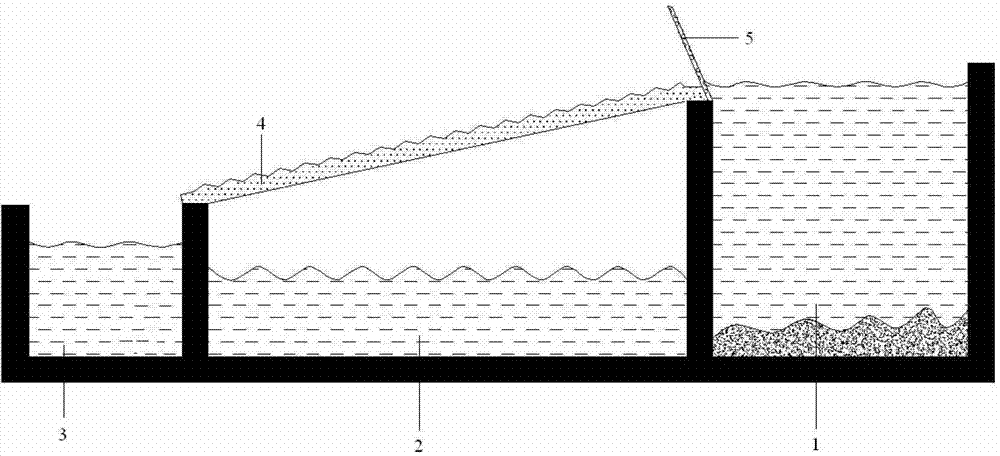

Oil-water separation system

An oil-water separation and lipophilic technology, applied in the field of water treatment, can solve problems such as poor separation effect of oil-water separation devices, and achieve the effects of improving oil-water separation effect, enhancing lipophilic and hydrophobic properties, and prolonging residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

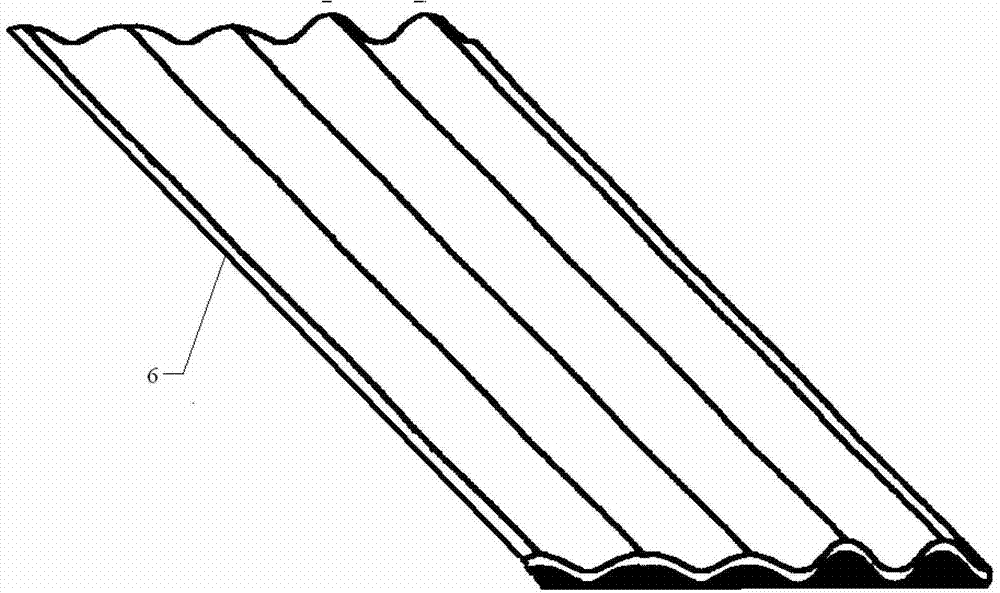

Method used

Image

Examples

Embodiment 1

[0051] Add 100g of quartz sand with a particle size of 0.074-0.085mm into the sand mixer and stir, then add 10g of fluorine-modified epoxy resin to the quartz sand and stir evenly to form a mixture, so that the fluorine-modified epoxy resin is mixed with the quartz sand Cover the surface with a film, then add 0.1g of silicon micropowder with a particle size of 0.015-0.020 microns, and stir evenly to make the silicon micropowder adhere to the fluorine-modified epoxy resin, then add 7g of curing agent phenalkamine and stir evenly to promote fluorine For the curing of the modified epoxy resin, add 2g of dispersant paraffin before the above-mentioned mixture is agglomerated and continue to stir to reduce adhesion. After the normal temperature curing is complete, the obtained mixture is crushed and sieved to obtain coated particles, and the coated particles are calcined at 400-600°C for 2 minutes to form a micro-nano composite structure on the surface of the coated particles to obta...

Embodiment 2

[0053] Add 100g of ceramsite with a particle size of 0.085-1.18mm to the sand mixer and stir, then add 1g of silicon-modified epoxy resin to the quartz sand and stir evenly to form a mixture, so that the silicon-modified epoxy resin is mixed with the ceramsite Surface coating, then add 0.4g of alumina powder with a particle size of 0.015-0.020 microns, and stir evenly to make the alumina powder adhere to the silicon-modified epoxy resin, then add 0.5g of curing agent cycloaliphatic amine and stir evenly , to promote the curing of silicon-modified epoxy resin, add 0.5g of dispersant calcium-based grease before the above-mentioned mixture is agglomerated and continue to stir to reduce adhesion. After the normal temperature curing is complete, the obtained mixture is crushed and sieved to obtain coated particles, and the coated particles are calcined at 400-600°C for 2 minutes to form a micro-nano composite structure on the surface of the coated particles to obtain the final produ...

Embodiment 3

[0055] Add 100g of gravel with a particle size of 0.074-0.085mm into the sand mixer and stir, then add 30g of polysulfide rubber modified epoxy resin (epoxy resin: polysulfide rubber mass ratio 5:1) to the gravel and stir evenly Form a mixture, make the polysulfide rubber modified epoxy resin film on the surface of the gravel, then add 9g of a mixture of microsilica powder and alumina powder with a particle size of 0.015-0.020 microns, and stir evenly to make the microsilica powder and alumina powder Adhere to polysulfide rubber modified epoxy resin, then add 25g curing agent aliphatic amine and stir evenly to promote the curing of polysulfide rubber modified epoxy resin, add 0.3g dispersion before the above mixture is agglomerated Add lithium-based grease and continue stirring to reduce sticking. After the normal temperature curing is complete, the obtained mixture is crushed and sieved to obtain coated particles, and the coated particles are calcined at 400-600°C for 2 minut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com