Oil absorption felt material with skin/core composite structure

A technology of composite structure and oil-absorbing felt, which can be used in household appliances, synthetic resin layered products, applications, etc., and can solve problems such as secondary pollution, oil leakage, and oil-absorbing performance of oil-absorbing felts.

Inactive Publication Date: 2015-03-25

BC P INC CHINA NAT PETROLEUM CORP +1

View PDF4 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] The existing polypropylene oil-absorbing felt products have good oil-absorbing performance, but generally have the defects of poor oil-holding performance and poor oil-water selectivity

When the oil-absorbing felt absorbs a lot of oil, when the oil-absorbing felt is dragged, transported and transferred, the oil is likely to leak from the oil-absorbing felt and cause secondary pollution

Polypropylene oil-absorbing felt products are used in the process of recovering floating oil on the water surface. If they are exposed to water for a long time, they will have a certain degree of water absorption, which will affect the oil-absorbing performance of the oil-absorbing felt.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

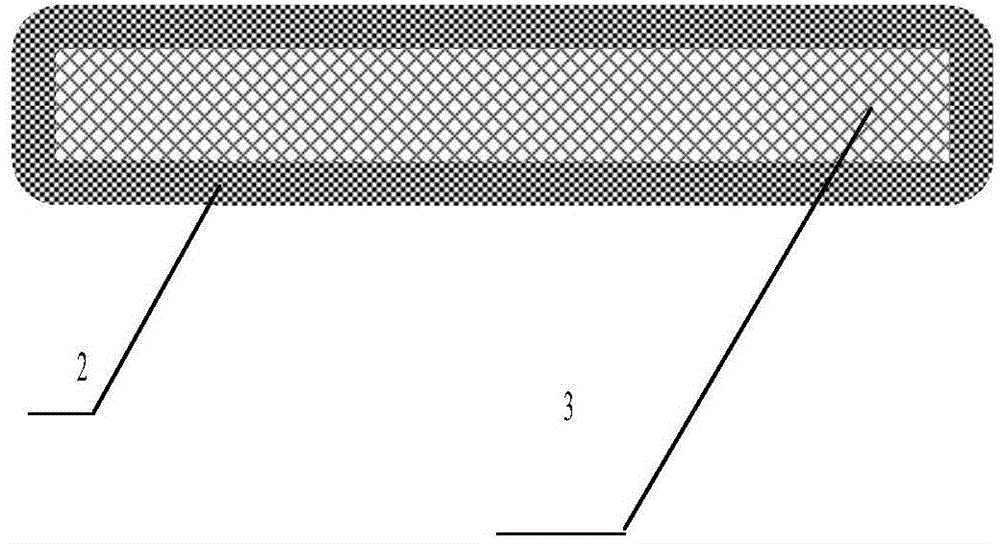

[0010] The present invention is the oil-absorbing felt with skin / core composite structure, comprises dense polypropylene fiber melt blown nonwoven fabric skin layer 2 material, loose polypropylene fiber / polyester fiber melt blown nonwoven fabric core layer 3 material. The cortex 2 material is coated on the outside of the core 3 material, and the cortex 2 material is sealed around by hot pressing.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Login to View More

Abstract

The invention relates to an oil absorption felt material with a skin / core composite structure. A compact non-woven material forms a skin layer, and a core layer material is composed of multilayers of loose non-woven materials. The skin layer material is a polypropylene melt-blown non-woven material with a gram weight of 15-50g / m<2>, the core layer material is a polypropylene / polyester mixed melt-blown non-woven material with a thickness of 3-5cm, the core layer material is coated by the skin layer material hermetically, and the periphery is sealed by means of hot pressing. For the oil absorption felt material, the skin layer material has high oleophylic and hydrophobic effects, when the oil absorption felt contacts oil, oil molecules can be led into the oil absorption felt inner core to be adsorbed by the inner core layer material, and water molecules cannot enter the core layer through the skin layer material, the core layer material can adsorb oil products with a self weight of 10-15 times, the oil products are sealed and stored in the oil absorption felt core layer and do not leak. The oil absorption felt provided by the invention has high oil absorption and oil holding performance.

Description

technical field [0001] The invention relates to an oil-absorbing felt material with a skin / core composite structure for absorbing floating oil on the water surface. Background technique [0002] In recent years, environmental and water resource pollution caused by leakage of toxic organic liquids and crude oil has become a major concern at home and abroad. After a leakage accident occurs on the water surface, a large amount of organic matter will spread on the water surface and form a dense oil film, which will sharply reduce the oxygen content in the water, causing plankton, fish, shrimp and other organisms to suffocate and die due to lack of oxygen, resulting in severe environmental and biological disasters. In 1989, the Exxon Vadez oil tanker leaked 11 million gallons of crude oil. Twenty years later, the coast of Alaska, USA is still covered with a large amount of oil; the oil spill in the Gulf of Mexico in 2010 shocked the whole world. The benzene factory exploded, an...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B32B27/02B32B27/08B32B27/32B32B27/36

CPCB32B3/04B32B5/08B32B5/26B32B2262/0253B32B2262/0276B32B2262/14B32B2432/00

Inventor 裴玉起魏俊富刘牧张环储胜利李绍宁栾国华周翔宇齐智

Owner BC P INC CHINA NAT PETROLEUM CORP

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com