Clutch type drilling rod connection apparatus

A connecting device and clutch-type technology, applied in drill pipes, drill pipes, drilling equipment, etc., can solve the problems of cumbersome operation, inability to realize the connection and disassembly of drill pipes, etc., so as to simplify the connection process and improve the efficiency of the connection. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

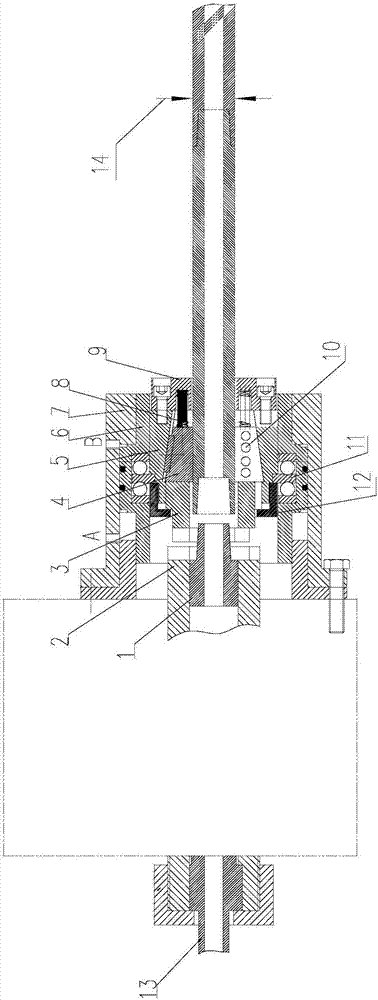

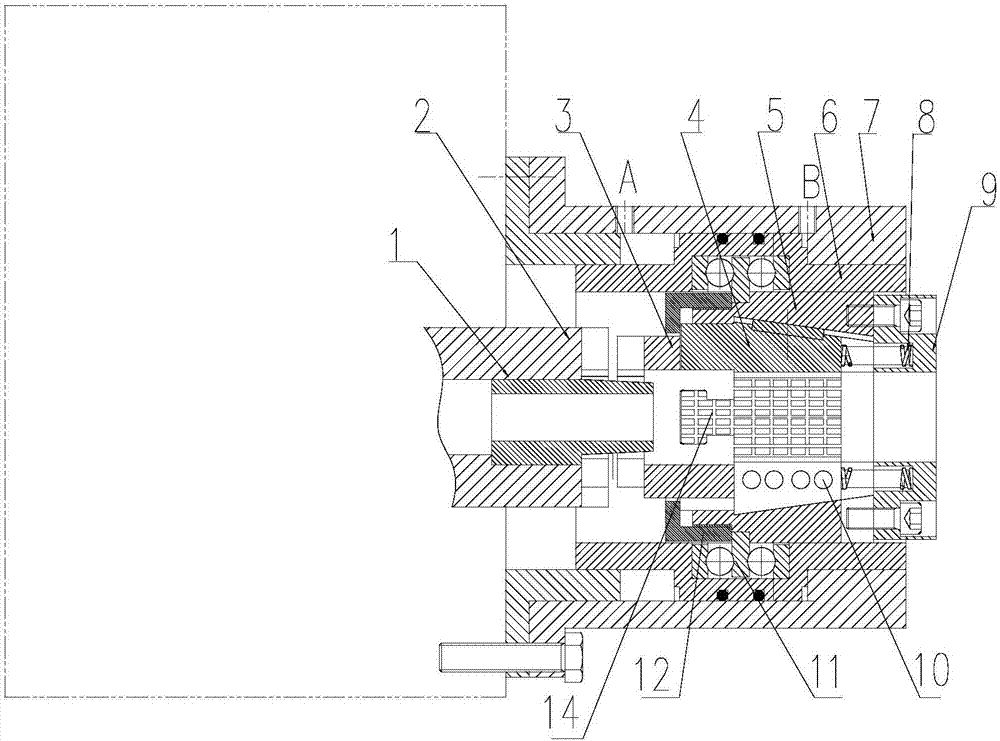

[0020] figure 1 Schematic diagram of the work of the present invention; figure 2 It is a schematic structural diagram of the present invention; as shown in the figure, the clutch type drill pipe connecting device of the present invention includes a drill pipe connector 1 and a hydraulic chuck; the drill pipe connector 1 is coaxially fixed to the main shaft of the drilling power box 2. The hydraulic chuck is used to clamp the drill rod and drive the drill rod to rotate synchronously with the spindle 2 when the drill rod is disassembled; the clutch type drill rod connection device of the present invention combines the drill rod connector 1 with the hydraulic chuck Combination of drill rods, the drill pipe connector is used in combination with the hydraulic chuck. When the drill pipe is connected, the spindle is directly used to drive the drill pipe connector to rotate, and each section of the drill pipe is added in turn, so that no water braid is required. Dismantling and joinin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com