Integral blast furnace combined circulation method

A combined cycle, blast furnace technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

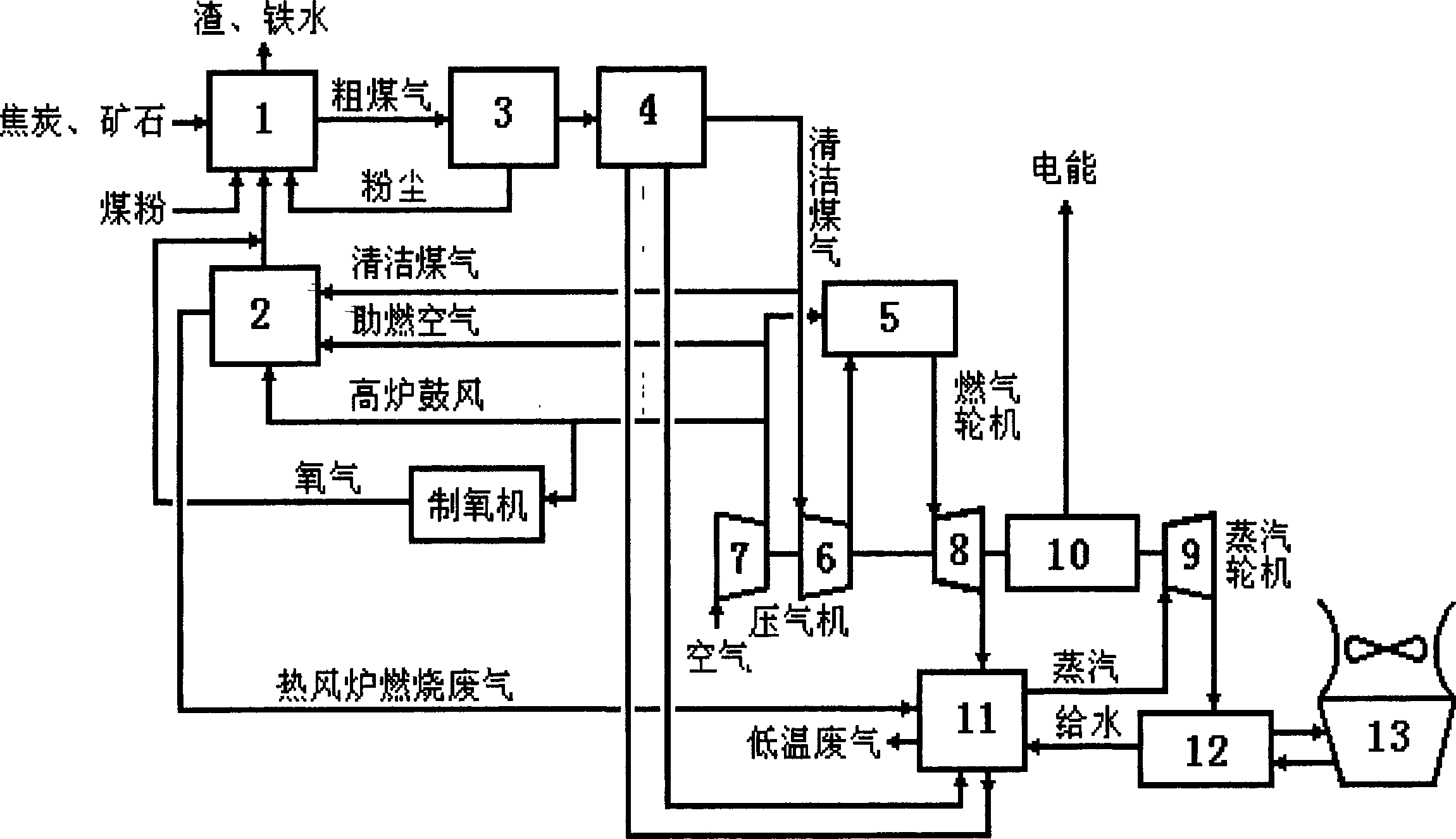

[0030] Adopt the method described in the present invention, in the blast furnace of 300 cubic meters and its subsidiary figure 1On the corresponding supporting device shown, according to its technological process, three overall blast furnace combined cycle tests were carried out, namely, blast furnace iron smelting, gas and steam combined cycle power generation, and oxygen production were carried out simultaneously and interactively cycled. The composition, gas volume and gas outlet temperature of the crude gas produced by blast furnace ironmaking are shown in Table 1. The crude gas becomes clean gas after dedusting at medium temperature, and then it is cooled down. The dust content of the dedusted gas and the temperature of the cooled gas are listed in Table 3. After the clean gas cools down, part of it enters the hot blast stove, and the other part enters the gas compressor, and then enters the combustion chamber of the gas turbine for combustion. The high-temperature and hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com