be applied to machine room outer wall film covering, and the prepared film is used for wall laying and is low in cost and good in heat conductivity and mechanical property.

Owner:南通金威复合材料有限公司

Method for carrying out oleophylic and hydrophobic modification on surface of water-soluble inorganic oxidant or inorganic salt

InactiveCN103613078AImprove lipophilic and hydrophobic propertiesPeroxyhydrates/peroxyacidsRare earth metal compoundsIonSolid phases

The invention discloses a method for carrying out oleophylic and hydrophobic modification on the surface of a water-soluble inorganic oxidant or inorganic salt, and belongs to the fields of materials, chemistry and chemical technology. The method comprises the following steps: firstly, adding methanol and propylene glycol into a deionized water solution of aluminium chloride, heating the obtained mixture until a reflux is formed, and after methanol is separated, carrying out vacuum drying on the obtained object so as to obtain an intermediate product; then, after oleic acid, n-butyl alcohol, n-hexylic acid and titanous sulfate are mixed to react, adding the intermediate product obtained in the step 1), and the water-soluble inorganic oxidant or inorganic salt into the obtained mixture to continue to react, after the reaction is completed, cooling the obtained object to room temperature, standing and separating the obtained object so as to obtain a solid phase, and then, drying the solid phase so as to obtain a modified water-soluble inorganic oxidant or inorganic salt. The method is adopted for carrying out oleophylic and hydrophobic modification on the surface of the water-soluble inorganic oxidant or inorganic salt, so that the storage stability of the water-soluble inorganic oxidant or inorganic salt in moist air and the particle dispersity of the water-soluble inorganic oxidant or inorganic salt in solutions are improved, therefore, the universality of the water-soluble inorganic oxidant or inorganic salt in industrialized applications can be further improved.

Owner:YANGZHOU UNIV

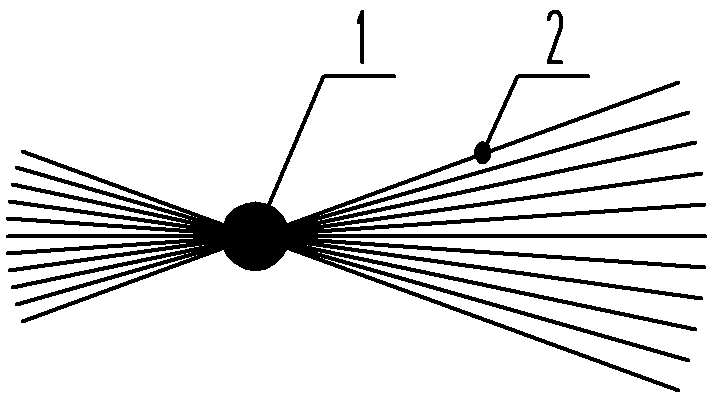

Preparation method of modified comet fiber filtering material

InactiveCN103394239ALarge specific surface areaIncrease elasticityFiltration separationPolyesterYarn

The invention relates to a preparation method of a modified comet fiber filtering material. According to the preparation method, polyester fiber raw material is spun into yarns, the polyester fiber yarns are bundled, the polyester fiber yarn bundles are subjected to injection molding and ball pressing and then cut off to obtain the modified comet fiber filtering material. The preparation method further comprises the following steps of: 1, stirring the mechanically processed modified comet fiber filtering material in a rinsing tank, then fishing out and draining water for later use; 2, uniformly stirring a chemical solution in a container and then conveying the prepared chemical solution into an autoclave, wherein the chemical solution comprises the following components in percentage by volume: 2vol% of viscose oil, 1.5vol% of silica gel oil and the balance of water; 3, putting the modified comet fiber filtering material in the autoclave, turning on a heating power supply for increasing temperature, cutting off the power supply when the temperature rises to 110 DEG C, keeping the pressure of 0.11-0.15MPa for 2-3 minutes, then adding cooling water to the autoclave to reduce the temperature to 50 DEG C, turning on an outlet valve so that the fiber filtering material subjected to modification chemical treatment and the chemical solution flow into another container at the same time; 4, fishing out the fiber filtering material subjected to modification chemical treatment, drying in a spin dryer, taking out of the spin dryer and air-drying to obtain the finished product.

Owner:HENAN LVYUAN WATER TREATMENT TECH

Waterproof coiled material with excellent low-temperature softness and preparation method thereof

InactiveCN108949053AImprove waterproof performanceGood low temperature flexibilityNon-macromolecular adhesive additivesFilm/foil adhesivesMulliteEthylene bis

The invention discloses a waterproof coiled material with excellent low-temperature softness. The waterproof coiled material comprises a basic blank layer and an asphalt self-binding layer, and the waterproof coiled material is characterized in that the asphalt self-binding layer is prepared from the following raw materials in parts by weight: asphalt, naphtha, mineral oil, polyisoprene, hydrogenated styrene-butadiene block copolymer, styrene-butadiene rubber, ethylene propylene diene terpolymer rubber, mullite, an anti-aging agent DNP and ethylene bis-stearmide. The invention also discloses apreparation method of the waterproof coiled material. The waterproof coiled material prepared by adopting a method disclosed by the invention has excellent waterproof performance and also has excellent low-temperature softness. According to the waterproof coiled material disclosed by the invention, through mutual cooperation among the polyisoprene, the mullite and the ethylene propylene diene terpolymer rubber, assisted with ultrasonic microwave combined treatment, the synergistic effect is achieved, the low-temperature softness performance of the waterproof coiled material can be effectivelyimproved, the phenomenon that embrittlement occurs under a lower temperature environment is effectively avoided, and the waterproof coiled material has abroad market prospects.

Owner:孙志成

Preparation method of modified comet fiber filtering material

The invention relates to a preparation method of a modified comet fiber filtering material. According to the preparation method, polyester fiber raw material is spun into yarns, the polyester fiber yarns are bundled, the polyester fiber yarn bundles are subjected to injection molding and ball pressing and then cut off to obtain the modified comet fiber filtering material. The preparation method further comprises the following steps of: 1, stirring the mechanically processed modified comet fiber filtering material in a rinsing tank, then fishing out and draining water for later use; 2, uniformly stirring a chemical solution in a container and then conveying the prepared chemical solution into an autoclave, wherein the chemical solution comprises the following components in percentage by volume: 2vol% of viscose oil, 1.5vol% of silica gel oil and the balance of water; 3, putting the modified comet fiber filtering material in the autoclave, turning on a heating power supply for increasing temperature, cutting off the power supply when the temperature rises to 110 DEG C, keeping the pressure of 0.11-0.15MPa for 2-3 minutes, then adding cooling water to the autoclave to reduce the temperature to 50 DEG C, turning on an outlet valve so that the fiber filtering material subjected to modification chemical treatment and the chemical solution flow into another container at the same time; 4, fishing out the fiber filtering material subjected to modification chemical treatment, drying in a spin dryer, taking out of the spin dryer and air-drying to obtain the finished product.

Owner:HENAN LVYUAN WATER TREATMENT TECH

TPE/PVB composite fresh keeping box cover and preparation method thereof

InactiveCN107353567AImprove high temperature resistanceEnhanced couplingPolyvinyl butyralMagnesium salt

The invention discloses a TPE / PVB composite fresh keeping box cover and a preparation method thereof. The preparation method comprises the following steps: (1) mixing soluble aluminum salts, soluble magnesium salts, soluble zirconium salts, urea, and water to prepare a salt solution, and then carrying out hydrothermal reactions to prepare a hydrothermal product; (2) adding the hydrothermal product into a silane coupling agent, and carrying out ball milling to obtain a modified hydrothermal product; and (3) mixing TPE (thermoplastic elastomer), PVB (polyvinyl butyral), kaolin, stearic acid, paraffin oil, diisononyl phthalate, silica powder, the modified hydrothermal product, and oleic acid, and carrying out moulding to obtain the TPE / PVB composite fresh keeping box cover. The TPE / PVB composite fresh keeping box cover has an excellent high temperature resistant performance; and the preparation method has the advantages of simple process and easily available raw materials.

Owner:ANHUI YUEERWEI PLASTIC MACHINE CO LTD

A kind of Nadic acid anhydride surface modified calcium carbonate filler

ActiveCN103788411BGood filling and reinforcing effectSimple production processPigment treatment with macromolecular organic compoundsPigment treatment with organosilicon compoundsPolyvinyl chloridePerformance index

The invention relates to calcium carbonate fillers and particularly relates to a nadic anhydride surface modified calcium carbonate filler. Modified calcium carbonate is prepared from the following raw materials in parts by weight: 200 parts of calcium carbonate, 1-2 parts of sorbitan aliphatic ester, 1-2 parts of silver nitrate, 5-6 parts of alums, 1-2 parts of silicon dioxide, 1-2 parts of calcium alginate, 3-4 parts of nano clay, 1-2 parts of nadic anhydride and 4-5 parts of an auxiliary agent. The modified calcium carbonate powder is obtained by carrying out modification treatment on the calcium carbonate raw materials including the nadic anhydride, the sorbitan aliphatic ester and the like; the performance indexes including oil absorption values, viscosity, the activating rate and the like of the obtained modified calcium carbonate powder are improved; the nadic anhydride surface modified calcium carbonate filler can be easily dispersed and dissolved in high-molecular polymers and the mechanical property of a PVC (Polyvinyl Chloride) material can be effectively improved; the toughening and reinforcing effects are realized.

Owner:安徽雪城超细碳酸钙有限公司

A kind of oil-water separation material and preparation method thereof

The invention discloses an oil-water separation material and a preparation method thereof. The oil-water separation material comprises aggregates and an oleophylic and hydrophobic resin film coating the aggregates, wherein the oleophylic and hydrophobic resin film is formed by one or more of fluorine, silicon and sulfur. The oil-water separation material has a micro-nano composite structure. The oil-water separation material further comprises an additive, wherein the grain diameter of the additive is 0.015-0.020 microns, and the mass ratio of the additive to the oleophylic and hydrophobic resin film is equal to (1-50):100; and the additive can be silica powder and / or alumina powder. The oil-water separation material has super-hydrophobic and super-oleophylic performance, and has a good oil-water separation effect; and the oil-water separation material is prepared by a reactive film coating technique, the binding strength between the aggregates and the resin film is high, and thus the resin film is less prone to falling in use.

Owner:BEIJING RECHSAND SCI & TECH GRP

A recovery treatment agent for lauric acid modified magnetorheological fluid and its preparation method

InactiveCN105884088BAccelerated settlementImprove lipophilic and hydrophobic propertiesWater treatment compoundsMagnetic liquidsPorosityMagnetorheological fluid

The invention discloses a recycling agent for a magnetorheological fluid modified by lauric acid and a preparation method for the recycling agent, and belongs to the technical field of recycling of the magnetorheological fluid. The recycling agent comprises the following components in parts by mass (based on 100 parts): 15-20 parts of corn cobs, 15-20 parts of peanut shells, 5-8 parts of sodium dodecyl benzene sulfonate and the balance of water. According to the recycling agent, hydroxyls contained on cellulose, hemicellulose and lignin of a biological material and carboxyl on lauric acid generate esterification reaction to form an alkyl chain in which an ester group is connected with lauric acid, so that the lipophilic-hydrophobic property is strengthened; due to the pore-forming effect of the recycling agent, micro pores of the biological material are further increased, and the porosity of the biological material is increased, therefore, main dispersion particles in the magnetorheological fluid settle; and moreover, due to the adsorption effect of the biological material, a surfactant and an additive are adsorbed, so that other components in the magnetorheological fluid are further separated, and the effect of treating waste with waste is achieved.

Owner:MAANSHAN FULAIYI ENVIRONMENT PROTECTION TECH CO LTD

TPE/PVAC composite fresh-keeping box cover and preparation method thereof

InactiveCN107189322AImprove high temperature resistanceEnhanced couplingMagnesium saltPolyvinyl chloride

The invention discloses a TPE / PVAC composite fresh-keeping box cover and a preparation method thereof. The preparation method comprises: 1) mixing a soluble aluminum salt, a soluble magnesium salt, a soluble zirconium salt, urea and water into a salt solution, and then carrying out hydrothermal reaction to obtain a hydrothermal product; 2) subjecting the hydrothermal product to ball milling in a silane coupling agent to obtain a modified hydrothermal product; and 3) subjecting TPE (thermoplastic elastomer), PVAC (polyvinyl acetate), bentonite, stearic acid, paraffin oil, diisononyl phthalate, silica powder, the modified hydrothermal product and oleic acid to mixing, and performing molding so as to obtain the TPE / PVAC composite fresh-keeping box cover. The TPE / PVAC composite fresh-keeping box cover has excellent high-temperature resistance, and the preparation method also has the advantages of simple process and easily available raw materials.

Owner:ANHUI YUEERWEI PLASTIC MACHINE CO LTD

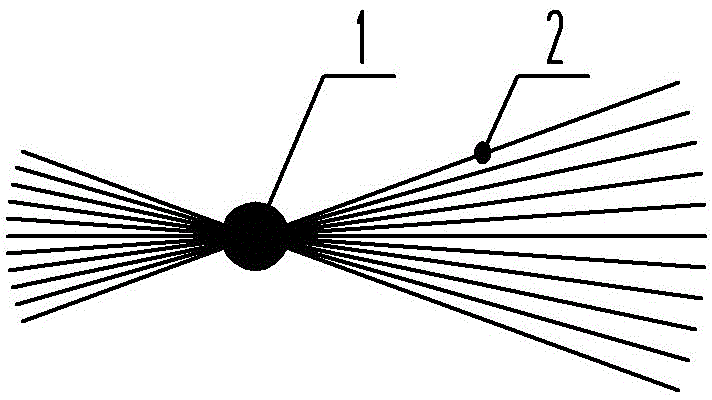

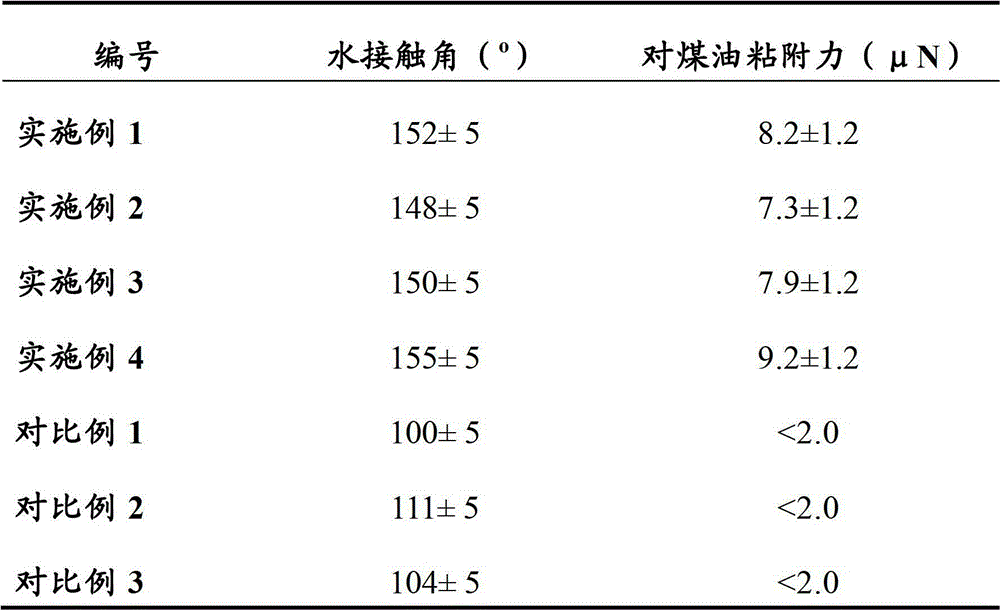

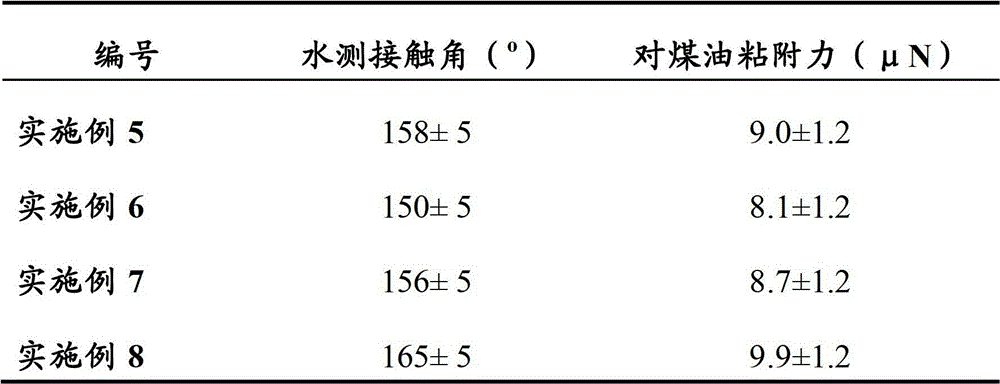

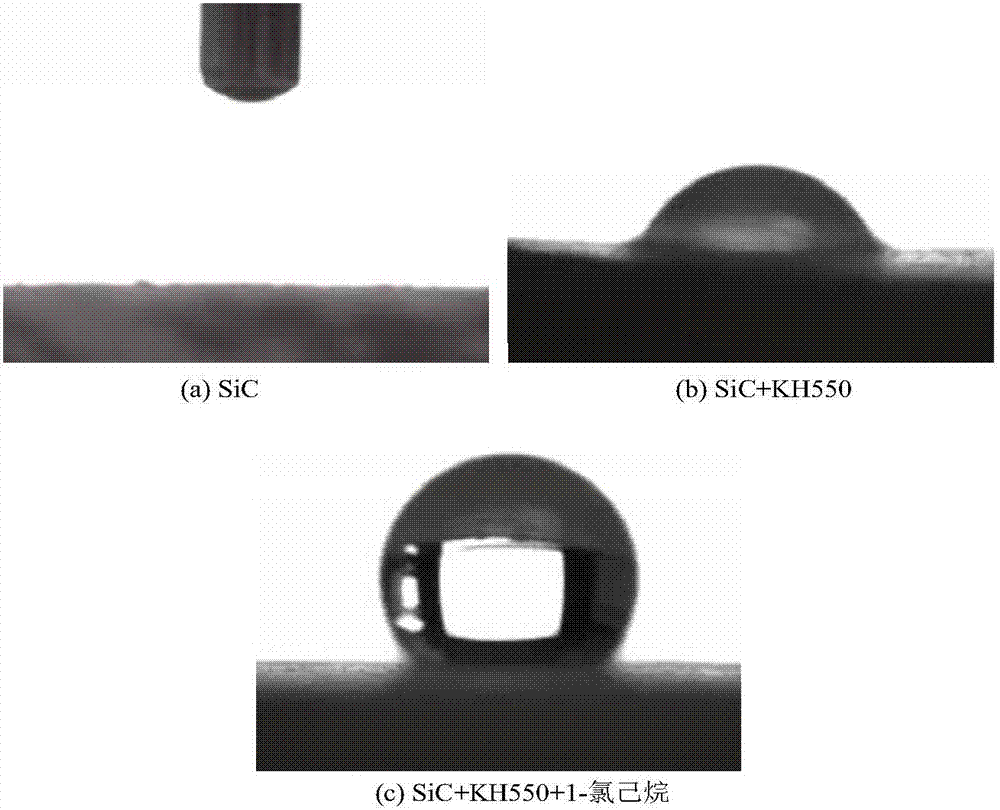

A kind of preparation method of surface-modified silicon carbide based on oil-based grinding and polishing liquid

InactiveCN105733311BReduce reunionImprove lipophilic and hydrophobic propertiesPigment treatment with organosilicon compoundsPolishing compositions with abrasivesCarbide siliconSurface reaction

The invention discloses a preparing method for surface modified silicon carbide based on an oil-based grinding and polishing agent.The preparing method includes the steps that silicon carbide is pretreated through acid pickling or alkali cleaning, surface impurities of micro powder are removed, and surface reaction activity is enhanced; a silane coupling agent is used for modifying silicon carbide particles preliminarily to improve surface hydrophobicity, and then halohydrocarbon is used for modifying the preliminary modified particles secondarily.By means of the surface hydrophobic modification technology, oleophylic hydrophobicity of the surface of the silicon carbide micro powder is effectively improved, the micro powder is dispersed in an oil-based medium better, particle aggregation is reduced, and oil-based silicon carbide suspension liquid high in suspension performance is prepared.

Owner:TIANJIN UNIV

A kind of preparation method of highly dispersed precipitated white carbon black

ActiveCN105273442BImprove hydrophobicityImprove wear resistancePigment treatment with organosilicon compoundsPolymer scienceRolling resistance

The invention relates to a preparation method of white carbon black, in particular to a preparation method of highly dispersed precipitated white carbon black. Mix silica suspension, umbrella-shaped siloxane dispersant and siloxane coupling agent containing mercapto or carbon-carbon double bond, adjust the pH value to 2-7 after mixing, heat to 30-79°C, and react 1 -6 hours to obtain the high-dispersion precipitated silica; wherein, umbrella-shaped siloxane dispersant and silica suspension are mixed in a ratio of 1:1-1:20 by mass ratio; siloxane coupling The agent and the silica suspension are also mixed in a mass ratio of 1:1-1:20. The white carbon black prepared by the present invention has super hydrophobicity, and can effectively improve the processing performance of the subsequent rubber compound, effectively improve the dynamic mechanical properties of the vulcanized rubber as tire tread rubber, and effectively reduce the The rolling resistance of the rubber improves the wear resistance of the tread rubber.

Owner:SHENYANG RES INST OF CHEM IND

A kind of thermal insulation coating of exterior wall board and preparation method thereof

ActiveCN109233476BImprove hydrophobicityHigh tinting strengthAntifouling/underwater paintsPaints with biocidesPolymer scienceMicrosphere

The invention discloses an external wall panel insulating coating and a preparation method of the insulating coating. The insulating coating comprises the following ingredients in parts by mass: 100-130 parts of vinyl chloride / vinyl acetate / acrylate copolymerization emulsion, 20-40 parts of silane coupling agent, 6-18 parts of rutile titanium dioxide, 5-10 parts of texanol, 3-7 parts of modified bentonite, 2-5 parts of nano antibacterial high polymer microsphere, 0.1-0.8 parts of curing agent, 0.6-1.3 parts of anti-alga agent and 40-70 parts of tetrahydrofuran. The preparation method comprisesthe steps of emulsion particle preparation, antibacterial and anti-alga mixed solution preparation, mixed emulsion preparation and insulating coating preparation. The external wall panel insulating coating has better hydrophobicity and chemical resistance, and good mold and alga growth inhibition performance after absorbing moisture, and a low heat conductivity coefficient and a heat insulating effect of the coating are kept.

Owner:浙江立盛新型墙体材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com