Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "Simplify the joining process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

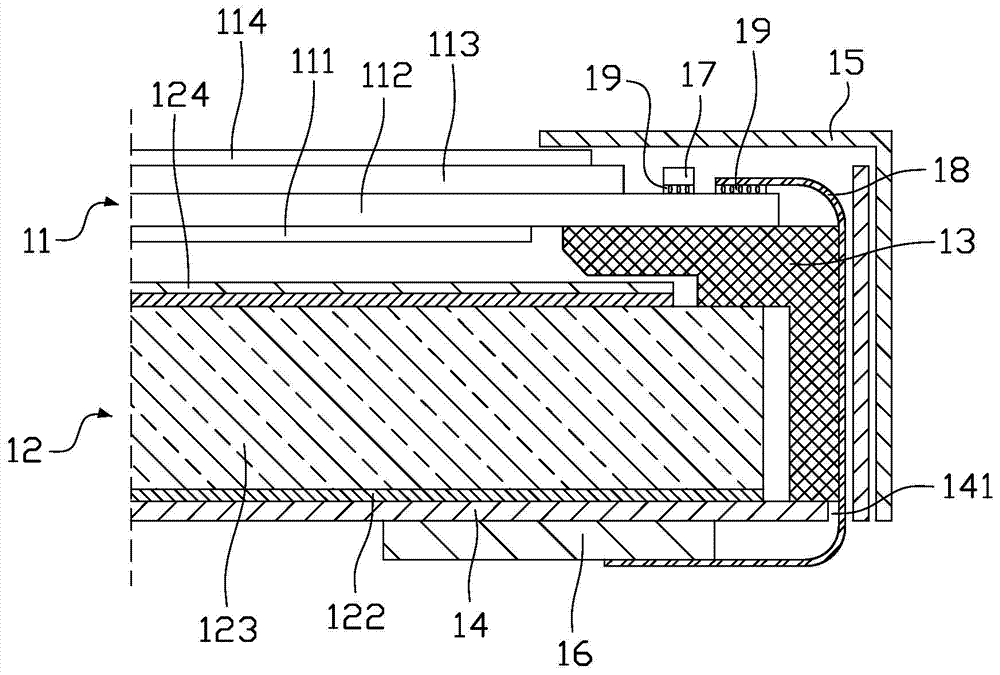

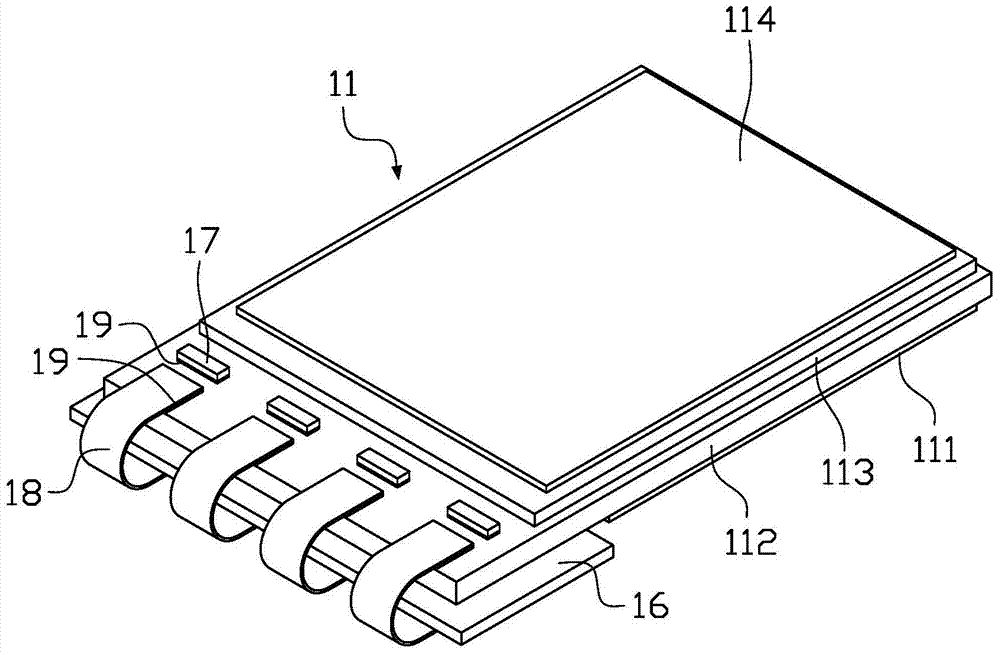

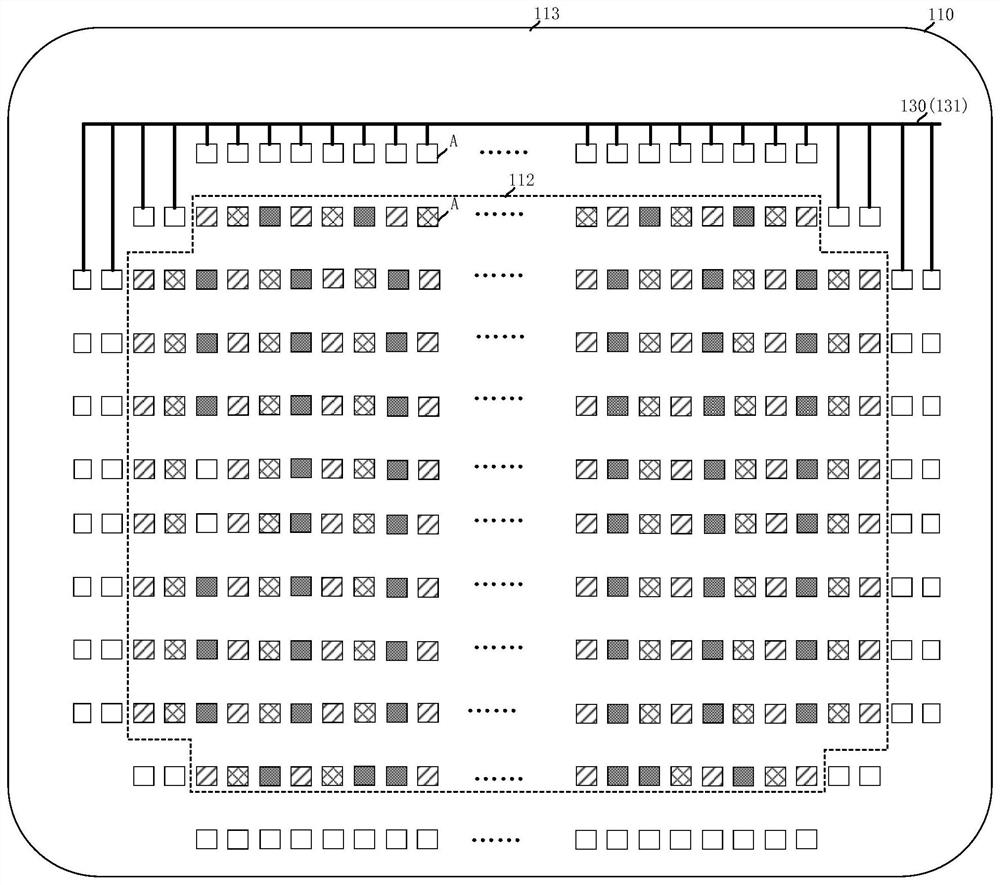

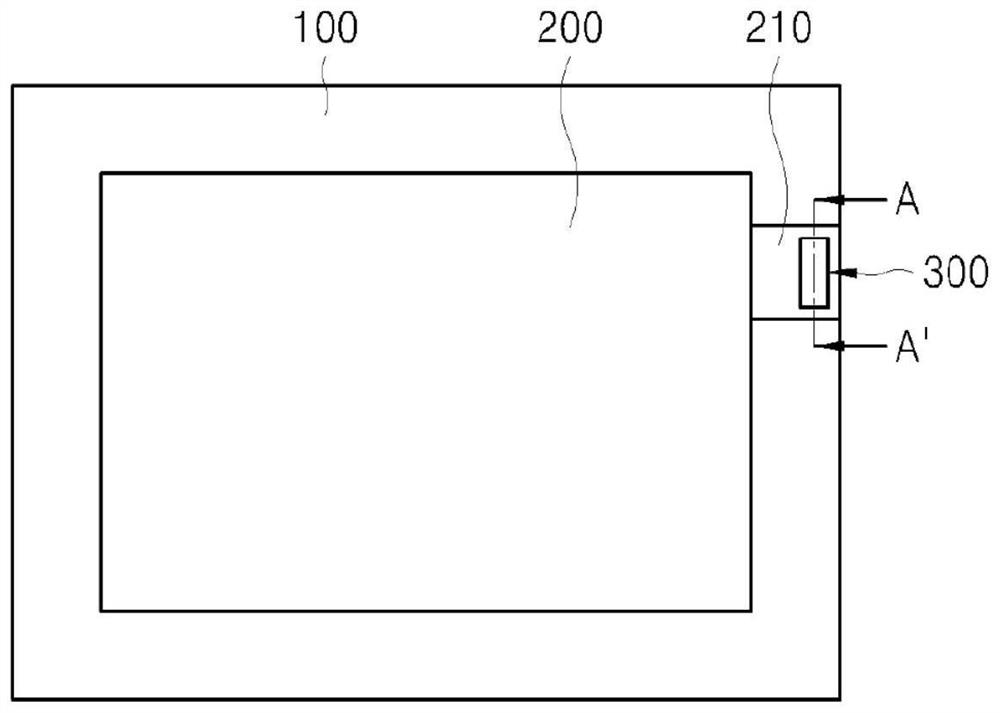

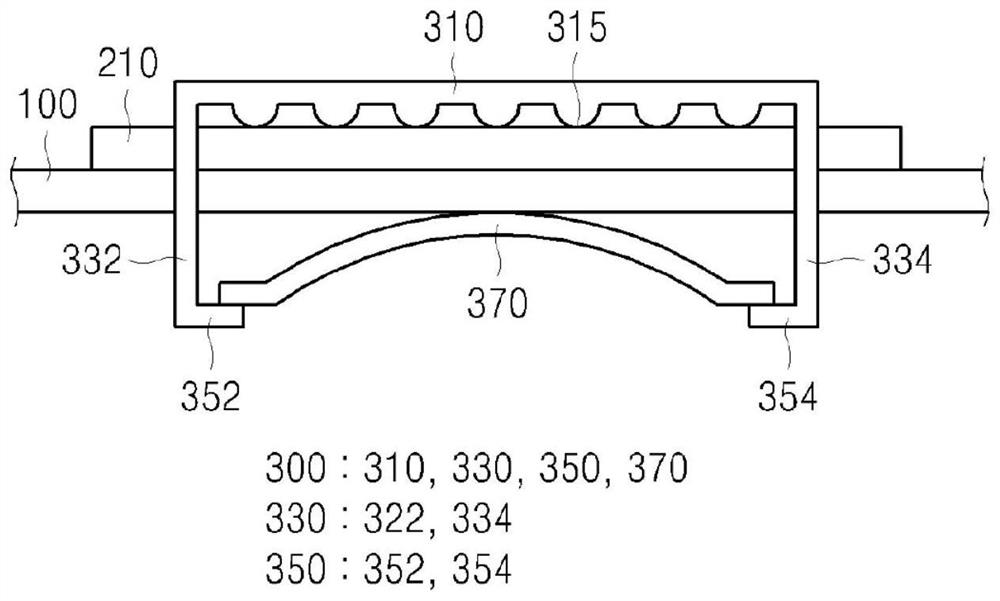

Display panel assembly structure and display device

ActiveCN104777644ASimplify the joining processReduce manufacturing costNon-linear opticsPrinted circuit boardSurface plate

The invention discloses a display panel assembly structure, which comprises a hard circuit board and a display panel, wherein an insertion end is arranged on one side of the display panel; a plurality of pins are arranged on the insertion end; the display panel assembly structure further comprises a connector fixed on the hard circuit board; the connector is provided with a slot in one lateral surface leaning against the display panel along the horizontal direction; a plurality of probes are arranged in the slot; the insertion end is fixedly inserted into the slot; the plurality of probes are respectively connected to the plurality of pins. According to the display panel assembly structure, the connector replaces the existing flexible circuit board, and the flexible circuit board is not in need of use, so that a process for jointing the flexible circuit board to the display panel by utilizing an OLB (Outer Lead Bonding) machine table is eliminated, and a processing for connecting the hard circuit board and the display panel is simplified, the production cost is reduced, and meanwhile, the broken phenomenon of the flexible circuit board due to application of the flexible circuit board is completed avoided.

Owner:KUSN INFOVISION OPTOELECTRONICS

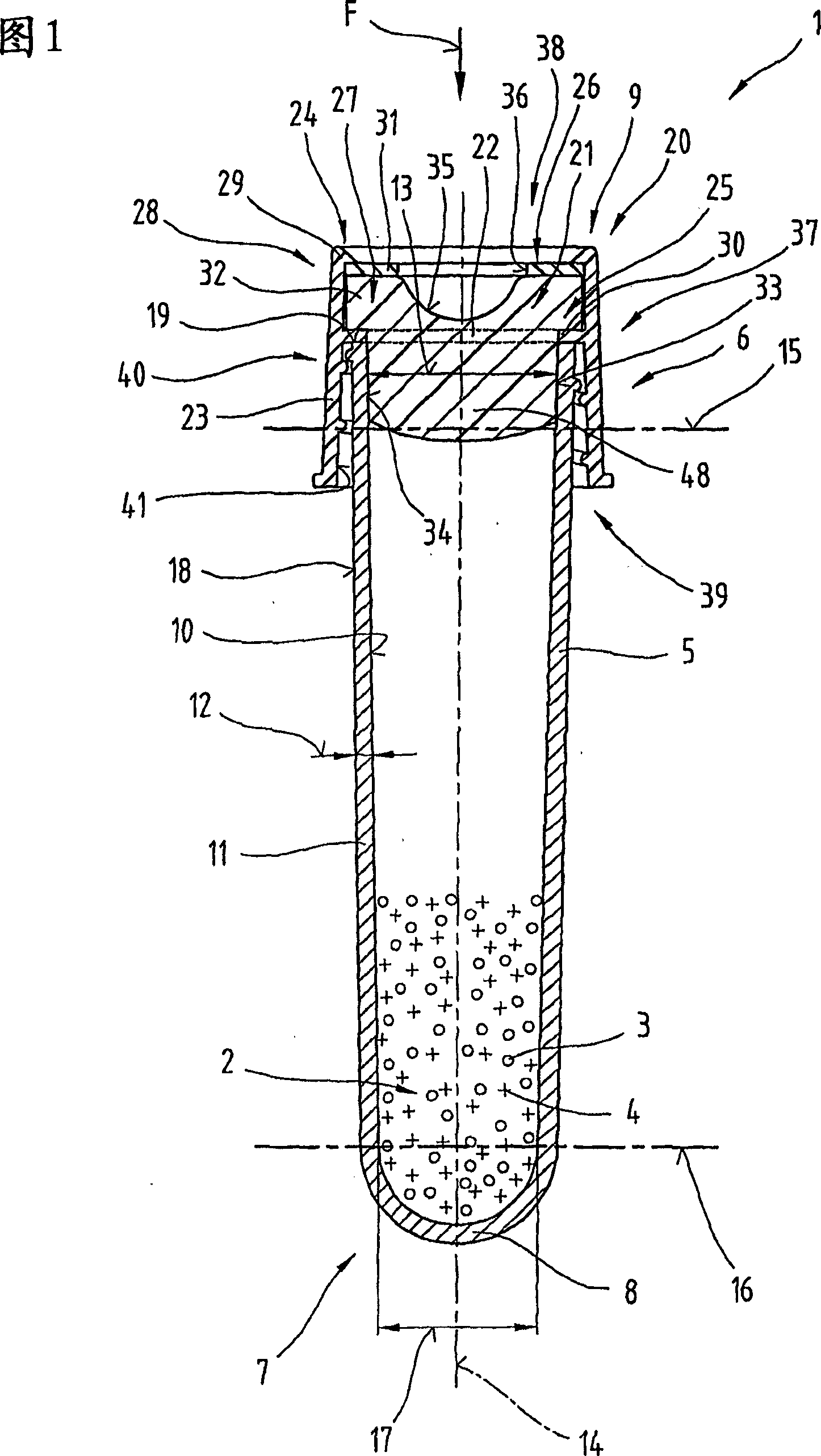

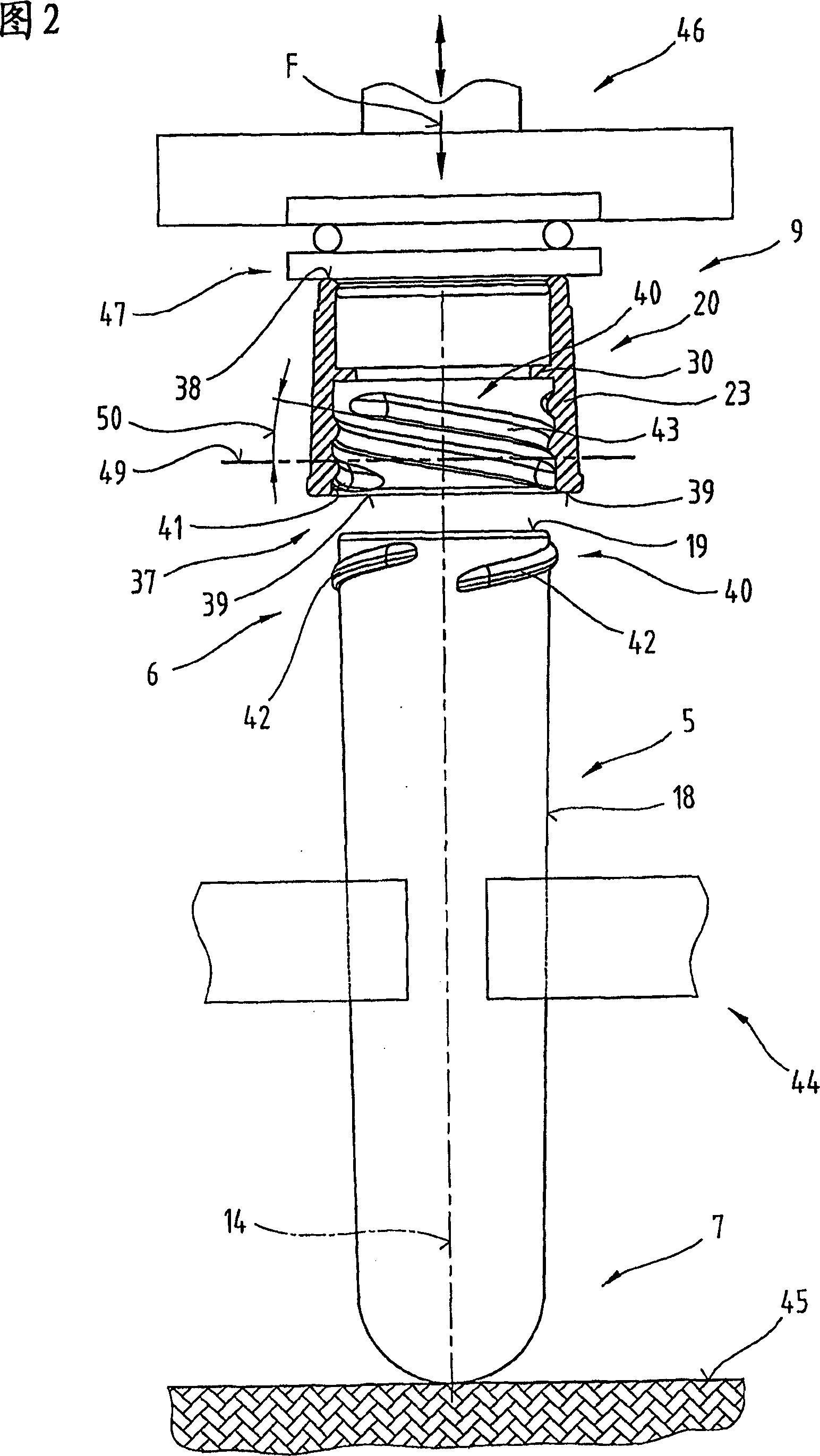

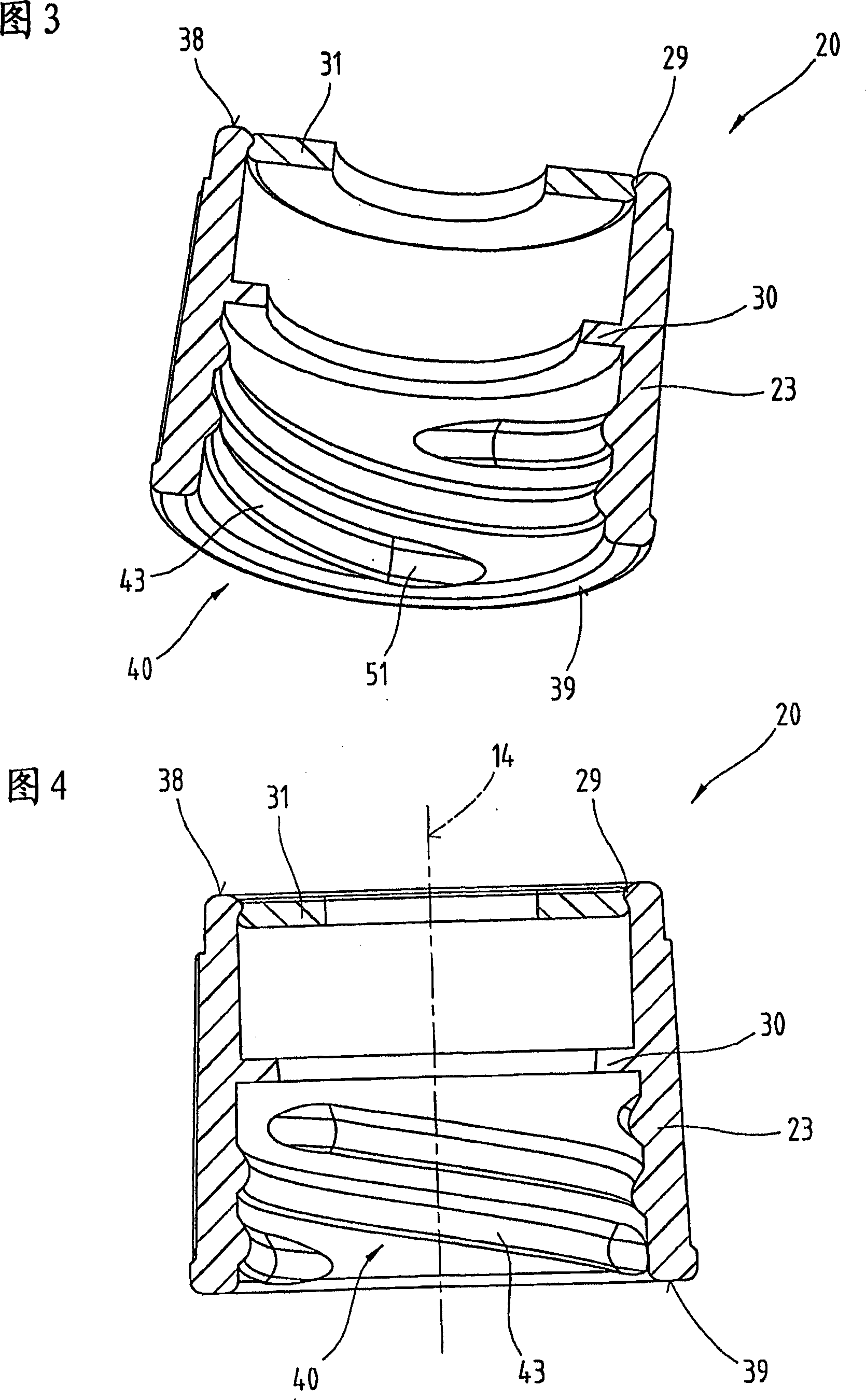

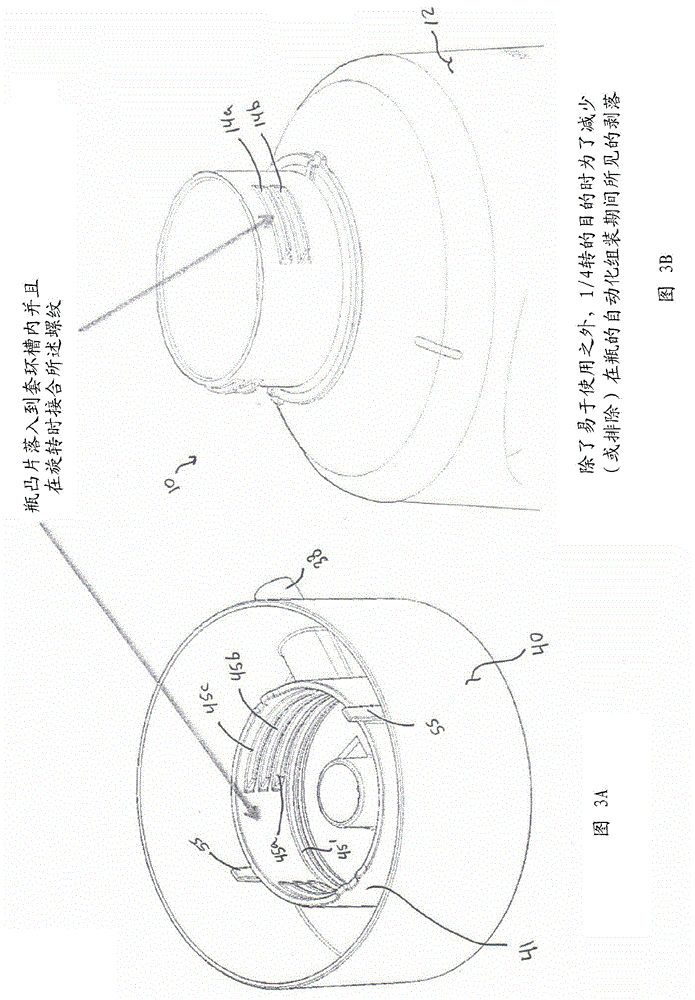

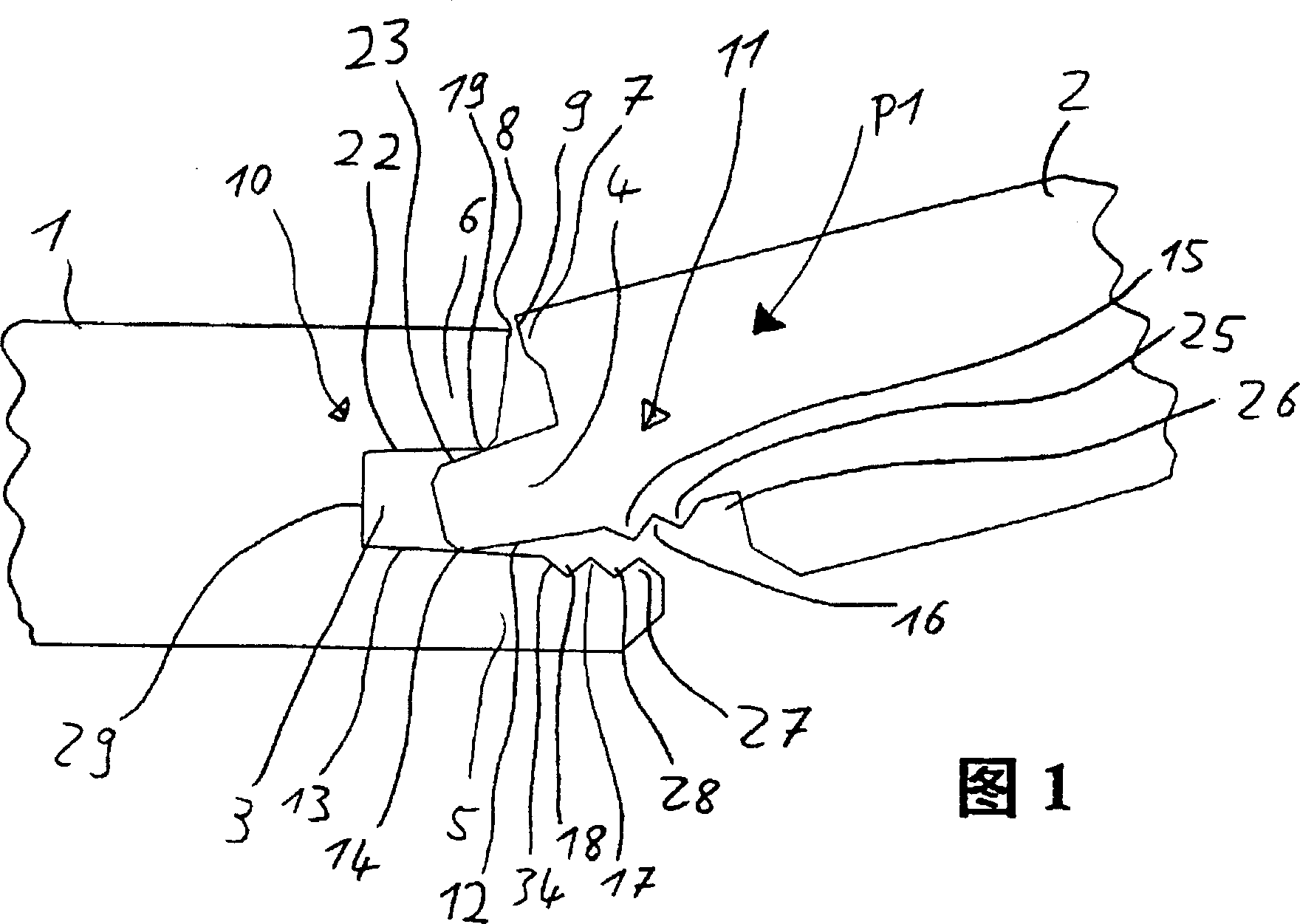

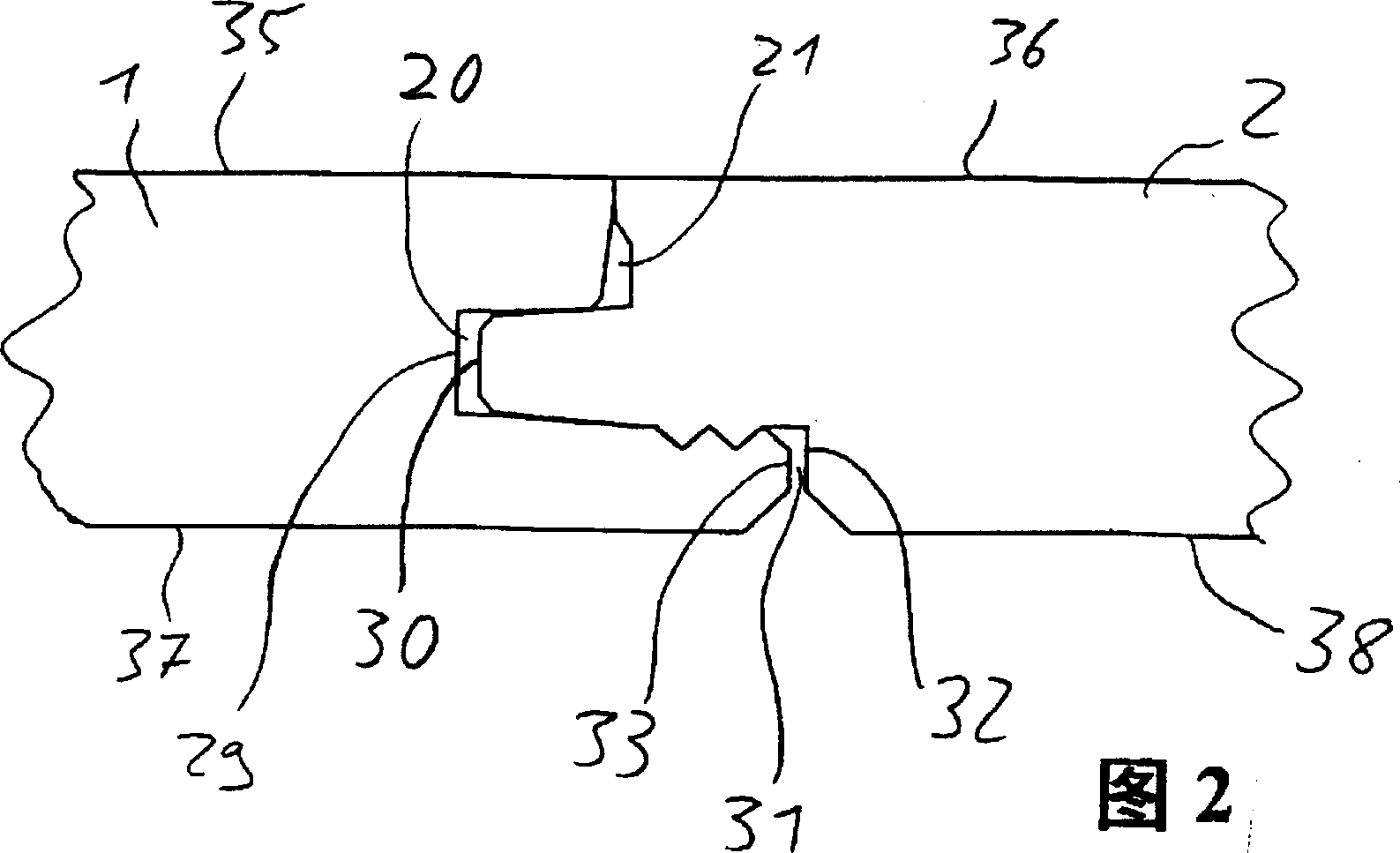

Method for the assembly of a cap with a receptacle

ActiveCN1997455AAvoid blockingClose enoughCapsThreaded caps applicationRelative displacementEngineering

The invention relates to a method for the assembly of a cap (20) of a sealing device (9) with an open end (6, 7) of a receptacle (5), to form a storage device (1) for bodily fluids, tissue parts, or tissue cultures, whereby a relative turning or pivoting motion between the cap (20) and the receptacle (5) is carried out about a common longitudinal axis (14). The relative displacement is carried out by exerting a pressure force (F) on at least one of the assembly components, approximately in the direction of the longitudinal axis (14). The invention further relates to a cap (20) to form the sealing device (9), a receptacle (5) and a storage device (1) formed therefrom, comprising at least the cap (20), a sealing device (21) retained therein and the receptacle (5).

Owner:GREINER BIO ONE GMBH

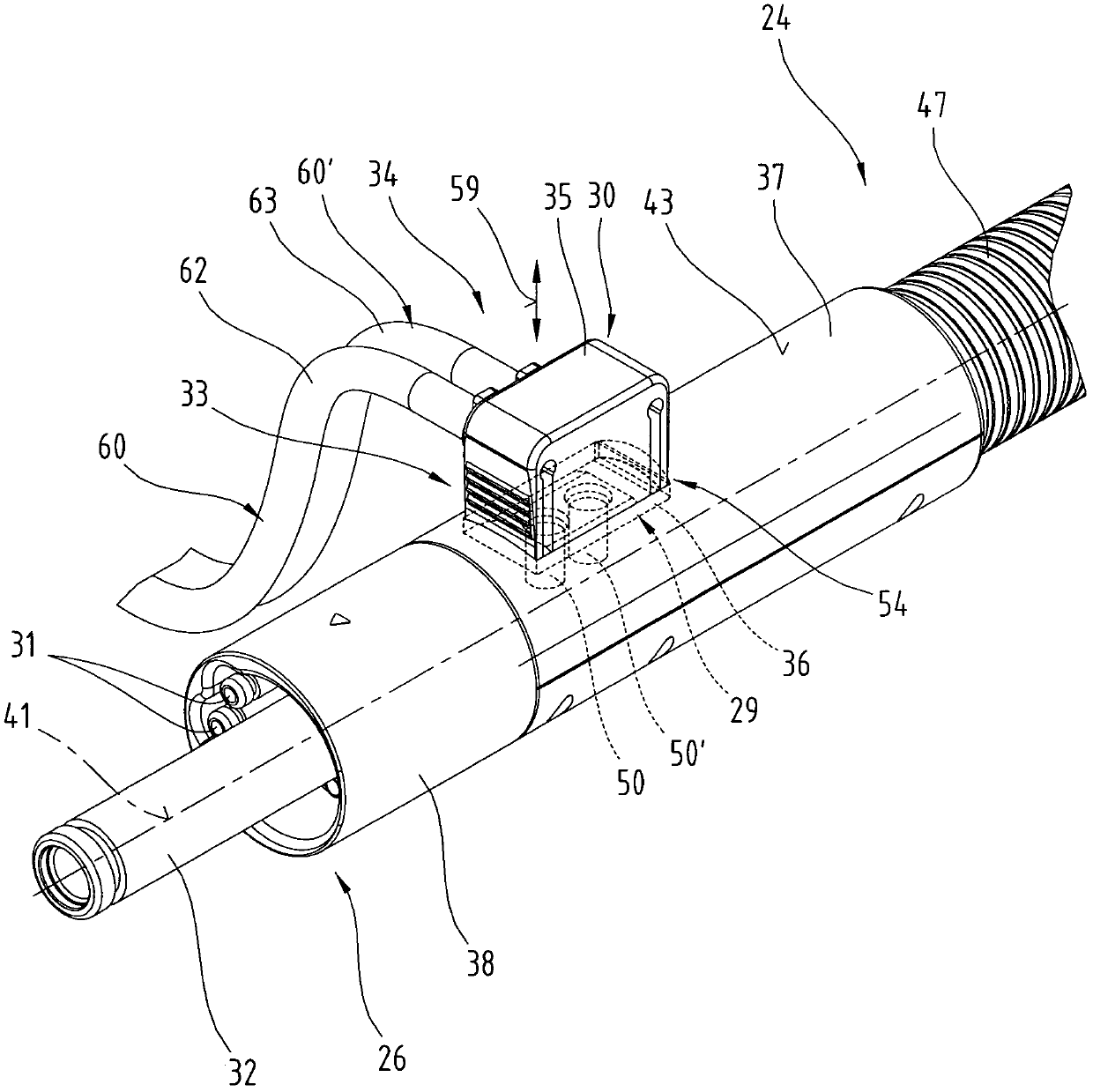

Hose assembly and coupling device for a welding device

The invention relates to a hose assembly (24), comprising a plurality of lines (7; 12; 17; 25) for supplying a welding torch (10) with operating media, such as welding current, welding wire, protective gas, and / or control signals, and having at least one coolant line (19, 19') for feeding a cooling medium of a coolant source (21) to a welding torch (10), and having at least one coupling element (26) for detachably connecting to a welding unit (2) or to a welding torch (10) if necessary. A further coupling element (29) for the at least one coolant line (19, 19') is integrated in the coupling element (26), the coupling and decoupling direction of the further coupling element being oriented perpendicular to a longitudinal axis of the hose assembly (24), wherein the coupling elements (26, 29) can each be coupled and decoupled independently of each other.; The invention further relates to a coupling element (26) designed correspondingly, a connector element (35) used therein or a plug-in connection for the at least one coolant line (19, 19'), and a welding device equipped with said elements.

Owner:FRONIUS INTERNATIONAL GMBH

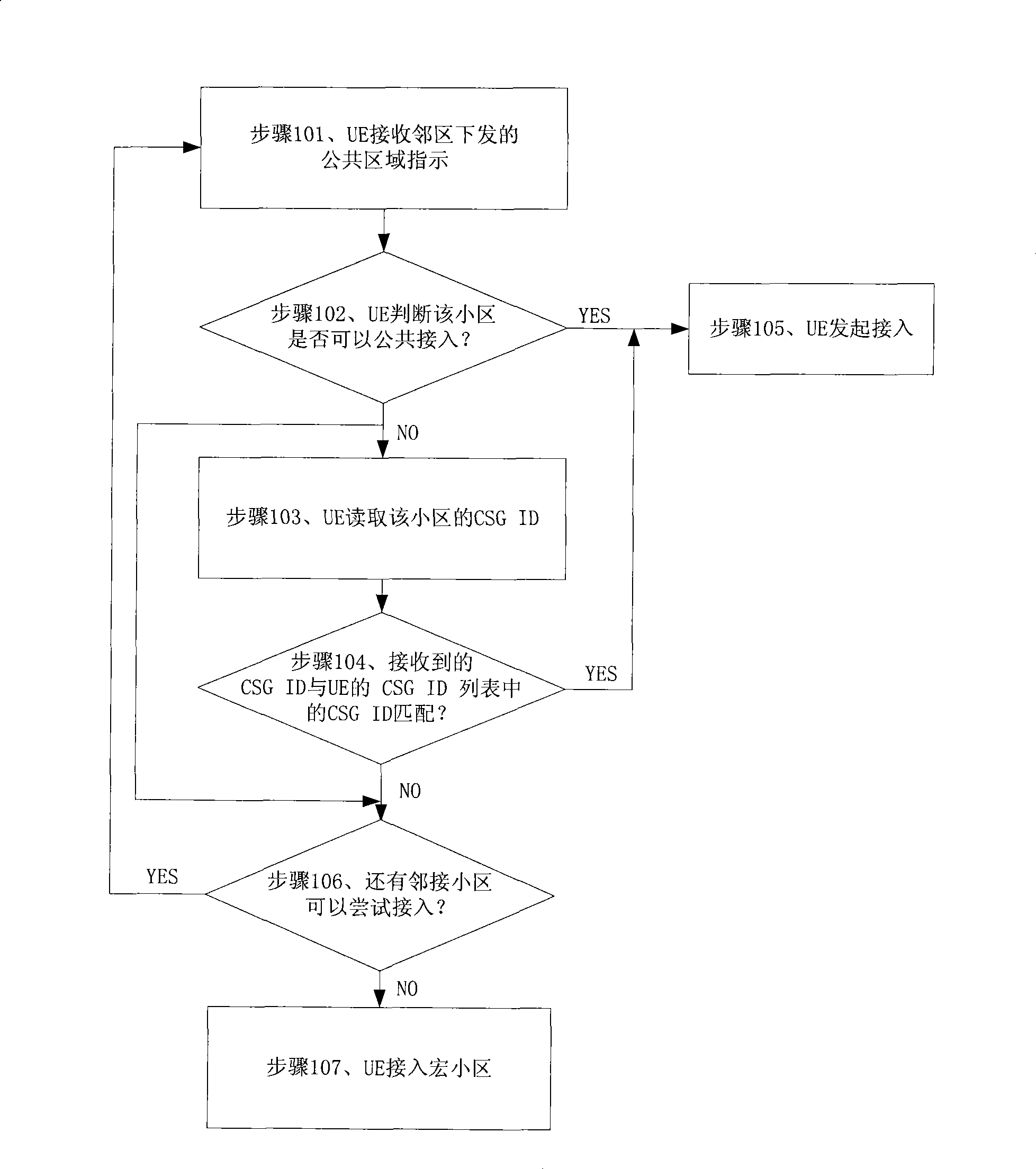

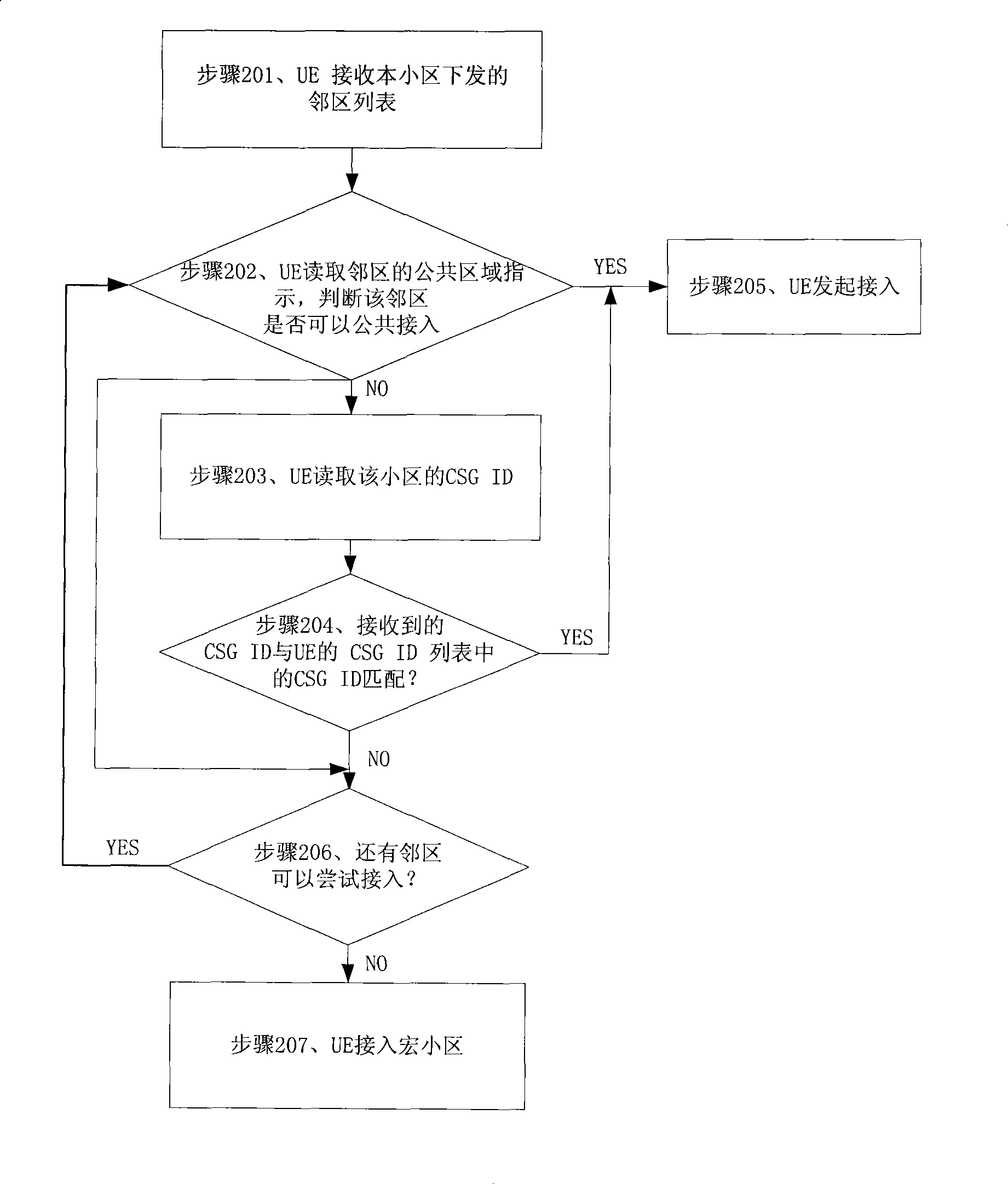

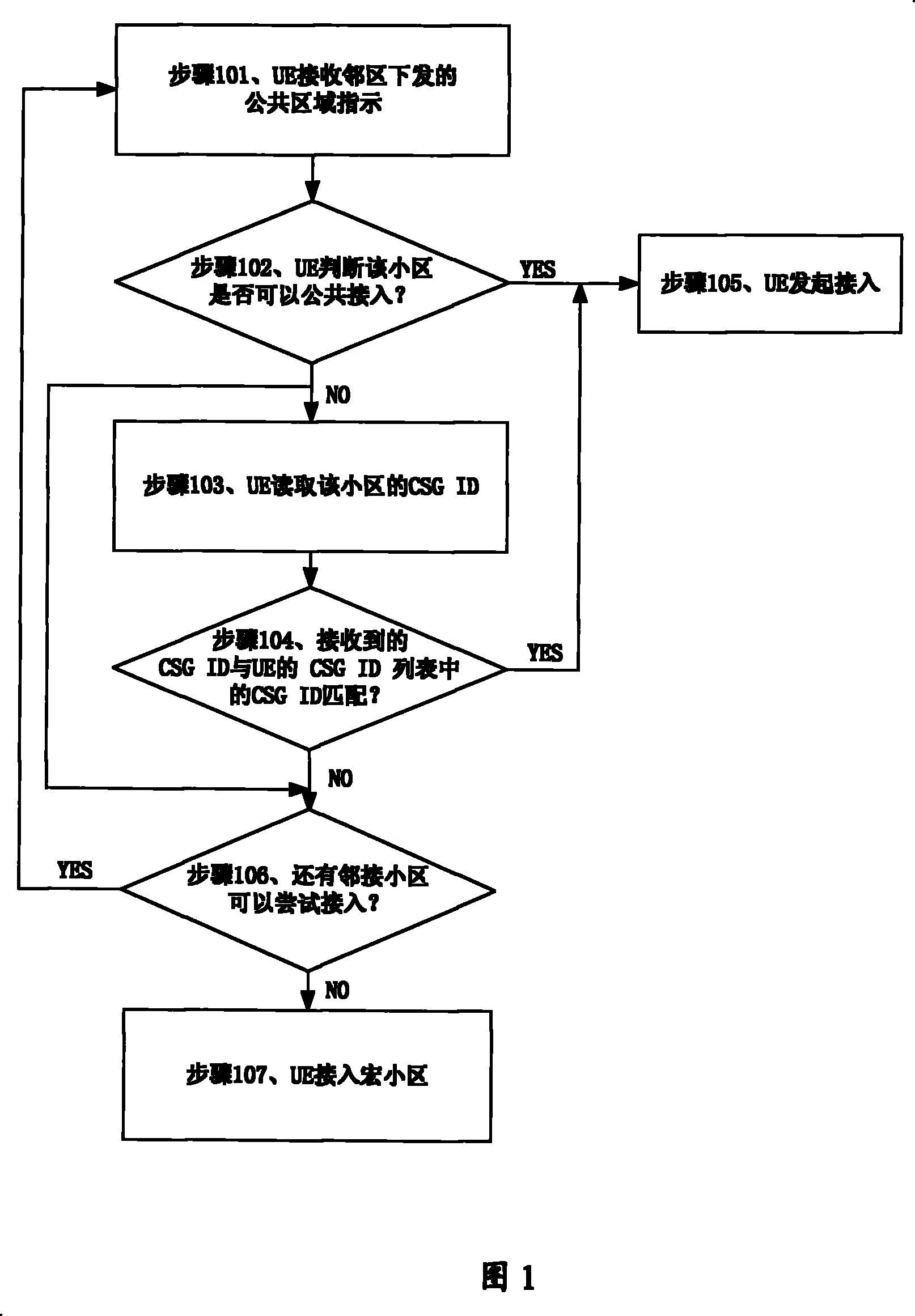

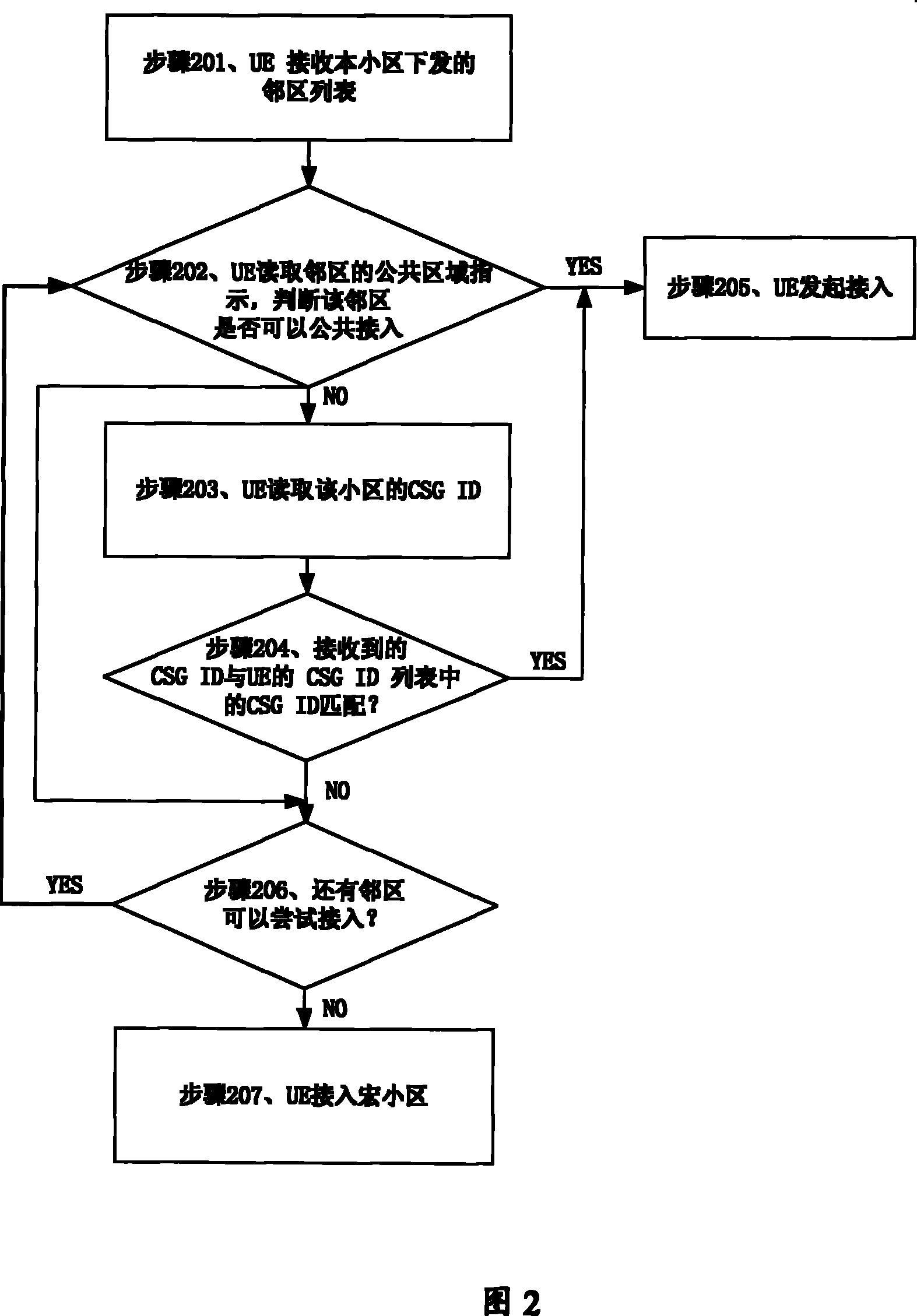

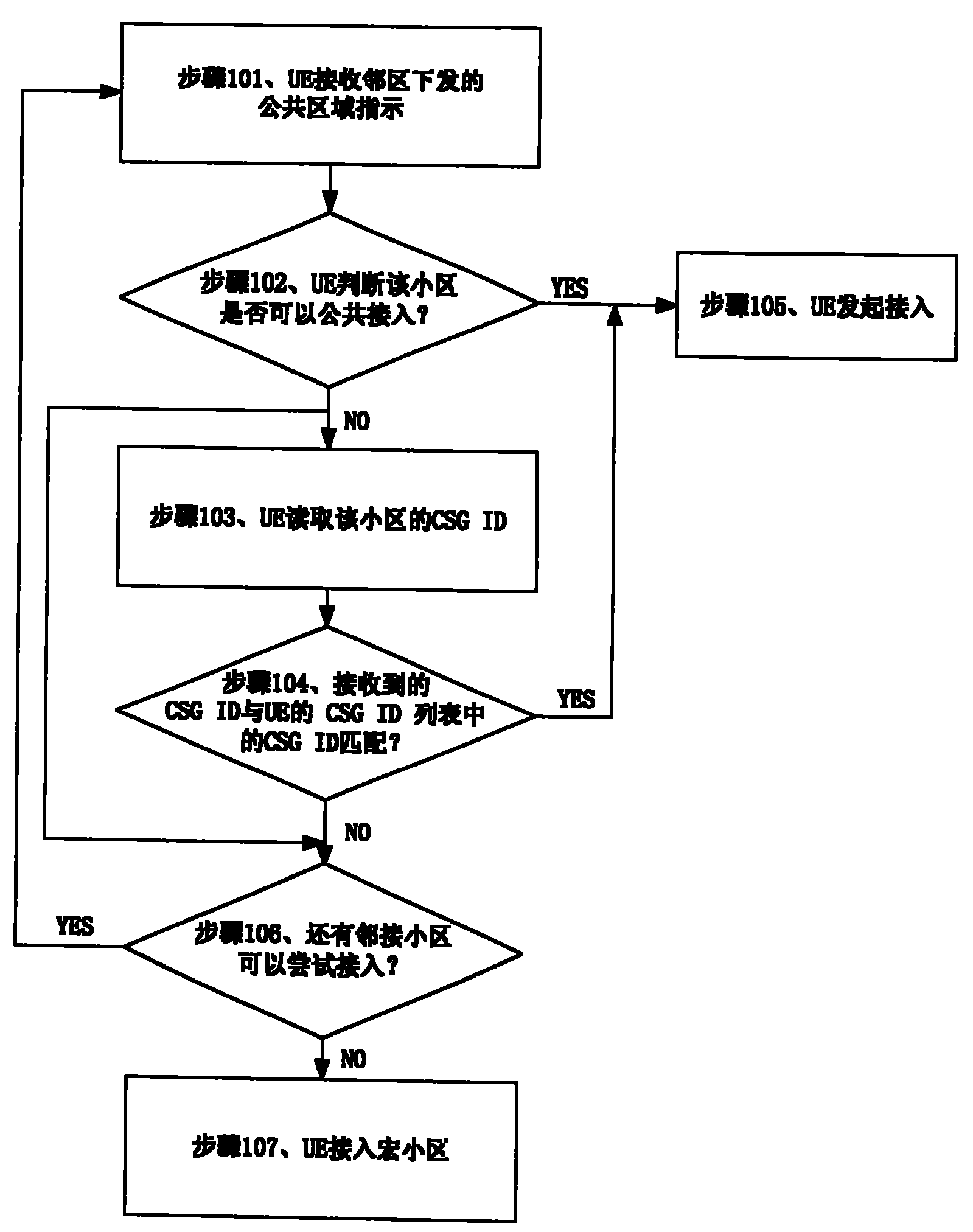

Method for accessing wireless network

ActiveCN101415221AEasy accessSimplify the joining processAssess restrictionData switching by path configurationWireless mesh networkExecution unit

The invention discloses a method for accessing a wireless network. The method comprises the following steps: user equipment (UE) acquires a public domain instruction of an neighbor cell; if the public domain instruction represents that the neighbor cell can be accessed in a public manner, the UE initiates an access to the neighbor cell; if the public domain instruction represents that the neighbor cell can not be accessed in the public manner, the UE accesses the neighbor cell in an access limited manner, or judges whether the other neighbor cells can be accessed. The invention further discloses the user equipment, and the user equipment comprises a receiving unit, a memory unit, a judgment unit and an execution unit. The method and the equipment can simplify the operation in using a home base station, and improve the experience and feeling of a customer.

Owner:HUAWEI TECH CO LTD

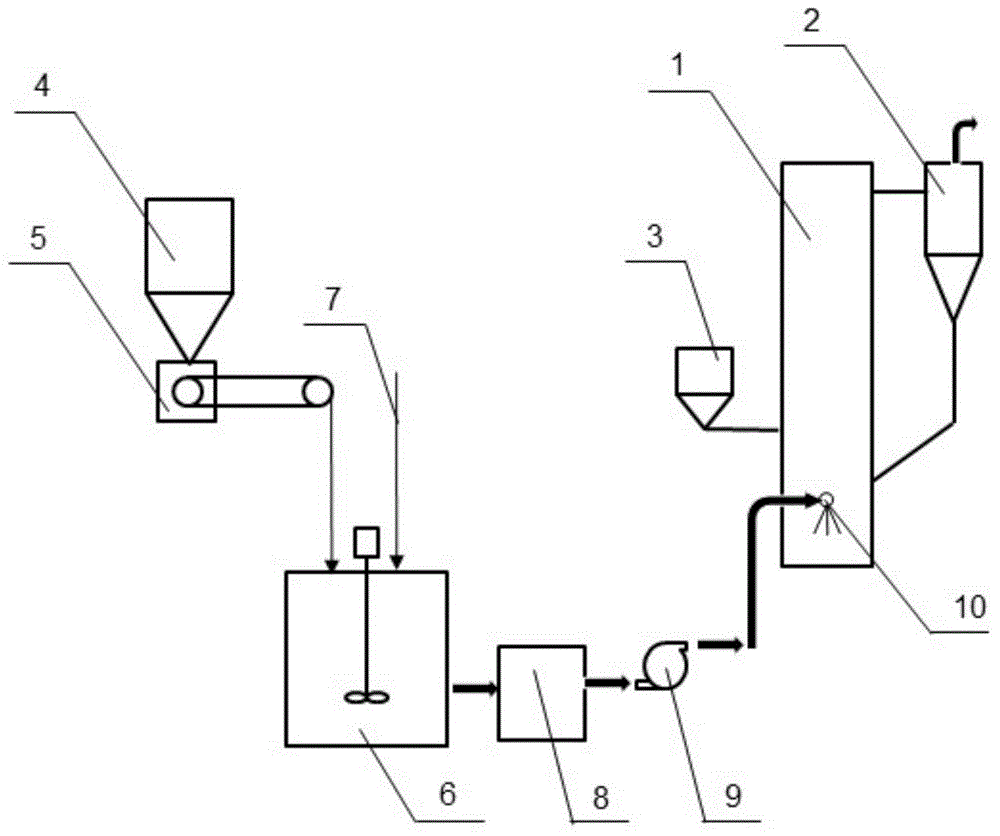

Normal temperature semi-dry method circulating fluidized bed flue gas desulphurization system and method

ActiveCN104941435AIncrease surface areaExtended stayDispersed particle separationFlue gasFluidized bed

The invention discloses a normal temperature semi-dry method circulating fluidized bed flue gas desulphurization system and a method, which relate to a method for removing sulfur oxides in flue gas discharged from a burning device and a system. The normal temperature semi-dry method circulating fluidized bed flue gas desulphurization system and the method use a circulating fluidized bed as a desulphurization reactor, and are characterized in that slurry with super fine desulfurizer particles is injected into a circulating fluidized bed reactor, circulating material particles are added into the circulating fluidized bed reactor simultaneously, and the circulating material particles in the circulating fluidized bed reactor and desulfurizer slurry are fully collided and contacted, and generate a desulfurization reaction. The normal temperature semi-dry method circulating fluidized bed flue gas desulphurization system and the method can achieve the purpose that desulfurizer equipment and desulfurization reaction process are coupled and the use rate of desulfurizer is obviously improved. Compared with existing semi-dry method flue gas desulphurization prior, the normal temperature semi-dry method circulating fluidized bed flue gas desulphurization system and the method have the advantages of high desulphurization efficiency, simple system structure and low investment and maintenance cost of operation, and can be used for flue gas purification process of industrial boilers and station boilers.

Owner:清义(山西)新材料科技有限公司

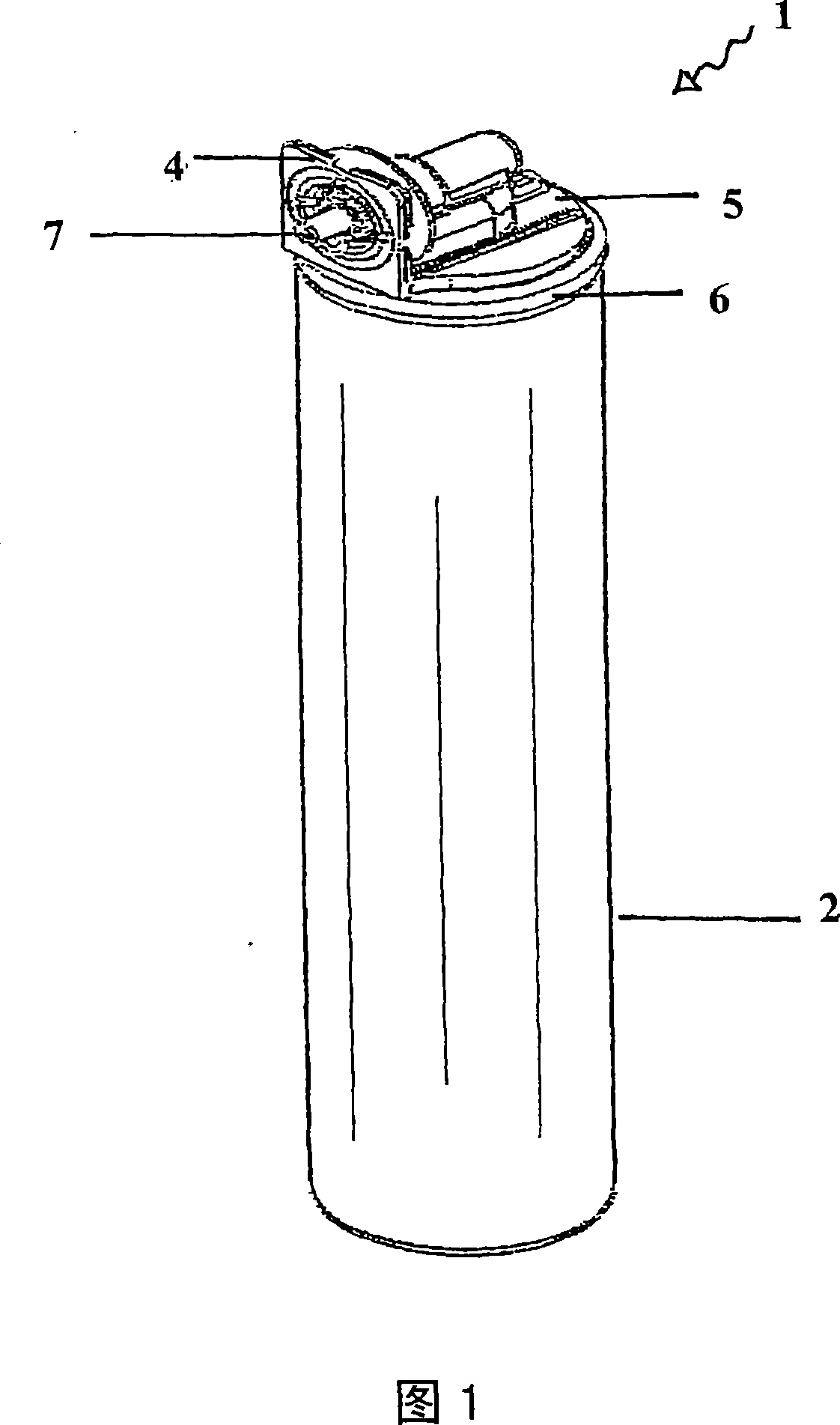

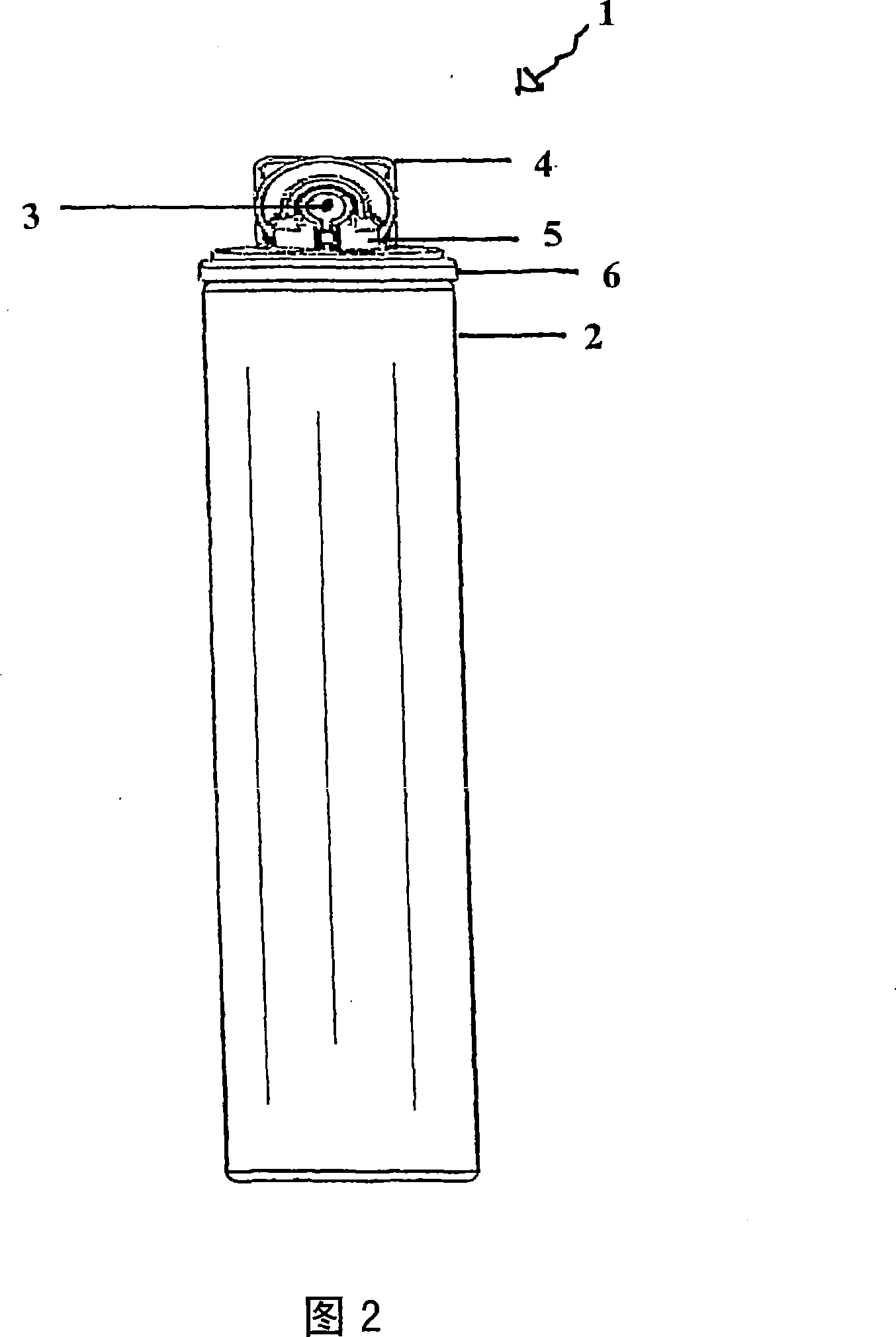

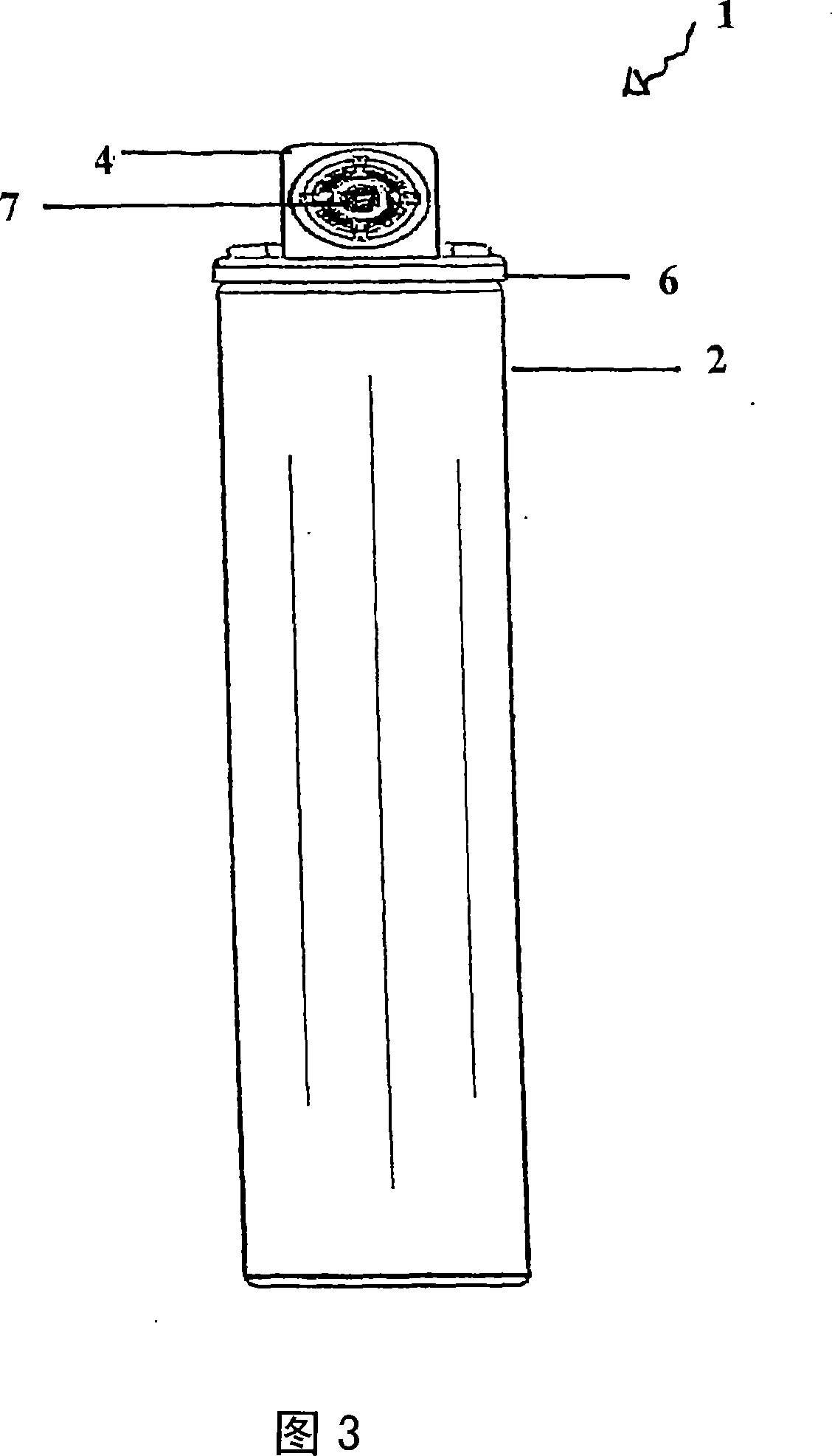

Refillable dosing valve

InactiveCN101023005ASimplify the joining processExtended service lifeLiquid dispensingFuel cellsFeed drive

This invention relates to a refillable external dosing valve for use with a fuel cell, aerosol can, or dispenser for a dispensable fluid. In particular, the invention relates to a refillable external dosing valve for use in dispensing a hydrocarbon fuel for a gas auto-feed drive tool. The refillable dosage valve includes an entry point and a non-return valve so that the fuel canister is able to be reloaded after the fuel bag internally of the canister has been totally deflated. The valve is adapted to engage the fuel canister in a manner allowing the valve to establish fluid communication with the fuel in the canister and to co-operate with a refilling nozzle of apparatus adapted to deliver a substance from a reservoir through the dosing valve to refill a receptacle with said substance, with which the dosing valve is used. The valve is also configured to include an internal metering feature which enables a predetermined amount of fuel to be delivered to a metering chamber within the gas auto-feed drive tool. The invention also provides a system to enable removal of residual gas within a canister to be removed when the canister is to be disposed of.

Owner:雷克斯・马柯雷玛克 +1

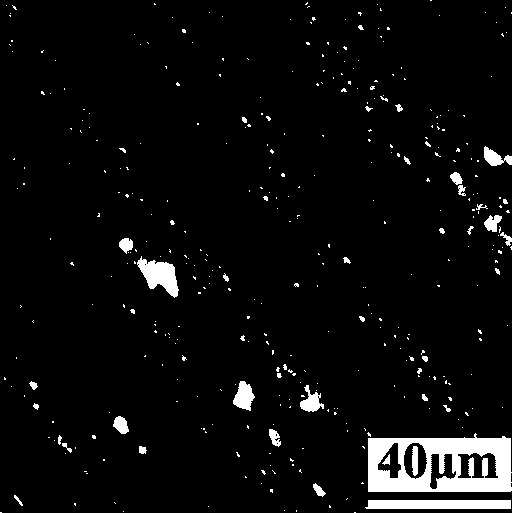

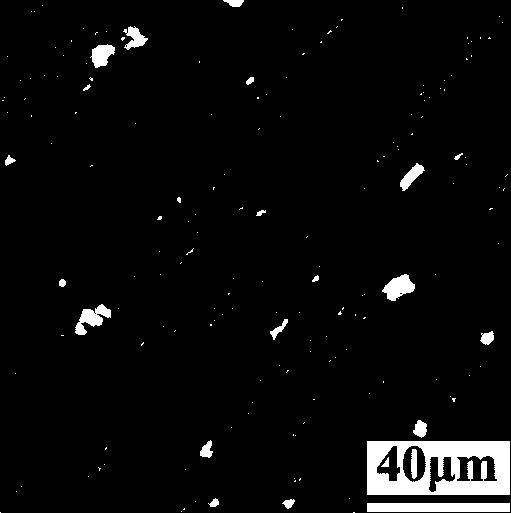

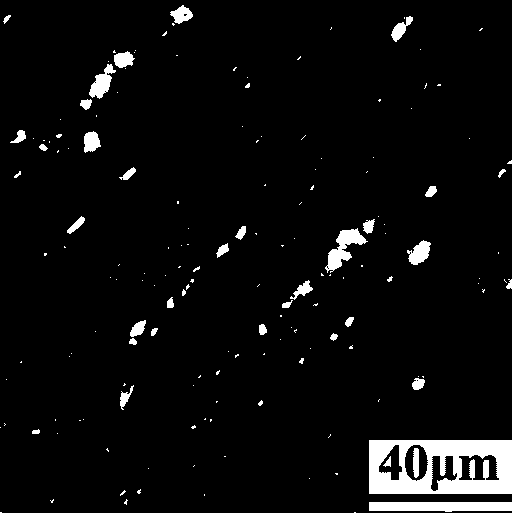

Aluminum alloy refiner and aluminum alloy produced with the refiner

InactiveCN101294247AImproved post-processing performanceSimplify the joining processCrystalliteAluminium alloy

The invention discloses an aluminum alloy refiner and an aluminum alloy which is prepared by using the refiner. The aluminum alloy refiner is Zr-Cr-Nb, wherein, Zr, Cr, and Nb elements account for 0.2 to 0.5 percent of total mass percent of the alloy which is obtained from the preparation. By using the refiner, the aluminum alloy is prepared and obtained, the grains of which are small. When the refiner is used for preparing the aluminum alloy, the lattice type and the parameter of Al3Zr can be adjusted to form stable a L12 structure, the interfacial energy and the mispairing degree are reduced, the grain refining effect is increased, the fine uniform equiaxial cast structure is facilitated to be formed, and the subsequent processability of the aluminum alloy is increased. The adding technology of the refiner is simple, the price of the Zr, the Cr and the Nb is relatively cheap, and the aluminum alloy refiner and the aluminum alloy are applied to the industrialized production.

Owner:CENT SOUTH UNIV

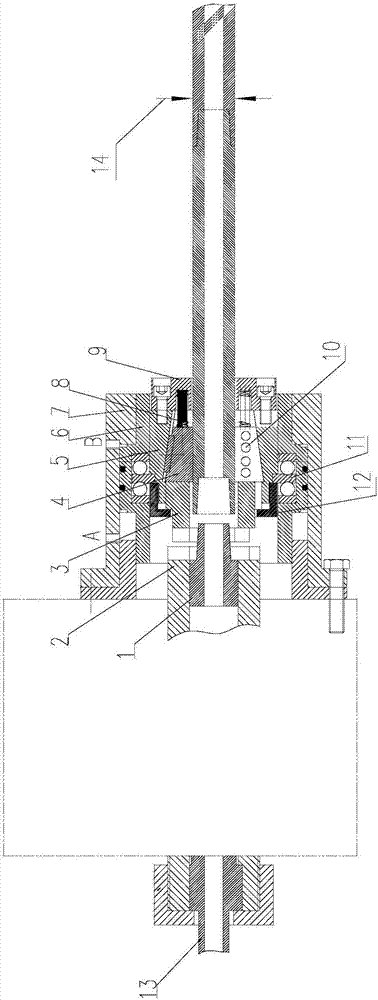

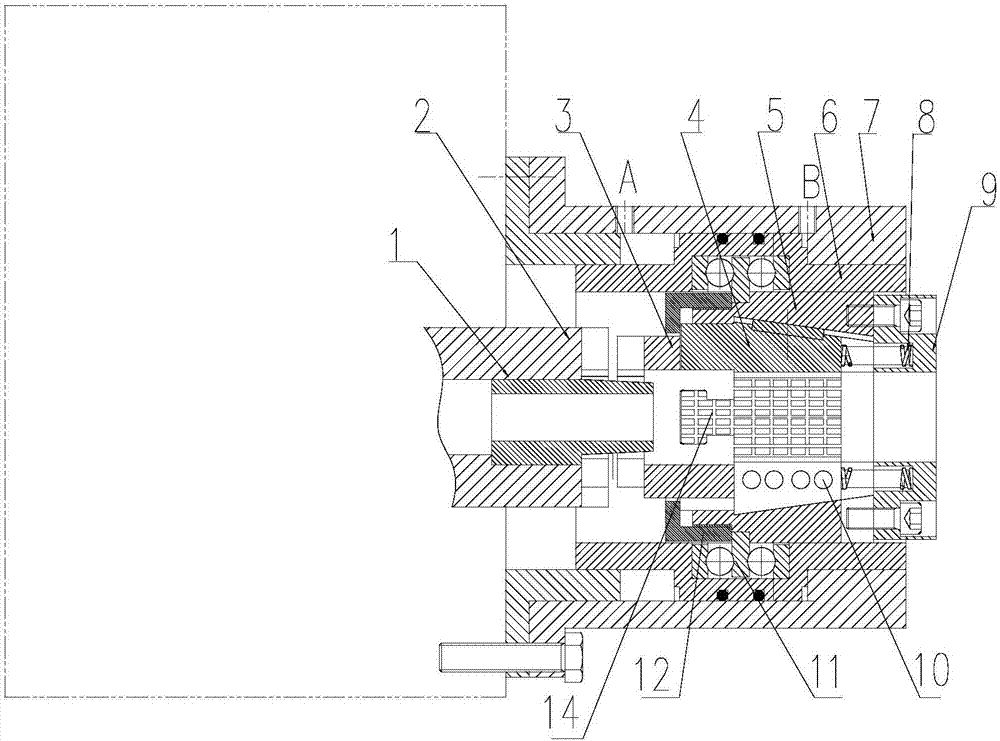

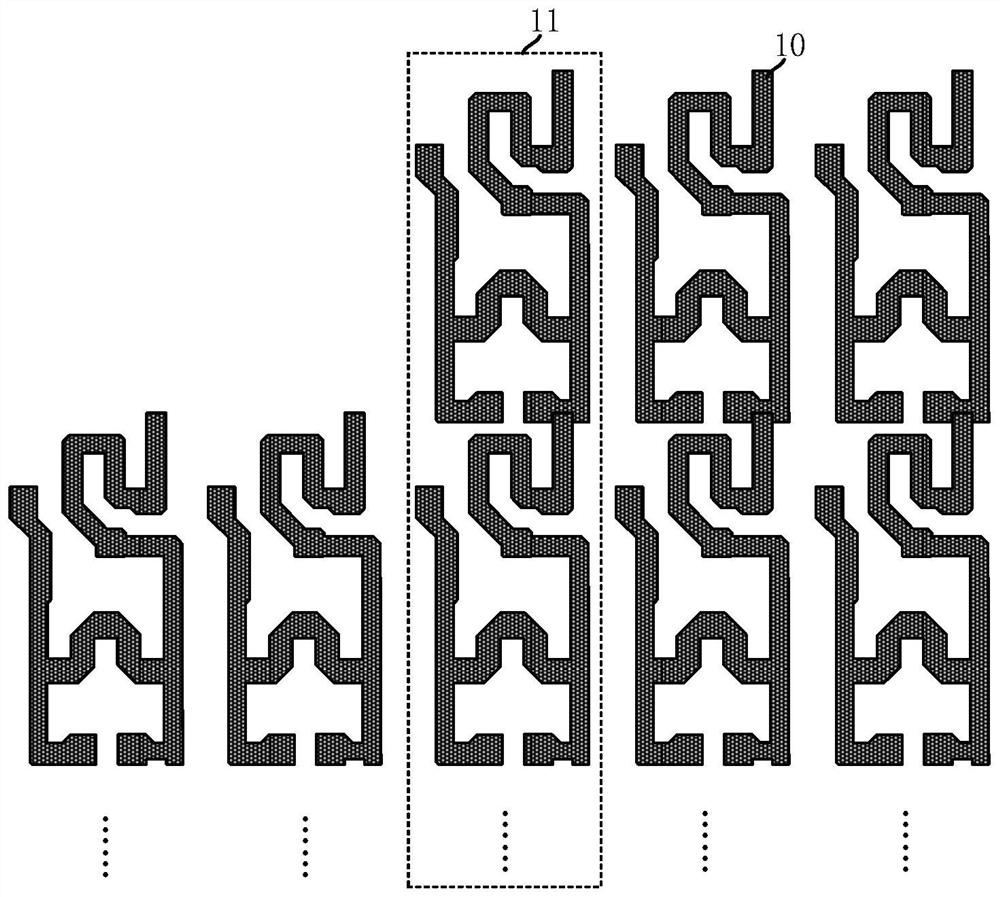

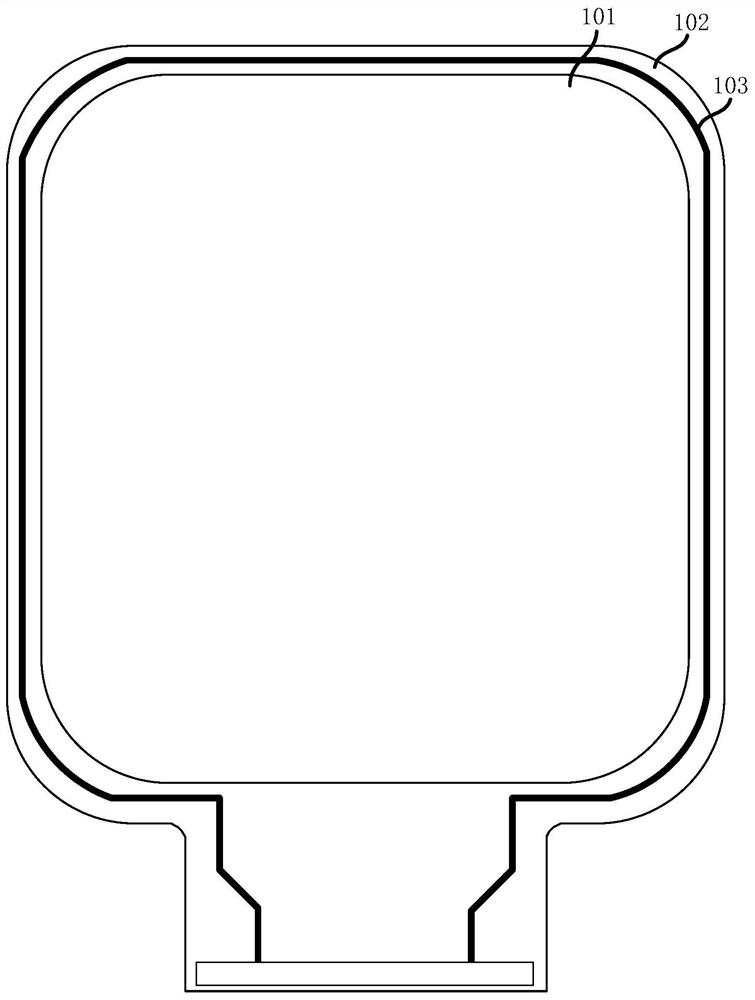

Clutch type drilling rod connection apparatus

PendingCN106907118ASimplify the joining processImprove joining efficiencyDrilling rodsDrilling casingsPetroleum engineeringClutch

The invention discloses a clutch type drilling rod connection apparatus comprising a drilling rod connector and a hydraulic chuck. The drilling rod connector is coaxially fixed on a main shaft of drilling into a power case; the hydraulic chuck clamps the drilling rod when the drilling rod is detached, and drives the drilling rod to synchronously rotate with the main shaft; the drilling rod connector and the hydraulic chuck can be combined for use; the chuck is connected with the main shaft via a clutchable way; adjunction of the drilling rod is completed via the drilling rod connector, so detachment and adjunction of a water braid; the drilling rod can be detached via the chuck, so drilling rod adjunction can be simplified and drilling rod adjunction efficiency can be improved; and technical guarantee is provided for intelligent adjunction of the drilling rod.

Owner:CHINA COAL TECH & ENG GRP CHONGQING RES INST CO LTD

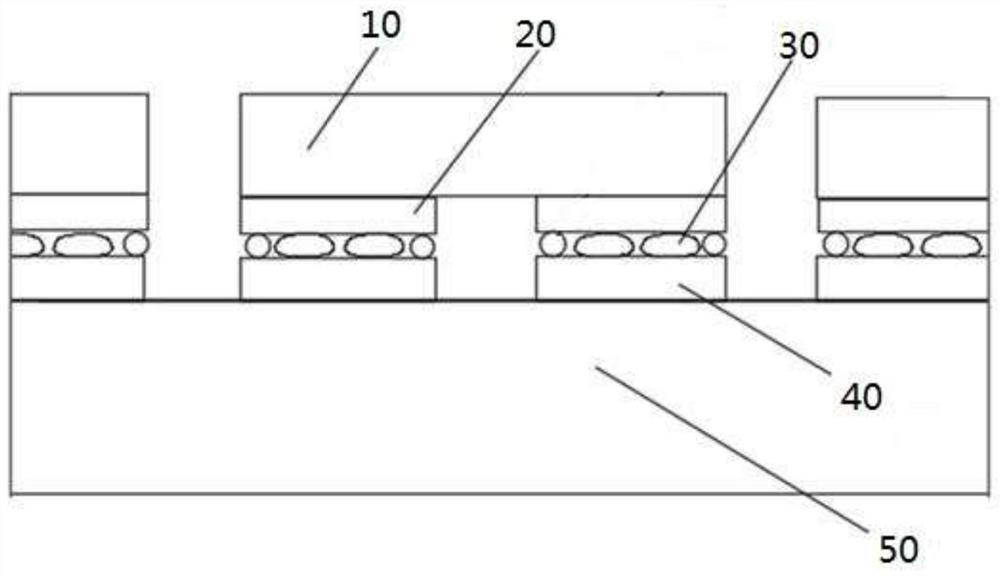

Array substrate and display panel

ActiveCN112670304AEvenly distributedImprove the problem of different degrees of threshold voltage biasSolid-state devicesSemiconductor devicesHemt circuitsEngineering

The invention discloses an array substrate and a display panel. The array substrate comprises a substrate, active layers and an electrically conductive layer; the active layer is arranged on the substrate, the active layers comprise a plurality of columns of patterned pixel circuit areas, each column of pixel circuit areas comprises a plurality of rows of connected pixel circuit subareas, and the pixel circuit subareas are used for forming pixel circuits; the electrically conductive layer is provided with electrically conductive wires, and the electrically conductive wires are connected with the end parts of the active layers in at least part of the pixel circuit areas, so that on the basis of not influencing the normal work of the pixel circuits, the quantity of electrostatic charges accumulated by the active layers corresponding to the pixel circuit areas in different columns can be uniformly distributed; therefore, the problem that the threshold voltage bias degrees of driving transistors formed by the active layers corresponding to different columns of pixel circuit areas are different can be solved, the electrostatic protection capability of the display panel is improved, the mura phenomenon of the display panel is improved, and the display uniformity of the display panel is improved.

Owner:KUNSHAN GO VISIONOX OPTO ELECTRONICS CO LTD

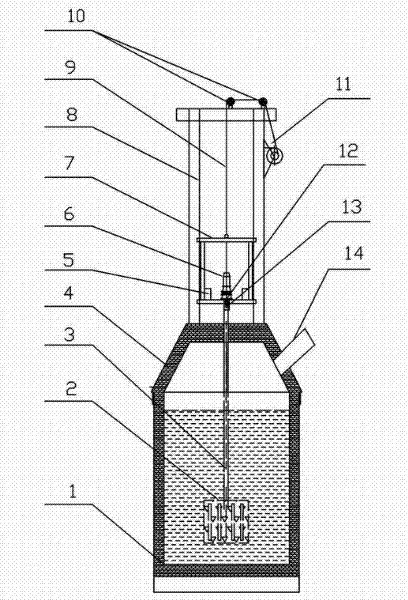

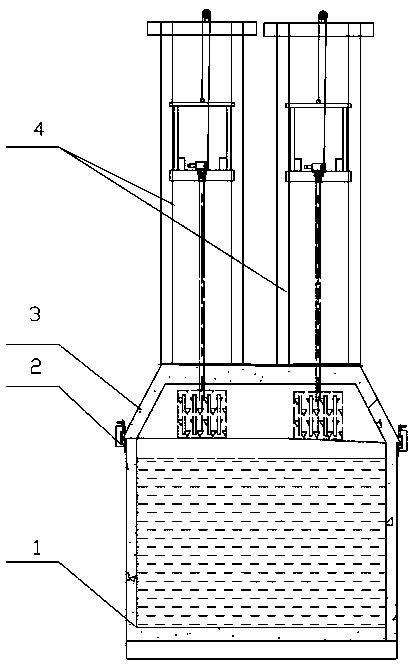

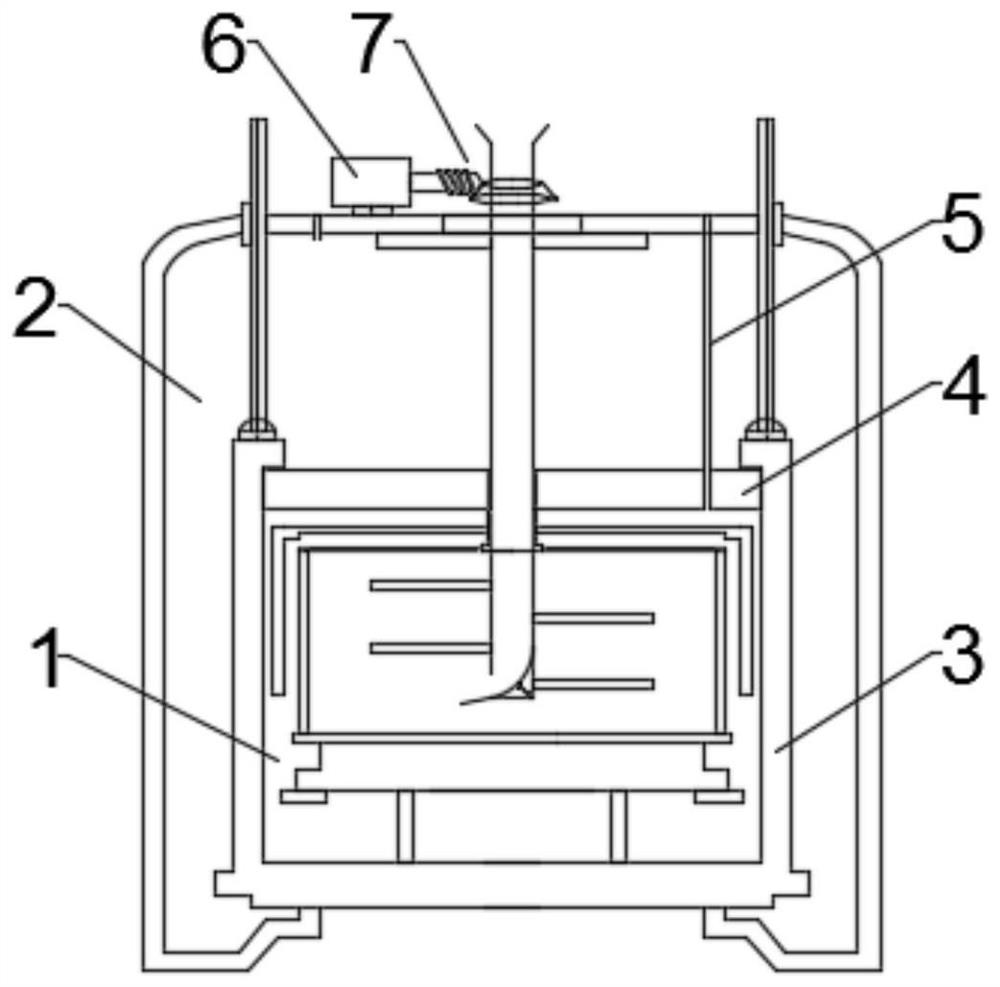

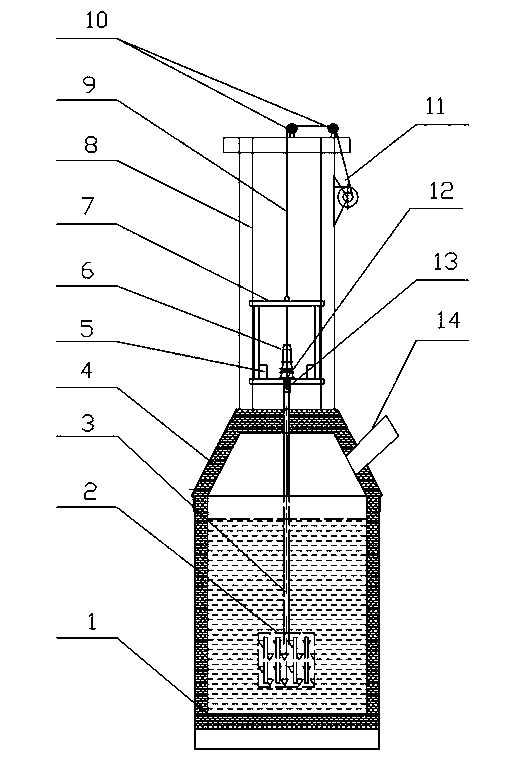

Device for metallurgically adding alloy

The invention discloses a device for metallurgically adding an alloy. A ladle cover of a conventional alloy liquid container is provided with a guide support; a guide frame is arranged in the guide support; a belt motor reducing gear and counter weight iron are arranged in the guide frame; a steel wire rope is sheathed onto guide wheel assemblies at the top part of the guide support; one end of the steel wire rope is connected with the guide frame; the other end of the steel wire rope is connected with an elevator arranged at one side of the guide support; one end of a material frame rod is fixedly connected with a material frame; and the other end of the material frame rod passes through a hole on the ladle cover and is mutually connected with the output shaft of the belt motor reducing gear through a shaft sleeve. The device for metallurgically adding the alloy has the advantages as follows: the alloy needs to be added is directly pressed into alloy liquid, is directly melted in thealloy liquid and cannot be contacted with the air, and thus, oxidation or burning loss cannot occur; the contact speed and the reaction speed of the alloy needs to be added and the alloy liquid can be controlled, thereby, the absorption evenness and the and the component evenness of the alloy in molten steel are enhanced. The addition process is simplified, the labor strength is reduced, and the application range is wide.

Owner:LONGNAN LONGYI HEAVY RARE EARTH TECH CO LTD

Polyester film with low-temperature resistance and high flexibility and preparation method of polyester film

InactiveCN108192301AImprove toughnessGood low temperature mechanical propertiesPolyesterPolyethylene terephthalate glycol

The invention relates to a polyester film with low-temperature resistance and high flexibility. The polyester film is characterized by being prepared from components in percentage by weight as follows: 67%-75% of polyethylene terephthalate, 3%-5% of glass fibers, 2%-4% of an antioxidant, 1%-3% of a flexibilizer and 16%-25% of a water-soluble acrylate-styrene-acrylic copolymer, wherein the water-soluble acrylate-styrene-acrylic copolymer is prepared from methyl acrylate, 2-ethylhexyl acrylate, butyl acrylate, styrene and acrylic acid by polymerization. By adding part of the water-soluble acrylate-styrene-acrylic copolymer with glass transition temperature being subzero 44 DEG C-subzero 23 DEG C as well as good ductility and flexibility, the flexibility of the polyester film, especially themechanical properties at low temperature are improved, and the application range of the polyester film is expanded. Meanwhile, the water-soluble acrylate-styrene-acrylic copolymer is lower in cost, the adding process is simple, non-toxic and environmentally friendly, and cost saving and resource saving are facilitated.

Owner:SUZHOU WILLOCK ELECTRONICS TECH CO LTD

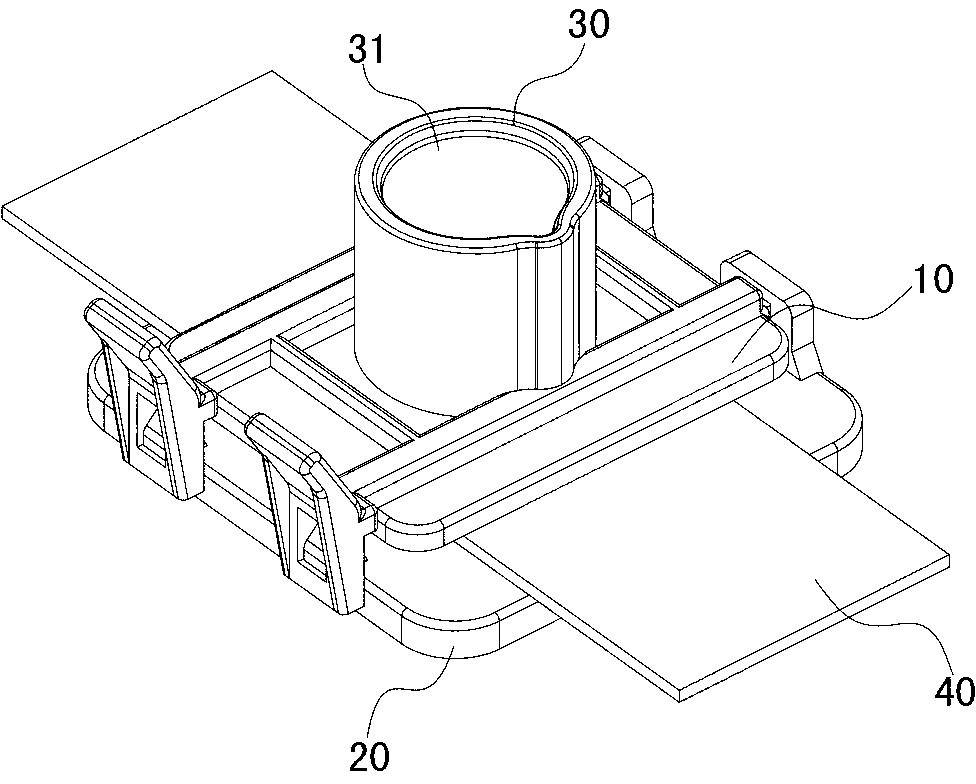

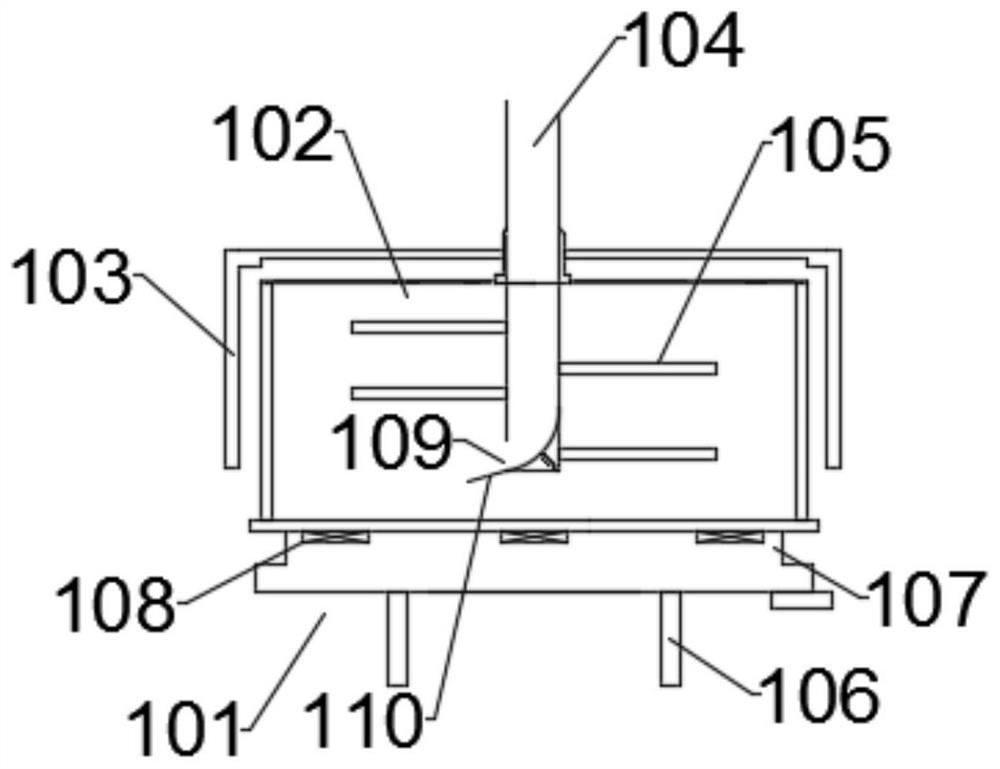

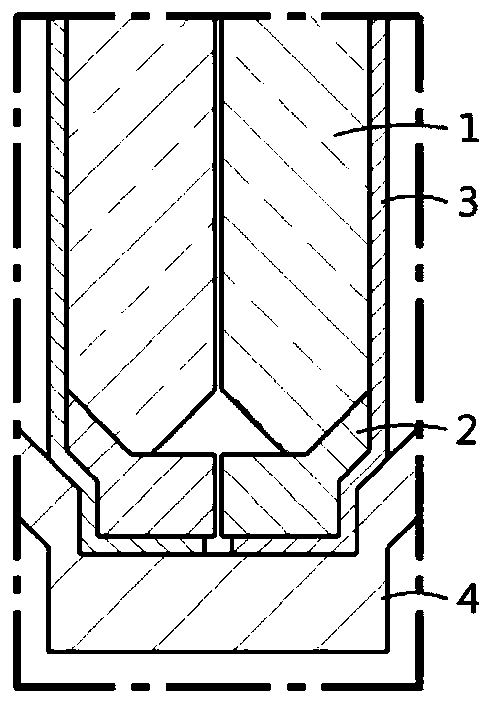

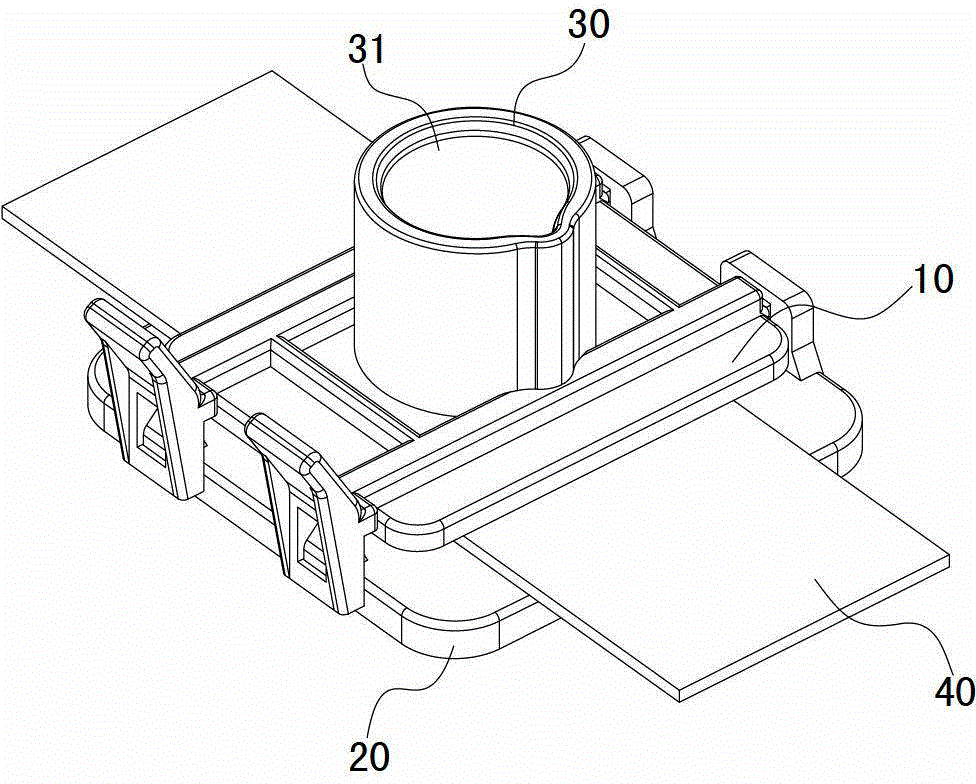

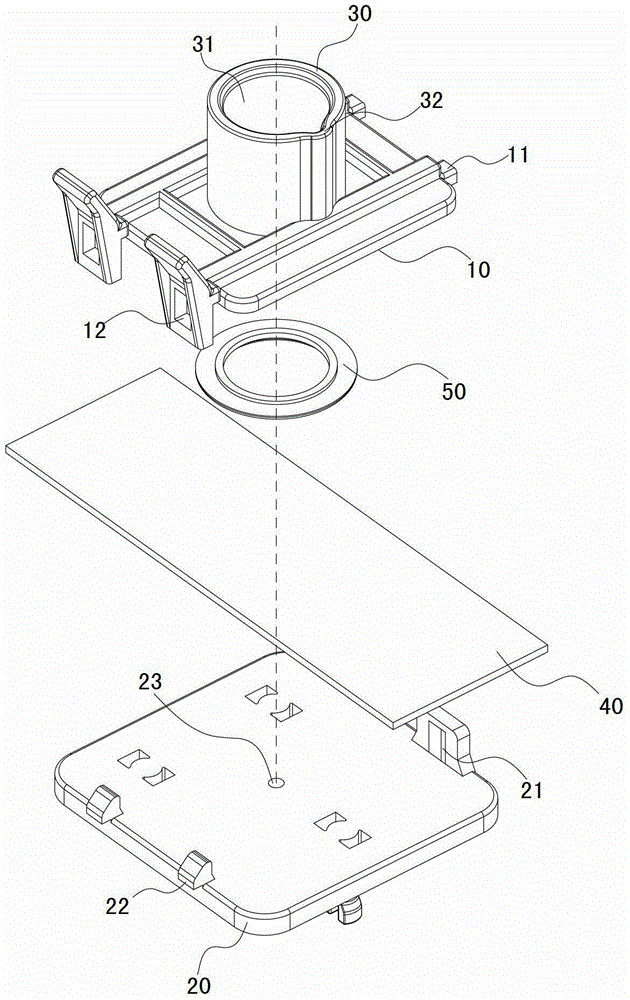

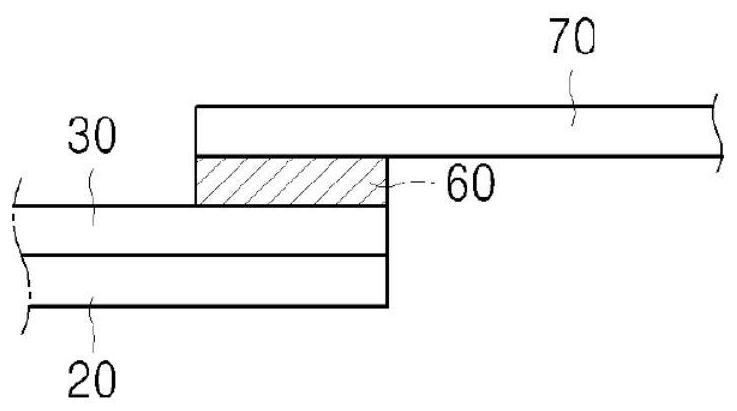

Sample reaction cabin and detection reagent adding method

ActiveCN103217326ASimplify the joining processReduce dosagePreparing sample for investigationCell smearEngineering

The invention discloses a sample reaction cabin and a detection reagent adding method. The sample reaction cabin comprises an upper cover and a lower cover which are fixed together in a detachable connection manner; a slide is arranged between the upper cover and the lower cover, and the upper part of the upper cover is provided with a cylinder; the cylinder comprises an upper opening in the top end and a lower opening in the lower surface of the upper cover, the lower cover is provided with a locating hole, the diameter of the locating hole is smaller than the inner diameter of the cylinder, and the projection area of the locating hole in the slide is in the projection area of the lower opening in the cylinder on the slide. In comparison with the prior art, the sample reaction cabin and the detection reagent adding method provided by the invention can accurately determine the positions of the tissue slices and cell smears by moving the slide in the detection process, subsequently can directly add the reagent needed for detection through locating by a machine, and thus, the adding process of the reagent is simplified, more obviously, dosage of the reagent can be reduced greatly, and the detection cost is saved.

Owner:GUANGZHOU LBP MEDICINE SCI & TECH

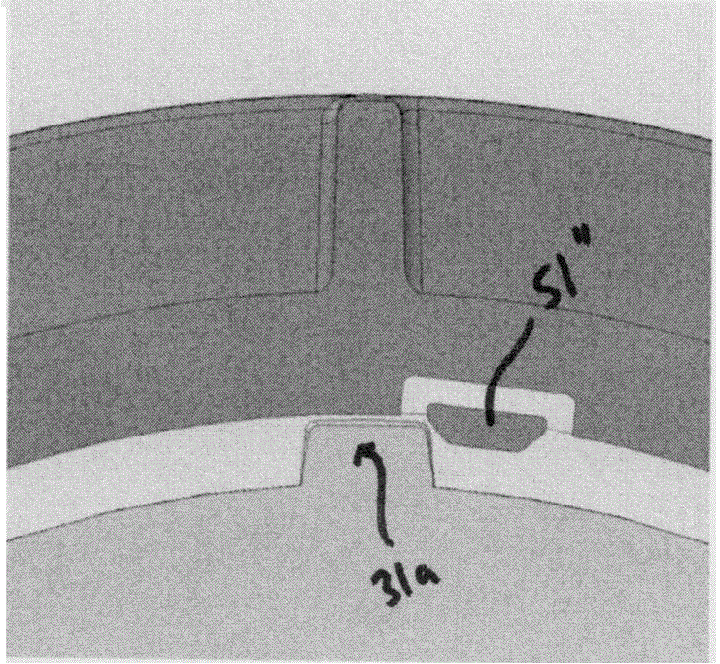

Container And Container Engaging Member Suitable For Vacuum Assisted Filtration

ActiveCN104925334ASimplify the joining processQuick breakCapsContainer decorationsVacuum assistedFiltration

A container and a container engaging member. The container engaging member may include a sample holder or reservoir, a filtration element and collar. In the assembled condition, the sample holder or reservoir is upstream of the filtration element, the container is downstream of the filtration element, and the sample holder or reservoir is attached to the container. The container engagement member is engageable and disengageable from the bottle or container in a quick attach, quick release manner, such as with only a 90 degree, ¼ turn. A tactile and / or audible indication that the engagement is complete is provided.

Owner:MILLIPORE CORP

A kind of mg-al-sn-sb magnesium alloy and preparation method thereof

The invention provides an Mg-Al-Sn-Sb magnesium alloy and a preparation method thereof, and belongs to the technical field of light metal materials. The Mg-Al-Sn-Sb magnesium alloy is prepared from, by mass percent, 8.0%-10.5% of Al, 2.0%-5.5% of Sn, 0-1.8% of Sb and the balance Mg and inevitable impurities, and the total quantity of the inevitable impurities is smaller than 0.05%. The Mg-Al-Sn-Sb magnesium alloy has good strength and heat resistance in an extrusion state and an aging state, contains no precious metal element and has good extrusion performance and forming performance, the preparation process is simple, and operation is easy; and adopted equipment such as a vacuum induction melting furnace and a hot extruder is modern general equipment, and the beneficial effect of high replicability is achieved.

Owner:鹤壁镁途科技有限公司

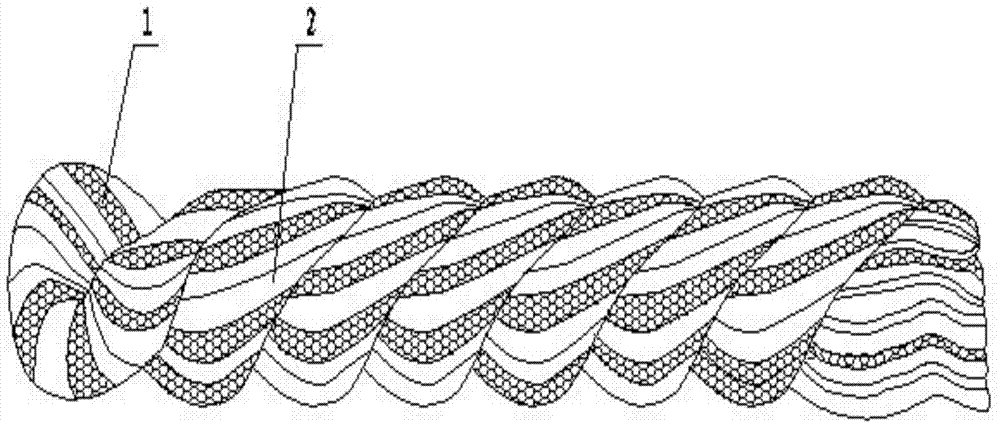

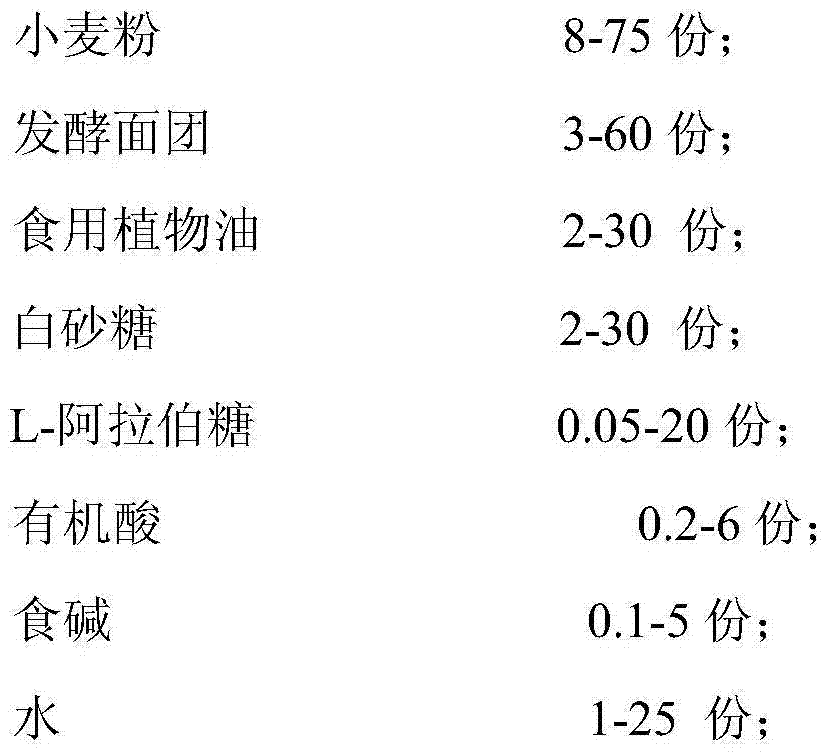

Stuffed fried dough twist capable of inhibiting absorption of sucrose and regulating fat metabolism after eating, and manufacturing method thereof

ActiveCN103975997BAvoid decompositionAvoid hydrolysisBakery productsFood preparationOrganic acidSucrose

Owner:天津桂发祥十八街麻花食品股份有限公司

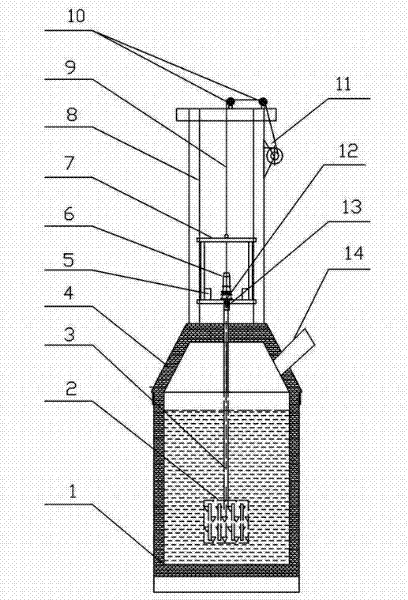

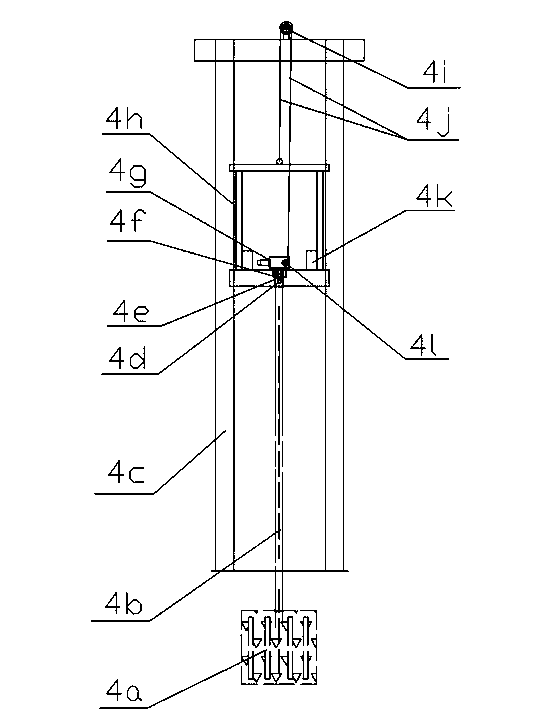

Multi-alloy step feed device for metallurgy smelting

The invention discloses a multi-alloy step feed device for metallurgy smelting. More than two alloy feeders are arranged on a ladle cover of a ladle; each of the alloy feeders comprises a bracket; a sliding frame is mounted in the bracket; a dual-output shaft belt motor reducer and counterweight iron are arranged on the sliding frame; a lifting wheel is mounted on one output shaft of the dual-output shaft belt motor reducer, and an electromagnetic clutch device is mounted on the other output shaft of the dual-output shaft belt motor reducer; a steel wire rope is sleeved onto a guide wheel assembly at the top of the bracket, and one end of the steel wire rope is connected with the sliding frame while the other end of the steel wire rope is connected with the lifting wheel; and an alloy frame is connected with a shaft sleeve fixed onto the electromagnetic clutch device through a connecting rod and a bolt. According to the multi-alloy step feed device for metallurgy smelting, the alloys are directly pressed into molten steel through a pressing-in device, are directly molten in the molten steel and cannot contact air so as to avoid oxidization and burning loss; the feeding amount of the alloys can be reduced while the absorption rate is greatly increased, so that the production cost is favorably reduced and the absorption and component uniformity of the alloys in the molten steel are improved at the same time; and the feeding process is simplified and the labor intensity is reduced.

Owner:LONGNAN LONGYI HEAVY RARE EARTH TECH CO LTD

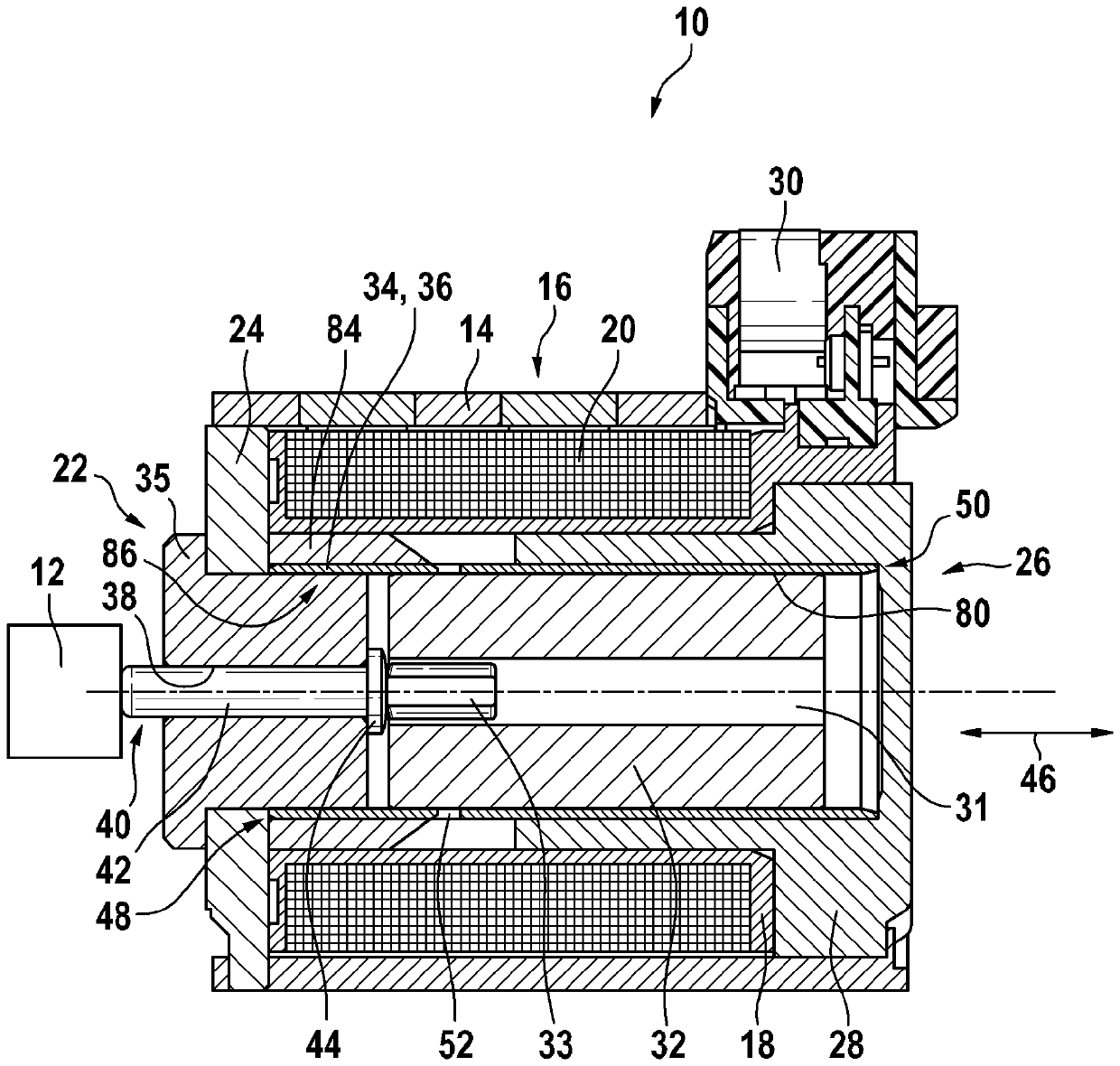

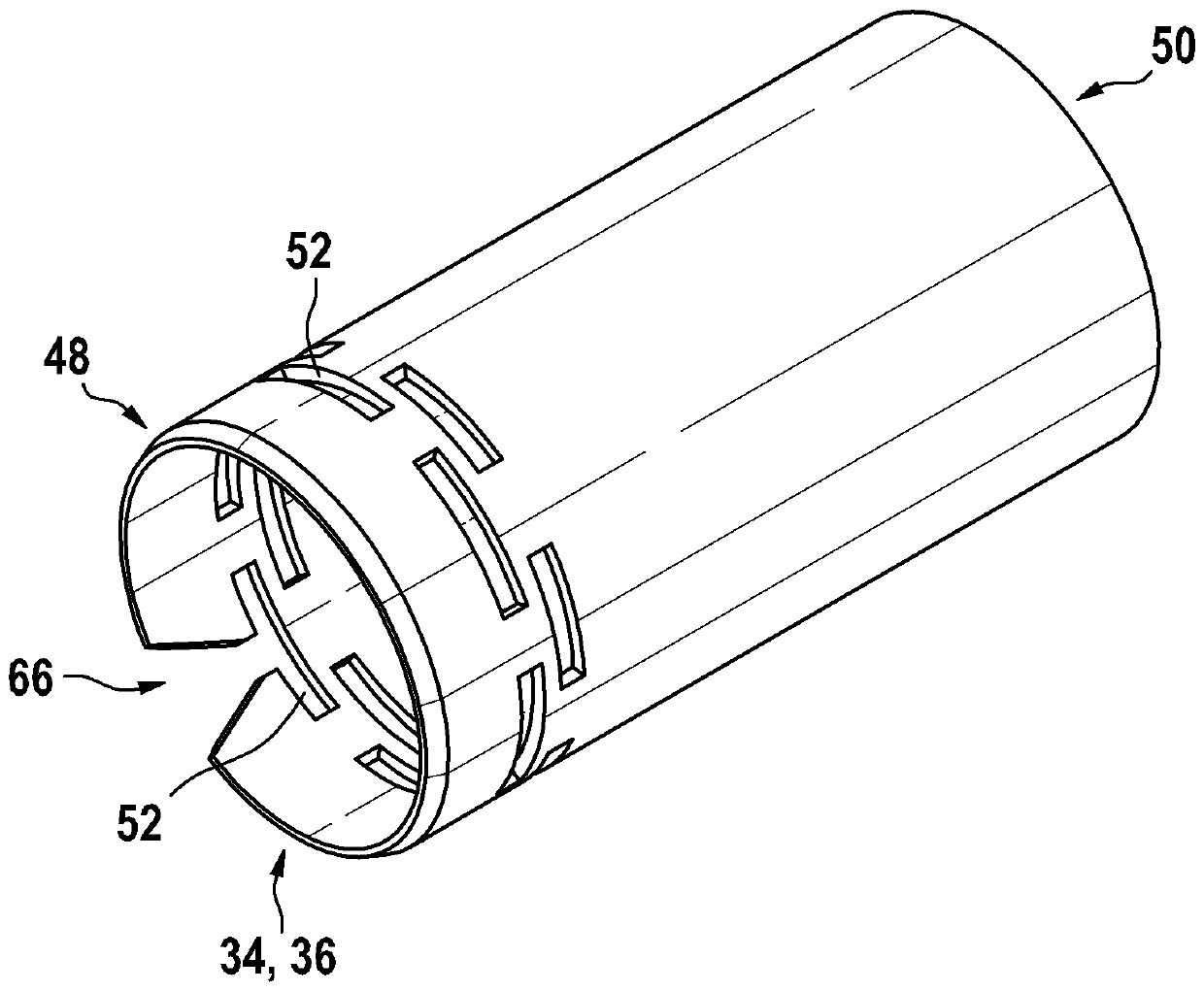

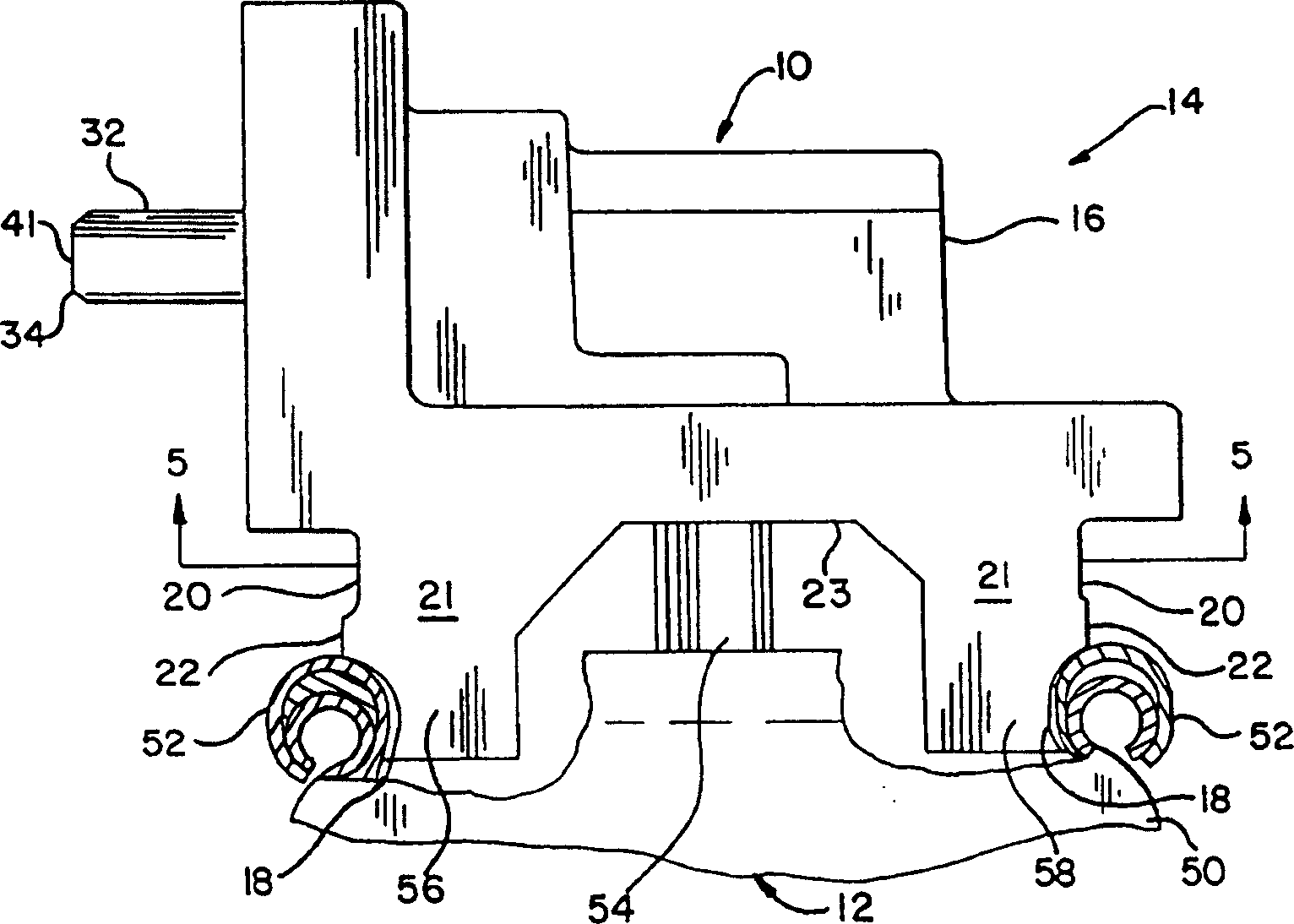

Electromagnetic actuating device

ActiveCN111350815ALow costManufactured in an inexpensive manner with improved magnetic efficiencyOperating means/releasing devices for valvesFluid actuated clutchesEngineeringMechanical engineering

An electromagnetic actuating device (10) comprises a generally substantially cylindrical pole tube (34), an armature (32) arranged radially inside the pole tube (34), and an electromagnetic coil (16)arranged radially outside the pole tube (34), wherein the pole tube (34) has a first axial end (48) and a second axial end (50). According to the invention, the pole tube (34) is designed as a punchedsleeve (36) having the shape thereof by deformation, said sleeve (36) having perforations (52) extending in the circumferential direction in the vicinity of the first axial end (48).

Owner:ROBERT BOSCH GMBH

Anisotropic conductive solder paste and its preparation method and integrated preparation device

ActiveCN112122822BImprove thermal conductivityPrevent extrusionWelding/cutting media/materialsMetal working apparatusPolymer resinAdhesive

The invention relates to an anisotropic conductive solder paste, which comprises tin-bismuth-silver solder balls, adhesives, polymer resins, interstitial particles and auxiliary additives; the preparation method comprises the following steps: placing a reactor in a protective gas environment and Add components to the reactor in sequence, then fully mix, then carry out differential settlement, and finally add curing agent and auxiliary agent for vacuum degassing; the preparation device includes an inner operating chamber and an outer environment chamber, the inner operating chamber It includes a differentiation base and a fusion chamber, the fusion chamber is installed with a rotary shear feeding pipe, the differentiation base includes a hydraulic telescopic support, a chassis is fixedly installed on the top of the hydraulic telescopic support, and several distribution boxes are installed on the chassis. Uniform and mutually independent vibrating pieces; the invention disperses low-melting tin-bismuth-silver solder balls in the adhesive to form anisotropic conductive solder, the preparation process is simple, and seamless processing is realized through the integrated preparation device, improving product quality.

Owner:深圳远芯光路科技有限公司

A normal temperature semi-dry circulating fluidized bed flue gas desulfurization system and method

A normal temperature semi-dry circulating fluidized bed flue gas desulfurization system and method relate to a method and system for removing sulfur oxides in flue gas discharged from combustion equipment. The present invention uses a circulating fluidized bed as a desulfurization reactor, which is characterized in that the slurry containing ultrafine desulfurizing agent particles is sprayed into the circulating fluidized bed reactor, and at the same time, circulating material particles are added into the circulating fluidized bed reactor to make the circulating fluidized bed reactor The circulating material particles in the fluidized bed reactor fully collide with the desulfurizer slurry, and the desulfurization reaction occurs. The invention can achieve the purpose of coupling the preparation of the desulfurizing agent with the desulfurizing reaction process and significantly improving the utilization rate of the desulfurizing agent. Compared with the existing semi-dry flue gas desulfurization technology, the present invention has the advantages of high desulfurization efficiency, simple system structure, low investment and operation and maintenance costs, and can be used in the flue gas purification process of industrial boilers and power plant boilers.

Owner:清义(山西)新材料科技有限公司

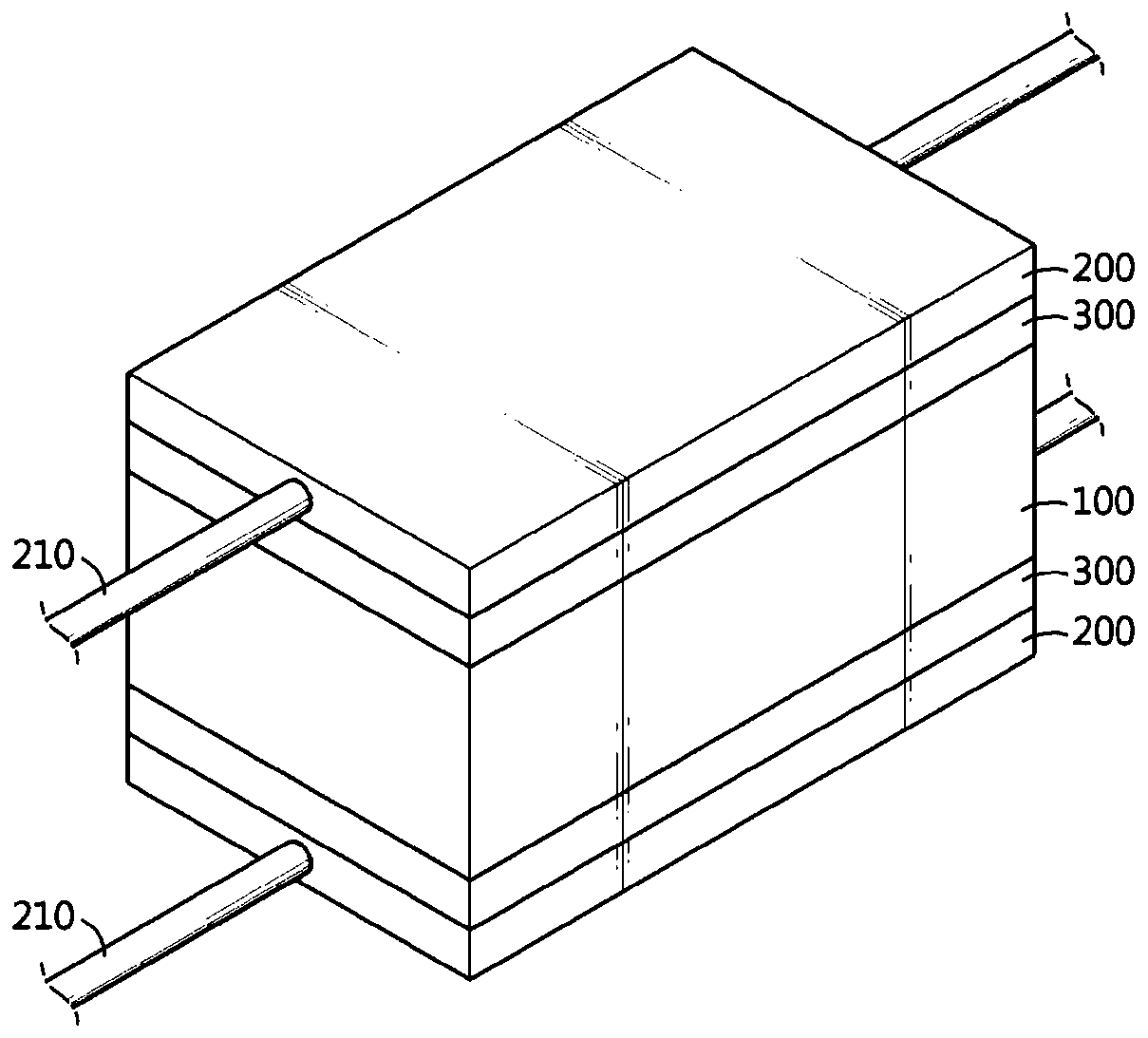

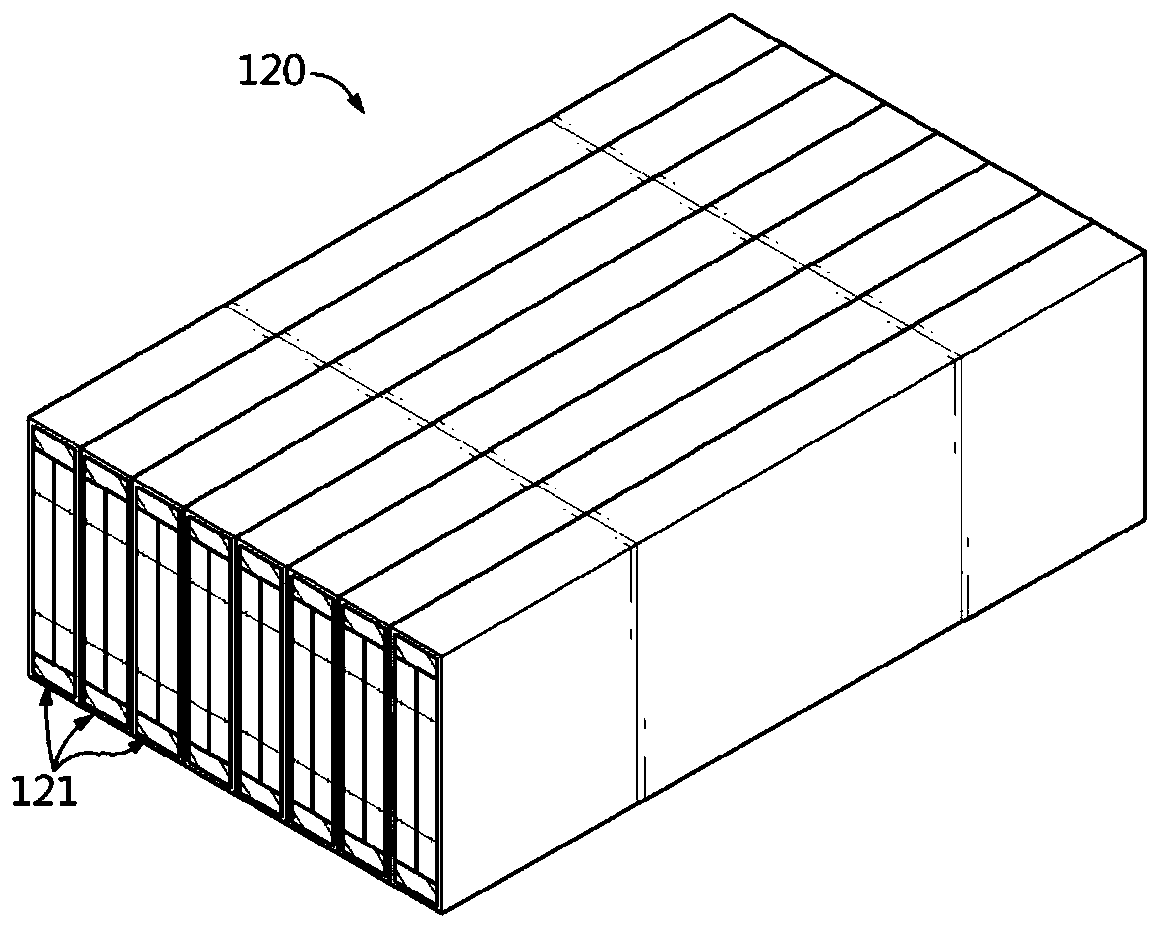

Cooling efficiency-enhanced battery module and battery pack comprising same

PendingCN111373598AImprove productivitySimple and Effective CoolingBattery isolationSecondary cellsEngineeringElectrical and Electronics engineering

A battery module, according to one embodiment of the present invention, comprises: a module main body comprising a cell assembly stack formed by stacking a plurality of cell assemblies, and a module case for accommodating the cell assembly stack; and a pair of heatsinks arranged on the upper and lower parts of the module main body so as to discharge heat transferred from the module case. The cellassembly comprises: at least one battery cell; a cartridge for accommodating the battery cell; and a pair of thermally conductive resin layers for filling empty spaces respectively formed between thetop end of the battery cell and the cartridge, and between the bottom end of the battery cell and the cartridge.

Owner:LG ENERGY SOLUTION LTD

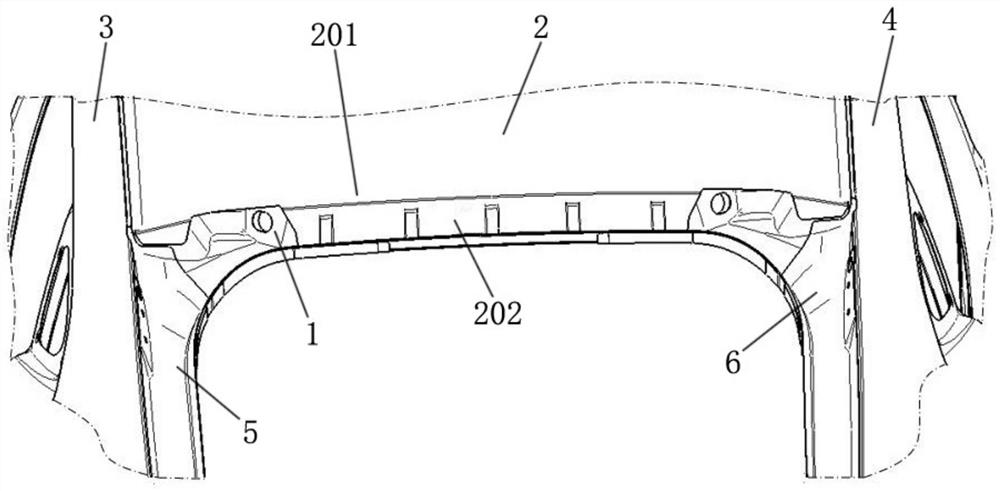

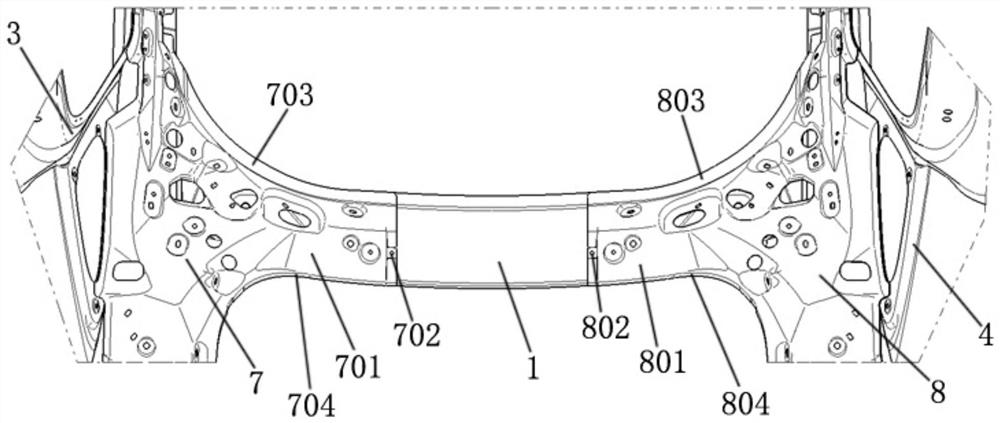

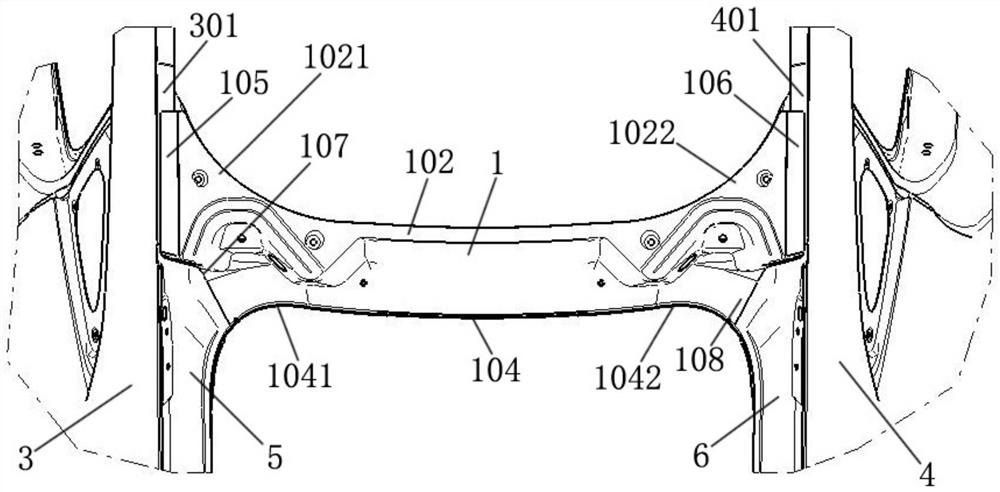

Vehicle body rear top structure and assembling method thereof

InactiveCN114771663AIncrease stiffnessHigh precisionSuperstructure subunitsLap jointMechanical engineering

The invention relates to a vehicle body rear top structure and an assembling method thereof.The vehicle body rear top structure comprises a left side wall assembly, a right side wall assembly, a rear cross beam and a top cover, the left section of the rear cross beam is in lap joint with the upper side of the left side wall assembly, the right section of the rear cross beam is in lap joint with the upper side of the right side wall assembly, and the rear portion of the top cover is in lap joint with the upper side of the rear cross beam; a left cavity is defined by the left section of the rear cross beam and the left side wall assembly, a right cavity is defined by the right section of the rear cross beam and the right side wall assembly, and a middle cavity is defined by the rear portion of the top cover and the middle section of the rear cross beam. The assembling method is used for assembling the vehicle body rear top structure. The automobile rear axle assembly has the advantages of few parts, light weight, reliable structure and simple manufacturing process, the production efficiency of the whole automobile is improved, the cost of the whole automobile is reduced, and the lightweight effect of the whole automobile is obvious.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

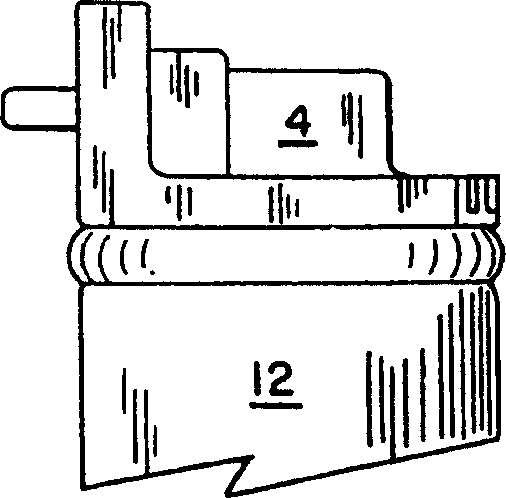

Outer metering valve for fuel tank

InactiveCN1256529CExtended service lifeEliminate needDecorative coversReactant parameters controlFuel tankEngineering

A valve constructed for use with a fuel tank in a disengaged position in which no fluid communication is established between the valve and the fuel tank and in an engaged position in which fluid communication is established between the valve and the fuel tank Liquid communication. The valve includes a valve body having a first member for maintaining a disengaged position, and a second member for maintaining an engaged position.

Owner:ILLINOIS TOOL WORKS INC

Method for accessing wireless network

ActiveCN101415221BEasy accessSimplify the joining processAssess restrictionData switching by path configurationWireless mesh networkExecution unit

The invention discloses a method for accessing a wireless network. The method comprises the following steps: user equipment (UE) acquires a public domain instruction of an neighbor cell; if the public domain instruction represents that the neighbor cell can be accessed in a public manner, the UE initiates an access to the neighbor cell; if the public domain instruction represents that the neighbor cell can not be accessed in the public manner, the UE accesses the neighbor cell in an access limited manner, or judges whether the other neighbor cells can be accessed. The invention further discloses the user equipment, and the user equipment comprises a receiving unit, a memory unit, a judgment unit and an execution unit. The method and the equipment can simplify the operation in using a homebase station, and improve the experience and feeling of a customer.

Owner:HUAWEI TECH CO LTD

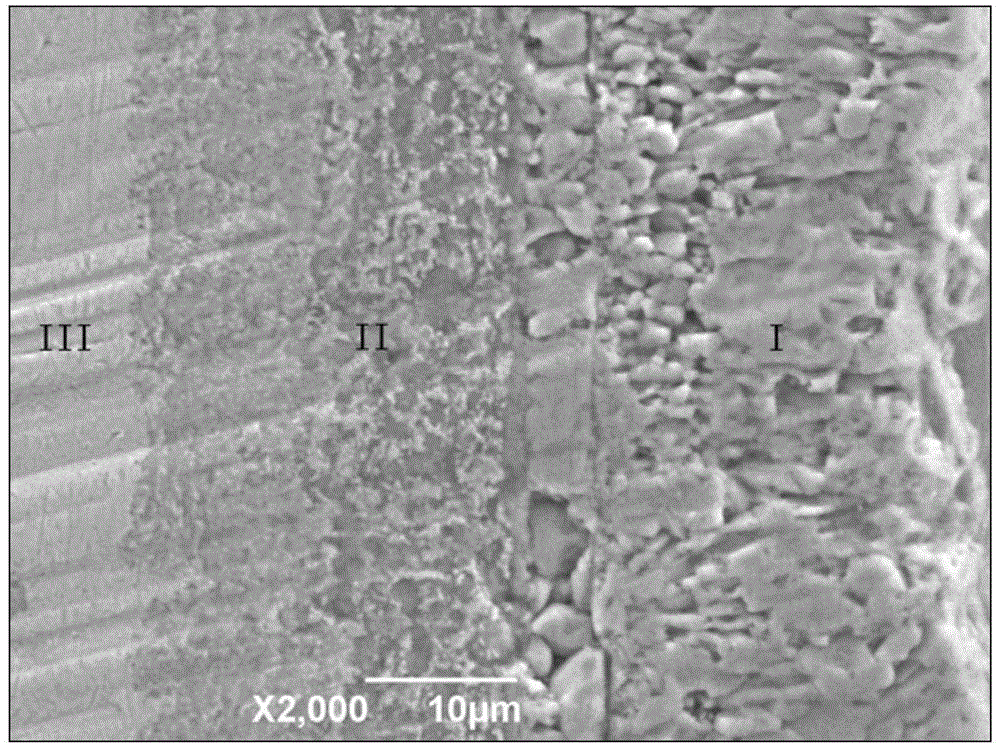

Steel material with surface containing rare earth yttrium element and preparation method thereof

InactiveCN101805887BReduce dosageImprove antioxidant capacityVacuum evaporation coatingSputtering coatingRare-earth elementPlasma diffusion

The invention discloses a steel material with the surface containing rare earth yttrium element, which is characterized in that plasma diffusion metalizing technology is used for the surface of medium and low carbon steel; rare earth yttrium element is permeated, and an alloy layer with the surface thickness of more than or equal to 50mu m can be obtained; and the steel material has the average yttrium content of 3-35% at the position 10-15mu m away from the surface. In a vacuum state, the rare earth yttrium element is permeated into the surface of the medium and low carbon steel by plasma surface metallurgical technology; and furthermore, the using quantity of the rare earth element is low, the adding technique is simple, the product cost is low, the steel material with the surface containing the rare earth yttrium element has the oxidation resistance and corrosion resistance which reach the performances of whole metallurgical rare earth steel, and the service life is long.

Owner:GUILIN UNIV OF ELECTRONIC TECH

Device for metallurgically adding alloy

Owner:LONGNAN LONGYI HEAVY RARE EARTH TECH CO LTD

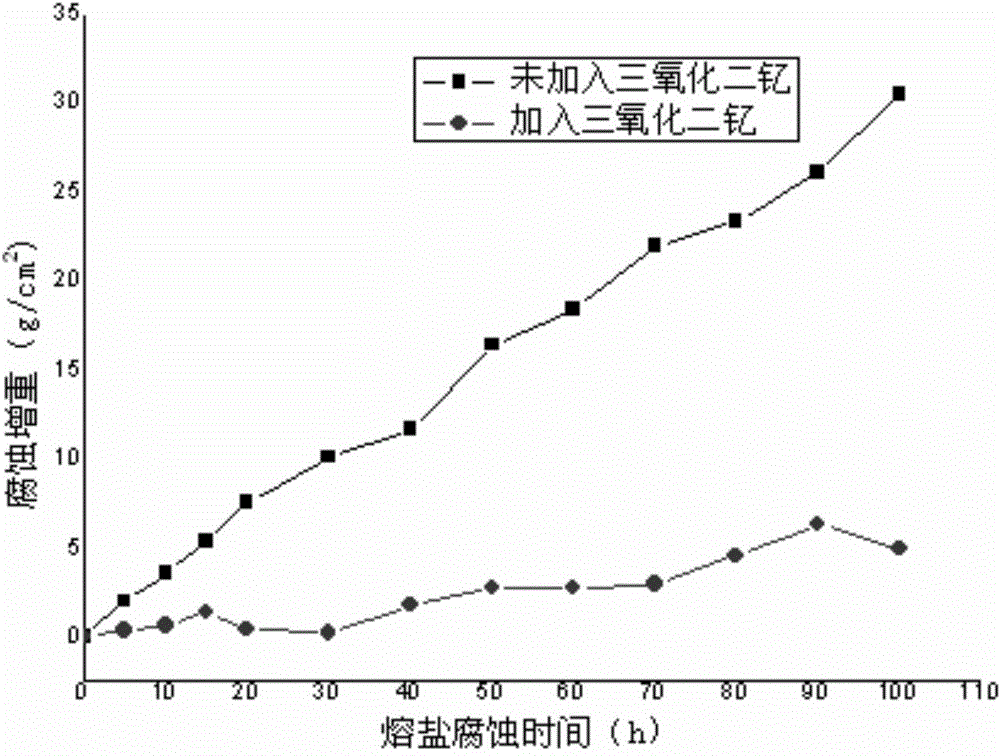

A method for reducing the corrosion performance of solar power generation heat storage molten salt

InactiveCN103776180BReduce corrosionReduce corrosion rateSolar heat devicesEnergy inputMolten saltSolar power

The invention provides a method for reducing corrosion property of solar power generation heat-storing fused salt. The method comprises a step of adding yttria into the solar power generation heat-storing fused salt and uniformly mixing, wherein the ratio of addition of the yttria to mass of the solar power generation heat-storing fused salt is 1:(1000-2000). According to the method provided by the invention, the corrosion rate of the equipment, such as a heat reservoir, a heat exchanger and a fused salt pump, in contact with the heat-storing fused salt is obviously reduced, the service life of the equipment, such as the heat reservoir, the heat exchanger and the fused salt pump, is prolonged, and the stability of a solar power generation system is increased. The method is simple and practicable, the production cost is low, the technique is easy to control and the effect is obvious.

Owner:XIAN UNIV OF SCI & TECH

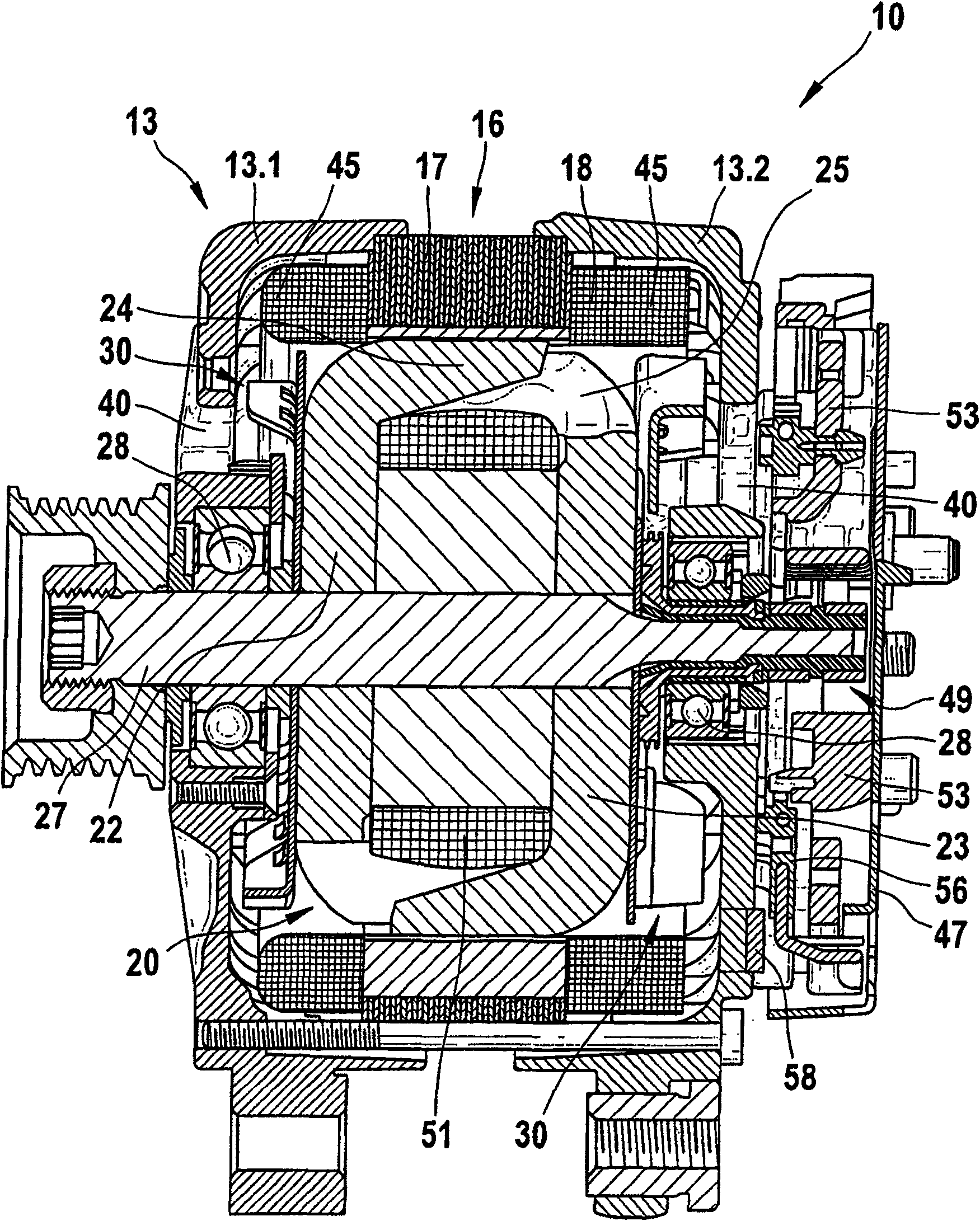

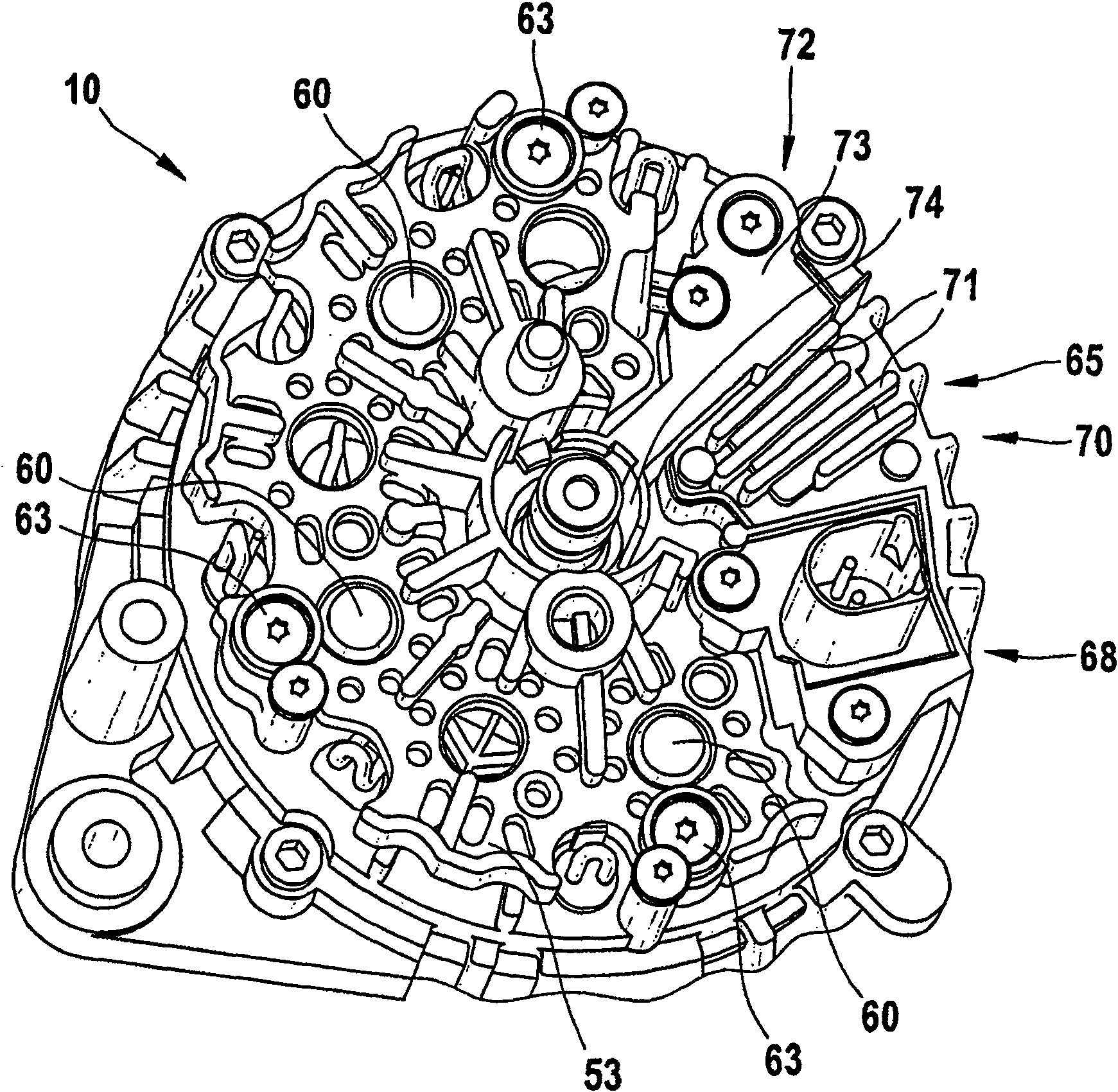

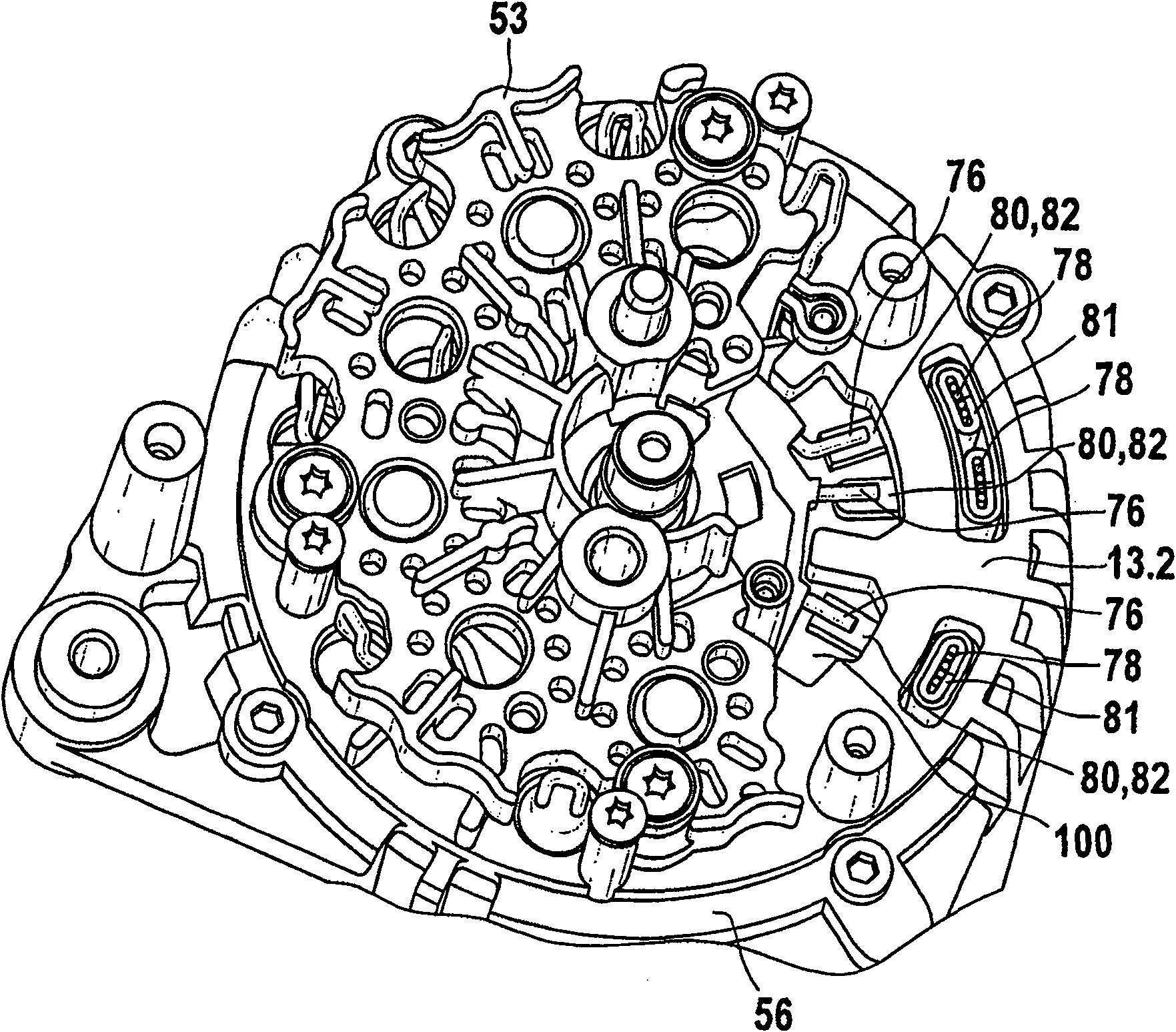

Electrical machine

InactiveCN100566078CEasy loadingImprove cooling effectSynchronous generatorsWindingsAlternatorElectrical conductor

An electric machine, in particular an alternator for a motor vehicle, having a stator (16) supporting a stator winding (18), wherein the stator winding (18) has winding ends (78), the electric machine also has a regulator structure assembly (65) and a rectifier. The electrical connection between the winding head (78) and the rectifier is located below the regulator assembly (65). Furthermore, a stator for an electric machine, in particular for an alternator of a motor vehicle, is proposed, which has a stator winding (18), wherein the stator winding (18) has winding ends (78). In this case, the winding head (78) is connected to an additional conductor part (80), which joins the individual conductors of the winding head (78) via a clip-shaped connection area (81), and is a thin plate part.

Owner:SEG AUTOMOTIVE GERMANY GMBH

Sample reaction cabin and detection reagent adding method

ActiveCN103217326BSimplify the joining processReduce dosagePreparing sample for investigationEngineeringReagent

The invention discloses a sample reaction cabin and a detection reagent adding method. The sample reaction cabin comprises an upper cover and a lower cover which are fixed together in a detachable connection manner; a slide is arranged between the upper cover and the lower cover, and the upper part of the upper cover is provided with a cylinder; the cylinder comprises an upper opening in the top end and a lower opening in the lower surface of the upper cover, the lower cover is provided with a locating hole, the diameter of the locating hole is smaller than the inner diameter of the cylinder, and the projection area of the locating hole in the slide is in the projection area of the lower opening in the cylinder on the slide. In comparison with the prior art, the sample reaction cabin and the detection reagent adding method provided by the invention can accurately determine the positions of the tissue slices and cell smears by moving the slide in the detection process, subsequently can directly add the reagent needed for detection through locating by a machine, and thus, the adding process of the reagent is simplified, more obviously, dosage of the reagent can be reduced greatly, and the detection cost is saved.

Owner:GUANGZHOU LBP MEDICINE SCI & TECH

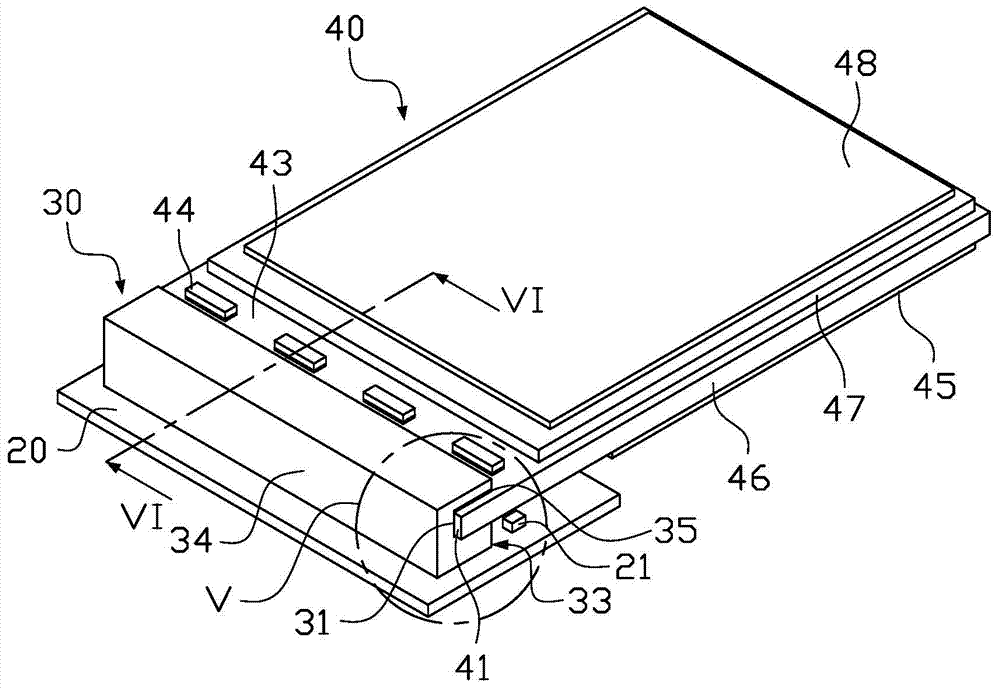

Electrode connection element, light-emitting device comprising same, and method for producing light-emitting device

PendingCN111684612AReduce manufacturing costImprove productivitySolid-state devicesSemiconductor devicesHemt circuitsLight emitting device

The present invention relates to an electrode connection element, a light-emitting device comprising same, and a method for producing a light-emitting device and, more specifically, to an electrode connection element for electrically connecting an electrode terminal and an external driver circuit, a light-emitting device comprising same, and a method for producing a light-emitting device. The electrode connection element according to an embodiment of the present invention comprises: an upper connection member in contact with the upper surface of an electrode terminal formed on a substrate; a lower connection member supporting the lower surface of the substrate; and a connecting member interconnecting the upper connection member and the lower connection member.

Owner:JUSUNG ENG

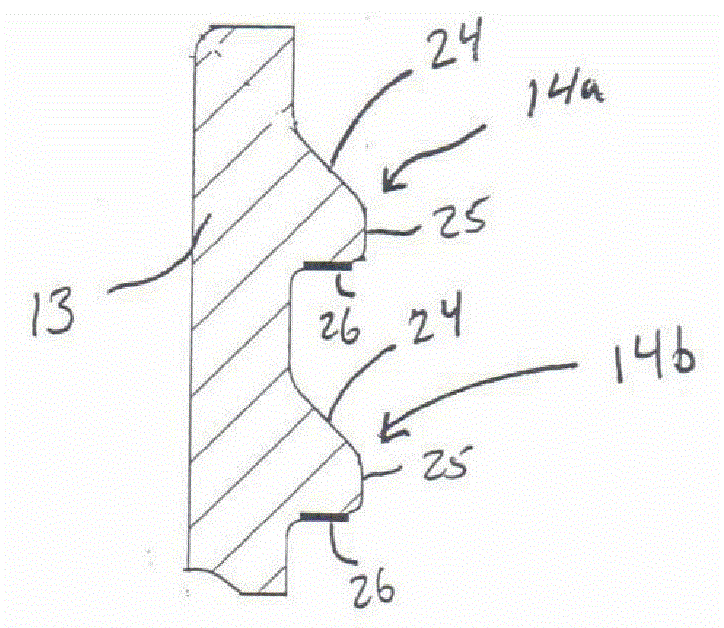

Floor board panel

InactiveCN1113140CEasy to reinforceReduced risk of damageSheet joiningFlooringEngineeringMechanical engineering

Flooring panel with two connection members whose sides face each other for attachment to other flooring panels of the same type. A first connection member has an upper projection, a lower projection, and groove between them. A second connecting member features a tongue for insertion in the groove of an adjacent connection member. In order to achieve good assembly as well as economical production of the panels, provision is made for a lower protuberance, lower indentation, lower auxiliary protuberance, and lower auxiliary indentation on the lower projection of the first connection member. The profile thus created is fitted to a corresponding profile on the lower side of the tongue which has an upper indentation, an upper protuberance, an upper auxiliary indentation, and an upper auxiliary protuberance. The floor panel is excellent in sealing function and can be costlessly manufactured with less labor.

Owner:克罗诺泰克斯木材及合成树脂材料进出口有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com