Floor board panel

A floor paneling and edge technology, which is applied in the direction of thin plate connection, floor, connection components, etc., can solve the problems of connection edge manufacturing technology difficulties, connection edge height clamping, wear and other problems, and achieve good force distribution and force distribution, Smooth joining process, good self-centering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

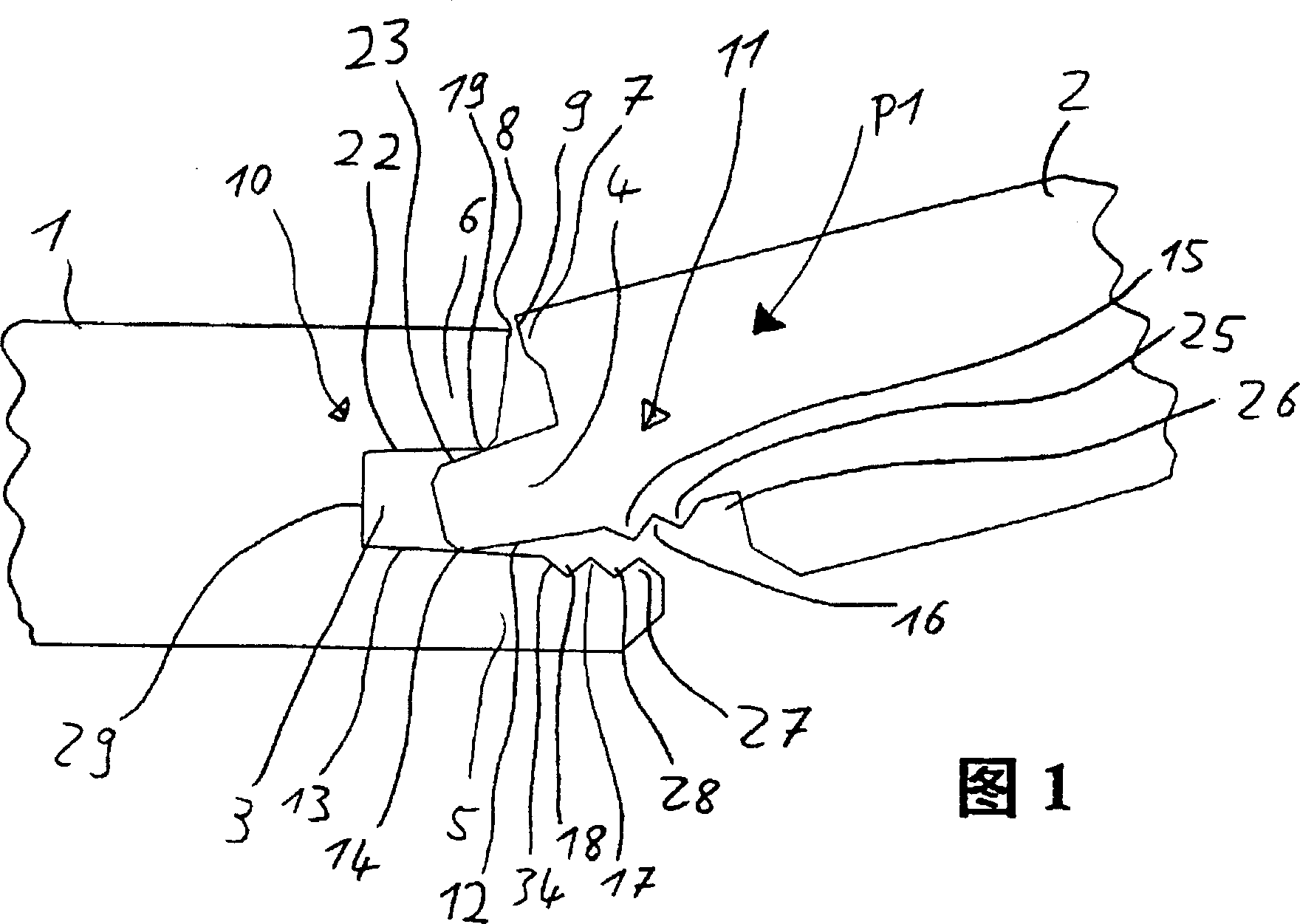

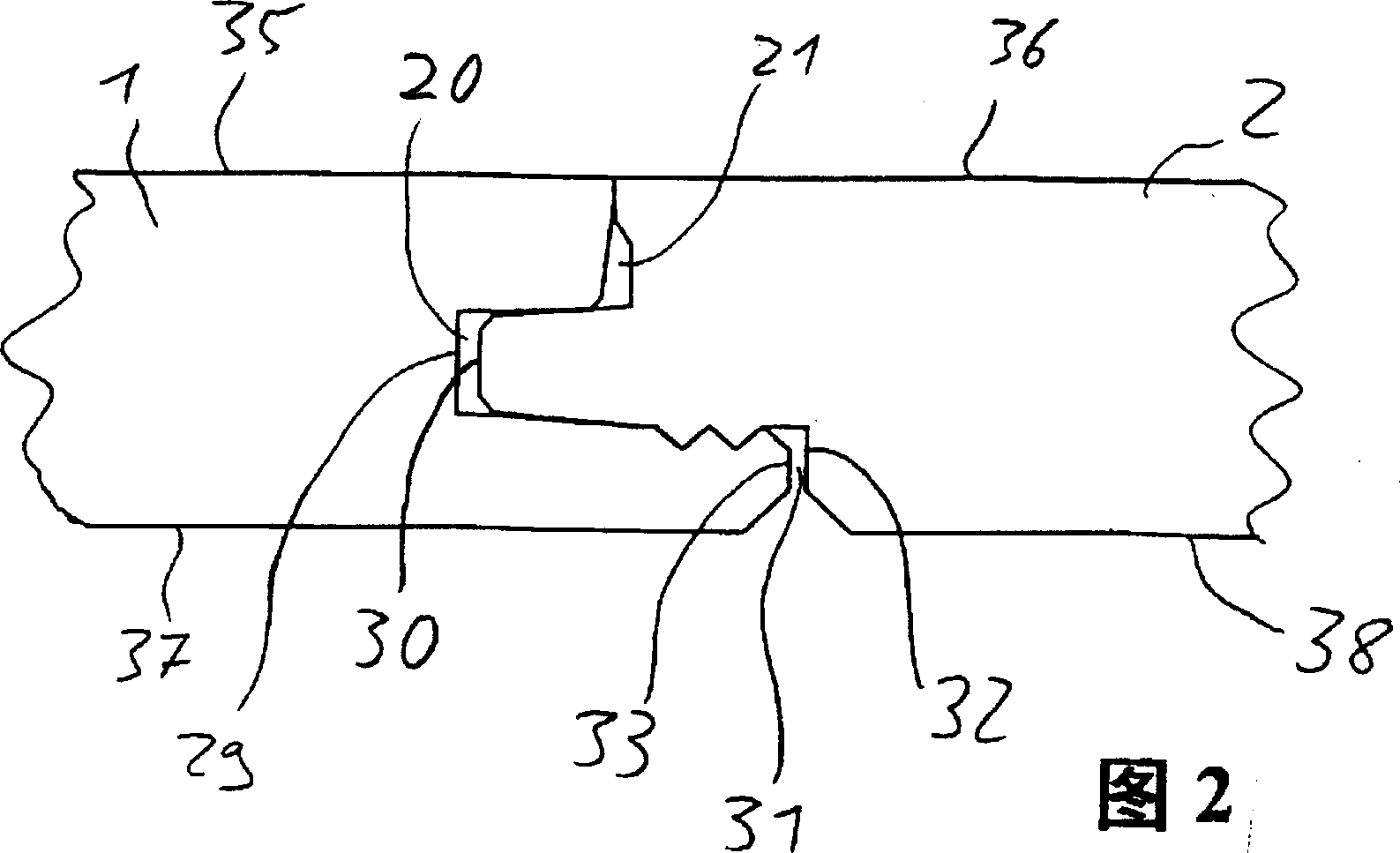

[0025] According to FIG. 5 , a connecting panel 1 has a first connecting edge 10 and, on the opposite side, a second connecting edge 11 . Here, the two connecting edges are formed in such a way that they are matched to each other for interlocking insertion, as shown in FIGS. 1 and 2 . Here, the first connecting edge 10 of the floor panels 1 has an upper projection 6 , a lower projection 5 and a groove 3 between the two projections. An abutment edge 8 is formed at the upper end of the upper extension 6 . Groove 3 has a groove bottom 29, is surrounded by the upper surface 13 of lower extension 5 and the bottom surface 22 of upper extension 6, and here, the bottom surface 22 of upper extension 6 and the upper surface 13 of lower extension 5 face The groove bottom 29 extends obliquely, so that the groove 3 tapers gradually in the direction of the groove bottom 29 . A connecting profile is formed at the outer end of the lower projection 5 , which has a lower bead 27 and a lower g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com