A method for reducing the corrosion performance of solar power generation heat storage molten salt

A technology of molten salt corrosion and solar energy, applied in the direction of solar thermal power generation, solar thermal devices, heating devices, etc., can solve the anti-corrosion problems of large-sized and complex-shaped equipment, reduce the corrosion of molten salt for solar power generation heat storage, and prepare equipment Problems such as limited size, to achieve good promotion value, low production cost, and less addition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The method for reducing the corrosiveness of solar power generation molten salt in this embodiment is: adding diyttrium trioxide to solar power generation molten salt (the molten salt is a binary carbonate, specifically 62wt%Li 2 CO 3 +38wt%K 2 CO 3 ), and stir evenly, wherein the ratio of the added amount of diyttrium trioxide to the mass of solar power heat storage molten salt is 1:1200, and the average particle size of said diyttrium trioxide is 120nm.

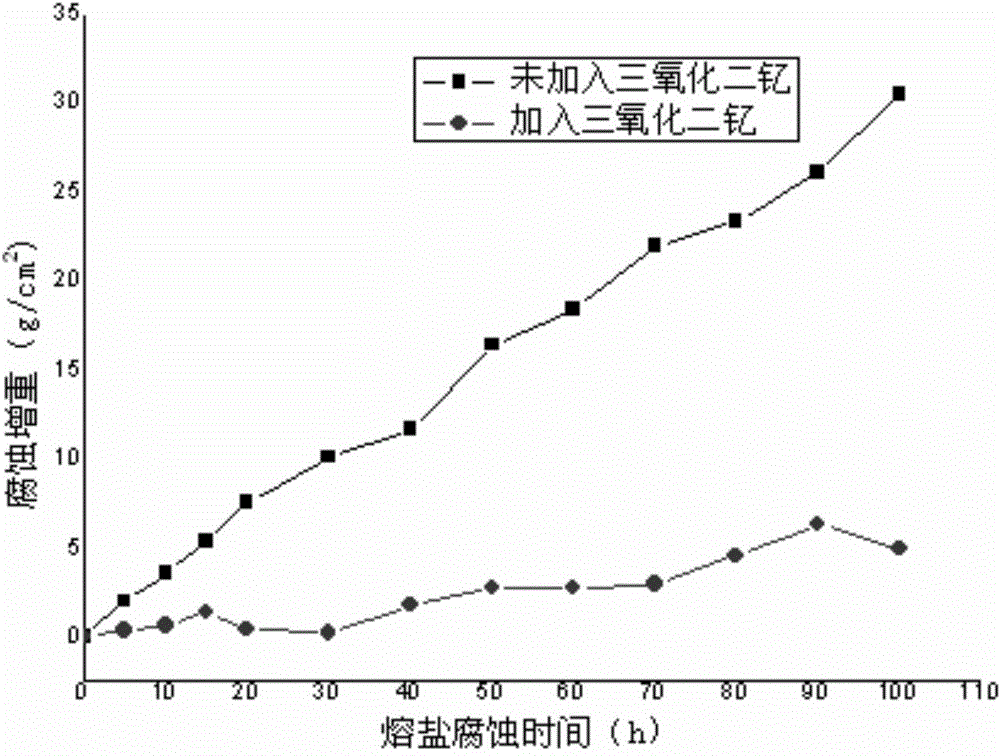

[0032] Put the molten salt with diyttrium trioxide added and the molten salt without diyttrium trioxide in this example into a box-type resistance furnace and heat to 650°C, and then put Inconel625 superalloy samples in both sets of molten salts to 650°C, and then take out the samples after the holding time reaches 5h, 10h, 15h, 20h, 30h, 40h, 50h, 60h, 70h, 80h, 90h and 100h, clean and dry, use ACCULAB ALC-210.4 Type electronic balance weighing. Thus obtain the corrosion weight gain contrast curve of Inconel625 ...

Embodiment 2

[0038] The method for reducing the corrosiveness of solar power generation heat storage molten salt in this embodiment is: adding diyttrium trioxide to solar power generation heat storage molten salt (the molten salt is ternary carbonate, specifically 43.5mol%Li 2 CO 3 +31.5mol%Na 2 CO 3 +25mol%K 2 CO 3 ), and stir evenly, wherein the ratio of the added amount of triyttrium trioxide to the mass of solar power heat storage molten salt is 1:2000, and the average particle size of said diyttrium trioxide is 140nm.

Embodiment 3

[0041] The method for reducing the corrosiveness of solar power generation molten salt in this embodiment is: adding diyttrium trioxide to solar power generation molten salt (Hitec molten salt, specifically 7wt%NaNO 3 +53wt%KNO 3 +40wt%NaNO 2 ), and stir evenly, wherein the ratio of the added amount of diyttrium trioxide to the mass of solar power heat storage molten salt is 1:1000, and the average particle size of said diyttrium trioxide is 150nm.

[0042] The molten salt with diyttrium trioxide added and the molten salt without diyttrium trioxide in this example were put into a box-type resistance furnace and heated to 650 ° C, and then 316S stainless steel samples were placed in both groups of molten salts to 650°C, after the holding time reaches 5h, 10h, 15h, 20h, 30h, 40h, 50h, 60h, 70h, 80h, 90h and 100h, take out the sample, clean and dry, use ACCULAB ALC-210.4 Electronic balance weighing. Obtain 316S stainless steel thus in the molten salt that has added diyttrium t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com