Device for metallurgically adding alloy

A technology of alloy and alloy liquid, which is applied in the direction of lighting and heating equipment, furnaces, furnace components, etc., can solve the problems of guarantee, difficult quenching and tempering treatment, and difficult homogenization of components, so as to simplify the joining process, reduce labor intensity, and wide application range wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

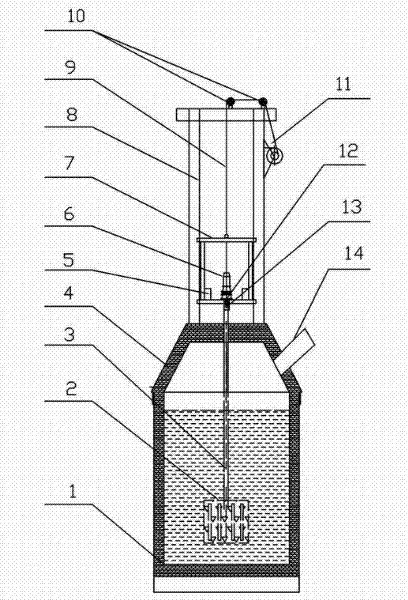

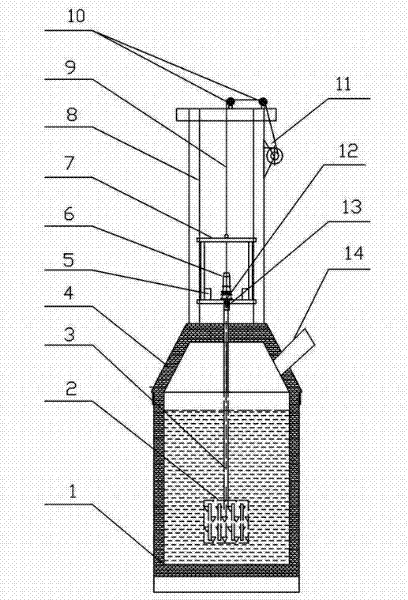

[0012] A device for metallurgically adding alloys. A guide bracket 8 is installed on the cover 4 of a conventional alloy liquid container 1. A guide frame 7 is installed in the guide bracket 8. A motor reducer 6 and a counterweight iron 5 are installed on the guide frame 7. Inside, the wire rope 9 is set on the guide wheel assembly 10 on the top of the guide bracket 8, one end of the wire rope 9 is connected with the guide frame 7, and the other end is connected with the hoist 11 installed on one side of the guide bracket 8, and one end of the material frame rod 3 is connected with the The material frame 2 is fixed, and the other end has a hole, which passes through the hole on the cover 4 and connects with the output shaft of the reducer with motor 6 through the bushing 12, and is fixed by the fixing pin 13, and the dust collection pipe 14 is welded on the cover 4 superior.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com