Modified polytetrafluoroethylene composite coalescent pack for oil-water mixed liquid separation

A technology of polytetrafluoroethylene and silanized polytetrafluoroethylene, which is applied in the field of modified polytetrafluoroethylene composite coalescence packing, can solve the problems of unstable collection of oil droplets, inability to coalesce and grow, low mechanical properties, etc. , to achieve the effect of increasing the contact area and interaction strength, improving the lipophilic and hydrophobic properties, and preventing breakage and shedding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Example 1: Advanced separation treatment of oily wastewater from a refinery in Zhejiang Province

[0044] Treatment object: Oily waste water from an oil refinery in Zhejiang Province, the oil content is 20-30%, the water content is 60-70%, and the solid and other impurities account for 5-10%. The oily wastewater has an oil content of 600-1000ppm after preliminary flocculation and sedimentation treatment.

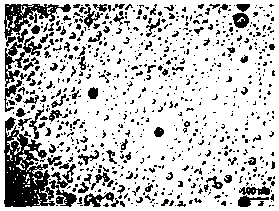

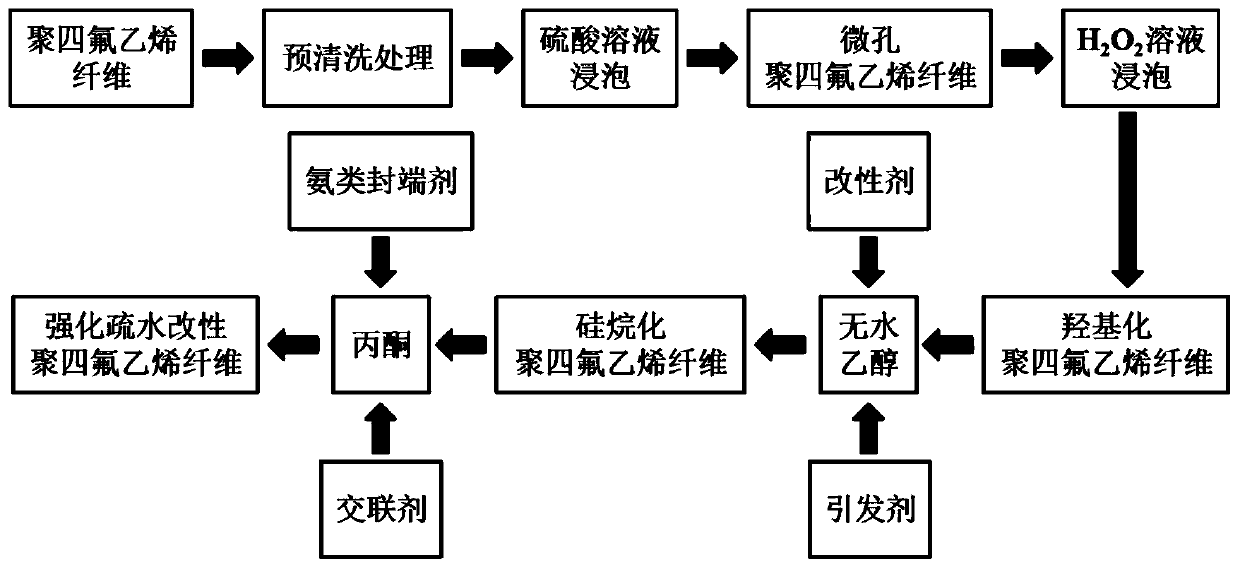

[0045] Strengthen the preparation of hydrophobically modified polytetrafluoroethylene fiber: Utilize the method described in the present invention, take the polytetrafluoroethylene fiber raw material 500g that diameter is 50 μm, utilize 50% (volume fraction) ethanol solution and 50% (volume fraction) successively Acetone solution was used to soak and clean it, and ultrasonic cleaning was used to remove impurities and oily substances on the surface of the fiber; then 35% (mass fraction) sulfuric acid solution was used to soak the pre-cleaned polytetrafluoroethylene fib...

Embodiment 2

[0048] Example 2: Advanced separation treatment of oil production wastewater in an oil production plant in Shaanxi Province

[0049] Treatment object: Oil production wastewater from an oil production plant in Shaanxi Province, with an oil content of 40-50%, a water content of 40-50%, and solids and other impurities accounting for 5-10%. The oil content of the oily wastewater after preliminary precipitation treatment is 2000-2500ppm.

[0050] The reinforced hydrophobically modified polytetrafluoroethylene fibers were prepared as described in Example 1.

[0051] Preparation of modified polytetrafluoroethylene composite coalescence filler: for the treatment of high-concentration and high-viscosity oily wastewater, 304 stainless steel fibers (200 μm in diameter) are used as the supporting skeleton, and five 304 stainless steel fibers are wound in a tooth-shaped weaving manner Strengthen the hydrophobic modified polytetrafluoroethylene fiber to ensure that the tooth shape directio...

Embodiment 3

[0053] Example 3: Advanced separation treatment of oily machining wastewater from a machinery processing plant in Jiangsu Province

[0054] Treatment object: Oily machining wastewater from a machinery processing factory in Jiangsu Province, with an oil content of 30-40%, a water content of 50-60%, and solids and other impurities accounting for 10-20%. The oil content of the oily machining waste water after preliminary filtration and sedimentation treatment is 1600-2000ppm.

[0055] The reinforced hydrophobically modified polytetrafluoroethylene fibers were prepared as described in Example 1.

[0056] Preparation of modified polytetrafluoroethylene composite coalescence filler: for the treatment of high-concentration and low-viscosity oily wastewater, 304 stainless steel fibers (200 μm in diameter) are used as the supporting skeleton, and five 304 stainless steel fibers are wound in a tooth-shaped weaving manner Strengthen the hydrophobic modified polytetrafluoroethylene fiber...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com